Processing method of weakly rigid I-shaped component

A processing method and technology with weak rigidity, applied in metal processing equipment, manufacturing tools, details of milling machine equipment, etc., to achieve the effect of minimizing cutting stress, efficient processing, and improving clamping rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

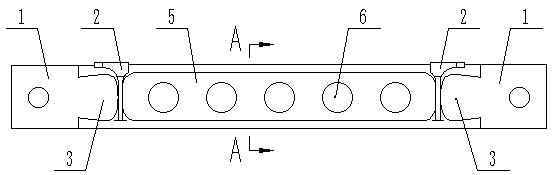

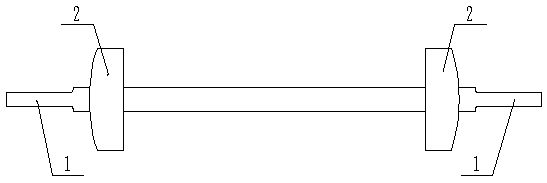

[0080] A processing method for a weakly rigid I-shaped member, specifically comprising the following steps:

[0081] The first step, semi-finishing the upper and lower surfaces in the height direction

[0082] 1) The thickness direction of the clamping member of the flat vise;

[0083] 2) Semi-finishing the upper surface in the height direction

[0084] The φ100mm end face toothed disc milling cutter processes the upper surface in the height direction, the speed is 570r / min, the feed rate is 190mm / min, the depth of cut is 2mm, and a margin of 0.5mm is left for the upper surface in the height direction;

[0085] 3) Flip clamping;

[0086] 4) Semi-finishing the lower surface in the height direction

[0087] The φ100mm end face toothed disc milling cutter processes the lower surface in the height direction, the speed is 570r / min, the feed rate is 190mm / min, the depth of cut is 2mm, and a margin of 0.5mm is left for the lower surface in the height direction;

[0088] The secon...

Embodiment 2

[0127] A processing method for a weakly rigid I-shaped member, the specific steps are the same as those in Embodiment 1, except for the following changes.

[0128] In the first step step 2), the milling cutter speed is 600r / min, the feed rate is 200mm / min, the depth of cut is 2mm, and a margin of 0.8mm is left on the upper surface in the height direction;

[0129]In step 4) of the first step, the milling cutter speed is 600r / min, the feed rate is 200mm / min, the depth of cut is 2mm, and a margin of 0.8mm is left on the lower surface in the height direction;

[0130] In the second step step 2), the milling cutter rotates at 600r / min, the feed rate is 200mm / min, the depth of cut is 2mm, and a margin of 2.2mm is left for the front side in the thickness direction and the front side of the two lug ribs 2;

[0131] In the second step step 3), the rotation speed of the milling cutter is 3000r / min, the feed rate is 1500mm / min, the depth of cut is 1mm, and a margin of 2.2mm is left on t...

Embodiment 3

[0144] A processing method for a weakly rigid I-shaped member, the specific steps are the same as those in Embodiment 1, except for the following changes.

[0145] In the first step step 2), the milling cutter speed is 630r / min, the feed rate is 210mm / min, the depth of cut is 2mm, and a margin of 1mm is left on the upper surface in the height direction;

[0146] In step 4) of the first step, the milling cutter speed is 630r / min, the feed rate is 210mm / min, the depth of cut is 2mm, and a margin of 1mm is left on the lower surface in the height direction;

[0147] In the second step step 2), the milling cutter speed is 630r / min, the feed rate is 210mm / min, the depth of cut is 2mm, and a margin of 2.5mm is left for the front side in the thickness direction and the front side of the two lug ribs 2;

[0148] In the second step step 3), the milling cutter speed is 3100r / min, the feed rate is 1560mm / min, the depth of cut is 1mm, and a margin of 2.5mm is left on the left and right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com