A tool box fixture for machining piston ring grooves

A technology of piston ring groove and ring groove cutter, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of small handle size, influence of ring groove cutter rigidity, and inability to cool, so as to improve clamping Rigidity, strong clamping stability, firm and reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

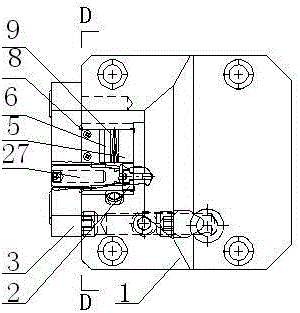

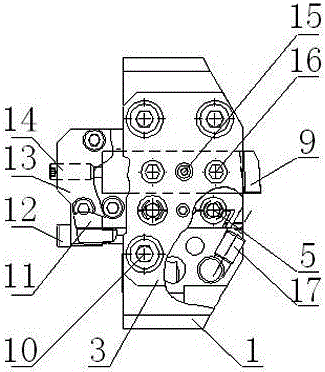

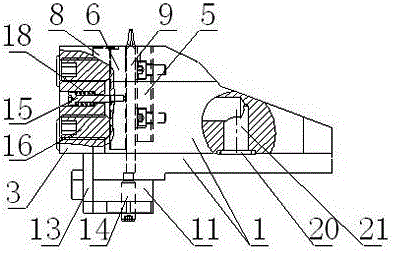

[0031] Such as figure 1 , figure 2 , image 3 As shown, a knife box fixture for processing piston ring grooves includes a knife box body 1, a side pressure knife plate 3, an annular groove knife 9 and an annular groove knife fixture. The knife box body 1 is provided with a mounting groove 25, and the annular groove The knife 9 and the ring groove knife fixture are installed in the installation groove 25, and the side pressure knife plate 3 is installed on the side where the knife box body 1 is provided with the installation groove 25 through the side pressure knife plate mounting screw 10;

[0032] Such as Image 6 As shown, the ring groove knife holder includes a backing block A5, a backing block B6, a side compression screw 16, an elastic tensioning block 31 and an elastic tensioning screw 27, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com