Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Avoid setup errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

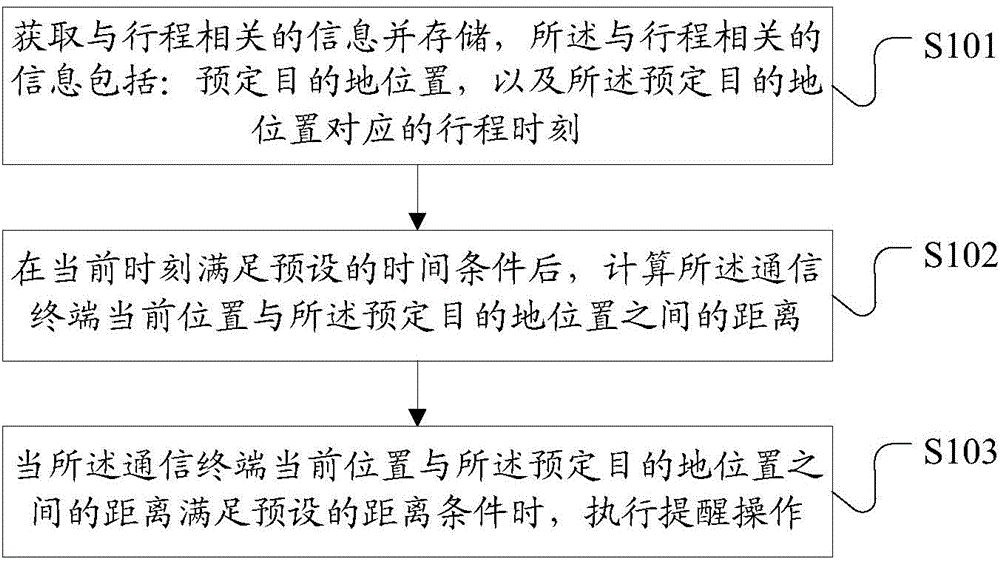

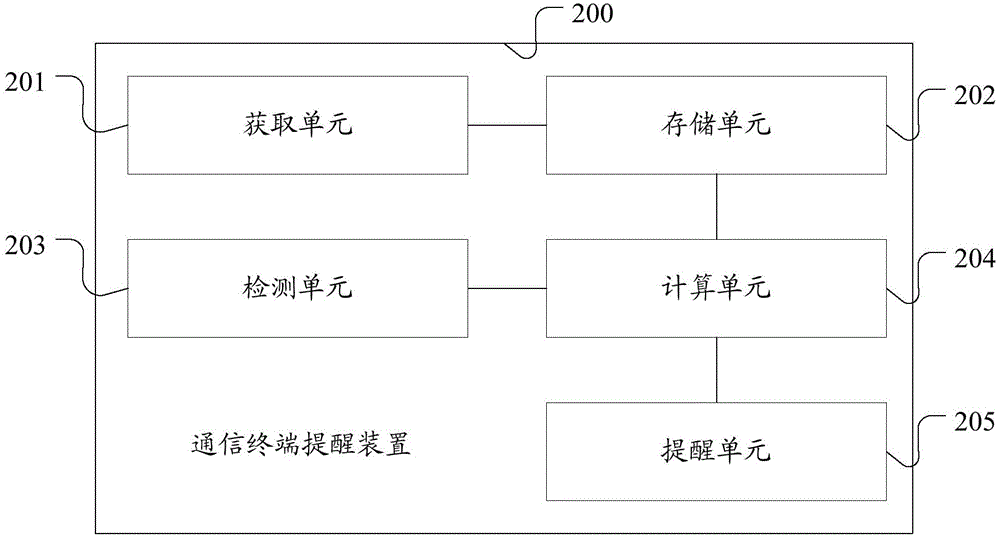

Communication terminal and prompting method and device

InactiveCN105333880AMeet travel reminder needsRemind in timeInstruments for road network navigationLocation information based serviceTime conditionPresent moment

A communication terminal, a prompting method and a device are provided. The method includes: acquiring and storing travel related information, wherein the travel related information includes a predetermined destination location, and travel time corresponding to the predetermined destination location; when the present moment meets the preset time conditions, calculating the distance between the current location of the communication terminal and the predetermined destination location; and when the distance between the current location of the communication terminal and the predetermined destination location meets the preset distance condition, executing the prompting operation. The above method, device and communication terminal can timely and actively prompt the users at the right time and place, and does not cause interference to the user, so as to provide convenience for the users.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

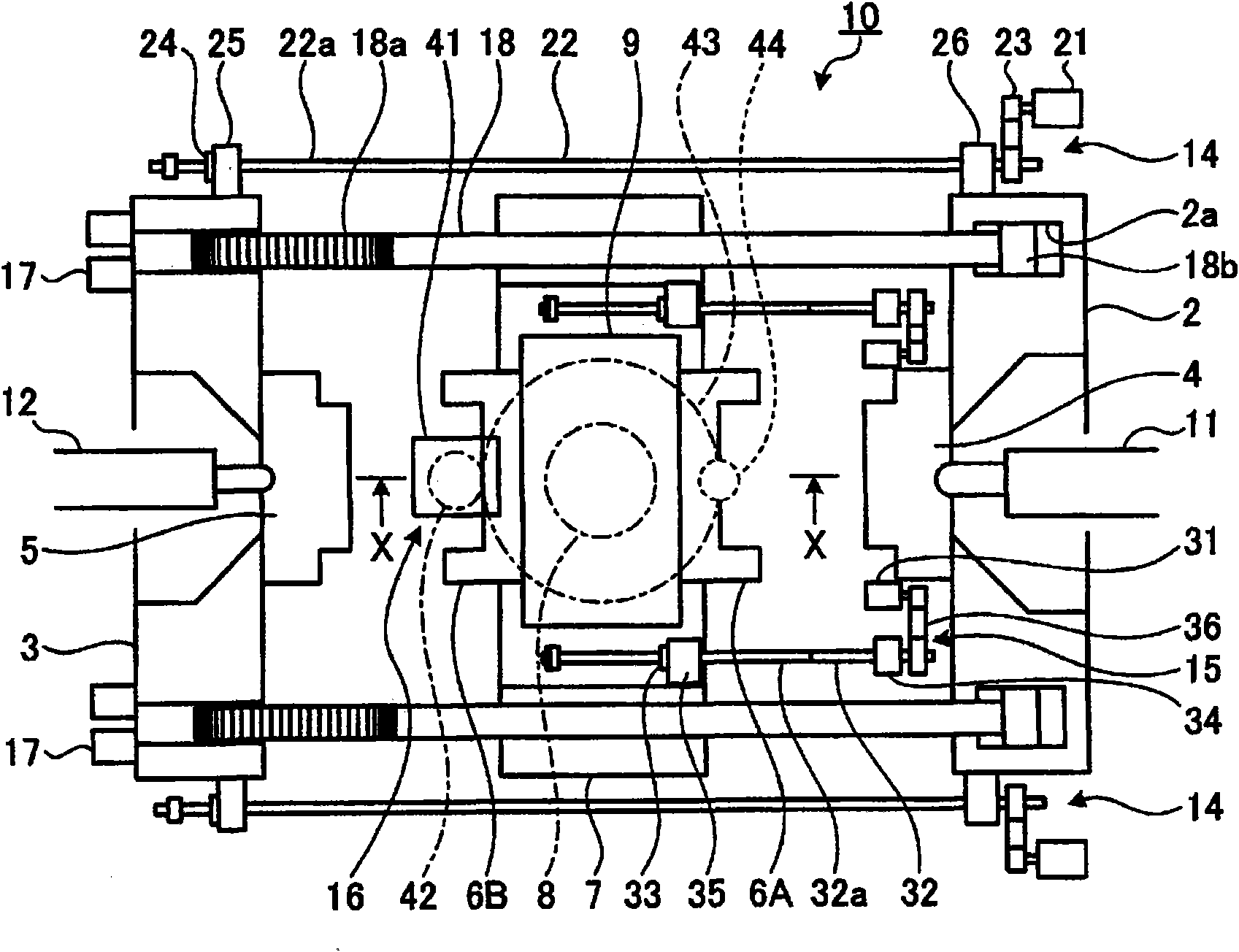

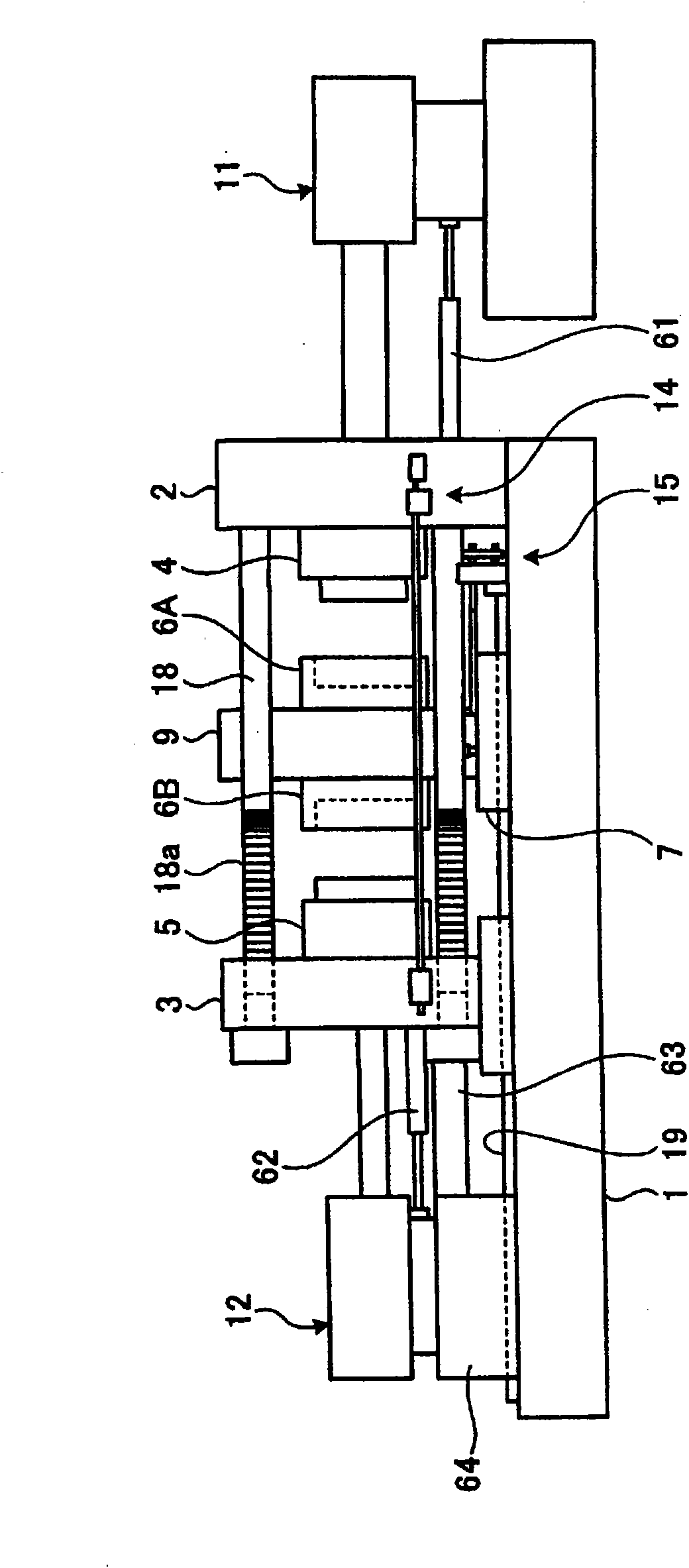

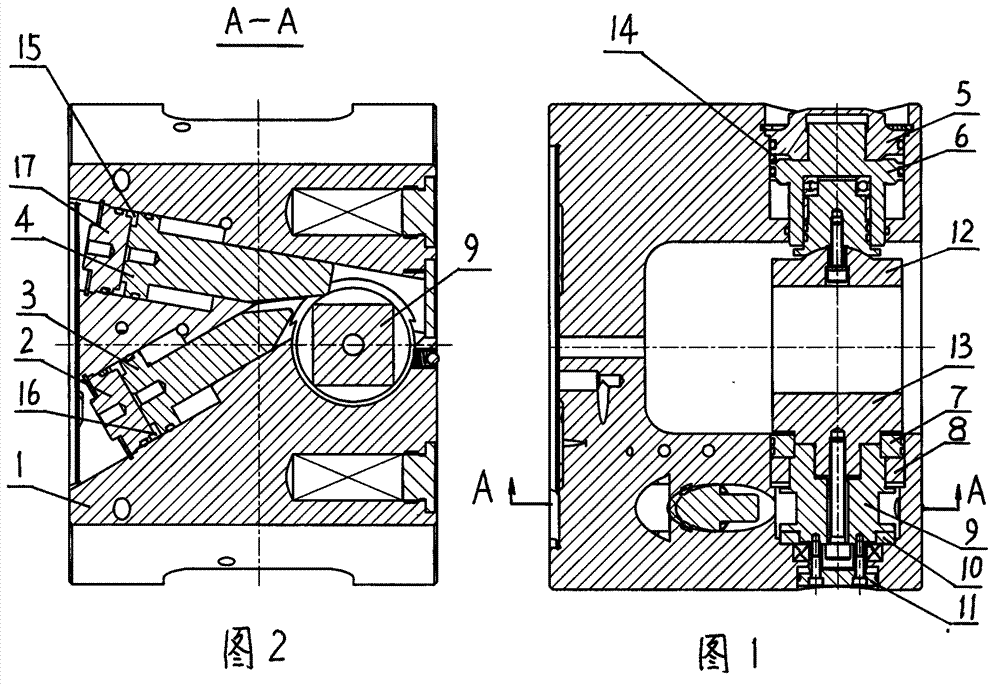

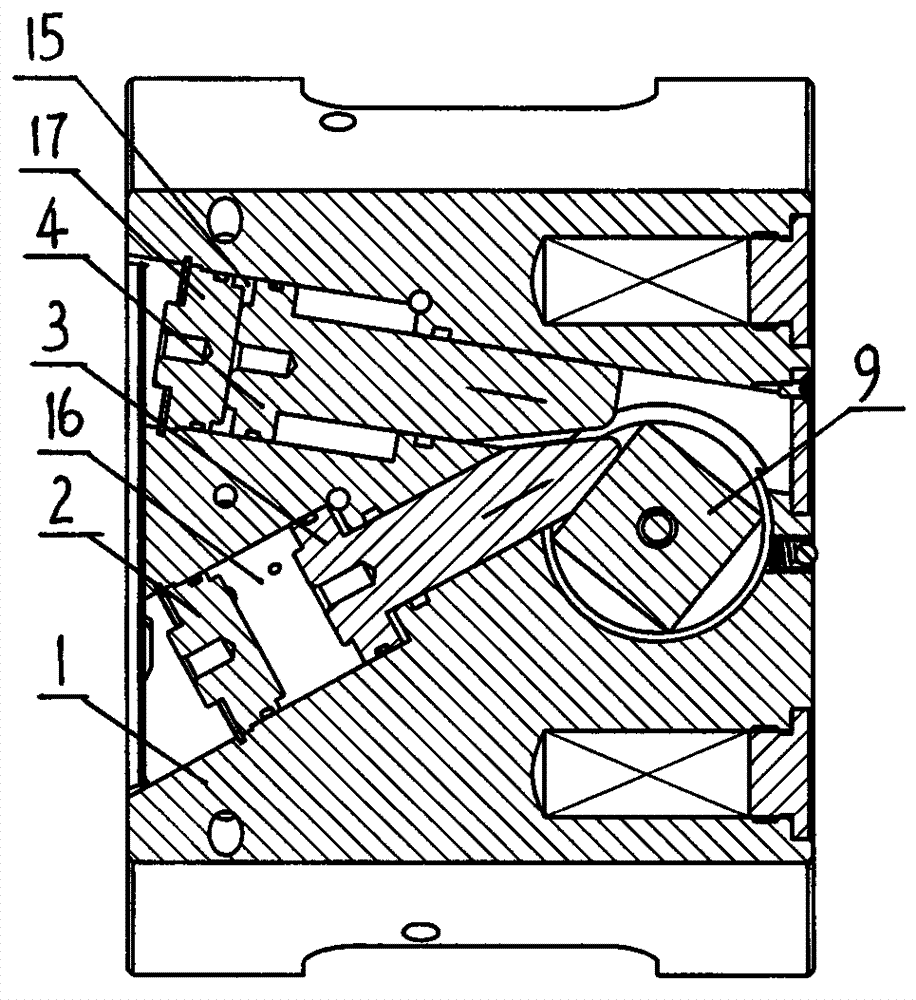

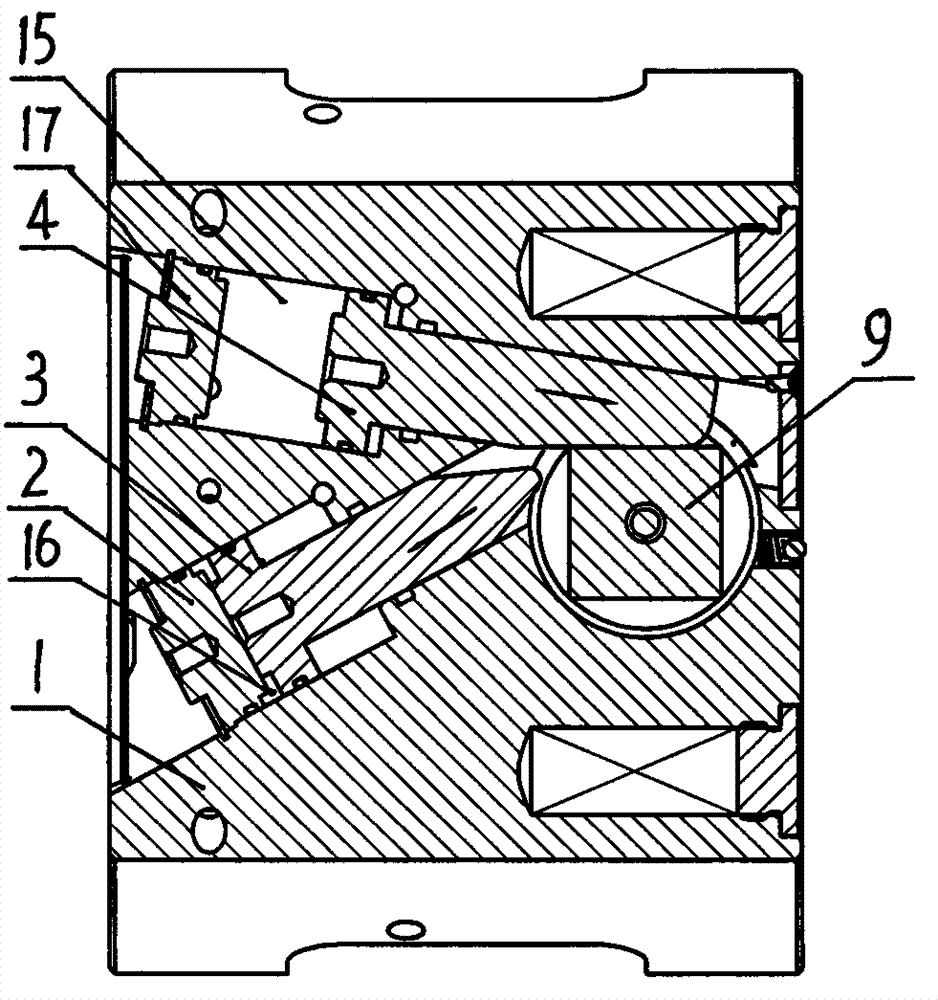

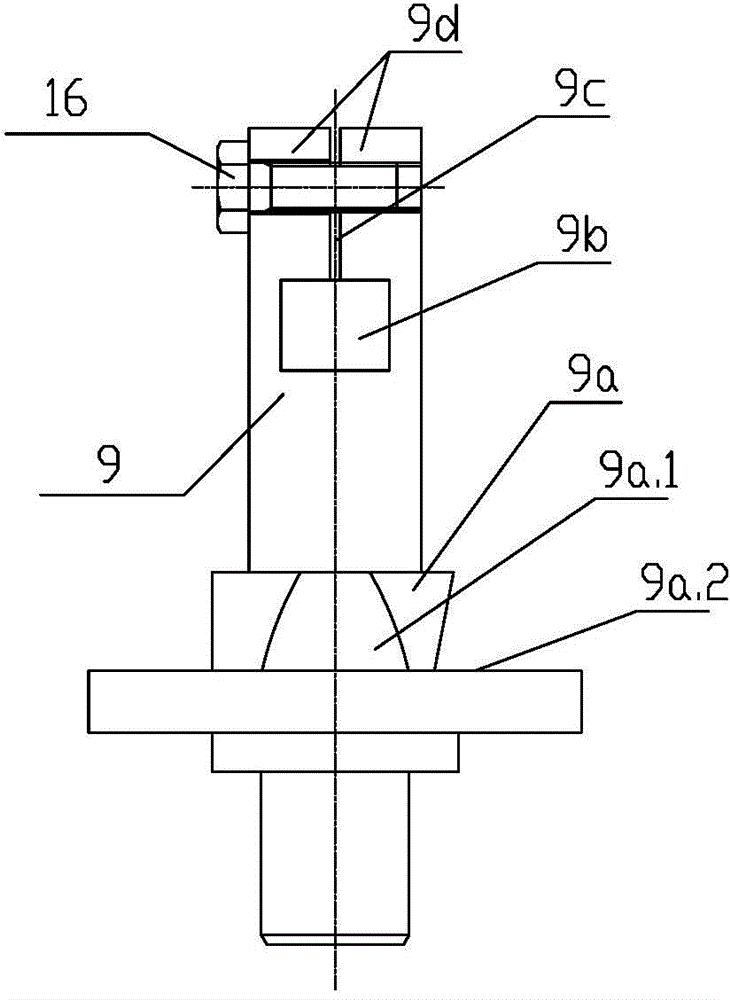

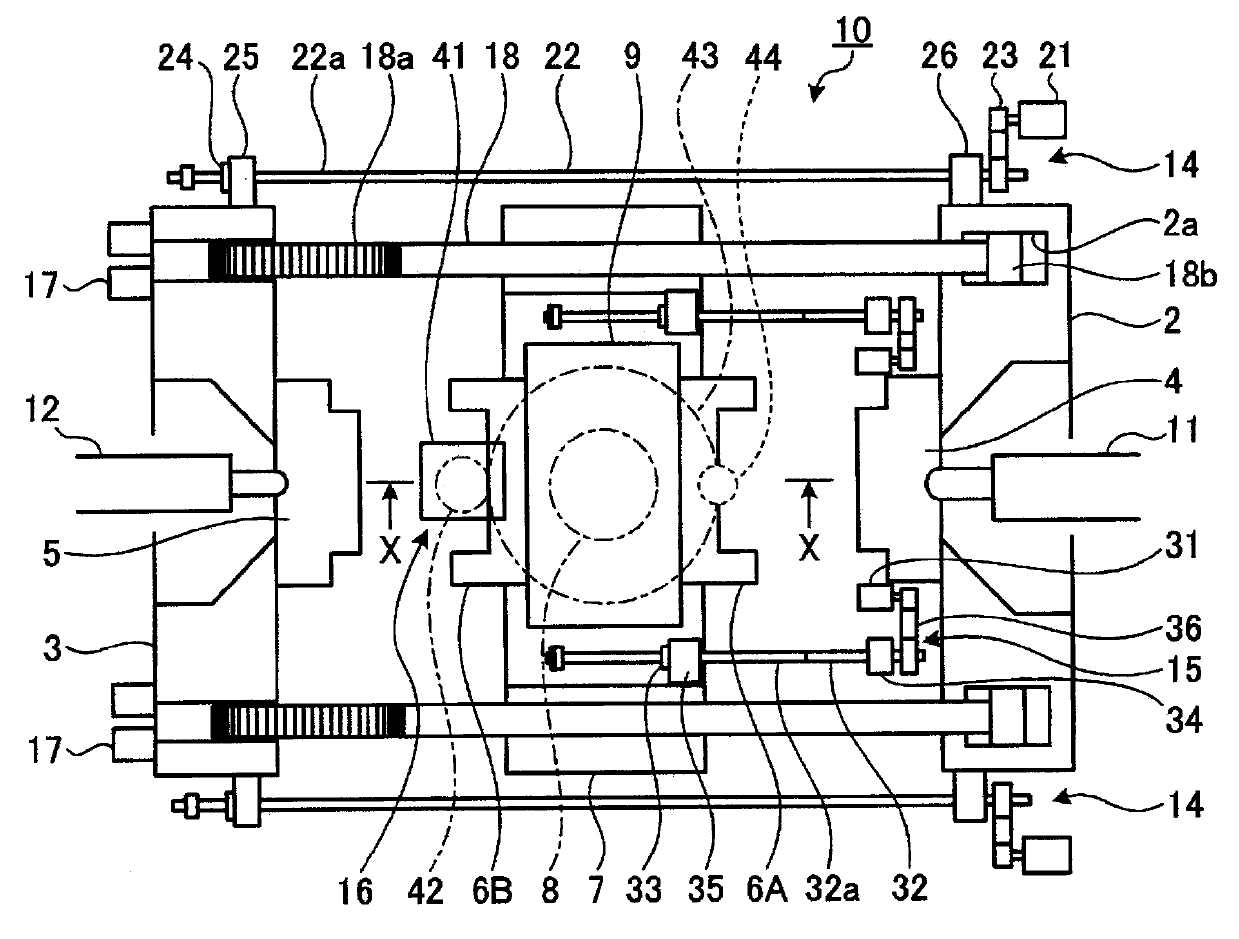

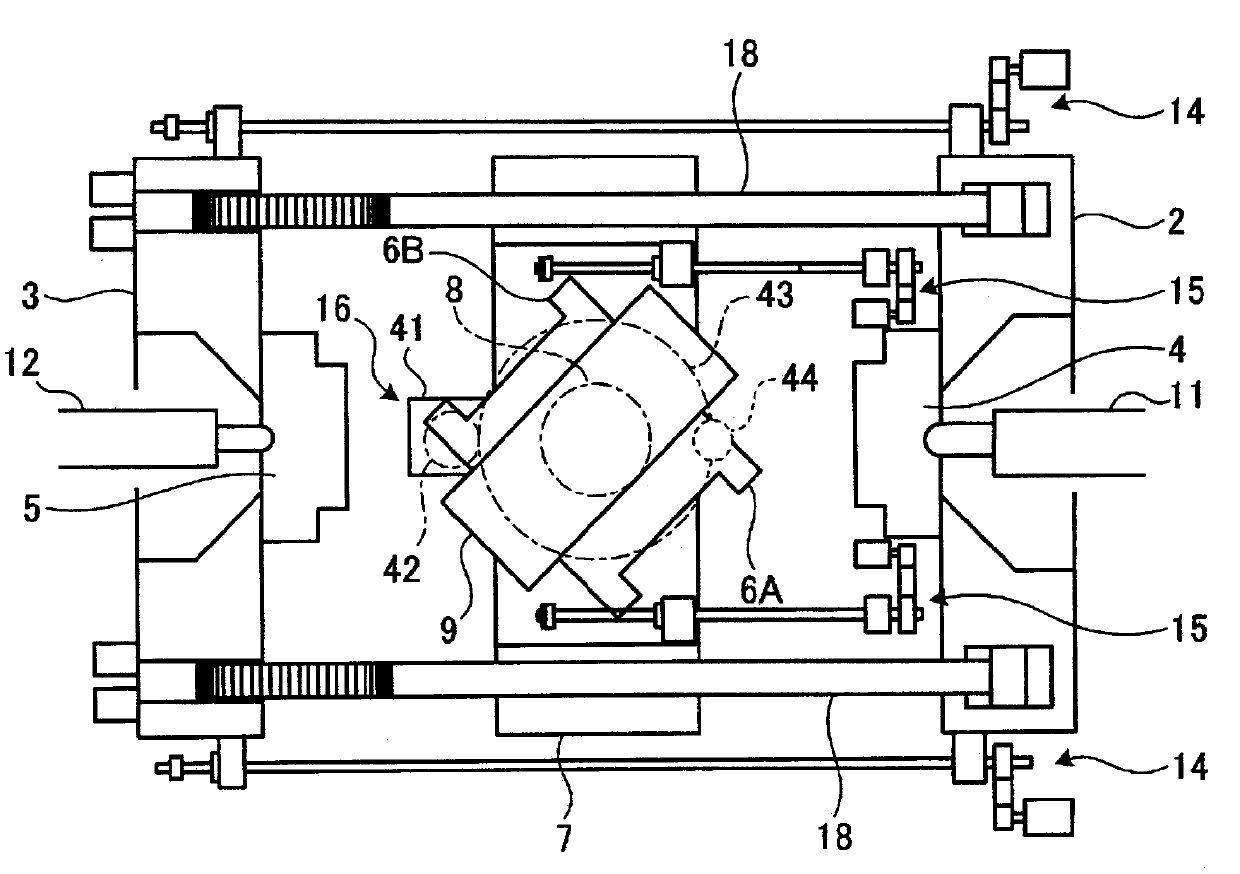

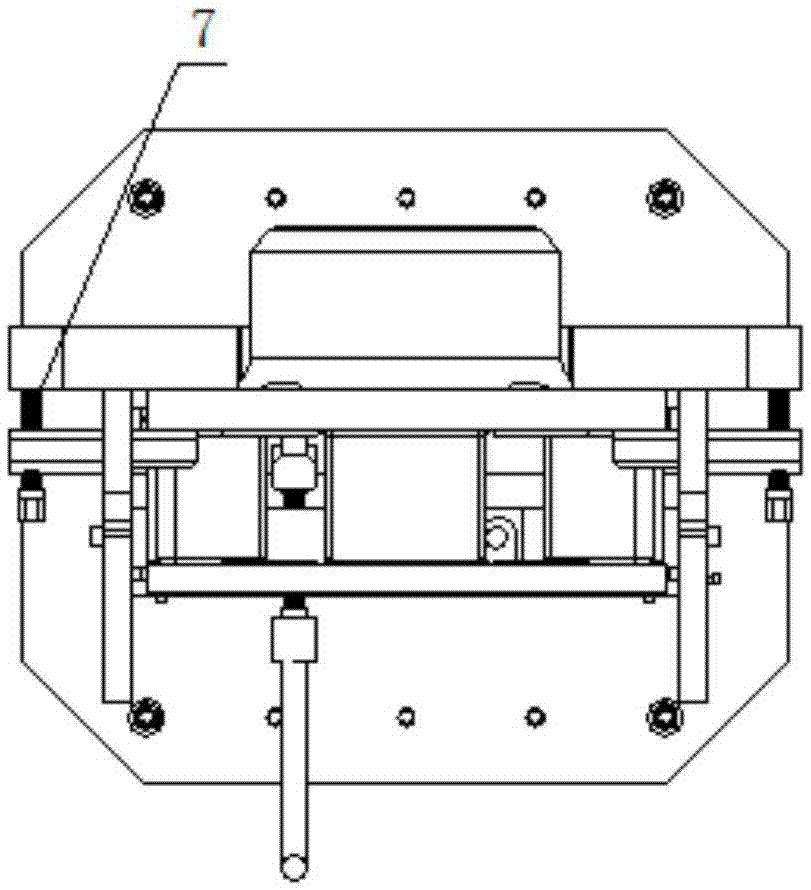

Injection molding machine for bimaterial molding and method of controlling the same

An injection molding machine for bimaterial molding equipped with two sets of injection units (11,12) capable of plasticization and injection filling of different resin materials, respectively, which injection molding machine comprises, as mold clamping means, hydraulic mold clamping means for simultaneously clamping three sets of die plates (2,3,9); as movable die plate opening / closing means (14), movable die plate opening / closing means driven by an electric motor; as rotary die plate opening / closing means (15), rotary die plate opening / closing means (14) driven by an electric motor; and, asrotating means for a rotary die plate (9), rotational driving means driven by an electric motor mounted on a reversal pedestal (7).

Owner:MITSUBISHI HEAVY INDS PLASTIC TECH

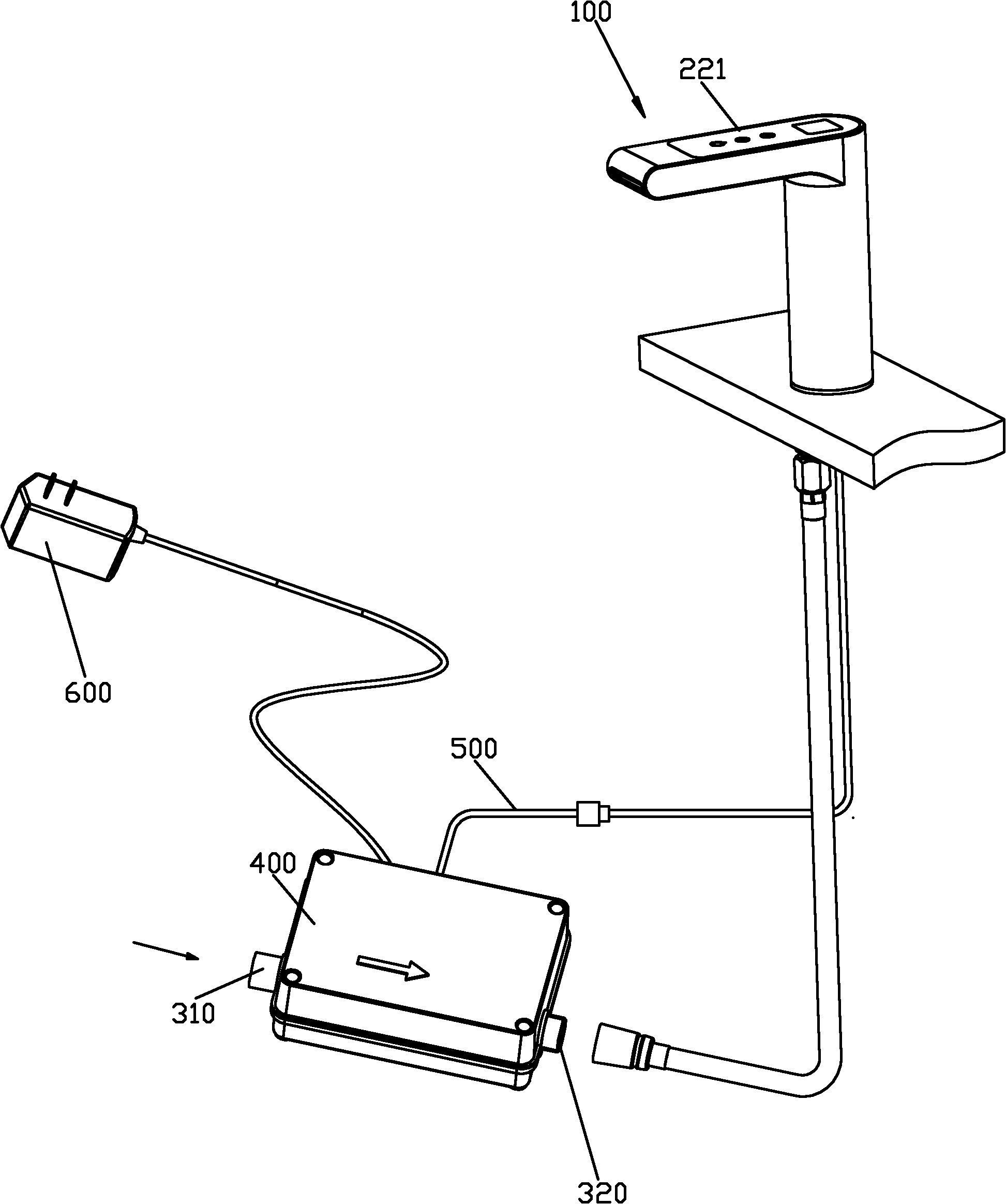

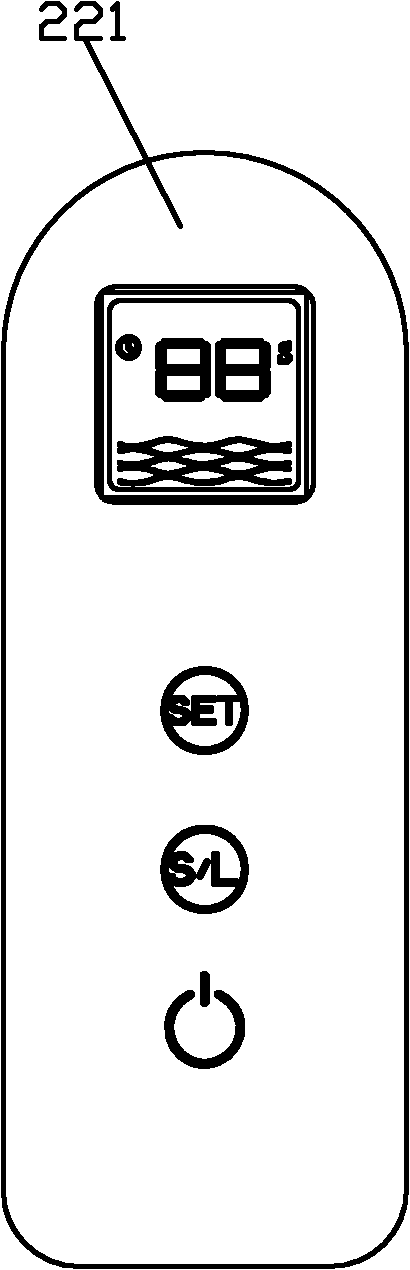

Timed touch tap and control method thereof

ActiveCN101858451AEasy to operate, fast and accurateConvenient, fast and accurate timing value settingOperating means/releasing devices for valvesFluid-delivery valvesWater savingControl signal

The invention discloses a timed touch tap and a control method thereof. The timing touch tap comprises a tap main body, an electromagnetic valve and a control device, wherein the electromagnetic valve is connected with a water source and the tap main body, the control device is connected with the electromagnetic valve and can control the electromagnetic valve to switch, the control device comprises a touch unit, two processors and an electromagnetic valve driving circuit, the touch unit is used for receiving a touch signal which is generated by the touch of a user and at least comprises a switch instruction and a timing value instruction, the first processor is used for sending a control signal when receiving the switch instruction, storing a timing value when receiving the timing value instruction, timing according to the timing value and sending the control signal in due time, the second processor is used for generating a driving signal after receiving the control signal, and the electromagnetic valve driving circuit is connected with the second processor and used for controlling the electromagnetic valve to switch after receiving the driving signal. The invention has the advantages that the water-saving effect can be achieved and is more humanized by combining a touch mode and an automatic system.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

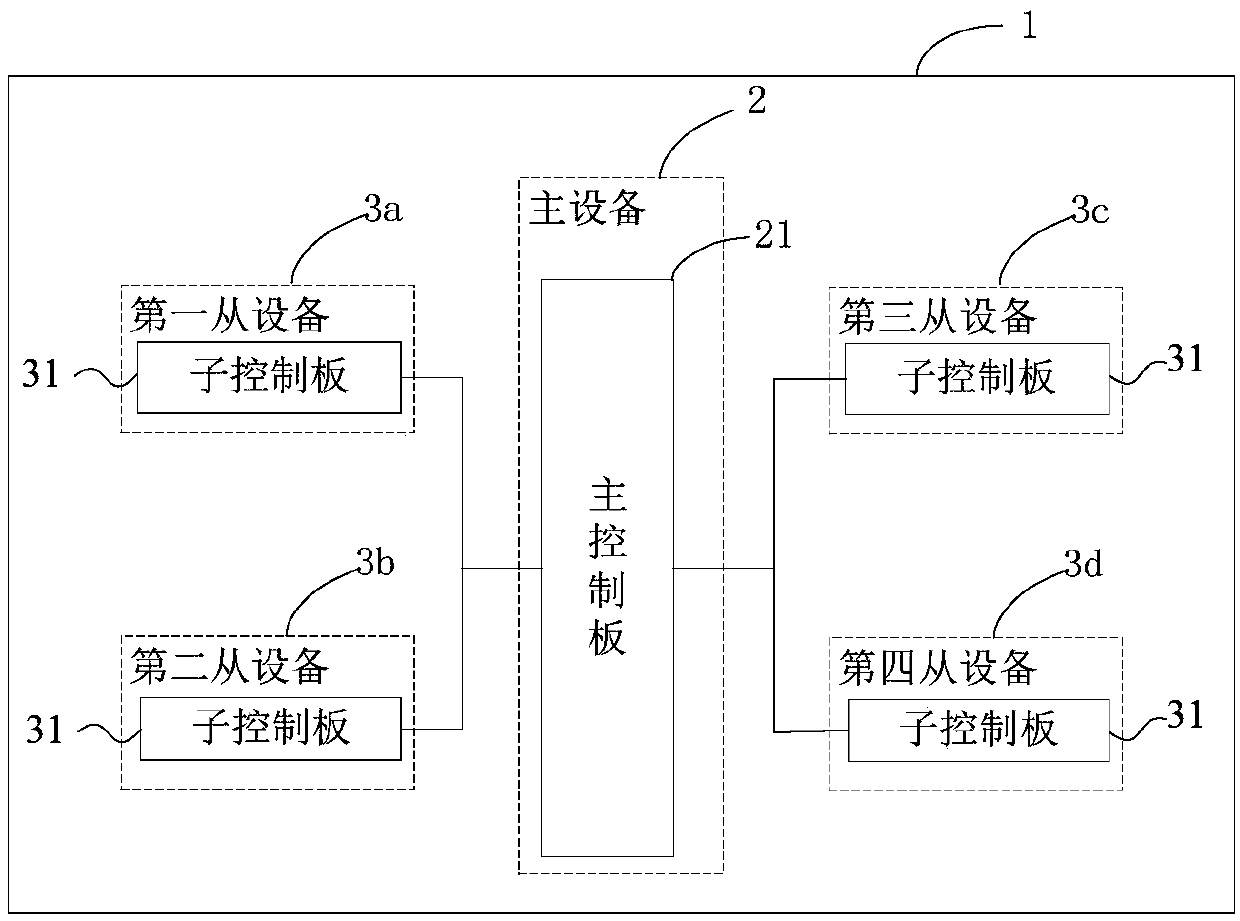

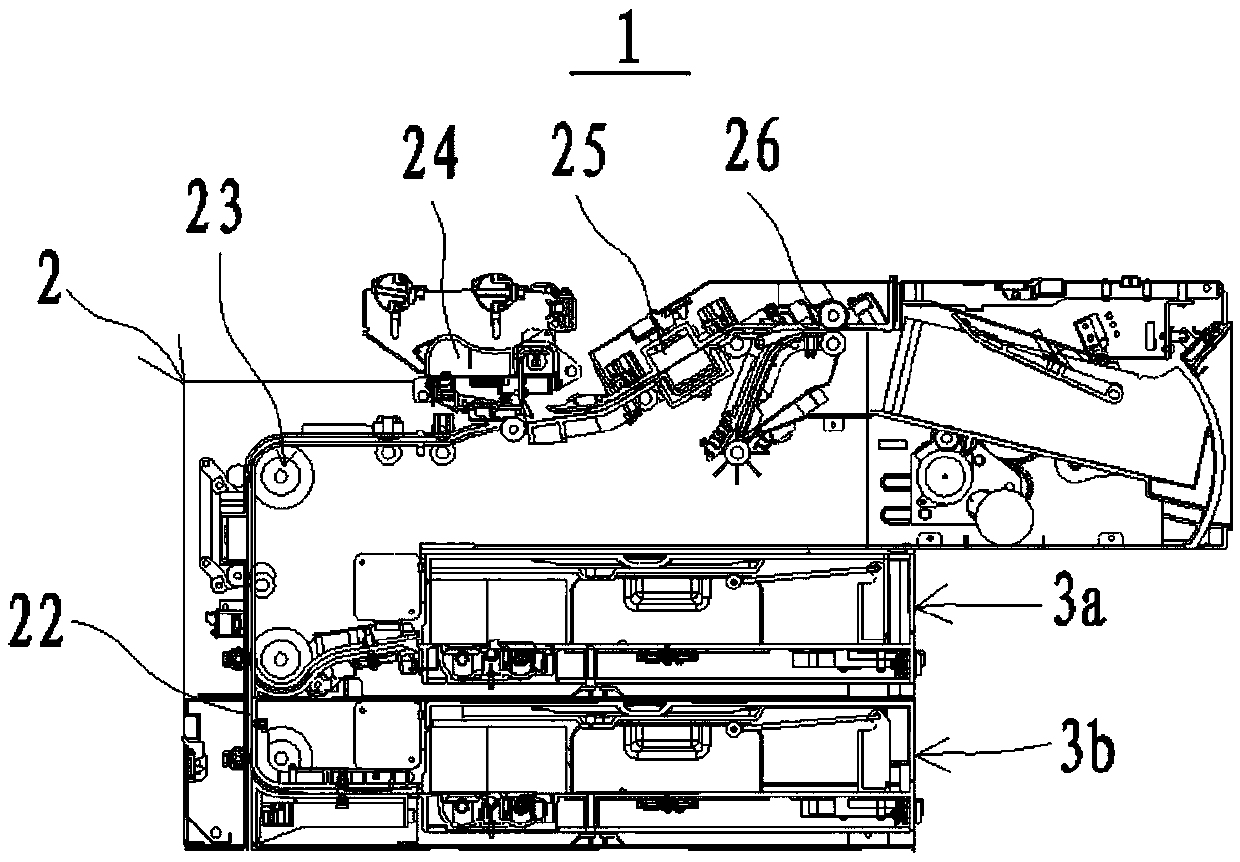

System with master and slave devices and ID number setting method of the slave devices

ActiveCN111245635AImprove convenienceReduce complexityData switching networksComputer hardwareEngineering

The invention relates to the technical field of communication, and discloses a system with master and slave devices and an ID number setting method of the slave devices. According to the system with the master device and the slave devices and the ID number setting method of the slave devices, the master device included in the system can automatically set the ID number of each slave device in sequence according to the cascading sequence of the multiple slave devices. When the slave devices are mounted or replaced, a user does not need to manually distinguish and set the slave devices; therefore, the convenience for a user to install or replace the slave devices can be greatly improved, the setting error caused by the fact that the user manually distinguishes and sets the slave devices is avoided, and the problems that in the prior art, when a system is used for installing and replacing the slave devices, operation is tedious, and errors are prone to occurring are solved. Because a new slave device can be directly cascaded behind the last existing slave device, the expansion is convenient. And a dial switch does not need to be arranged on the slave devices, so that the cost of the slave devices and the complexity of the circuit are reduced.

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

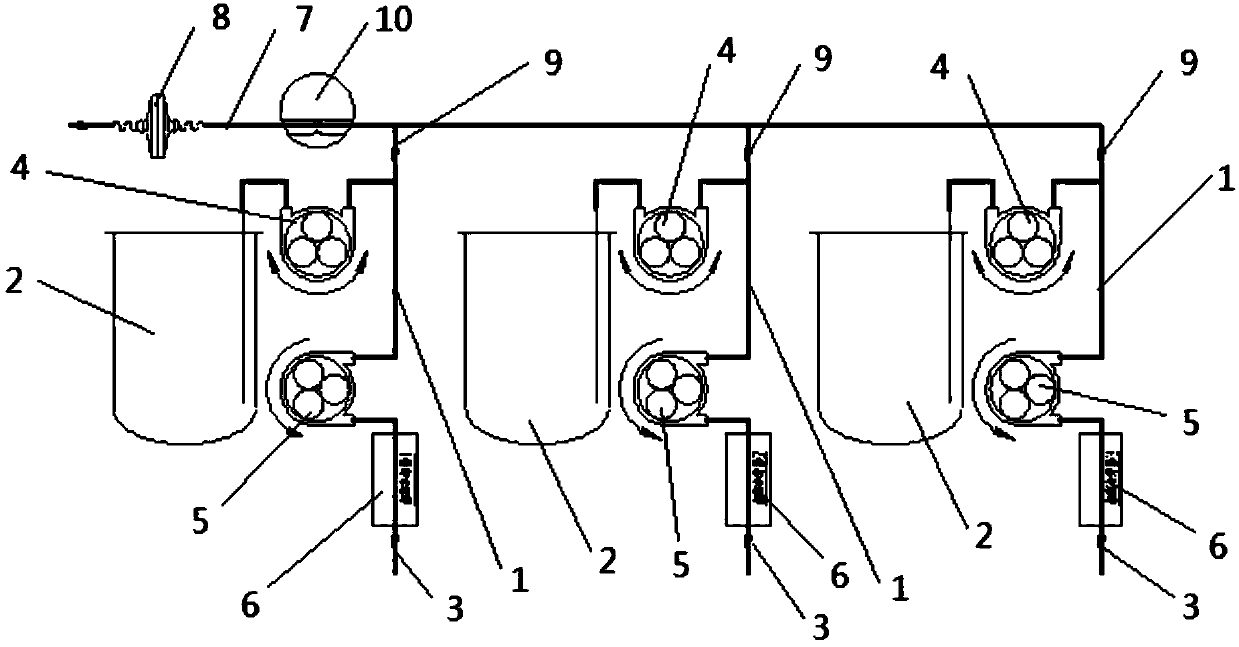

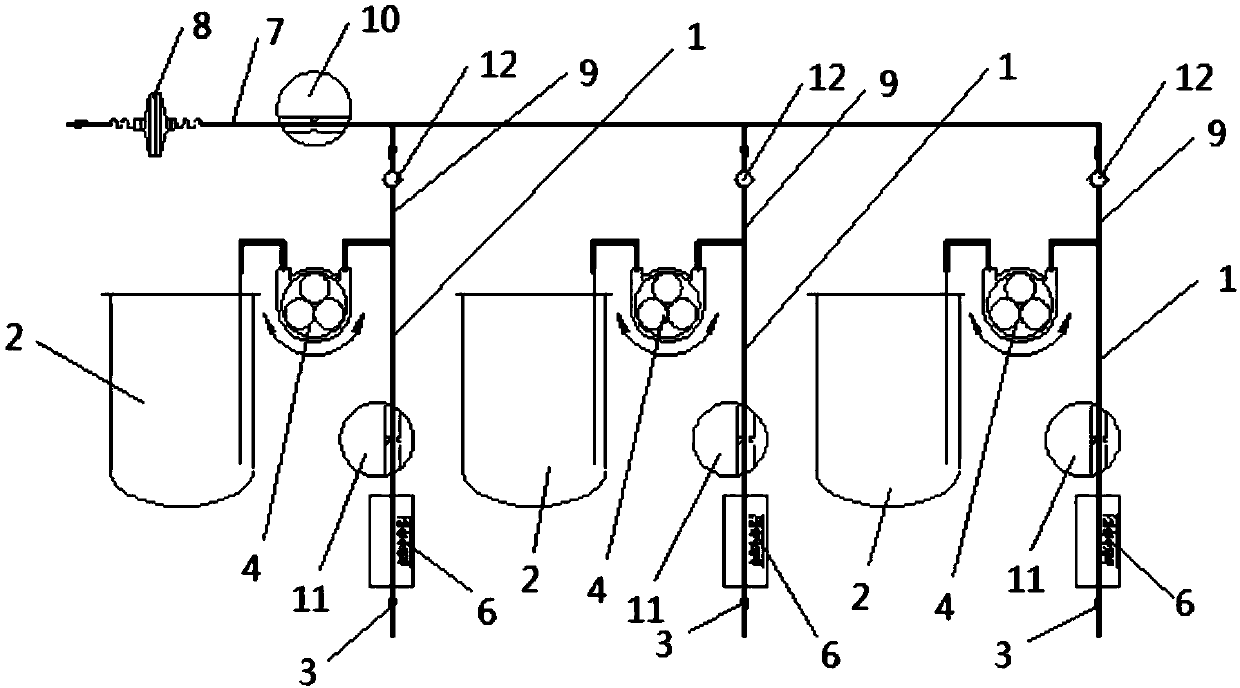

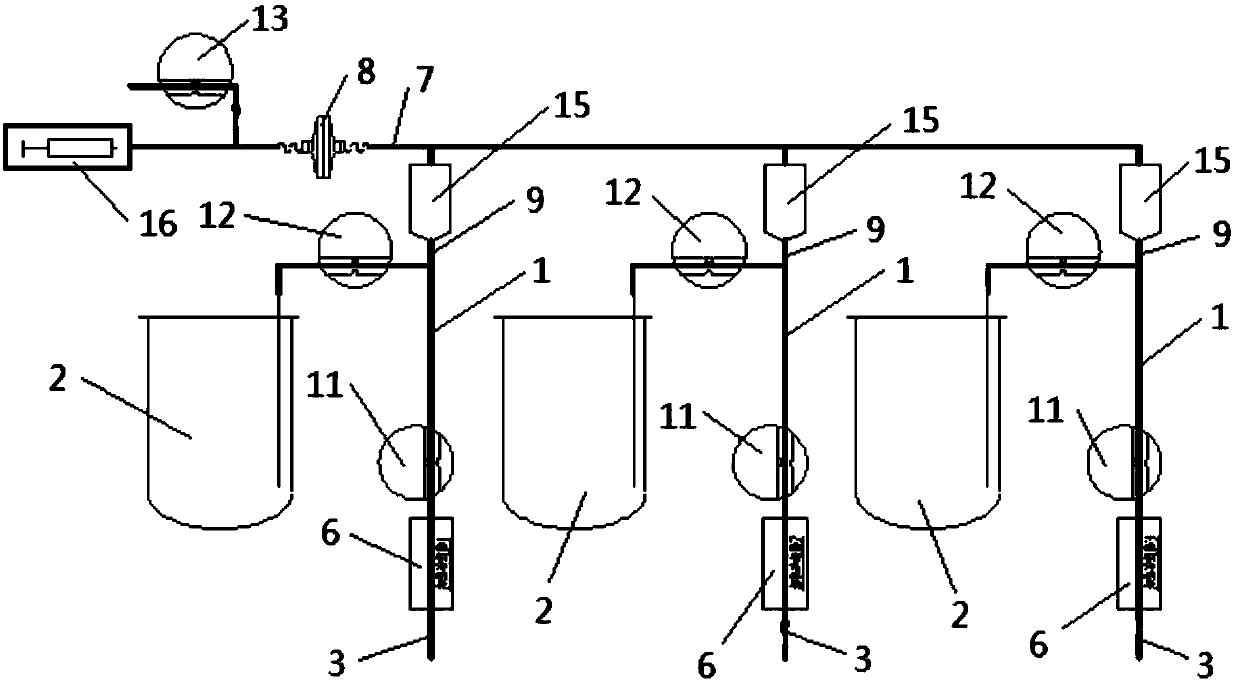

Multi-channel automatic quantitative sterile sampling device and bioreactor with same

PendingCN107641596AGuaranteed credibilityEliminate biasBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpPinch valve

The invention discloses a multi-channel automatic quantitative sterile sampling device and a bioreactor with the same. The multi-channel automatic quantitative sterile sampling device comprises a plurality of sampling pipes, first peristaltic pumps, second peristaltic pumps, first heating and cooling units, a main gas pipe and a first pinch valve, wherein the sampling ends of the sampling pipes are positioned inside different bioreactors, and the other ends of the sampling pipes are sample outlets; one first peristaltic pump is arranged on each sampling pipe, and all first peristaltic pumps are positioned between the bioreactors and the sample outlets; one second peristaltic pump is arranged on each sampling pipe, and all second peristaltic pumps are positioned between the first peristaltic pumps and the sample outlets; one first heating and cooling unit is arranged on each sampling pipe, and all first heating and cooling units are positioned between the second peristaltic pumps and the sample outlets; one end of the main gas pipe is connected with an air filter, and a plurality of branched gas pipes are arranged at the other end of the main gas pipe; each branched gas pipe is communicated with one sampling pipe, and all conjunctions are positioned between the first peristaltic pumps and the second peristaltic pump; the first pinch valve is arranged on the main gas pipe, and ispositioned between the air filter and the branched gas pipes.

Owner:SHANGHAI GUOQIANG BIOCHEMICAL ENG EQUIP CO LTD +1

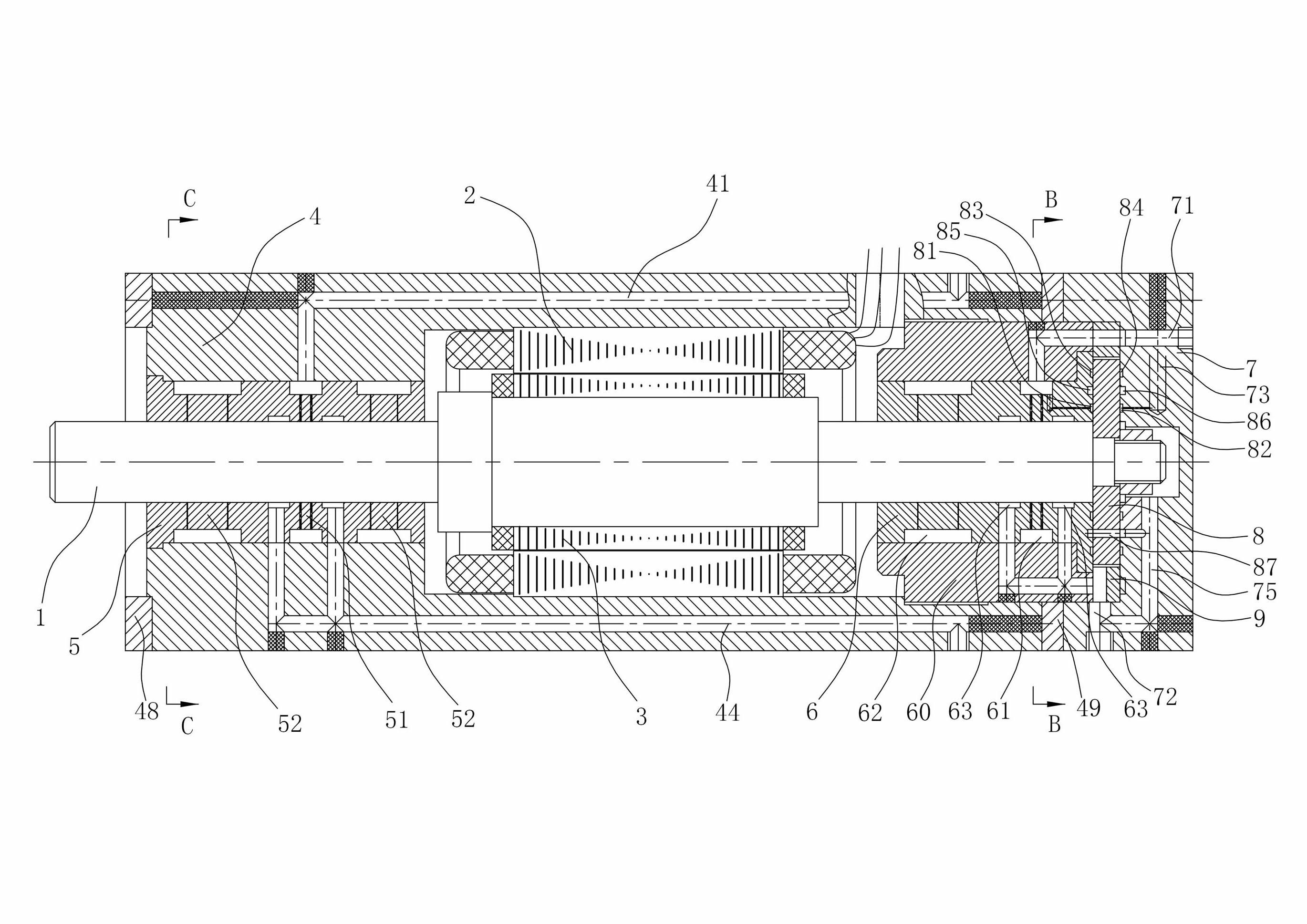

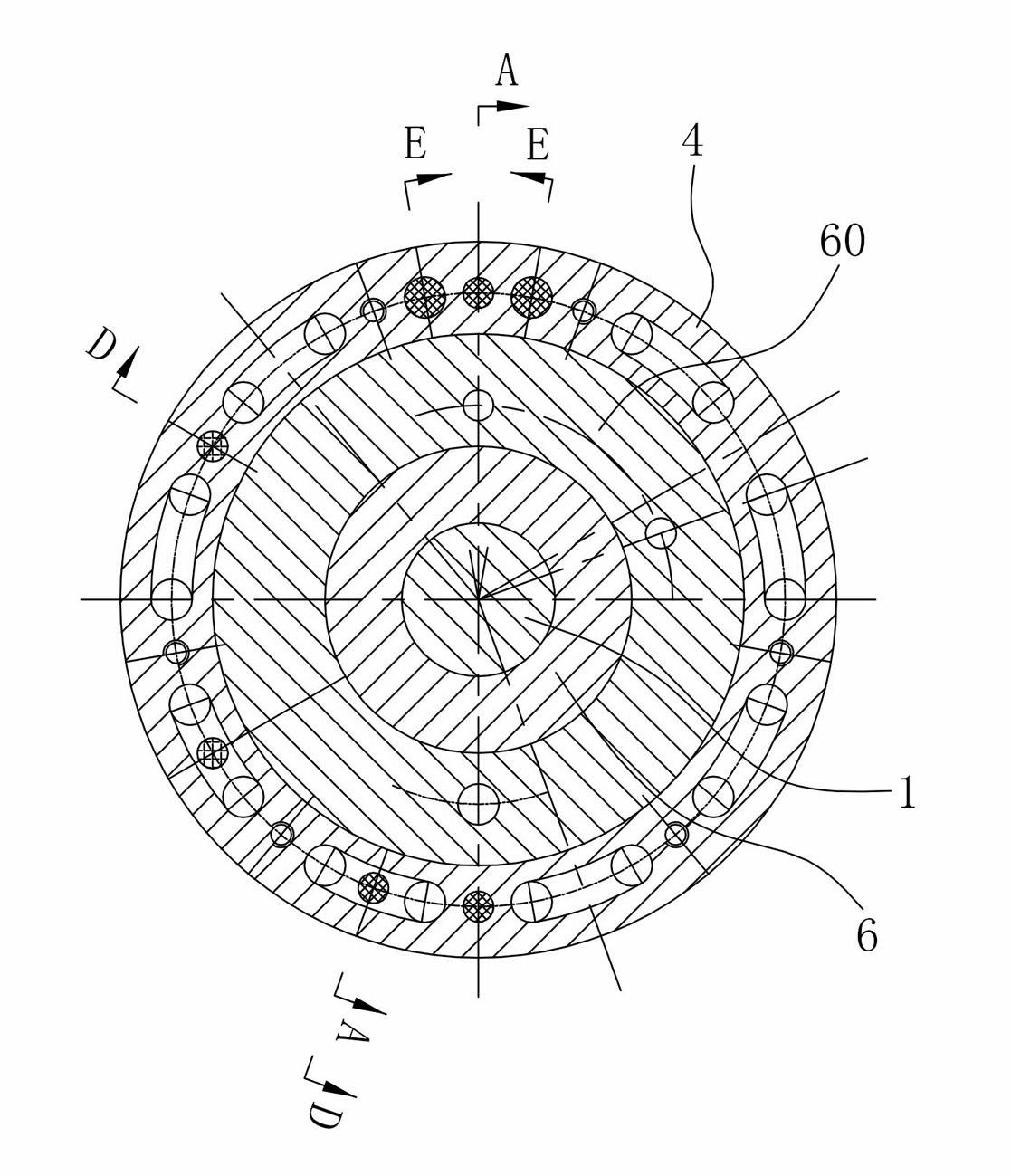

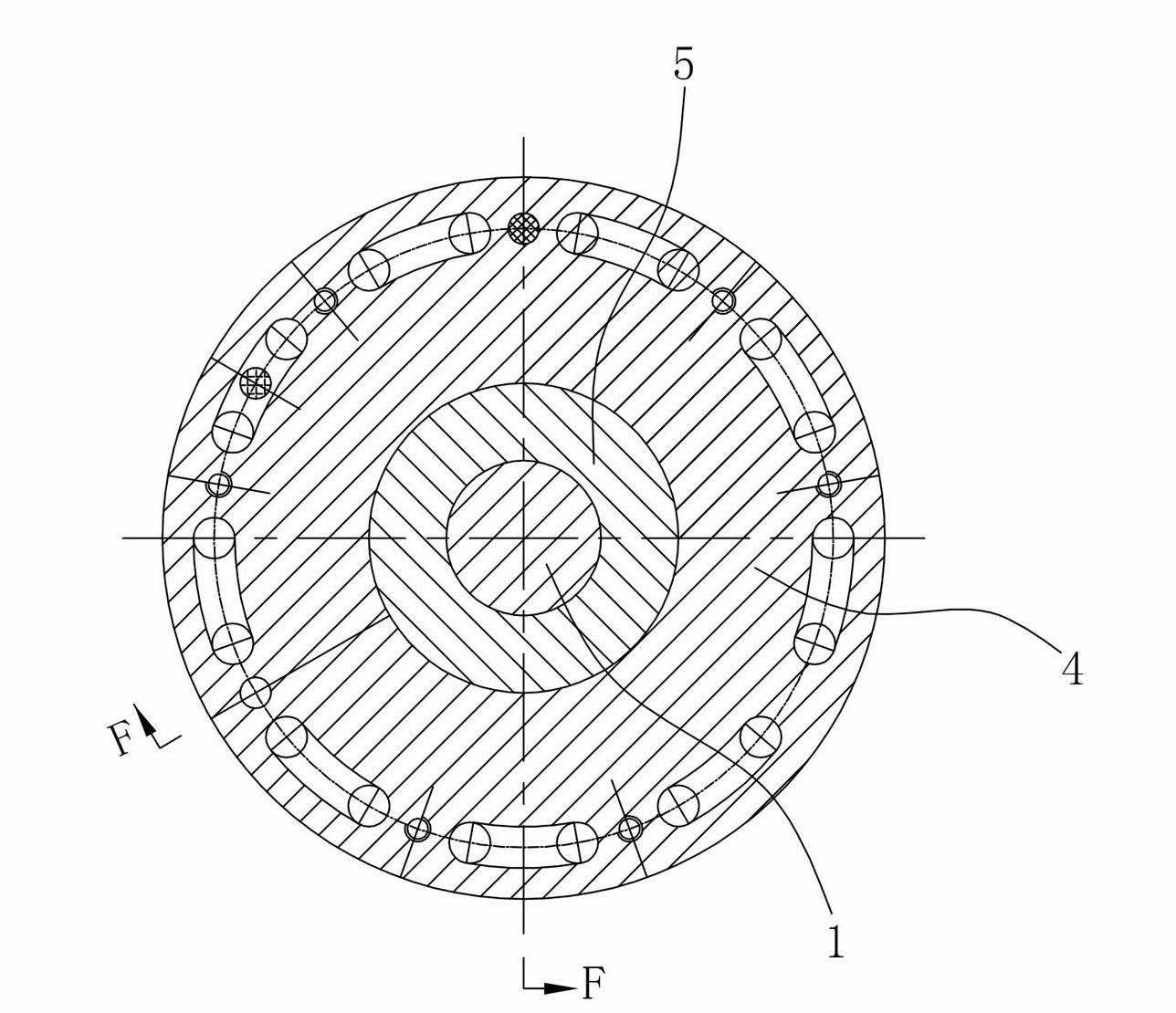

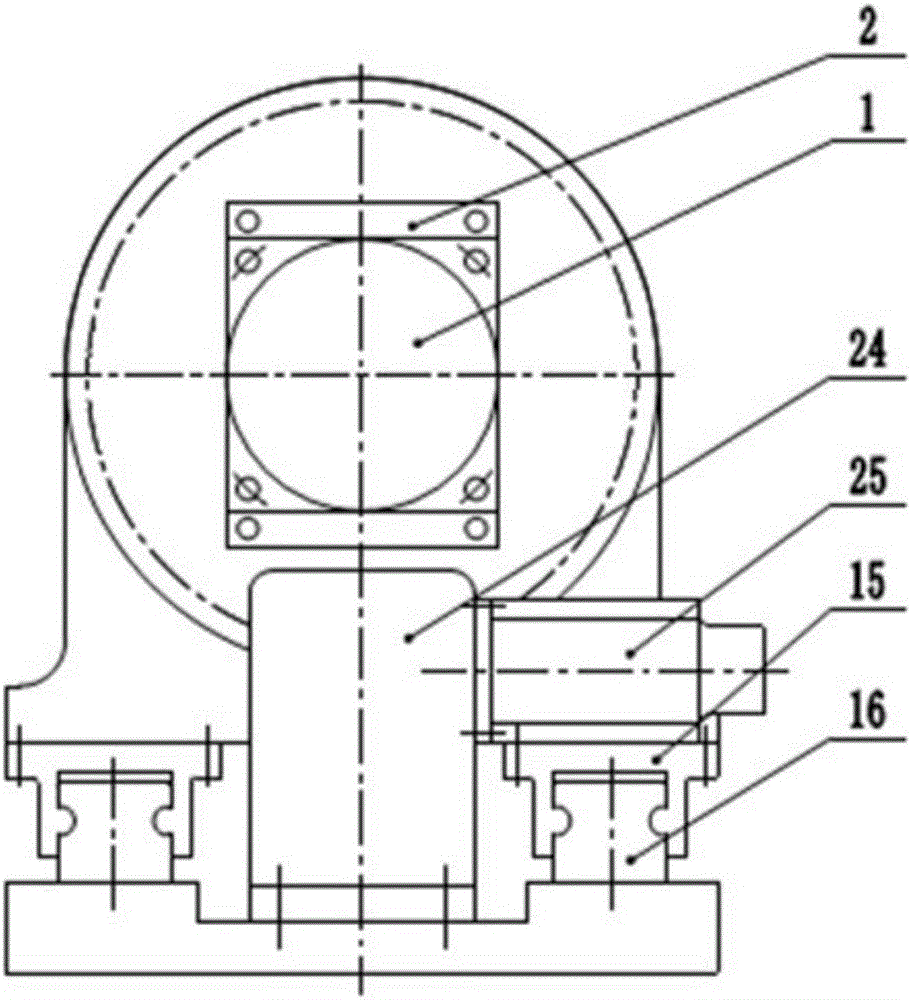

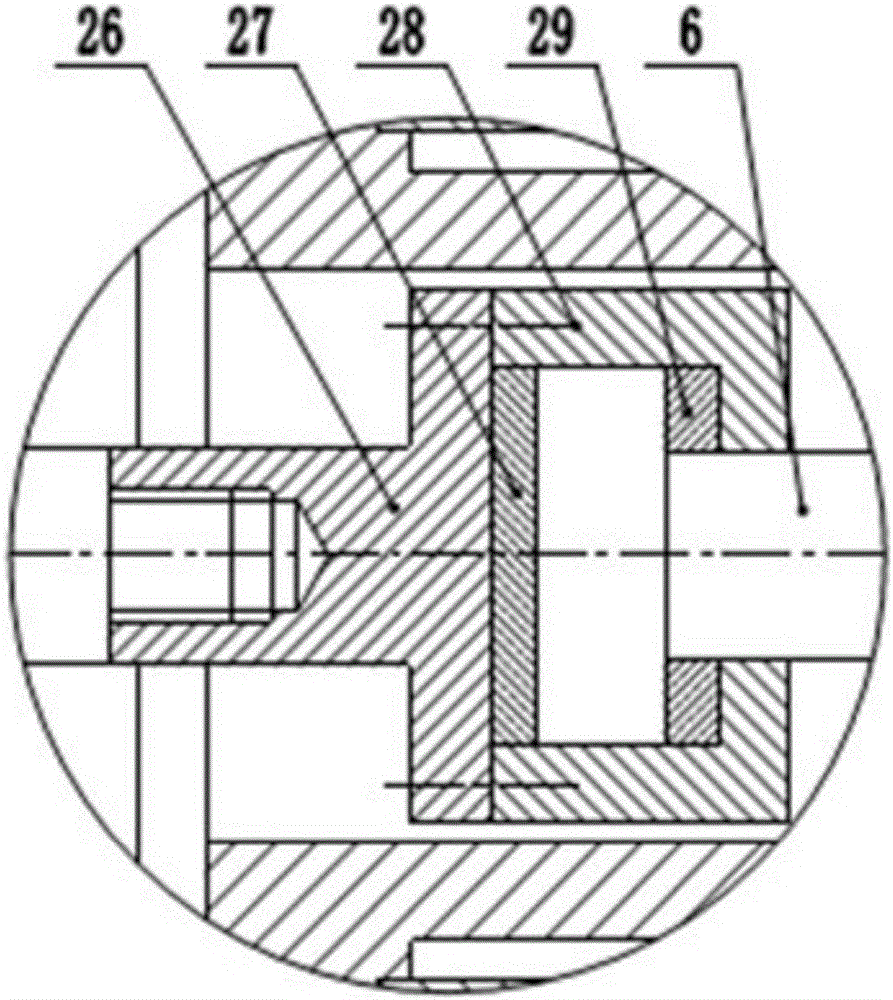

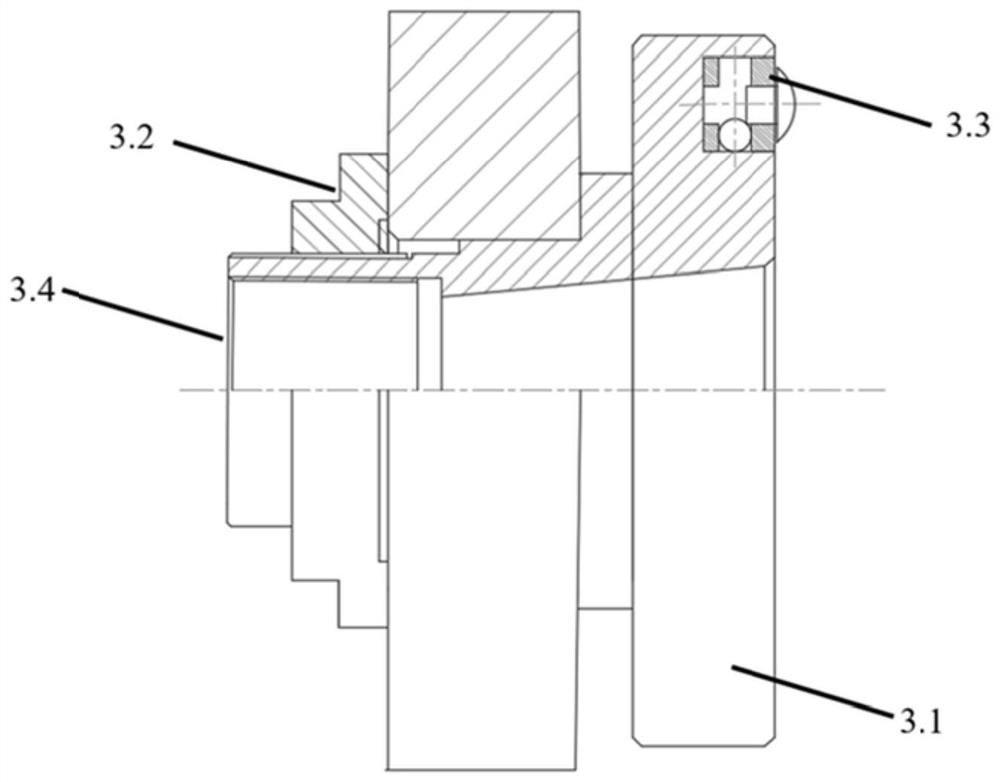

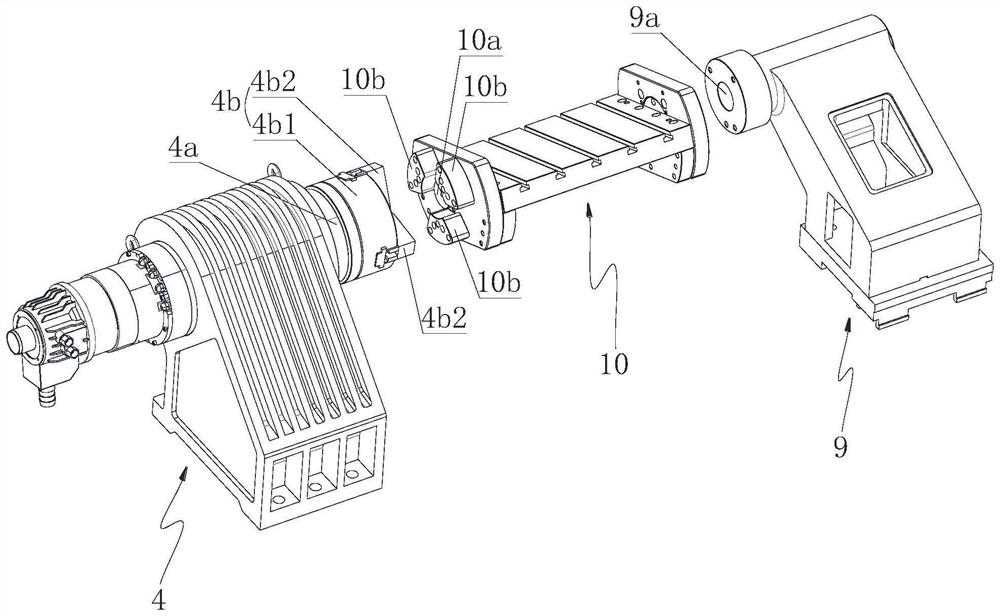

Liquid-gas suspension electric main shaft

InactiveCN102101180AImprove efficiencyHigh precisionMetal-working apparatusEngineeringMechanical engineering

The invention discloses a liquid-gas suspension electric main shaft. The liquid-gas suspension electric main shaft comprises a main shaft, a motor stator, a motor rotor, a box body, a front bearing assembly and a rear bearing assembly, wherein the motor stator is sleeved in the box body; the motor rotor is sleeved on the main shaft; the main shaft is placed into the motor stator and is supported on the box body through the front bearing assembly and the rear bearing assembly; the front bearing assembly is provided with at least one front liquid bearing and at least one front gas bearing; and the front liquid bearing and the front gas bearing are arranged axially. The liquid-gas suspension electric main shaft can meet requirements of high-efficiency processing and high-precision processing at the same time.

Owner:HUNAN UNIV

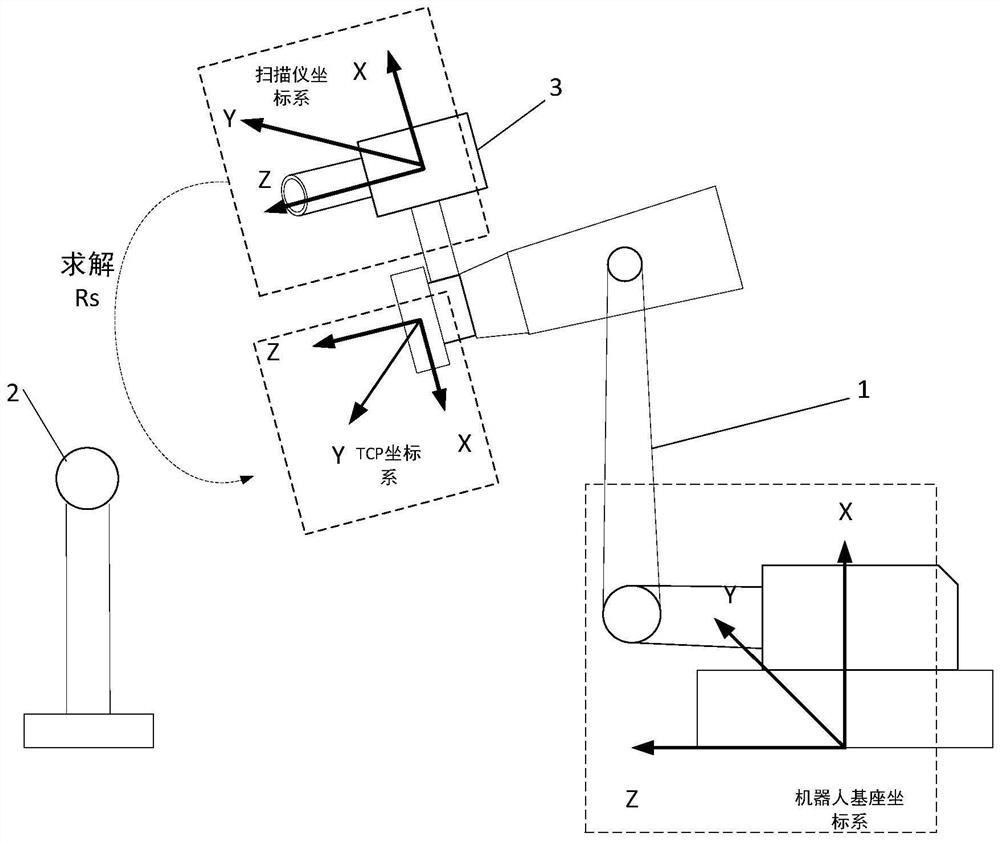

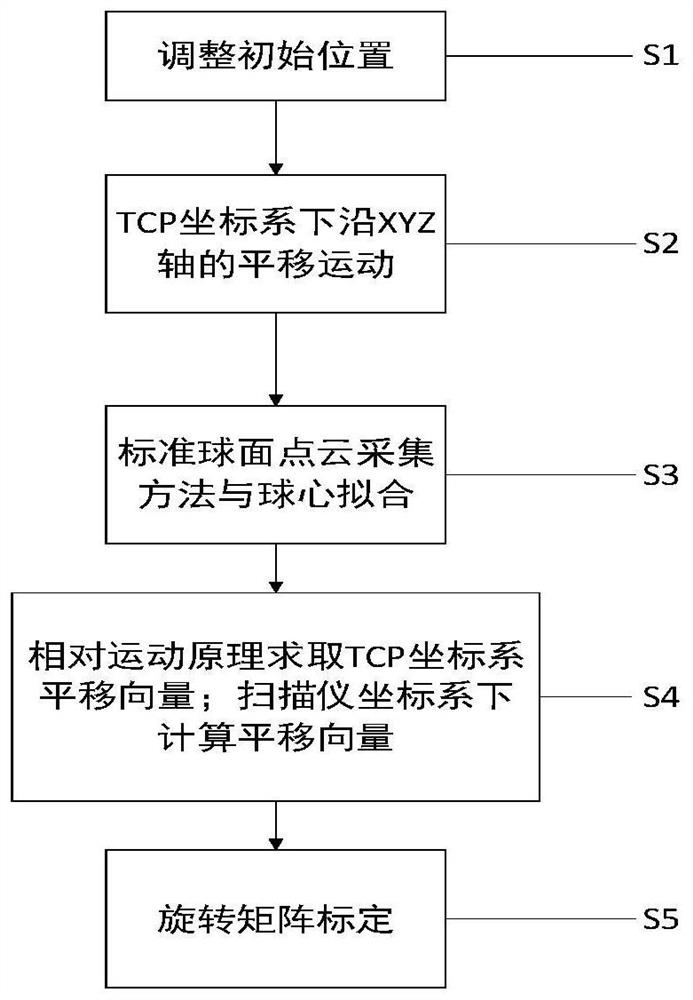

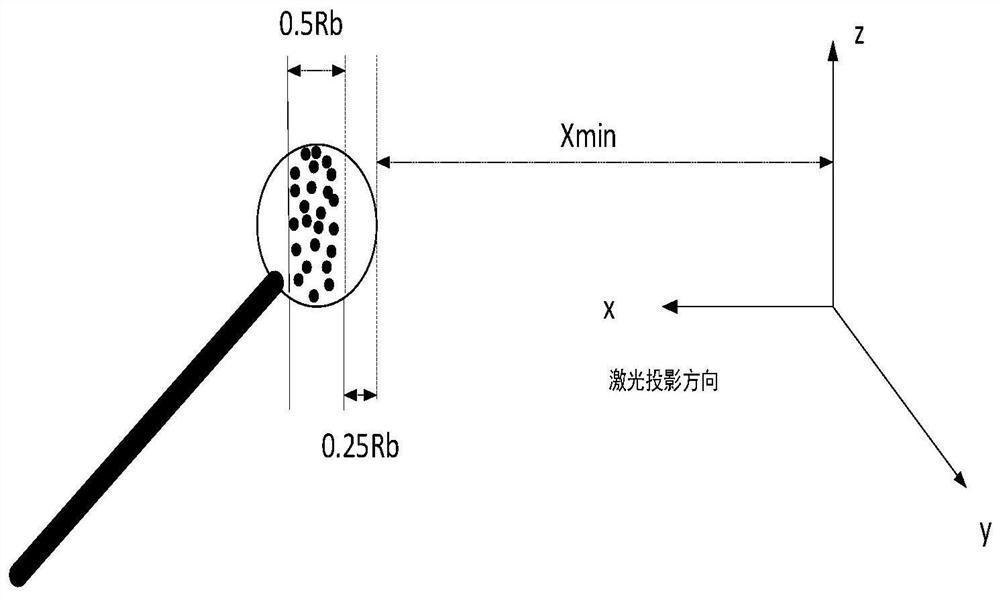

Rotation matrix calibration method based on transverse moving motion in TCP coordinate system

ActiveCN111633643AAvoid setup errorsHigh precisionProgramme-controlled manipulatorScannerPoint cloud

The invention discloses a rotation matrix calibration method based on transverse moving motion in a TCP coordinate system. The method comprises the steps that firstly, a standard ball is set, a robotis controlled to carry a scanner to do transverse moving motion in three axis directions of the TCP coordinate system in the TCP coordinate system, and in the motion process, the standard ball is scanned; point cloud data of the standard at the different positions in the motion and coordinates of the ball center in the scanner coordinate system are obtained; and calculation is carried out to obtain three orthogonal unit transverse moving vectors of the ball center in the TCP coordinate system and the scanner coordinate system, and according to the corresponding transverse moving vectors, calibration of a rotation matrix can be finished. The automatic calibration flow is adopted, calibration of the rotation matrix can be finished through three times of transverse moving in the three coordinate axis directions in the TCP coordinate system, characteristic points, a calibration plate and the like do not need to be set, operation is easy, the calibration efficiency is high, the clamping error can be avoided, the calibration precision is high, and the method is suitable for measuring and machining integration of complex part robots in fields of machines, cars and the like.

Owner:WUHAN UNIV OF TECH

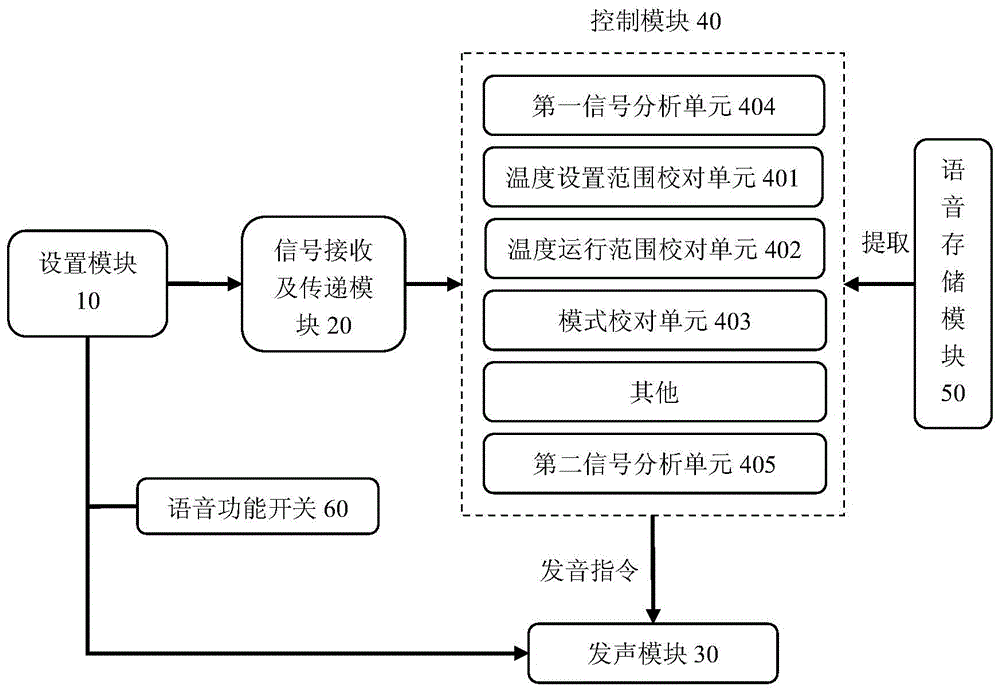

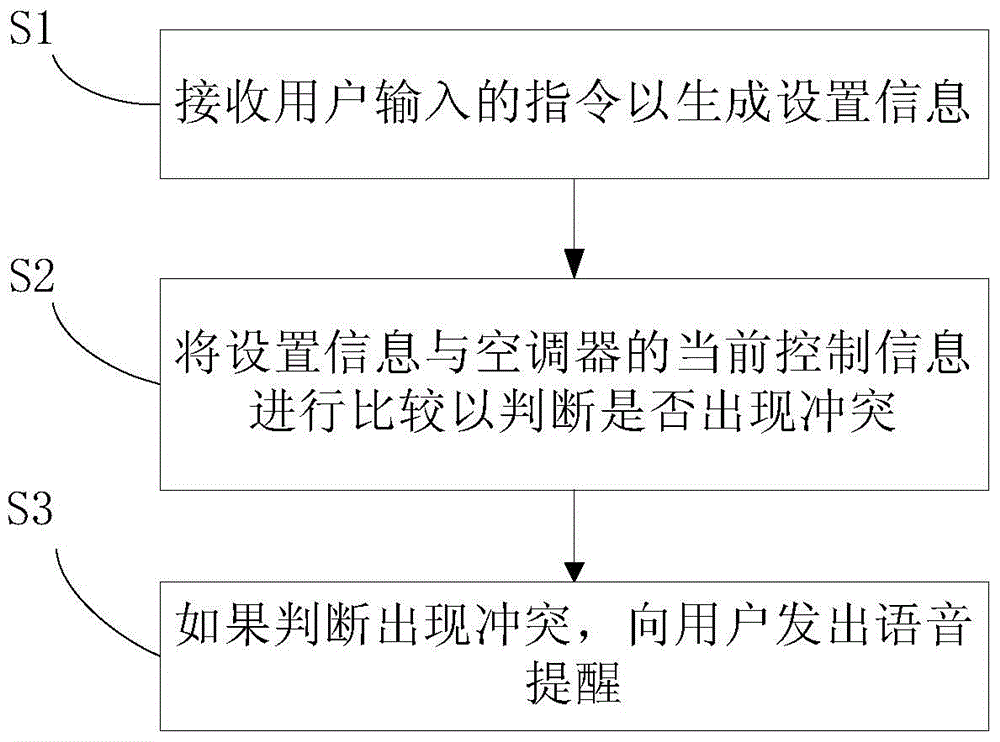

Air conditioner and voice reminding system and method of air conditioner

InactiveCN104697130AAvoid setup errorsEasy to useMechanical apparatusSpace heating and ventilation safety systemsComputer science

The invention discloses a voice reminding system of an air conditioner. The voice reminding system comprises a setting module, a signal receiving and transmitting module, a voice making module and a control module, wherein the setting module is used for receiving an instruction input by a user to generate setting information; the signal receiving and transmitting module is used for receiving the setting information sent by the setting module and transmitting the setting information; the control module is connected with the signal receiving and transmitting module and the voice making module; the control module is used for receiving the setting information sent by the signal receiving and transmitting module, and comparing the setting information with current control information of the air conditioner to judge whether a conflict appears or not; if so, the control module is used for controlling the voice making module to send out voice reminding to the user. The voice reminding system can be used for providing the voice reminding in time when starting setting of the air conditioner of the user has the faults, and the use satisfying degree of the user is improved to a certain extent. The invention further discloses the air conditioner comprising the voice reminding system and a voice reminding method of the air conditioner.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

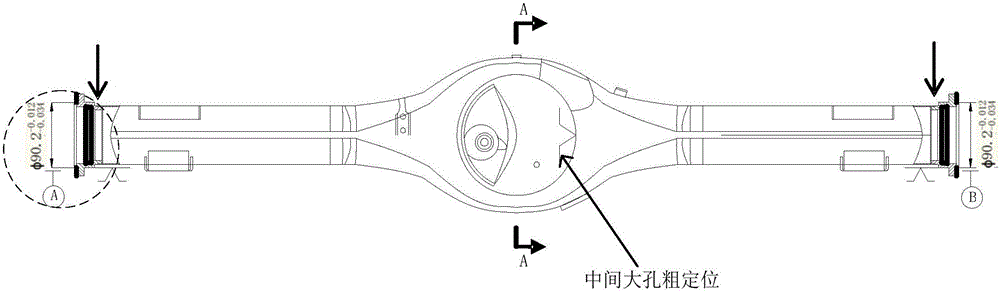

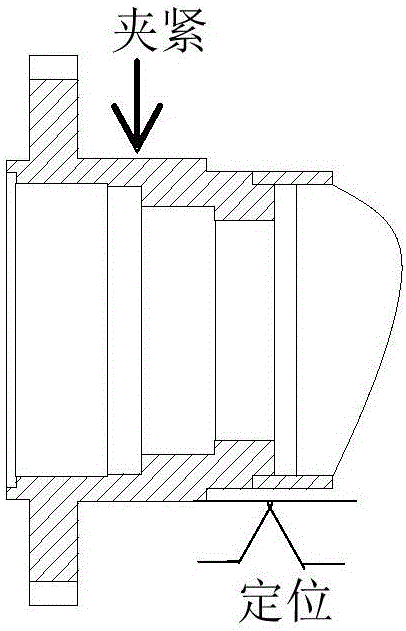

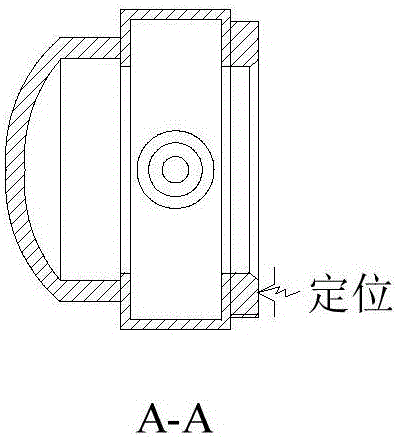

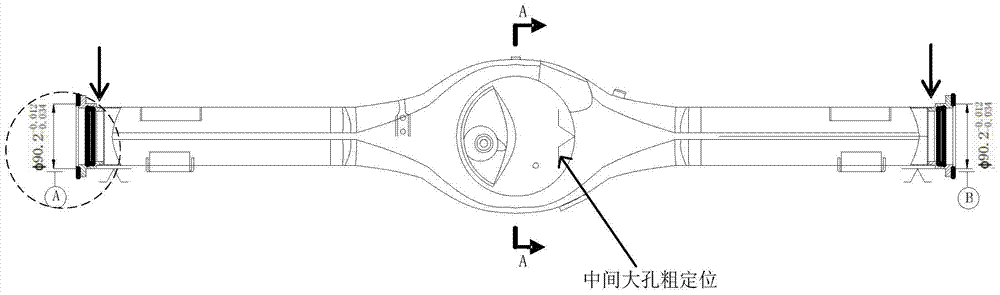

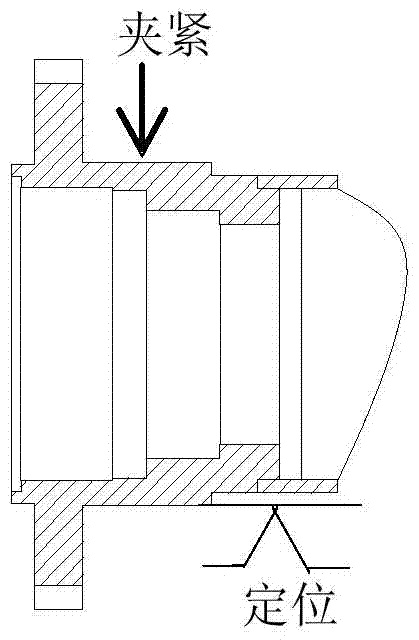

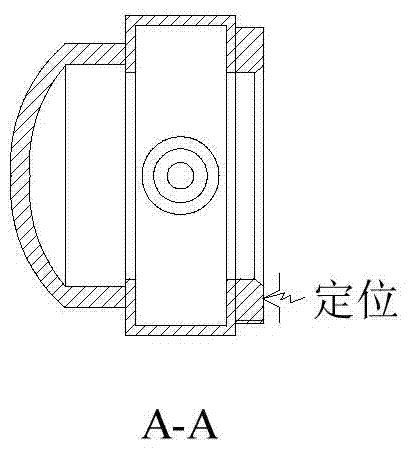

Method for synchronously machining flange plates at two ends of rear axle housing welding assembly

ActiveCN105033284AGuaranteed coaxiality requirementsAvoid misalignmentWork clamping meansPositioning apparatusEngineeringMachining

The invention relates to a method for synchronously machining flange plates at the two ends of a rear axle housing welding assembly. The method comprises the steps that firstly, rough locating is conducted through a middle large hole of a rear axle housing, and V-shaped main locating and clamping are conducted through outer circles of the flanges at the two ends; secondly, main shafts at the two ends drive end face facing head end face roughing tools at the same time to rough turn large end faces and spigot end faces, and an axial machining allowance is reserved; thirdly, the main shafts at the two ends drive end face facing head end face finishing tools at the same time to fine turn the large end faces and the spigot end faces, and the requirements for the size of the large end faces, the size between the spigot end faces and the large end faces, the roughness of the large end faces, the circular run-out of the large end faces and the perpendicularity between the end faces and the axis of the outer circles of inner holes are met; fourthly, the main shafts at the two ends drive inner hole outer circle combined roughing tools to turn the spigot outer circles and the inner holes of flange heads at the two ends, and machining allowance is reserved; and finally, the main shafts at the two ends drive inner hole outer circle combined finishing tools to fine turn the spigot outer circles and the inner holes, and the requirements for coaxiality between the flanges at the two ends and the coaxiality between the inner circle and the outer circle of each flange are met. By the adoption of the method, multiple procedures are completed through one-time clamping.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

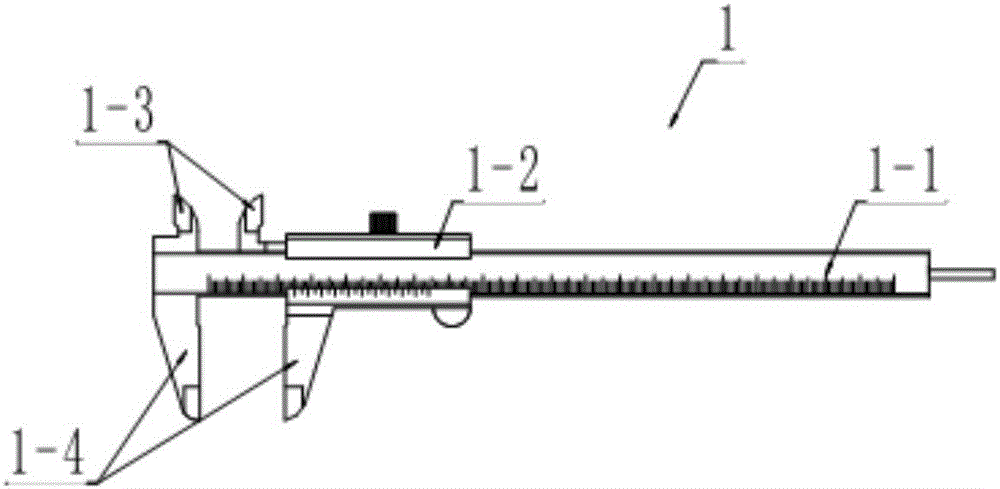

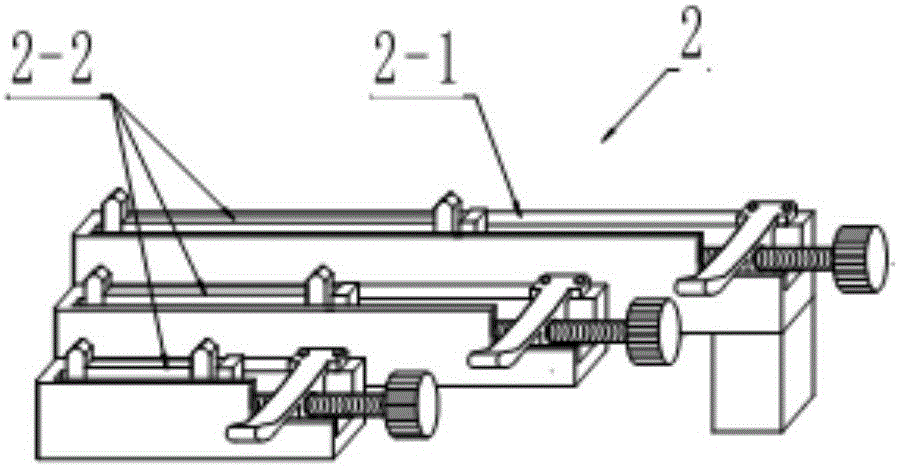

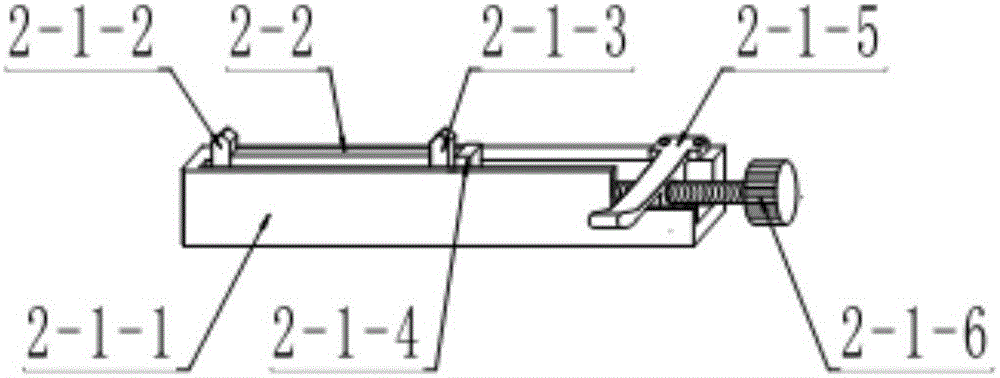

Vernier caliper internal measuring claw reading accuracy detection fixture and detection method

The invention provides a vernier caliper internal measuring claw reading accuracy detection fixture and detection method, and belongs to the technical field of test and measurement. The vernier caliper internal measuring claw reading accuracy detection fixture comprises a clamp and a standard gauge block. The clamp is composed of at least three sets of clamp units which are different in length. Each set of clamp unit is provided with a base, a fixed reference block, a flexible reference block and a flexible reference block abutting mechanism. The base is provided with a slide groove. One end of the slide groove is provided with the fixed reference block. The flexible reference block is arranged in the slide groove. The flexible reference block can horizontally move in the slide groove. The flexible reference block is abutted and located by the flexible reference block abutting mechanism. With application of the vernier caliper internal measuring claw reading accuracy detection fixture and detection method, the influence of artificial factors and environmental factors on the measurement result can be reduced so that the working efficiency can be enhanced, and the accuracy of vernier caliper internal measuring claw reading accuracy detection can be guaranteed.

Owner:FACTORY 5721 OF PLA

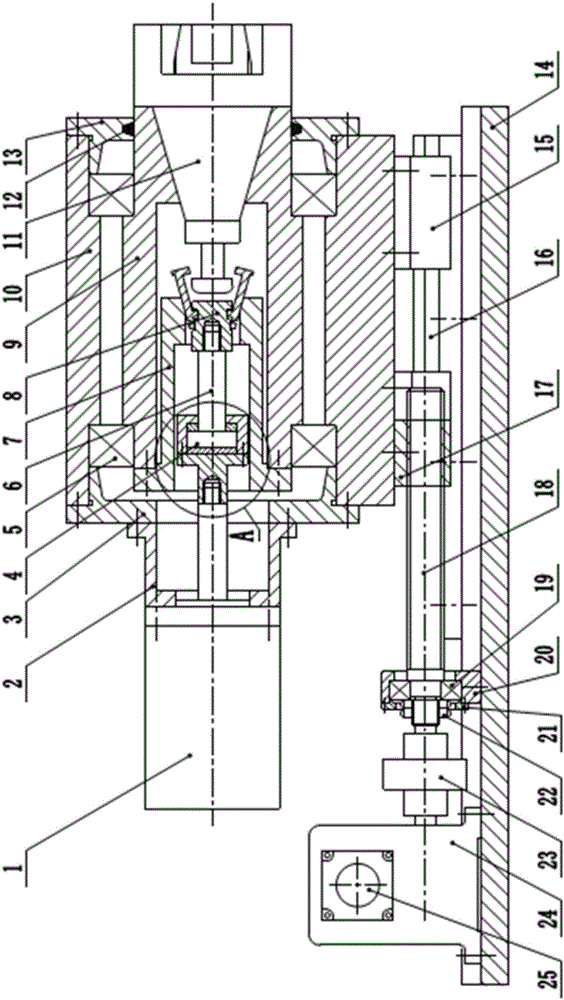

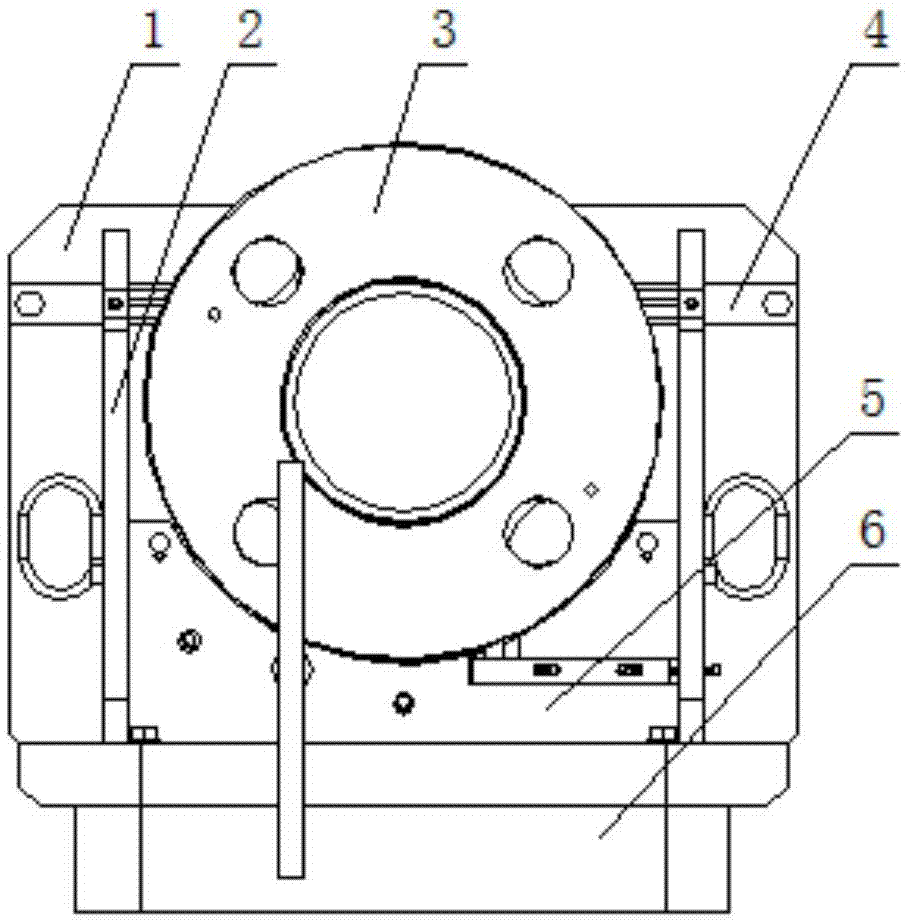

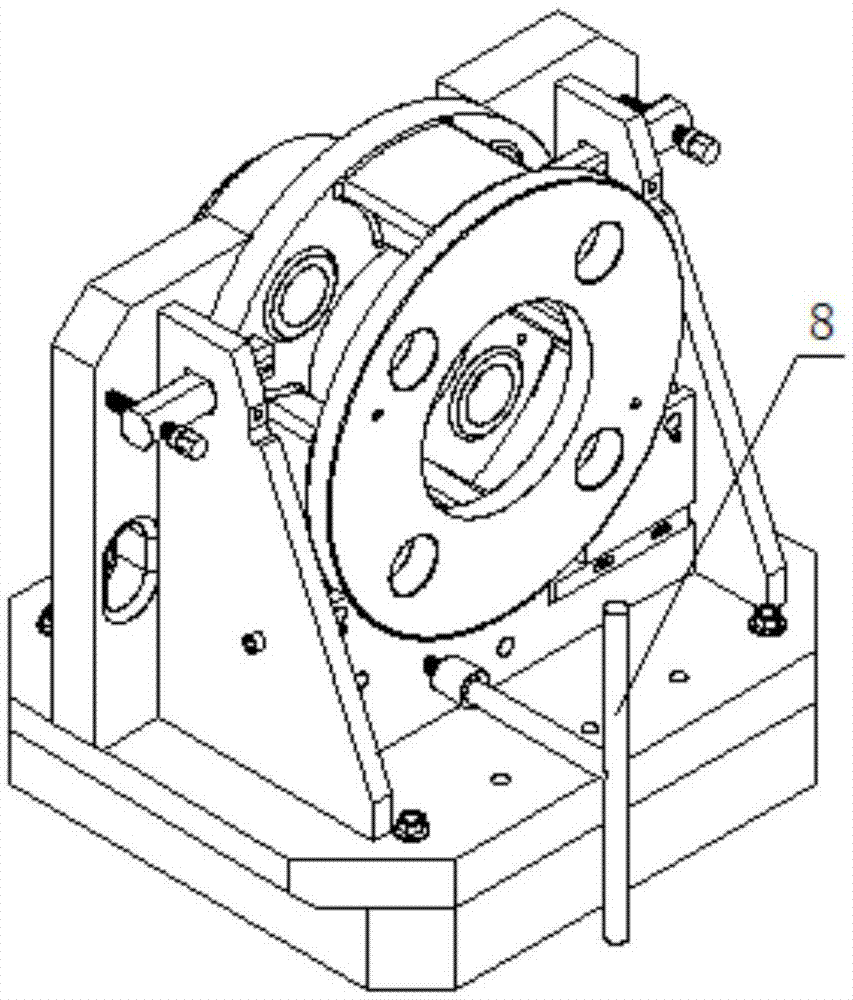

Tensioning clamp for sheet-type part subjected to rotary milling processing

ActiveCN105729182AImprove clamping rigidityImprove processing qualityPositioning apparatusMetal-working holdersEngineeringProcessing cost

The invention provides a tensioning clamp for a sheet-type part subjected to rotary milling processing. The tensioning clamp for the sheet-type part subjected to the rotary milling processing consists of a pedestal, a tensioning component and a clamping component, wherein the clamping component comprises a clamping driving device, a box body, a rotary shaft, a retainer cup, a movement crossover joint, a connecting rod, a pulling claw and a symmetrical clamping head; the tensioning component comprises a tensioning driving device, a transmission device and a guide rail sliding block device. According to the tensioning clamp for the sheet-type part subjected to the rotary milling processing, the sheet-type part is fixed by adopting a tensioning way; the clamping rigidity of the part can be effectively improved; the cutter relieving deformation in the processing process of the part is reduced; the processing vibration is restrained; the processing quality of the part is improved; the service life of a knife tool is prolonged; therefore, the processing cost is decreased; tensioning force is controlled through the tensioning driving device; the tensioning force can be guaranteed to be uniform and can be further regulated according to requirement; the symmetrical clamping head is tensioned to clamp the part through the clamping driving device; the rotary center of the part can be guaranteed to be unchangeable in a clamping process; the clamping deformation cannot be caused; further, the operation is simple; a clamping error caused by a human factor can be avoided.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

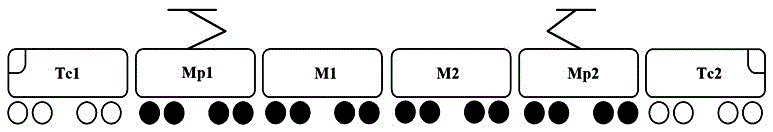

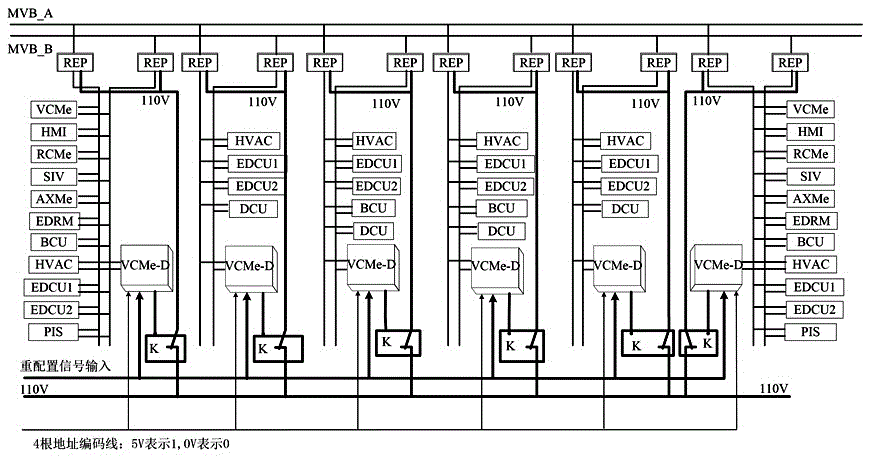

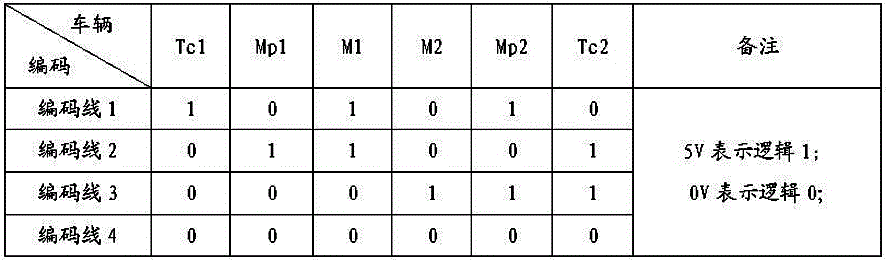

Device address reconfiguration method based on MVB communication

ActiveCN105491177AAvoid Address Setting MistakesImprove efficiencyLoop networksHuman errorBackbone network

The invention discloses a device address reconfiguration method based on MVB communication. The device address reconfiguration method comprises the following steps: S1, a TCMS sends an ''address reconfiguration'' signal to a VCMe-D of each vehicle in a train; S2, the VCMe-D receives the ''address reconfiguration'' signal and makes a vehicle MVB network switched out from a train backbone network, and the VCMe-D enters a master device working mode; S3, the VCMe-D sends address reconfiguration information to each device in the network to complete address reconfiguration of each device in the vehicle MVB network; S4, the VCMe-D switches the network state to the train backbone network and resumes a slave device working mode; and S5, the TCMS judges whether all devices are normal and terminates the address configuration process. By adopting the device address reconfiguration method disclosed by the invention, no manual operation is needed in the address configuration process, therefore an address setting error caused by human errors is avoided, and the address reconfiguration is efficient, flexible, convenient and good in reliability.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

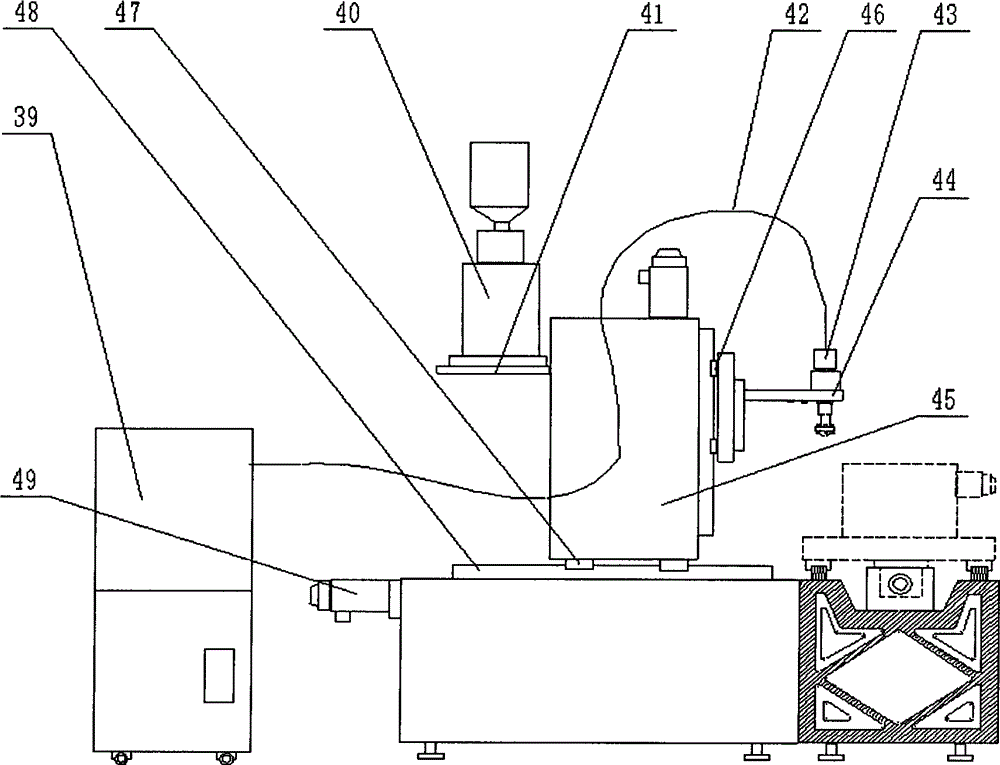

Grinding wheel sharpening device based on microwave-induced graphite particle bursting effect

ActiveCN112975753ARealize online detectionEfficient removalBlast gunsAbrasive machine appurtenancesEngineeringGraphite particle

The invention relates to a grinding wheel sharpening device based on a microwave-induced graphite particle bursting effect. The grinding wheel sharpening device comprises a working base table, an electric spindle system, a grinding wheel mounting device and a microwave generating system; a to-be-sharpened grinding wheel is mounted on the working base table through the grinding wheel mounting device, and the electric spindle system is connected with the grinding wheel; the microwave generating system comprises a jetting device and a microwave generating element, and the jetting device and the microwave generating element are oppositely arranged on the two sides of the grinding wheel; the jetting device is used for shooting graphite particles to a grinding area on the surface of the grinding wheel; and the electric spindle system drives the grinding wheel to rotate, so that the grinding area, covered with the graphite particles, on the surface of the grinding wheel is rotated to the position below a heating opening of the microwave generating element, the microwave generating element heats the graphite particles in the grinding area, and the graphite particles are heated to burst to sharpen the grinding wheel. According to the grinding wheel sharpening device, the microwave-induced graphite particle bursting effect is utilized for efficiently completing high-precision sharpening of the grinding wheel, safety and reliability are achieved, efficiency is high, and practicability is high.

Owner:HUNAN UNIV

Automatic-revolving indexing machining device

The invention relates to an automatic-revolving indexing machining device which comprises a chuck and a clamping jaw. The clamping jaw is composed of an upper clamping jaw and a lower clamping jaw. The automatic-revolving indexing machining device is mainly characterized in that the upper clamping jaw is movably mounted in a shaft hole of a clamping piston by a mounting shaft, the clamping piston is mounted in a clamping oil cylinder on the chuck, the lower clamping jaw is in matched connection with a shaft hole in a turnplate by a mounting shaft, the turnplate is axially mounted on the chuck by a positioning block and is in radially movable fit with a chuck mounting hole, the middle section of an outer cylindrical face of the turnplate is made to be a polygonal column, a first oil cylinder and a second oil cylinder are arranged on the chuck on one side of the polygonal column, a first piston end and a second piston end extend into a plane of the polygonal column respectively, and a first piston and a second piston adopt a hydraulic system for interactive control. The first oil cylinder and the second oil cylinder sequentially push the turnplate to rotate, machining of multiple faces can be completed by clamping for one time, and the automatic-revolving indexing machining device has the advantages of high machining efficiency, few in machining error, high in machining accuracy and the like, and is a machining clamp suitable for key parts like a valve body and a valve cover of a valve.

Owner:浙江伯特利科技股份有限公司

Machining measurement device of sealing ring for triple eccentric butterfly valve

ActiveCN104476328AGuaranteed Leakage LevelHigh repeatabilityMeasurement/indication equipmentsMaximum diameterButterfly valve

The invention relates to a machining measurement device of a sealing ring for a triple eccentric butterfly valve. The size is measured through a measurement rod and profiling, the maximum diameter size from the straight side to the inclined side does not need to be measured through a caliper after the theoretical size is in place, a user only needs to directly read readings of a thread dial of a thread dial plate which is supported on a measurement pin, the rotary center of the thread dial plate is as same as the rotary center of a main shaft of a machine tool after the size is in place, and accordingly the size is in place when the reading of the thread dial is zero theoretically, the theoretical size is ensured fundamentally and meanwhile the repeated precision of the measurement is improved and accordingly the measurement does not rely on the technical level of workers, the size accuracy is ensured, and the leakage level of the valve is ensured; the machining measurement device is particularly suitable for the high temperature, high pressure difference and two-way sealing situations and suitable for the coal chemical industry, power plant boiler system application situations; the structure is simple, the use is convenient, the repeated accuracy of the measurement is high, the measurement is simple, the dependency on the workers is not required, the interchangeability of the sealing ring is good, and the import is completely replaced.

Owner:WUXI YADI FLUID CONTROL TECH CO LTD

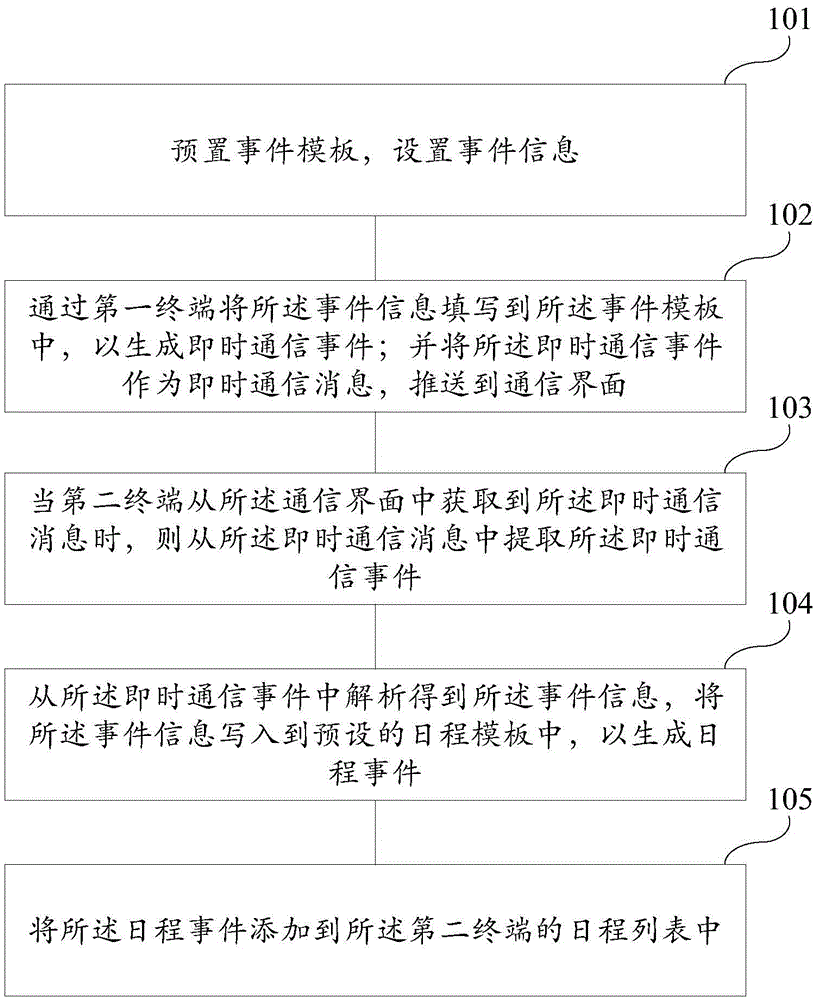

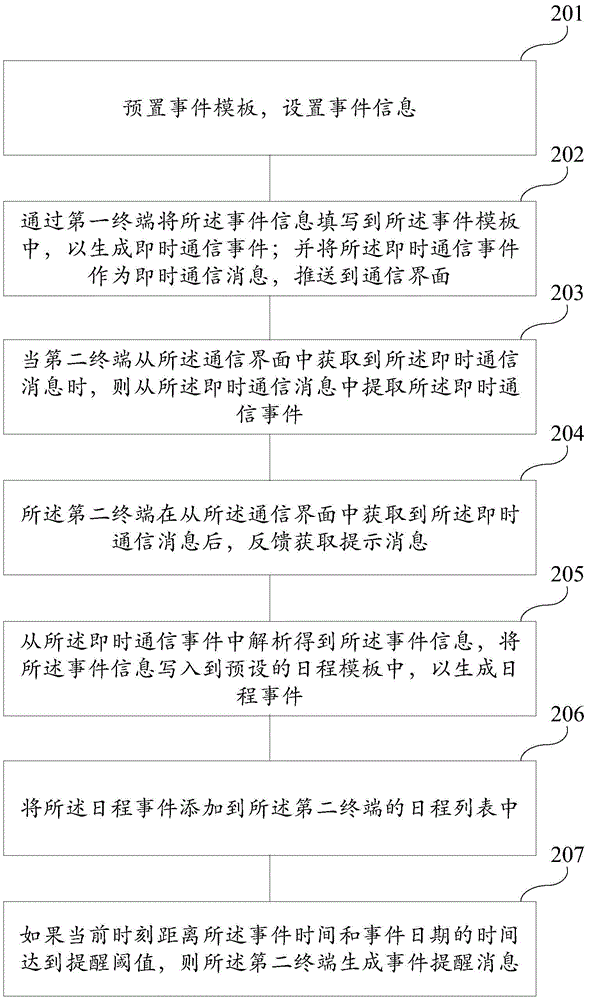

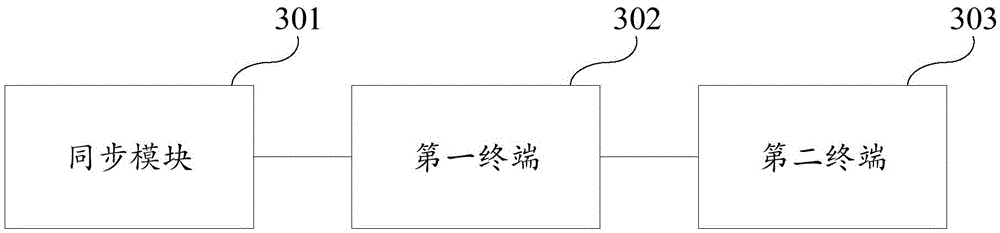

Method and system for synchronizing instant messaging event

ActiveCN105530168AAcquisition is clearEasy to implementSpecial service provision for substationCommunication interfaceComputer terminal

The invention discloses a method and a system for synchronizing an instant messaging event. The method comprises the following steps: presetting an event template, and setting event information; filling the event information in the event template by a first terminal to generate the instant messaging event; pushing the instant messaging event to a communication interface to serve as an instant messaging message; when a second terminal obtains the instant messaging message from the communication interface, extracting the instant messaging event from the instant messaging message, wherein one or more second terminals are provided; analyzing the event information from the instant messaging event, and writing the event information in a preset schedule template to generate a schedule event; and adding the schedule event in a schedule list of the second terminal.

Owner:BEIJING LOCOJOY TECH

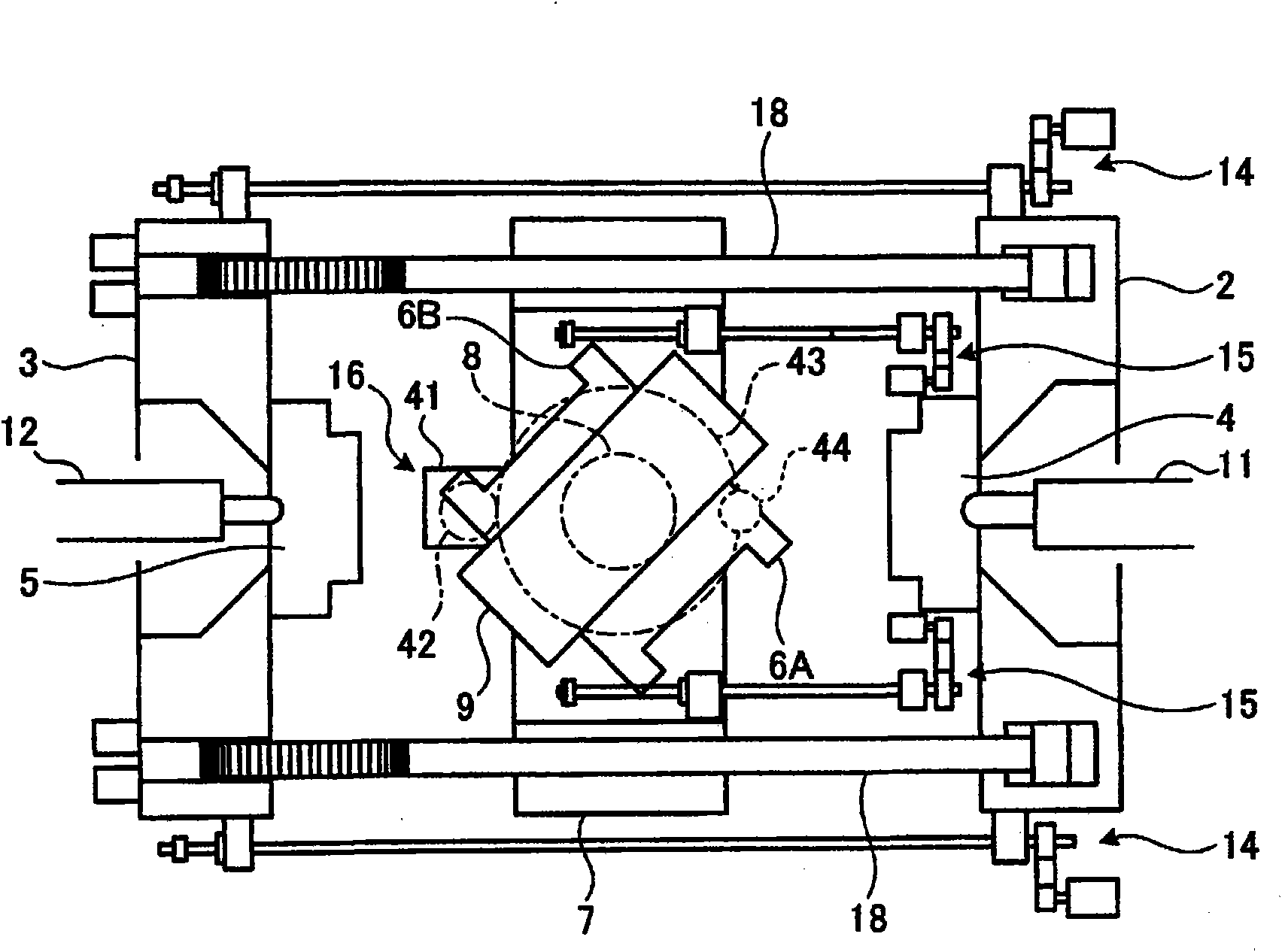

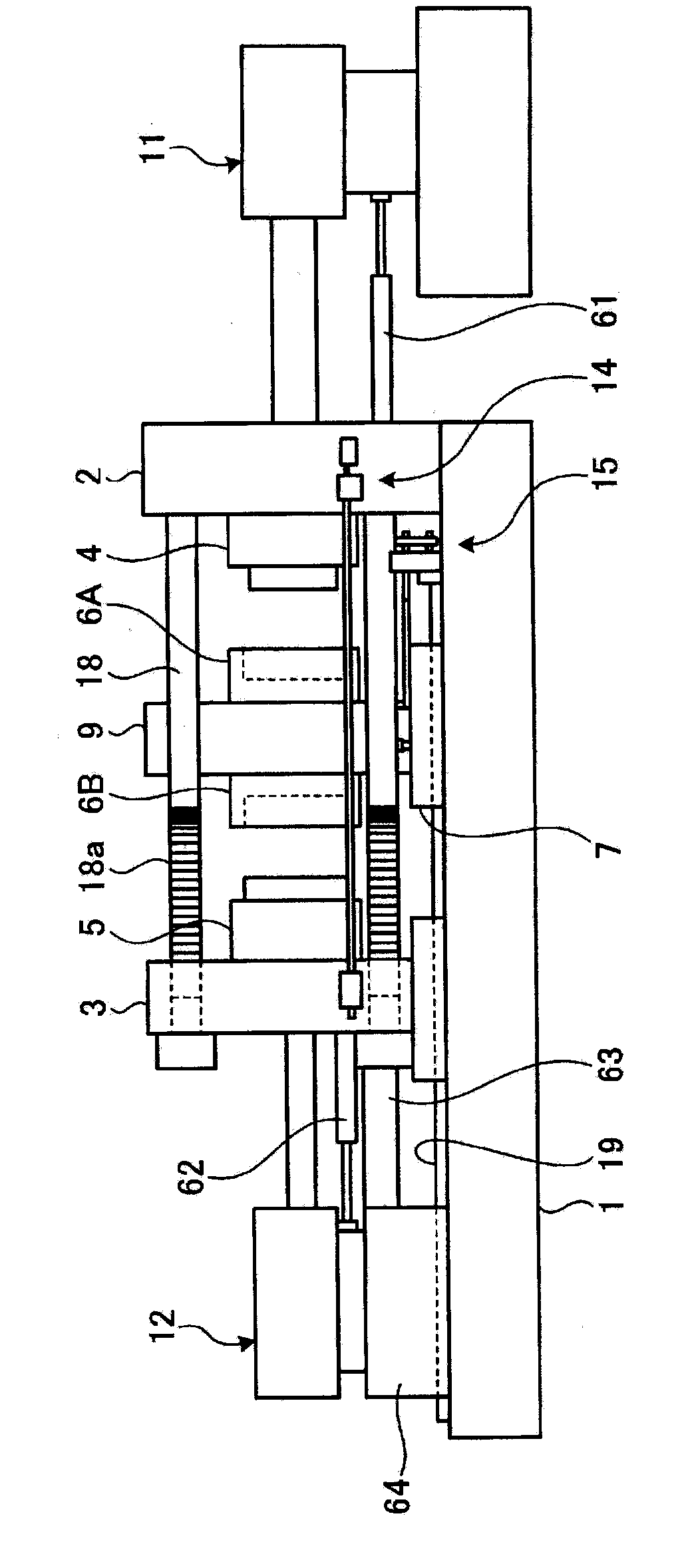

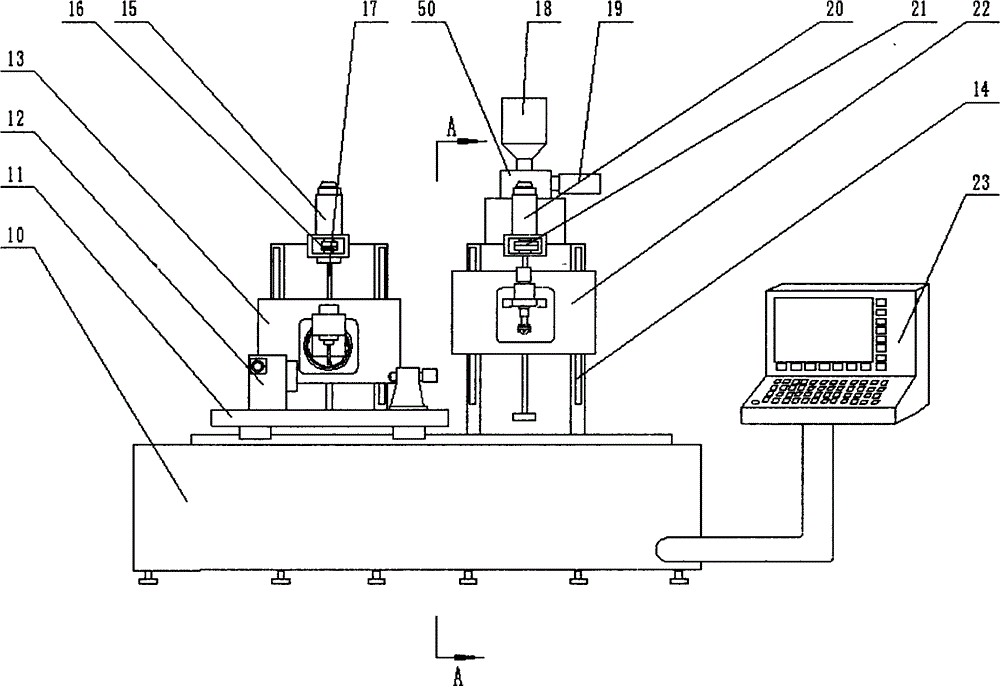

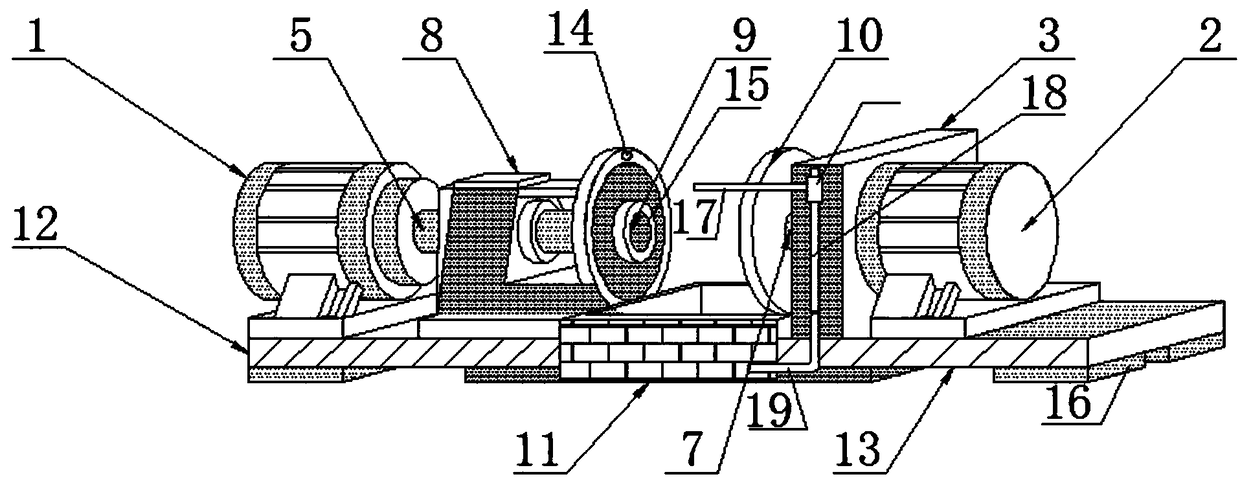

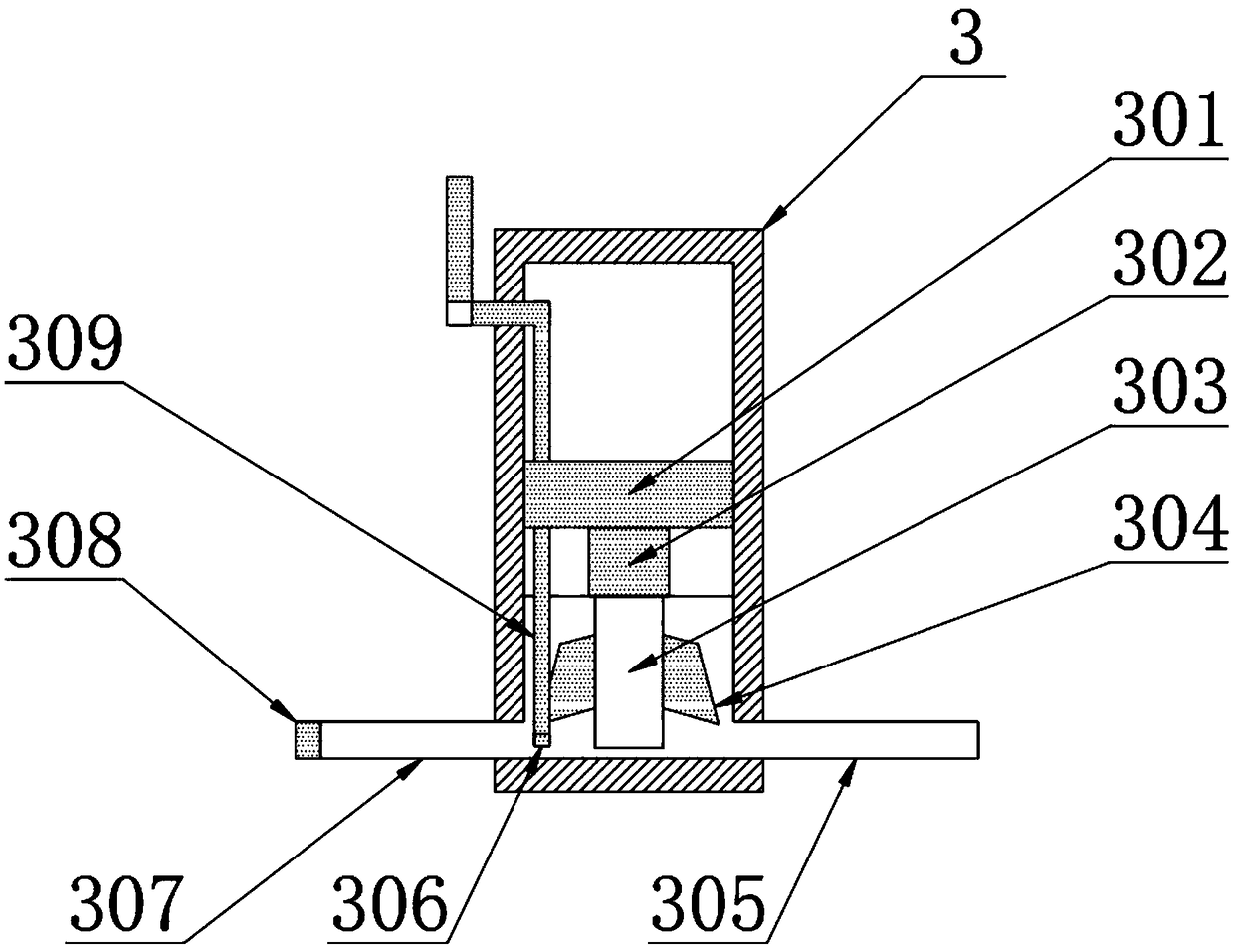

Injection molding machine for molding double materials and control method thereof

ActiveCN103722664AHigh speed accuracyHigh positioning accuracyInjection mouldingInjection molding machine

The invention discloses an injection molding machine for molding double materials and a control method thereof. The injection molding machine comprises two groups of injection units (11, 12) used for respectively plastifying different resin materials for injection filling, wherein a mold clamping mechanism is a hydraulic mold clamping unit which can simultaneously clamp three groups of molding plates (2, 3, 9); a movable molding plate opening-closing unit (12) is driven by a motor; a rotary molding plate opening-closing unit (15) is a rotary molding plate opening-closing unit (14) which is driven by a motor; a rotary unit of the rotary molding plate (9) is a rotary driven device which is driven by a motor mounted on a reverse table (7).

Owner:MITSUBISHI HEAVY INDS PLASTIC TECH

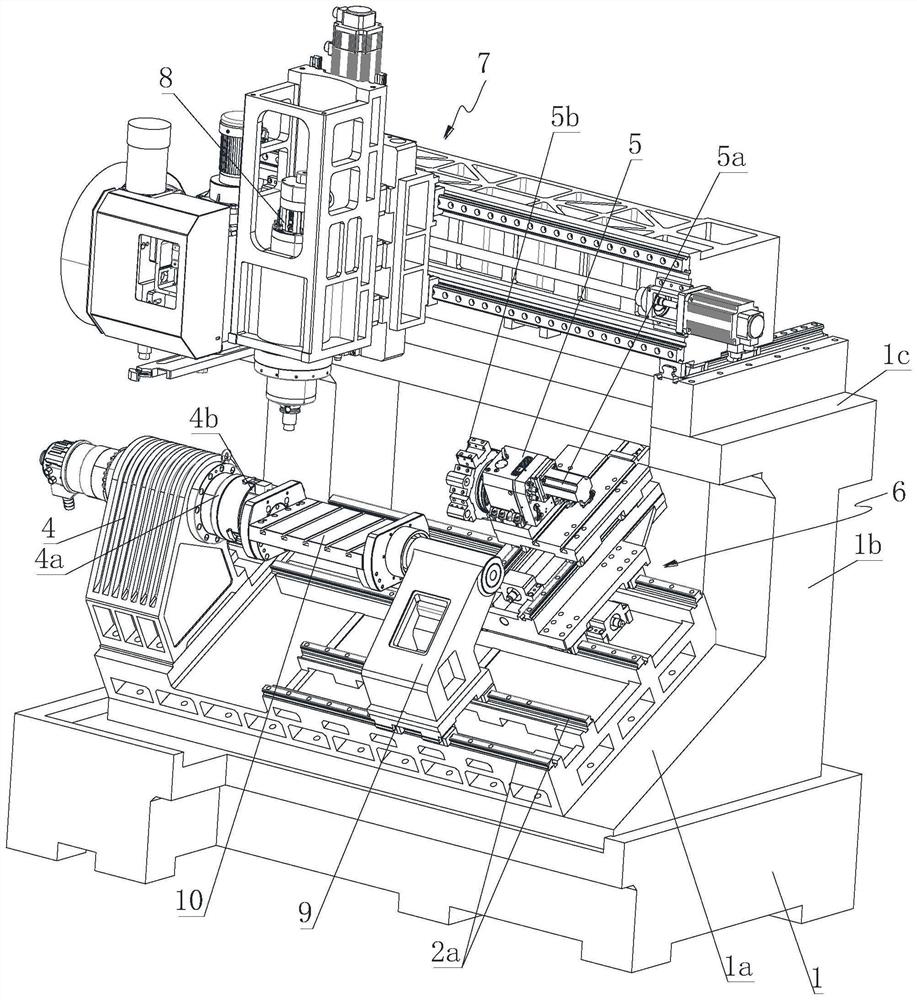

Turning and milling integrated machining machine tool

PendingCN113941861AAvoid setup errorsIn line with the principle of process concentrationOther manufacturing equipments/toolsMachine toolIndustrial engineering

The invention discloses a turning and milling integrated machining machine tool. A first mounting platform and a second mounting platform which are distributed in the height direction of a machine tool body are mounted on the machine tool body, a turning spindle box and a turning tool apron are arranged on the first mounting platform, a clamping mechanism is arranged on a spindle of the turning spindle box, the turning tool apron is assembled on the first mounting platform through a lower moving module, the lower moving module can drive the turning tool apron to move in the length direction and the width direction of the first mounting platform, a milling spindle box is assembled on the second mounting platform through an upper moving module, and the upper moving module can drive the milling spindle box to move in the left-right direction, the front-back direction and the up-down direction of the machine tool body. The turning and milling integrated machining machine tool has the beneficial effects that turning and milling can be completed on the same machine tool, the part clamping frequency can be reduced, and the machining precision is improved.

Owner:重庆怡驰机械有限责任公司

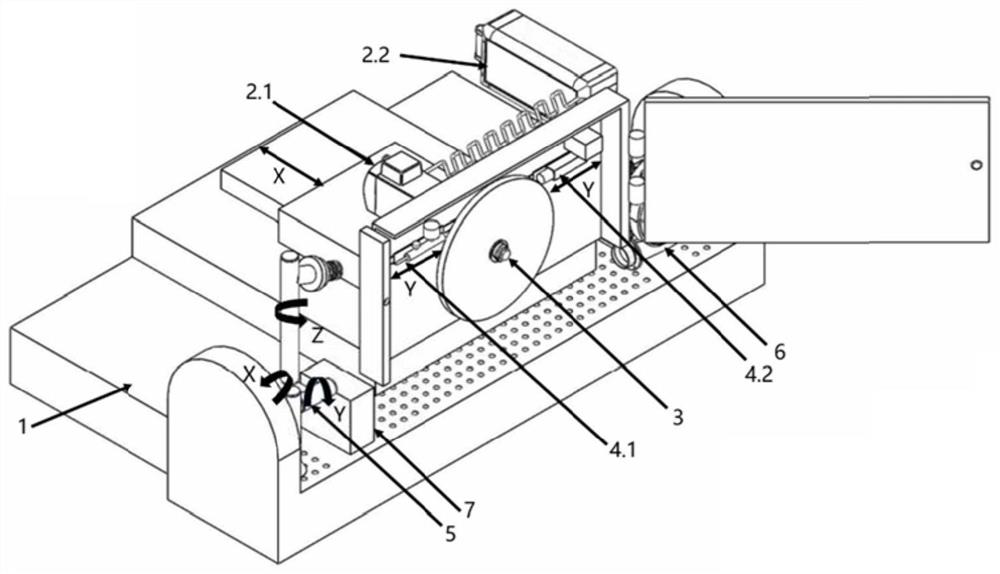

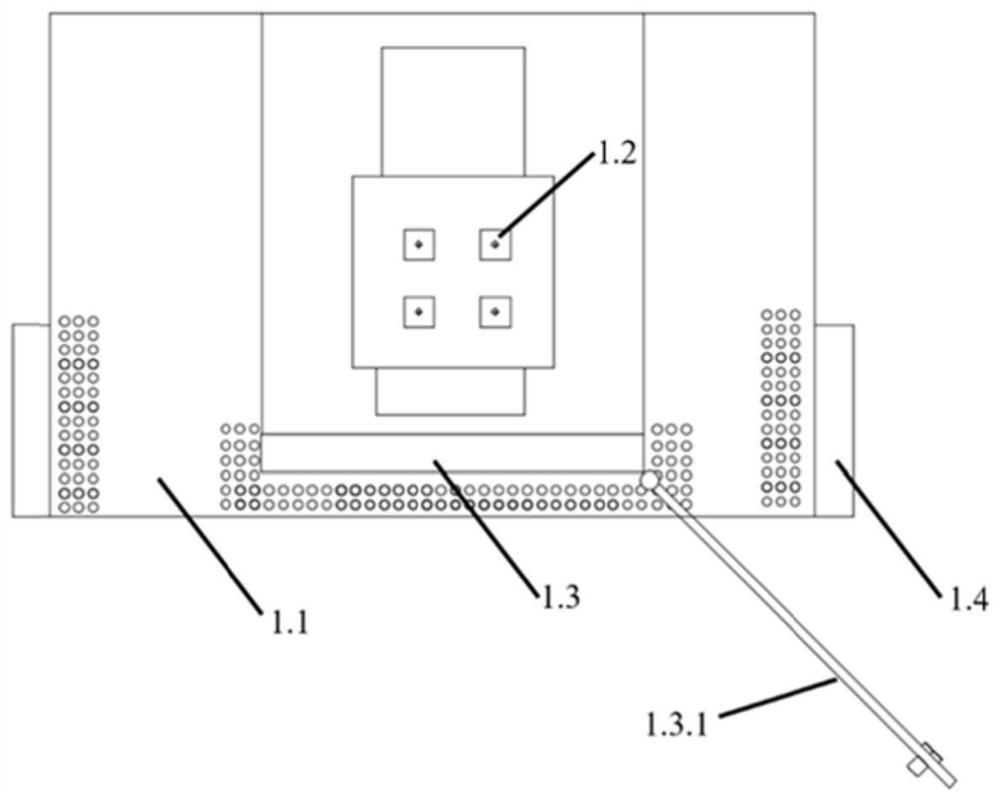

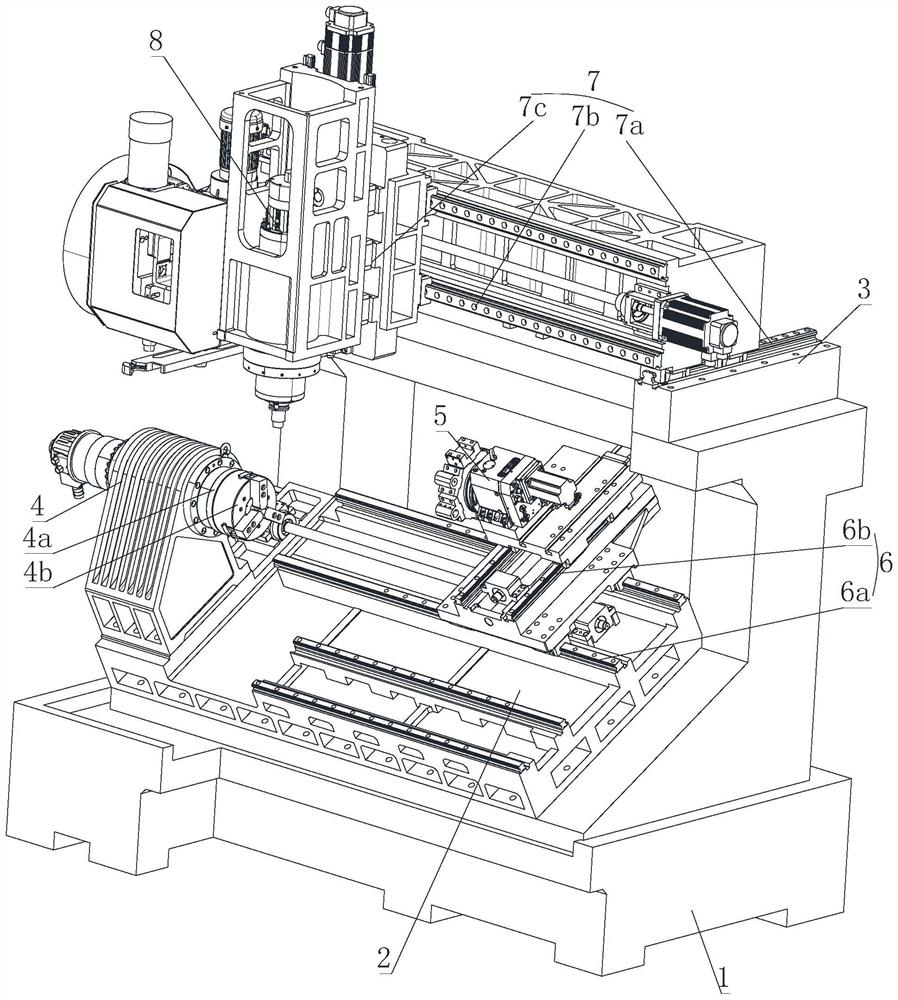

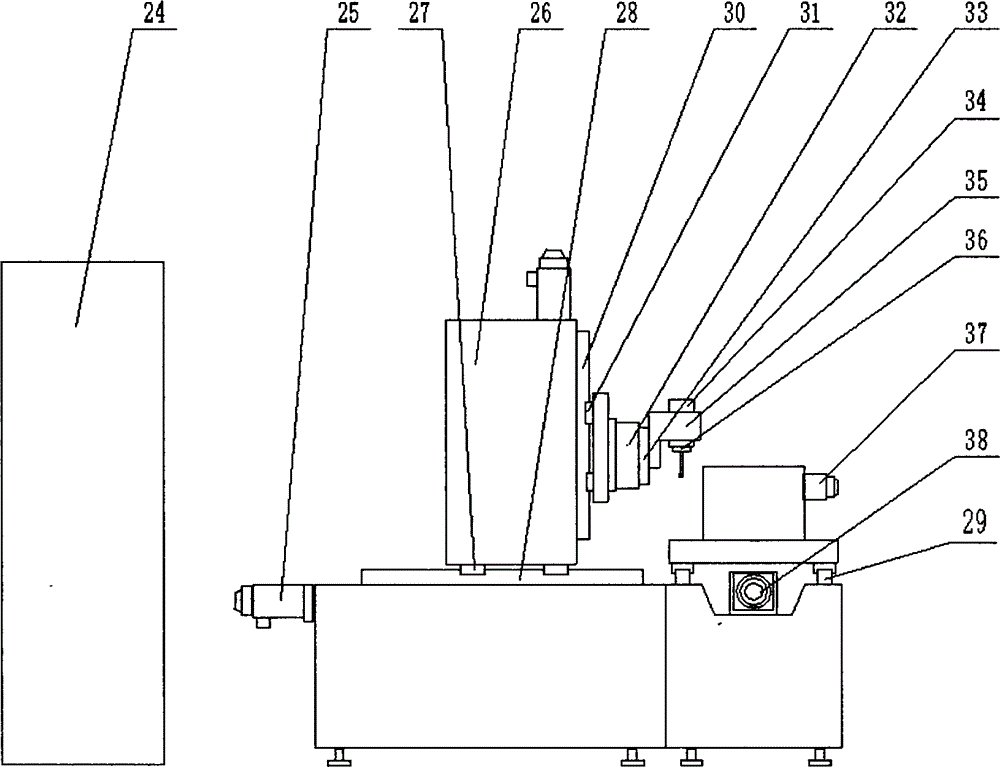

Laser cladding and self-adaptive milling integrated combined numerical-control machine tool for repairing blade

ActiveCN105312903AAvoid setup errorsImprove stabilityOther manufacturing equipments/toolsSelf adaptiveProcessing accuracy

The invention discloses a laser cladding and self-adaptive milling integrated combined numerical-control machine tool for repairing a blade. By the adoption of the laser cladding and self-adaptive milling integrated combined numerical-control machine tool for repairing the blade, the problems that margin cutting residues are large and a repair layer is likely to be cut due to reapeated clamping and the machining precision is not stable and the efficiency is low due to manual copping are mainly solved. The laser cladding and self-adaptive milling integrated combined numerical-control machine tool for repairing the blade mainly comprises a double-T-shaped tool body, a first stand column mechanism, a second stand column mechanism, a numerical-control rotary workbench, a tip, a milling spindle and a laser powder cladding device. The milling spindle which can swing is arranged on a sliding plate of the first stand column mechanism. A milling tool or a coordinate measuring head can be installed on the milling spindle. A gas protective nozzle is arranged on a sliding plate of the second stand column mechanism. The blade is clamped between the numerical-control rotary workbench and the tip so as to be repaired. The laser cladding and self-adaptive milling integrated combined numerical-control machine tool for repairing the blade is ingenious in structural design, flexible in technological combination, high in universality and high in repairing and removing precision, the rate of finished products is high, the production cost is greatly reduced, and the laser cladding and self-adaptive milling integrated combined numerical-control machine tool has high practical value and promotional value.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

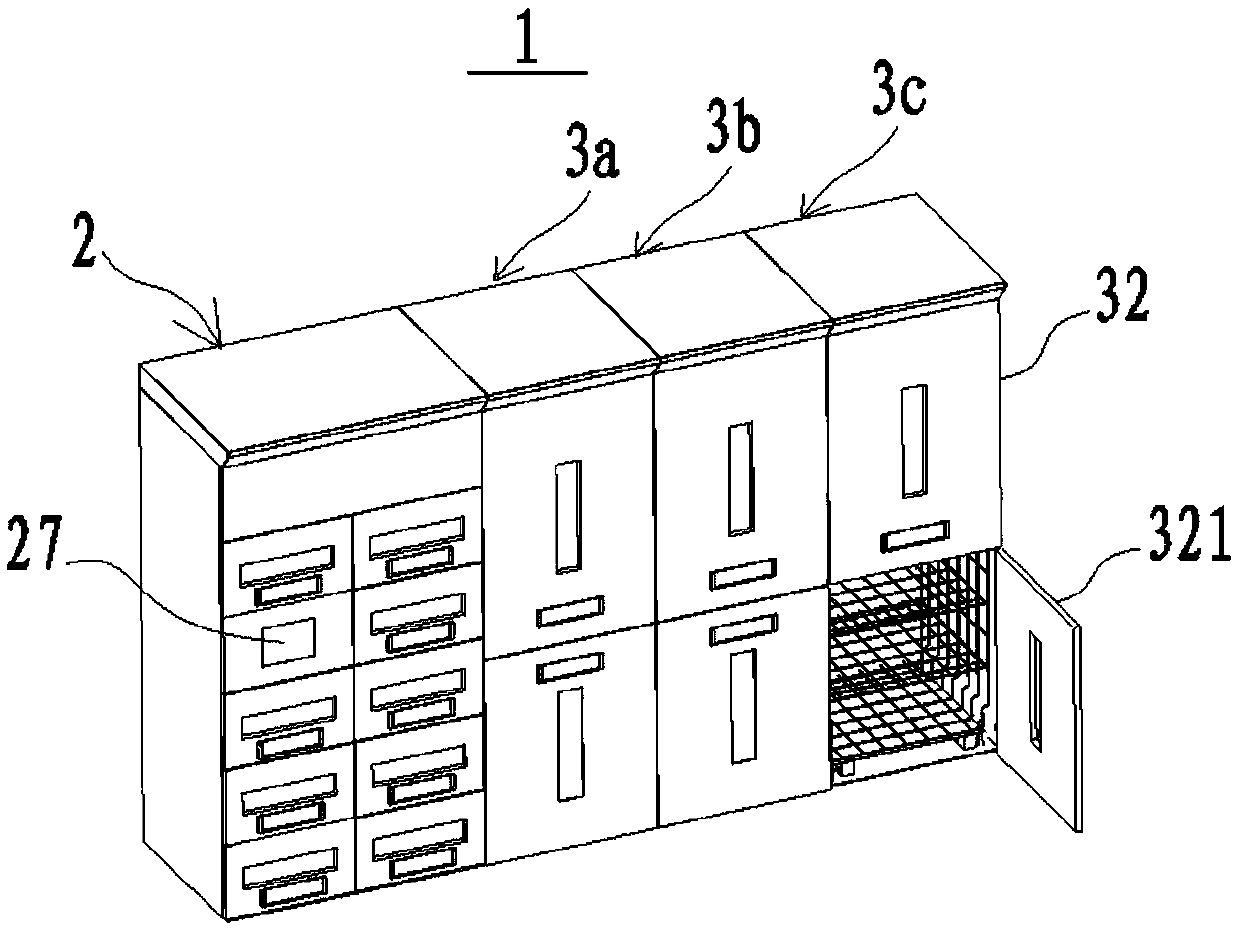

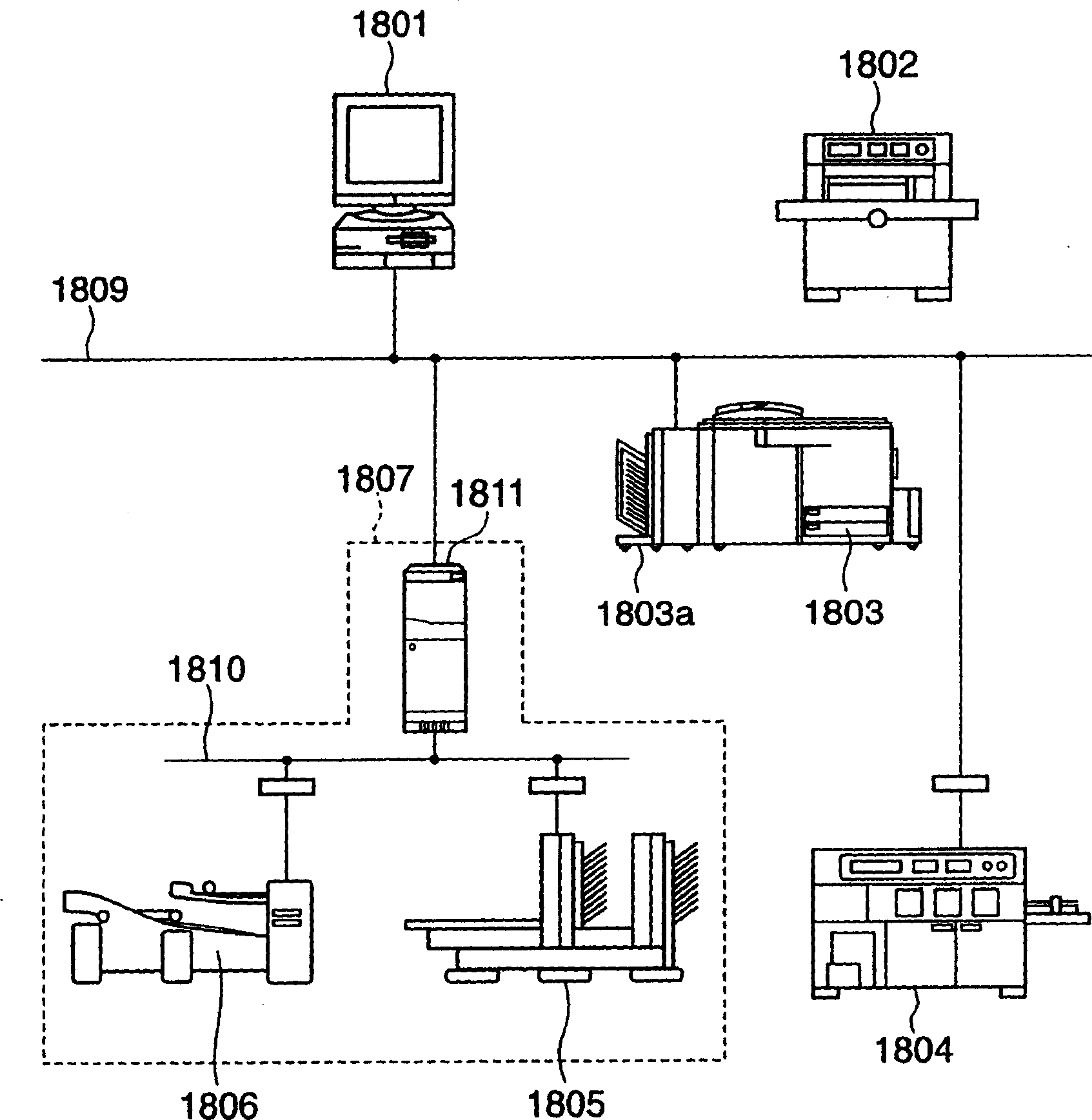

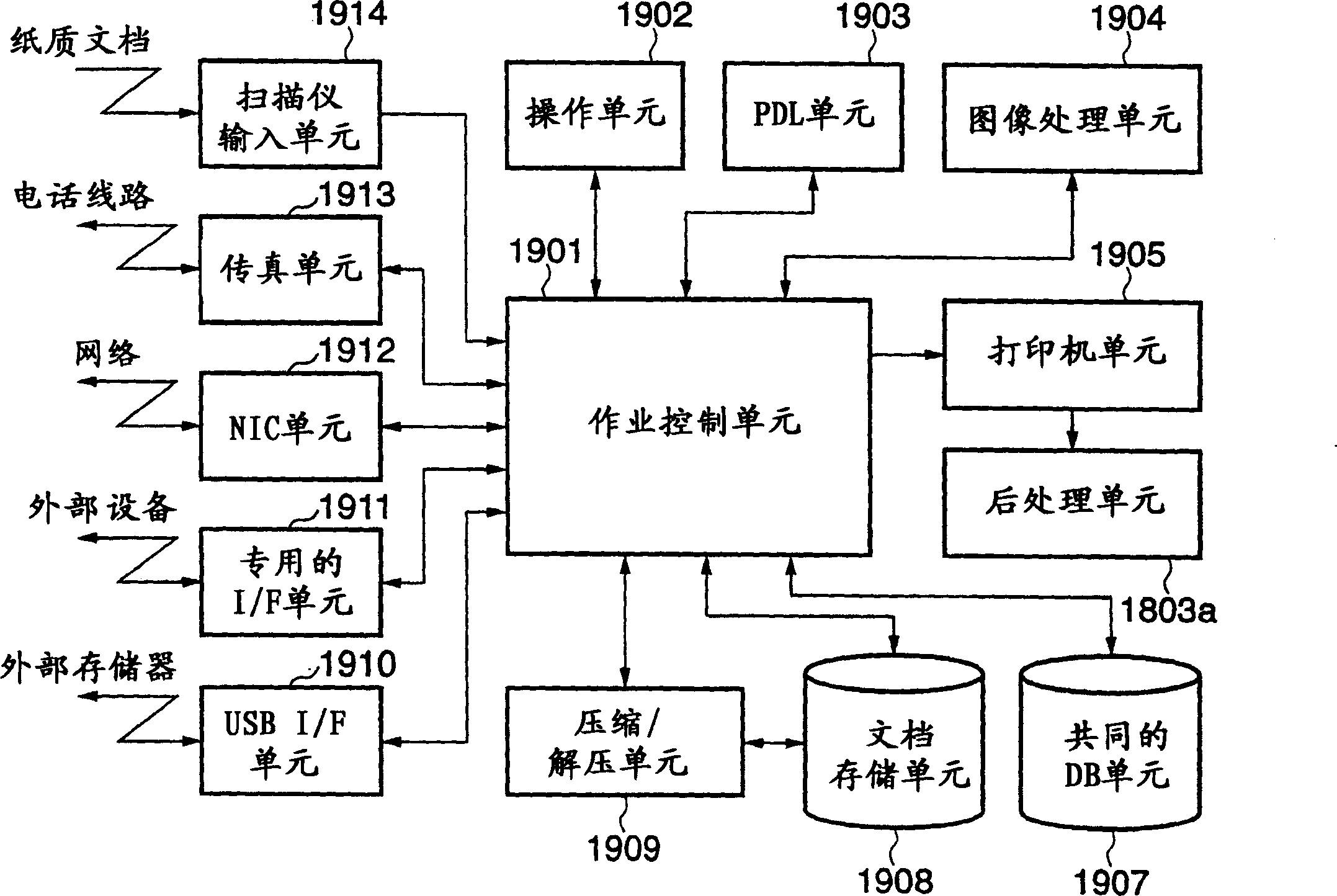

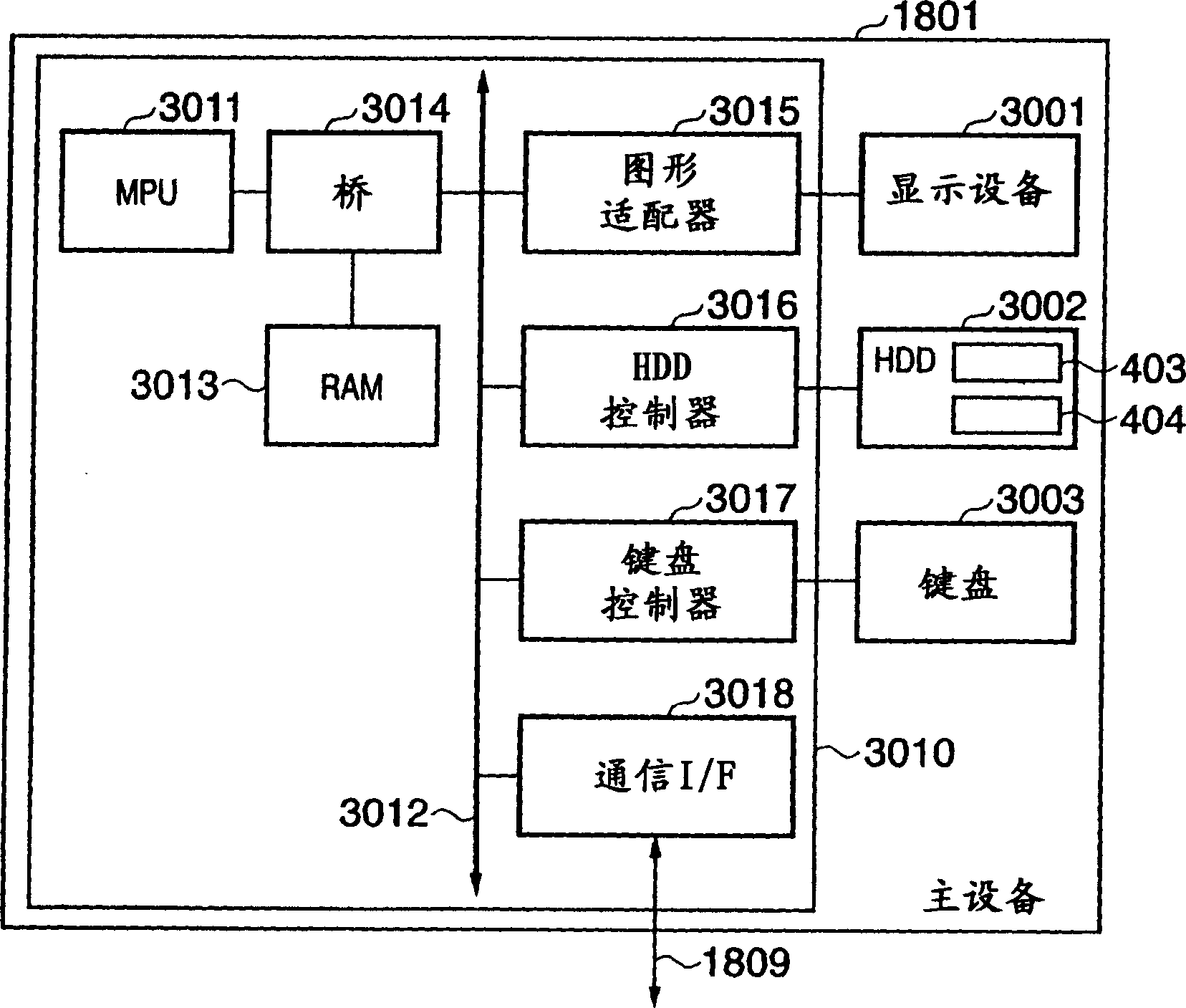

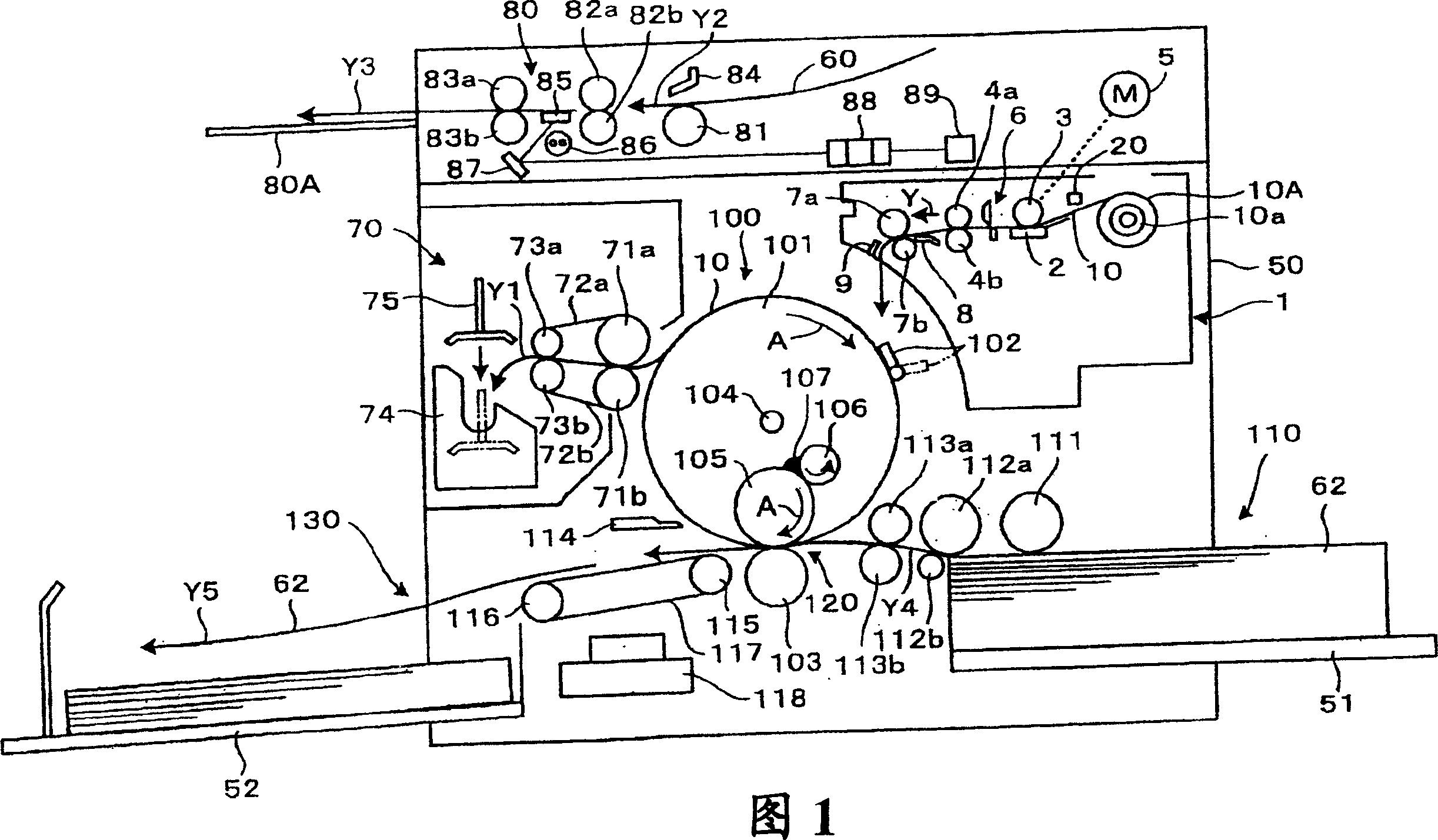

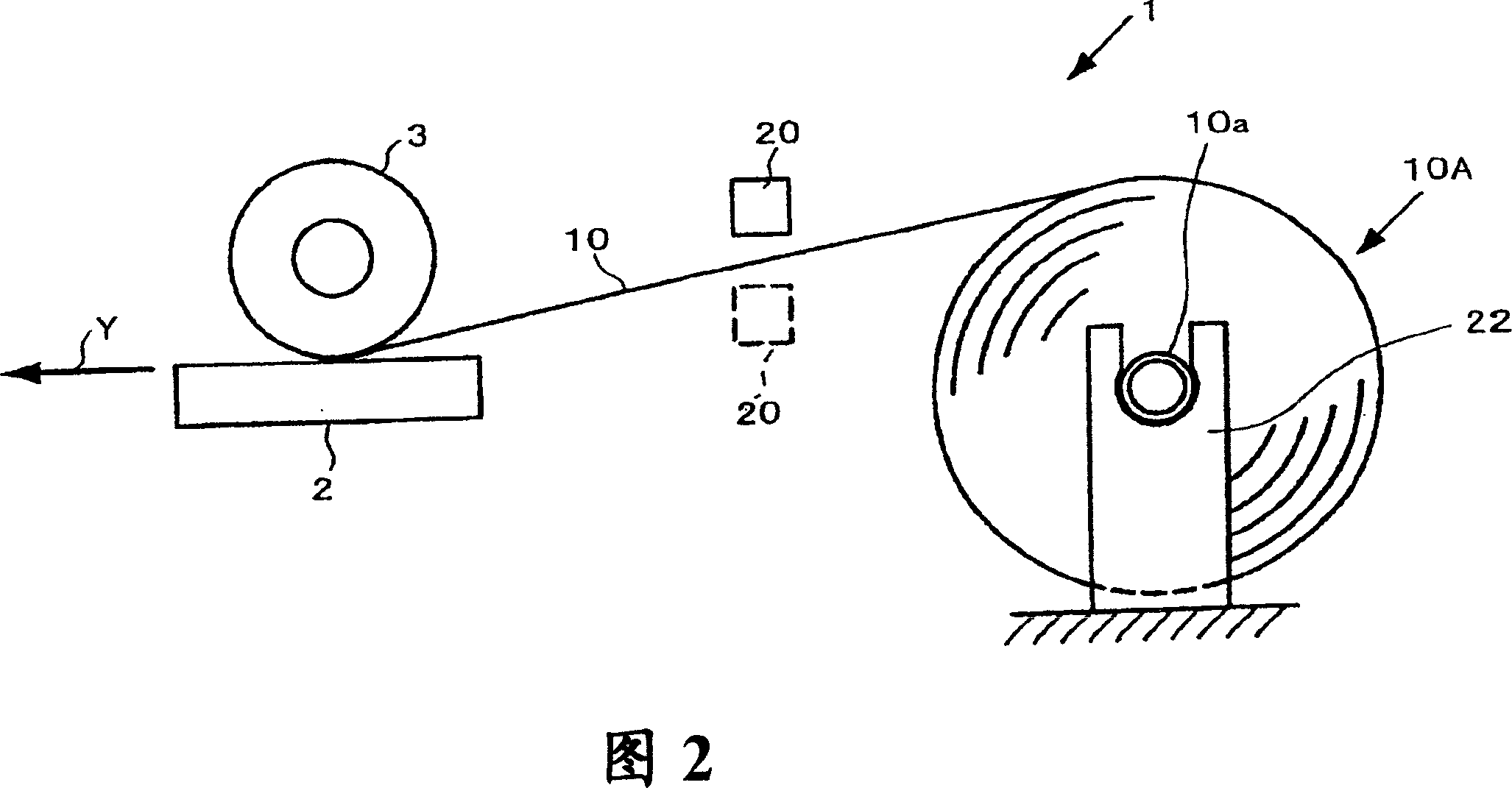

On-demand publishing system

InactiveCN1862480AIncrease production capacityAvoid setup errorsDigital output to print unitsInformation processingOn demand

According to the present invention, an information processing apparatus comprises: a loading unit which loads function information representing a function of the post-printing processing device; an identification unit which identifies a printing function processible by the printing device and a post-processing function processible after printing by the post-printing processing device; a display control unit which displays a setting window for setting the printing function and post-processing function; a data generation unit which generates printing data to be printed by the printing device; and a setting information generation unit which generates post-processing setting information subjected to post-printing processing by the post-printing processing device, wherein the printing data is transmitted to the printing device, and the post-processing setting information is transmitted to the post-printing processing device.

Owner:CANON KK

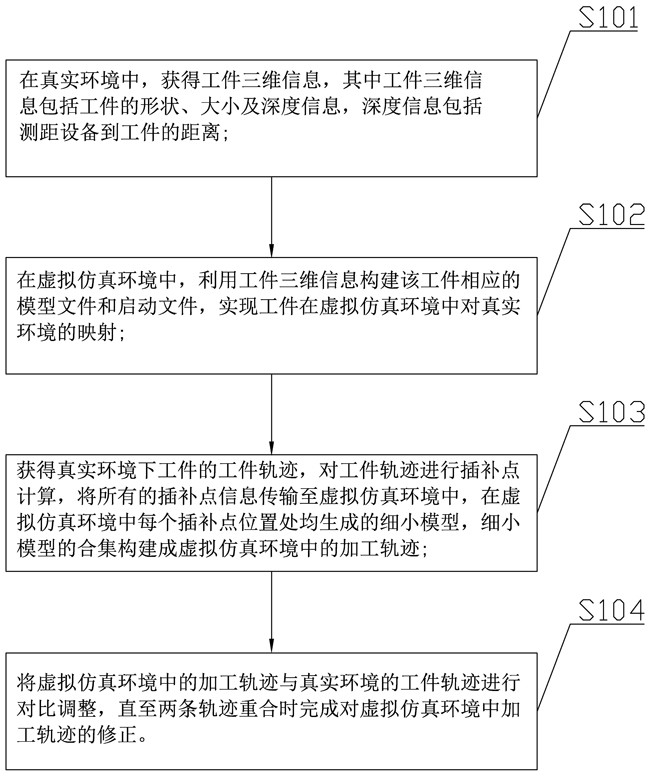

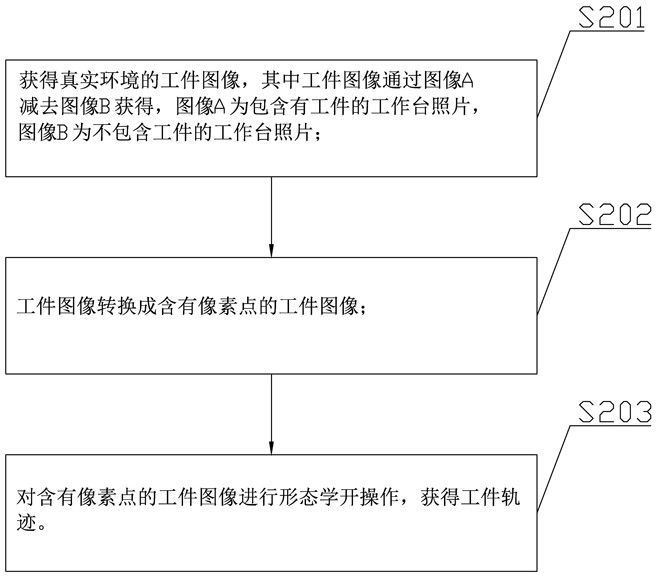

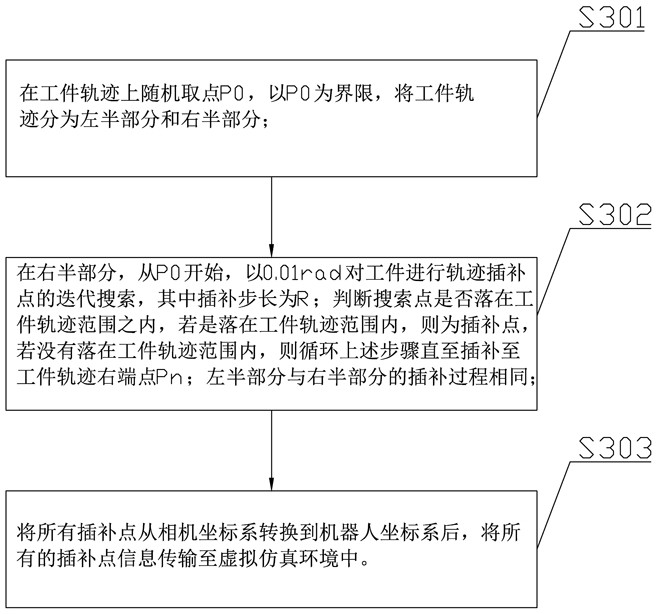

Workpiece track three-dimensional reconstruction method and system based on digital twinning

PendingCN113554757AFast processingAvoid cumbersome stepsImage enhancementDesign optimisation/simulationComputer graphics (images)ModelSim

Owner:XINJIANG UNIVERSITY

Special clamping equipment for horizontal hole machining and forming of planet carrier

InactiveCN106914765ARealize fast installationMeet processing needsPositioning apparatusMetal-working holdersRejection rateMachining

The invention relates to special clamping equipment for horizontal hole machining and forming of a planet carrier. The special clamping equipment comprises a base, a supporting plate, supporting attaching plates and a positioning bottom support. The supporting plate is vertically arranged on the base, and a clamping groove used for containing a workpiece and provided with an upward opening is manufactured in the supporting plate. Each of the left side and the right side of the supporting plate is provided with the corresponding supporting attaching plate. A positioning baffle penetrates the upper portion of each of the two supporting attaching plates. The part, between the two supporting attaching plates, of the base is provided with the positioning bottom support. The upper surface of the positioning bottom support is made into the arc. A vertical positioning rod is arranged on the right side of the upper surface of the positioning bottom support. The special clamping equipment for horizontal hole machining and forming of the planet carrier is ingenious in design, reasonable in structure, convenient to use, firm in clamping and high in practicability. The equipment is specially designed according to the requirement of a horizontal machining center, the beneficial effect of high pertinence is achieved, and after the equipment is used, the clamping speed can be increased, the machining precision can be guaranteed, and the rejection rate is reduced.

Owner:TIANJIN JINLAI PRECISION MACHINERY

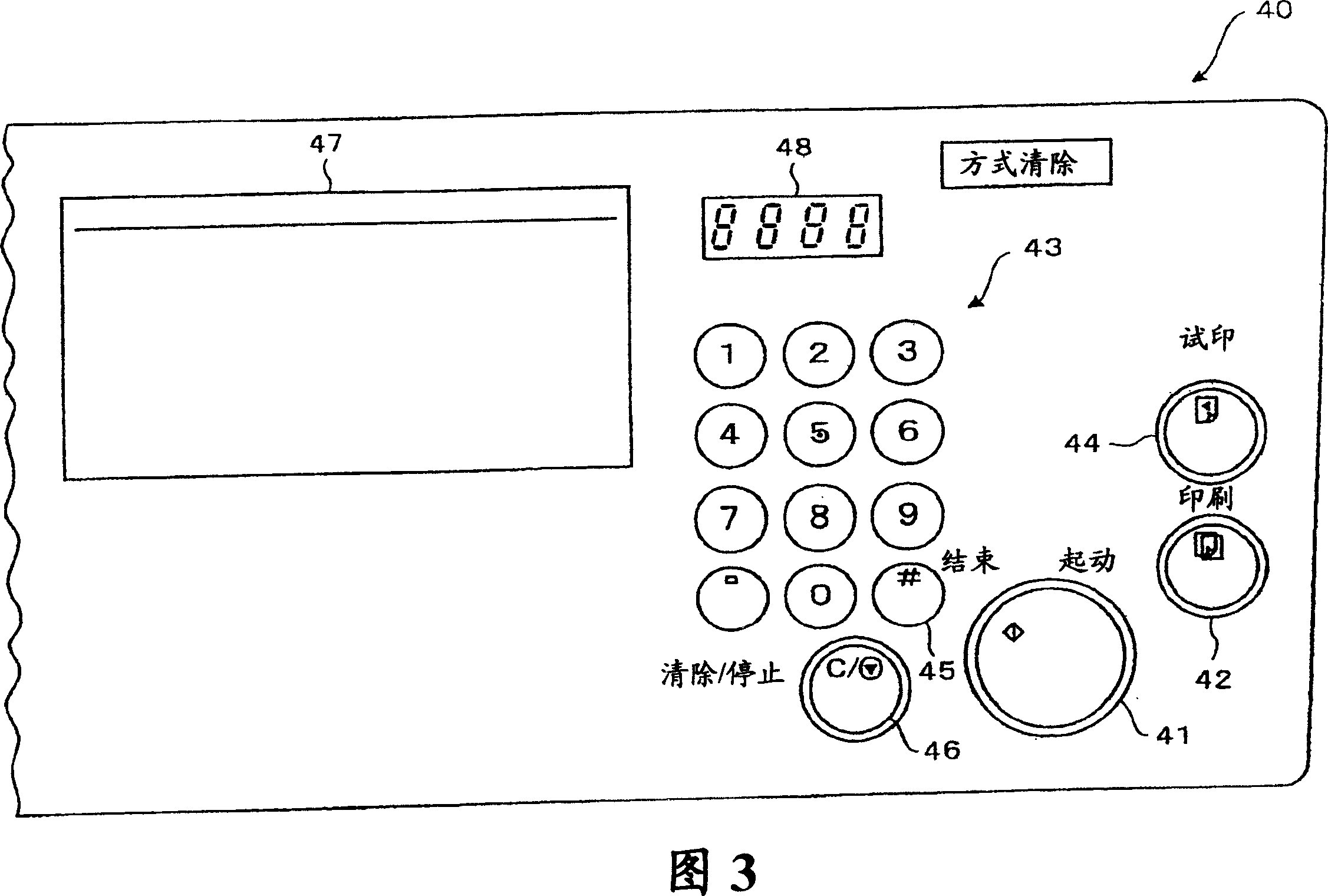

Mother matrix surface detecting method and device, mother matrix class detecting device and print device

InactiveCN101088773AAvoid setup errorsHalf the costStencilling apparatusPlate printingOptical transducersEmbedded system

The present invention reduces the number of reflection-type optical transducer to one, reduces the cost and reduces the restriction in the mechanical layout, and it can detect the surface / back side of the master mask to prevent the master mask setting error. The master mask surface / back side detecting device (23) is provided with the following components: a single optical sensor (20) which scans and detects the surface of back side of the master mask (10); a master mask delivering motor (5) which movers the master mask (10) relative to the optical sensor (20) and a guide roller (3); a special hardware 24 which is inputted with the detected electric tension that is detected by the optical sensor (20) and is relative to the surface or back side of the master mask (10); and a judging component which controls the action of the thermal head (2) by the master mask delivering motor (5), a LCD displaying part (47) of the operator panel (40) and the plate making control part (21), and at the same time the judging component judges the surface / back side of the master mask (10) according to the margin of the detected electric tension inputted by the special hardware (24).

Owner:RISO KAGAKU CORP

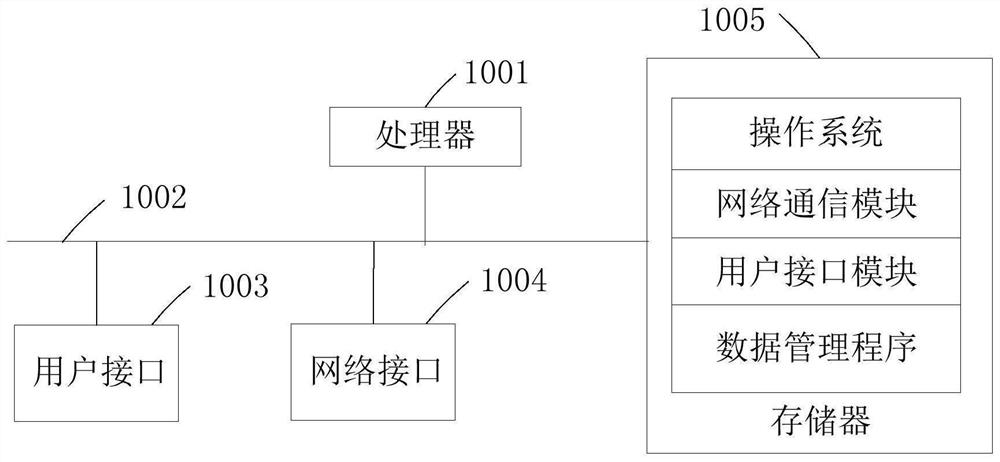

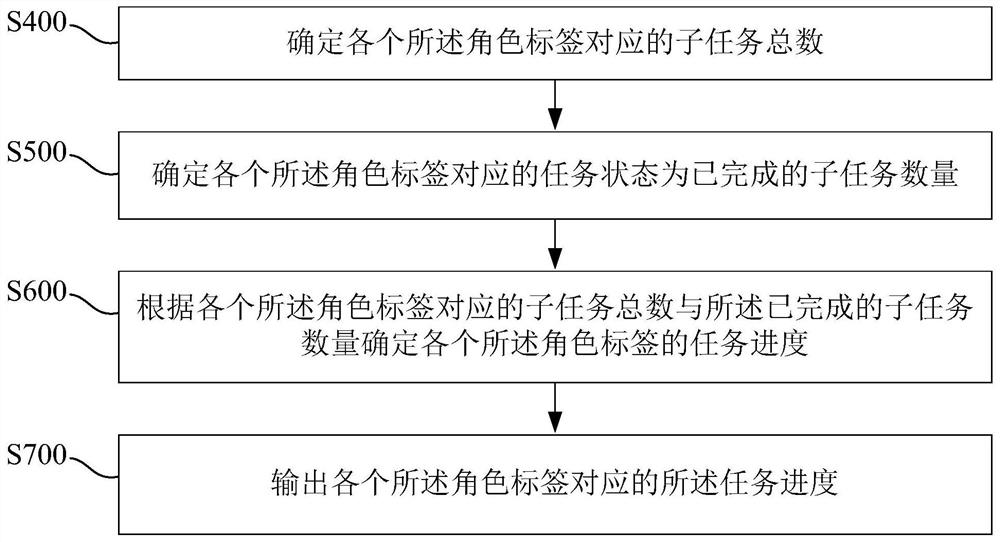

Data management method, electronic equipment and readable storage medium

PendingCN113392382AImprove confidentialityAvoid setup errorsDigital data authenticationOffice automationData packConfidentiality

The invention discloses a data management method, electronic equipment and a readable storage medium, and the data management method comprises the following steps: obtaining a role tag associated with a first user identifier, and determining first authority information associated with the role tag; obtaining task data are obtained, second permission information associated with all subtask data of the task data, wherein the task data comprise at least one piece of subtask data; and determining first sub-task data corresponding to the first user identifier according to a matching result between the first permission information and the second permission information, and carrying out associated storage on the first user identifier and the first sub-task data. According to the permission information associated with the role label associated with the user identifier, the user identifier and the sub-task data corresponding to the permission information are associated, and the problem of low data confidentiality caused by the fact that errors are easily made when the permission information corresponding to the user identifier is independently set is solved.

Owner:乐刷科技有限公司

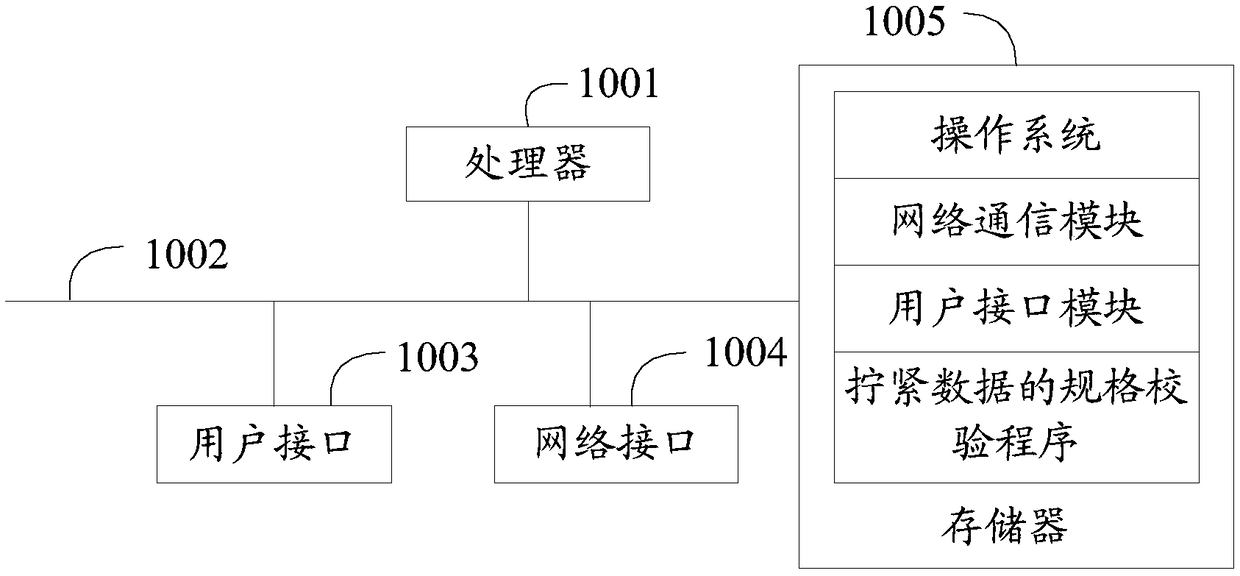

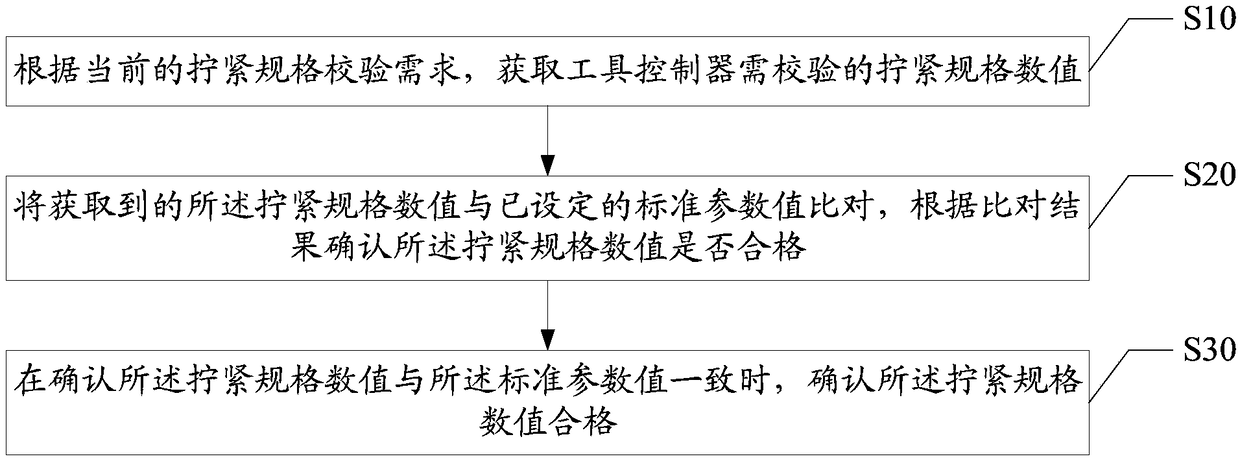

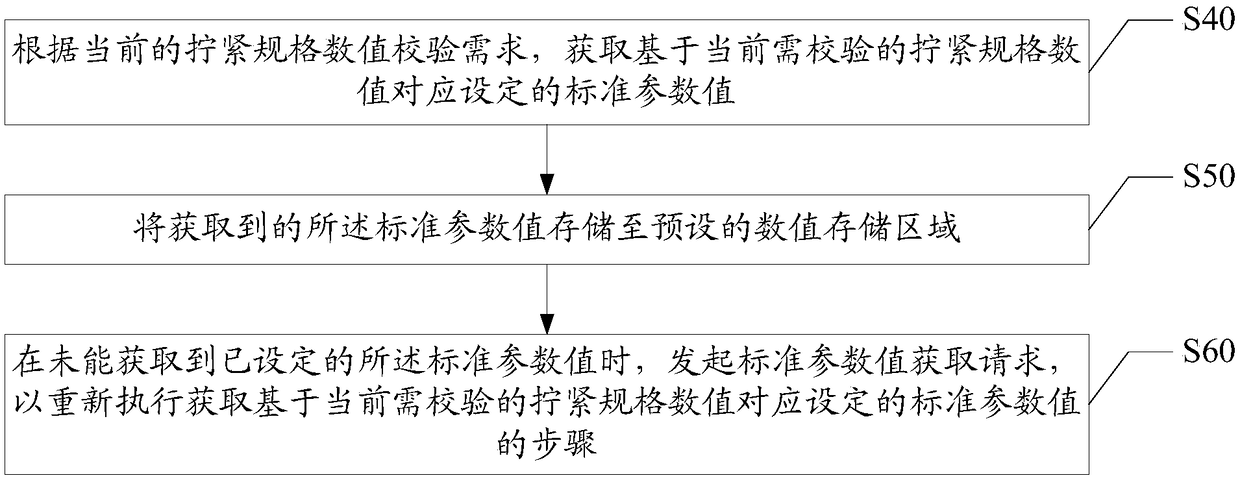

Specification verification method and device of tightening data, readable storage medium and system

ActiveCN109377405AAvoid setup errorsImprove the qualification rate of tightening workData processing applicationsMetal working apparatusNumerical verificationSoftware engineering

The invention discloses a specification verification method of tightening data, which comprises the following steps of according to the current tightening specification calibration requirement, obtaining the tightening specification value to be calibrated by a tool controller; comparing the obtained tightening specification value with the set standard parameter value, and confirming whether the tightening specification value is qualified according to the comparison result; when it is confirmed that the tightening specification value is consistent with the standard parameter value, confirming that the tightening specification value is qualified. The invention also discloses a specification verification device of the tightening data, a readable storage medium and a system. At present, when that numerical calibration requirement of the screw tighten specification is met, by comparing the tightening specification value currently applied by the current tool controller with the set standardparameter value, and confirming whether the tightening specification values currently applied by the current tool controllers are qualified, the numerical verification of the tightening specificationvalues of the tool controllers is realized so as to avoid the setting errors of the tightening specification parameters and further improve the qualification rate of the tightening operation.

Owner:GAC TOYOTA MOTOR

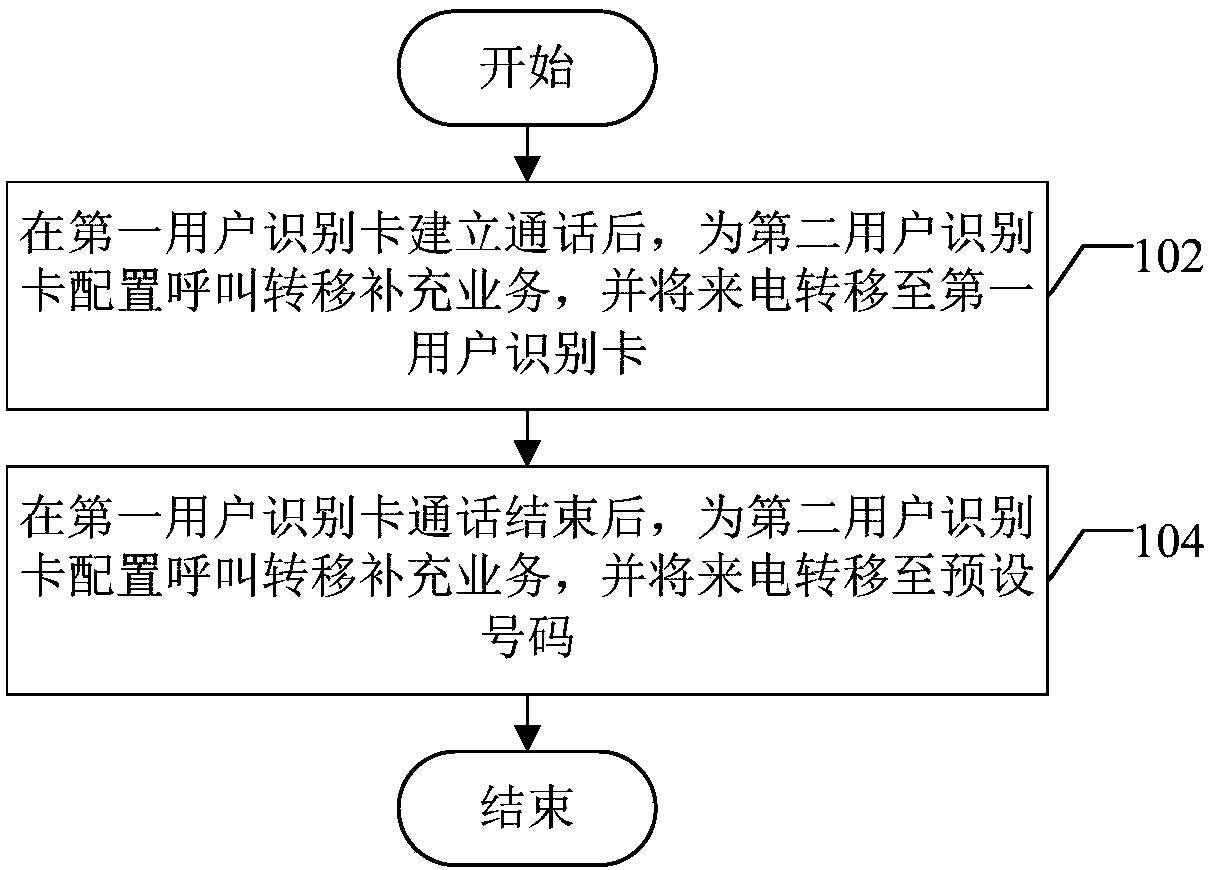

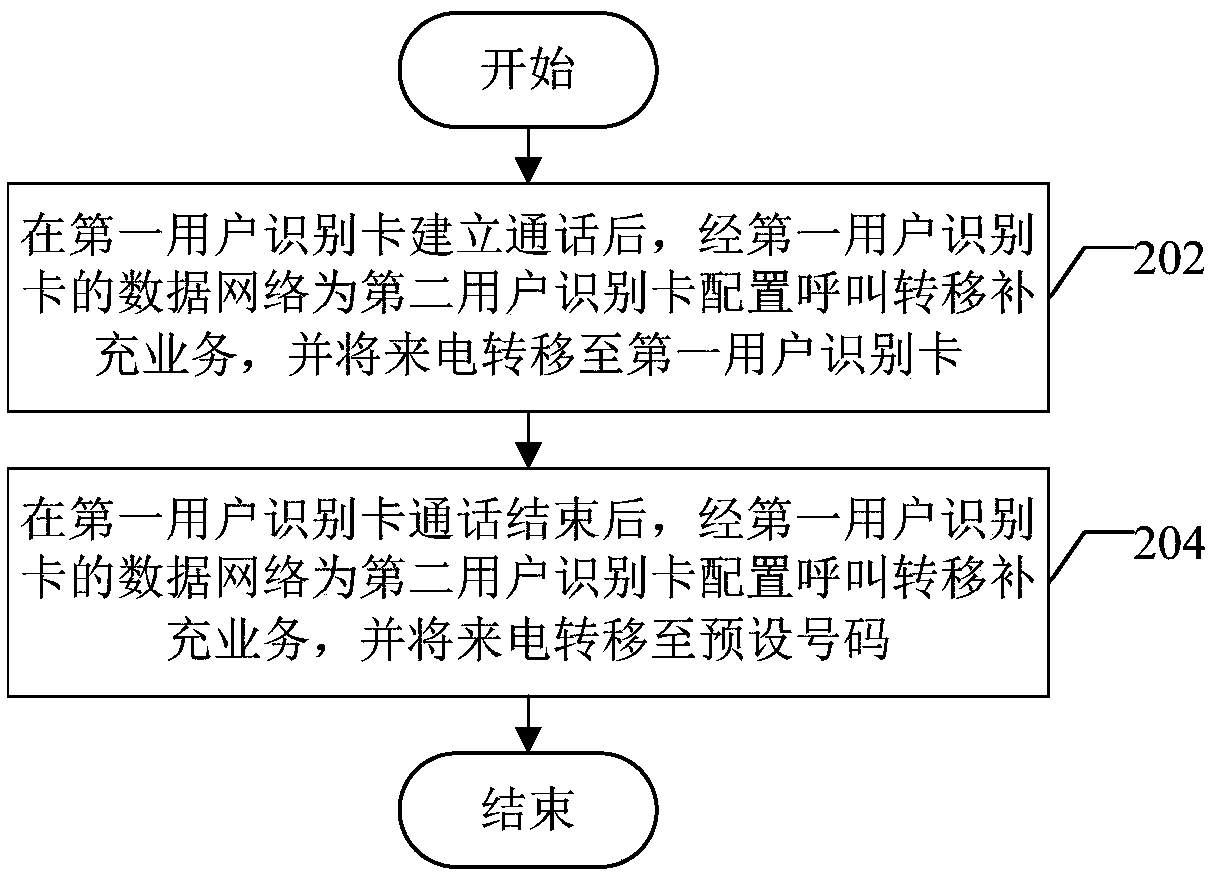

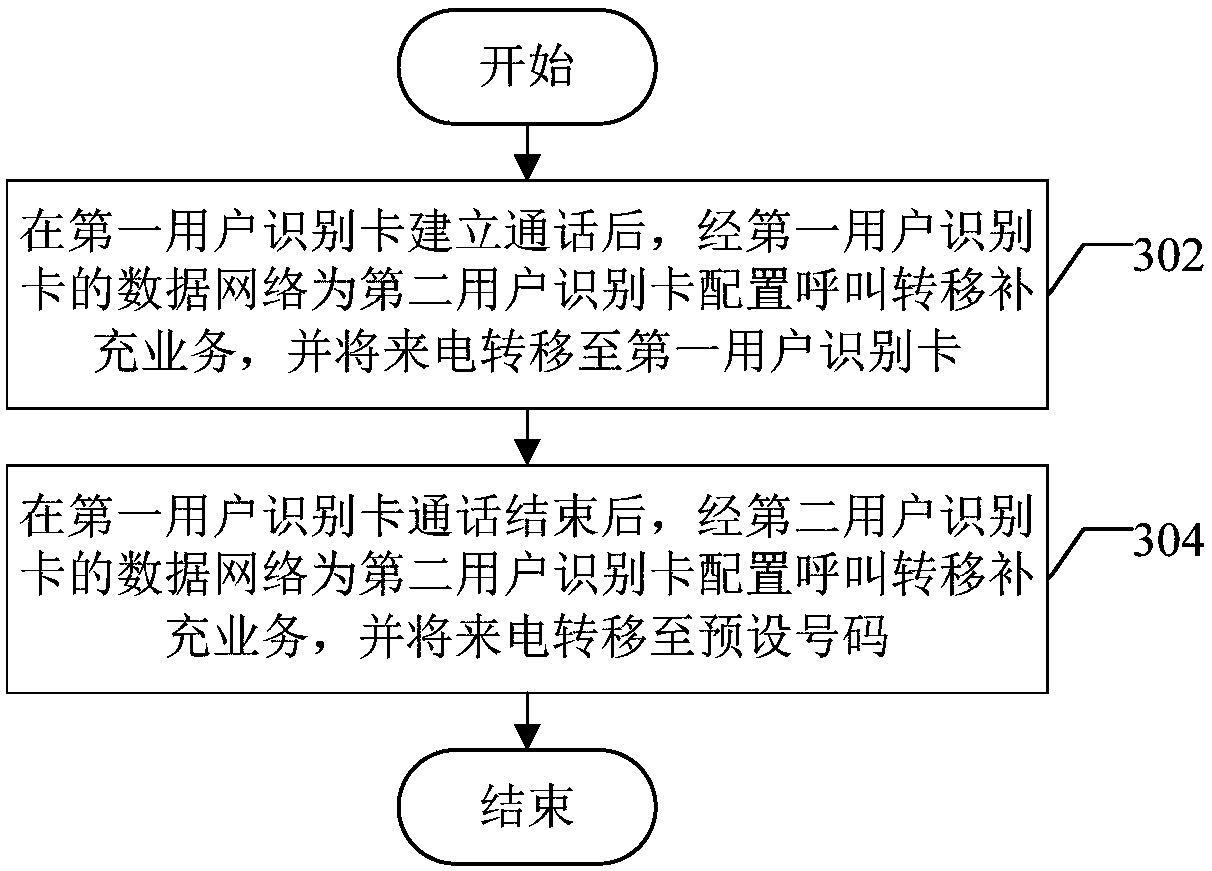

Call forwarding configuration method and device, computer equipment and computer storage medium

ActiveCN109819413AAvoid missing callsImprove single-way mobile phone call experienceSpecial service for subscribersCommmunication supplementary servicesComputer equipmentMobile phone

The invention discloses a call forwarding configuration method and device, computer equipment and a computer storage medium. The call forwarding configuration method comprises the following steps: after a first subscriber identity module card establishes a call, configuring a call forwarding supplementary service for a second subscriber identity module card, and forwarding the call to the first subscriber identity module card; and after the call of the first subscriber identity module card is finished, configuring a call forwarding supplementary service for the second subscriber identity module card, and forwarding the incoming call to a preset number. According to the embodiment of the invention, the method comprises the following steps: obtaining data;, configuring supplementary serviceof the second subscriber identity module card when the first subscriber identity module card is in communication, According to the invention, the first subscriber identity module is used for transferring the call to the first subscriber identity module, so that the call omission of the second subscriber identity module is avoided, the call is recovered to the preset number after the call is finished, the preset call transfer service is not influenced, the trouble of manually setting the call transfer and possible setting errors of the user are avoided, and the call experience of the one-way mobile phone is improved.

Owner:CHINA MOBILE COMM GRP TERMINAL +1

Method for Synchronously Machining Flanges at Both Ends of Rear Axle Housing Welding Assembly

ActiveCN105033284BGuaranteed coaxiality requirementsAvoid misalignmentWork clamping meansTurning machinesEngineeringMachining

The invention relates to a method for synchronously machining flange plates at the two ends of a rear axle housing welding assembly. The method comprises the steps that firstly, rough locating is conducted through a middle large hole of a rear axle housing, and V-shaped main locating and clamping are conducted through outer circles of the flanges at the two ends; secondly, main shafts at the two ends drive end face facing head end face roughing tools at the same time to rough turn large end faces and spigot end faces, and an axial machining allowance is reserved; thirdly, the main shafts at the two ends drive end face facing head end face finishing tools at the same time to fine turn the large end faces and the spigot end faces, and the requirements for the size of the large end faces, the size between the spigot end faces and the large end faces, the roughness of the large end faces, the circular run-out of the large end faces and the perpendicularity between the end faces and the axis of the outer circles of inner holes are met; fourthly, the main shafts at the two ends drive inner hole outer circle combined roughing tools to turn the spigot outer circles and the inner holes of flange heads at the two ends, and machining allowance is reserved; and finally, the main shafts at the two ends drive inner hole outer circle combined finishing tools to fine turn the spigot outer circles and the inner holes, and the requirements for coaxiality between the flanges at the two ends and the coaxiality between the inner circle and the outer circle of each flange are met. By the adoption of the method, multiple procedures are completed through one-time clamping.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

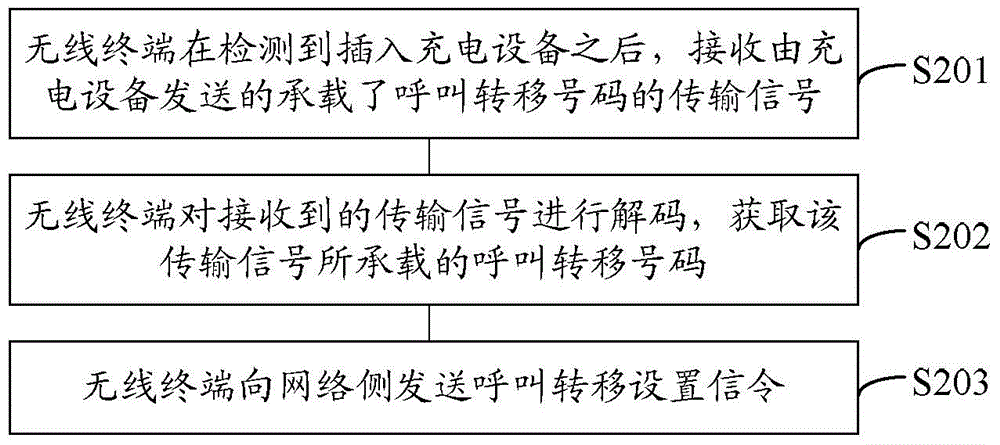

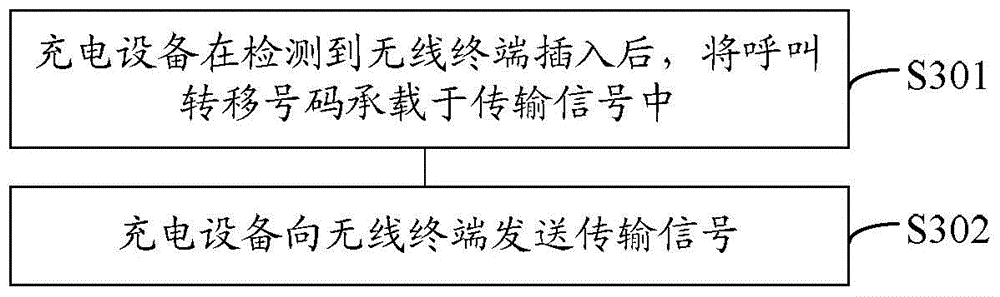

Call forwarding method, device and system

InactiveCN106162585AAvoid setup errorsRealize call forwarding functionCommmunication supplementary servicesCall forwarding

The embodiment of the invention discloses a call forwarding method, device and system. The method can be applied to a wireless terminal. The method comprises the steps of receiving a transmission signal which is sent by a charging device and carries a call forwarding number after the wireless terminal detects that the charging device is plugged in; decoding the transmission signal received by the wireless terminal, and obtaining the call forwarding number carried by the transmission signal; and sending a call forwarding setting signal to a network side by the wireless terminal, wherein the call forwarding setting signal is used for forwarding a call initiated to the wireless terminal to the call forwarding number.

Owner:ZTE CORP

Electric-controlled wind power processing device

ActiveCN109454243AReduce Oscillating PhenomenonAvoid wear and tearDriving apparatusTurning machinesElectric controlControl theory

The invention discloses an electric-controlled wind power processing device, and relates to the technical field of wind power processing. When motors are started to drive a workpiece to rotate, the rotation speed of the first motor and the rotation speed of the second motor are both improved intermittently, the interval time is identical, and the interval tempo of the first motor 1 and the interval tempo of the second motor 2 are opposite and are conducted alternately. That is, in the constant-speed intermittent movement period after the first motor is accelerated, the second motor enters theacceleration time, in the constant-speed intermittent movement period after the second motor is accelerated, the first motor enters the acceleration time, the process is repeated until the rotation speed needed by processing is achieved. The two motors run alternately, the motors are effectively prevented from being burnt out due to too high power, the oscillation phenomenon caused when the motorsdrive the workpiece to rotate is reduced, abrasion to the motors is avoided, the loss rate of equipment is further lowered, and the loss cost of the equipment is reduced.

Owner:HUNAN INSTITUTE OF ENGINEERING +1

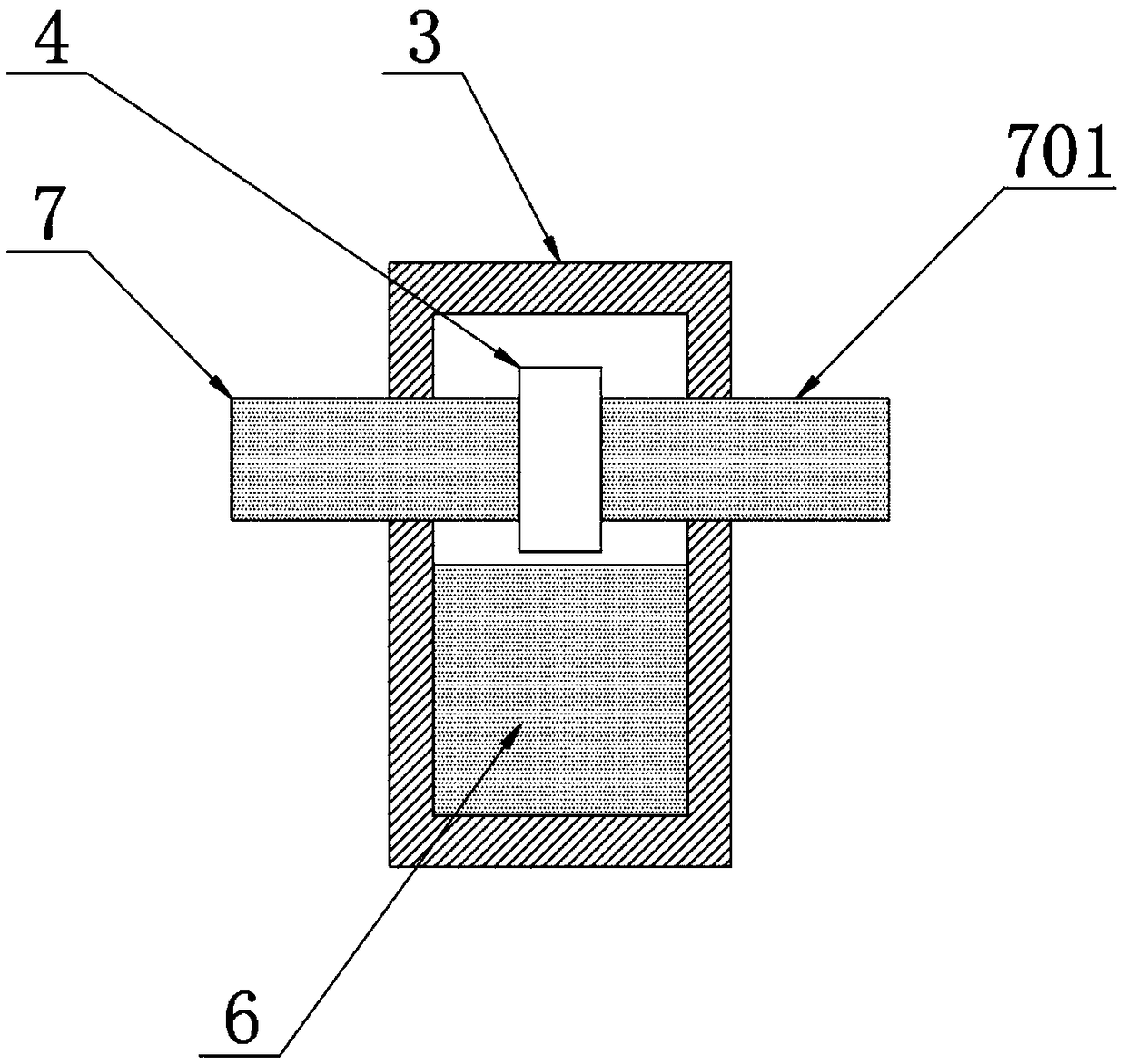

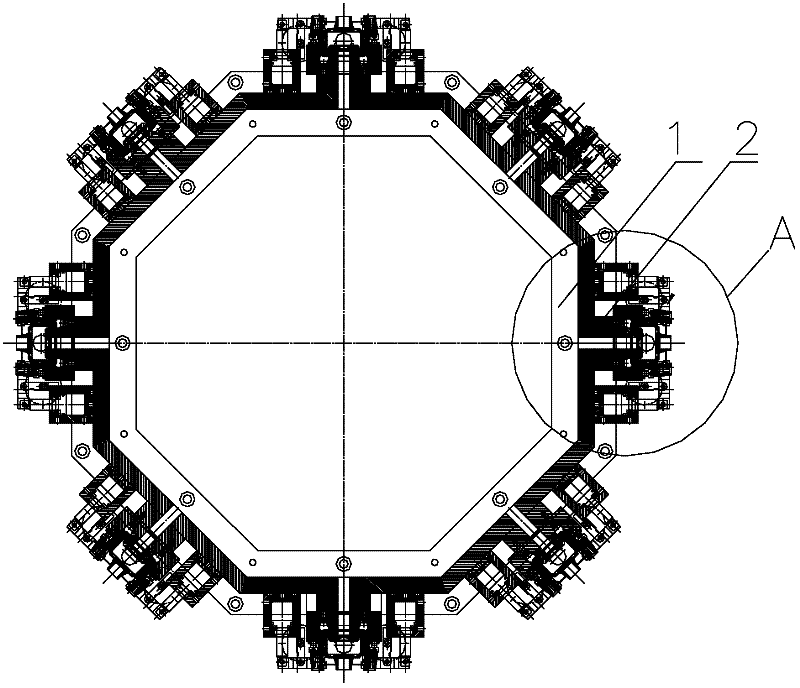

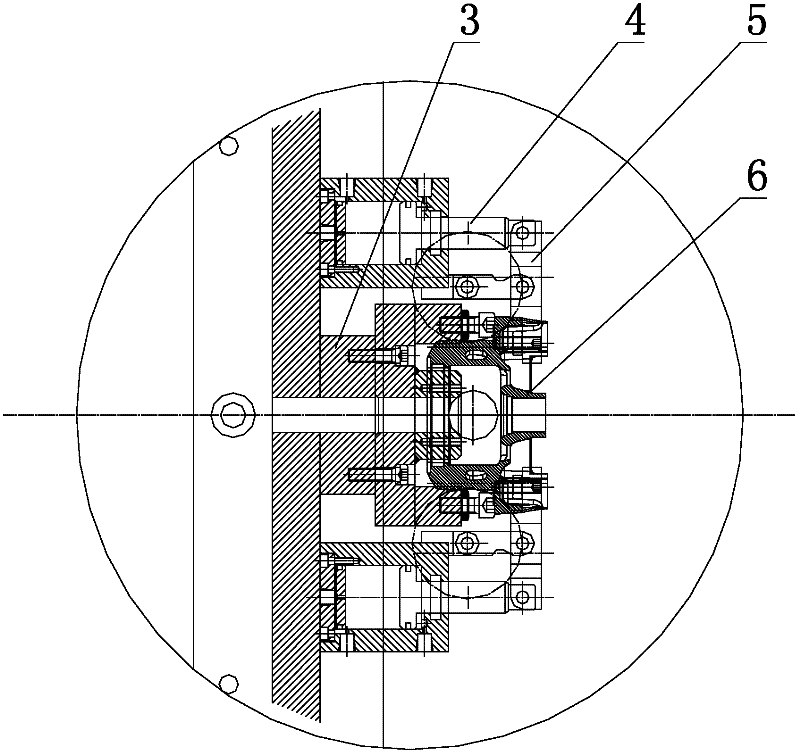

Octahedron clamping device

InactiveCN102335830AReduce the number of repeated clampingAvoid setup errorsPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention relates to an octahedron clamping device, which has the innovation that the octahedron clamping device is composed of a fitting seat and a clamping unit, wherein the fitting seat is in regular octagon; each edge of the regular octagon fitting seat is respectively provided with a fixture unit; the fixture unit is respectively composed of a fixture main body, hydraulic cylinders and platens; the fixture main body is fixedly arranged on each outer side surface of the regular octagon fitting seat; two sides of the fixture main body are symmetrically provided with hydraulic cylinders; and the tops of the cylinder rods of the hydraulic cylinder are respectively fixedly provided with the platen. The octahedron clamping device is scientific and reasonable in design, has the advantages of simple structure, accuracy in measurement, guaranteed product quality, high production efficiency and low labor intensity, is simple to operate, and is a fixture with higher innovation.

Owner:TIANJIN BAOLAI PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com