Automatic-revolving indexing machining device

A processing device and automatic rotation technology, which is applied in the field of machining fixtures, can solve the problems of affecting the processing accuracy of the valve body, affecting the processing speed of the valve body, and machining coaxial errors, so as to achieve less processing errors, reduce clamping time, and avoid assembly The effect of clamping error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

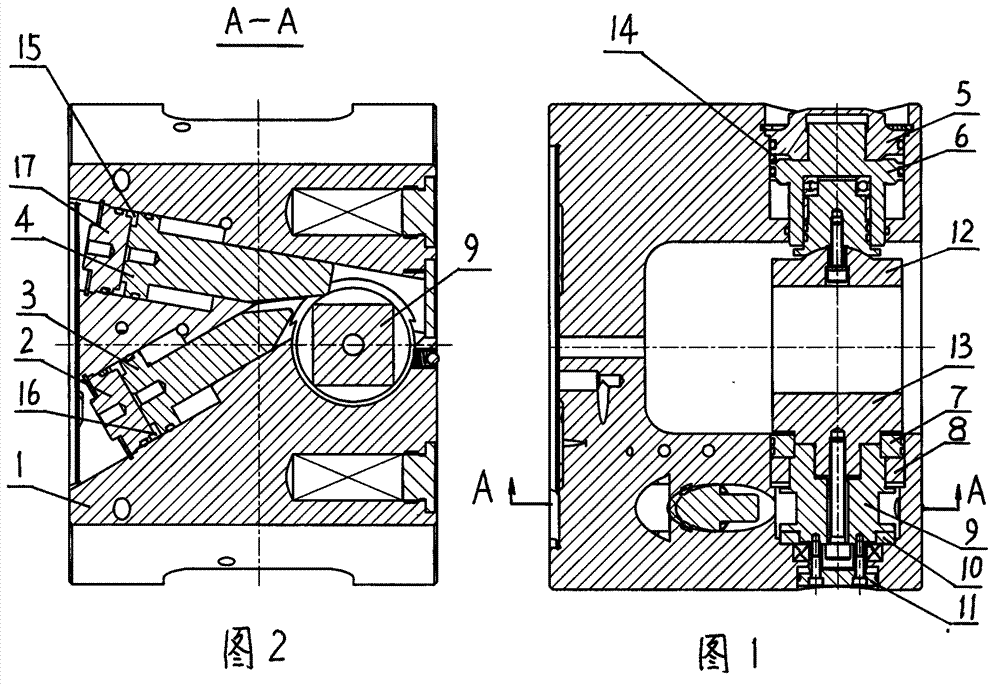

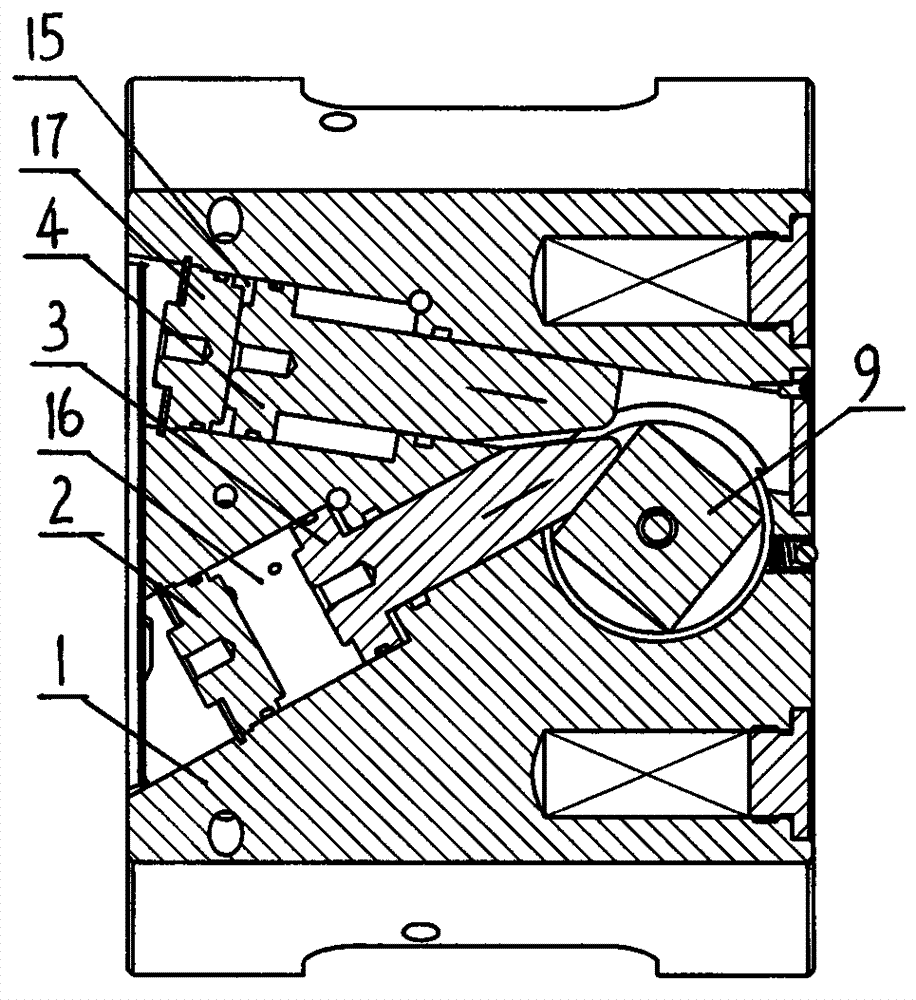

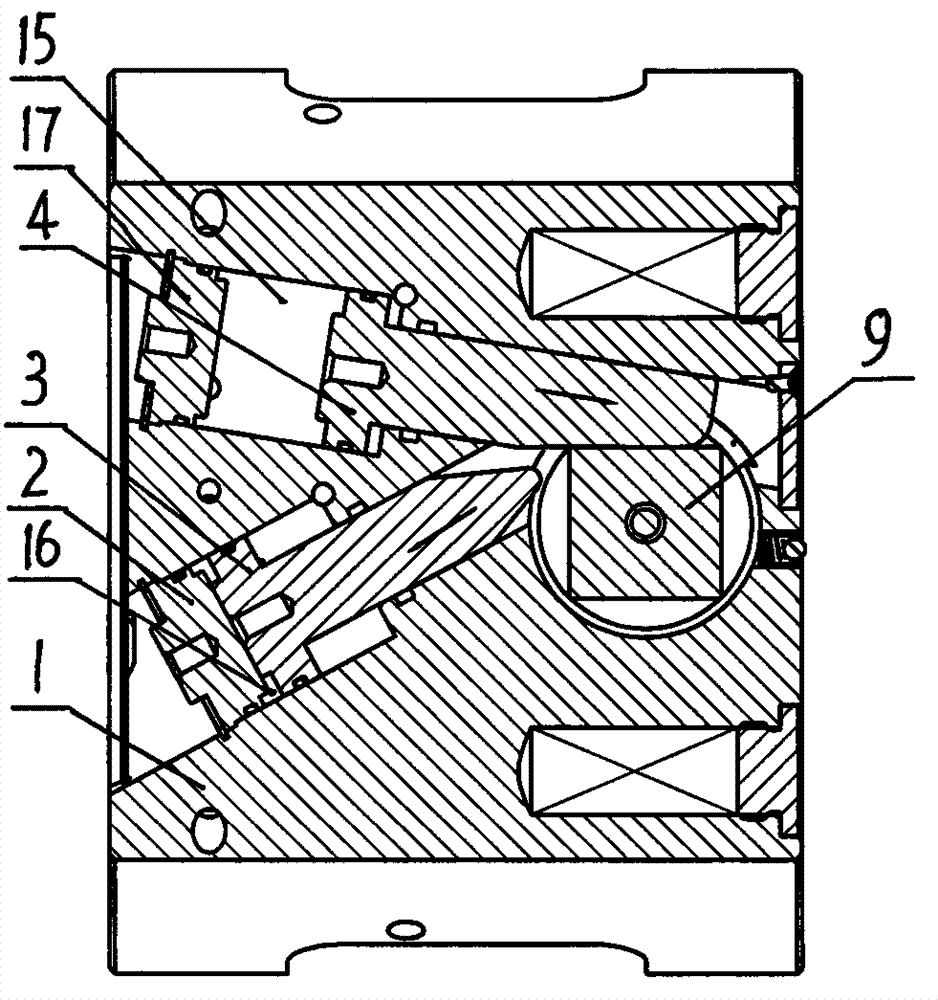

[0012] Such as figure 1 The automatic rotary indexing processing device shown includes a chuck 1 and jaws, the jaws are composed of an upper jaw 12 and a lower jaw 13, and the outer side of the chuck 1 is clamped on the machine tool; the upper jaw 12 is moved by the installation shaft Installed in the shaft hole of the clamping piston 6, so that the upper jaw 12 and the clamping piston 6 can rotate relatively, the clamping piston 6 is installed in the clamping cylinder 14 on the chuck 1, and the clamping piston is pushed by hydraulic pressure 6 Make the upper jaw 12 and the lower jaw 13 clamp the workpiece, and the upper jaw 12 and the lower jaw 13 can choose to replace the corresponding shape according to the shape of the workpiece; Fitting connection, the rotating disk 9 is axially installed on the chuck 1 by the positioning block 7, and the rotating disk 9 radially cooperates with the inner wall of the mounting hole of the chuck 1, so that the rotating disk 9 can rotate rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com