Special clamping equipment for horizontal hole machining and forming of planet carrier

A technology of clamping equipment and planetary carrier, which is applied in the direction of metal processing equipment, clamping, metal processing machinery parts, etc., can solve the problems of cumbersome clamping, inability to meet horizontal machining centers, structural restrictions, etc., and achieve firm clamping, Ingenious design, the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

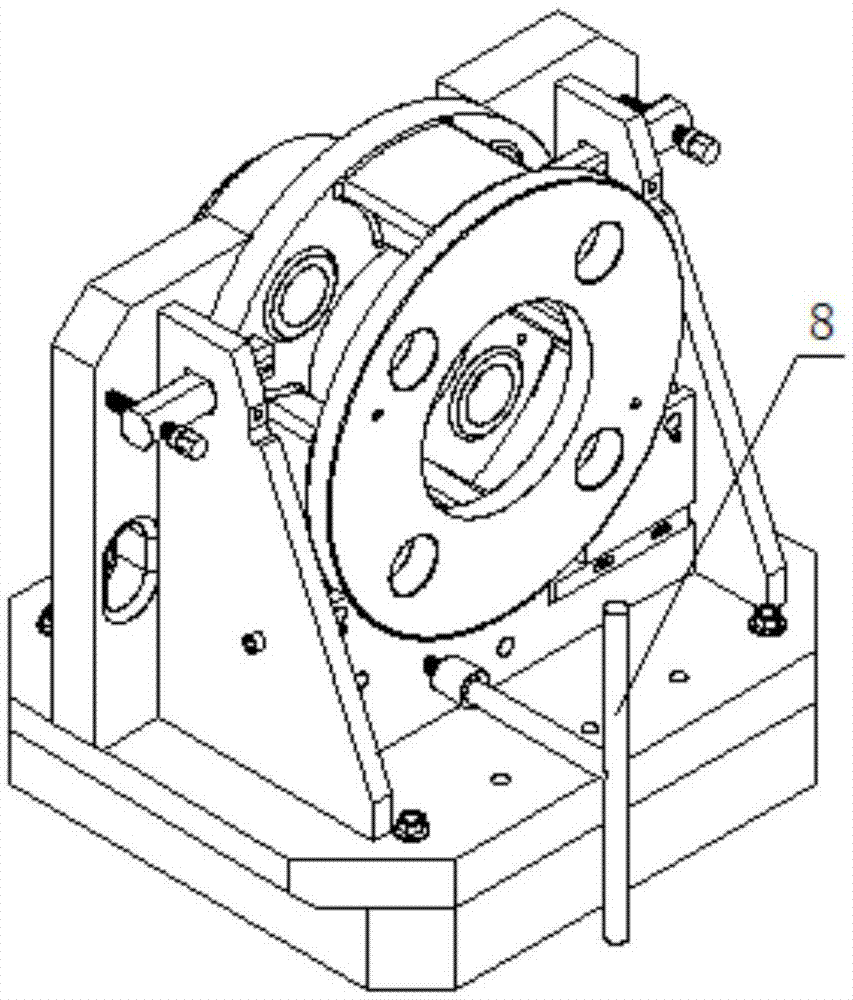

[0016] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

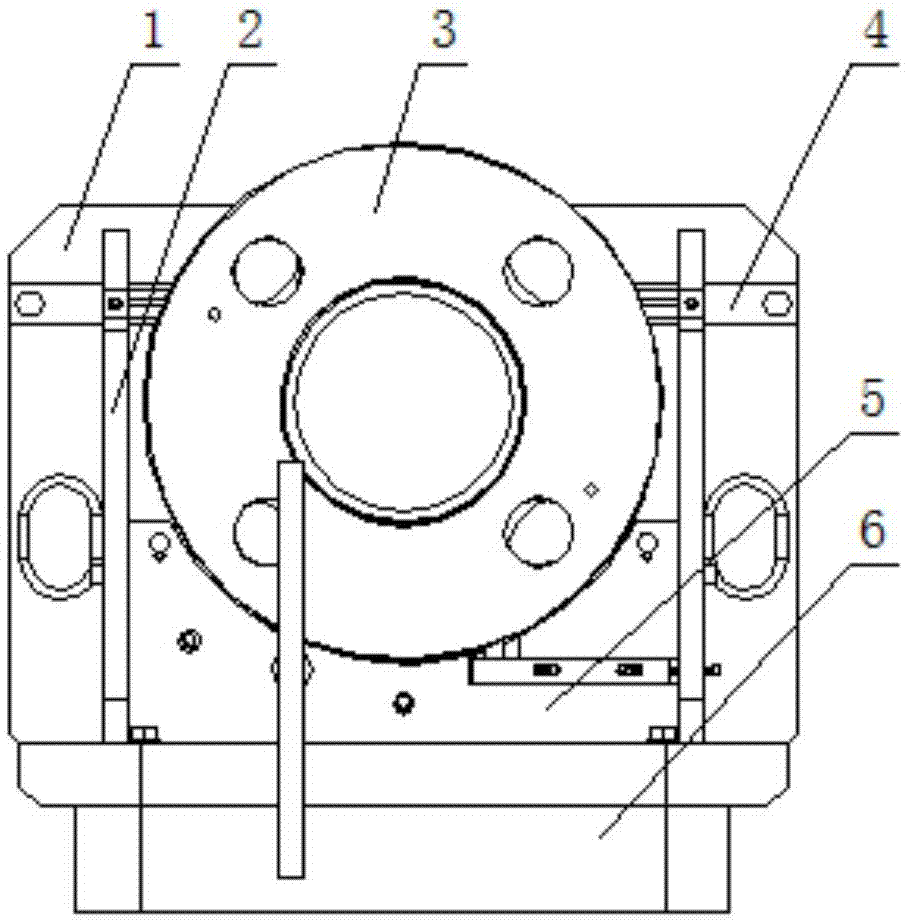

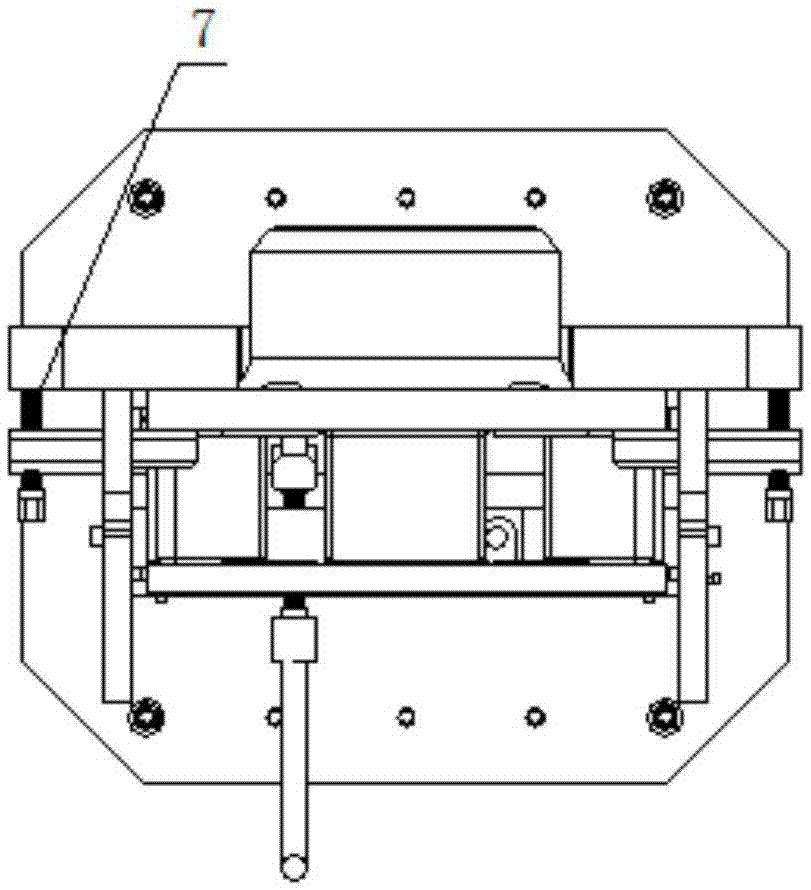

[0017] A special clamping device for horizontally adding and making holes on a planetary frame, including a base 6, a support plate 1, a support attachment plate 2 and a positioning bottom bracket 5, the support plate is vertically installed on the base, and a support plate is made on the support plate for placing workpieces. The card slot 9 with the opening facing upwards. The left and right sides of the support plate are respectively equipped with a support attachment plate, and a positioning baffle plate 4 is installed on the top of the two support attachment plates, and a long hole is made in the middle part of the positioning baffle plate, and a pin rod is installed on the support attachment plate. The pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com