Dustproof blanking equipment for alloy ingredient processing

A technology of alloy batching and dust prevention, which is applied in the directions of transportation and packaging, conveyor objects, loading/unloading, etc. It can solve the problems of pollution, drifting out, waste of alloy batching resources and processing environment, etc., so as to weaken the drifting process, ensure the environment, Effect of suppressing dust scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the specific embodiments, structures, features and effects of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

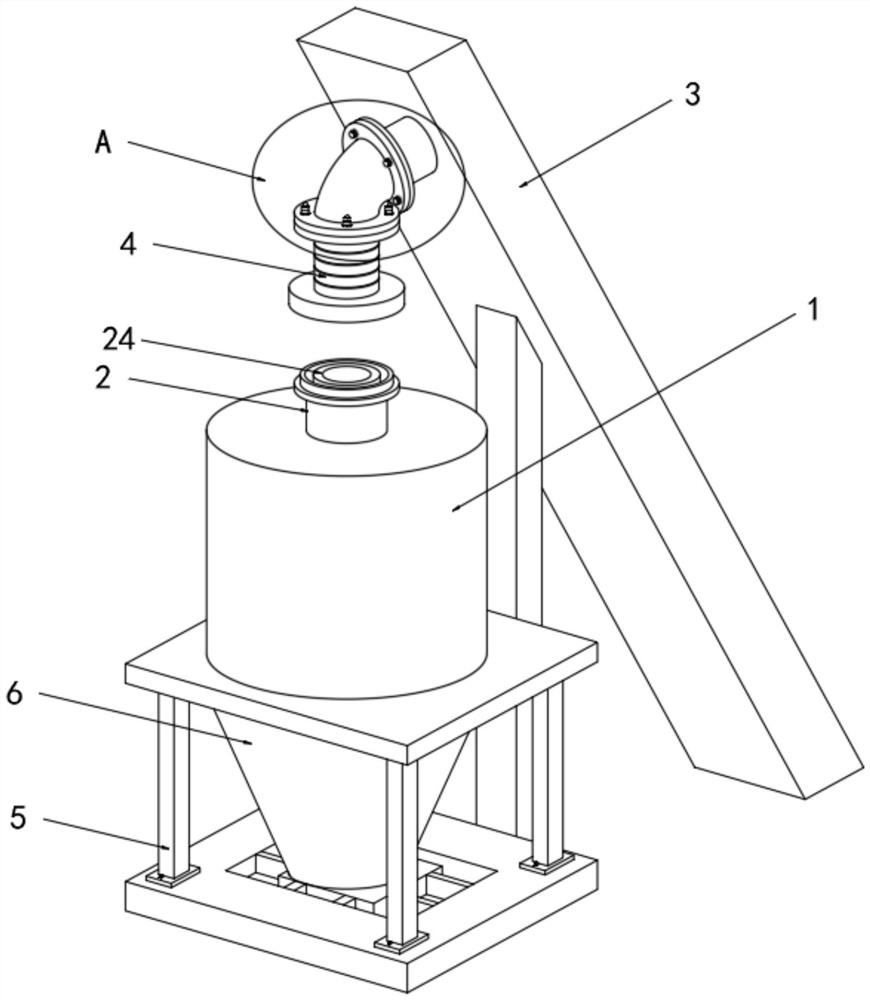

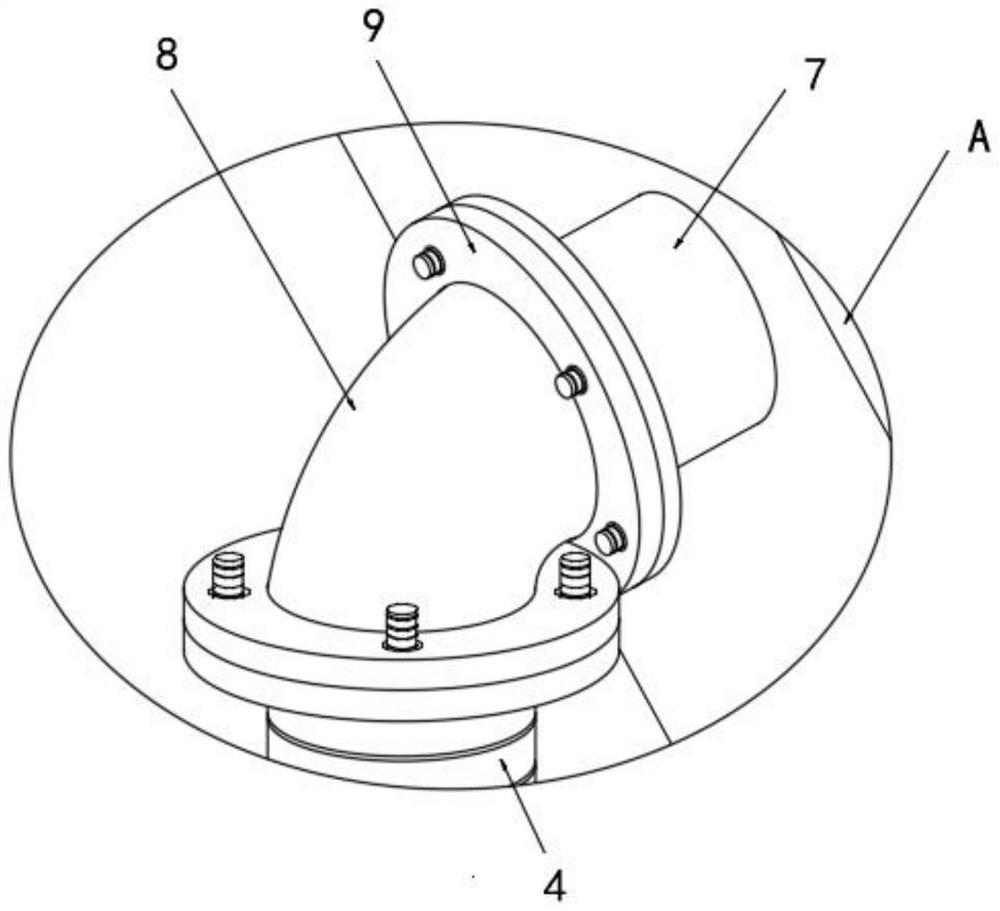

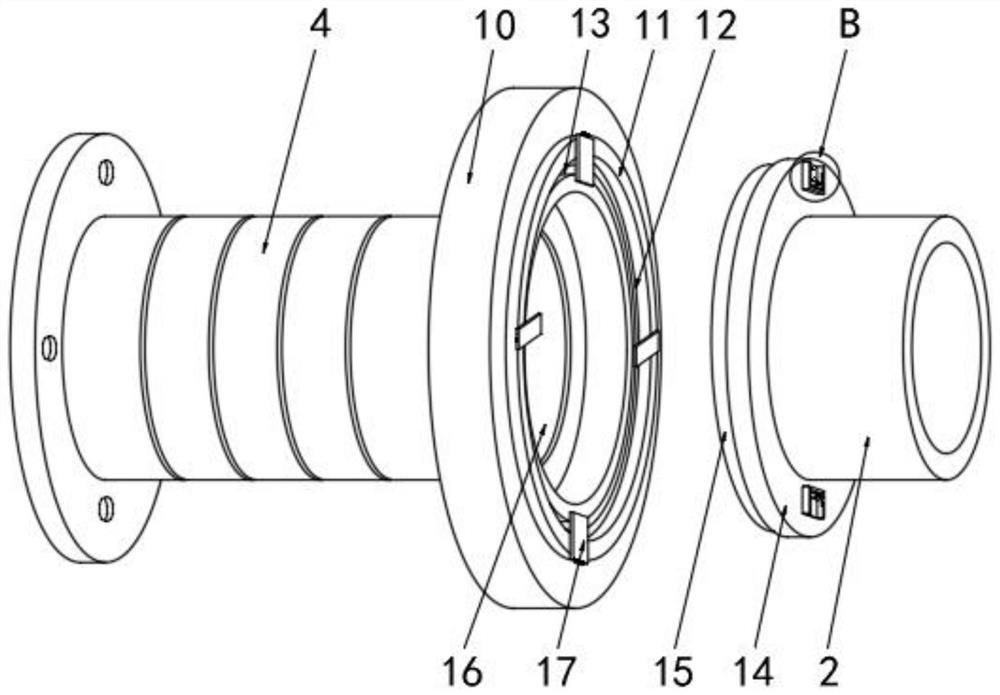

[0033] see Figure 1-Figure 8 As shown, the present invention provides an anti-dust feeding equipment for alloy batching processing, including a container barrel 1, a feeding port 2 is provided in the middle of the top surface of the container barrel 1, and one side of the container barrel 1 is provided with a feeding port 2 for feeding The top of the feeding port 2 is fixedly connected with a clamping seat 14, and a telescopic hose 4 is arranged above the feeding port 2, and the bottom surface of the telescopic hose 4 is fixedly connected with a mounting seat 10;

[0034] The bottom surface of the mounting seat 10 is provided with a do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com