Machine special for cutting waist-shaped arc groove

A technology of arc groove and special machine, which is applied in the details of milling machine equipment, metal processing equipment, milling machine equipment, etc., can solve the problems of insufficient rigidity, inability to process, low processing efficiency, etc., and achieve high surface roughness, high dimensional accuracy, The effect of high clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

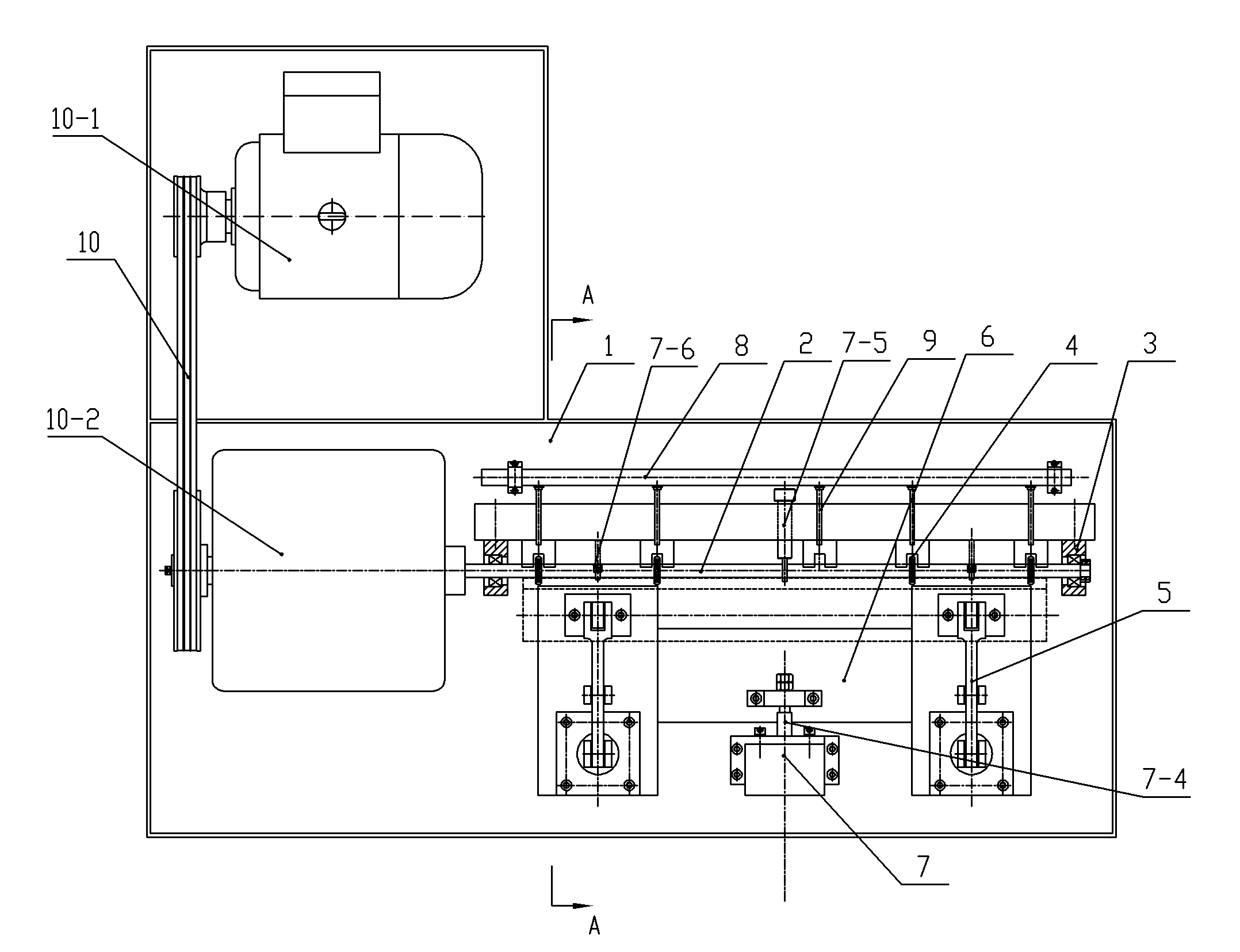

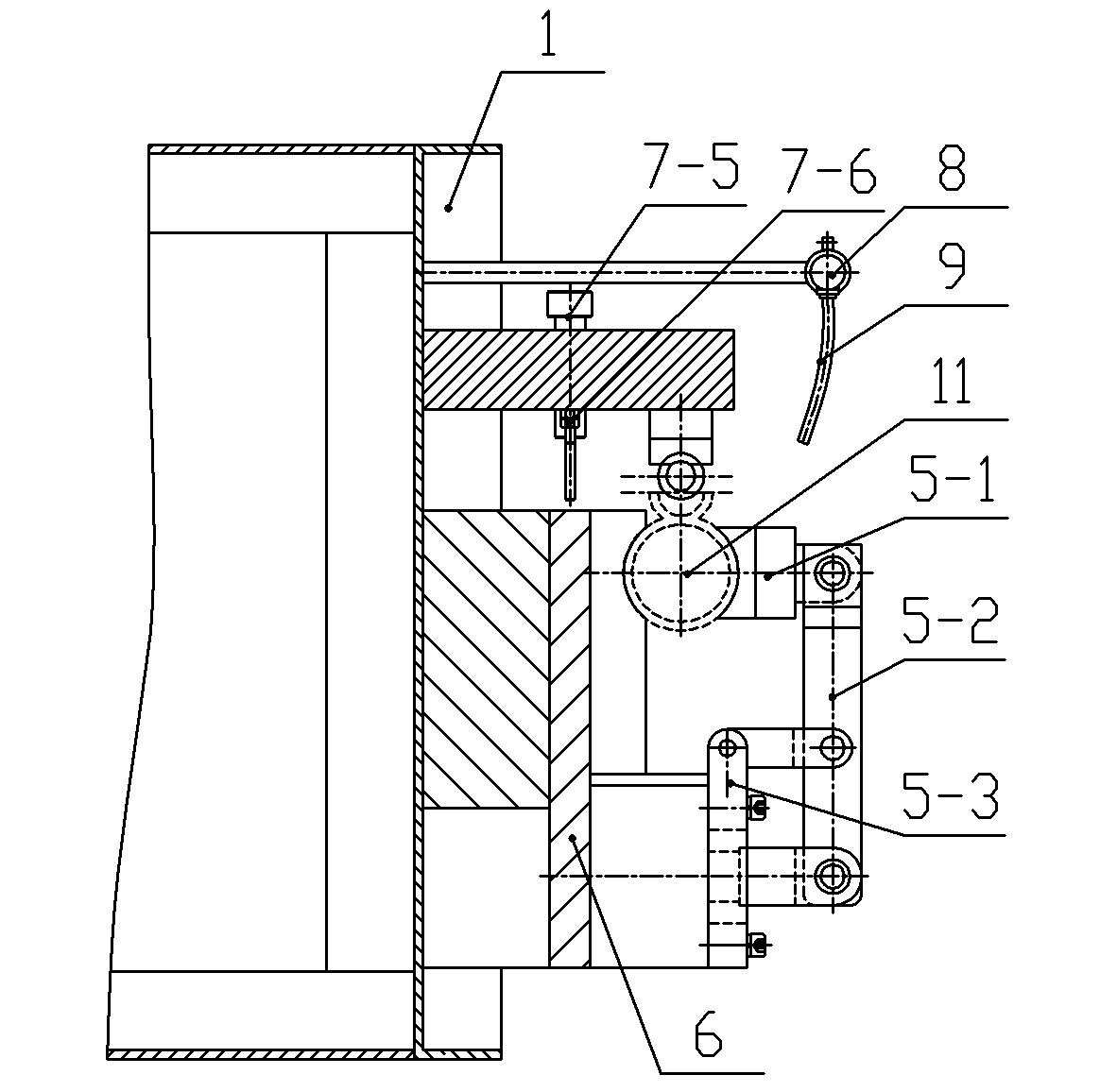

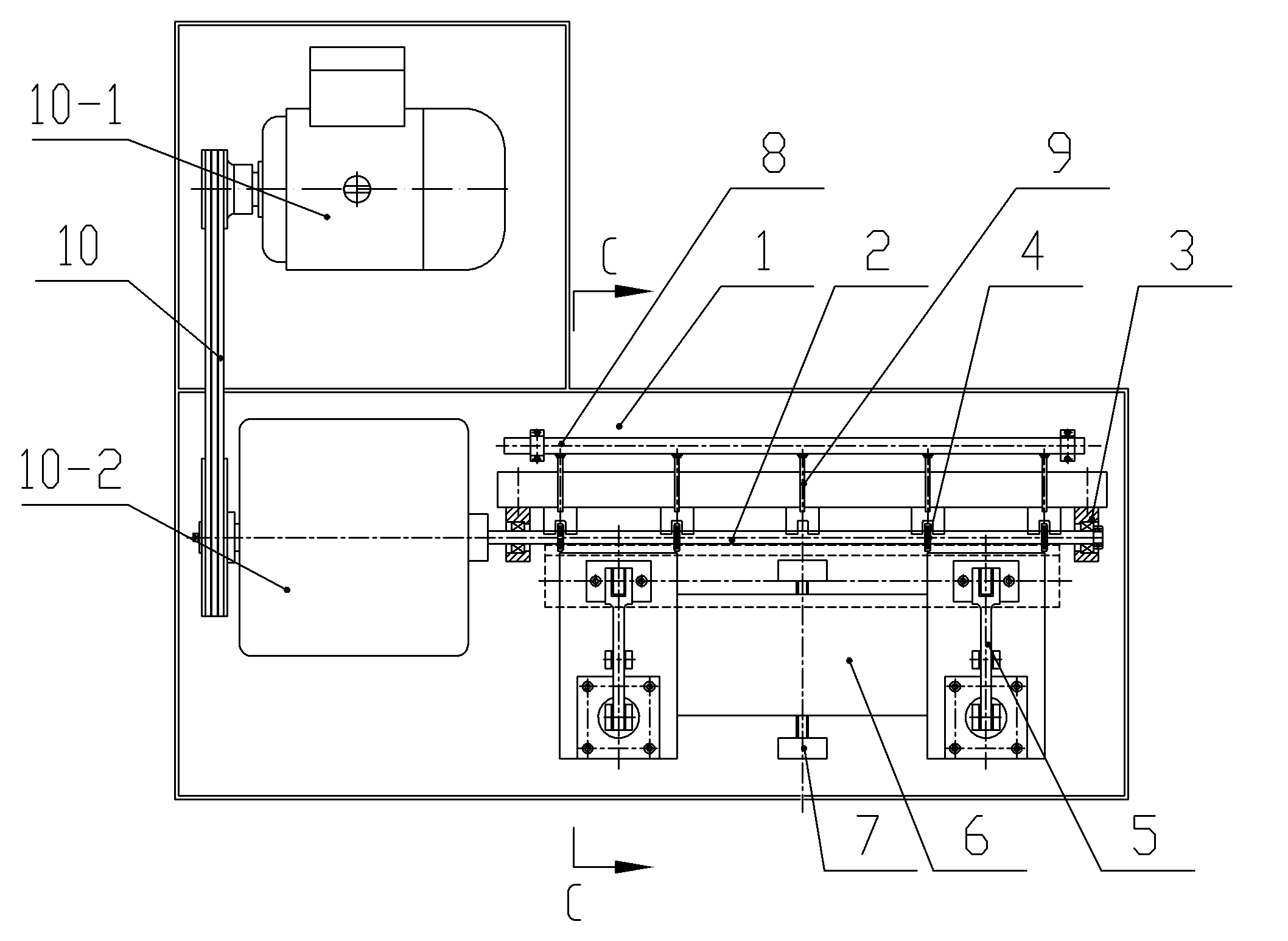

[0020] Such as figure 1 and figure 2 The first embodiment of the waist-shaped circular arc groove grooving machine shown in the present invention includes a workbench 1, a grooving mechanism, a workpiece clamping mechanism 5 for clamping workpieces, and a grooving feed mechanism. The grooving mechanism includes a tool shaft 2 with a grooving tool 4, a power mechanism 10 for transmitting power to the tool shaft 2 to rotate the grooving tool 4 for grooving operations, and a tool shaft bracket 3 for supporting the tool shaft 2 , the power mechanism 10 includes a motor 10-1 and a transmission mechanism 10-2, and the tool shaft 2 is coupled with the output shaft of the transmission mechanism 10-2. The power mechanism 10 and the tool shaft bracket 3 are fixedly installed on the workbench 1; the grooving feeding mechanism includes a carriage 6 and a carriage driving mechanism 7 installed on the workbench 1 for driving the carriage to feed or retreat; Plate driving mechanism 7 comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com