Clamping and auxiliary supporting linkage mechanism

A linkage mechanism and clamping technology, applied in the direction of support, clamping, workpiece clamping device, etc., can solve the problem of time-consuming and labor-intensive, and achieve the effect of improving stability and reliability, improving clamping rigidity, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

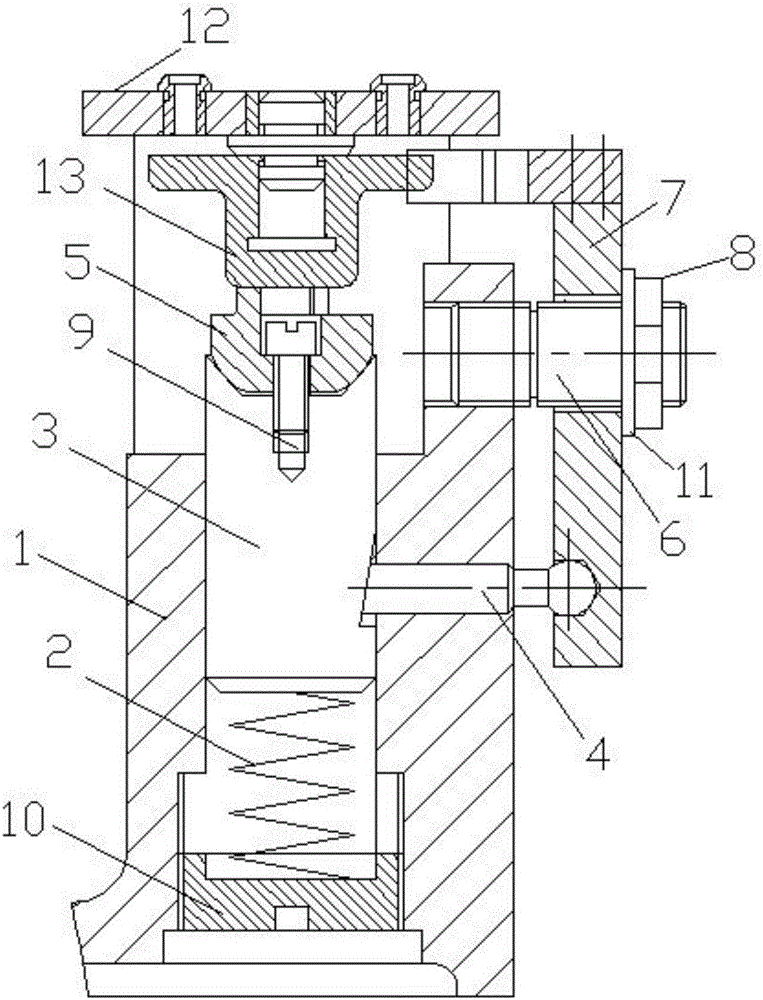

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] attached figure 1 It is a clamping and auxiliary support linkage mechanism described in the present invention, including clamp body 1, spring 2, wedge pin 3, spherical adjustment rod 4, three-point auxiliary support 5, locking stud 6, clamping plate 7 and Lock nut 8; a spring 2 is arranged in the inner center of the clamp body 1; one end of the spring 2 is connected to the clamp body 1, and the other end is connected to the wedge pin 3; the wedge of the wedge pin 3 is provided with a spherical adjustment rod 4; the spherical adjusting rod 4 extends out of the clamp body 1, and the spherical part faces outward; the top of the wedge pin 3 is provided with a three-point auxiliary support 5; the clamp body 1 above the spherical adjusting rod 4 is provided There is a locking stud 6; the locking stud 6 is provided with a clamping pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com