Special clamp for realizing multi-point clamping

A special fixture and multi-point technology, applied in the field of workpiece clamping, can solve the problems of easy loosening of the workpiece, easy to scratch the surface, and reduce the stability and reliability of the clamping, so as to improve the stability and reliability and improve the clamping The effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

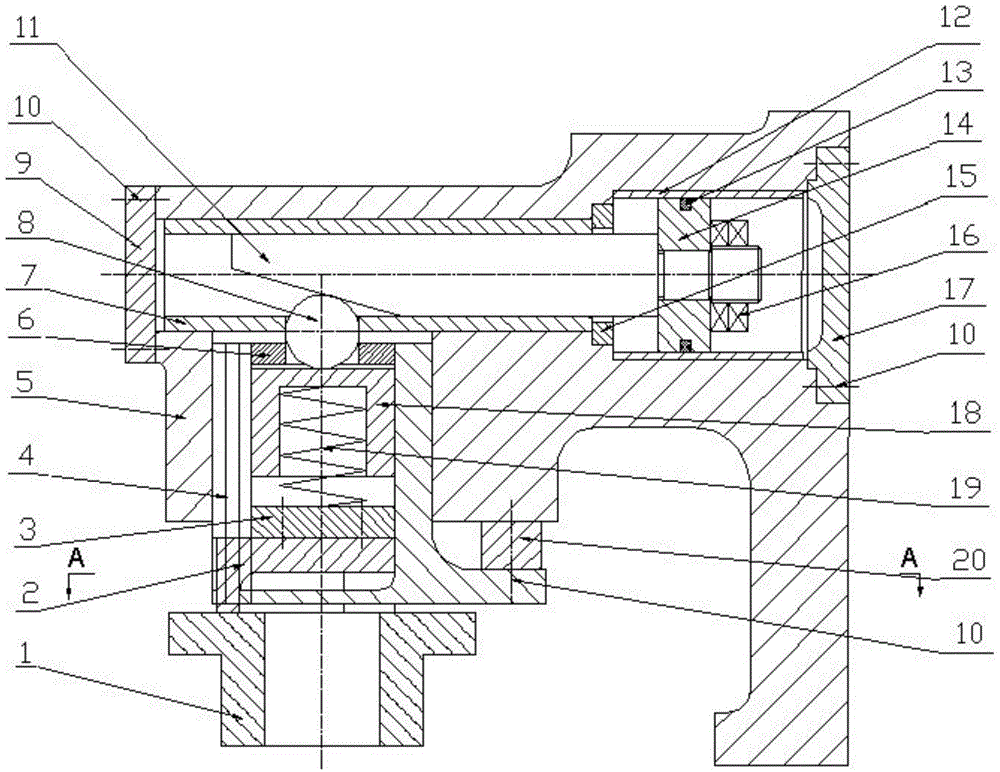

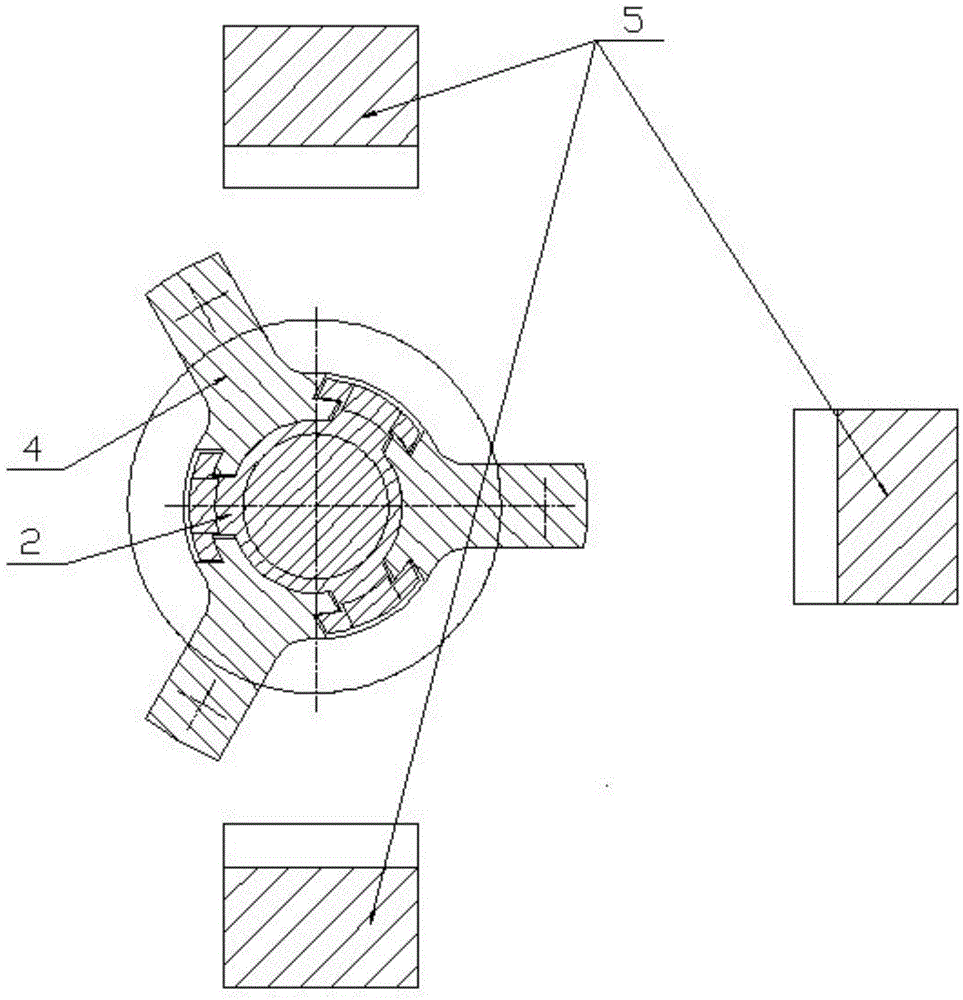

[0017] attached Figure 1-2 It is a special fixture for realizing multi-point clamping according to the present invention, which includes a clamp body 5; a piston rod 11 arranged horizontally and capable of moving left and right is arranged in the clamp body 5; the two ends of the piston rod 11 are correspondingly provided with The left end cover 9 and the right end cover 17; the left end cover 9 and the right end cover 17 are respectively fixed on the clamp body 5 by screws 10 to play a sealing role; the lower side of the left end of the piston rod 11 is provided with a slope, and the right end is provided with a piston 14 and nut 16; the piston 14 is fixed on the piston rod 11 by the nut 16; a bushing 7 is arranged between the piston rod 11 and the clamp body 5; a piston bushing is arranged between the piston 14 and the clamp body 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com