Clamp for drilling of shifting fork

A fixture and threaded hole technology, which is applied in the field of fork drilling fixtures, can solve problems such as shifting fork movement or jumping, inaccurate threaded hole positions, and unstable clamping methods, so as to reduce calibration time and achieve good clamping effects , Improve the effect of accuracy and drilling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

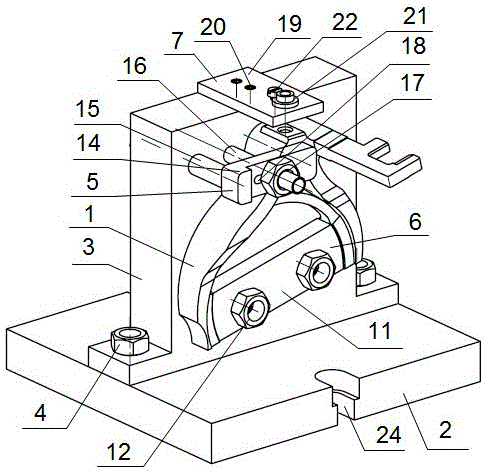

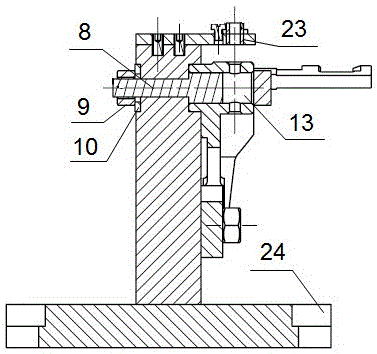

[0014] Such as figure 1 with figure 2 As shown, a jig for drilling holes for a shift fork includes a shift fork 1, a base 2, a support base 3, a mounting screw 4, a pressing assembly 5, a positioning assembly 6, and a threaded hole guide assembly 7. The positioning assembly 6 realizes The installation hole 13 of the shift fork 1 is used as the main positioning reference, and the inner end faces of the two feet of the shift fork 1 are used as the anti-rotation reference, effectively realizing the positioning of the shift fork 1, so that the lower end face of the shift fork 1 and the support support 3 Parallel, so that the axis of the threaded hole is perpendicular to the supporting base 3, reducing the correction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com