Circular blade with accurate positioning structure and cutting tool

An accurate positioning, round blade technology, applied in the field of cutting, can solve the problems of round blade chipping, cutting life, low cutting efficiency, fastener deformation, etc., to avoid cutting vibration, improve cutting accuracy, and improve clamping rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

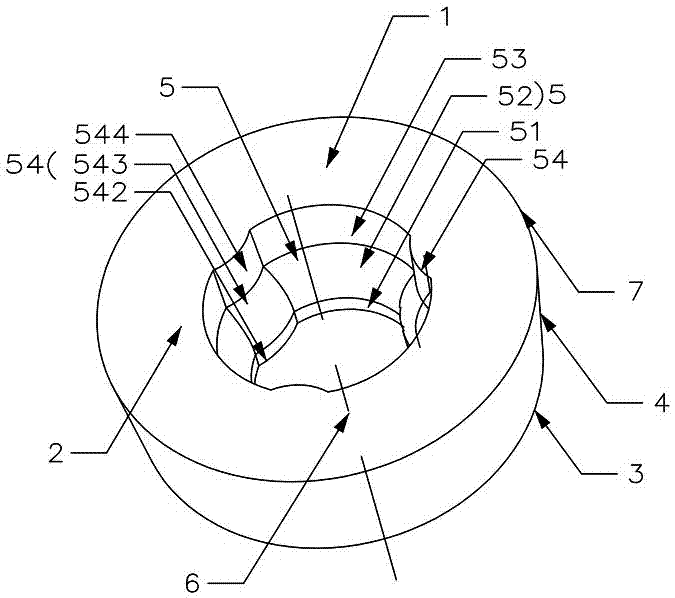

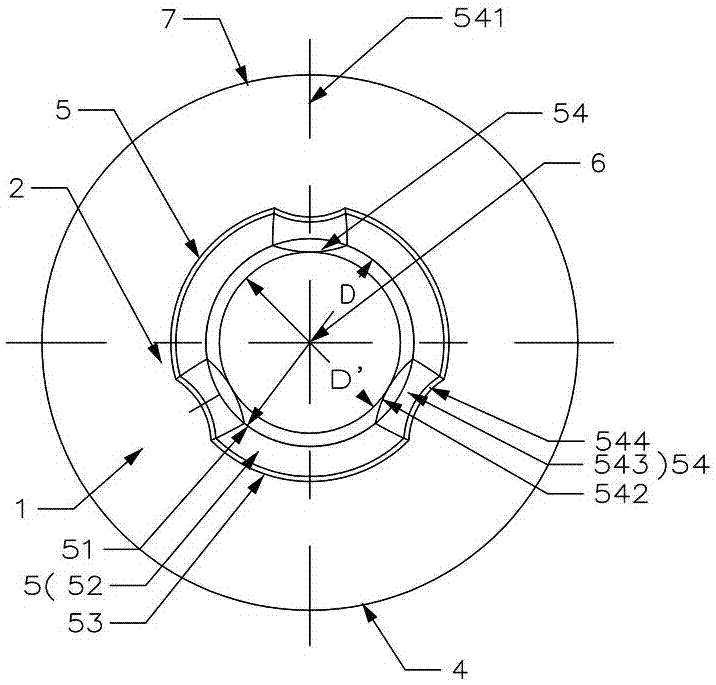

[0035] Such as Figure 1 to Figure 4 As shown, the circular blade with an accurate positioning structure in this embodiment includes a circular plate-shaped blade body 1 composed of an upper surface 2, a lower surface 3, and a side 4 connecting the upper surface 2 and the lower surface 3. The blade body 1 There is a central hole 5 that runs through the upper surface 2 and the lower surface 3. The blade body 1 is symmetrical about the central axis 6 of the central hole 5. The upper surface 2 intersects with the side 4 to form a cutting edge 7. The inner surface of the central hole 5 is provided with at least two protruding portions, the angle between two adjacent protruding portions 54 is less than 180°.

[0036] In this embodiment, taking three protrusions 54 as an example, each protrusion 54 is uniformly arranged along the circumferential direction of the central hole 5 . Each protrusion 54 is provided with a protrusion symmetry plane 541 .

[0037] In this example, if im...

Embodiment 2

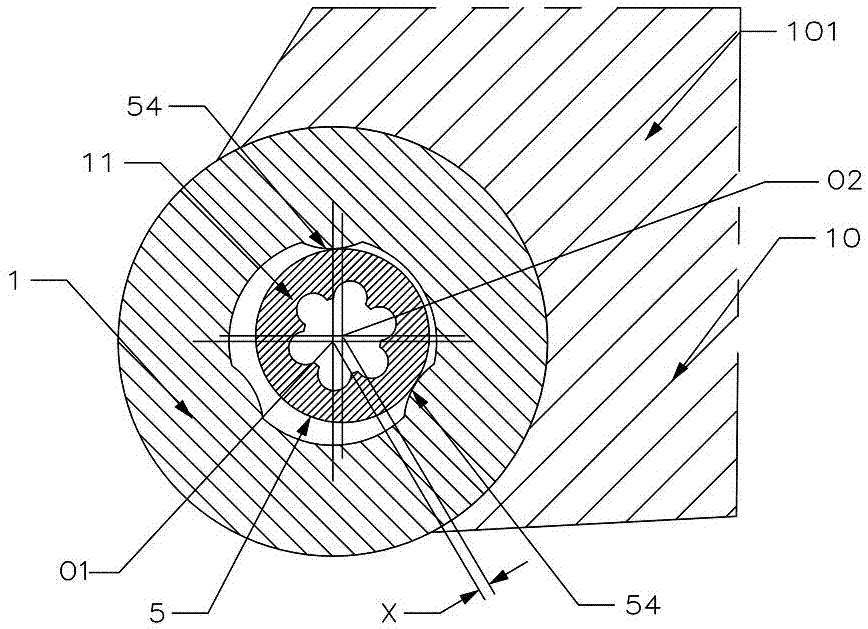

[0042] Such as Figure 5 As shown, the cutting tool of the present embodiment includes a cutter body 10 and a fastening screw 11. The cutter body 10 is provided with a sipe 101. The cutting tool includes the round blade in Embodiment 1, and the round blade is installed in the sipe 101. , the fastening screw 11 is in contact with at least two protrusions 54 in the central hole 5 , and presses the blade body 1 into the knife groove 101 . When the deformation of the fastening screw 11 increases with the increase of the cutting force, the third protrusion 54 will also come into contact with the fastening screw 11 , thereby finally forming a triple-constrained over-clamping positioning.

[0043] In this embodiment, since there are three protrusions 54, the circular blade can be rotated three times and installed and positioned three times.

[0044] In order to ensure that the blade body 1 is installed in the knife groove 101 for use, the adjacent two protrusions 54, the third protr...

Embodiment 3

[0048] Such as Figures 6 to 9 As shown, this embodiment is substantially the same as Embodiment 1, the difference is that in this embodiment, there are four raised portions 54, and a corner raised portion is provided between two adjacent raised portions 54 55, with four corner protrusions 55 in total.

[0049] In this embodiment, each protrusion 54 is provided with a protrusion symmetry plane 541, the corner protrusion 55 has a corner protrusion symmetry plane 551, the protrusion symmetry plane 541 and the corner protrusion symmetry plane 551 Both pass through the central axis 6. The purpose of setting the corner protrusion 55 is: when the fastening screw 11 is tightened, when the fastening screw 11 is pressed against the two adjacent protrusions 54, it will be raised with the corner between the two protrusions 54 at the same time. The part 55 is pressed tightly, and the three-point contact between the fastening screw 11 and the inner surface of the center hole 5 is realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com