Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "High pitch accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

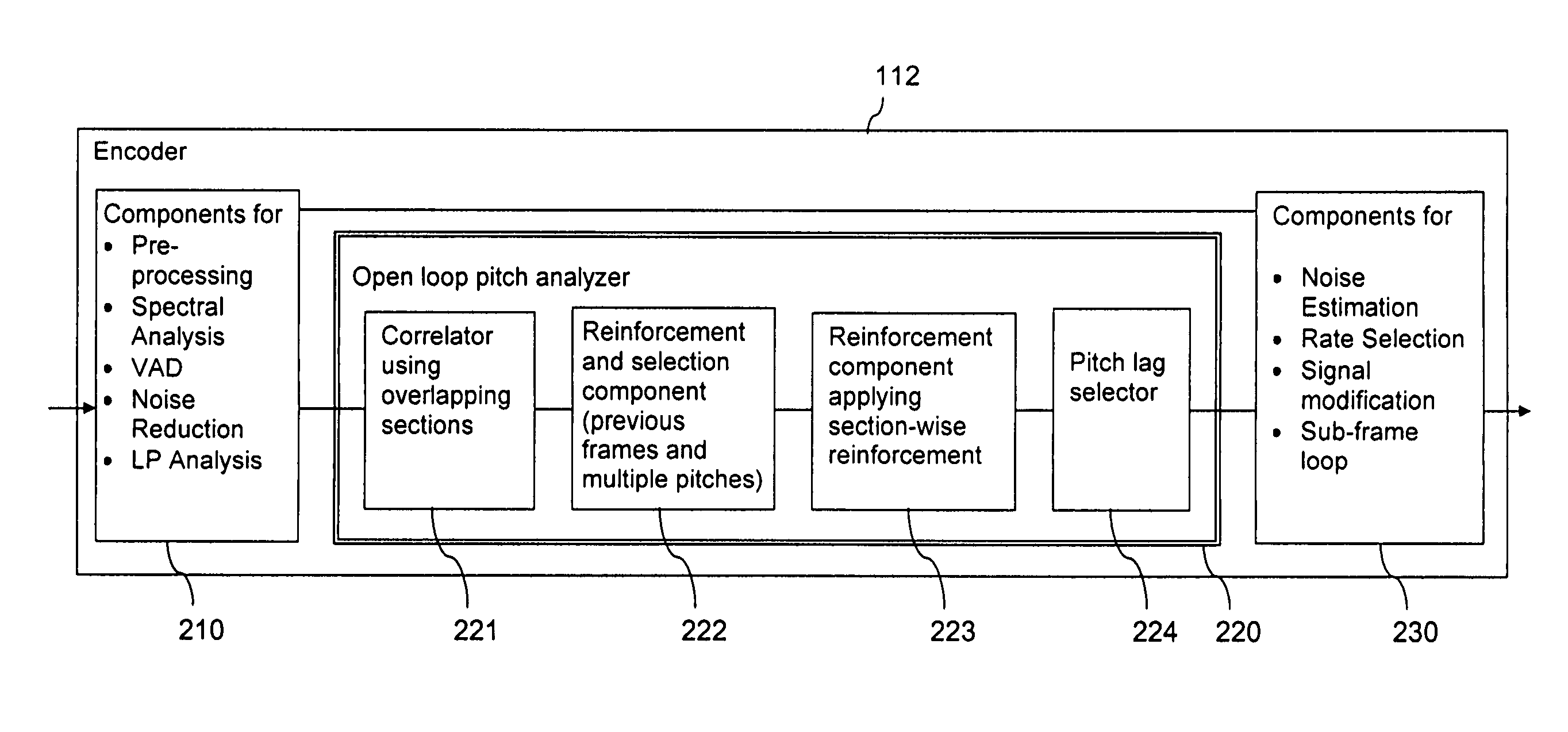

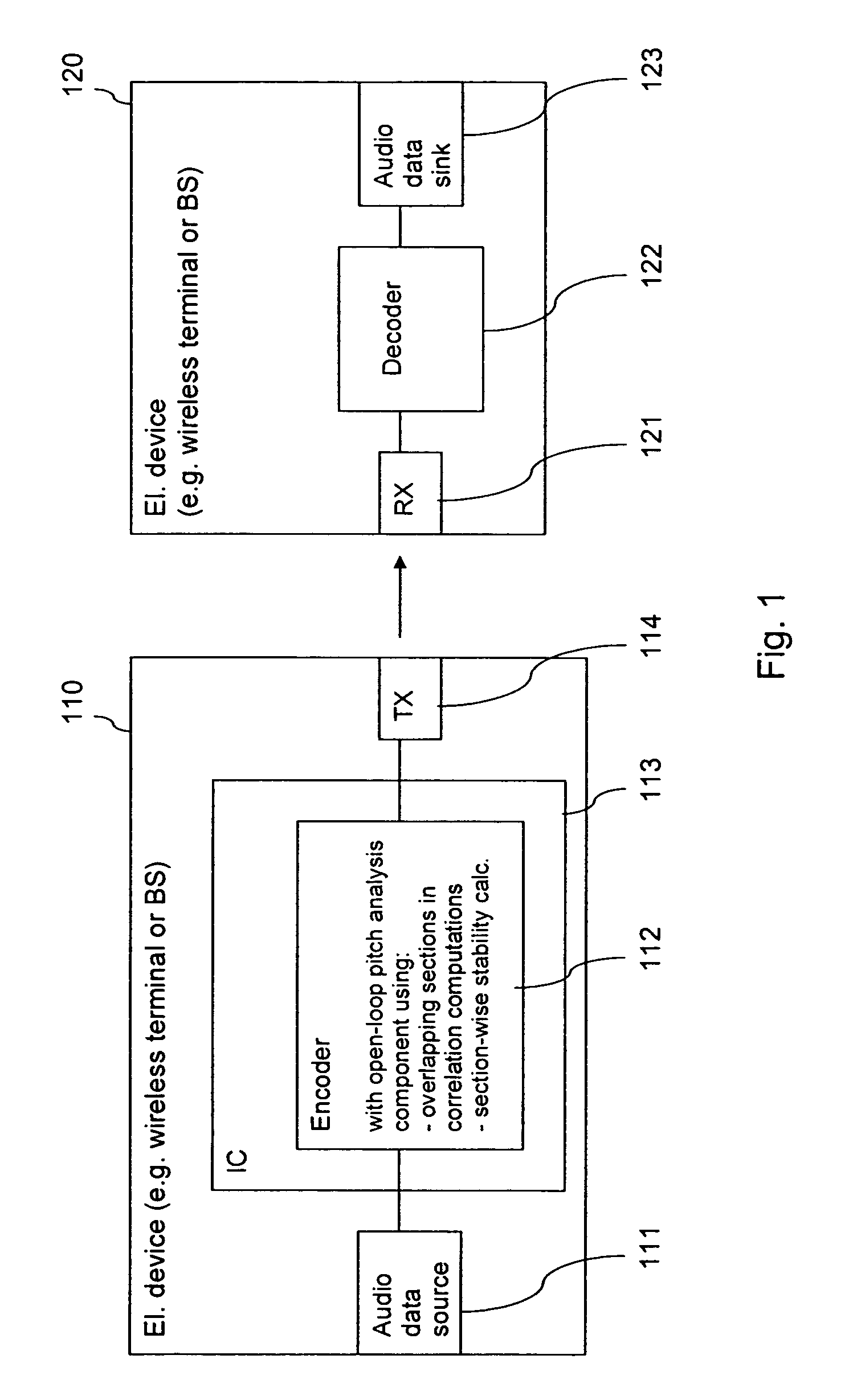

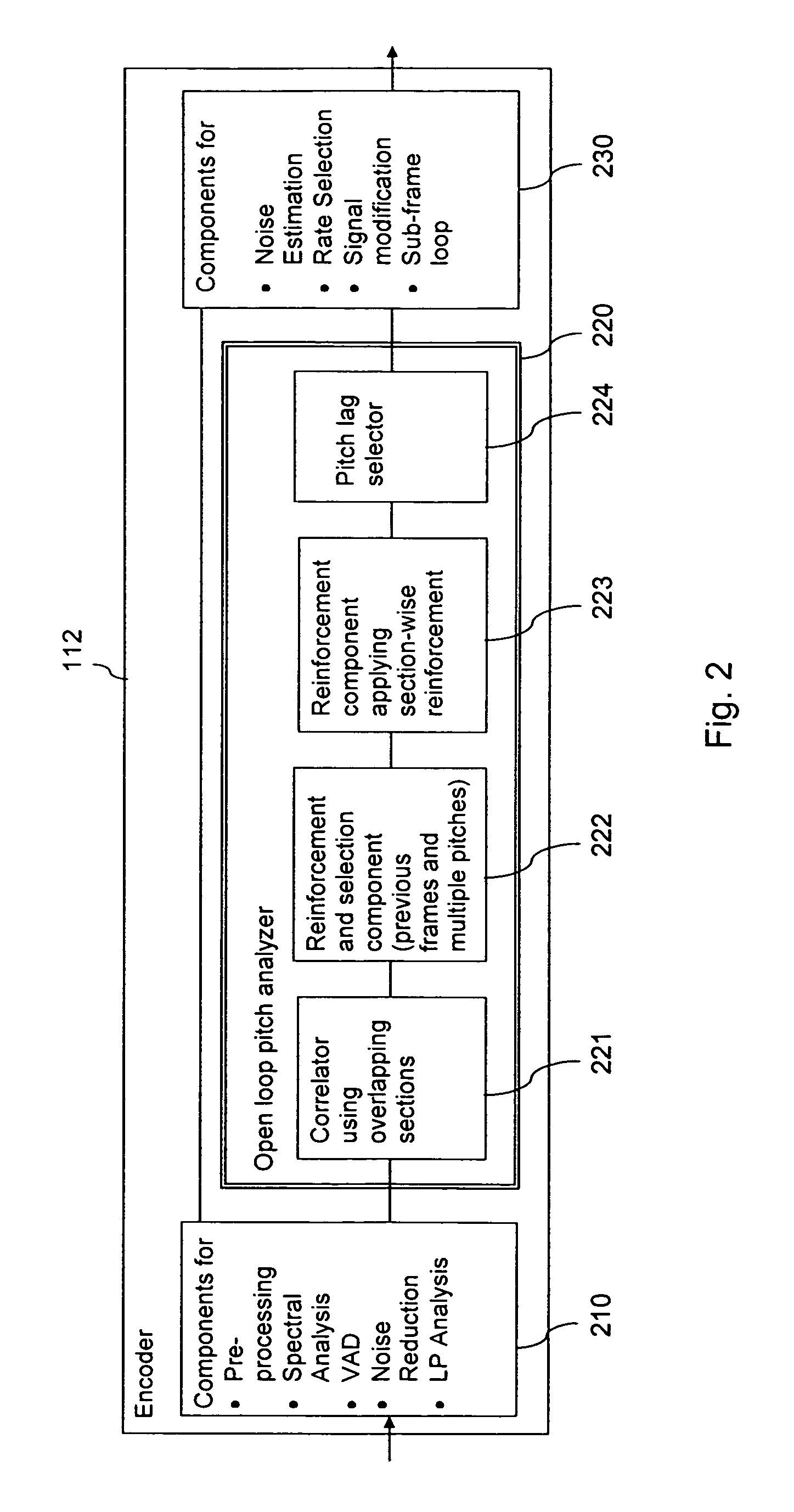

Pitch lag estimation

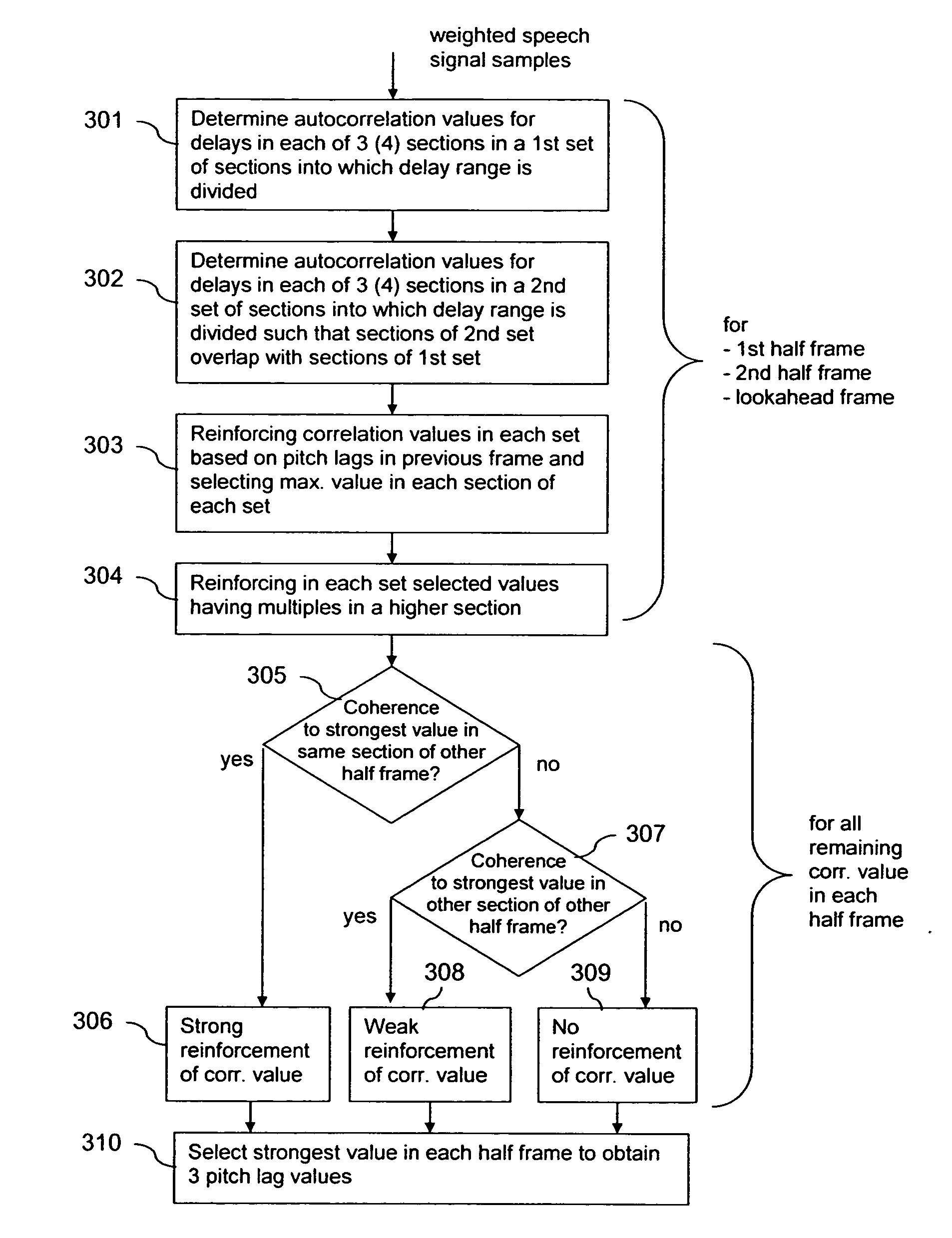

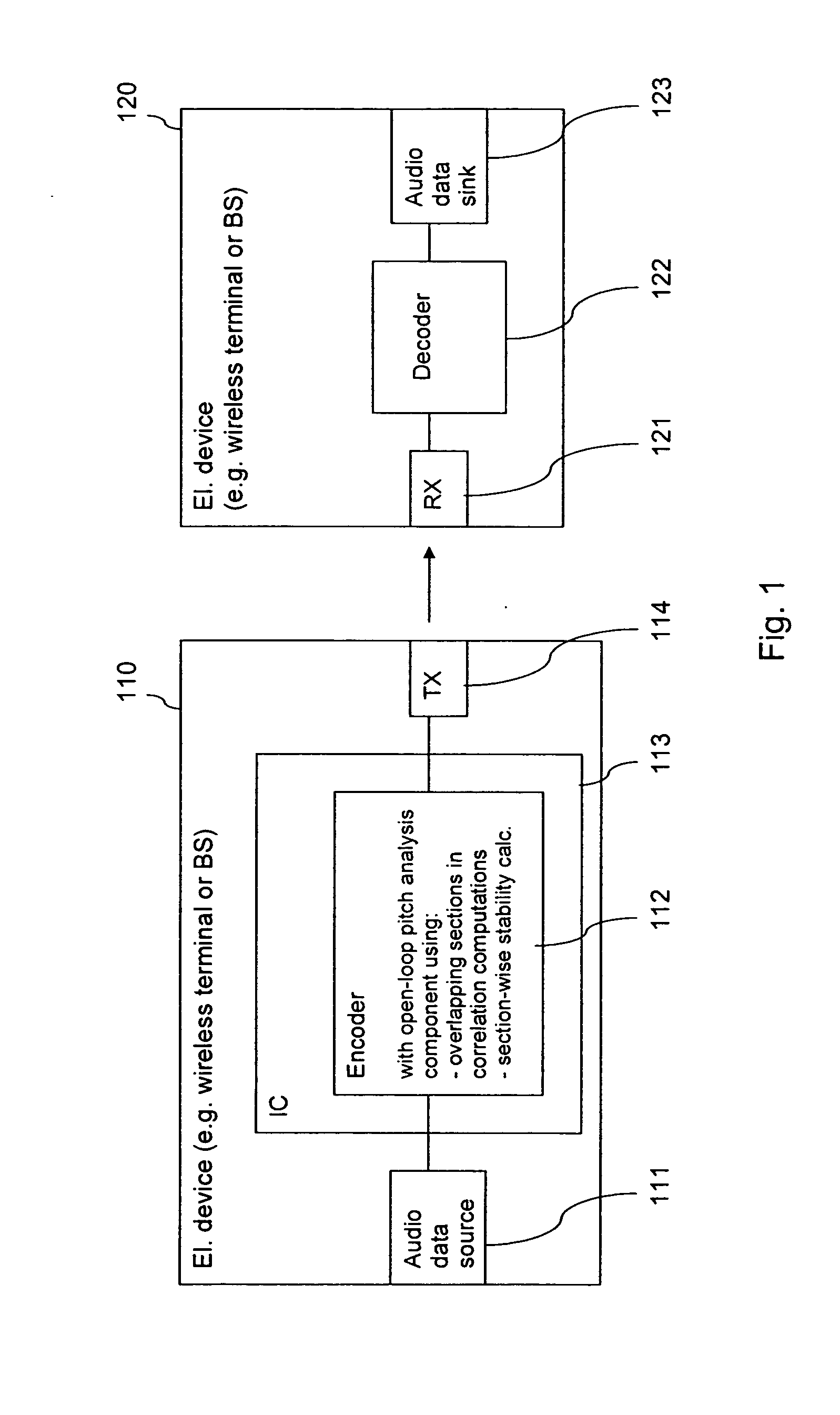

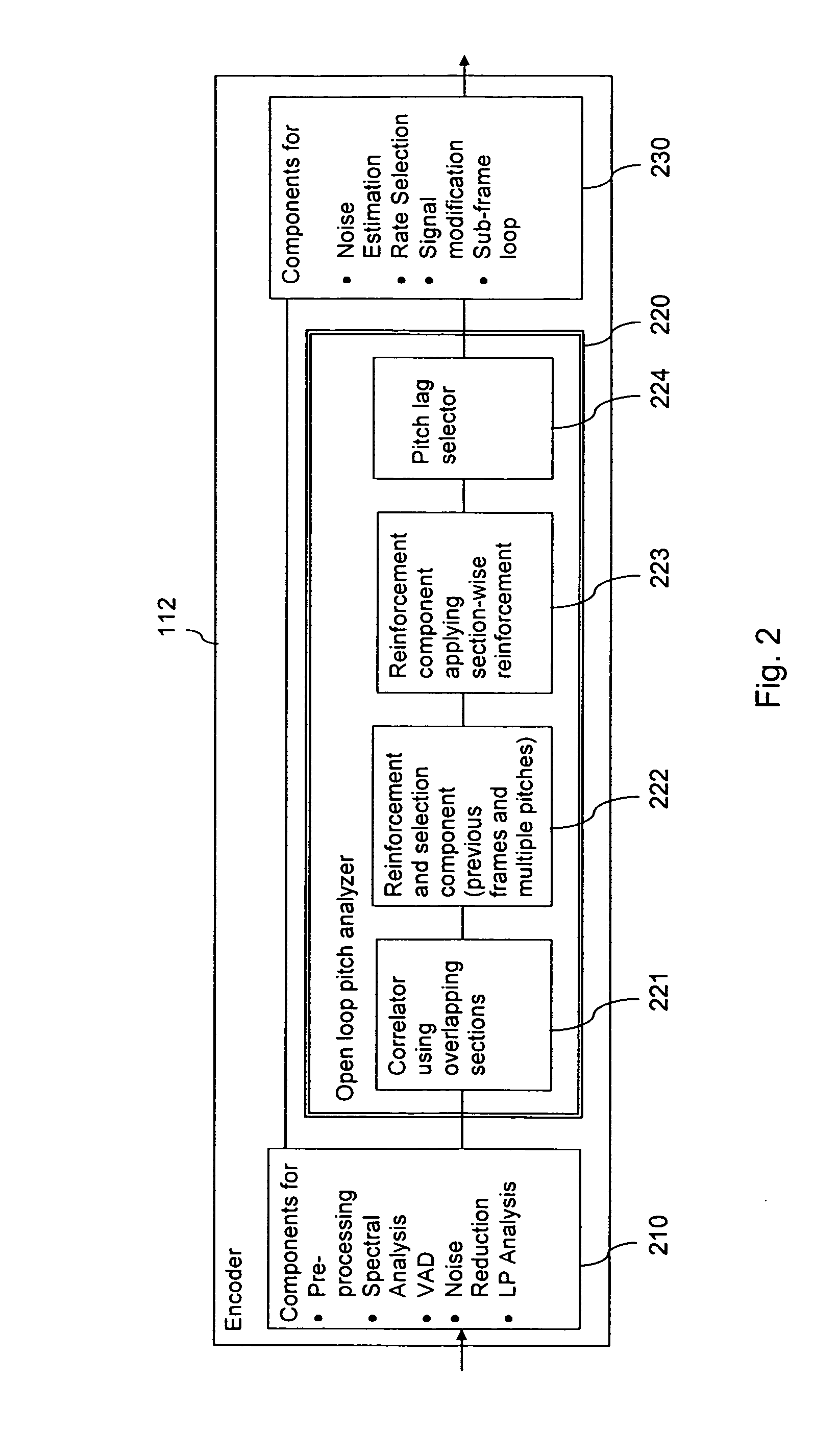

Autocorrelation values are determined as a basis for an estimation of a pitch lag in a segment of an audio signal. A first considered delay range for the autocorrelation computations is divided into a first set of sections, and first autocorrelation values are determined for delays in a plurality of sections of this first set of sections. A second considered delay range for the autocorrelation computations is divided into a second set of sections such that sections of the first set and sections of the second set are overlapping. Second autocorrelation values are determined for delays in a plurality of sections of this second set of sections.

Owner:NOKIA TECHNOLOGLES OY

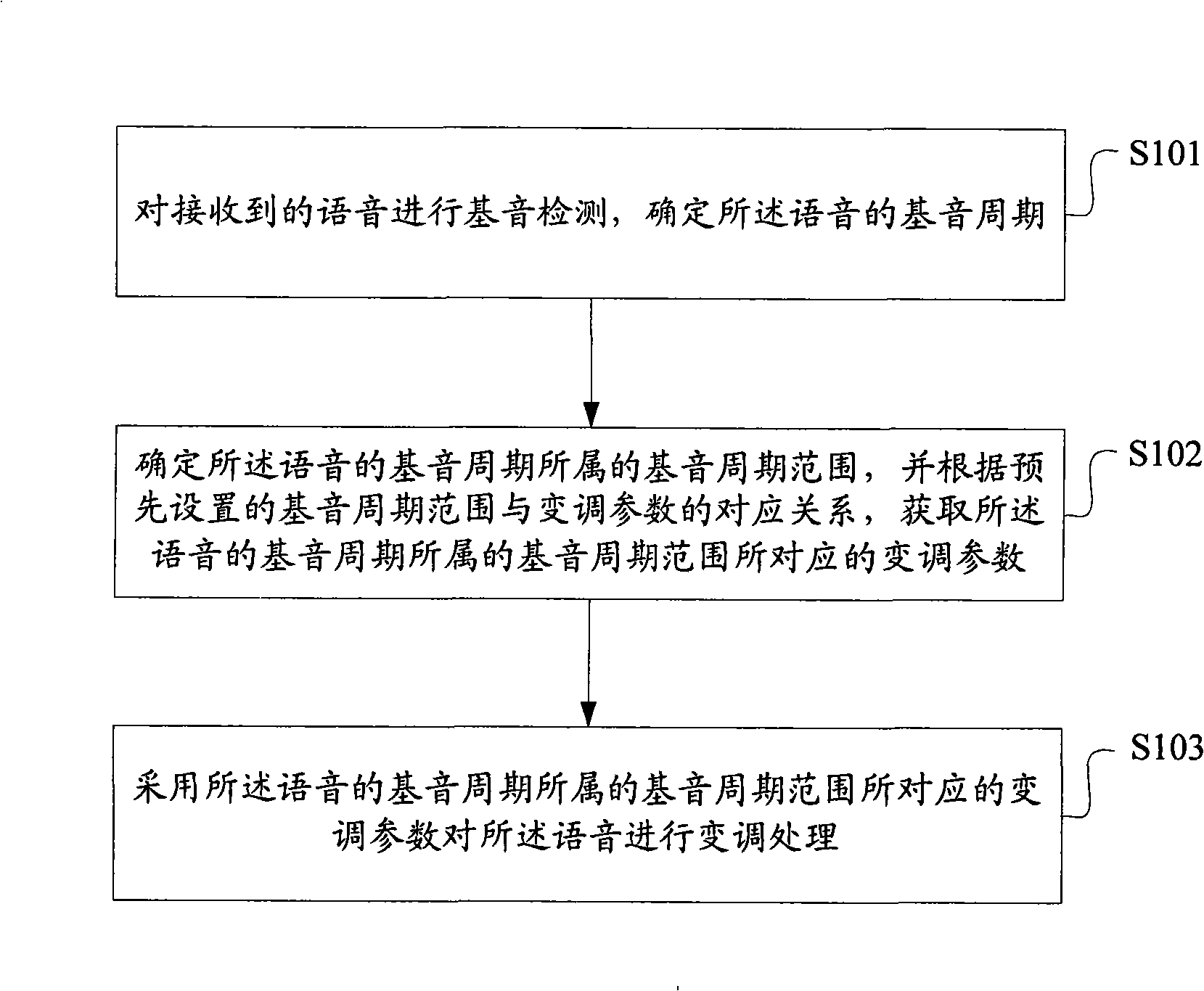

Method and apparatus for tonal modification of voice

InactiveCN101354889ARealize adaptive pitch shiftingEasy to operateSpeech analysisSelf adaptiveSpeech sound

The invention discloses a speech tone modification method and a device thereof, which are used to realize the self-adaptive tone modification of speech. The speech tone modification method provided by the invention comprises the following steps: received speech is subjected to pitch detection to determine the pitch period of the speech; the range of pitch period to which the pitch period of the speech belongs is determined; according to the preset corresponding relation between the range of the tone period and pitch modification parameters, the tone modification parameters corresponding to the range of the pitch period to which the pitch period of the speech belongs is obtained; and the tone modification parameters are adopted to carry out tone modification processing to the speech. The speech tone modification method and the device are used for realizing the self-adaptive tone modification of the speech and avoids the fact that the prior art needs the user to fixedly change tone through manually setting the tone rising amplitude or the tone falling amplitude, thereby being convenient to operate by the user and improving the accuracy of tone modification.

Owner:VIMICRO CORP

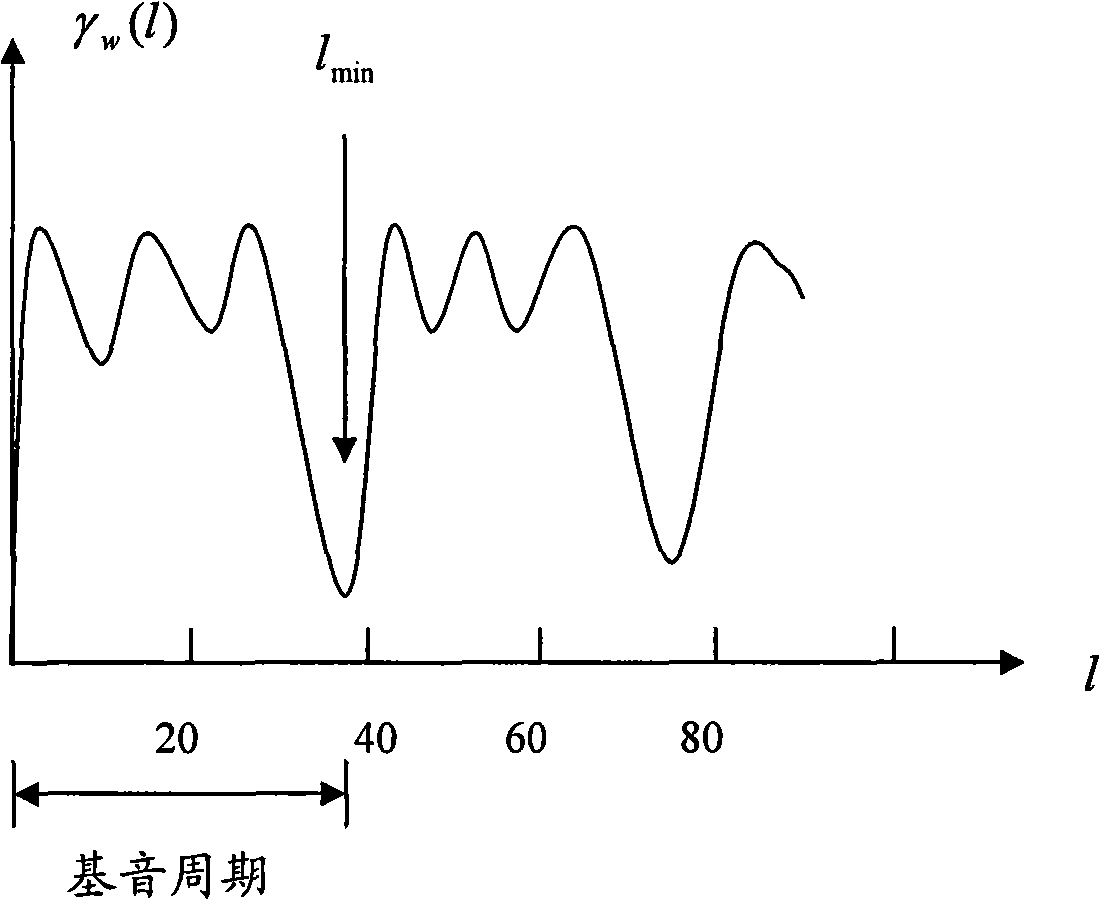

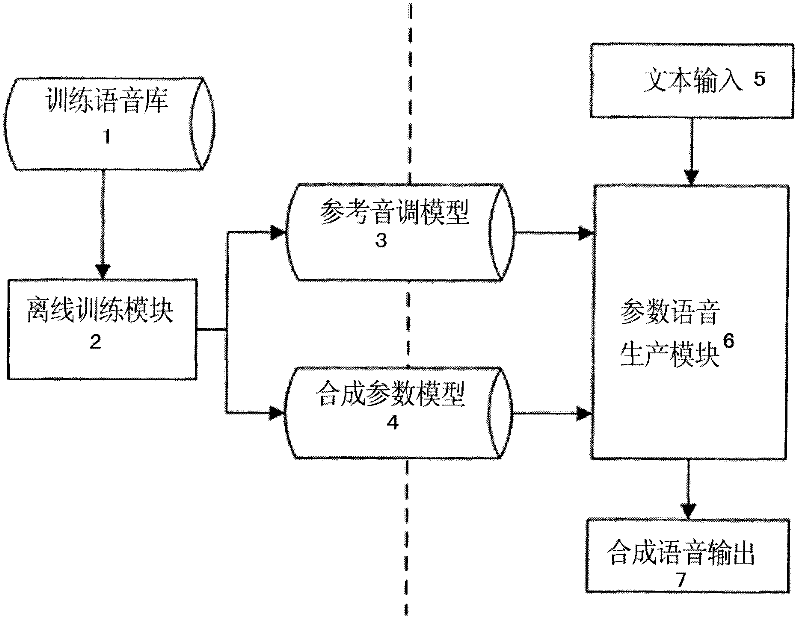

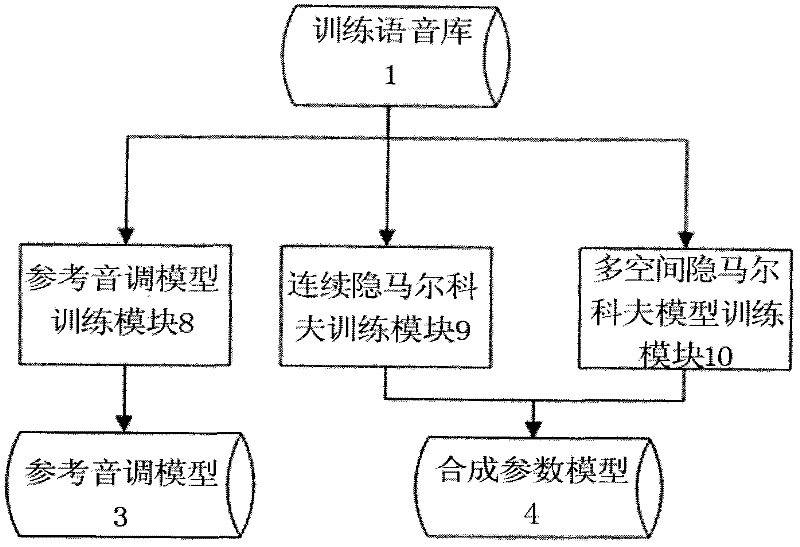

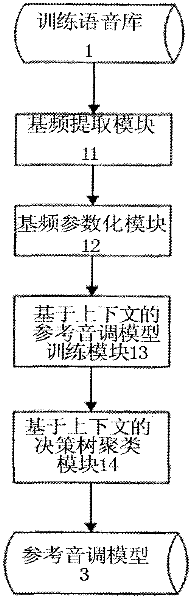

Correction method for Chinese speech synthesis tone

The invention discloses a correction method for Chinese speech synthesis tone. According to the invention, a text analysis module receives optional text information to be synthetized; integral synthesis tagging information is outputted according to the syllable and rhythm hierarchical structure; a parameter voice synthesis module receives the synthesis tagging information of the text analysis module; synthetic voice signal is outputted through a parameter generation method of reftone; an off-line training module is responsible for the training of hidden Markov models; a reftone model is used for generating individual syllabic reference base frequency envelope; and a synthesis parameter model is used for gaining synthetic parameter sequence. The invention can solve the problem that the Chinese speech synthesis middle tone based on the hidden Markov model is unstable, thereby greatly improving the natural degree and rhythm of the synthetic speech.

Owner:北京宇音天下科技有限公司 +1

Pitch lag estimation

Autocorrelation values are determined as a basis for an estimation of a pitch lag in a segment of an audio signal. A first considered delay range for the autocorrelation computations is divided into a first set of sections, and first autocorrelation values are determined for delays in a plurality of sections of this first set of sections. A second considered delay range for the autocorrelation computations is divided into a second set of sections such that sections of the first set and sections of the second set are overlapping. Second autocorrelation values are determined for delays in a plurality of sections of this second set of sections.

Owner:NOKIA TECHNOLOGLES OY

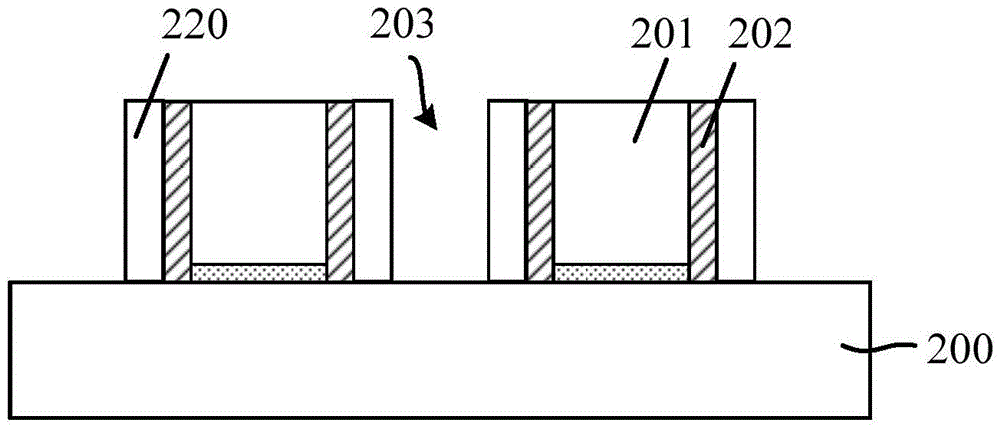

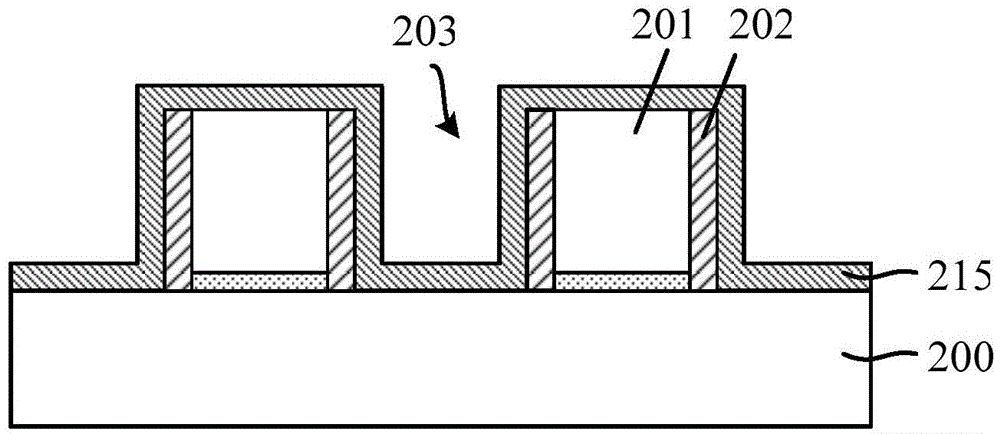

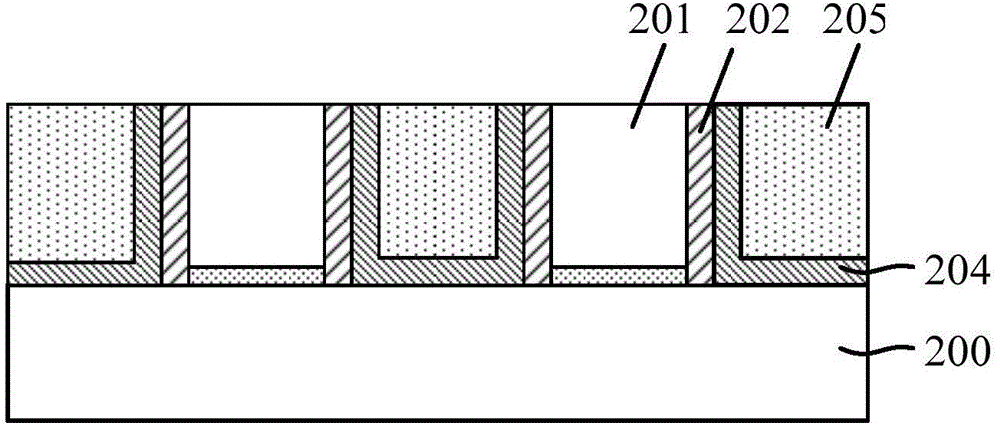

Formation method of semiconductor structure

ActiveCN105097649AHighly integratedPrevent bridgingSemiconductor/solid-state device manufacturingSemiconductor structureDielectric layer

A formation method of a semiconductor structure comprises the steps of providing a semiconductor substrate, wherein a plurality of grid structures are formed on the semiconductor substrate, first openings are formed between the adjacent grid structures, source / drain regions are formed at the two sides of the grid structures, and etching stop layers are arranged on the surfaces of the grid structures; forming first dielectric layers in the first openings, wherein the surfaces of the first dielectric layers are lower than the top surfaces of the grid structures; forming size adjusting material layers covering the surfaces of the first dielectric layers and the grid structures; using a markless etching technology to etch the size adjusting material layers, and forming size adjusting side walls on the surfaces of the side walls of the etching stop layers; forming second dielectric layers covering the grid structures and the size adjusting side walls; etching the second dielectric layers, and forming second openings in the second dielectric layers, wherein the second openings expose out of the size adjusting side walls; etching the first dielectric layers in the first openings and the etching stop layers to form third openings. By forming the size adjusting side walls, a photoetching technology window is enlarged, and a bridging phenomenon is prevented.

Owner:SEMICON MFG INT (SHANGHAI) CORP

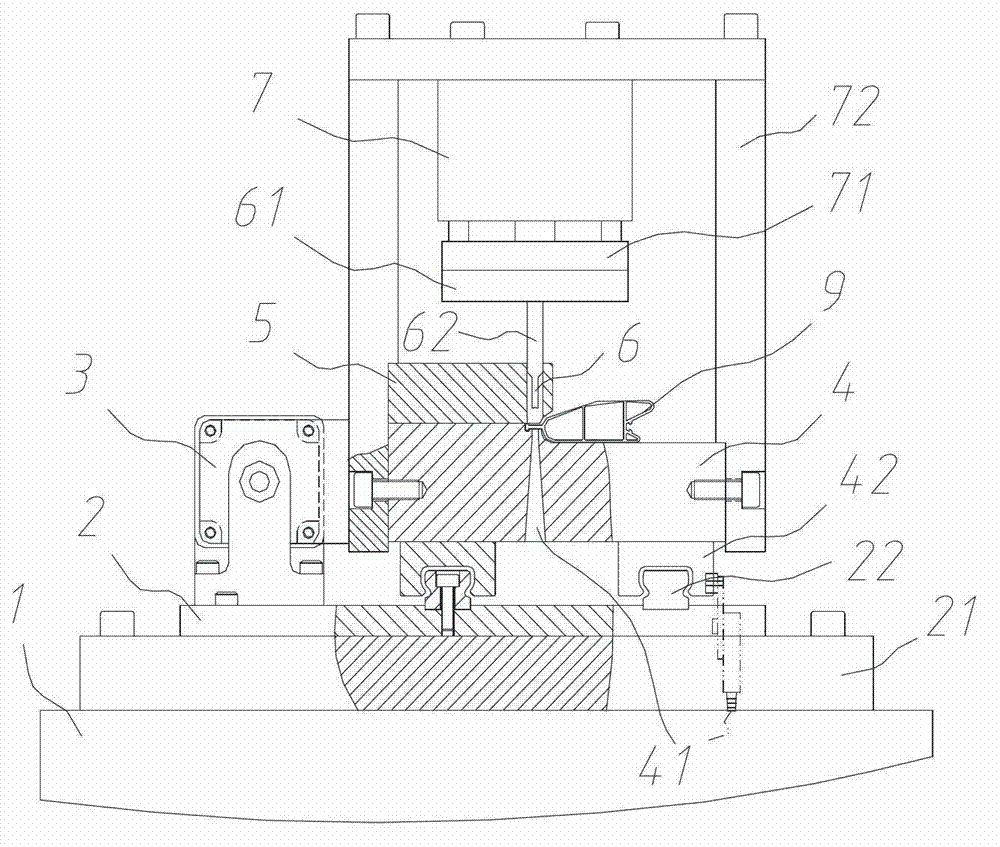

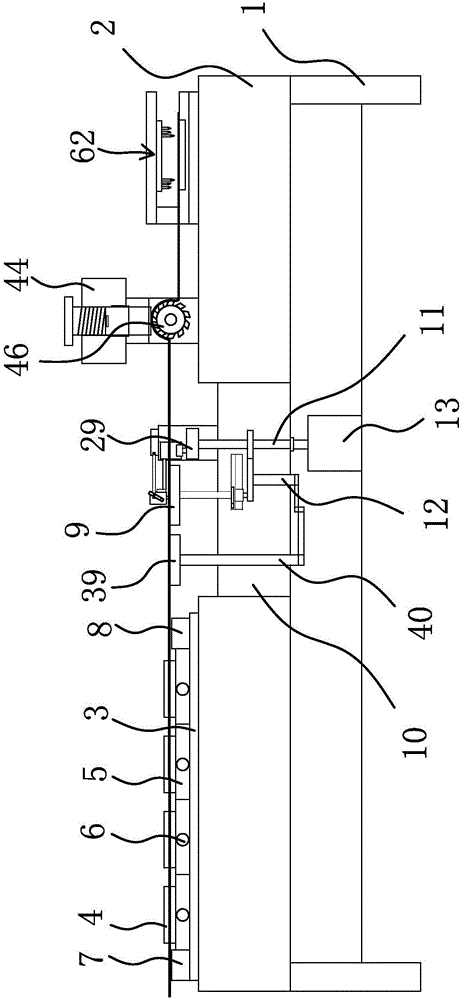

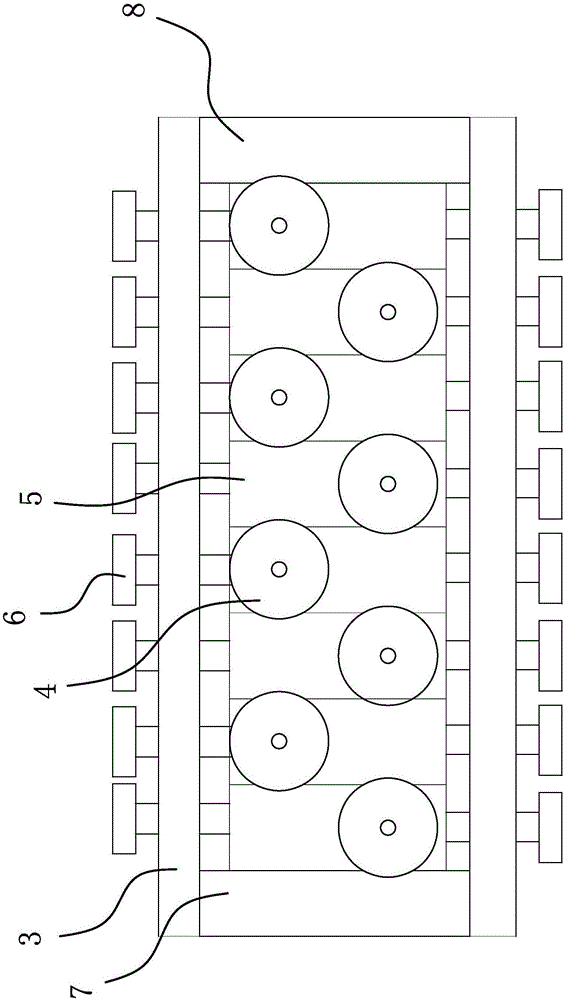

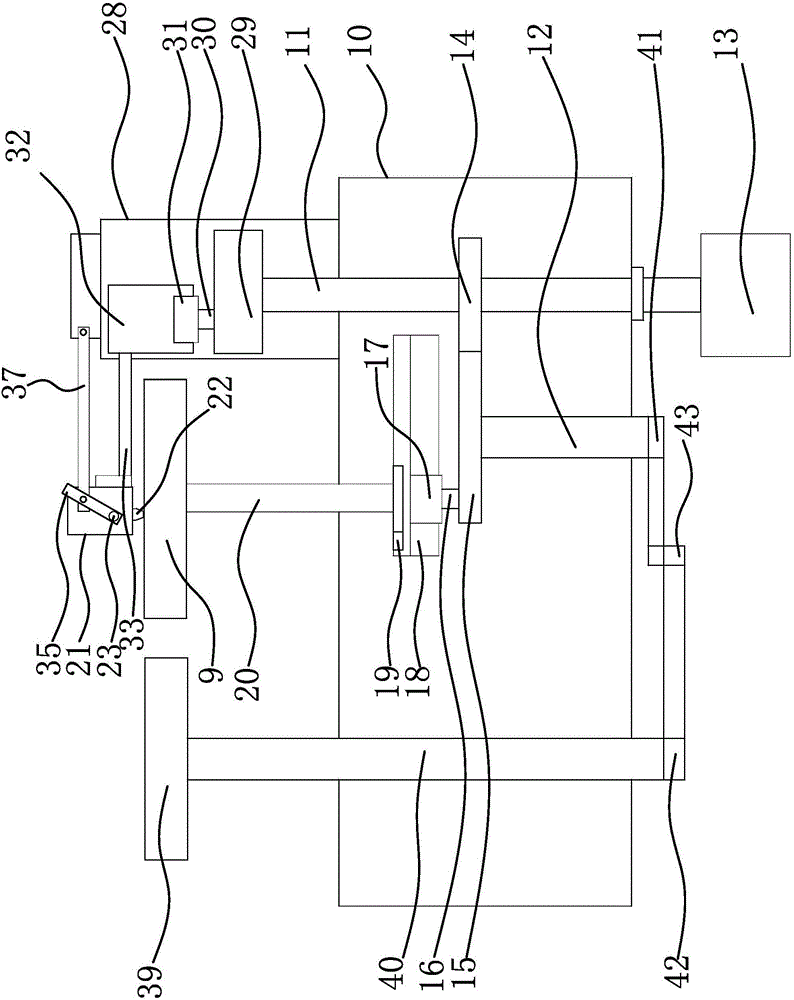

Plastic profile line-following punching machine

InactiveCN103112043AEasy to moveMove preciselyMetal working apparatusPunchingProgrammable logic controller

The invention relates to a plastic profile line-following punching machine. The plastic line-following punching machine comprises a punching die, a base, a line guide rail which is arranged at the upper end of the base and a sliding block which is fixed at the bottom of the die and is matched with the line guide rail, a die driving device, a travel switch, a speed sensor and a programmable logic controller (PLC) system, wherein the die driving device comprises a servo motor, a screw and a coupler, the travel switch is fixed on the base and controls a moving starting point position and a final position of the die, the speed sensor measures a moving distance of a profile online, and the PLC system controls the servo motor to rotate and reverse, controls the rotating speed of the servo motor and drives an air cylinder to act according to the profile moving speed. The plastic profile line-following punching machine can automatically adjust the punching frequency, moving speed and the like of the punching die, and the plastic profile line-following punching machine has the advantages that the precision of the interval between punching holes or grooves is high, punching efficiency is high, punching stability is good, the waste produced is little and the like.

Owner:TONGLING GREAT EXTRUSION TECH

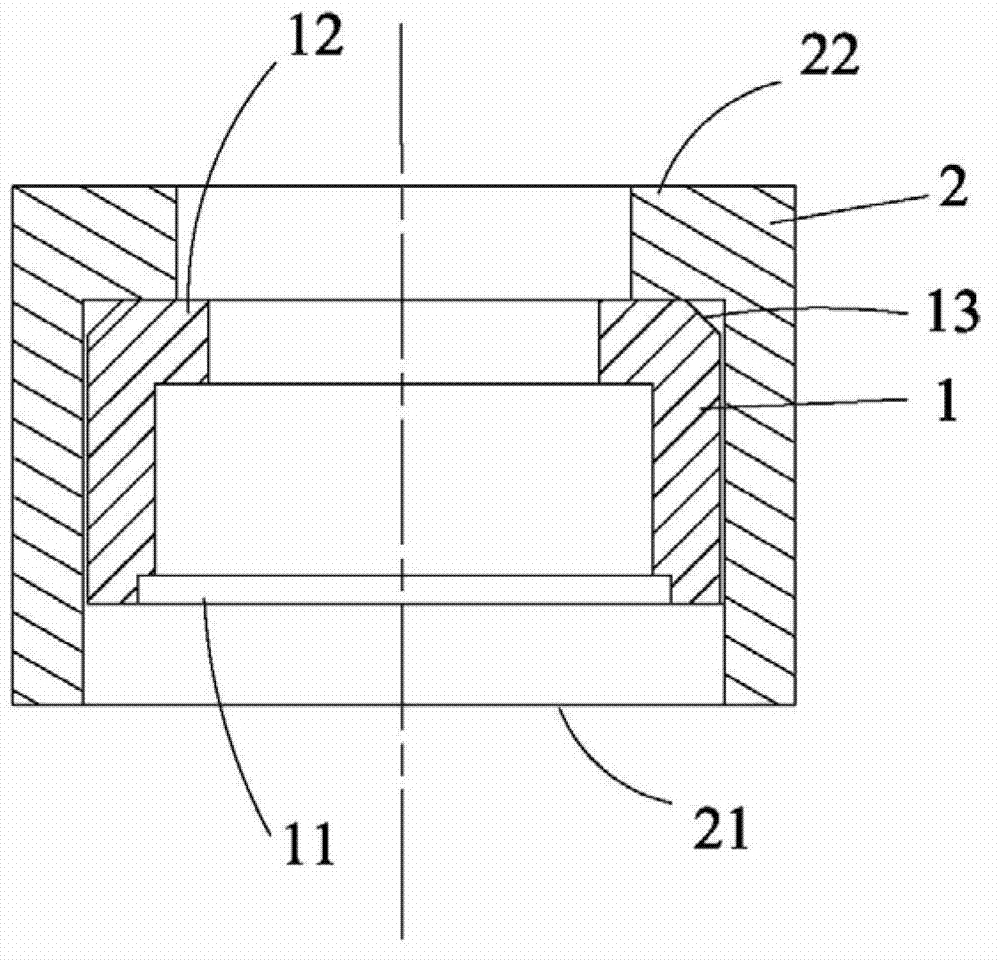

Laser light source collimating device, collimating device array, lighting system and projection equipment

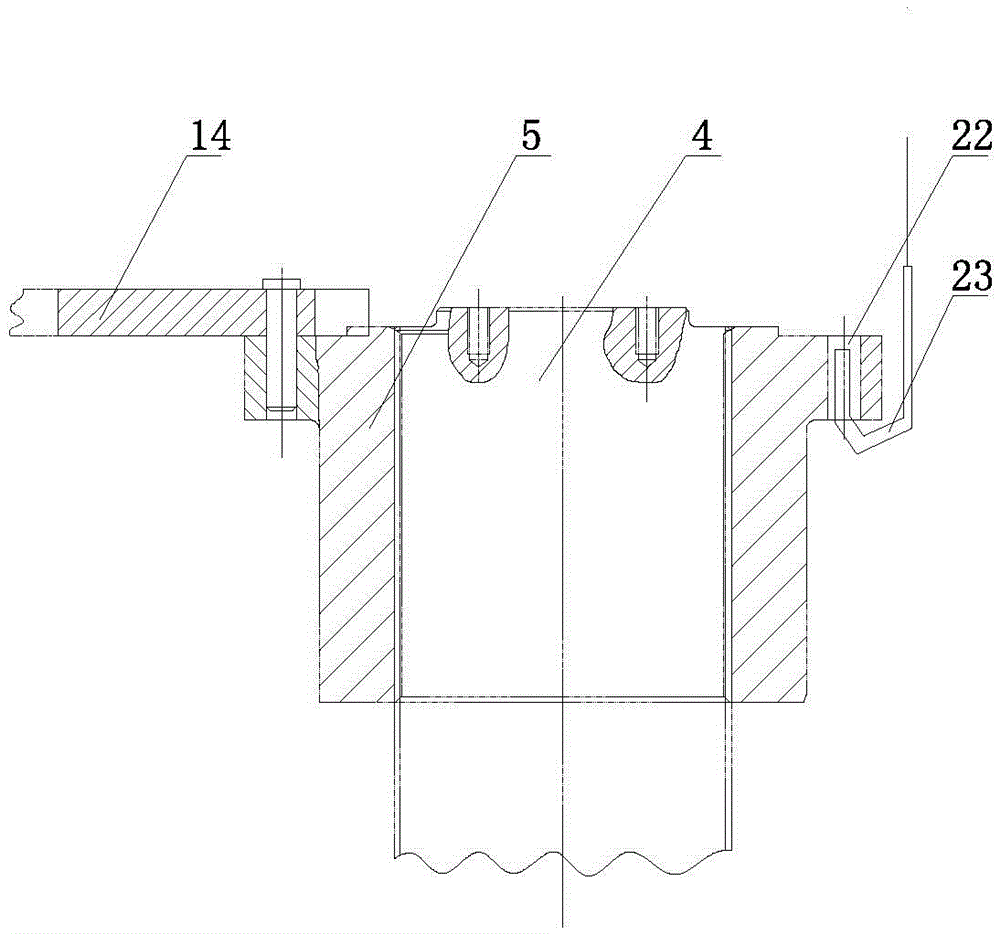

InactiveCN102854632AGood effectGuaranteed concentricityLaser detailsProjectorsEngineeringLaser light

The invention is suitable for the technical filed of optics and provides a laser light source collimating device, a collimating device array, a lighting system and projection equipment. The collimating device comprises an inner sleeve and an outer sleeve, wherein both ends of the inner sleeve are located in the outer sleeve; one end of the outer sleeve is provided with a first opening and the other end of the outer sleeve is provided with a first flange extending inwards; the center axes of the first flange and the first opening are overlapped; one end (close to the first opening) of the inner sleeve is provided with a second opening and the other end of the inner sleeve is provided with a second flange extending inwards; and the upper surface of the second flange presses against the lower surface of the first flange and the second flange is bulged inwards relative to the first flange so as to form a step structure. According to the laser light source collimating device, the collimating device array, the lighting system and the projection equipment, the spacing design and the concentricity design of a laser and a collimating lens are respectively realized through two independent sleeves; the inner and outer sleeves can be individually manufactured thus being convenient to process; and therefore, the collimating device is convenient to process, high in processing accuracy, suitable for batch production and relatively good in laser collimating effect at the same time.

Owner:WUHU AMT MICRO DISPLAY TECH

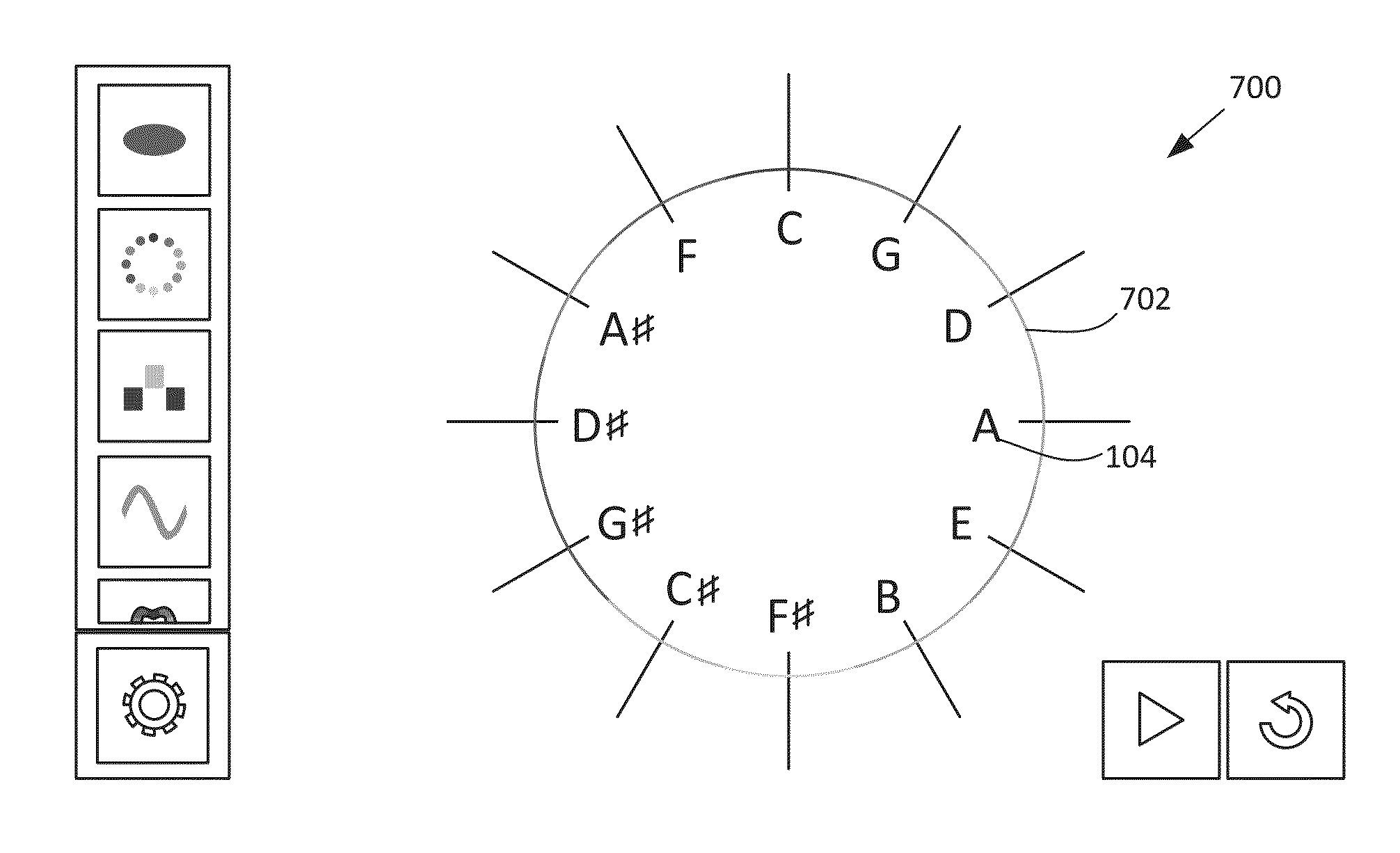

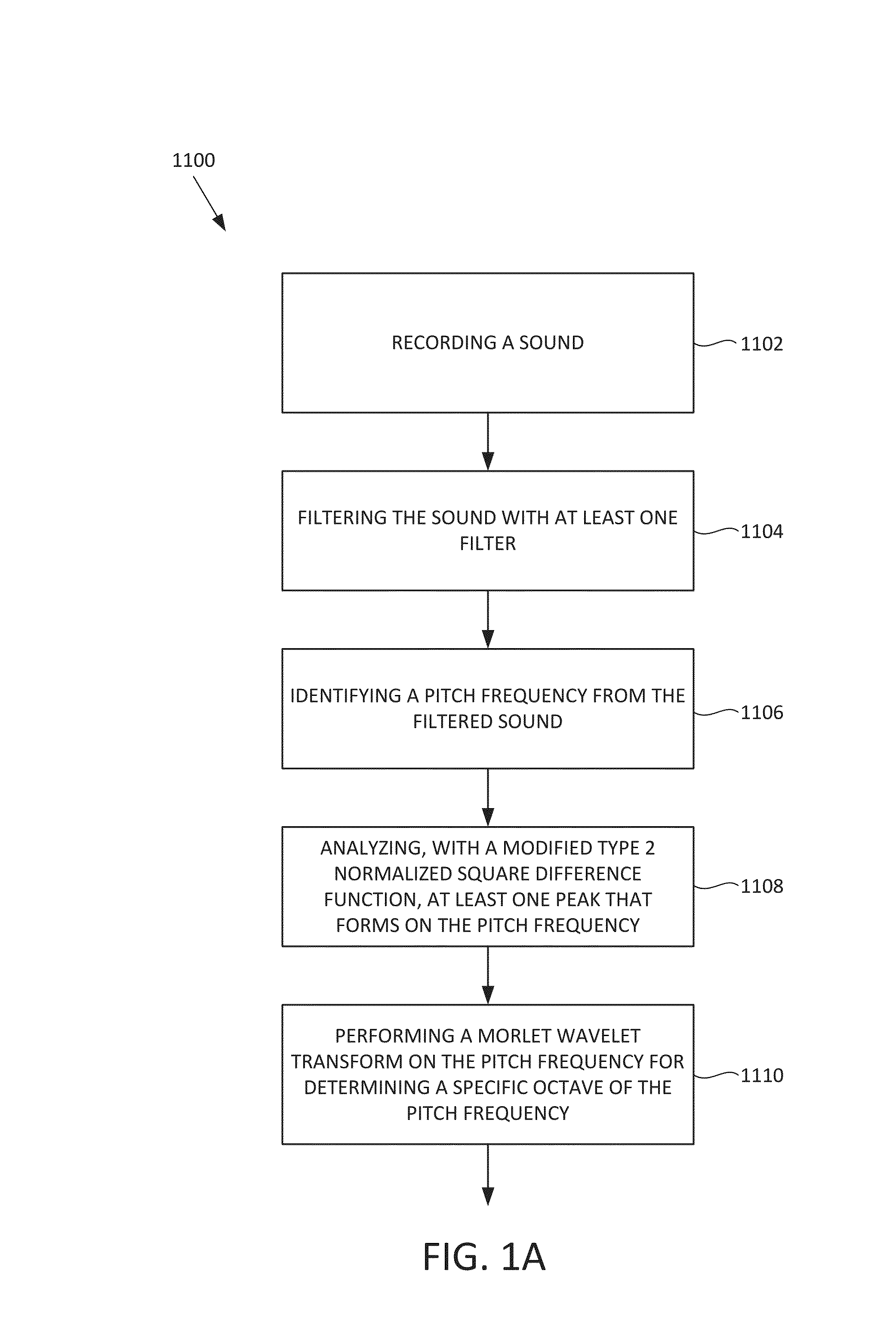

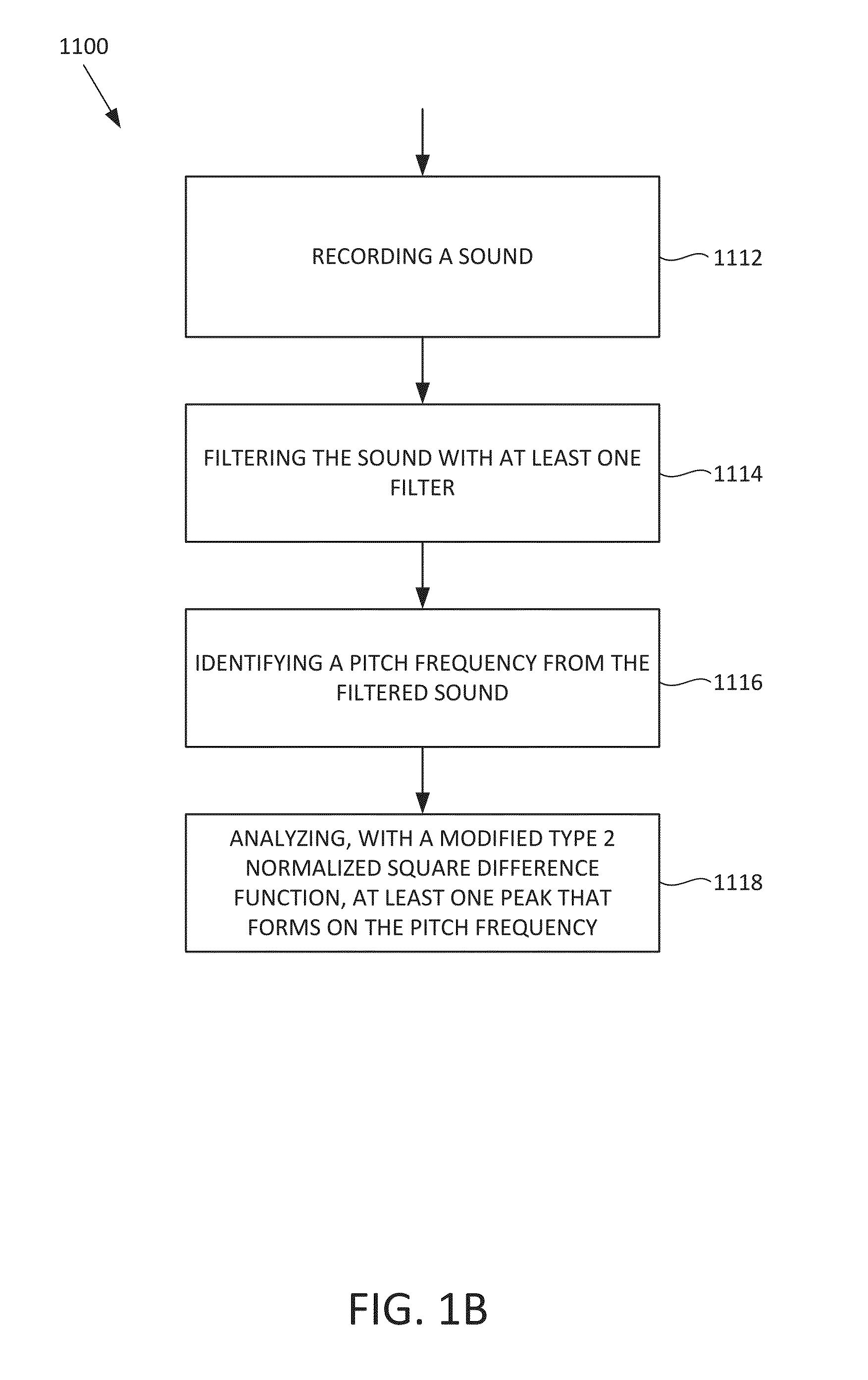

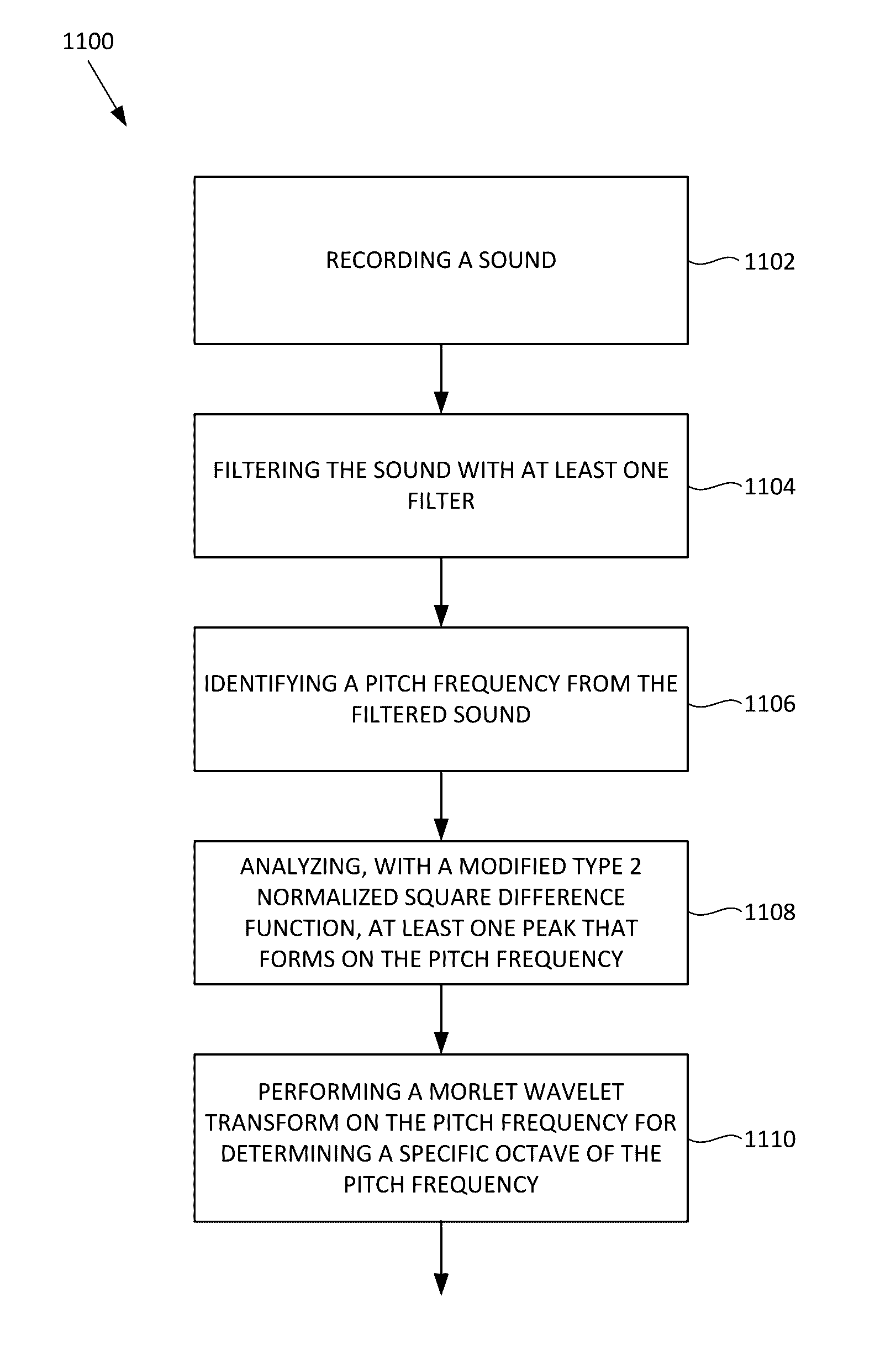

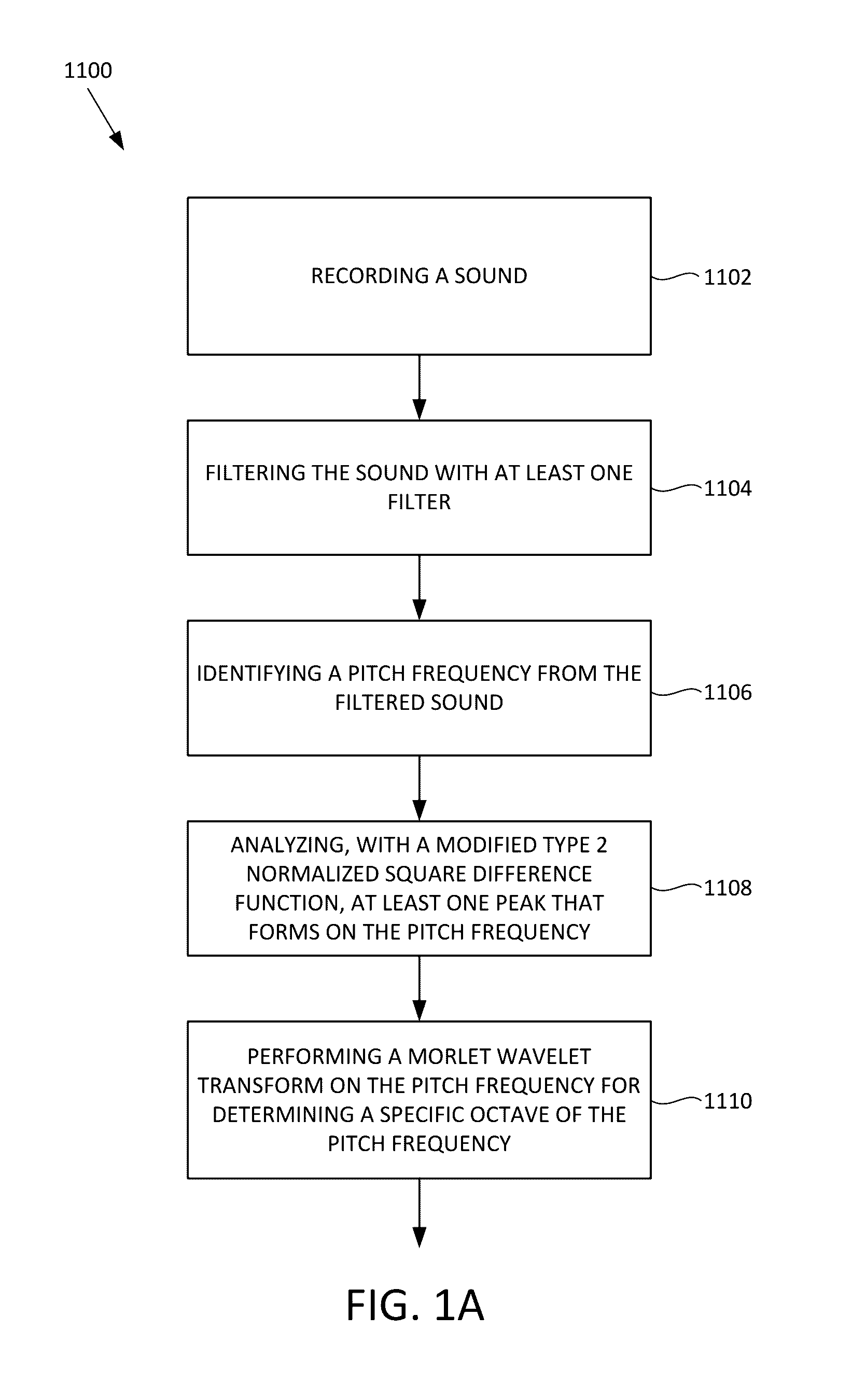

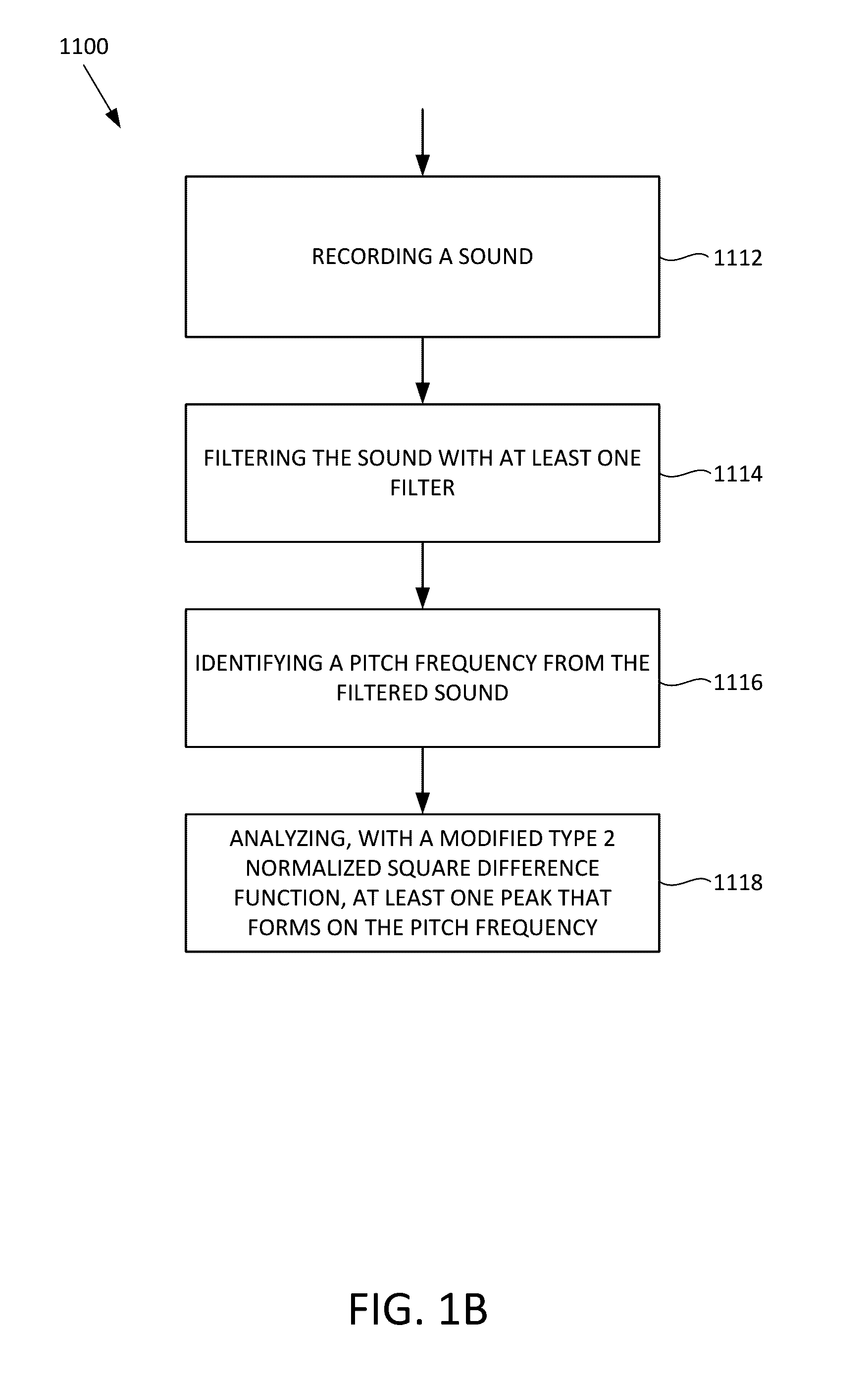

Systems and methods for quantifying a sound into dynamic pitch-based graphs

InactiveUS20160042657A1High pitch accuracyMaintain stabilityElectrophonic musical instrumentsMusicVariance functionAnalysis of algorithms

A system and method that quantifies a sound into dynamic pitch-based graphs that correlate to the pitch frequencies of the sound. The system records a sound, such as musical notes. A pitch detection algorithm identifies and quantifies the pitch frequencies of the notes. The algorithm analyzes the pitch frequencies, and graphically displays the pitch frequency and notes in real time as fluctuating circles, rectangular bars, and lines that represent variances in pitch. The algorithm comprises a modified Type 2 Normalized Square Difference Function that transforms the musical notes into the pitch frequencies. The Type 2 Normalized Square Difference Function analyzes the peaks of the pitch frequency to arrive at a precise pitch frequency, such as 440 Hertz. A Lagrangian interpolation enables comparative analysis and teaching of the pitches and notes. The algorithm also performs transformations and heuristic comparisons to generate the real time graphical representation of the pitch frequency.

Owner:QUANTZ COMPANY

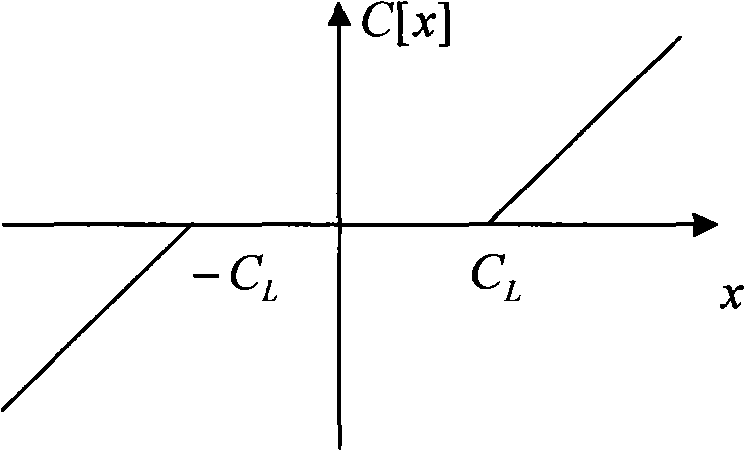

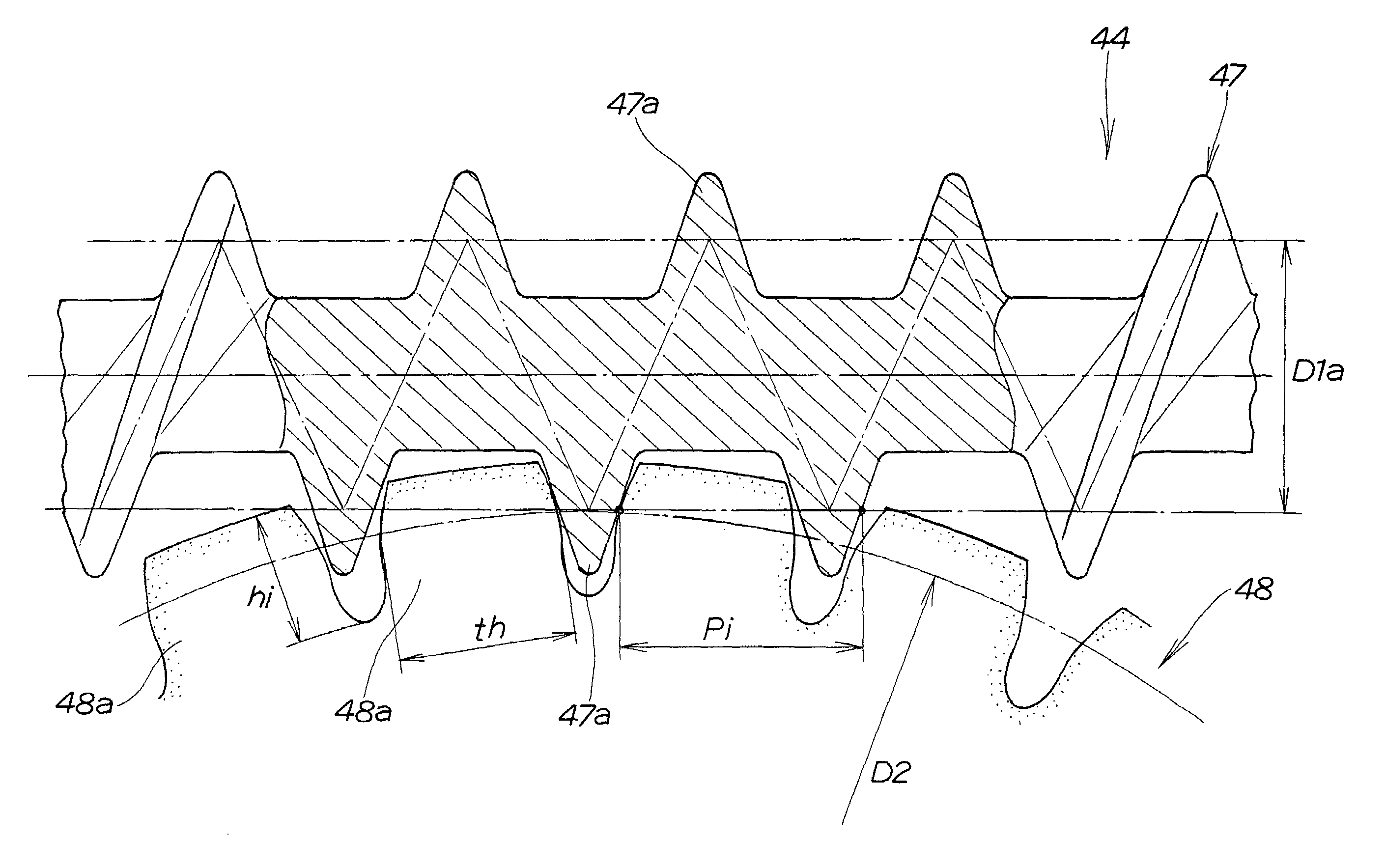

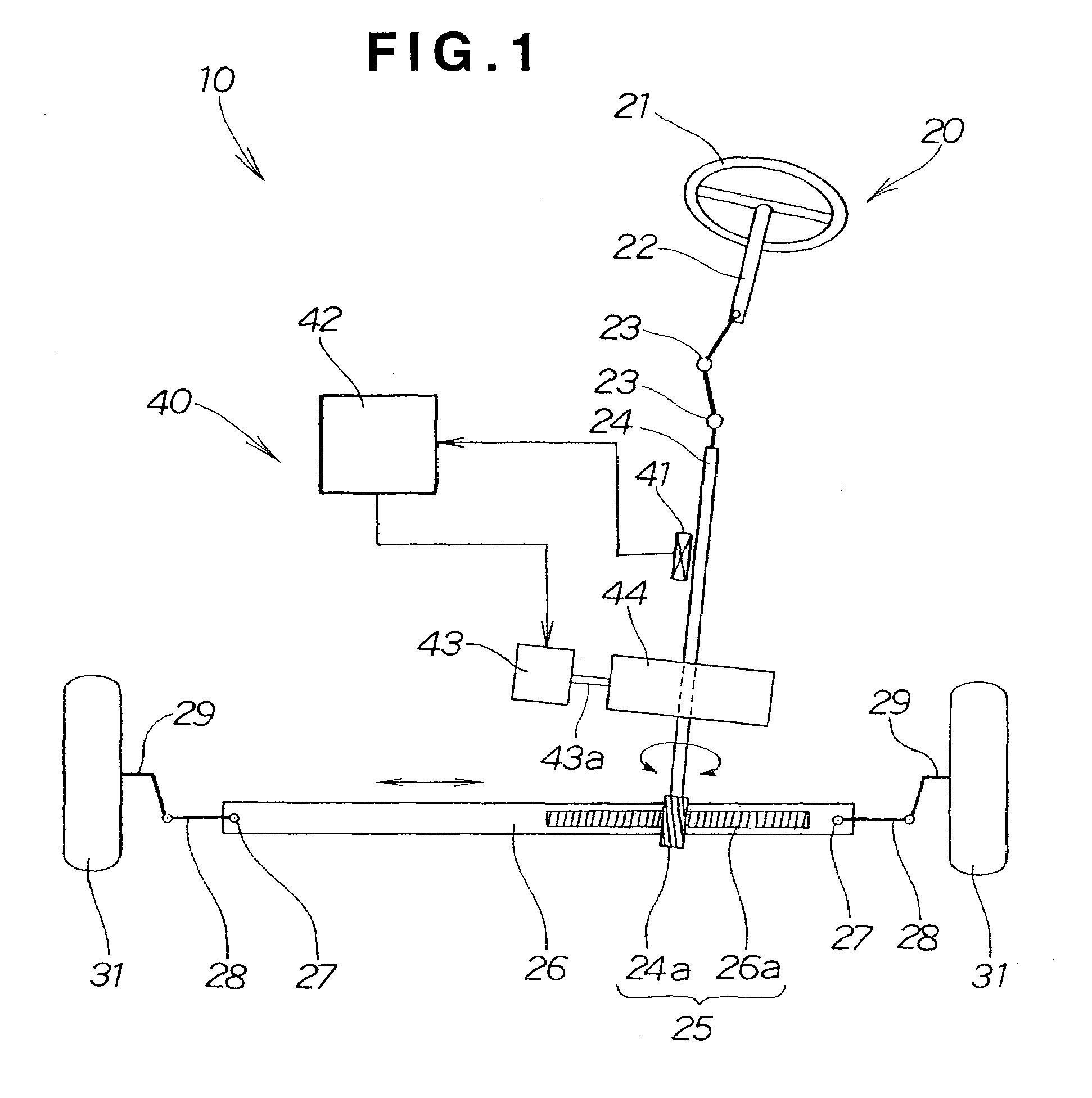

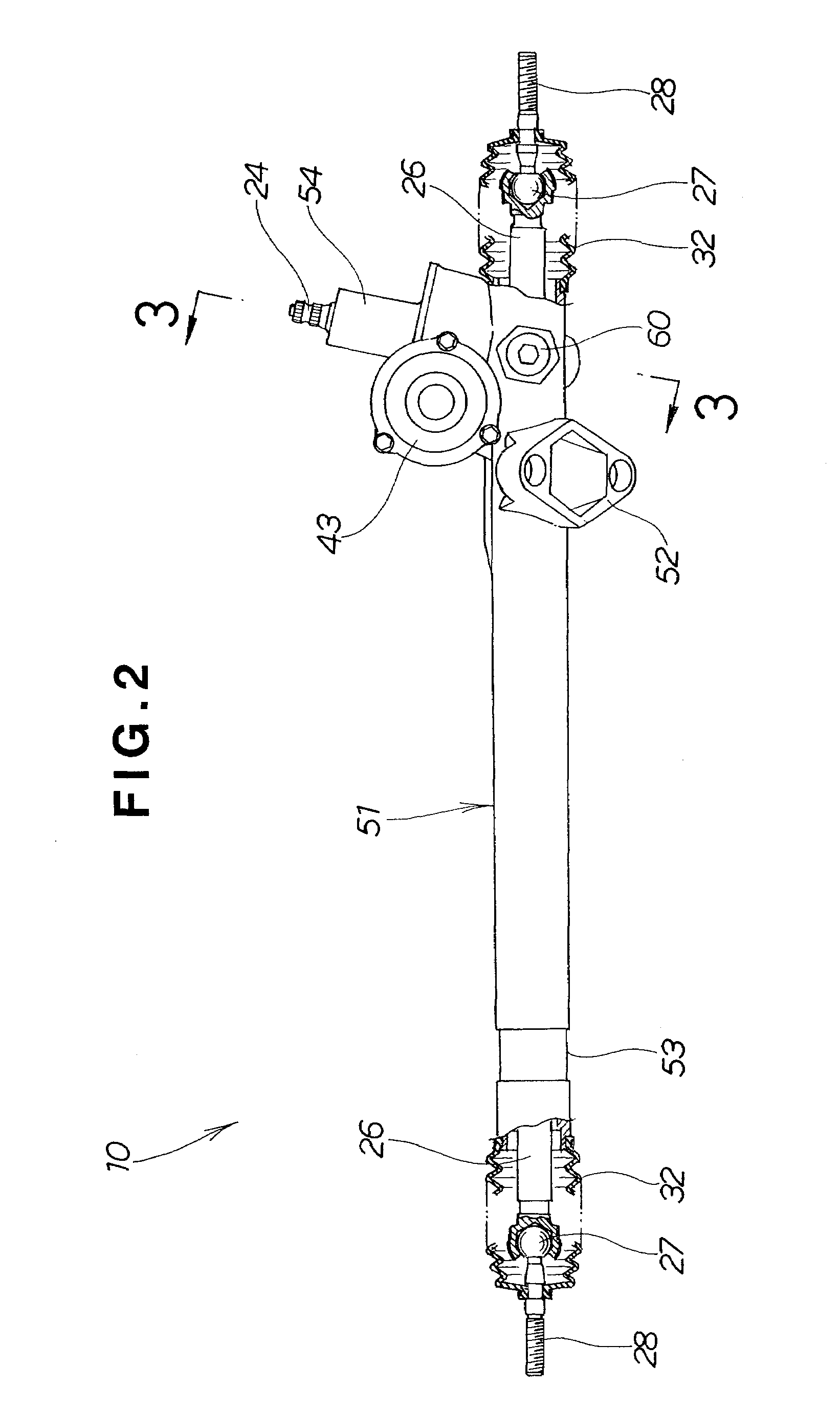

Electric power steering apparatus

InactiveUS6976556B2Reduce the amount of variationImprove smoothnessPortable liftingFluid steeringElectric power steeringTorque transmission

Electric power steering apparatus includes an electric motor for producing steering assist torque corresponding to steering torque applied to a steering system, and a worm gear mechanism for transmitting the steering assist torque to the steering system. The worm of the worm gear mechanism has a pressure angle greater than a pressure angle of the worm wheel, so as to reduce an actual meshing pitch circle diameter of the worm in the worm gear mechanism.

Owner:HONDA MOTOR CO LTD

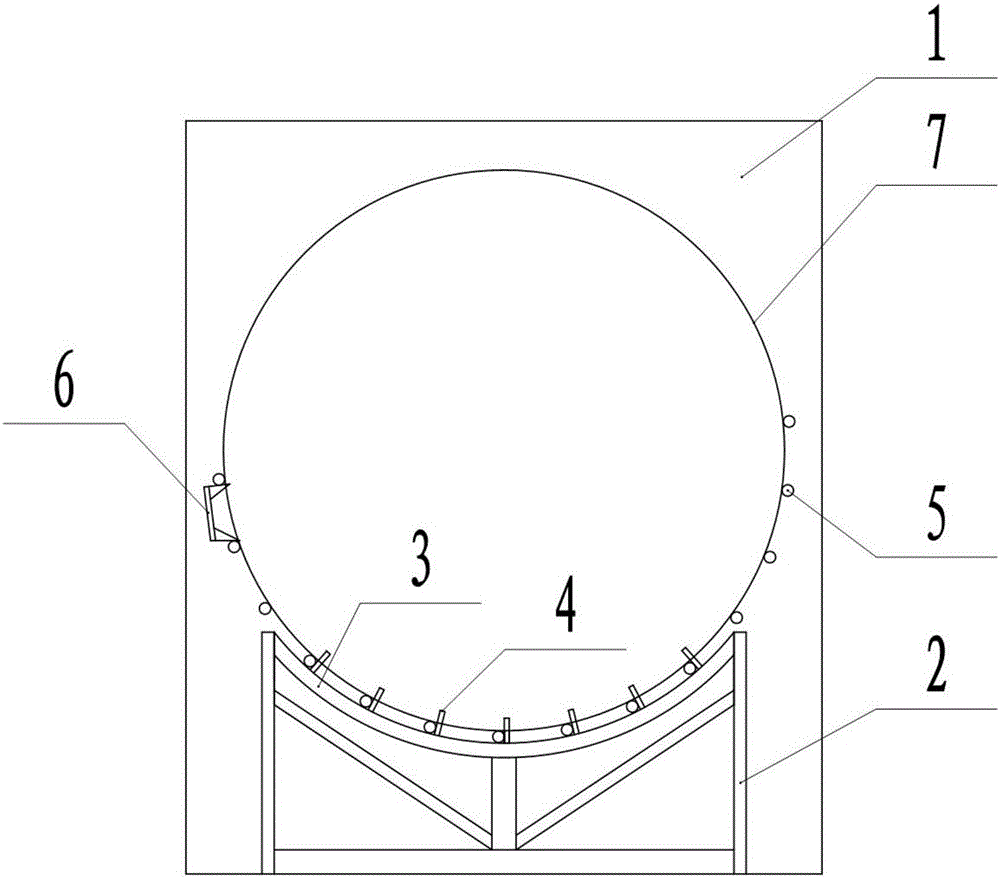

Cylindrical steel reinforcement cage quick precise connection machining formwork and manufacturing method for steel reinforcement cages

The invention discloses a manufacturing method for quickly and accurately connecting a cylindrical reinforcement cage to a processing formwork and a reinforcement cage. The processing formwork includes a positioning baffle, an operating platform, a steel ring of the reinforcement cage and positioning ribs, and the positioning baffle is arranged at one end of the operating platform. , the positioning baffle is perpendicular to the ground, and the steel cage steel ring is set on the operating platform. The steel cage steel ring is concave arc-shaped, and the diameter matches the diameter of the processed steel cage. 2, and the central connection line is perpendicular to the positioning baffle, the positioning rib is arranged on the inner side of the steel ring of the steel cage, the spacing of the positioning ribs is set to be the same as the spacing between the main bars of the processed steel cage, the positioning baffle is a steel plate, and the operation The platform is a combination of channel steel, angle steel and steel plate. The invention can accurately fix the main reinforcement of the reinforcement cage. The spacing precision of the main reinforcement is high. The processed cylindrical reinforcement cage has a regular shape. high.

Owner:CCCC FIRST HARBOR ENG +1

Multilayered polyamide film with excellent processability

InactiveUS6645640B1Improve pinhole resistanceHigh pitch accuracyLamination ancillary operationsLayered product treatmentPolyamide

The present invention provides a multilayered polyamide film having at least two polyamide resin layers, which develops less than 10 pinholes when evaluated for pinhole resistance by flexing it 1,000-times at 25° C. and which has an elongation of 6 mm or less at 120° C. in vertical pitch evaluation. This film has excellent resistance to pinholes and is well suited for lamination.

Owner:GUNZE LTD

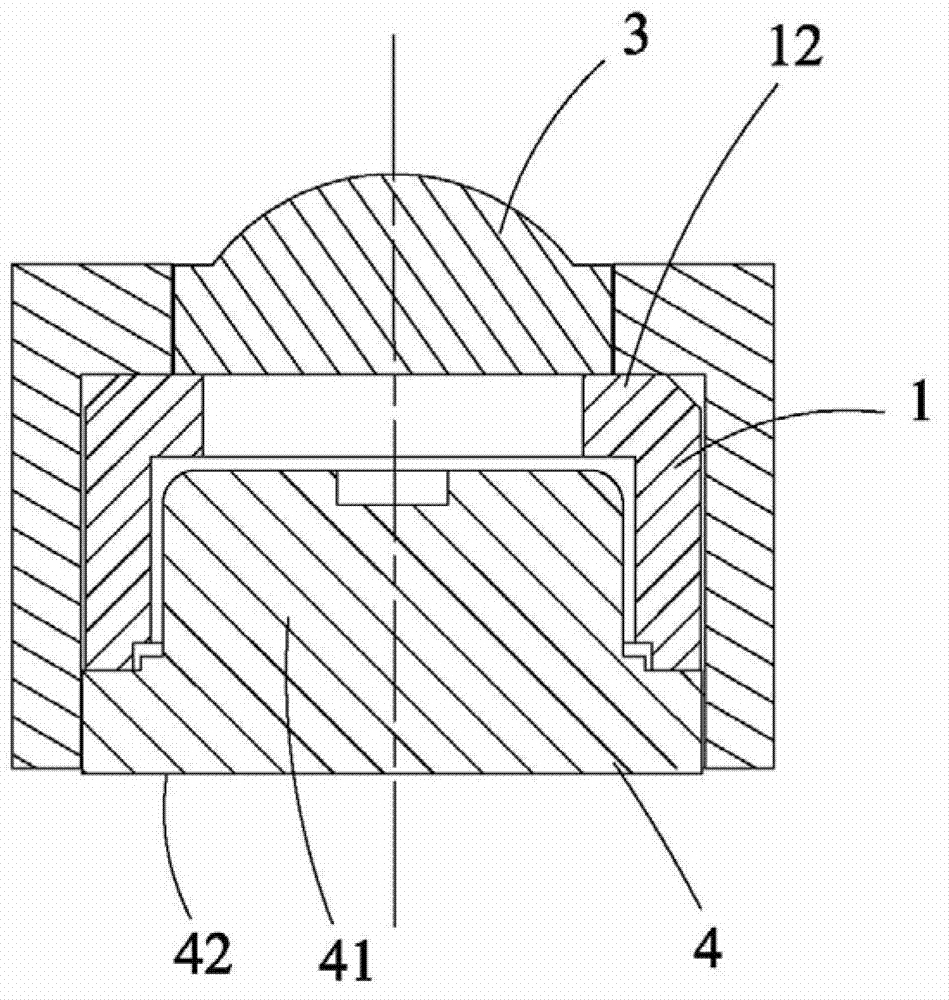

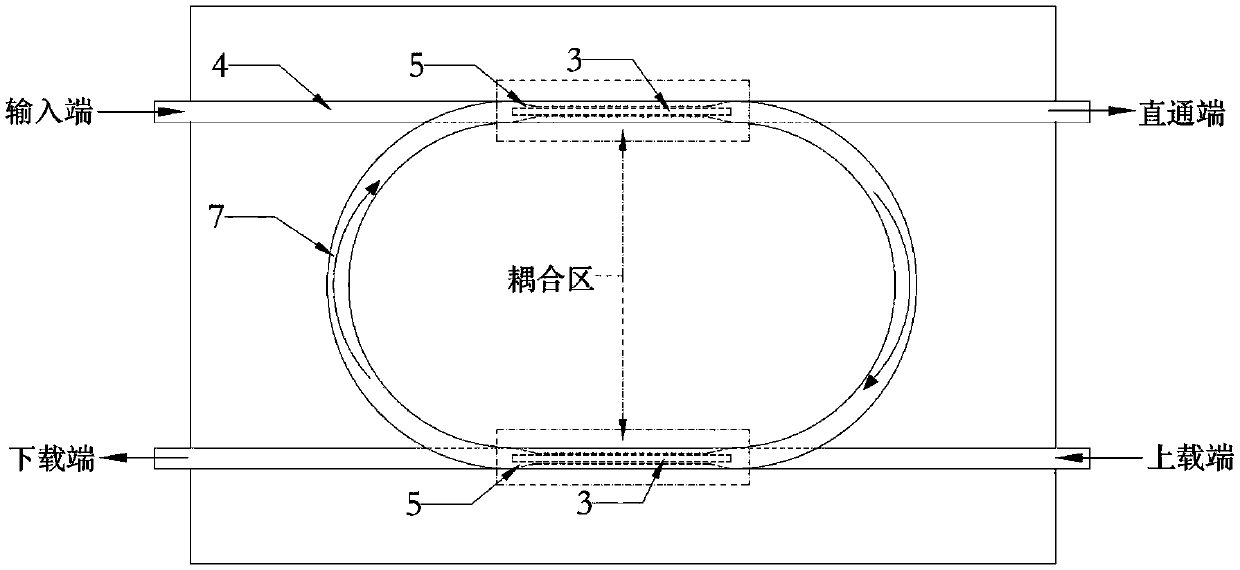

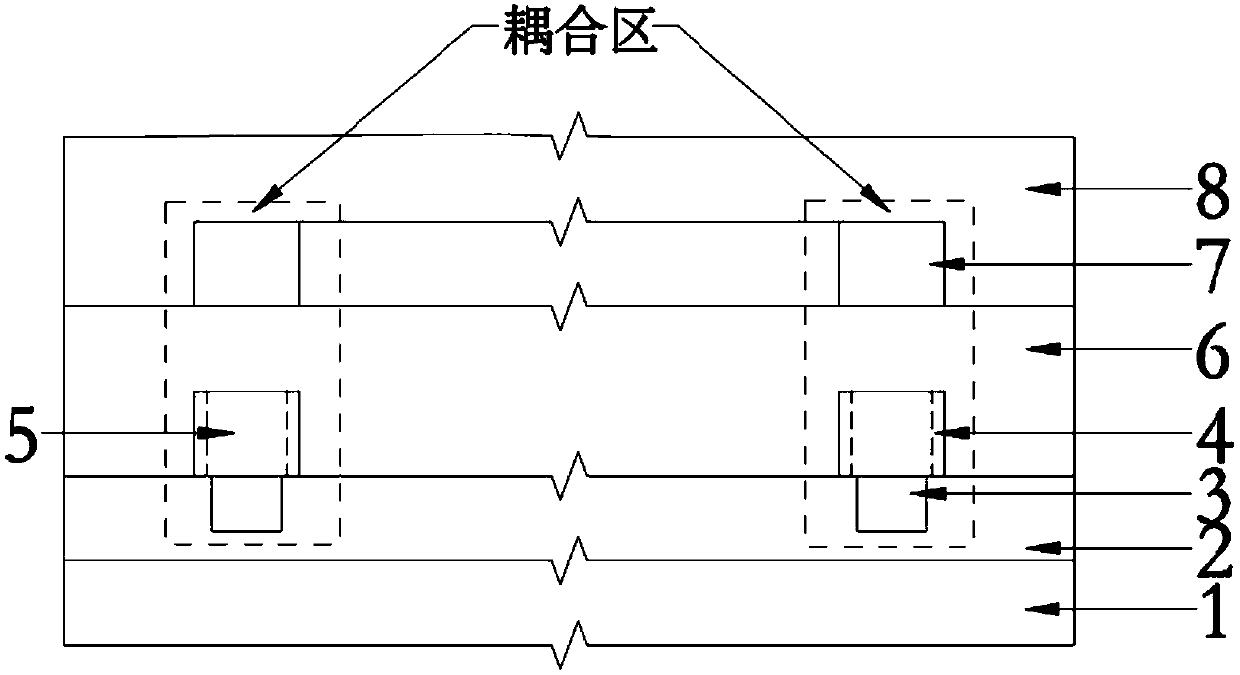

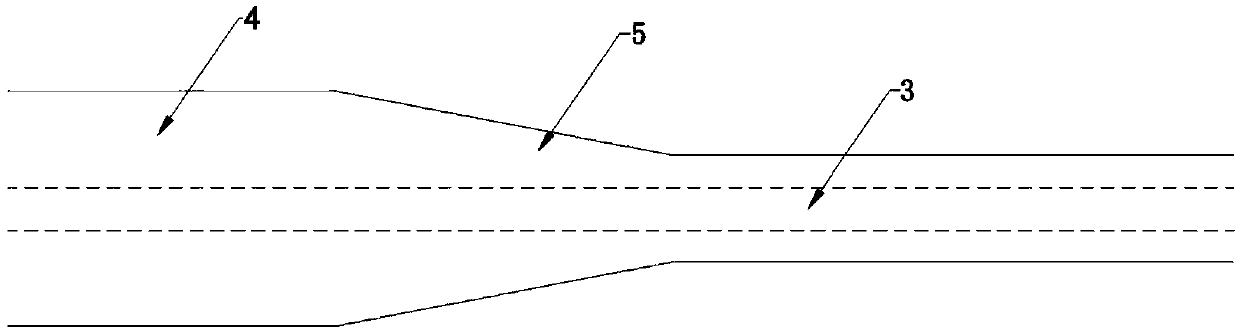

Microring resonator with improved coupled zone and manufacturing method thereof

ActiveCN109541745AReduce leakage lossEasy transferOptical waveguide light guideRidge waveguidesTransfer procedure

The invention provides a microring resonator with an improved coupled zone and a manufacturing method thereof, and belongs to the field of integrated optics. The device comprises a substrate 1, a bonding layer 2, a straight waveguide 4, a dielectric layer 6 and a racetrack type waveguide 7; the bonding layer 2 is disposed on the substrate 1, the dielectric layer 6 is disposed on the bonding layer2, the straight waveguide 4 is disposed in the dielectric layer 6, a straight channel portion of the racetrack type waveguide 7 is located directly above the straight waveguide 4. The device is characterized by further comprising a burying groove 3, which is formed in the bonding layer 2 in a coupling area, and located directly under the straight waveguide 4; and the refractive index of the burying groove 3 is smaller than the refractive index of the substrate 1. According to the microring resonator with the improved coupled zone and the manufacturing method thereof, by adopting the burying groove structure, leakage loss of a light field during transmission can be reduced, and transferring from the light field to other media can be promoted, thereby improving coupling efficiency, and an advantage of promoting change from a multimode mode to mode reduction in a ridge waveguide can be obtained.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

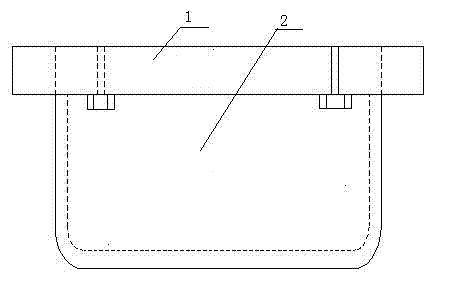

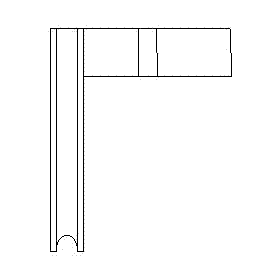

Precise U-shaped bending die for magnesium alloy sectional materials

ActiveCN102950207AGuaranteed uniform speedEnsure balanceShaping toolsMaterials scienceMagnesium alloy

A precise U-shaped bending die for magnesium alloy sectional materials is mainly used for processing the magnesium alloy sectional materials. The die comprises an upper die frame and a lower die plate and is characterized in that the rectangular upper die frame consists of an upper crossbeam plate, a lower crossbeam steel pad and two precisely feeding racks, wherein the upper crossbeam plate and the lower crossbeam steel pad are horizontally arranged, the precisely feeding racks are vertically arranged as vertical sides, and the precisely feeding racks are connected to the upper crossbeam plate and the lower crossbeam steel pad; retaining plates are embedded on the outer sides of the precisely feeding racks, grooves are formed between the precisely feeding racks and the retaining plates, and rotating gear discs can slide in the grooves and are meshed with the precisely feeding racks; and two adjustable support wheels, the rotating gear discs and a retainer are arranged on the lower die plate, and a guide wheel and a molding wheel are arranged on each rotating gear disc. The deformation and breakage problems of magnesium alloy are basically solved. Through the fine adjustment of a wheel gap, the gap accuracy of the sectional materials is increased by 50%, and the defective rate is reduced by 80%.

Owner:山西东银实业有限公司

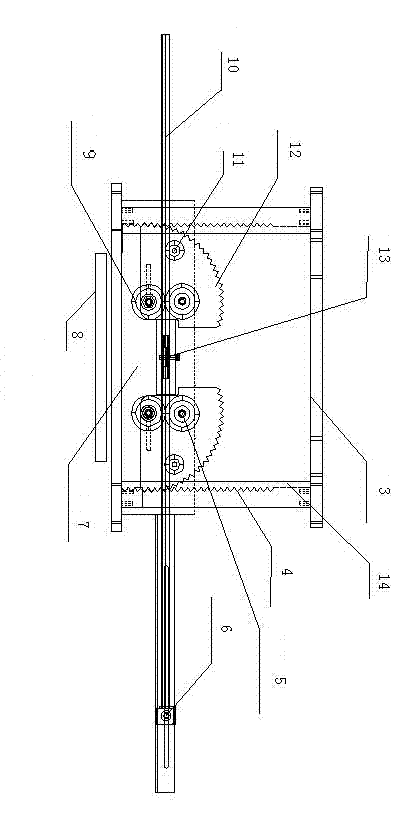

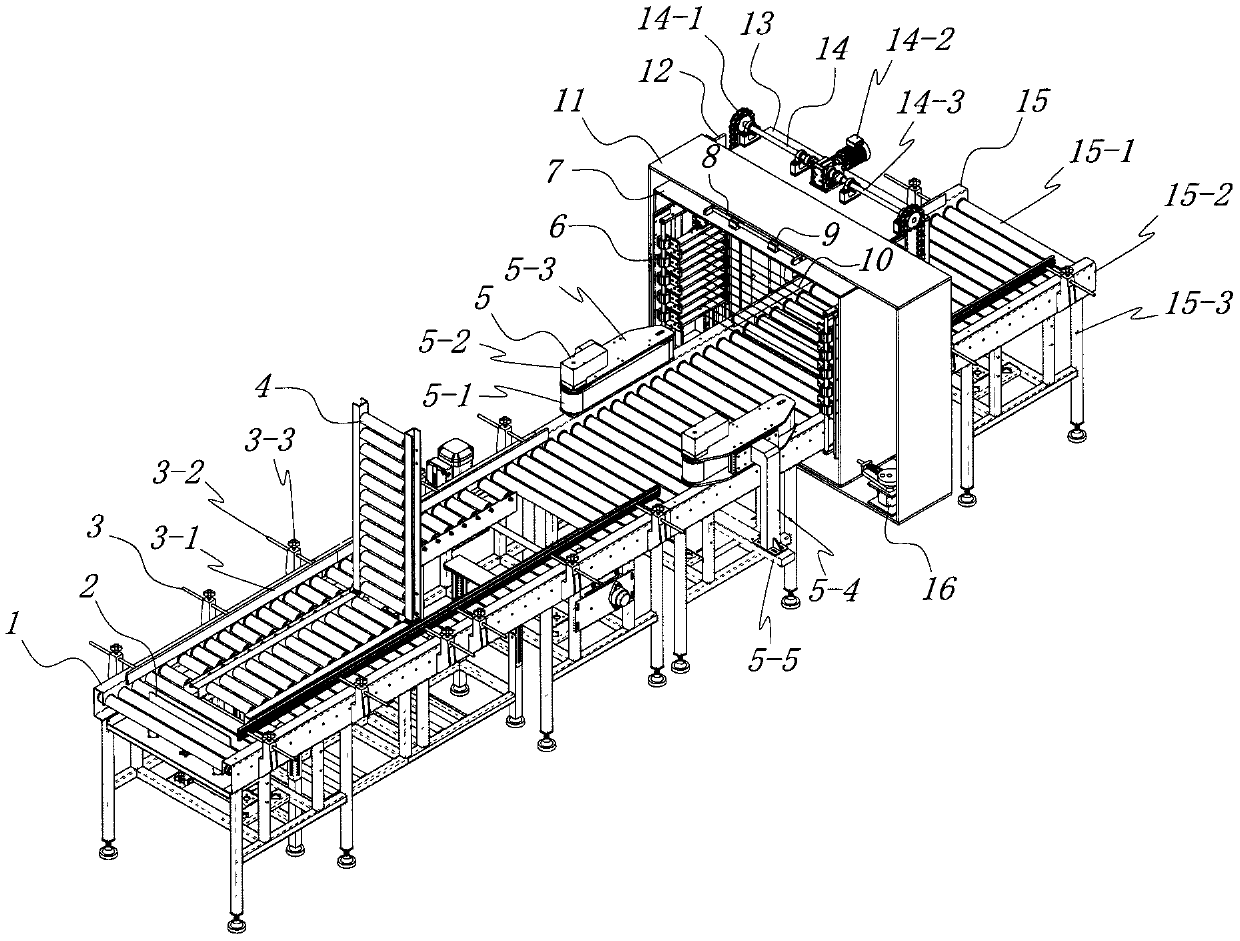

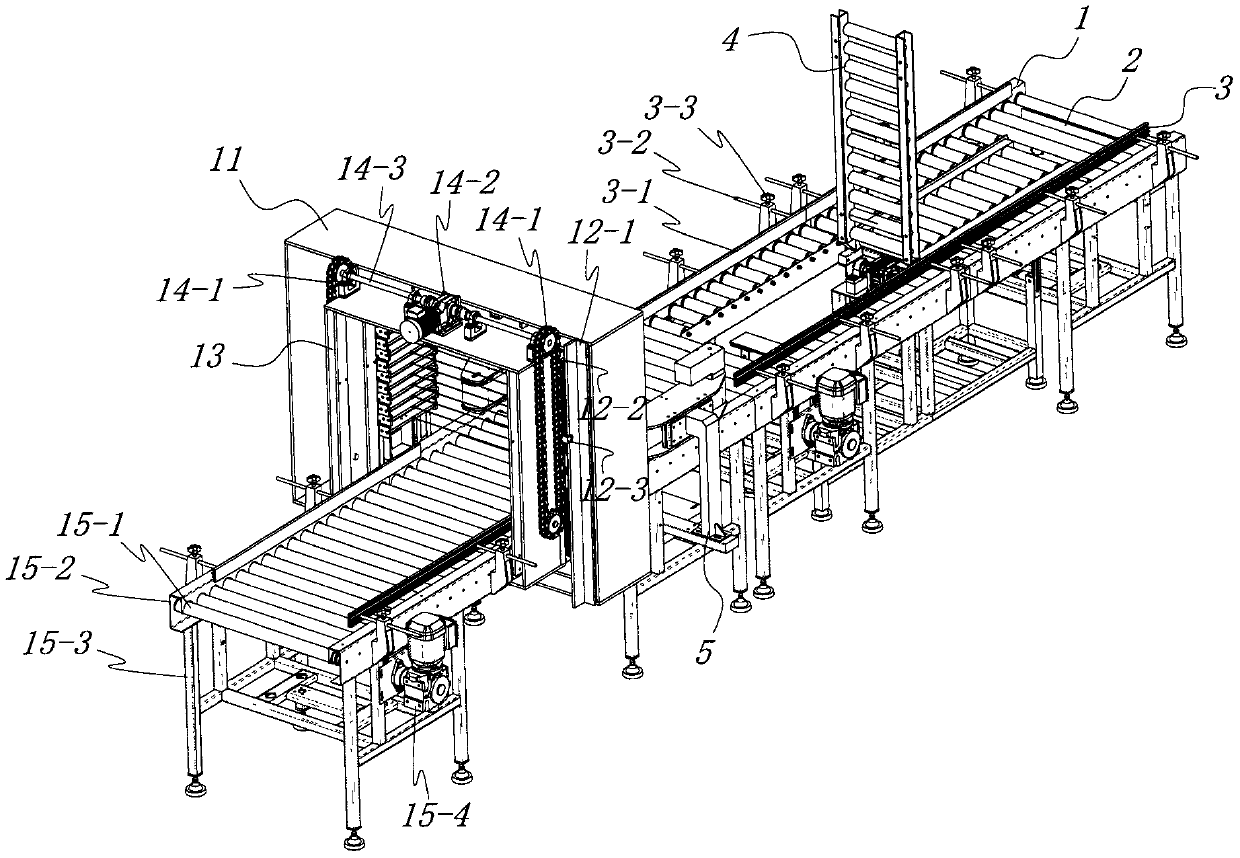

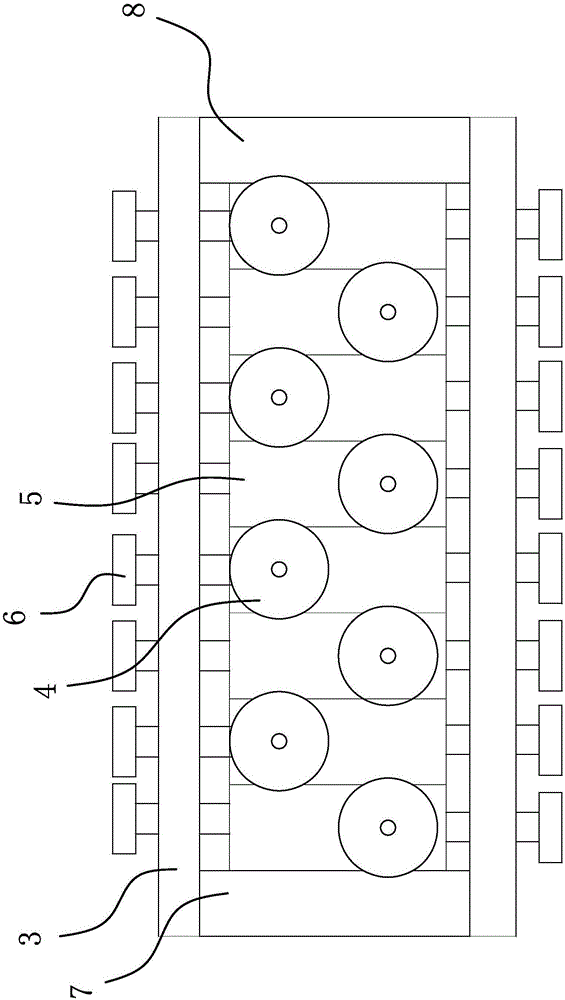

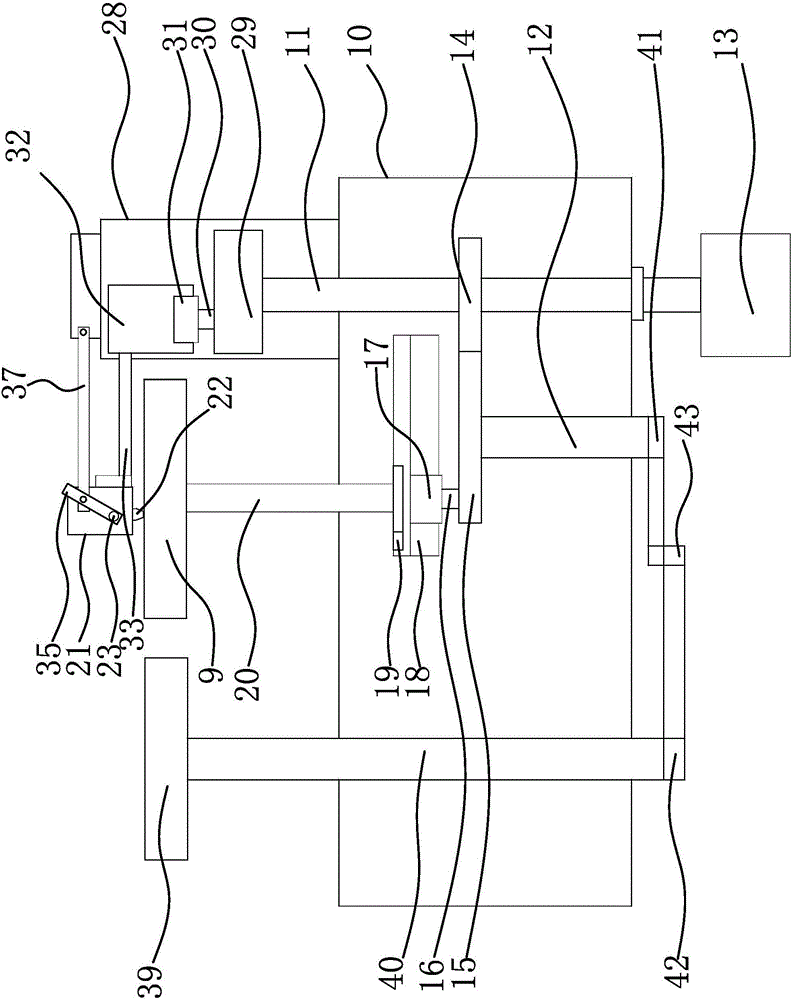

Conveying and cutting device for production of polystyrene foam boards

InactiveCN110480753ALabor savingImprove work efficiencyMetal working apparatusEngineeringPolystyrene

The invention relates to a conveying and cutting device for production of polystyrene foam boards. The device comprises a material overturning transporting device with a notch, and a material overturning device is arranged in the notch of the material overturning transporting device; the upstream of the material overturning device is provided with a material blocking device; a linear conveying device is in butt joint with the discharging end of the material overturning transporting device; a portal frame is fixedly connected to the side wall of the linear conveying device; the upstream of theportal frame is provided with a peripheral fixed frame in sliding connection with the portal frame and a longitudinal moving driving device capable of driving the peripheral fixed frame to move longitudinally; a reciprocating movement frame is in sliding connection in the peripheral fixed frame, and a reciprocating driving device is arranged between the peripheral fixed frame and the reciprocatingmovement frame; a plurality of cutting wires are arranged in the reciprocating movement frame; the two ends of the cutting wires are each provided with a tangential distance adjusting device fixedlyconnected with the reciprocating movement frame; the upstream positions of the cutting wires are provided with a material pushing device; and the material overturning transporting device and the linear conveying device are each connected with a guardrail limiting device. The conveying and cutting device for production of the polystyrene foam boards is fast and efficient in the cutting process, simple and fast in the wire adjusting process, high in accuracy and capable of being used for overturning materials.

Owner:HEBEI UNIV OF TECH

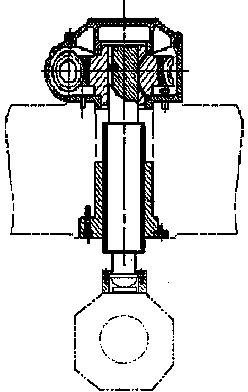

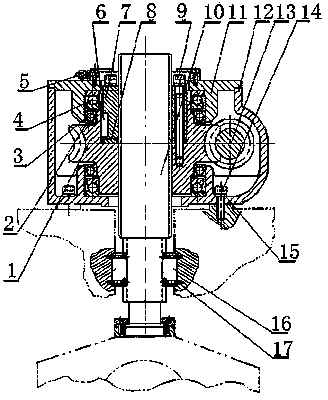

Double-nut distance-adjusting device for extrusion tablet machine

The invention discloses a double-nut distance-adjusting device for an extrusion tablet machine. The double-nut distance-adjusting device comprises a screw rod (10), a shell body pressing cover (11) and a shell body (12); a closed cavity is formed by the shell pressing cover (11) and the shell body (12), the shell body (12) is internally equipped with a worm gear and worm mechanism, the shell body (12) is fixedly connected with a rack, and the screw rod (10) is fixedly connected with a roller bearing. The double-nut distance-adjusting device also comprises distance-adjusting nuts (7) and distance-adjusting pads (8), a worm gear nut (1) of the worm gear and worm mechanism is in threaded connection with the screw rod (10), the distance-adjusting nuts (7) and the distance-adjusting pads (8) are connected with the worm gear nut (1) through first screws (9), the distance-adjusting nuts (7) are in threaded connection with the screw rod (10), the screw rod (10) is fixedly connected with the rack, and the worm gear nut (1) drives the distance-adjusting nuts (7) to together rotate around the screw rod (10) so as to allow the screw rod (10) to move up and down. The double-nut distance-adjusting device has high distance-adjusting precision and low adjustment costs, and can adjust the distance under load.

Owner:大连橡胶塑料机械有限公司

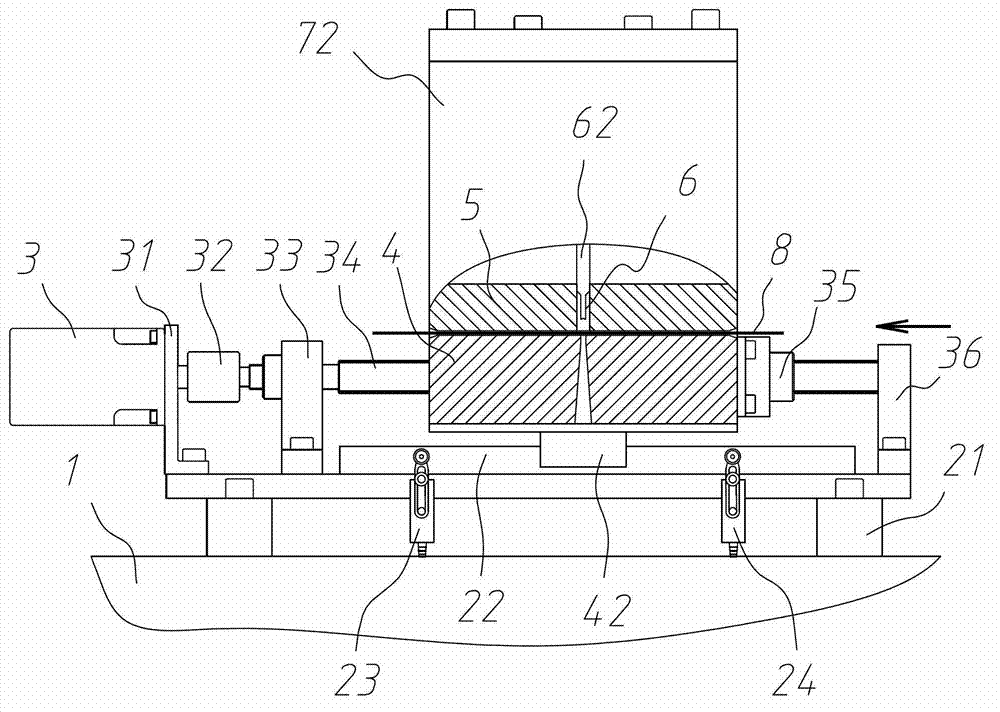

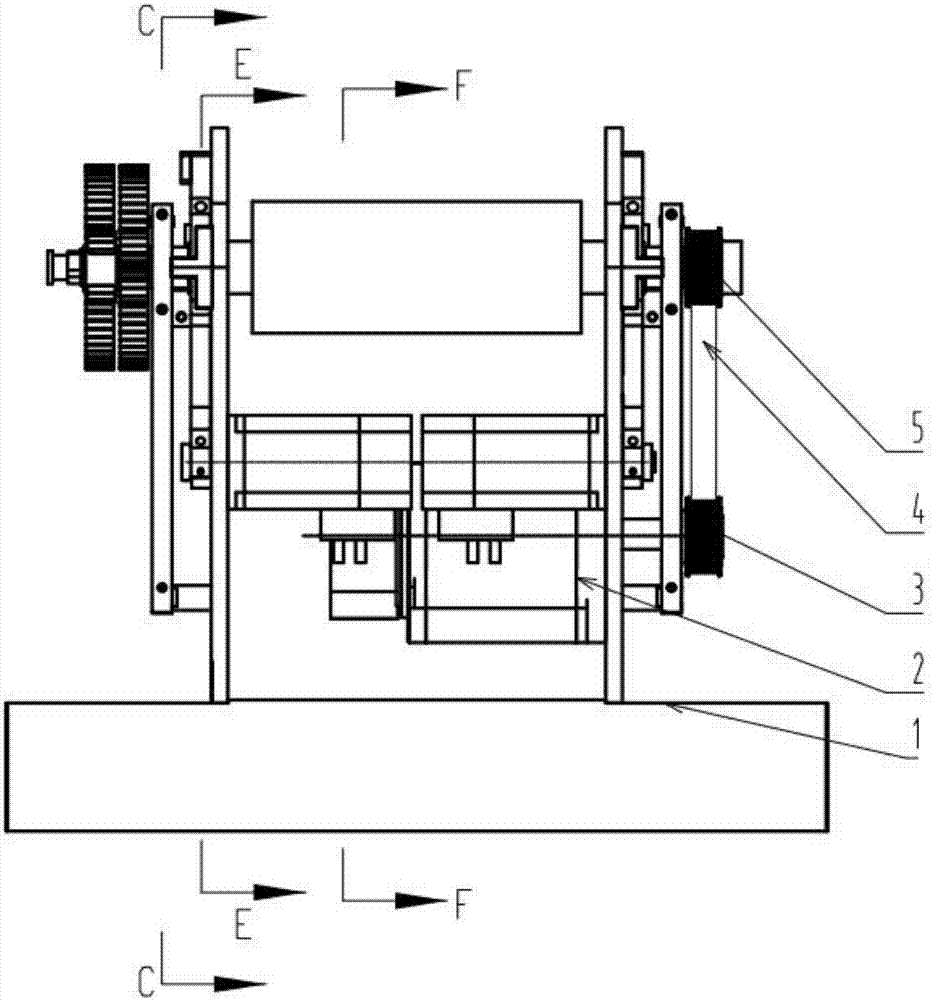

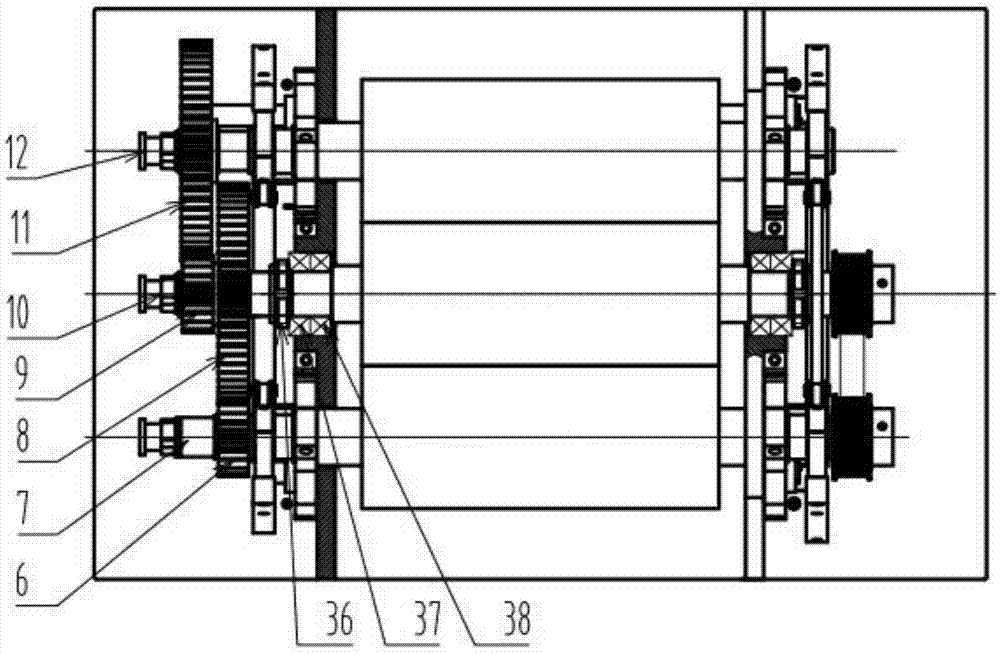

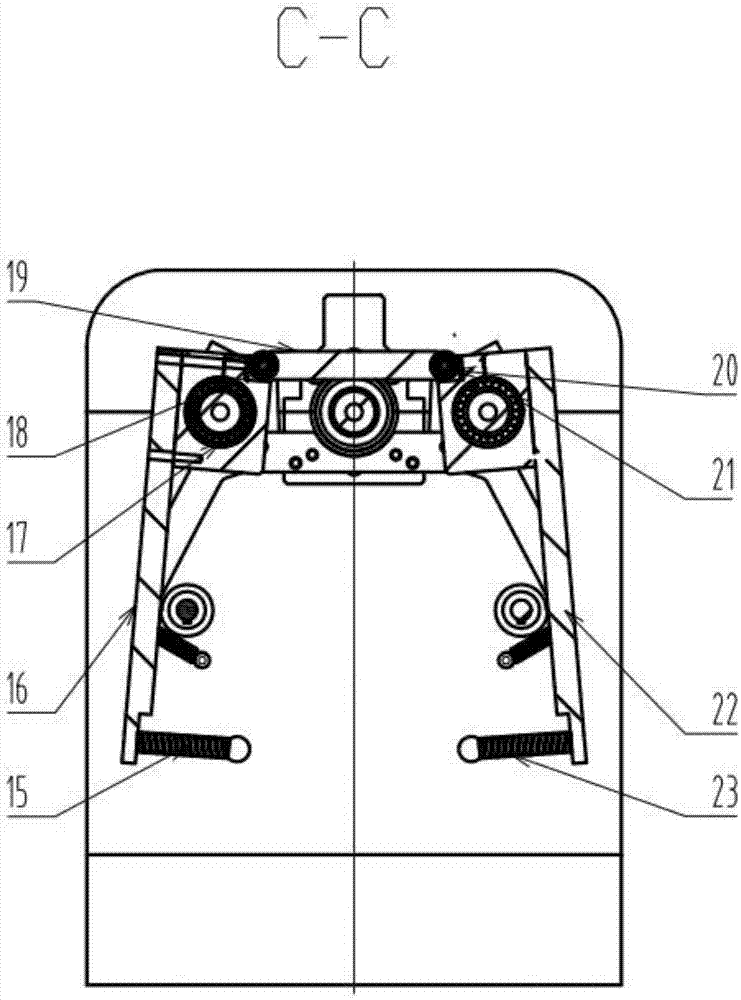

Precision control type three-roller grinding machine

The invention discloses a precision control type three-roller grinding machine. The precision control type three-roller grinding machine comprises a machine frame, vertical plates, and a front roller, a middle roller, a rear roller, a roller transmission part, a roller spacing control part and a roller floating gap eliminating part which are arranged on the machine frame and the vertical plates, wherein the roller spacing control part comprises a front power source, a front spacing adjusting cam, a second front bearing, a front spacing adjusting swinging arm, a front spacing adjusting rotating pin, a front adjusting screw and a front tension spring; the front spacing adjusting rotating pin and the front spacing adjusting swinging arm form a rotating pair; the front adjusting screw and the front spacing adjusting swinging arm form a screw thread pair; and the front power source drives the front spacing adjusting cam to rotate to push the front spacing adjusting swinging arm to rotate so as to adjust roller spacing. The precision control type three-roller grinding machine is precise in spacing adjustment and is time-saving and labour-saving by utilizing the roller spacing control part with a lever and the roller floating gap eliminating part.

Owner:SHENZHEN ZYE TECH LTD

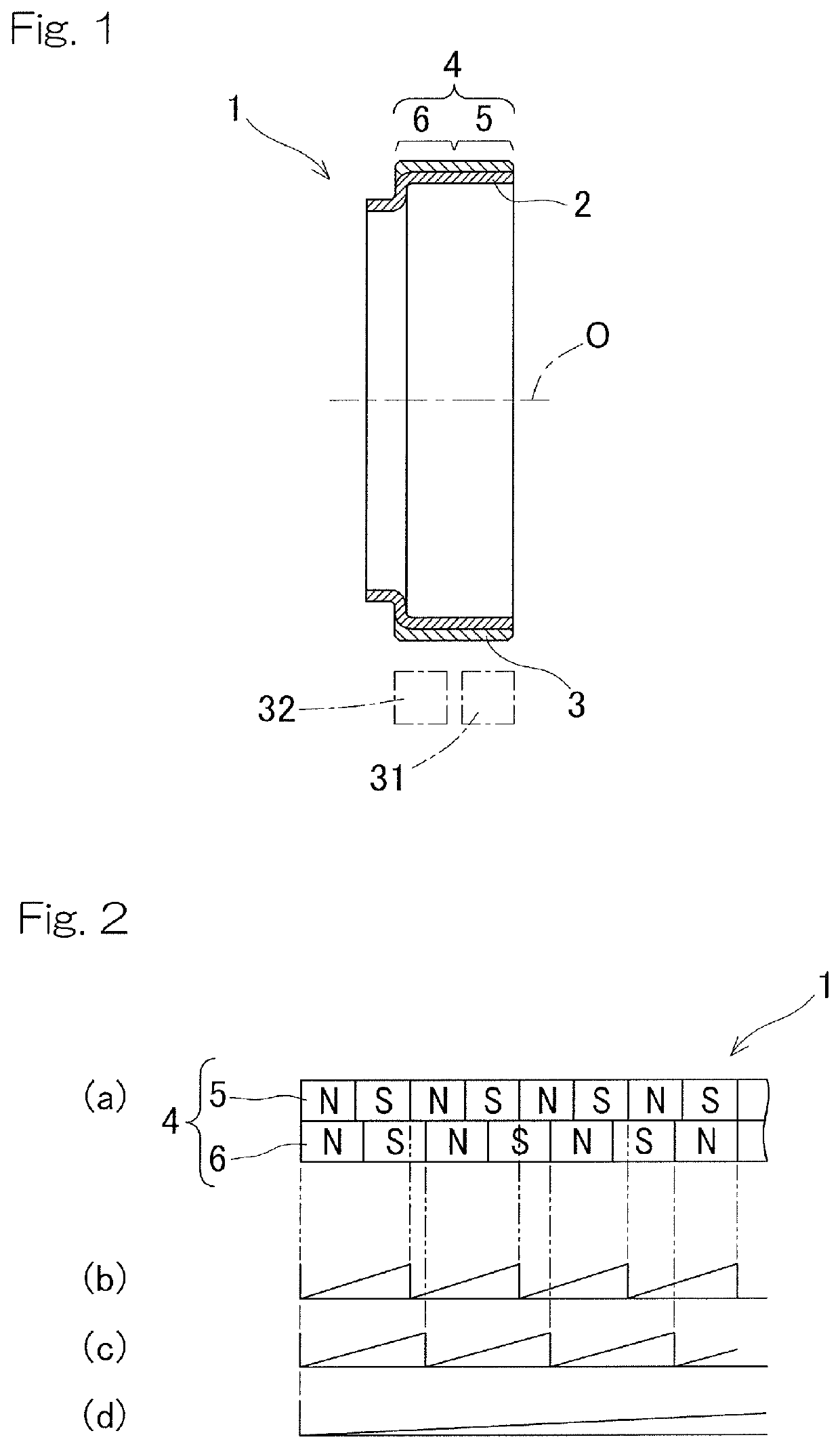

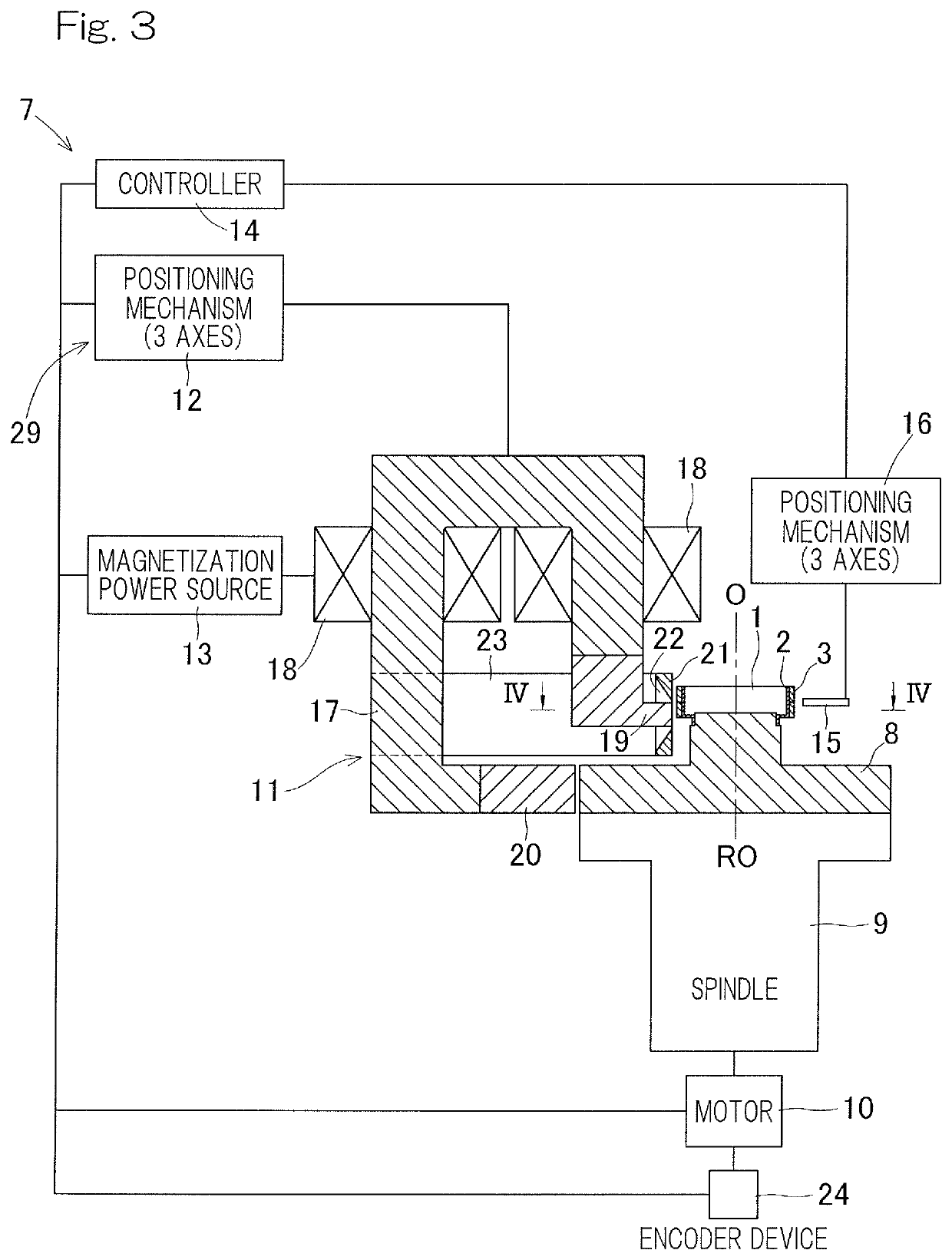

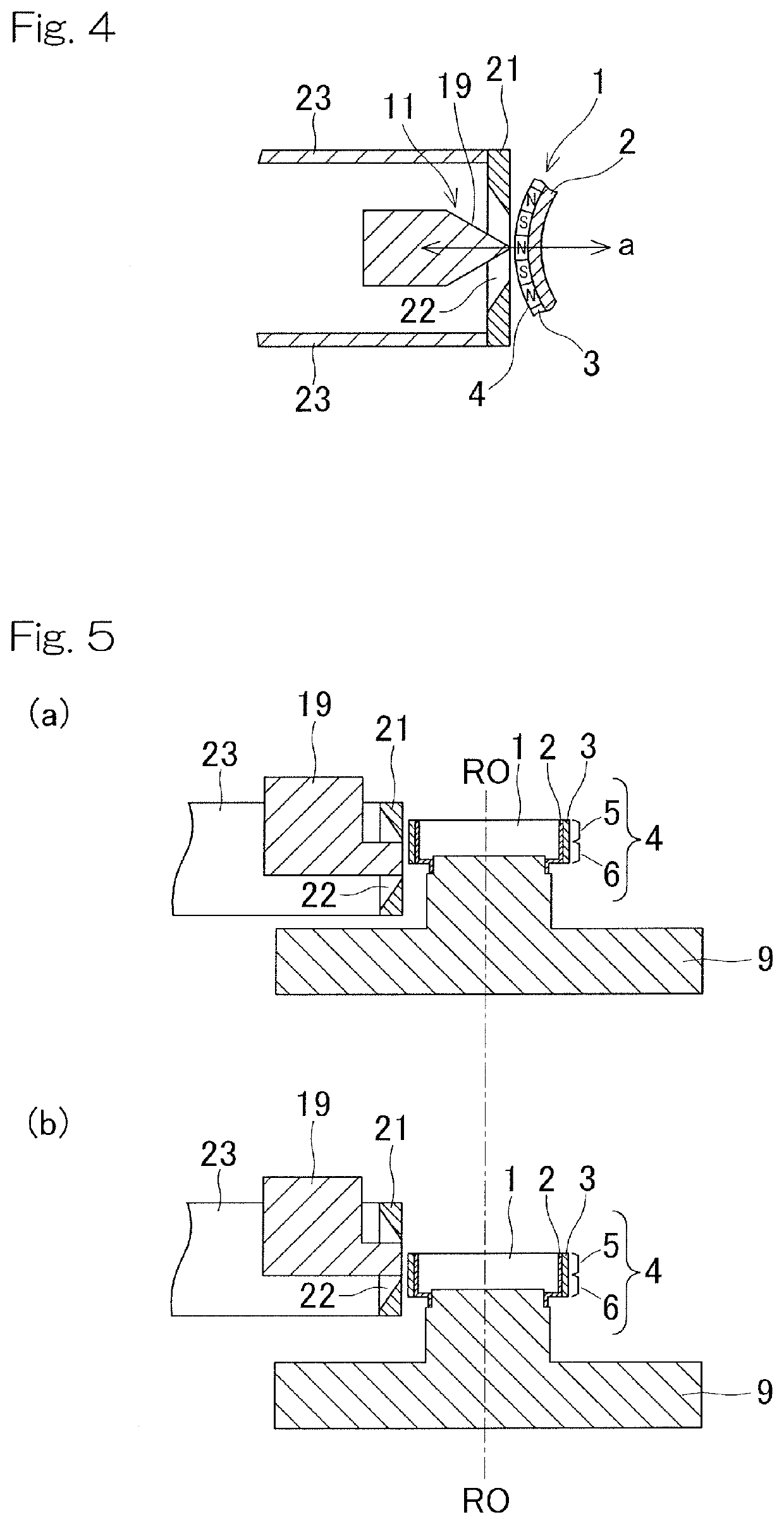

Magnetic encoder, and method and device for producing same

InactiveUS20190346292A1Improve accuracyConvenient and accurateMagnetic bodiesConverting sensor output electrically/magneticallyPhase differenceMagnetic poles

Provided is a magnetic encoder that can be produced by a simple modification of an existing production method and that can detect an absolute angle with high efficiency, and a method and an apparatus for producing the magnetic encoder. In a magnetic encoder, a plurality of rows of magnetic tracks, each having N poles and S poles arranged alternately, are disposed adjacent to each other. The rows of magnetic tracks include a main track used for calculating an angle and a sub track used for calculating a phase difference from the main track. The number of magnetic poles of the main track is larger than that of the sub track. The main track is magnetized after the sub track. Thus, accuracy of pitch of the magnetic poles is higher in the main track than in the sub track.

Owner:NTN CORP

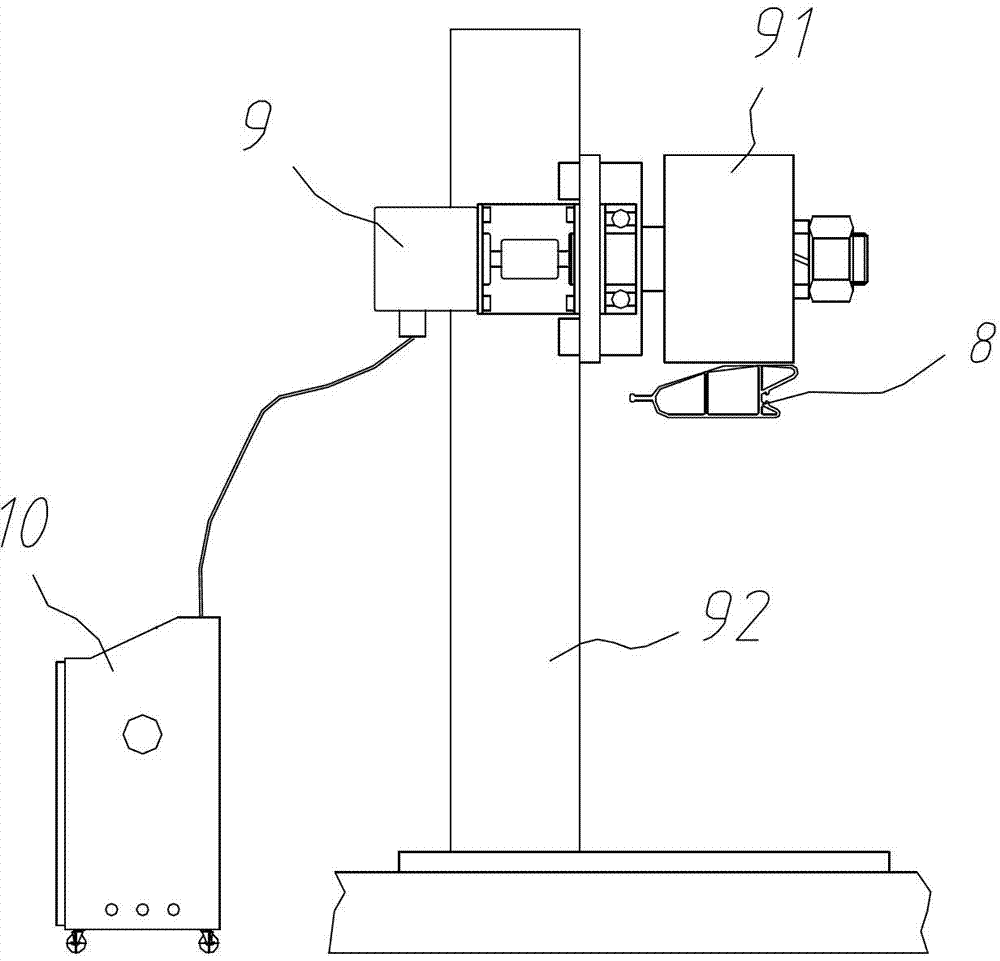

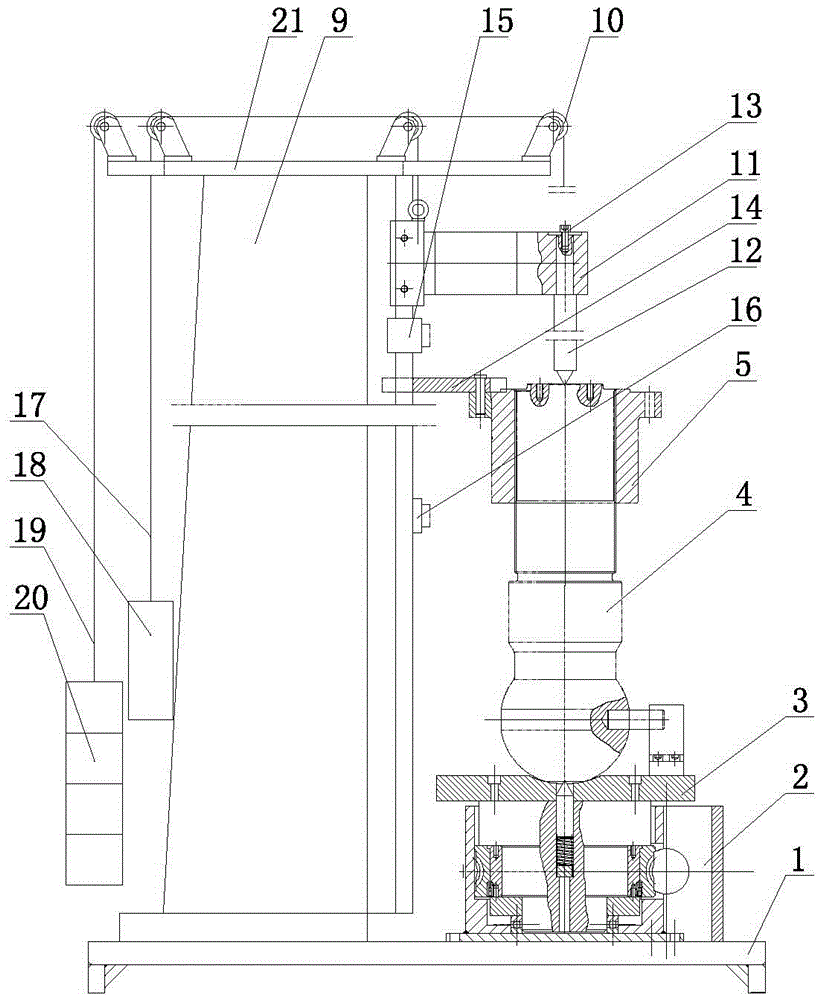

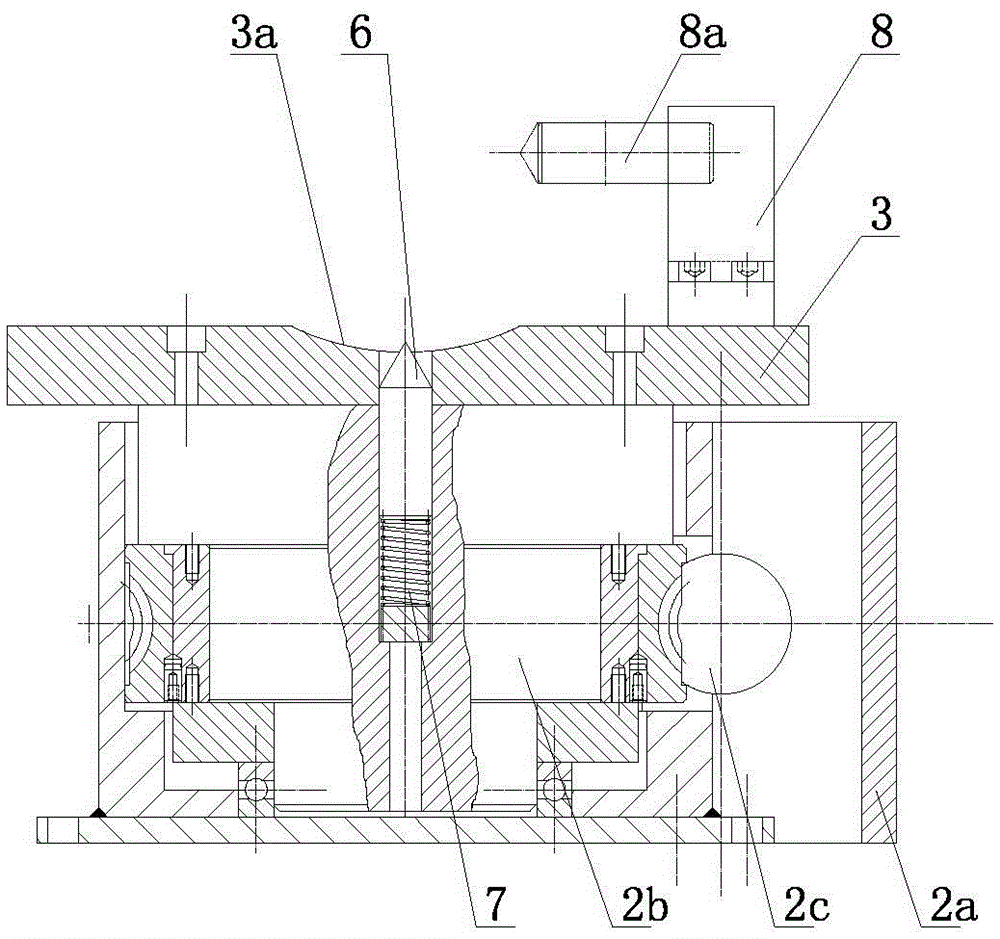

Device for grinding threads of screw rod and screw rod sleeve

ActiveCN106001793AImprove grinding efficiencyHigh pitch accuracyThread cutting machinesArchitectural engineeringScrew thread

The invention discloses a device for grinding threads of a screw rod and a screw rod sleeve in the field of thread machining devices. The device comprises a bottom plate. A rotating mechanism is arranged on the bottom plate. A positioning plate is connected to the rotating mechanism. A positioning groove is formed in the positioning plate. A lower centre is arranged below the positioning plate and abuts against the lower end of the screw rod. A locating pin seat is arranged on the positioning plate. A locating pin is connected to the locating pin seat. A stand column is arranged on the bottom plate. Fixed pulleys are arranged at the upper end of the stand column. A guide rail plate is connected to the stand column in a sliding manner. An upper centre is connected to the guide rail plate. The screw rod sleeve is connected with the stand column in a sliding manner. The stand column is provided with an upper limiting switch and a lower limiting switch. A connecting wrench moves vertically along the stand column. A first steel wire rope is connected to the guide rail plate. A second steel wire rope is connected to the screw rod sleeve. The end portion of the first steel wire rope is connected with a guide rail plate balancing weight, and the second steel wire rope is connected with a screw rod sleeve balancing weight. By means of the device, the thread grinding efficiency is improved, time and labor are saved, the quality of the ground threads is better, the precision of the thread pitch is higher, and the automation degree is higher.

Owner:YANGLI GRP CORP LTD

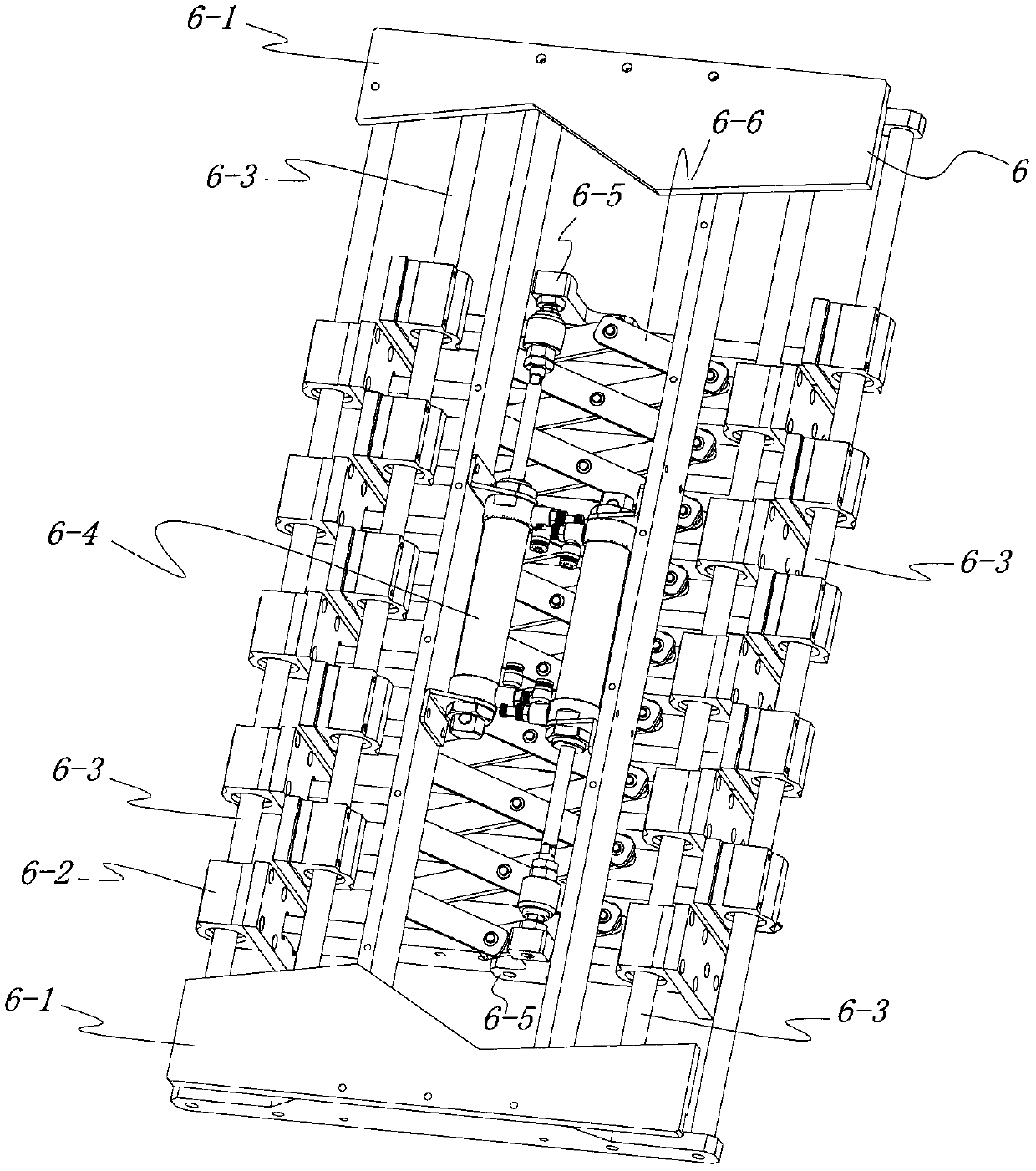

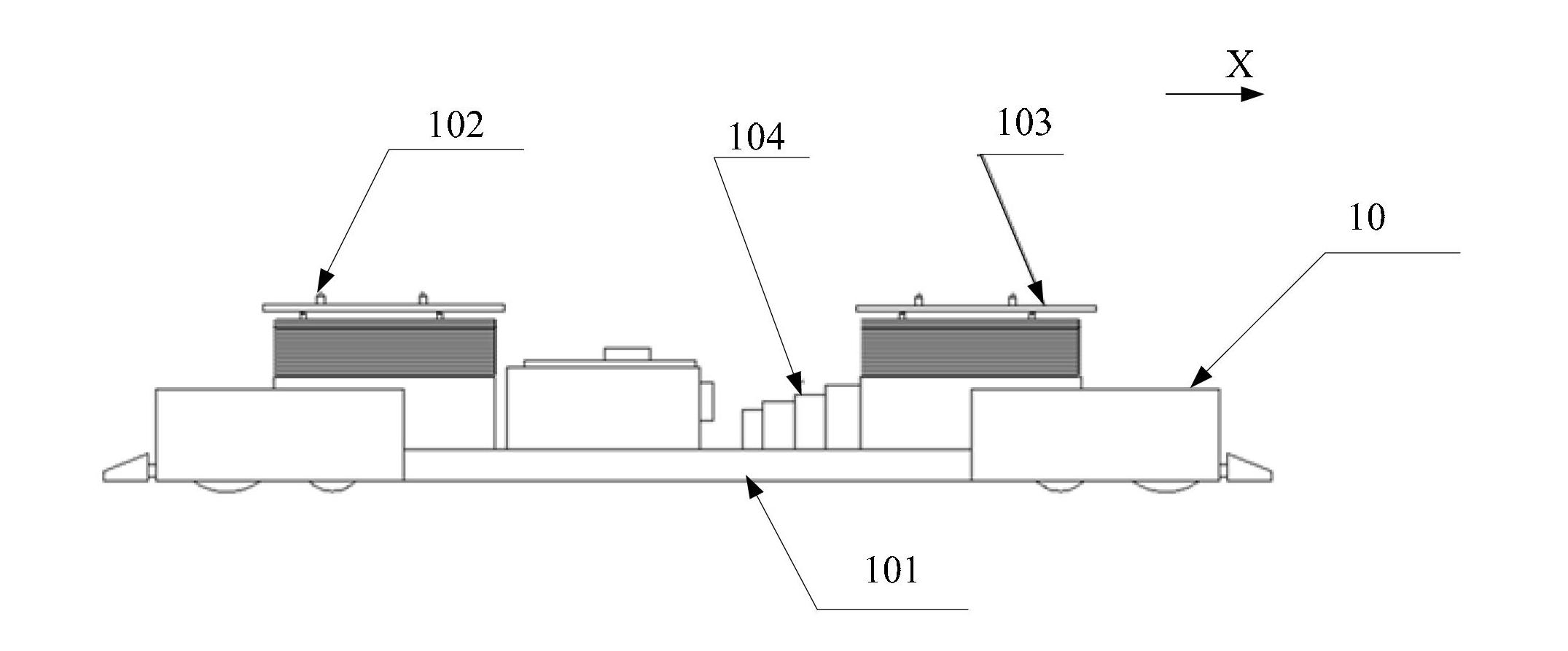

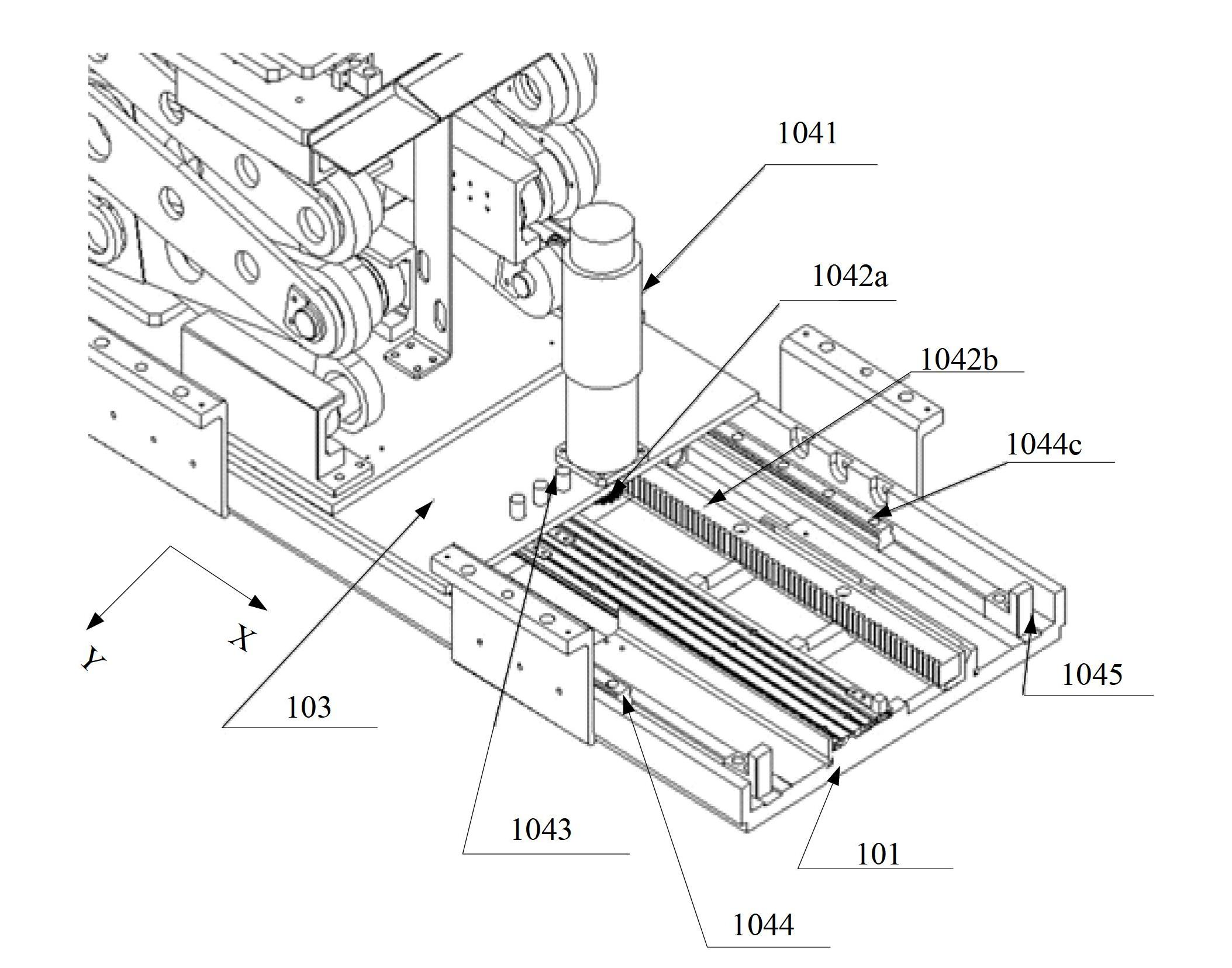

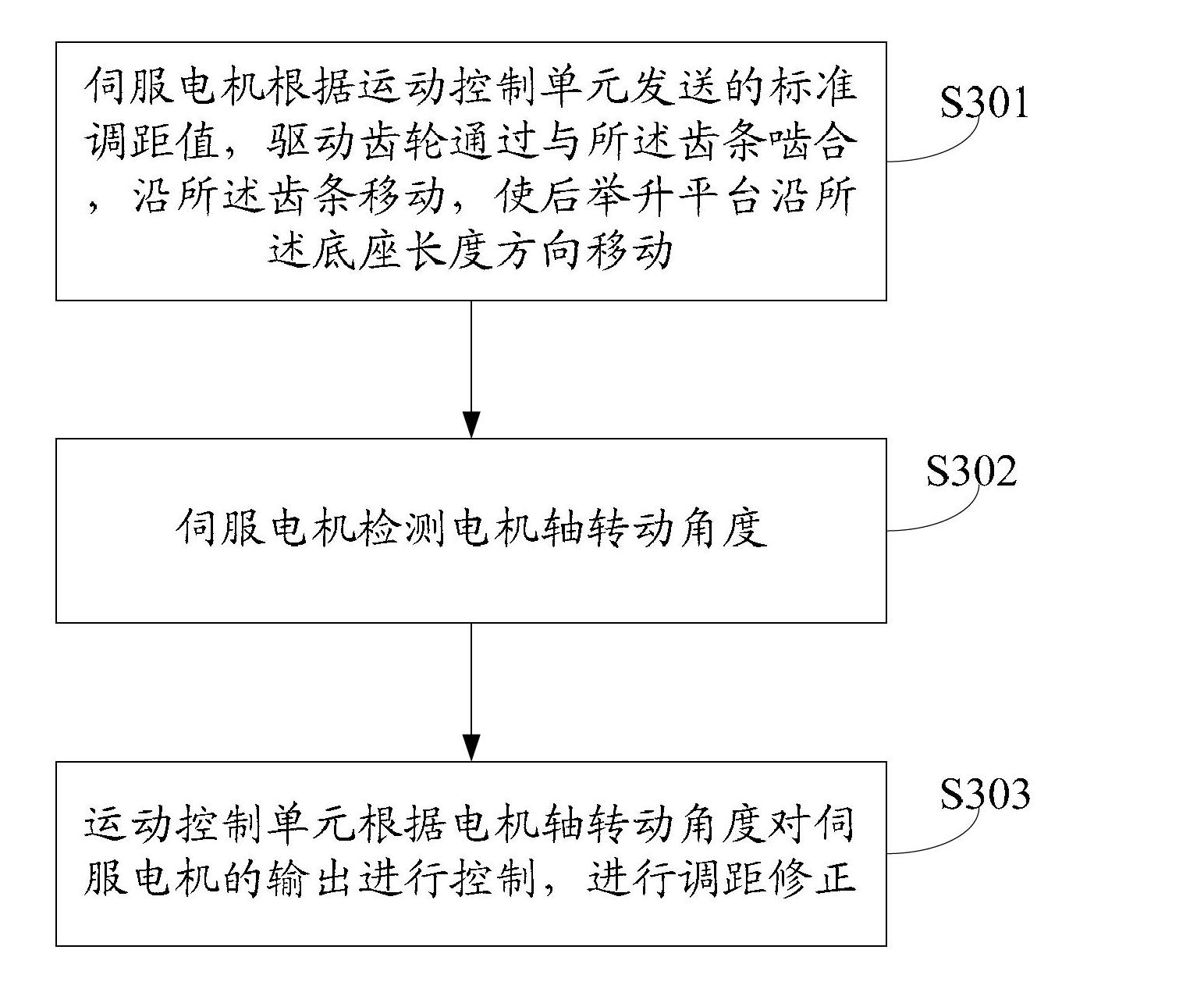

AGV (automated guided vehicle) and method for regulating distance

ActiveCN102674202ARealize automatic distance adjustmentHigh pitch accuracyLifting framesEngineeringAutomated guided vehicle

The embodiment of the invention provides an AGV (automated guided vehicle) and a method for regulating distance, relating to the field of mechanical design. According to the AGV and the method for regulating the distance, the distance of the AGV can be automatically regulated, the distance regulating accuracy is improved, and the risk of manual misoperation is avoided. The AGV comprises a base, a front lifting platform, a rear lifting platform and a distance regulating unit, wherein the front lifting platform is positioned above the base and is used for lifting a front suspension assembly; the rear lifting platform is positioned above the base and is used for lifting a rear suspension assembly; the rear lifting platform and the front lifting platform are in linear arrangement along the length direction of the base; and the distance regulating unit is connected with the rear lifting platform and is used for making the rear lifting platform move along the length direction of the base. The AGV and the method for regulating the distance which are provided by the embodiment of the invention are used for adapting the front suspension assembly with the rear suspension assembly.

Owner:长城汽车股份有限公司平湖分公司

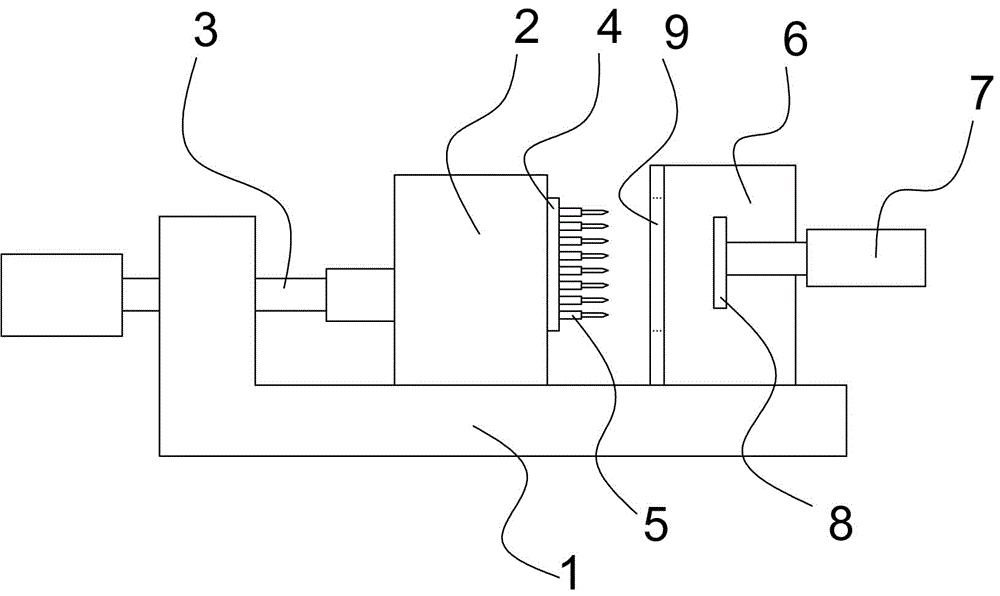

S-shaped spring machining device

The invention provides an S-shaped spring machining device and belongs to the technical field of machinery. The problem of low S-shaped spring production efficiency in the prior art is solved. The S-shaped spring machining device comprises a rack and a worktable arranged in the rack, wherein a straightening mechanism capable of straightening a steel wire, a forming device capable of coiling the straight steel wire to be S-shaped, a reshaping device capable of adjusting a pitch of the S-shaped spring and a cutting-off device capable of cutting off the S-shaped spring are sequentially arranged on the worktable. The forming device comprises a forming plate arranged on the worktable, a forming ring I and a forming ring II are symmetrically arranged on the forming plate, a channel for the S-shaped spring to pass through is formed between the forming ring I and the forming ring II, a forming piece is fixed to the upper portions of the forming ring I and the forming ring II, the forming plate can be connected with a reciprocating motion mechanism capable of driving the forming plate to perform reciprocating rotation, and an intermittent blocking mechanism capable of blocking advancing of the S-shaped spring in a spaced mode is arranged above the forming plate. The S-shaped spring machining device has the advantage of high S-shaped spring production efficiency.

Owner:浙江心梦享家居有限公司

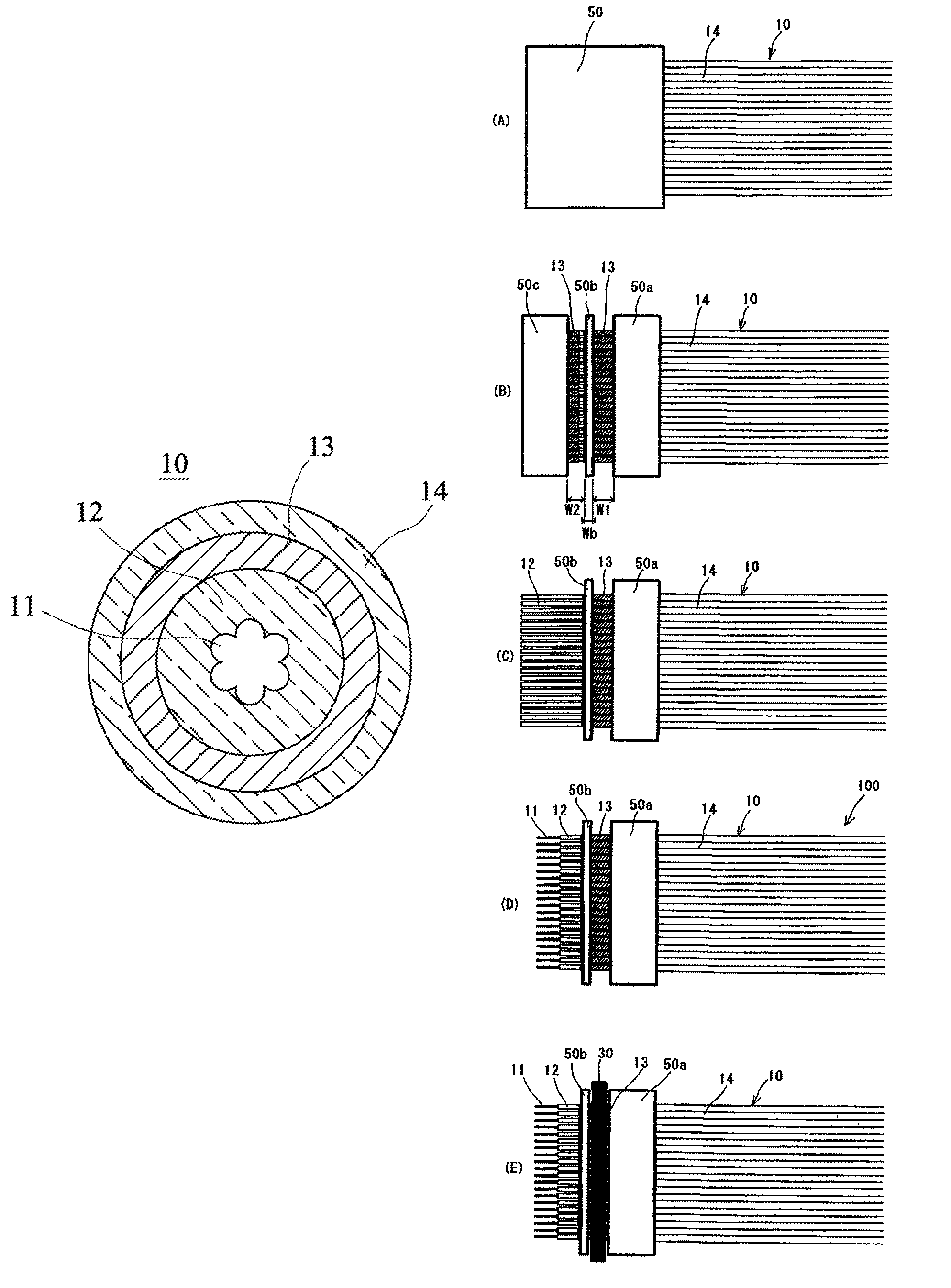

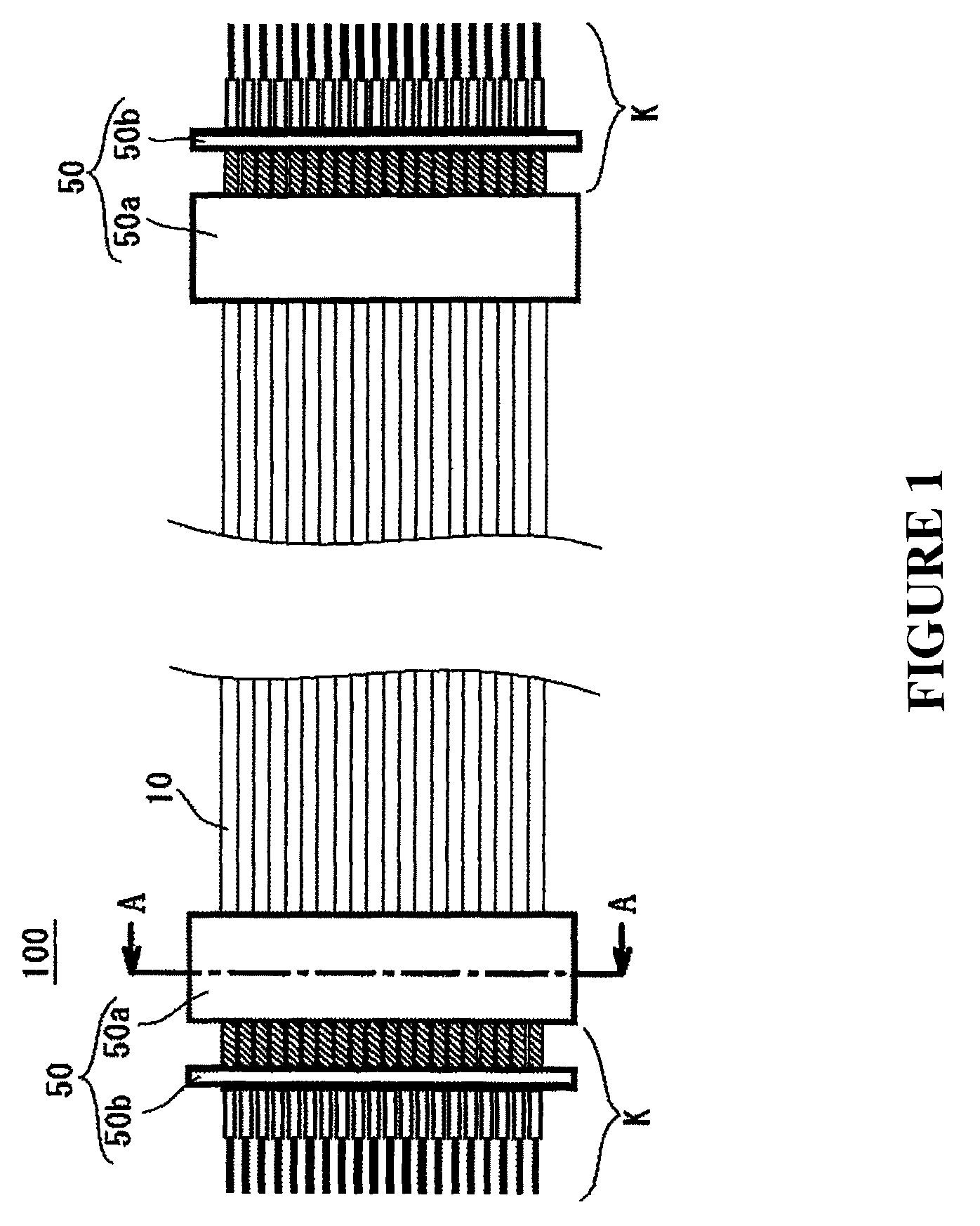

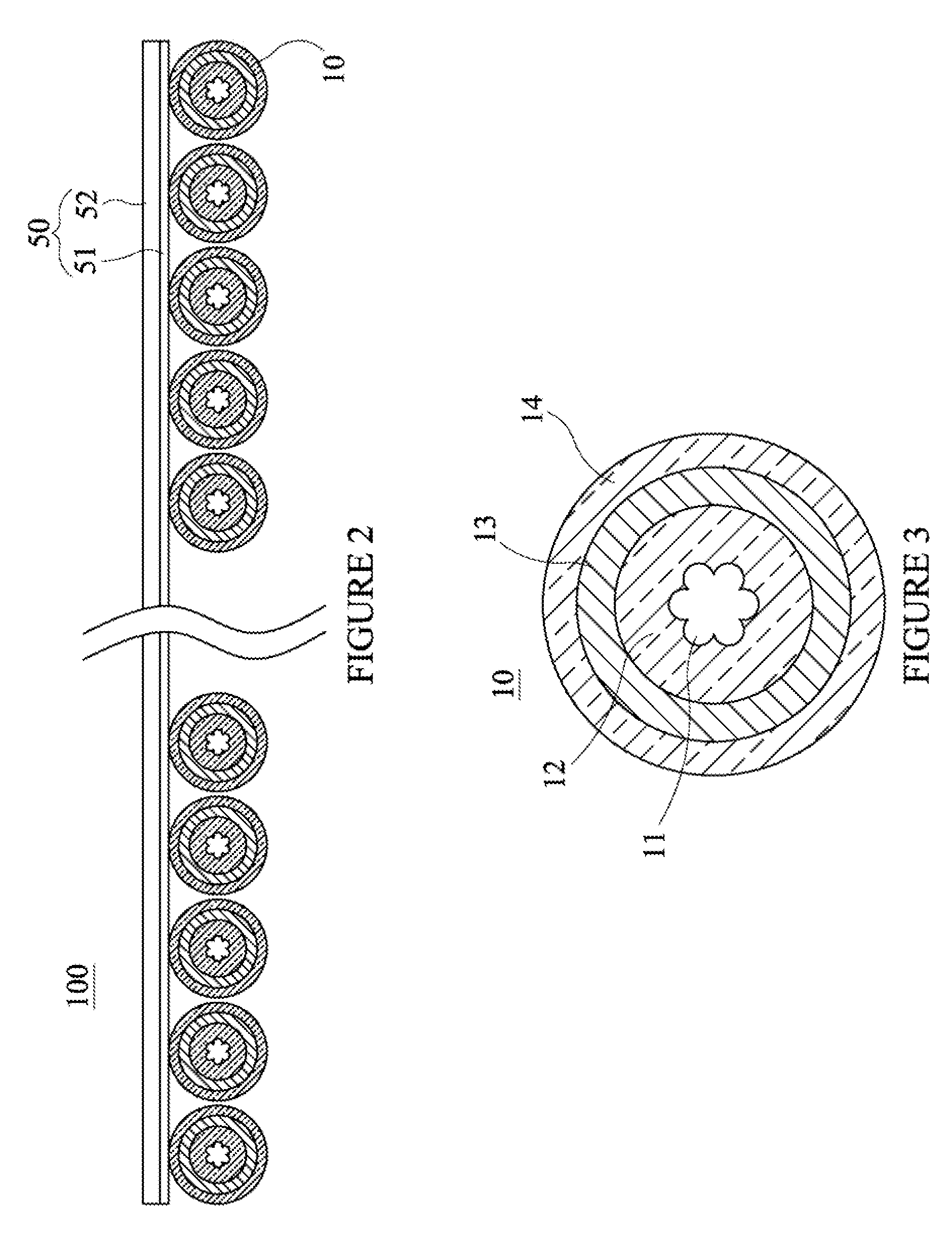

Flat cable

InactiveUS7772496B2Keep the accuracyStay healthyPower cables with screens/conductive layersCommunication cablesCoaxial cableBand shape

A flat cable in which at least end portions of a plurality of coaxial cables are securely arranged in parallel on a sheet is characterized in that a flat cable edge-machined portion for electric connection of the coaxial cables is formed at the end portion of the plurality of coaxial cables, and a part of the sheet is made to remain in a band shape across an entire width of the flat cable between a machined edge portion of the edge-machined portion and a distal end of the flat cable, and a jacket of the coaxial cable is secured to the band-shaped sheet.

Owner:JUNKOSHA

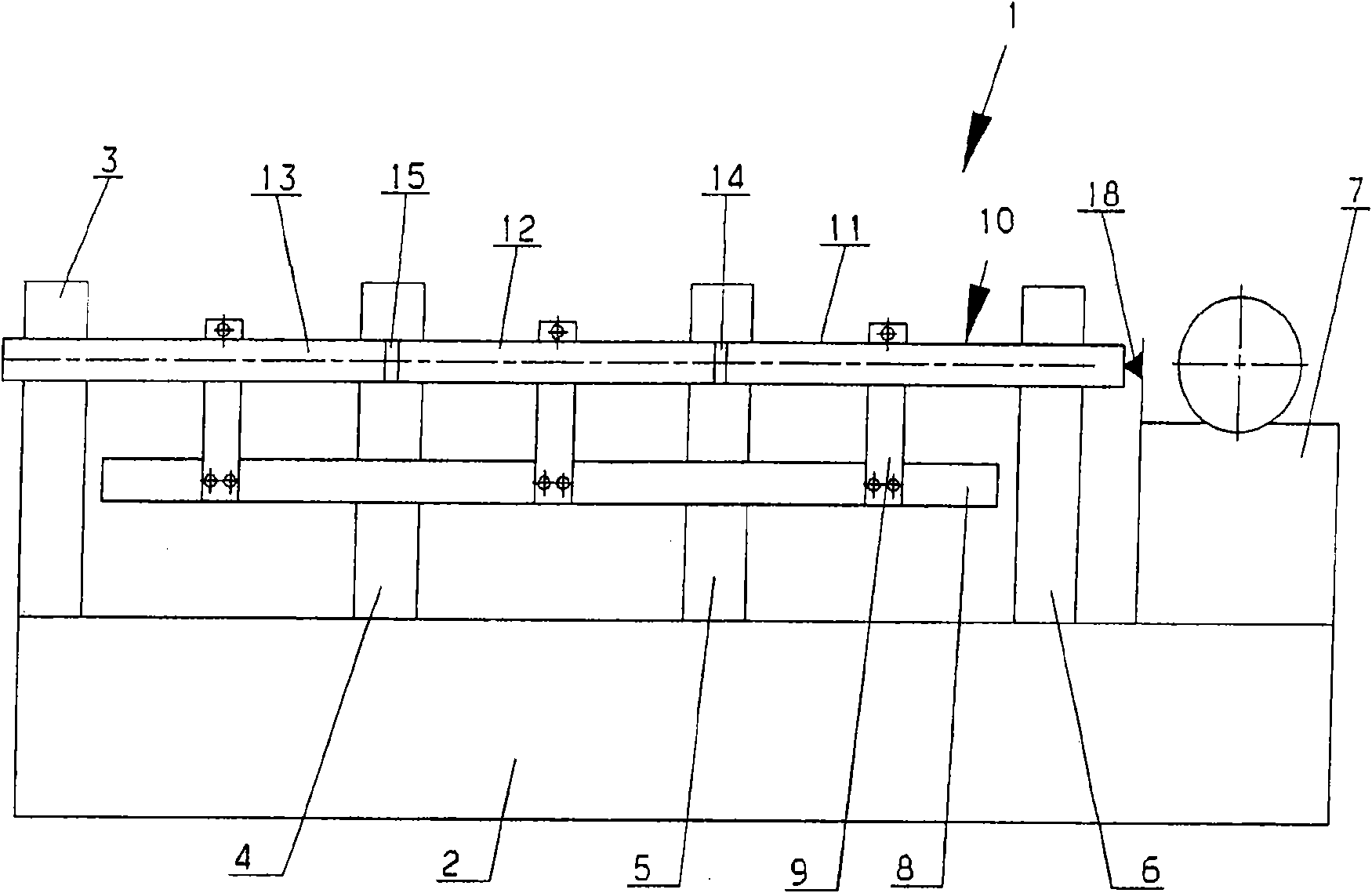

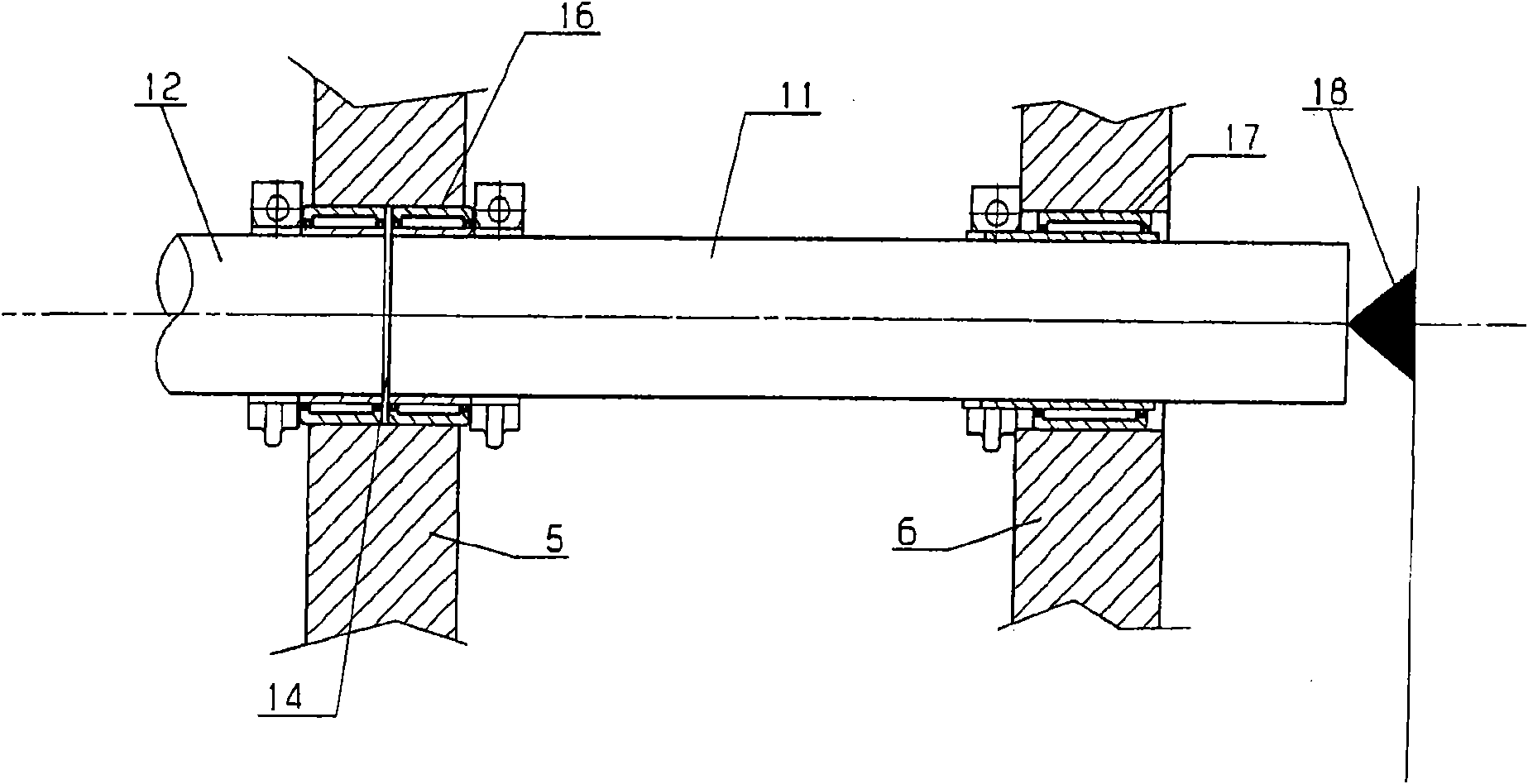

Warp knitting machine

InactiveCN101575765AGuaranteed temperatureStable supportWarp knittingEngineeringMechanical engineering

This invention relates to a warp knitting machine (1), including at least one loop-forming toolbar (8), on which several loop-forming tools are mounted. This is connected by levers (9) to a supporting shaft (10) which is divided into sections (11 - 13), wherein, each sections (11 - 13) is independently supported. Therefore the warp knitting machine has simply structure and simultaneously less sensitive to temperature affection.

Owner:KARL MAYER TEXTILMASCHFAB GMBH

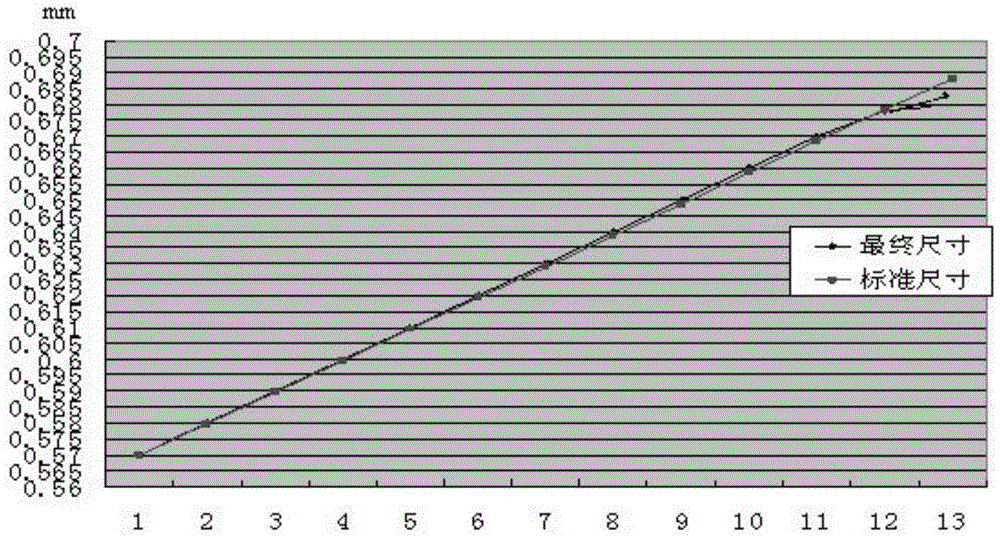

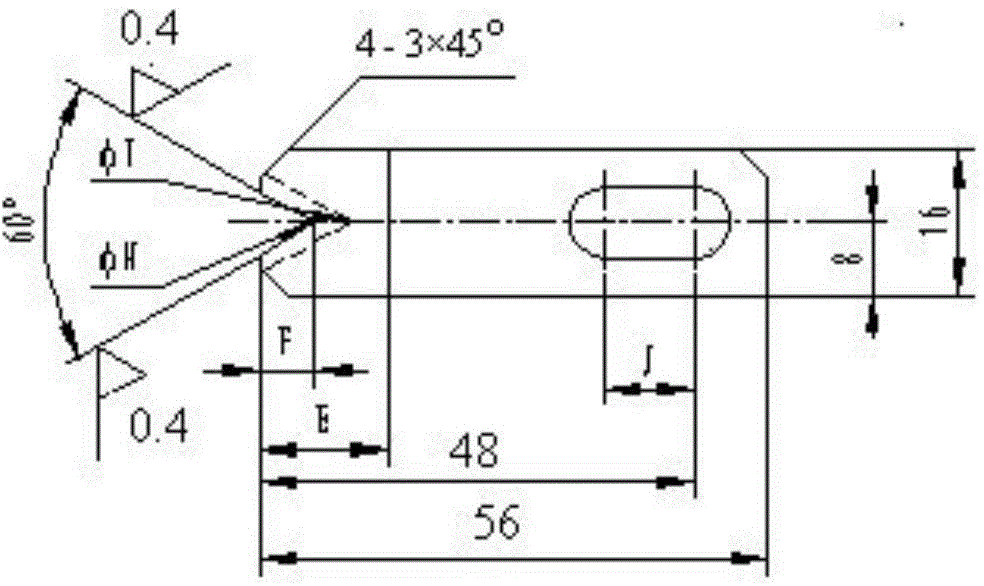

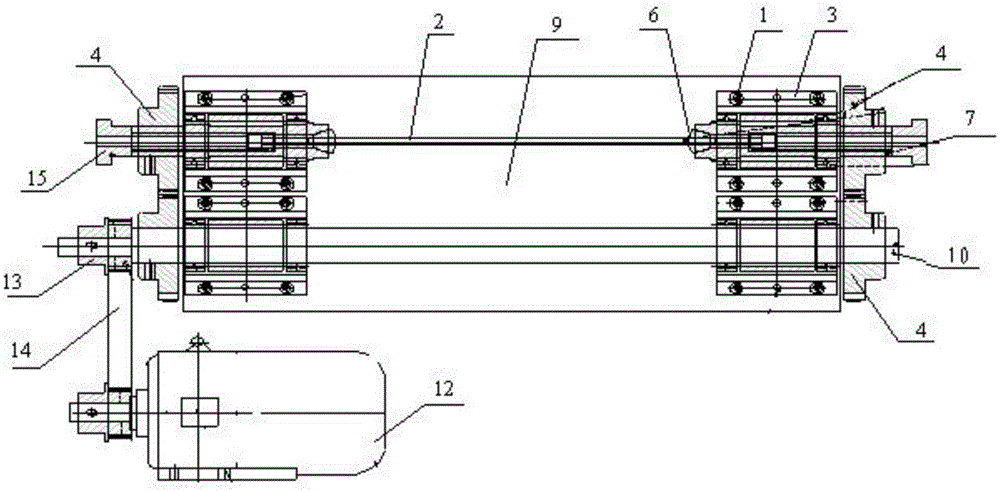

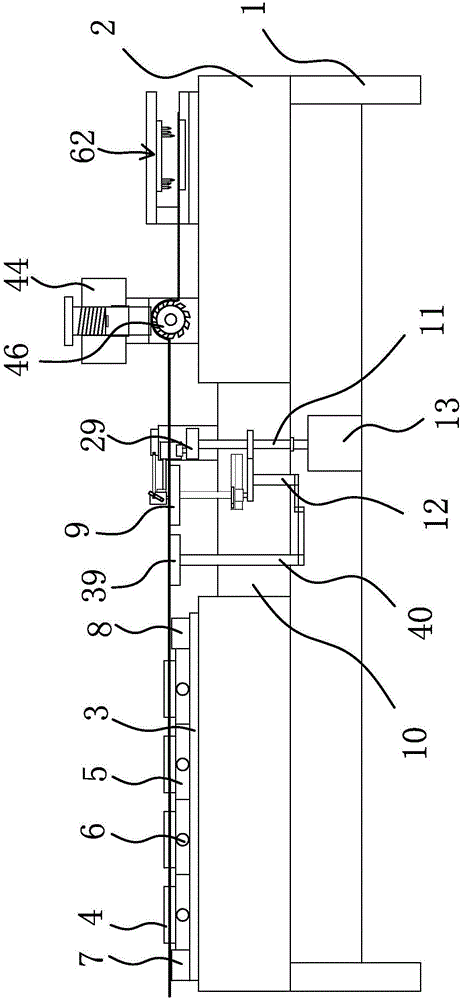

Ultra slender shaft tapered core bar, manufacturing method of ultra slender shaft tapered core bar and manufacturing method of ultra slender tapered spiral line

The invention discloses an ultra slender shaft tapered core bar, a manufacturing method of the ultra slender shaft tapered core bar and a manufacturing method of an ultra slender tapered spiral line. The core bar comprises 30 mm linear segments at the two ends and a 70 mm tapered segment in the middle, the diameter of the linear segment at one end ranges 0.55+ / -0.003 mm, the diameter of the other linear segment at the other end ranges from 0.7 mm + / -0.003 mm, and the taper of the middle tapered segment is 7'27''. The core bar is high in precision, the manufacturing method of the ultra slender shaft tapered core bar is high in operability and can overcome many bottleneck problems in the prior art, the ultra slender shaft tapered core bar which is high in requirements of diameter accuracy and taper accuracy is manufactured, the error is smaller than 0.002 mm, through the core bar, the three-section type ultra slender tapered spiral line with the three sections different in size and taper is manufactured, and the ultra slender tapered spiral line can be applied to traveling-wave tubes which are wide in frequency, high in output power and large in duty cycle and has important application value.

Owner:NANJING SANLE GROUP

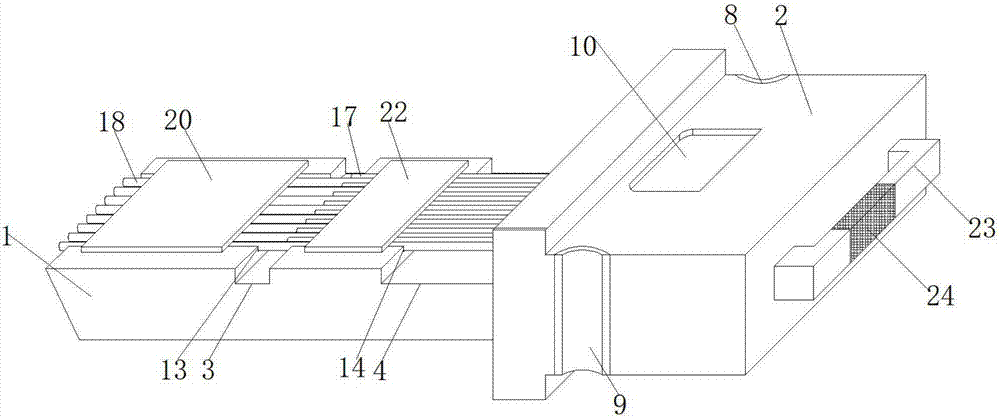

S-spring shaping device

ActiveCN106583605AIncrease productivityShaping speed is fastWire springsEngineeringMechanical engineering

The invention provides an S-spring shaping device, belongs to the technical field of machinery and solves the problem of poor shaping effect in the prior art. The S-spring shaping device comprises a rack and a worktable arranged in the rack, wherein a base with a conveying channel is fixed on the worktable; a rotating shaft is arranged in the conveying channel in a circumferential rotating and axial fixing manner; a mounting pillar is fixed on the rotating shaft; a plurality of driving teeth capable of adjusting the pitch of an S-spring are uniformly fixed on the mounting pillar in the circumferential direction; a limit disc I and a limit disc II which can limit the width of the S-spring are arranged at the two ends of the mounting pillar; a hold-down mechanism which can always press the S-spring on the rotating shaft is arranged on the base; and a driving structure which can drive the rotating shaft to rotate is arranged at one end of the rotating shaft. The S-spring shaping device has the advantage of excellent shaping effect.

Owner:浙江心梦享家居有限公司

Multi-bit drilling machine

InactiveCN105880667AImprove drilling efficiencyHigh pitch accuracyBoring/drilling machinesHydraulic cylinderFixed frame

The invention relates to a multi-bit drilling machine. The multi-bit drilling machine comprises a machine base. A drilling machine frame is movably connected to the machine base. A first hydraulic cylinder is connected to one side of the drilling machine frame. The other side of the drilling machine frame is connected with a drill bit disc. At least one drill bit is arranged on the drill bit disc. A fixing frame is arranged on the portion, at the front ends of the drill bits, of the machine base. A machining hole is formed in the end face of the rear end of the fixing frame. A second hydraulic cylinder is arranged at the front end of the fixing frame in a penetrating mode. A bearing disc is connected to the rear end of the second hydraulic cylinder. The drill bit disc, the first hydraulic cylinder and the second hydraulic cylinder are all connected with a motor through wires. By the adoption of the multi-bit drilling machine, the purposes of drilling a large number of holes in a panel at a time and improving the drilling efficiency can be achieved.

Owner:YUZHOU SHENYUN MACHINERY CO LTD

Fiber array connecting device with transmission and receiving integrated function

ActiveCN107577014AHigh pitch accuracyImprove optical coupling efficiencyCoupling light guidesFiber arrayPrinted circuit board

The invention discloses a fiber array connecting device with a transmission and receiving integrated function. The fiber array connecting device with the transmission and receiving integrated functioncomprises a fiber array substrate and a connecting block; the top of the fiber array substrate is provided with a first vertical groove, and the front surface and the back surface of the first vertical groove penetrate through the fiber array substrate; the top of the fiber array substrate is also provided with a second vertical groove on the right of the first vertical groove, the front surfaceand the back surface of the second vertical groove penetrate through the fiber array substrate, and the right of the second vertical groove penetrates through the right of the fiber array substrate; the left of the connecting block is provided with a groove, and the left inner wall of the groove is fixedly connected with a connecting plate. The fiber array connecting device with the transmission and receiving integrated function comprises a transmission signal fiber, a receiving signal fiber, a transmission signal arranging groove and a receiving groove arranging groove, wherein the transmission signal fiber and the receiving signal fiber are arranged on the same plane, so that wire layout of a PCB (printed circuit board) and coupling of FA (fiber array) can be facilitated, and the fiber arrays can be practical and convenient to use.

Owner:武汉福地科技有限公司

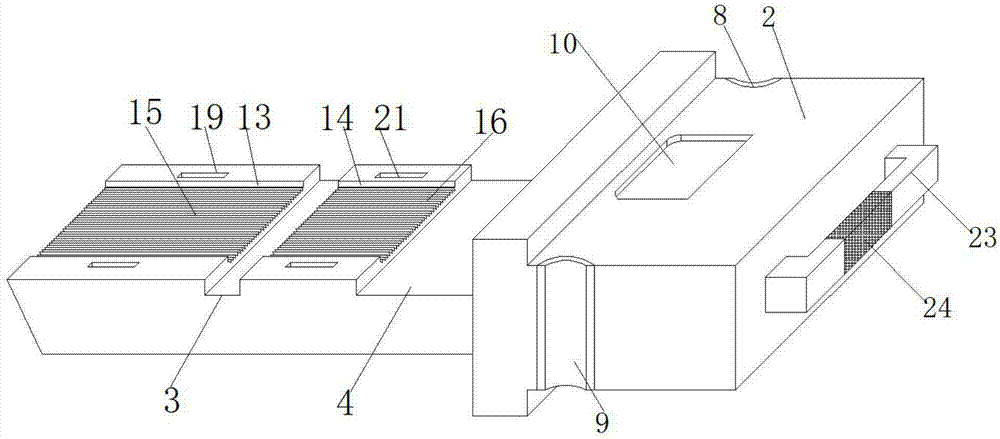

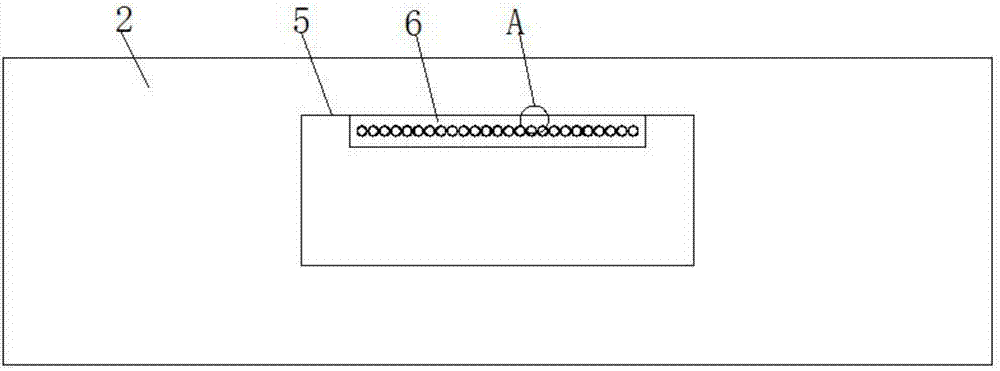

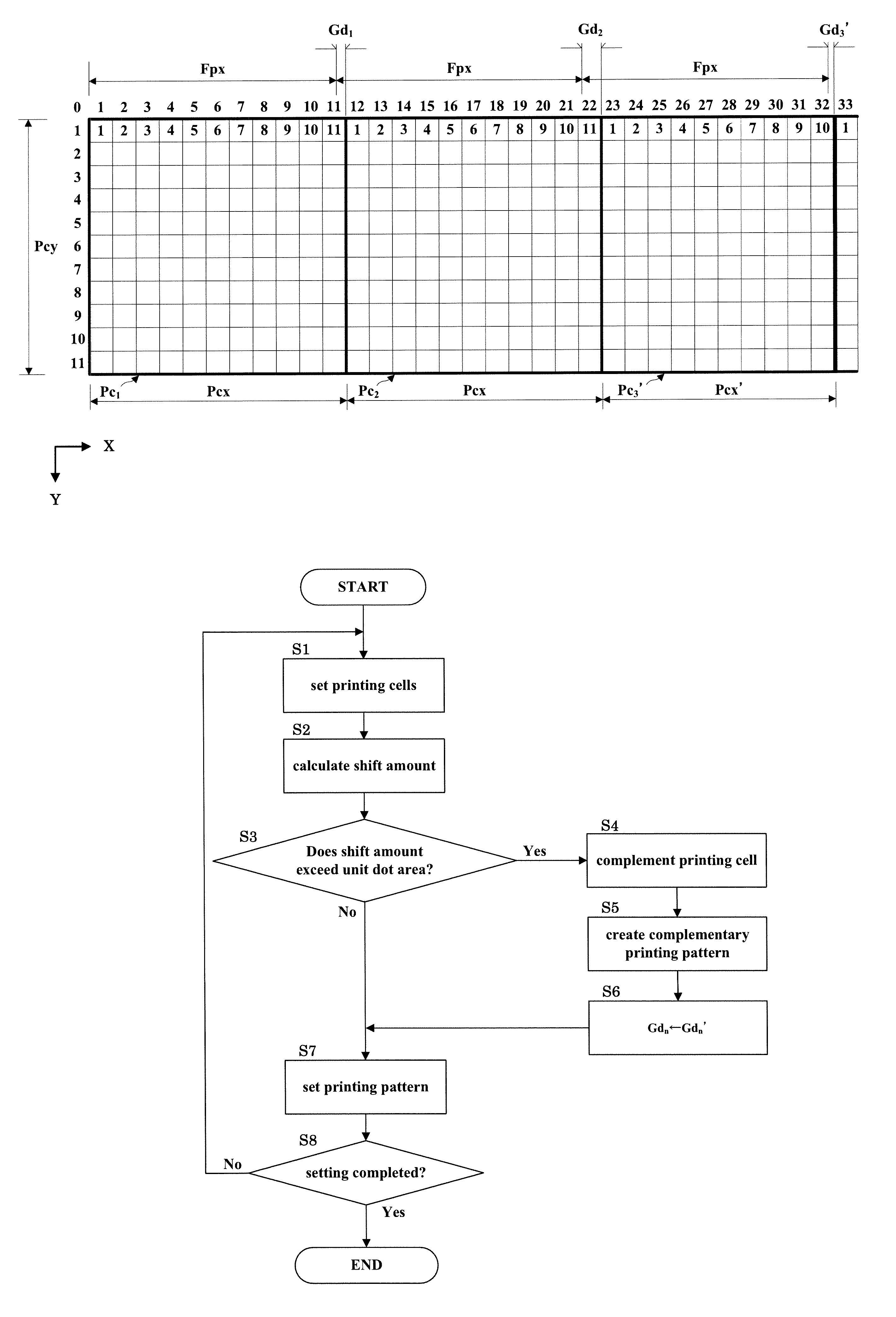

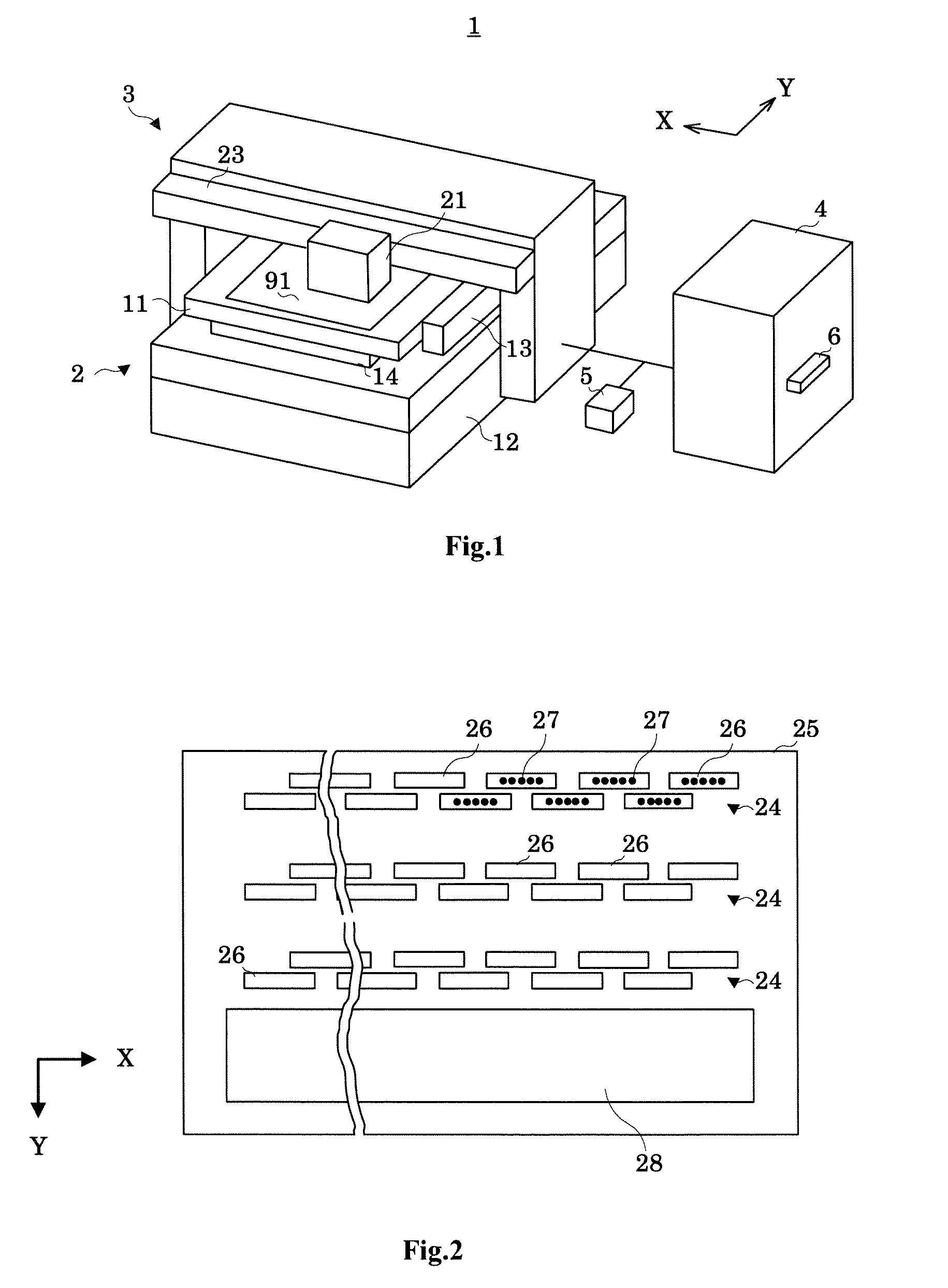

Filter manufacturing apparatus and filter manufacturing method

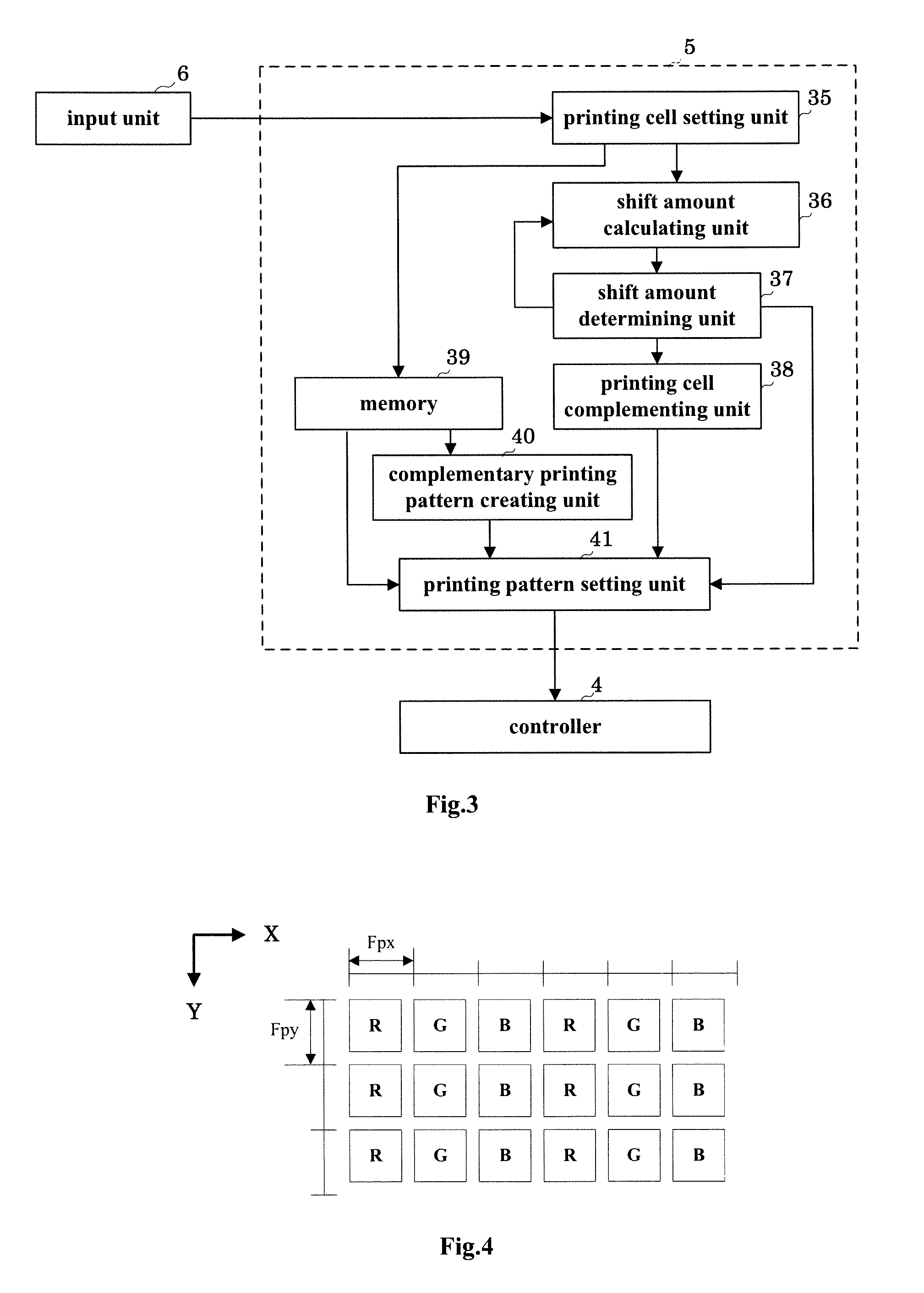

ActiveUS9180687B2High pitch accuracySmall shiftTypewritersOther printing apparatusManufactured apparatusEngineering

A filter manufacturing apparatus includes a printing cell setting unit that sets, based on a predetermined filter pitch and a head resolution, printing cells having an equal number of dot areas in the direction perpendicular to the transport direction of the printing medium, a shift amount calculating unit that calculates shift amounts between the filter pitch and the printing cells in the direction perpendicular to the transport direction of the printing medium, a shift amount determining unit that determines whether shift amounts of the printing cells exceed a unit dot area; and a printing cell complementing unit that complements the shift amounts of the printing cells exceeding the unit dot area by adjusting the number of dot areas included in the printing cells.

Owner:DAINIPPON SCREEN MTG CO LTD

Recyclable low-carbon portable building block die

InactiveCN104912250AAvoid manufacturing errorsEasy to fixBuilding componentsConstruction engineeringLintel

The invention discloses a recyclable low-carbon portable building block die. According to the invention, a building block manufacturing die is standardized and can flexibly move and can be used in a factory or worksite. A die chassis is used as a carrier, can be suitable for storey height according to wall design and is composed of one or two pieces of originally-sized plywood or OSB. A load-bearing frame structured keel below the chassis adopts standard timber, and has consistent size with a building block stud or keel, and reacting force produced by nailing or screw-driving can be absorbed. A movable SIMPSON angle iron-shaped A34 or Z4 right-angle connecting piece can be installed on the surface of the chassis; one end is fixed to the plywood or OSB through screws; and a pair of connecting pieces forms a groove for containing the stud. Through the systematic management and regulation, stipulation and control and calibration of the stud, column and lintel positions, the die chassis can be lifted and put on a stand or turnplate and is ergonomic to minimize occupational injuries, fault waste or rework and raise efficiency and accuracy. Measurement is not required, block production man-hour is shortened and space usage is reduced.

Owner:聂小勤

Systems and methods for quantifying a sound into dynamic pitch-based graphs

InactiveUS9552741B2High pitch accuracyMaintain stabilityElectrophonic musical instrumentsMusicDifference functionHertz

A system and method that quantifies a sound into dynamic pitch-based graphs that correlate to the pitch frequencies of the sound. The system records a sound, such as musical notes. A pitch detection algorithm identifies and quantifies the pitch frequencies of the notes. The algorithm analyzes the pitch frequencies, and graphically displays the pitch frequency and notes in real time as fluctuating circles, rectangular bars, and lines that represent variances in pitch. The algorithm comprises a modified Type 2 Normalized Square Difference Function that transforms the musical notes into the pitch frequencies. The Type 2 Normalized Square Difference Function analyzes the peaks of the pitch frequency to arrive at a precise pitch frequency, such as 440 Hertz. A Lagrangian interpolation enables comparative analysis and teaching of the pitches and notes. The algorithm also performs transformations and heuristic comparisons to generate the real time graphical representation of the pitch frequency.

Owner:QUANTZ COMPANY

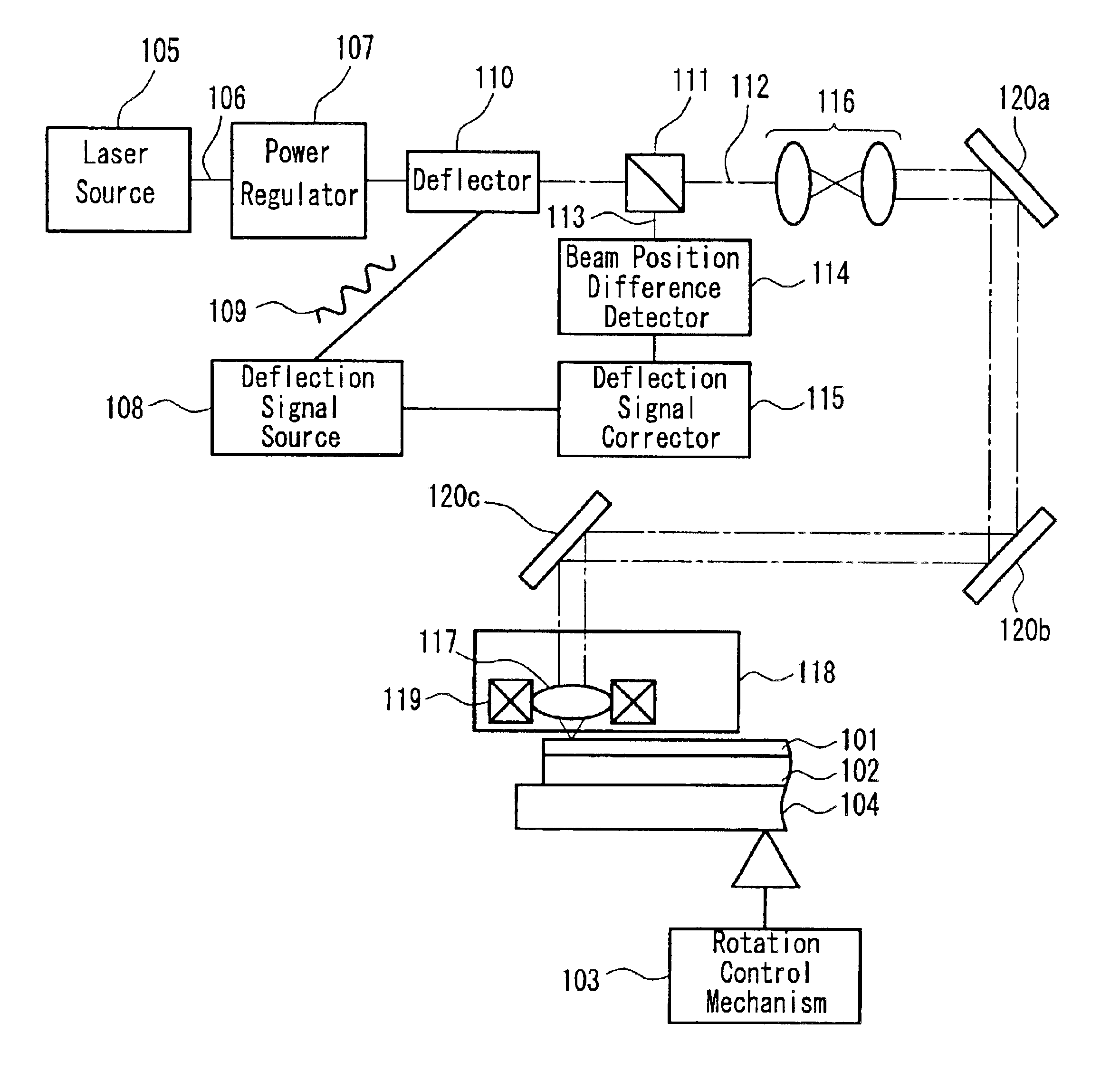

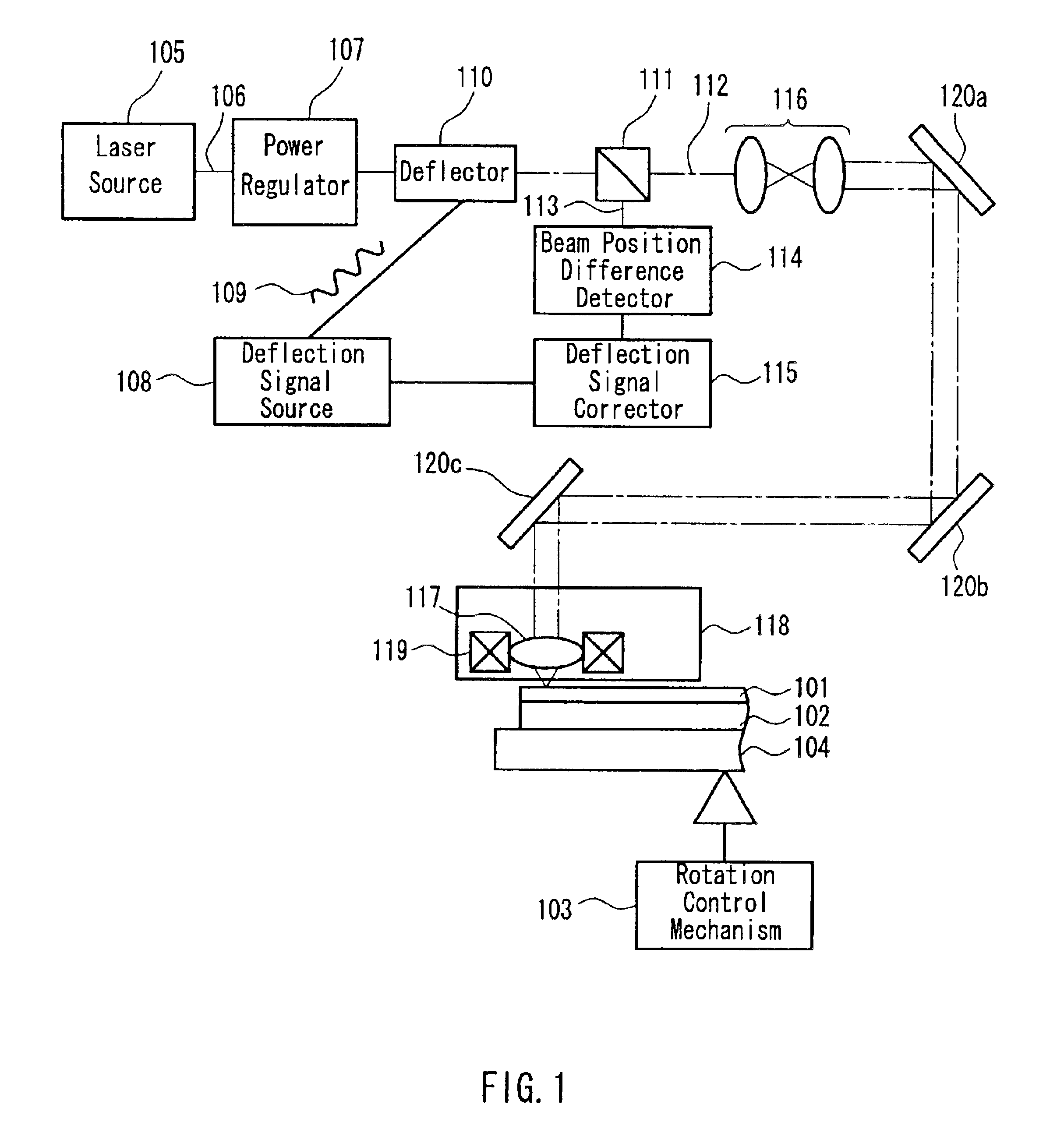

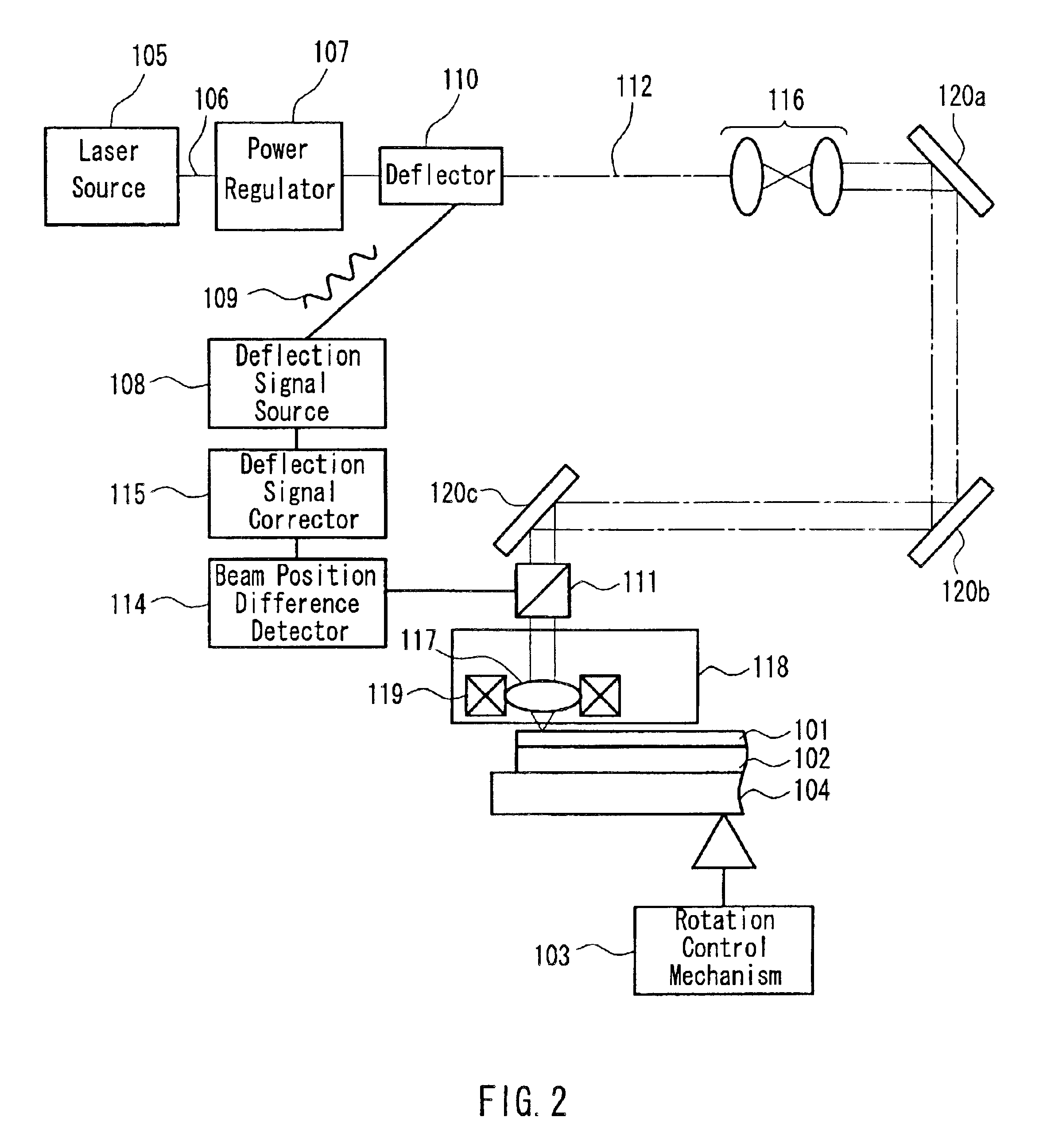

Method and apparatus for exposing optical disk master

InactiveUS6894959B2Improve track pitch accuracyHigh pitch accuracyCombination recordingInformation arrangementResistLight beam

A method for exposing an optical disk master includes rotating a substrate disk coated with a photoresist, focusing a beam on the photoresist for exposure through an objective lens, and exposing the photoresist so as to form tracks on the substrate disk in its circumferential direction. At this time, the beam is deflected at least temporarily by passing through a deflector. The beam is divided into a first beam and a second beam after passing through the deflector, and the first beam is focused on the photoresist. A difference between the current position and the target position of an optical path of the second beam is detected, and the deflection operation of the deflector is corrected based on the difference so that the optical path of the second beam is located at the target position. This method can improve the track pitch accuracy of an optical disk having a narrow track pitch.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com