Device for grinding threads of screw rod and screw rod sleeve

A screw sleeve and screw technology, applied in the direction of thread cutting devices, metal processing equipment, manufacturing tools, etc., can solve the problems of low pitch accuracy, increased labor intensity, and difficult threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

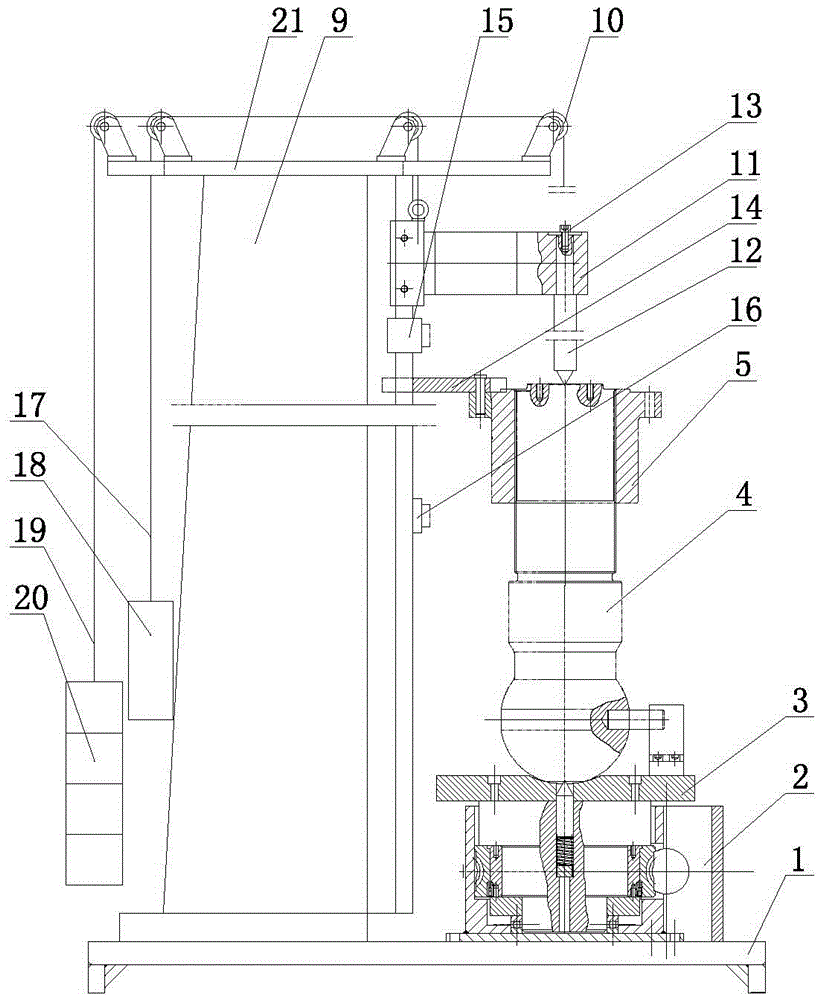

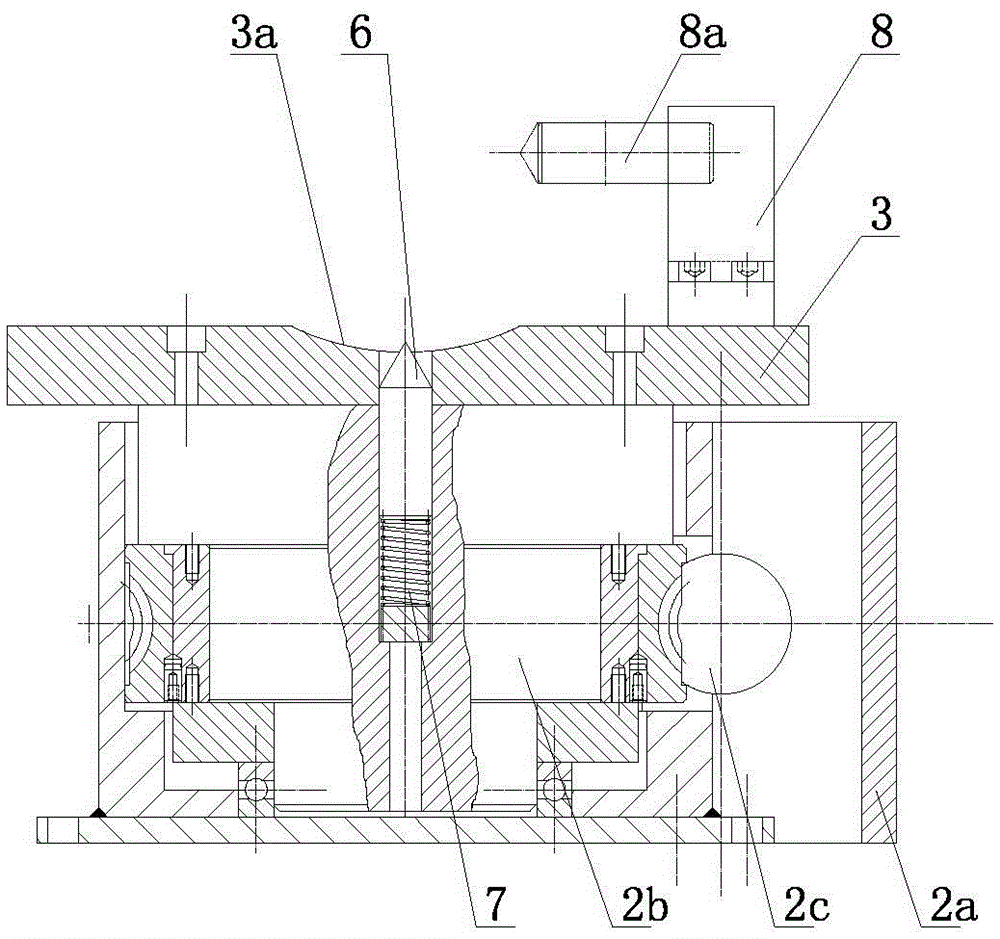

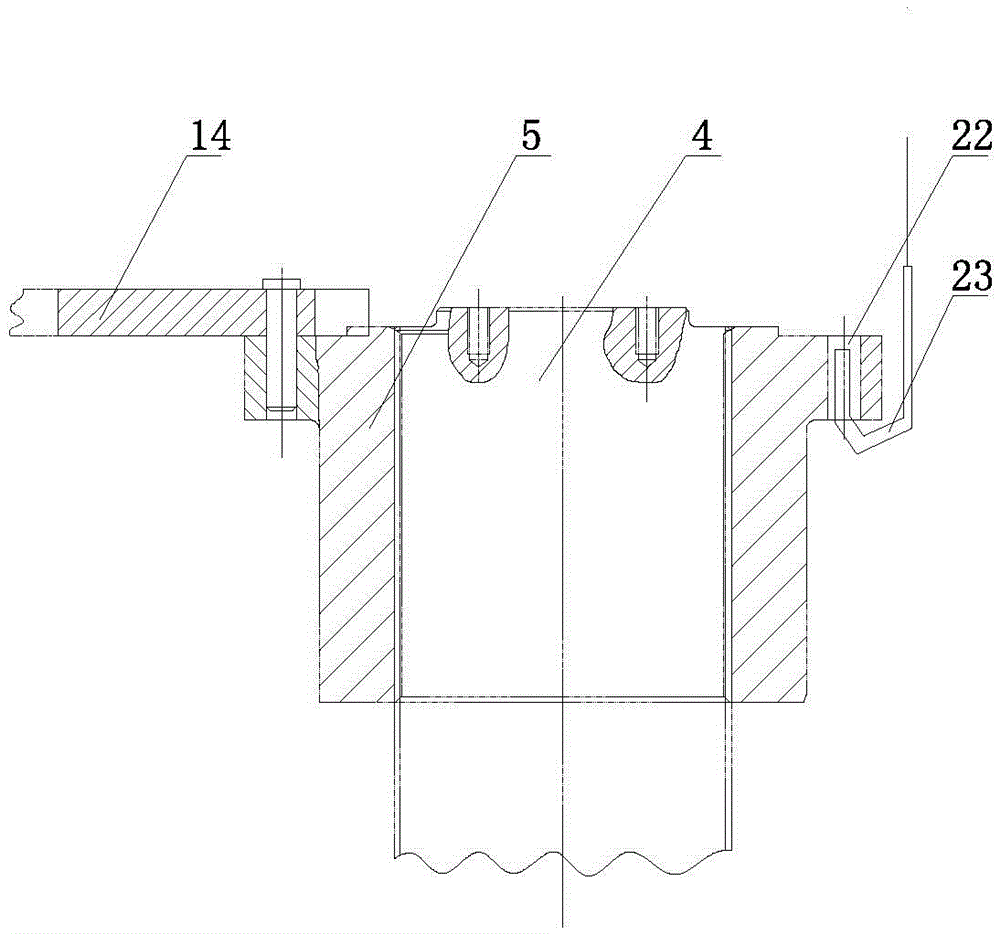

[0019] Such as Figure 1-3 Shown is a device for grinding the threads of a screw and a screw sleeve. It includes a bottom plate 1. The bottom plate 1 is provided with a rotating mechanism 2 with a rotating shaft perpendicular to the surface of the bottom plate 1. The rotating mechanism 2 is fixed to the screw sleeve 5 and the screw 4 to be ground. A horizontal positioning plate 3 is connected. The rotating mechanism is a worm gear mechanism installed in the worm gear box 2a. The positioning plate 3 is fixedly connected above the worm wheel 2b by fasteners; the middle of the positioning plate 3 is provided with the lower end of the screw 4 to be ground The matching positioning groove 3a is provided with a lower thimble 6 connected to the elastic mechanism 7 under the positioning plate 3. The lower thimble 6 passes through the positioning plate 3 and elastically abuts on the lower end of the screw 4 to be ground. The positioning plate 3 is also provided There is a locating pin se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com