Plastic profile line-following punching machine

A technology for plastic profiles and punching machines, which is applied in metal processing and other directions, can solve the problems of punching machine vibration, slow punching machine return, and many wastes, etc., and achieves improved punching efficiency, high punching accuracy, and high spacing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

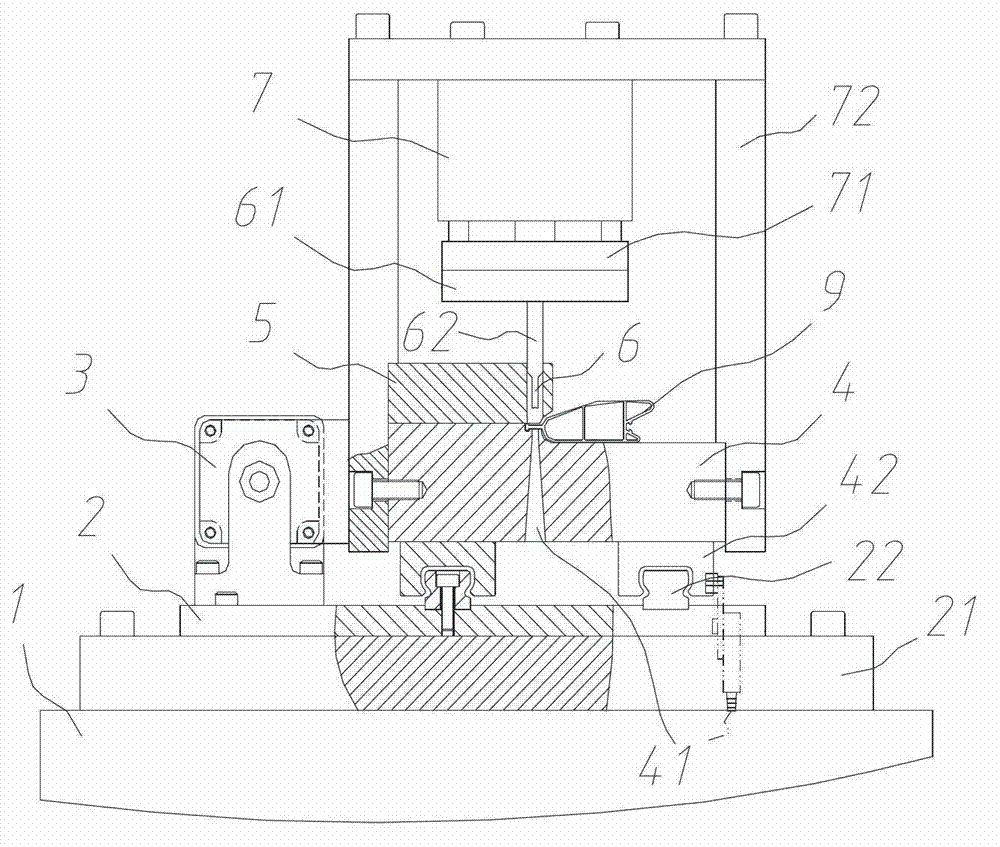

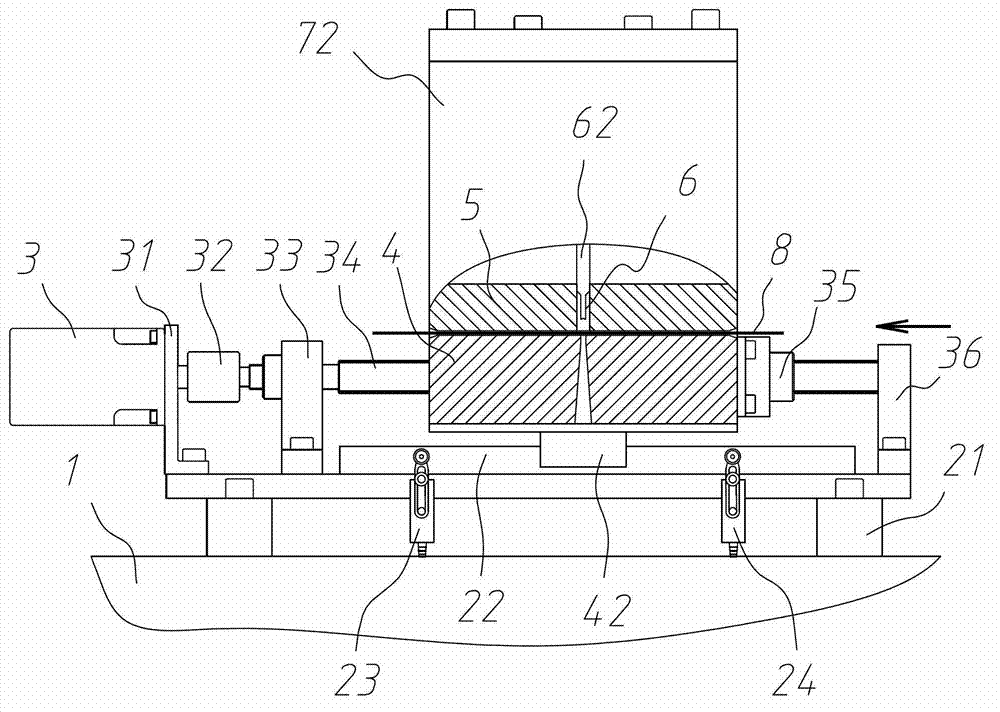

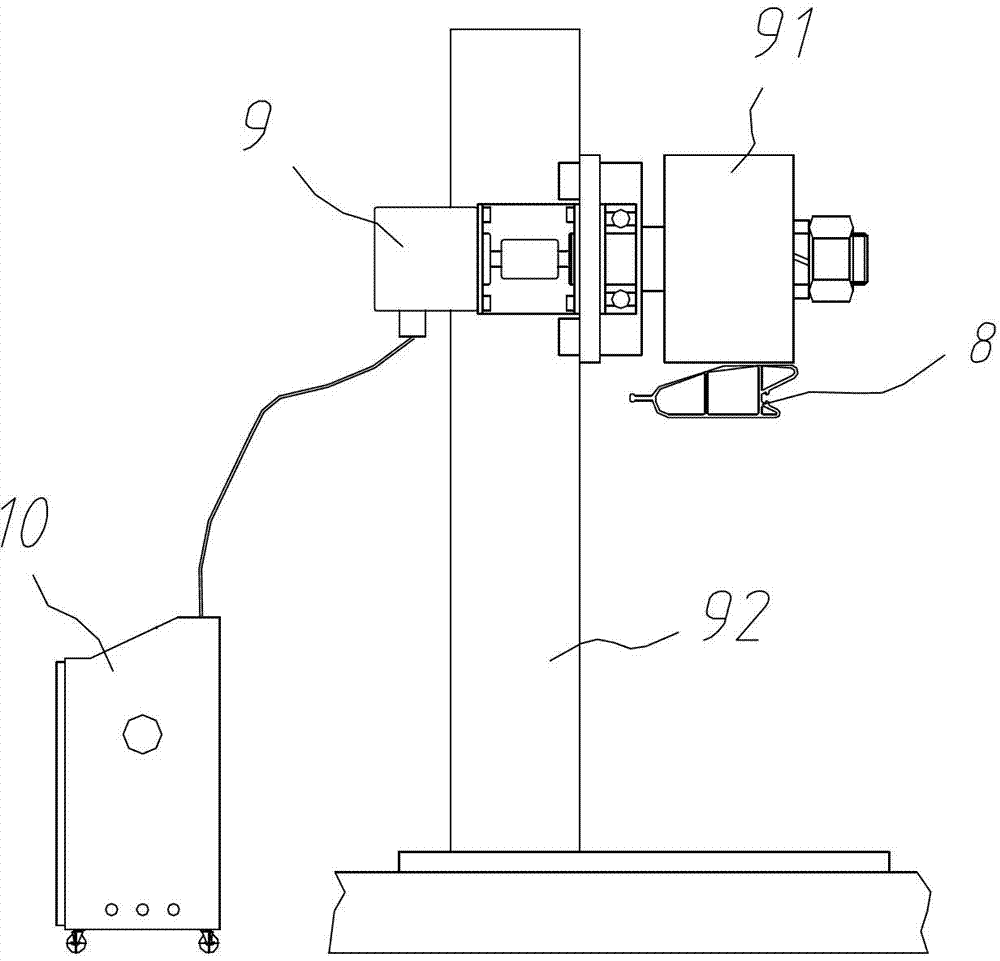

[0012] Such as figure 1 and figure 2 As shown, the two ends of the base 2 are fixed on the profile shaping table 1 at the end of the cooling water tank of the profile production line by the supporting feet 21, and a pair of parallel heavy-duty linear guide rails 22 are fixed on the upper end of the base 2 along the moving direction of the profile 8. The punching die is composed of a die 4, a punch 6 and a cylinder 7. The bottom of the die 4 is fixed with a slide block 42 respectively matched with a pair of linear guide rails 22; The mold 6 is fixed on the piston rod 71 of the cylinder 7 through the punch fixing plate 61; the upper end of the die 4 is fixed with a punch guide device, which is a guide plate 5 arranged above the die 4, and the guide plate 5 can be fixed On the die 4 or on the cylinder holder 72 , the guide plate 5 is provided with a vertical guide hole that matches the shape of the male die handle 62 .

[0013] The driving device for driving the die 4 to perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com