Recyclable low-carbon portable building block die

A portable, mold-based technology, applied in construction, building components, building structures, etc., can solve problems such as joint error module accuracy is not ideal, defects or need to be reworked, waste of materials, labor and time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

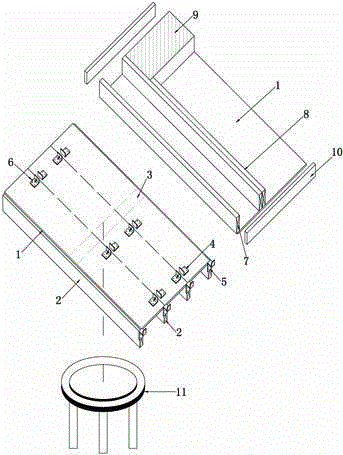

[0006] The design and implementation method of the present invention mainly provides a recyclable low-carbon portable building module mold, which is composed of a chassis panel, a skeleton and a control wall column angle steel component. Its chassis (1 in the figure) is used as the entire production module mold. According to the building wall design drawings to adapt to different layer heights, use one or two combinations of original size plywood or OSB boards, with a thickness of at least 12mm (15mm or 19mm) to maintain the flatness of the board surface, and its size is 1220mm wide and 1220mm long 2440mm or 3050mm or 3660mm can be recycled and reused without cutting and waste. The wood-based panel material is convenient for screw locking or removal of the connector, which can be recycled and reused to save materials. Mold chassis plywood or OSB board stability (1 in the picture), which is guaranteed by the joint of the load-bearing frame structure keel (2 in the picture) und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com