Permanent magnet motor

A permanent magnet motor and stator technology, applied to synchronous motors with stationary armatures and rotating magnets, electrical components, electromechanical devices, etc., can solve the problems of poor motor performance, jitter, movement, and large accumulated errors, etc. Achieve easy accuracy requirements, reduce processing difficulty, and reduce concentricity errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

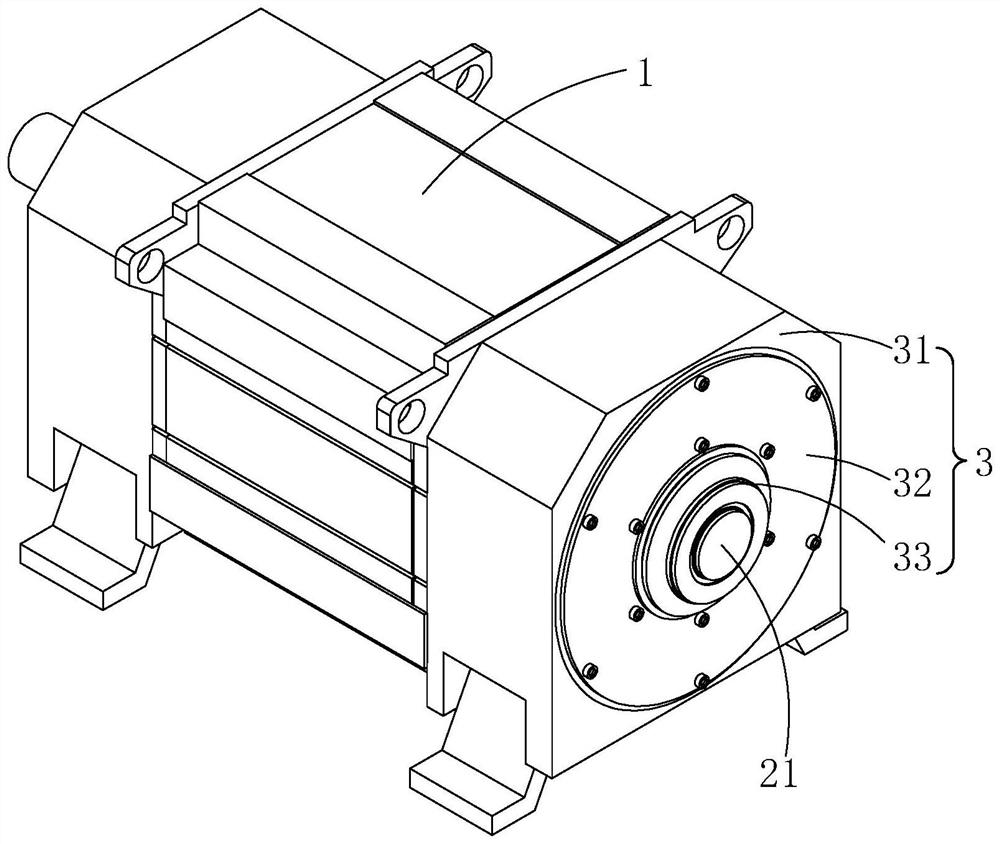

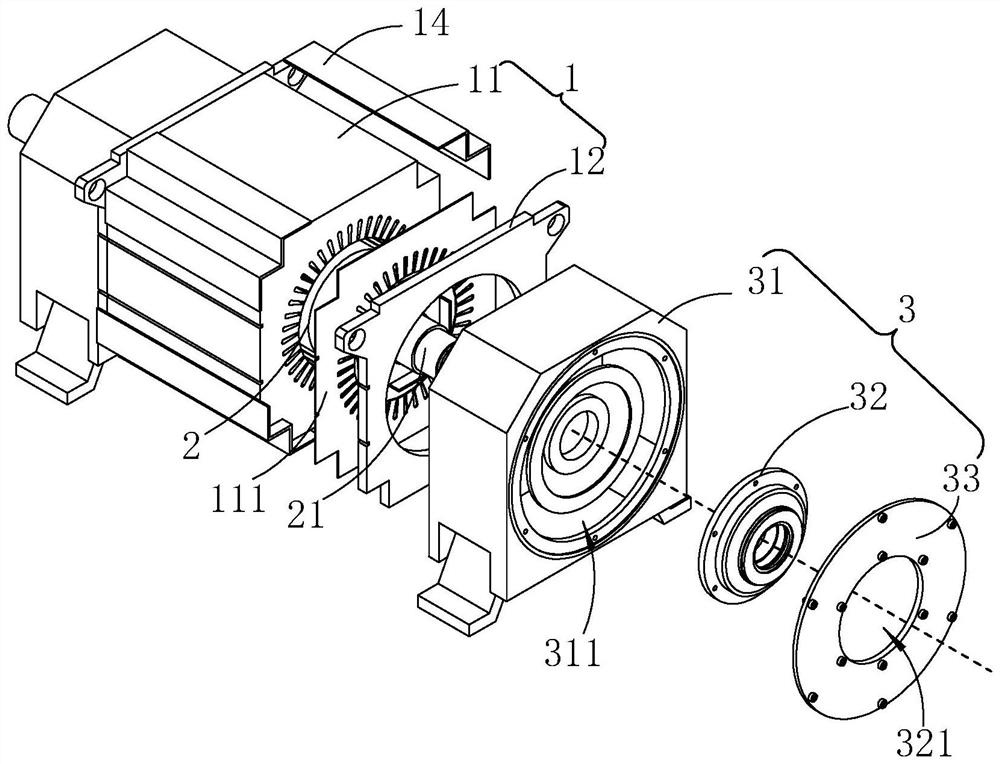

[0043] refer to figure 1 and figure 2 A permanent magnet motor includes a stator 1, a rotor 2 and an end cover 3, the end cover 3 is welded to the end face of the stator 1, the rotor 2 is connected with a rotating shaft 21, and the rotating shaft 21 is installed on the end cover 3.

[0044] The stator 1 includes a body 11 and an end plate 12, wherein the body 11 is formed by stacking and welding a plurality of unit pieces 111. The axial projection of the body 11 is polygonal, and a V-shaped groove 13 is recessed in the area where the corners of the polygon are located. In this implementation, the projection takes a regular quadrilateral as an example, a V-shaped groove 13 is provided at each corner, and the included angle of the walls of the V-shaped groove 13 is 90°. The end plates 12 are welded to both ends of the body 11 in the axial direction, and a W-shaped angle plate 14 is arranged between the two end plates 12. The W-shaped angle plate 14 covers the V-shaped groove 1...

Embodiment 2

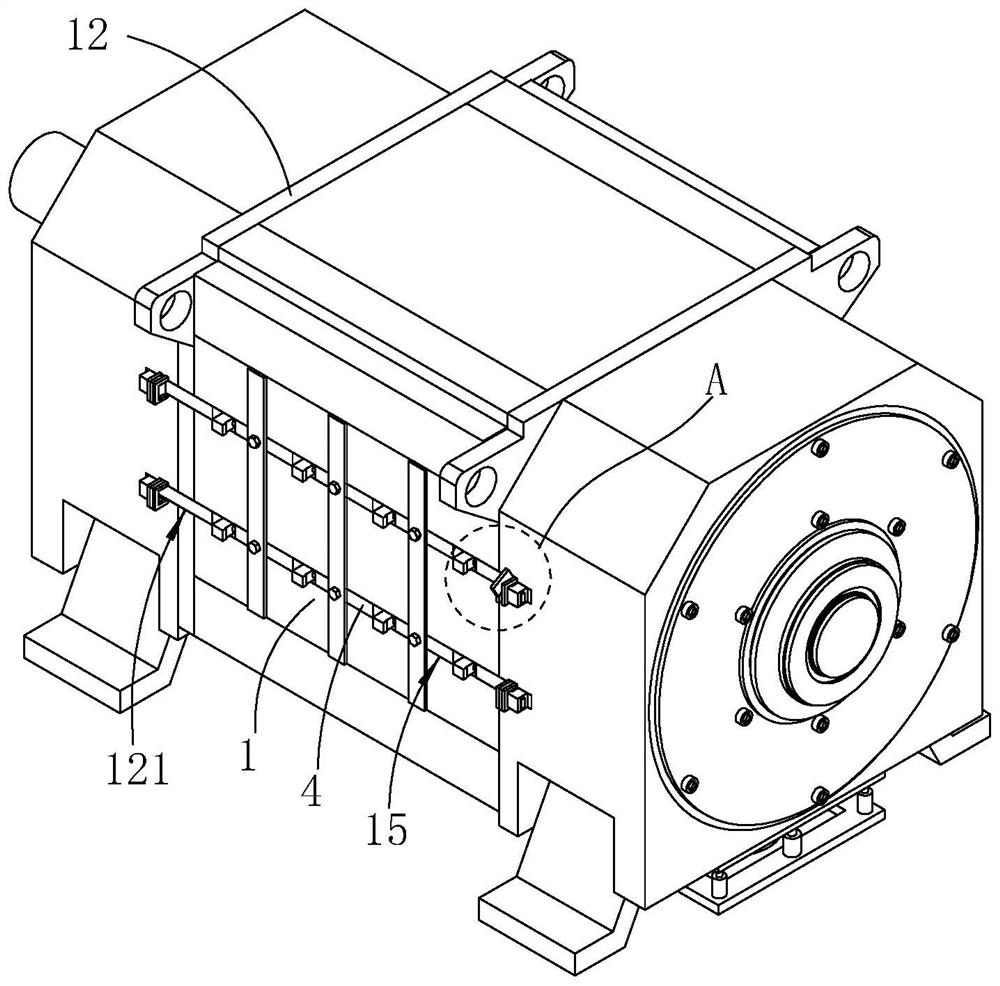

[0050] refer to image 3 and Figure 4 , the difference between this embodiment and embodiment 1 is that

[0051] The side wall of the stator 1 is provided with side slots 15 extending in the axial direction, and each side wall of the stator 1 is arranged with at least two side slots 15, and this embodiment takes two side slots 15 as an example. The side slot 15 is embedded with the side bar 4, and the shapes of the side slot 15 and the side bar 4 projected along the axial direction of the stator 1 are both square.

[0052] Positioning blocks 41 protrude from the side wall of the side bar 4 , and a plurality of annular grooves 42 arranged axially along the stator 1 are provided on the peripheral side wall of the side bar 4 . The side rod 4 is sleeved with a pressure block 43 and a swivel sleeve 44 in the annular groove 42 , wherein the swivel sleeve 44 is threadedly connected with the side rod 4 , and the outer wall of the swivel sleeve 44 does not exceed the annular groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com