Return trip universal adjustable combined ejector wheel device for round pipe belt conveyor

A round pipe belt type, conveyor technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of collapsed belts and overlapping belts, economic losses, tearing tapes, etc., to prevent belt collapse and overlapping belts , prolong the service life, and solve the effect of manufacturing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the accompanying drawings, the technical solutions in the present invention are clearly and completely described. The described embodiments are only a part of the present invention. All other inventions and creations obtained belong to the protection scope of the present invention.

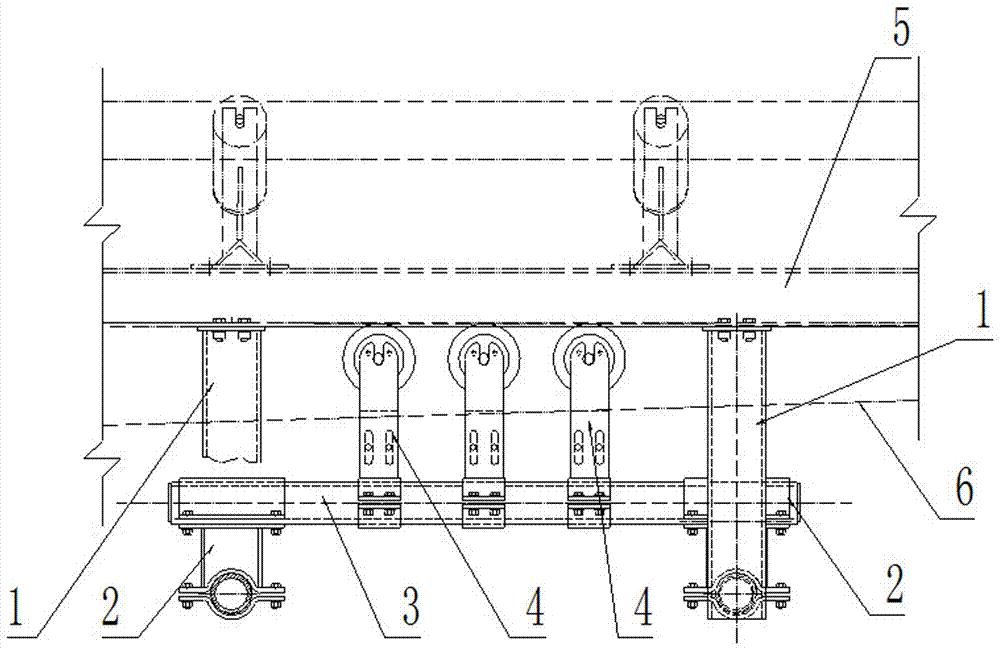

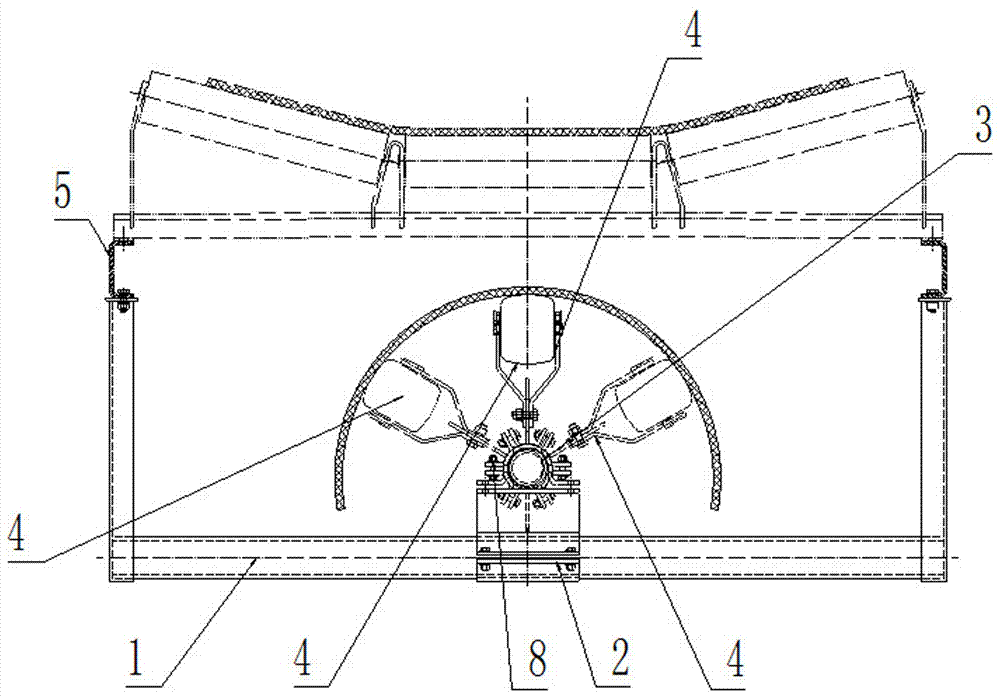

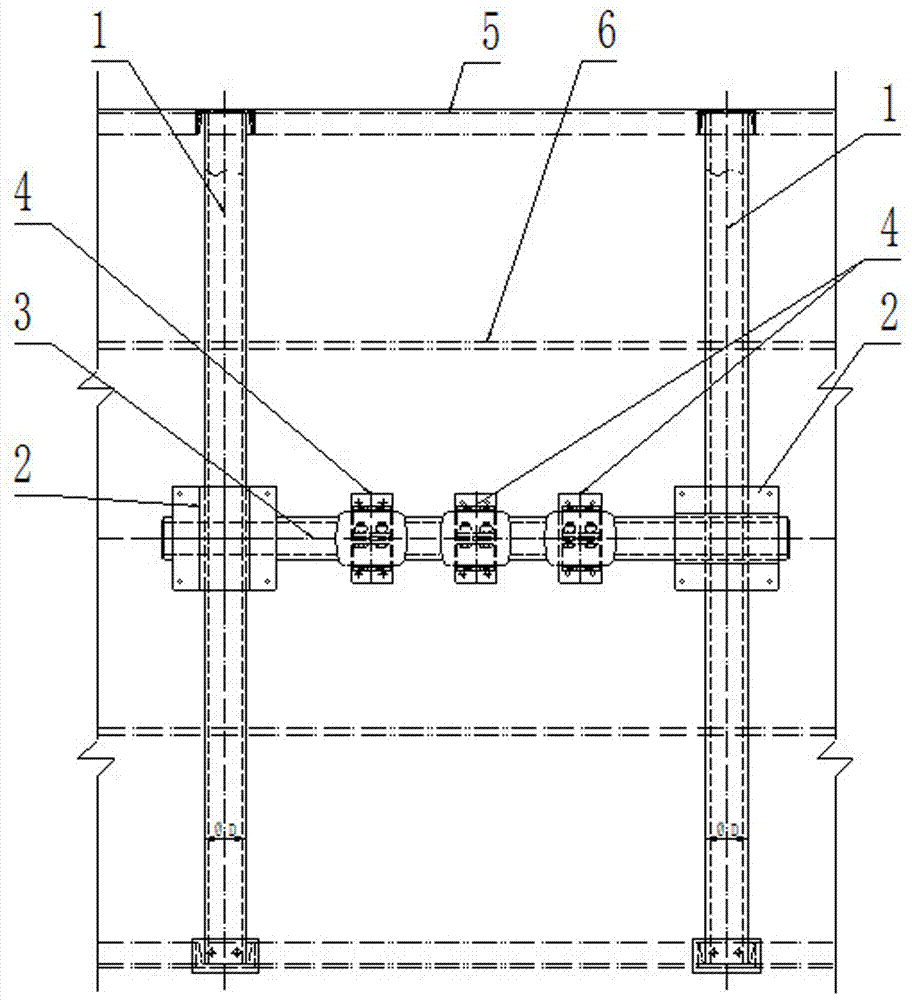

[0021] Such as figure 1 — Figure 9 As shown, the return universally adjustable combined top wheel device for the round pipe belt conveyor of this embodiment includes a fuselage longitudinal beam frame 5, and is characterized in that: the universally adjustable combined top wheel device also includes a mounting The hanger assembly 1, the adjustable Huff type support assembly 2, the longitudinal support steel pipe guide rod 3 and the adjustable top wheel assembly 4 below the longitudinal beam frame 5 of the fuselage.

[0022] Depend on figure 1 — Figure 4 It can be seen that the hanger assembly 1 of this embodiment has a "U"-shaped structure, and there are two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com