Ultra slender shaft tapered core bar, manufacturing method of ultra slender shaft tapered core bar and manufacturing method of ultra slender tapered spiral line

A slender shaft and helix technology, which is applied in the field of helix preparation, can solve the problems of performance degradation, high frequency damage of helical traveling wave tubes, and high precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

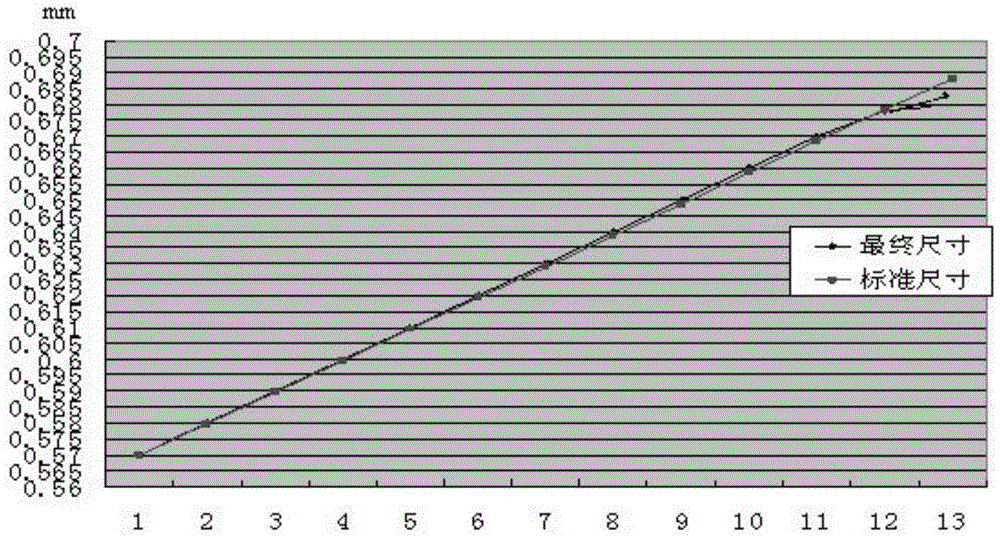

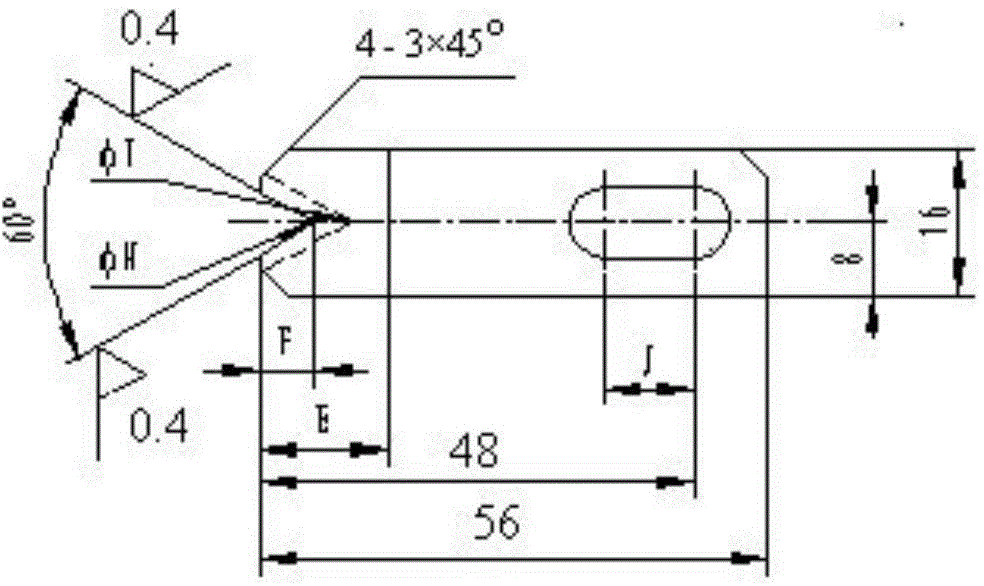

[0060] An ultra-slender long-axis tapered core rod, which includes a straight section of 30mm at both ends and a tapered section of 70mm in the middle, the diameter of the straight section at one end is 0.55 ± 0.003mm, and the diameter of the straight section at the other end is diameter 0.7±0.003mm, the taper of the middle tapered section is 7′27″.

Embodiment 2

[0062] A preparation method of an ultra-slender long-axis tapered core rod, comprising the following steps:

[0063] a. Take a polished molybdenum rod (2) with a diameter of 1mm and a length of 170mm, clamp it into the collet (6), and tighten it through the fixing rods (15) at both ends.

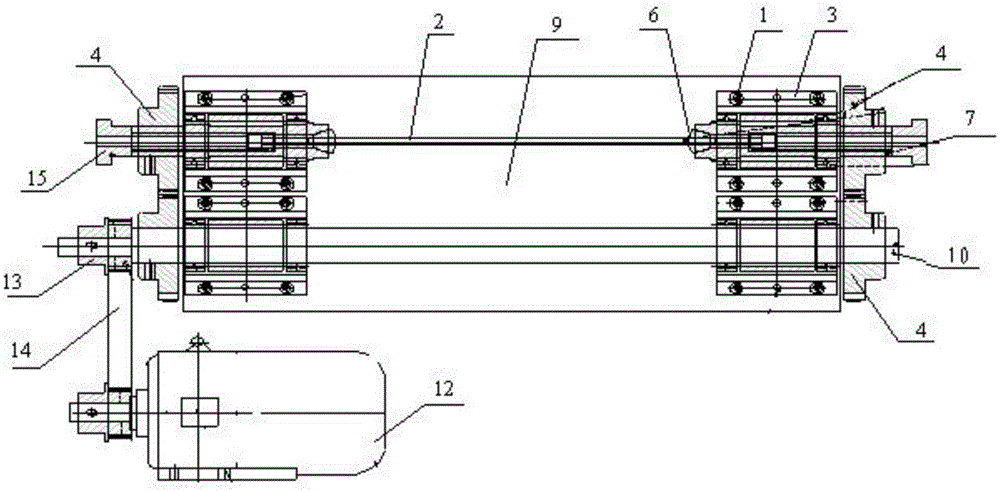

[0064] b. Steps of EDM core rod grinding:

[0065] Such as image 3 As shown, fix the EDM fixture base (3) on the EDM base plate (9) by the fixing screw (1), turn on the DC adjustable speed motor (12), and control it between 300 and 500rpm, the adjustable speed motor (12) drive the transmission shaft (10) to rotate through the synchronous toothed belt (14) and the synchronous toothed wheel (13), and the transmission shaft (10) transfers the power of the DC adjustable speed motor (12) through four gears (4) The shafts (7) transmitted to both ends drive the collets (6) at both ends and the molybdenum rods (2) clamped on the collets (6) to rotate synchronously;

[0066] Then use a 130mm wide...

Embodiment 3

[0072] A method for preparing an ultra-slender tapered helix, comprising the following steps:

[0073] Such as figure 2 and Figure 4 Shown:

[0074] a. Take the two ends of the ultra-slender long-axis tapered mandrel (13) described in the above embodiment 1 and fix it on the servo motor (14), install the tapered support nozzle clamp (15) on the high-precision spiral winding machine , and ensure that it closely fits with the ultra-slender tapered helical core rod, the tungsten strip (16) is pulled out through the pay-off mechanism (17), and then the tension is checked by the tension detection device (18), and the electric heating device ( 19) heating the tungsten strip (16), and then winding it on the ultra-slender long-axis tapered mandrel (13);

[0075] b. Place the helical wire wound in step a in a hot alkaline solution, use an ultrasonic cleaner to remove greasy and foreign matter on the surface of the helical wire, and after ultrasonication for about 10 to 15 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com