Cylindrical steel reinforcement cage quick precise connection machining formwork and manufacturing method for steel reinforcement cages

A steel cage and cylindrical technology, which is applied in the field of fast and accurate connection processing formwork for cylindrical steel cages and the production of steel cages, can solve the problems of unqualified steel bar spacing, difficult docking of steel cages, high processing costs, etc., and achieve the accuracy of main bar spacing High, low processing cost, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with embodiment:

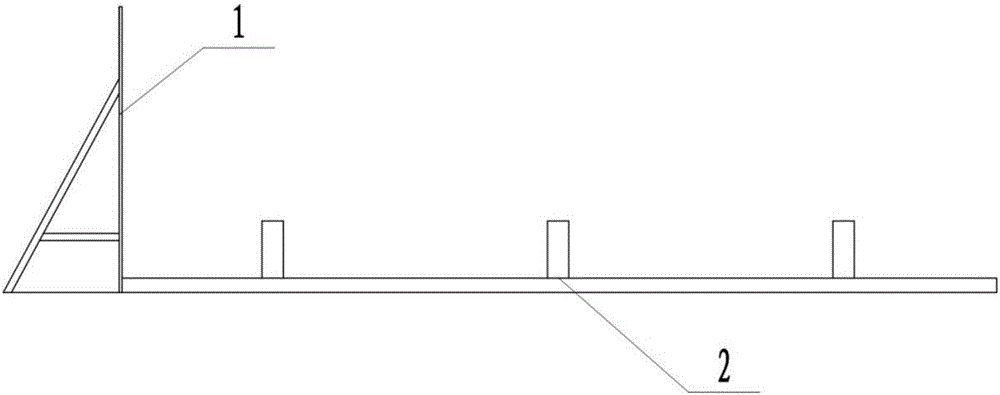

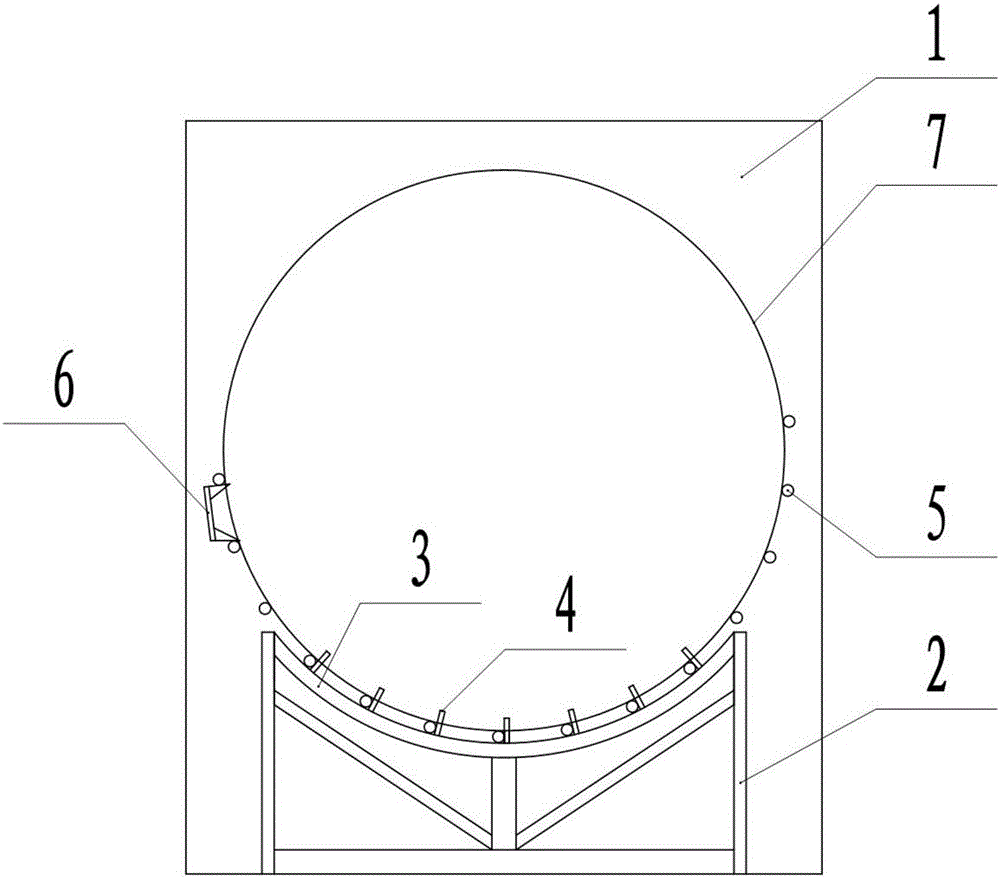

[0014] Such as figure 1 with figure 2 As shown, the present invention provides a cylindrical steel cage fast and accurate connection processing formwork, including a positioning baffle 1, an operating platform 2, a steel cage steel ring 3 and a positioning rib 4, and the positioning baffle 1 is arranged on the operating platform 2 At one end, the positioning baffle 1 is perpendicular to the ground, and the steel cage steel ring 3 is arranged on the operating platform 2. The steel cage steel ring 3 is concave arc-shaped, and its diameter matches the diameter of the processed steel cage. The number of 3 is not less than 2, and the central connection line is perpendicular to the positioning baffle 1, the positioning rib 4 is arranged on the inner side of the steel cage steel ring 3, and the spacing of the positioning rib 4 is set to be the same as the spacing of the main rib 5 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com