Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "High particle content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic Molding Material and Molding Elements Containing Nanometric Inorganic Particles for Making Said Molding Material and Said Molding Elements, and Uses Thereof

InactiveUS20080161469A1Promotes fine dustDevelopment of fine dust can be kept low or completely avoidedMaterial nanotechnologyConductive materialThermoplasticMolten state

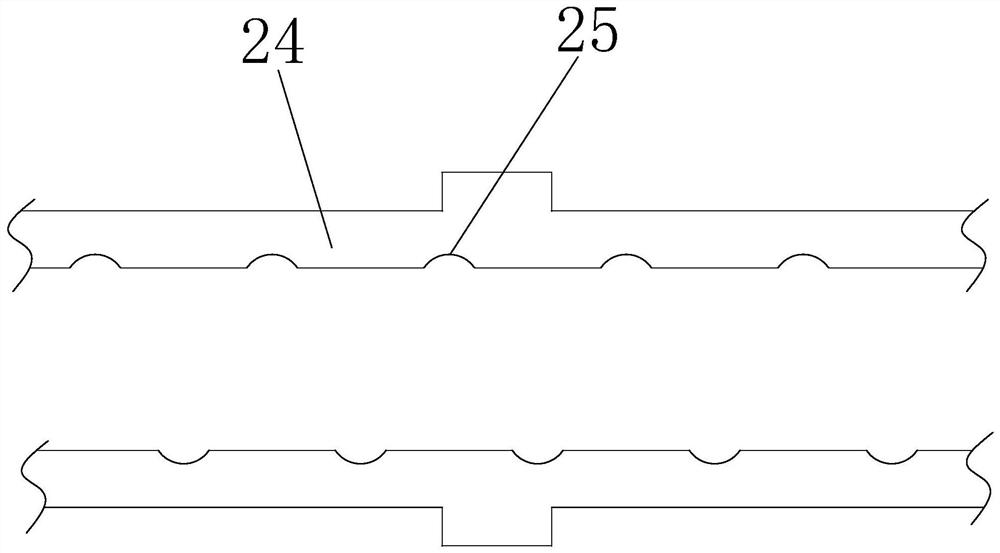

(EN) The invention concerns a method for producing a thermoplastic molding material or element, said material or element containing nanometric inorganic particles. In molten state, the thermoplastic is mixed with the nanometric inorganic particles and with a solubilizing agent in a conveyor screw extruder, the pressures and temperatures being adjusted so that the plastic is in melt form and the solubilizing agent in supercritical state. The invention is characterized in that at the output of the extruder, the mixture passes through a slot with a passage less than 20 $g(m)m to penetrate into an expansion zone and the molten material, wherein are incorporated the nanometric inorganic particles, is evacuated, reduced into molding material after cooling or transferred into a molding tool to be molded. The invention also concerns the molding material and the molding elements obtained by this method, as well as the uses thereof.

Owner:EVONIK ROEHM GMBH

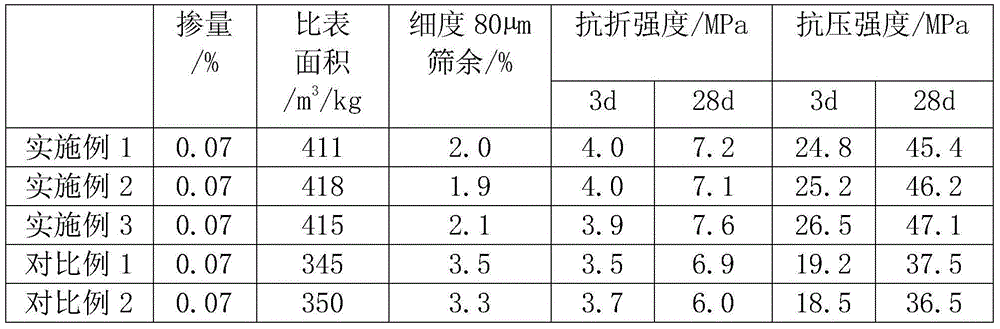

Reinforced cement grinding aid

The invention discloses a reinforced cement grinding aid which comprises the following ingredients in parts by weight: 10-15 parts of diethanolisopropanolamine, 3-5 parts of triethanolamine, 4-6 parts of sodium acetate, 6-10 parts of sodium thiosulfate, 10-12 parts of sodium chloride, 4-6 parts of sodium carboxymethylcellulose and 15-18 parts of papermaking black liquid. The reinforced cement grinding aid is low in mixing amount, good in reinforcement effect and low in cost.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for preparing poly alpha-olefin drag reduction agent suspension

ActiveCN101544766AFast dissolutionHigh particle contentPipeline systemsReduction ratePolymer science

The invention relates to the preparation of organic macromolecule compounds and the technical field of pipeline systems, in particular to a method for preparing a poly alpha-olefin drag reduction agent suspension. A solvent comprises 15-45 percent of poly alpha olefin particles, 5-15 percent of long carbon chain amide, 50-60 percent of solvent, 1-5 percent of surface active agent, 0.1-2 percent of thickening agent, and 10-20 percent of suspending agent and stabilizing agent according to the proportion when the total weight of the solvent is 100, and long carbon chain amide powder particles are fully contacted in the solvent containing at least one surface active agent and emulsified at a certain temperature, and the alpha-olefin drag reduction agent suspension is obtained by adding ground poly alpha-olefin particles with super high molecular weight and at least one of a surface active agent, a suspending agent, a stabilizing agent and a dispersing agent into the emulsified solvent. The suspension prepared by the method has long storage cycle, high content of poly alpha-olefin particles, large drag reduction rate, and low transportation and preparation costs.

Owner:PIPECHINA SOUTH CHINA CO

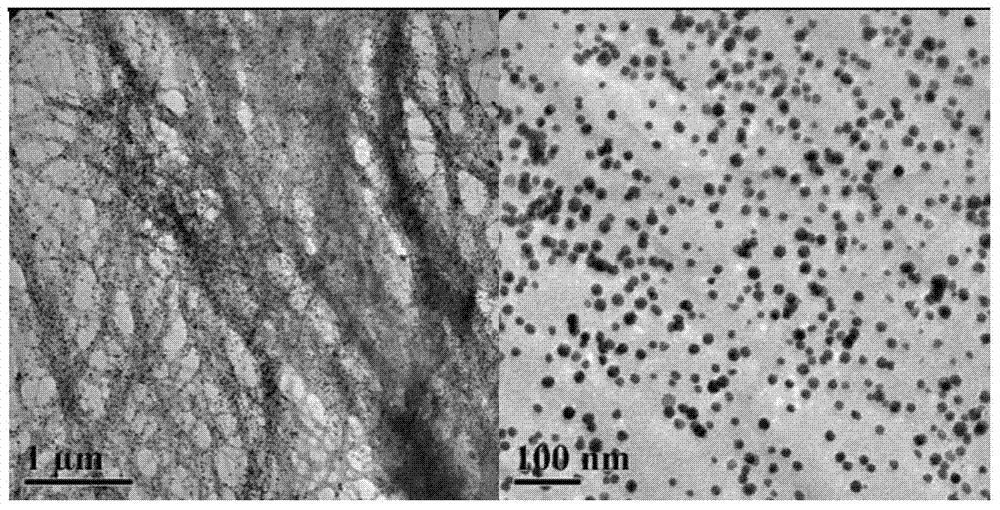

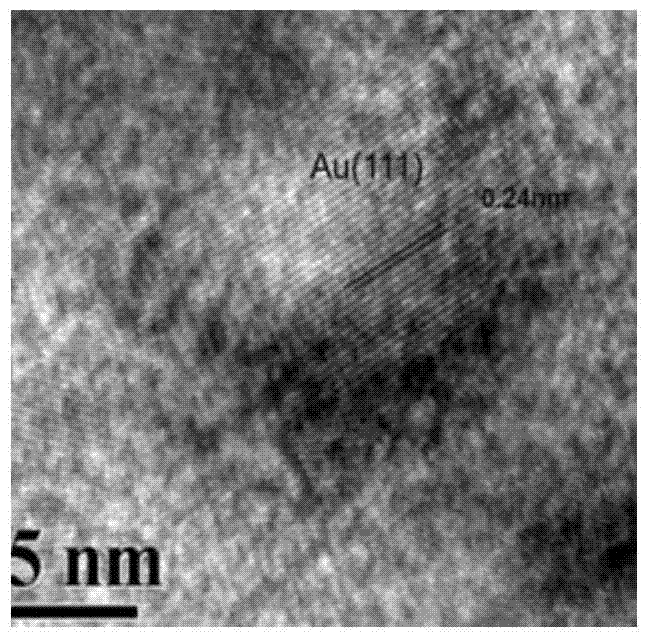

Biomass load type nano-metal catalyst and preparation method and application thereof

ActiveCN104492486AHigh load rateHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsUnit massMetal catalyst

The invention provides a biomass load type nano-metal catalyst and a preparation method and application thereof. The catalyst is MNPs@AOFC, and the loading capacity of MNPs is 1.6-25.8 mg / g. The metal is a precious metal or CU, and the particle size of the metal nano particle is 3-60 nm. In amidoxime group functionalized cellulose, the mass content of the amidoxime group is 3.88-16.84%; the cellulose is bacterial cellulose. The AOFC carrier both serves as a reducing agent and a stabilizer, reaction is carried out for 2 hours under a hydrothermal condition to uniformly load the metal nano particles on the surface of the AOFC carrier, and amidoxime groups with different mass percents can be controlled to obtain the catalyst of the metal nano particles with different particle sizes. The catalyst has good stability, and the metal catalyst with a unit mass can continuously reduce more than 3500 times of p-nitrophenol. The catalyst can be applied to catalytic reduction reaction.

Owner:INST OF CHEM CHINESE ACAD OF SCI

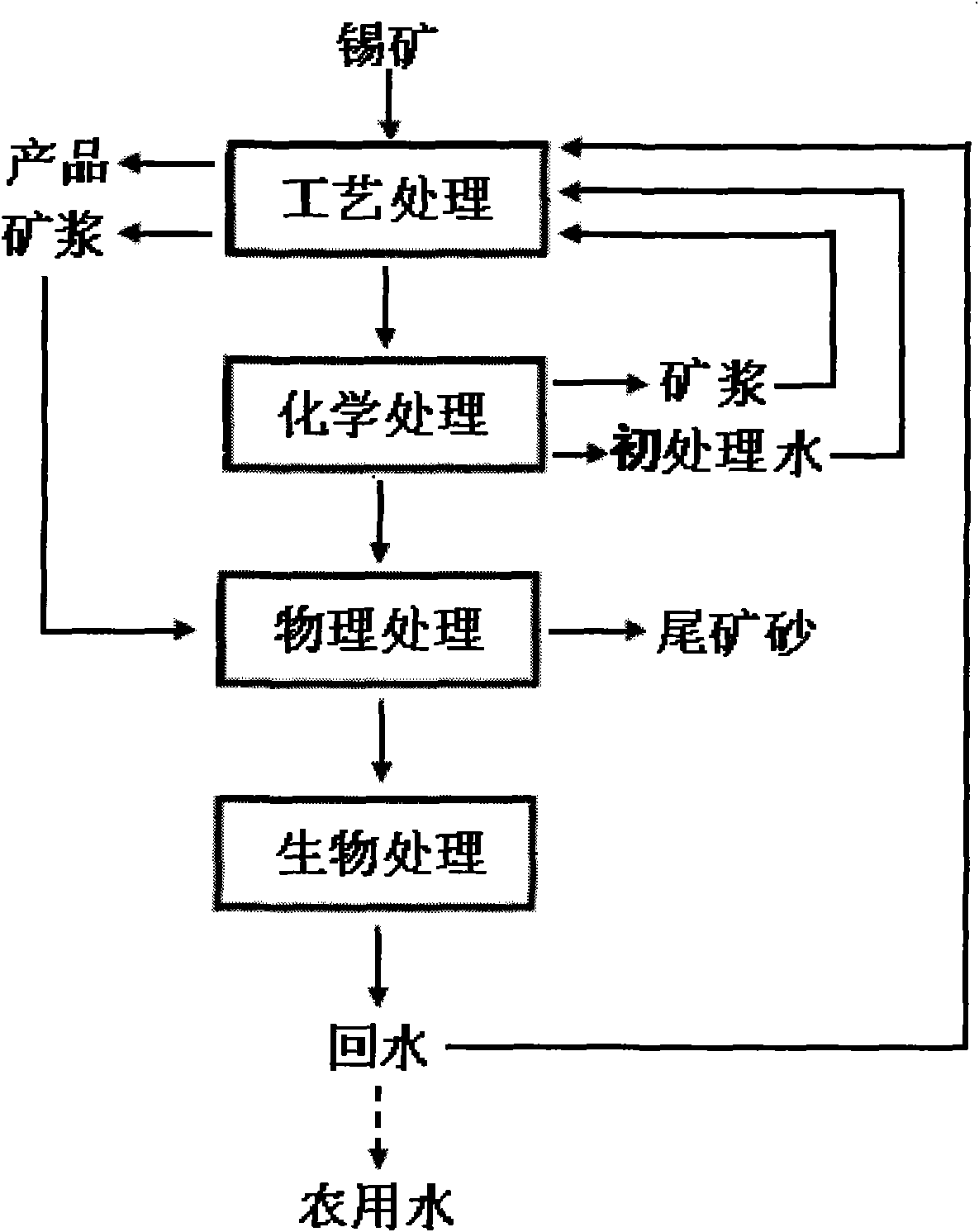

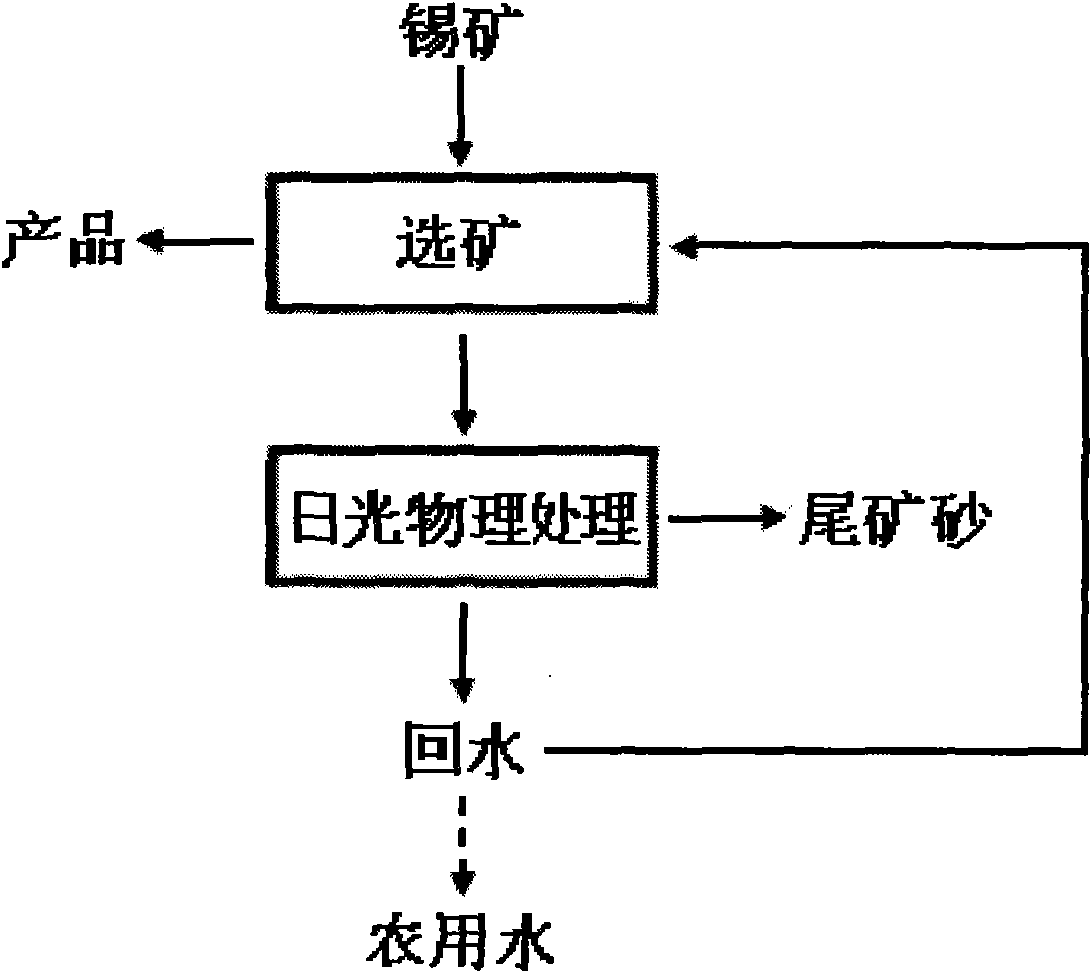

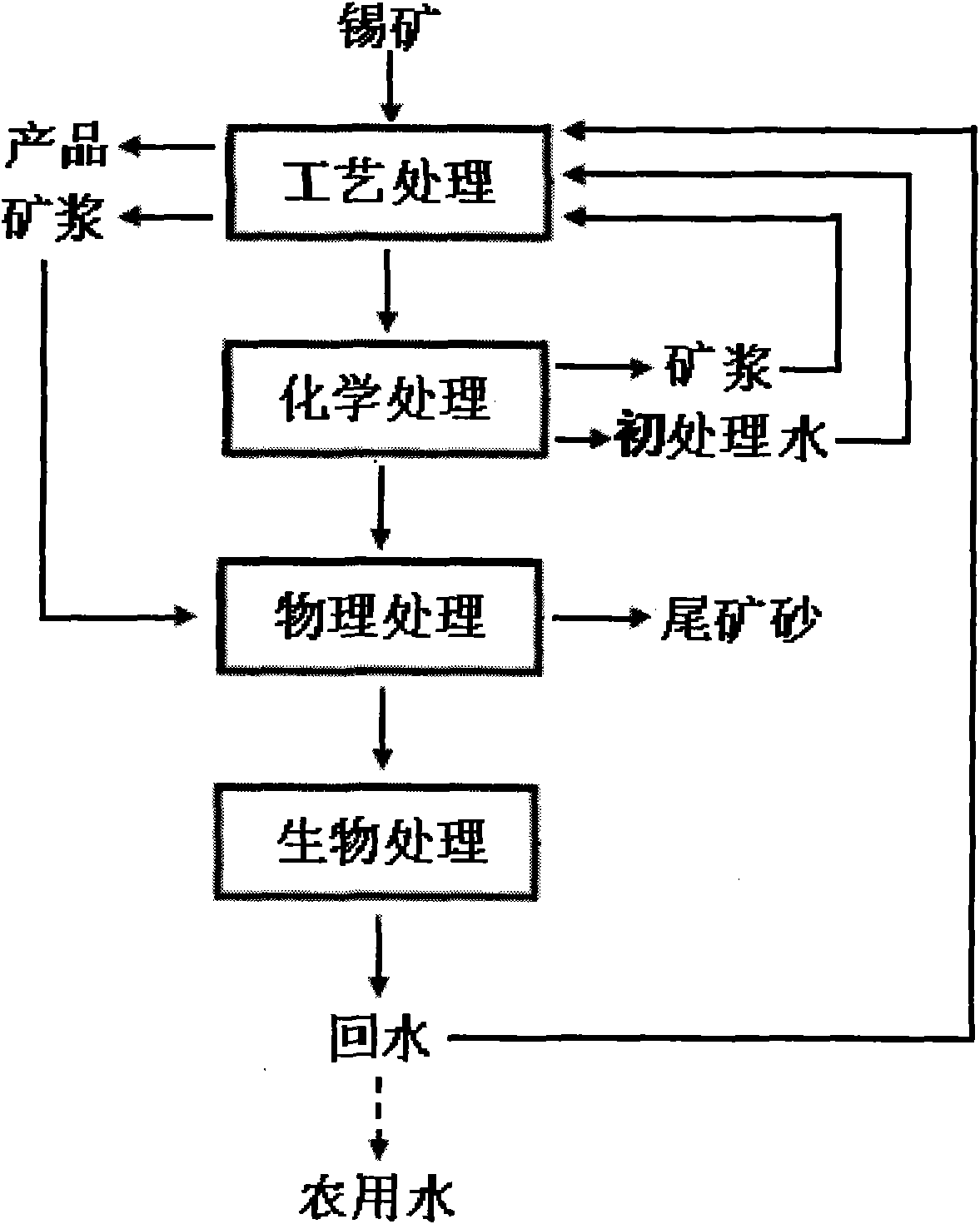

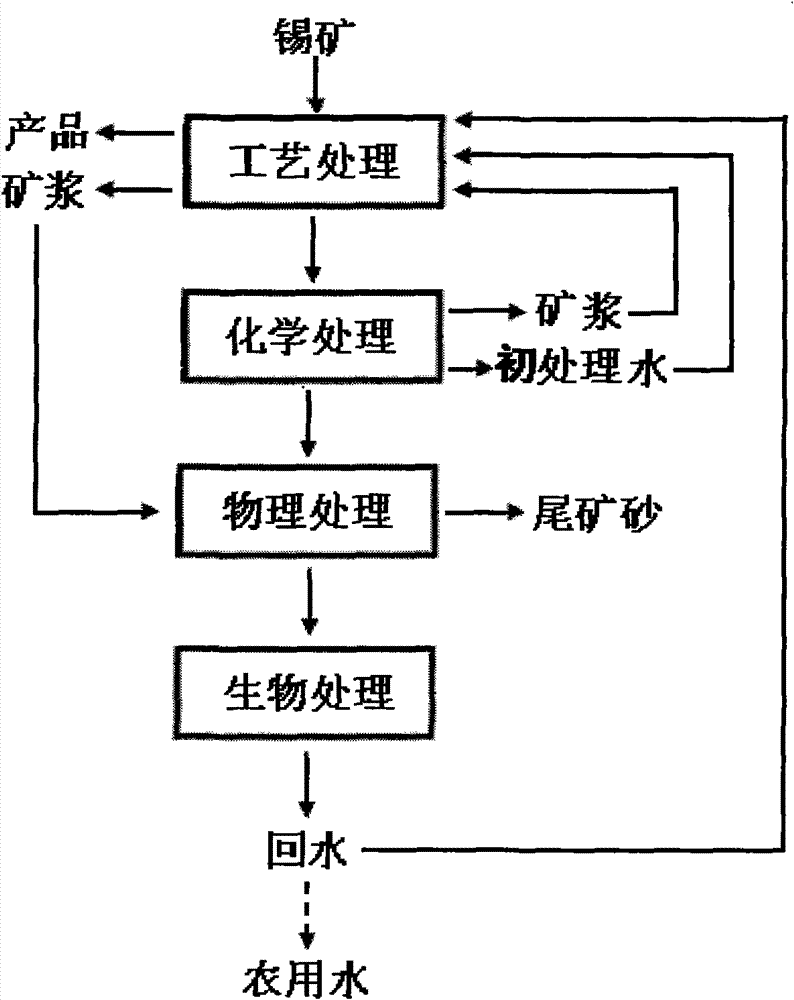

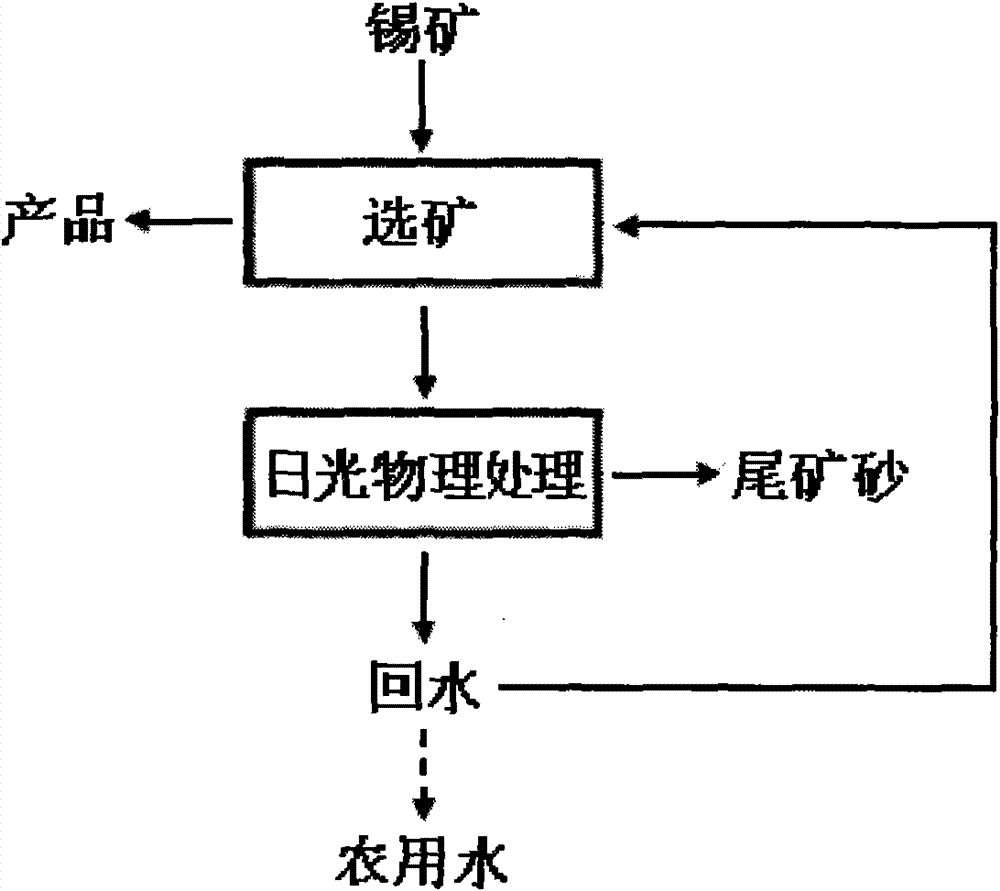

Four-step method for processing and recycling tin ore floatation wastewater

ActiveCN102030445AIncrease dosageImprove sedimentation rateMultistage water/sewage treatmentEnergy based wastewater treatmentChemical treatmentAgricultural irrigation

The invention discloses a four-step method for processing and recycling tin ore floatation wastewater, which comprises a new floatation technique, chemical treatment, physical treatment and biological treatment. The four-step method is characterized in that the principle of putting prevention first and providing prevention and control is adopted. The method is as follows: the new floatation technique and process are utilized to reduce the floatation wastewater and the microgranular particles from the headstream and reduce the usage amount of floatation reagents; because the chemical treatment method is used, the concentration of polyacrylamide in the tin ore floatation wastewater is increased from 0.5 percent to 0.9-1.1 percent, and the settling rate of part of the wastewater is improved; the physical treatment method is adopted to increase the settling distance and the settling time, the settling distance is extended for another 600 to 800m on the basis of 200m, and the settling time is increased for another 25 to 27 hours on the basis of 10 hours; aquatic organisms or plants, such as fish, frogs, aquatic weeds and the like are adopted to process the wastewater, the ecological reconstruction is realized, the agricultural irrigation standards are met, the utilization ratio of floatation return water is improved from 86 percent to above 97 percent, and peaceful and friendly coexistence of human and environment is realized.

Owner:广西华锡矿业有限公司铜坑矿业分公司

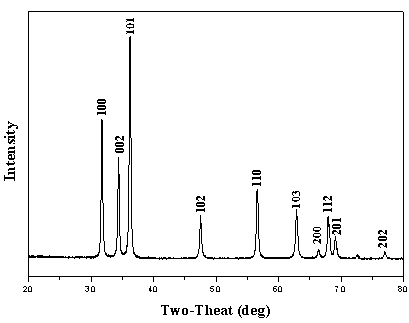

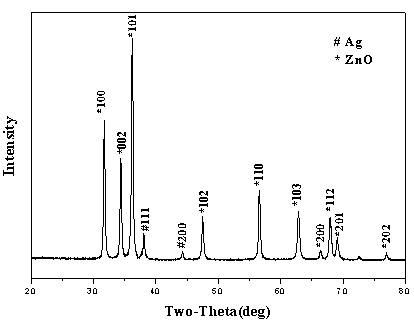

Preparation method of polyethylene glycol/ZnO/Ag nanoparticle composite fiber material

InactiveCN102704039AGood dispersionImprove uniformityInorganic material artificial filamentsFilament/thread formingFiberSpinning

The invention relates to the technical field of preparation of nanomaterials, in particular to a preparation method of a polyethylene glycol / ZnO / Ag nanoparticle composite fiber, and aims to provide the preparation method of a polyethylene glycol / ZnO / Ag nanoparticle composite fiber material. The preparation method comprises the following steps of: preparing spinning solution; preparing [PEG+PVP] / [Zn(NO3)2+AgNO3] composite nanofiber; and preparing ZnO / Ag composite nanofiber. The method has the advantages of simple process, low cost and capabilities of improving the dispersibility of the nanoparticles in polymer solution and the uniformity of the obtained fiber and being applied to a gas sensitive sensor.

Owner:CHANGZHOU UNIV

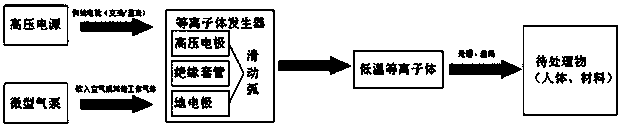

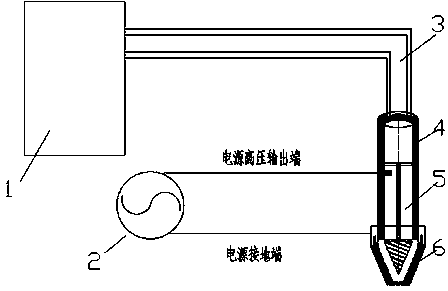

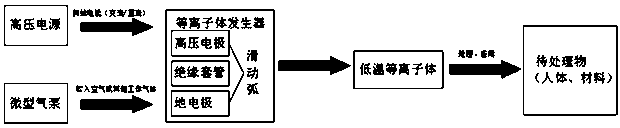

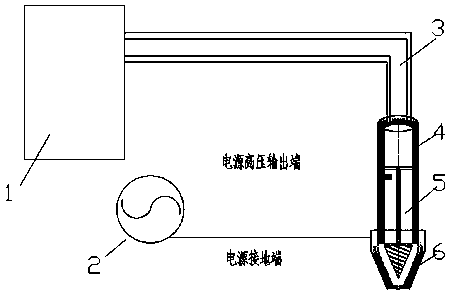

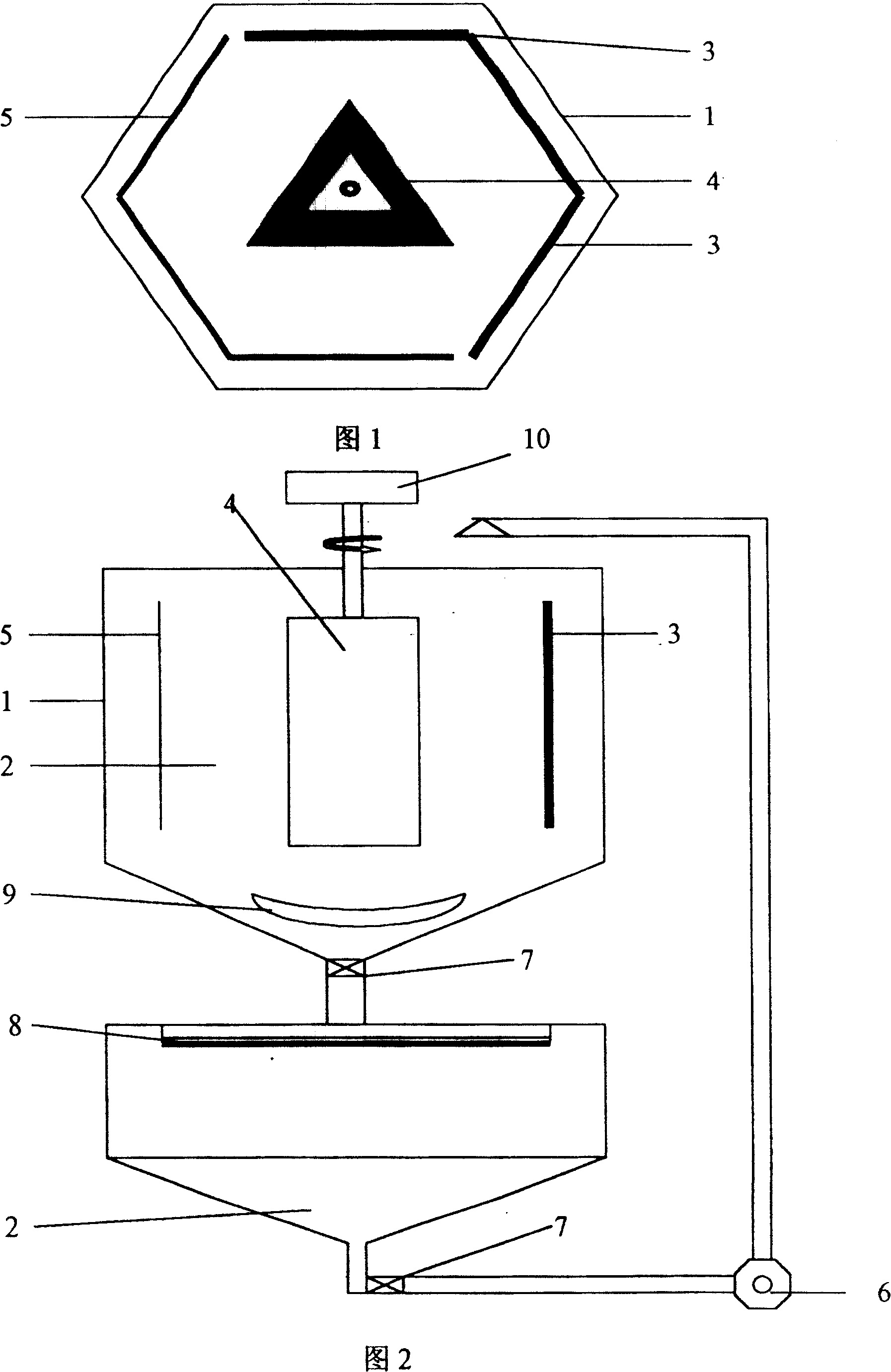

Handheld portable generating device for sliding arc low-temperature plasma

ActiveCN103997841AEasy to useSimple and flexible operationPlasma techniqueTreatment effectPlasma particle

The invention discloses a handheld portable generating device for sliding arc low-temperature plasma. According to the structure, a miniature air pump is connected with an insulating sleeve through a silica gel conduit, the insulating sleeve is located between a high-voltage electrode and a ground electrode, a high-voltage power source supplies power to the high-voltage electrode and the ground electrode, the high-voltage power source, the high-voltage electrode and the ground electrode are embedded in a handle, a hole is formed in the front end of the handle, so that the plasma is sprayed out, and a control switch is arranged on the handle so as to control the high-voltage power source to work. The generating device has the advantages that the length and the temperature of the plasma are changed through adjustment of the voltage, operation is simple and flexible, and the device can be used conveniently by an operator; the device is small in size, convenient to carry, attractive in appearance and low in cost; air or simple substance gas or a mixture of air and simple substance gas or a gaseous compound or gaseous organic matter serves as the working gas and various requirements can be met; other excitation devices are not needed, faults are reduced, and reliability of the device is improved; the generating device is different from a traditional plasma source, a sliding arc is more efficient, the activity of generated plasma particles is better, and the particles are more beneficial to the human body and the material treatment effect.

Owner:JIANGSU ROZENMED MEDICAL TECH CO LTD

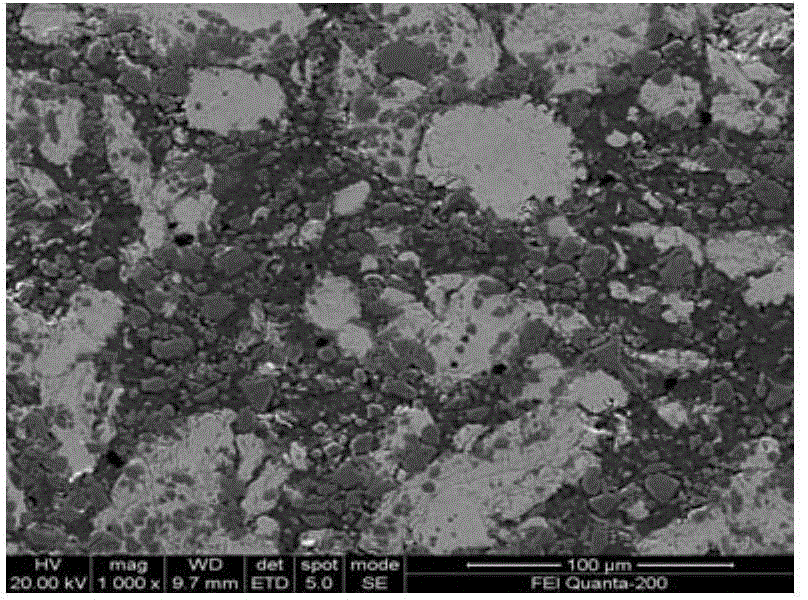

Hot pressing sintering particle reinforcing zinc-based composite material and preparation method thereof

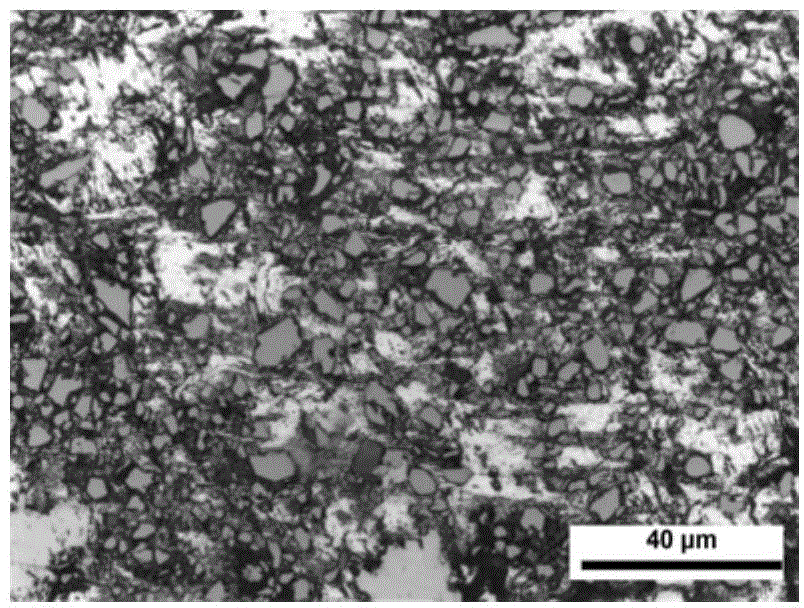

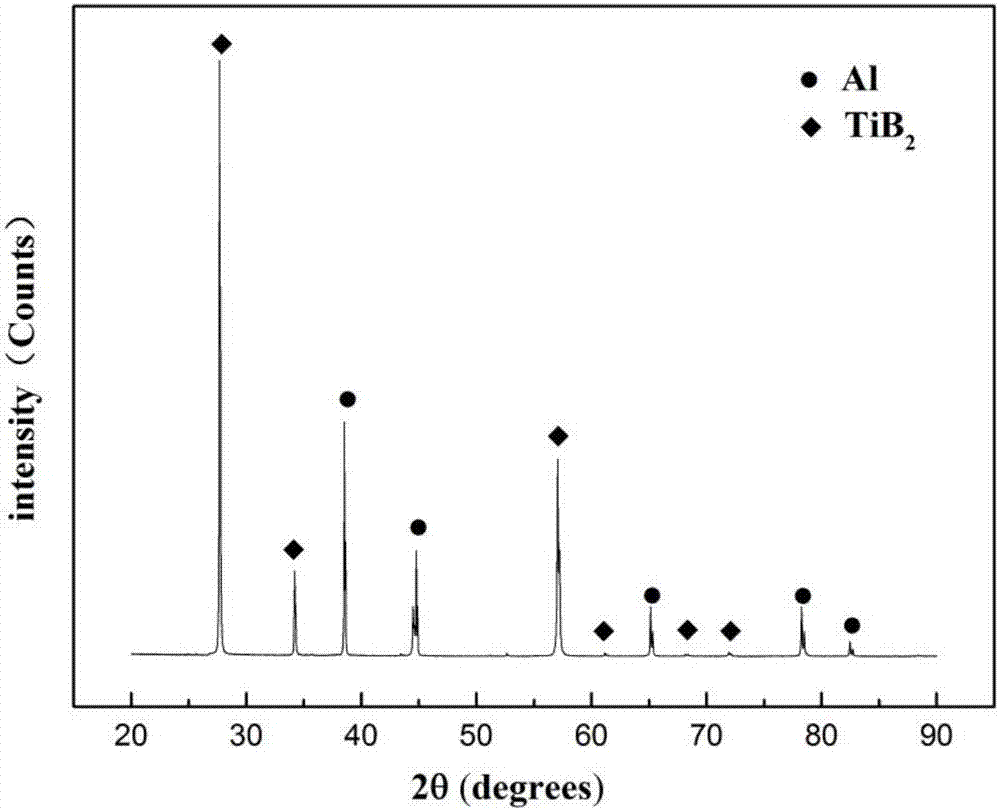

The invention relates to a hot pressing sintering particle reinforcing zinc-based composite material and a preparation method thereof, and belongs to the technical field of composite material preparation. The method includes the steps of preparing Zn powder, Al power, Cu power and TiB2 power as raw materials according to the mass ratio of 50-90 to 15-40 to 1-3 to 1-20, conducting high energy ball-milling and prepressing, and then obtaining the hot pressing sintering particle reinforcing zinc-based composite material through a segmented sintering method. The prepared components are reasonable in design, the preparation process is simple, and the zinc-based composite material which is high in interface combination strength and low in porosity and defect rate is obtained through the coordinative effects of all the components and all parameters.

Owner:CENT SOUTH UNIV

Thermoplastic molding material and molding elements containing nanometric Inorganic particles for making said molding material and said molding elements, and uses thereof

InactiveUS7790079B2Promotes fine dustDevelopment of fine dust can be kept low or completely avoidedMaterial nanotechnologyMixersThermoplasticMolten state

(EN) The invention concerns a method for producing a thermoplastic molding material or element, said material or element containing nanometric inorganic particles. In molten state, the thermoplastic is mixed with the nanometric inorganic particles and with a solubilizing agent in a conveyor screw extruder, the pressures and temperatures being adjusted so that the plastic is in melt form and the solubilizing agent in supercritical state. The invention is characterized in that at the output of the extruder, the mixture passes through a slot with a passage less than 20 $g(m)m to penetrate into an expansion zone and the molten material, wherein are incorporated the nanometric inorganic particles, is evacuated, reduced into molding material after cooling or transferred into a molding tool to be molded. The invention also concerns the molding material and the molding elements obtained by this method, as well as the uses thereof.

Owner:EVONIK ROEHM GMBH

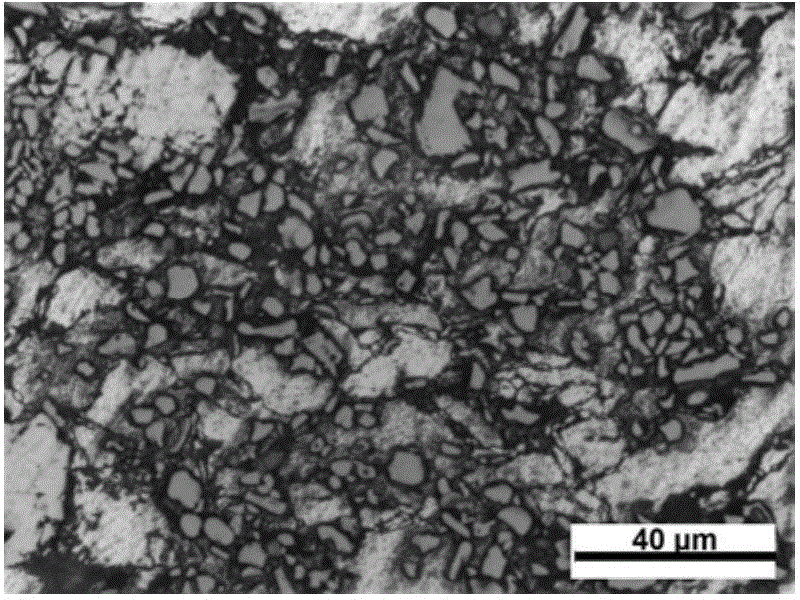

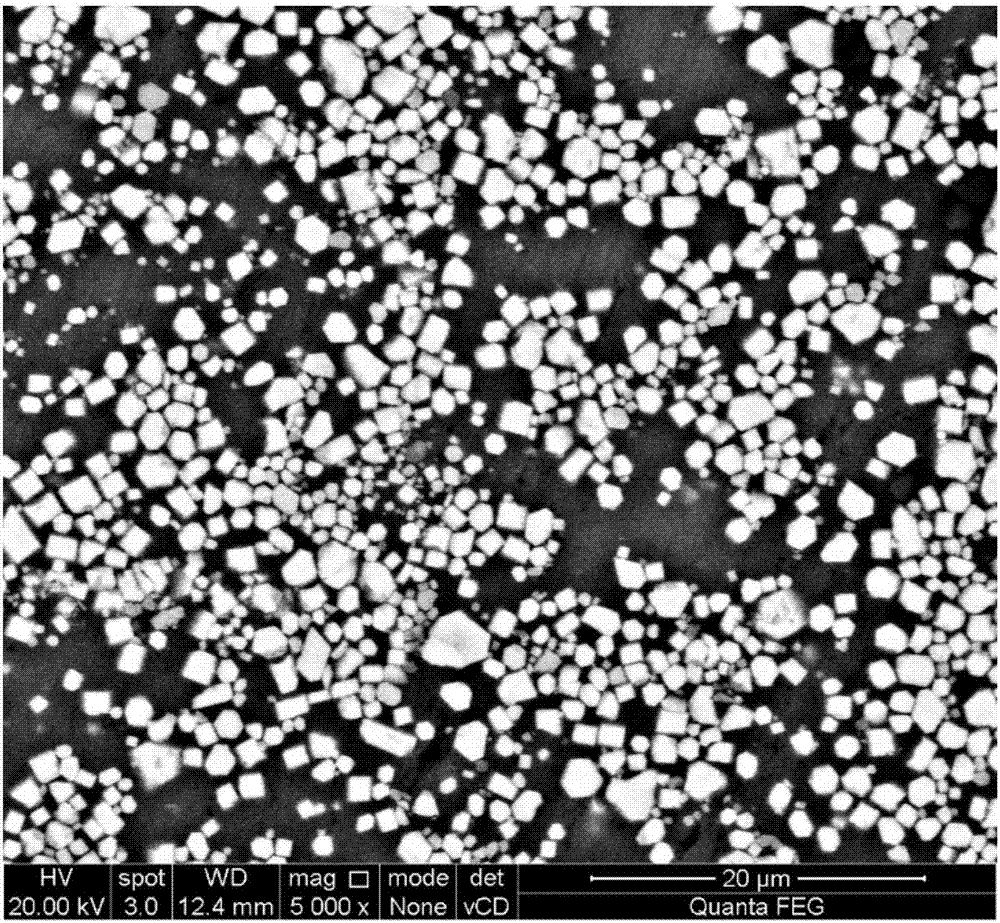

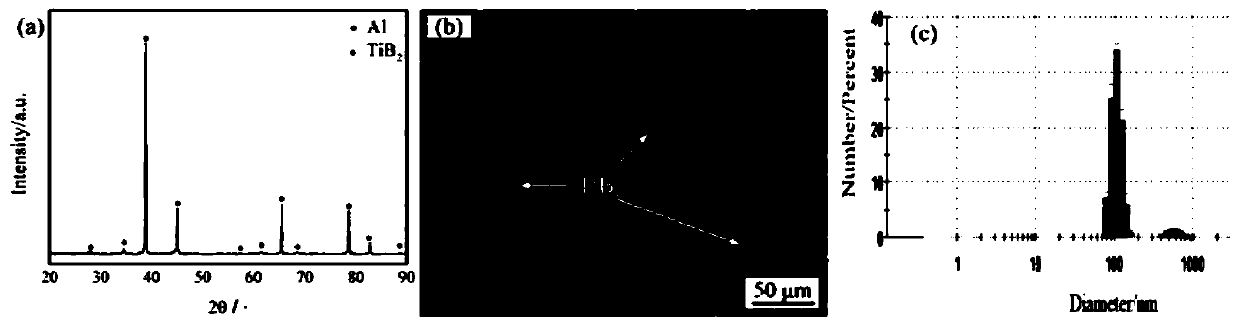

Al-TiB2 pure-phase intermediate alloy with high volume fraction and preparation method thereof

Al-TiB2 pure-phase intermediate alloy with a high volume fraction and a preparation method thereof belong to the technical field of intermediate alloy. The mass percent of B is 1.0-2.5%, the molar ratio of Ti / B is 1 / 2, the balance is Al, and a phase composition comprises alpha-Al and TiB2. The preparation method comprises the following steps: weighing H3BO3, TiO2, Al powder, Ti powder and aluminum ingots with the purity of 99.9%, wherein the molar ratio of H3BO3, TiO2, Al powder and Ti powder is (3.5-5.2):(0.5-2.1):(3.5-5.7):(0.2-1.5); mixing TiO2 with H3BO3, and performing uniform drying; mixing the heated powder with aluminum powder, placing the mixed powder in a die, and pressing the mixed powder into a block; and heating the aluminum ingots to be molten, pressing the melt into the block to enable ignition and reaction, after reaction, pressing C2C16 into the reactant, and then performing refining, stirring, drossing and casting. As a low-cost oxide serves as the raw material, the prepared intermediate alloy contains no brittle phases such as TiAl3.

Owner:大连科天新材料有限公司

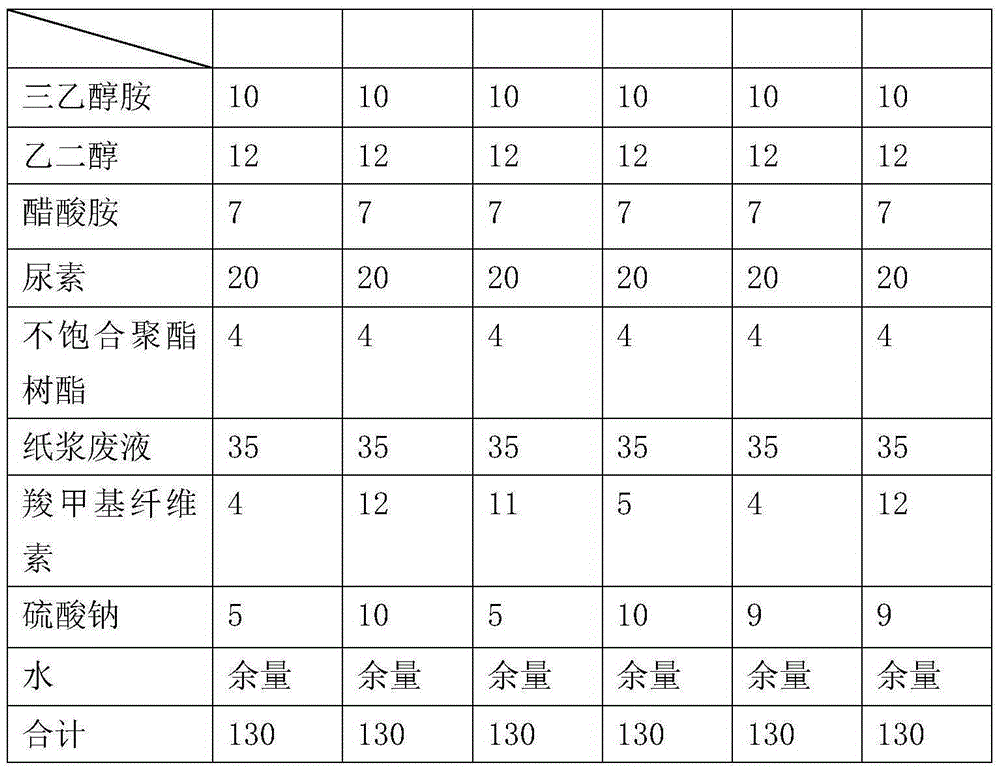

Cement grinding aid

The invention discloses a cement grinding aid. The cement grinding aid contains the ingredients in parts by mass: 4-20 parts of triethanolamine, 5-20 parts of ethylene glycol, 5-10 parts of ammoniom acetate, 18-23 parts of urea, 3-5 parts of unsaturated polyester resin, 30-40 parts of paper pulp waste lye, 4-12 parts of carboxymethyl cellulose and 5-10 parts of sodium sulfate. According to the cement grinding aid, carboxymethyl cellulose and sodium sulfate are added based on the original cement grinding aid, and carboxymethyl cellulose in the grinding aid can be used for overcoming the phenomenon of powder agglomeration and improving the gradation of granules. Sodium sulfate can be used for accelerating the hydrating and hardening speed of cement, and the degree of hydration of the cement can be increased through using sodium sulfate and triethanolamine in a matched manner. The condition that the fluidity and cohesion of the cement granules are not high can be changed through using carboxymethyl cellulose and sodium sulfate in a matched manner, the fluidity of cement powder can be improved by hydrophobic groups in carboxymethyl cellulose and hydrophilic group molecules in sodium sulfate, and the powder material can be fully ground, so that the fineness and strength of the cement can be improved.

Owner:重庆市南川区海峰水泥有限公司

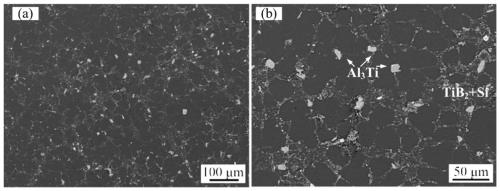

Transgranular grain boundary distribution micro-nano complex particle reinforced aluminum base composite material and preparation method thereof

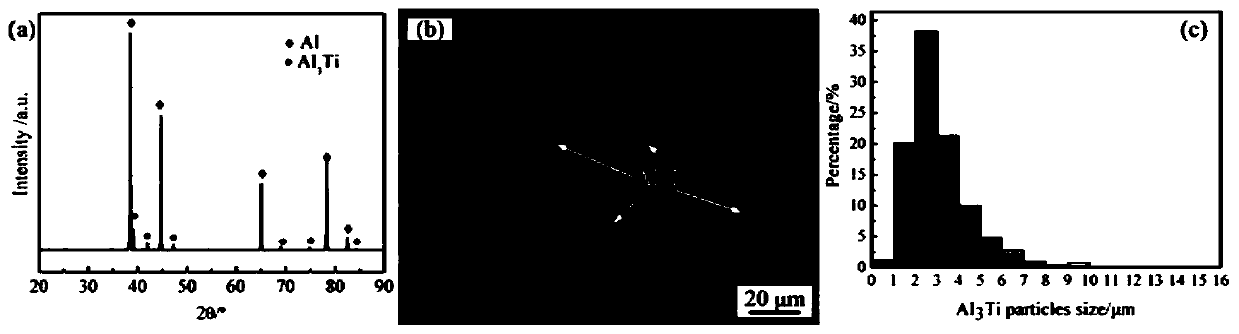

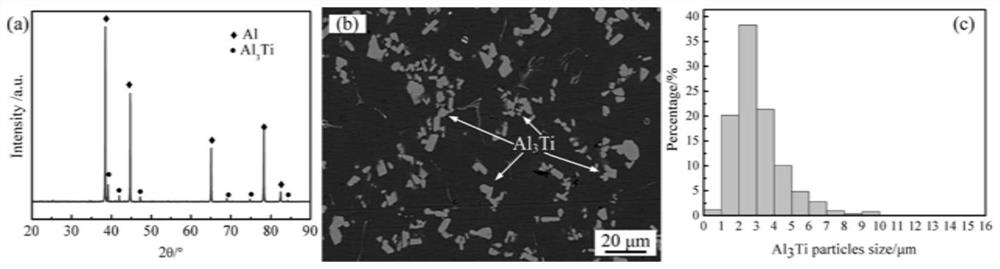

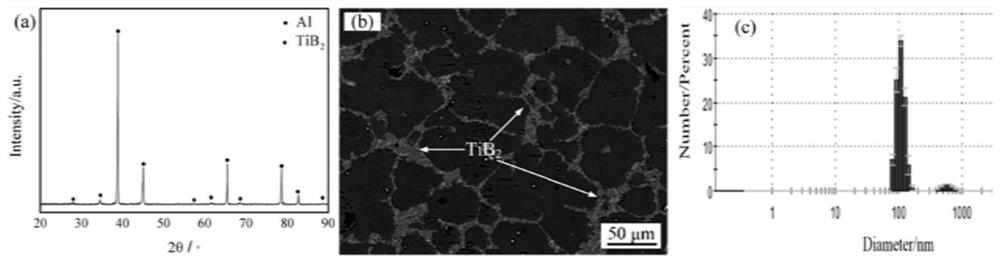

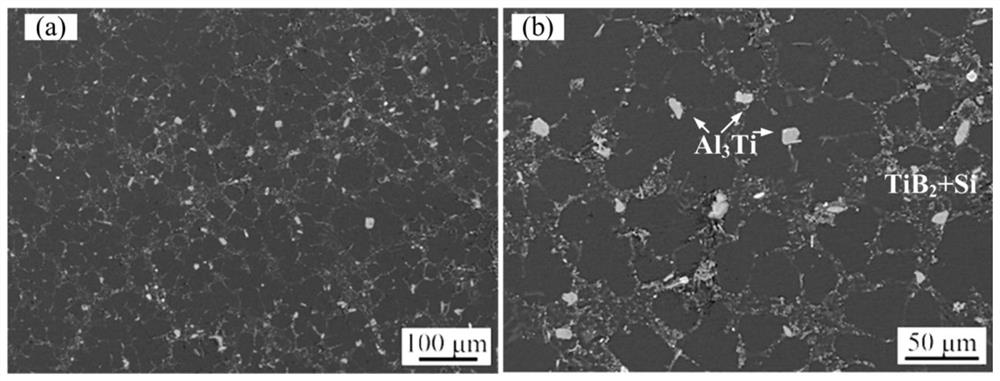

The invention discloses a transgranular grain boundary distribution micro-nano complex particle reinforced aluminum base composite material and a preparation method thereof. Firstly, K2TiF6 powder isfed in a pure aluminum melt to prepare an uniform-structured Al-Al3Ti intermediate alloy through assistance by ultrasonic stirring; the average particle size of Al3Ti particles in the obtained Al-Al3Ti intermediate alloy is smaller than 5 microns; then, the K2TiF6 powder and KBF4 powder are mixed according to a mole ratio of 1: 2, and are fed in the pure aluminum melt to prepare an uniform-structured Al-TiB2 intermediate alloy through assistance by ultrasonic stirring; the average particle size of TiB2 particles in the obtained Al-TiB2 intermediate alloy is smaller than 100 microns; finally, Al, the Al-Al3Ti intermediate alloy and the Al-TiB2 intermediate alloy are used as raw materials, or Al, alloy elements, the Al-Al3Ti intermediate alloy and the Al-TiB2 intermediate alloy are used as the raw materials; the raw materials are molten; reinforced particles are dispersed through assistance by ultrasonic stirring; and a transgranular grain boundary double-reinforcement aluminum base composite material is obtained after casting.

Owner:咸阳瞪羚谷新材料科技有限公司

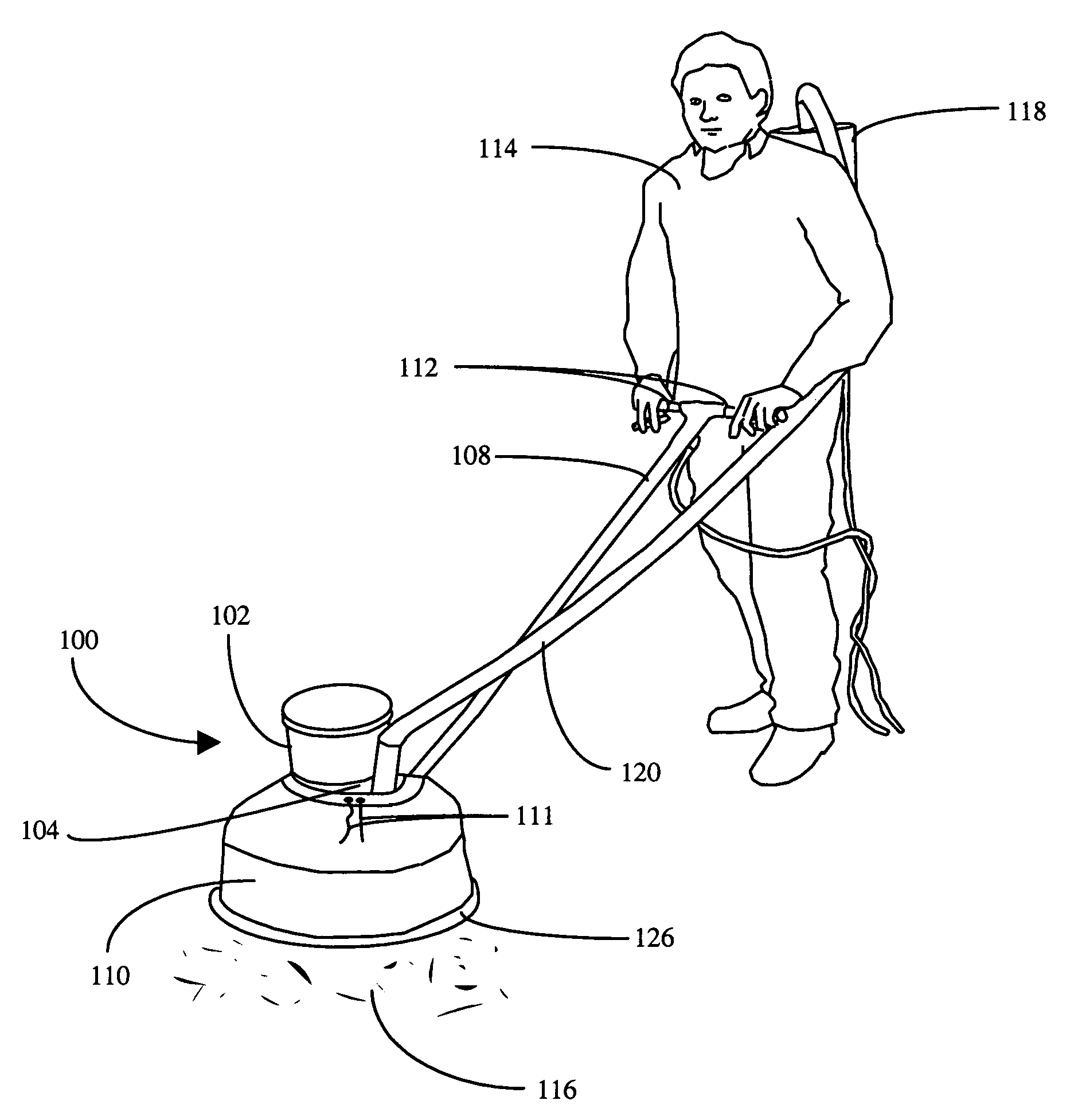

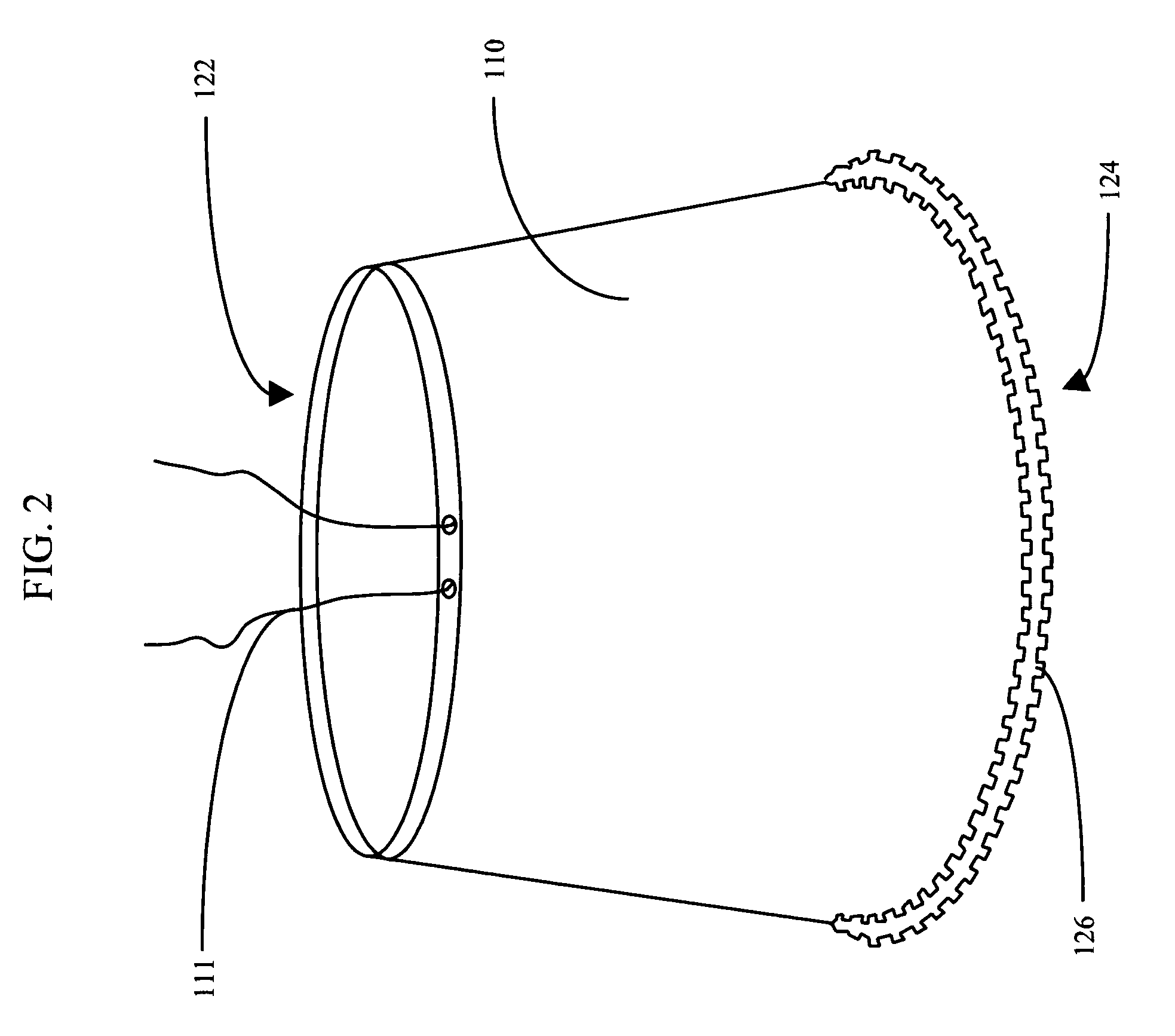

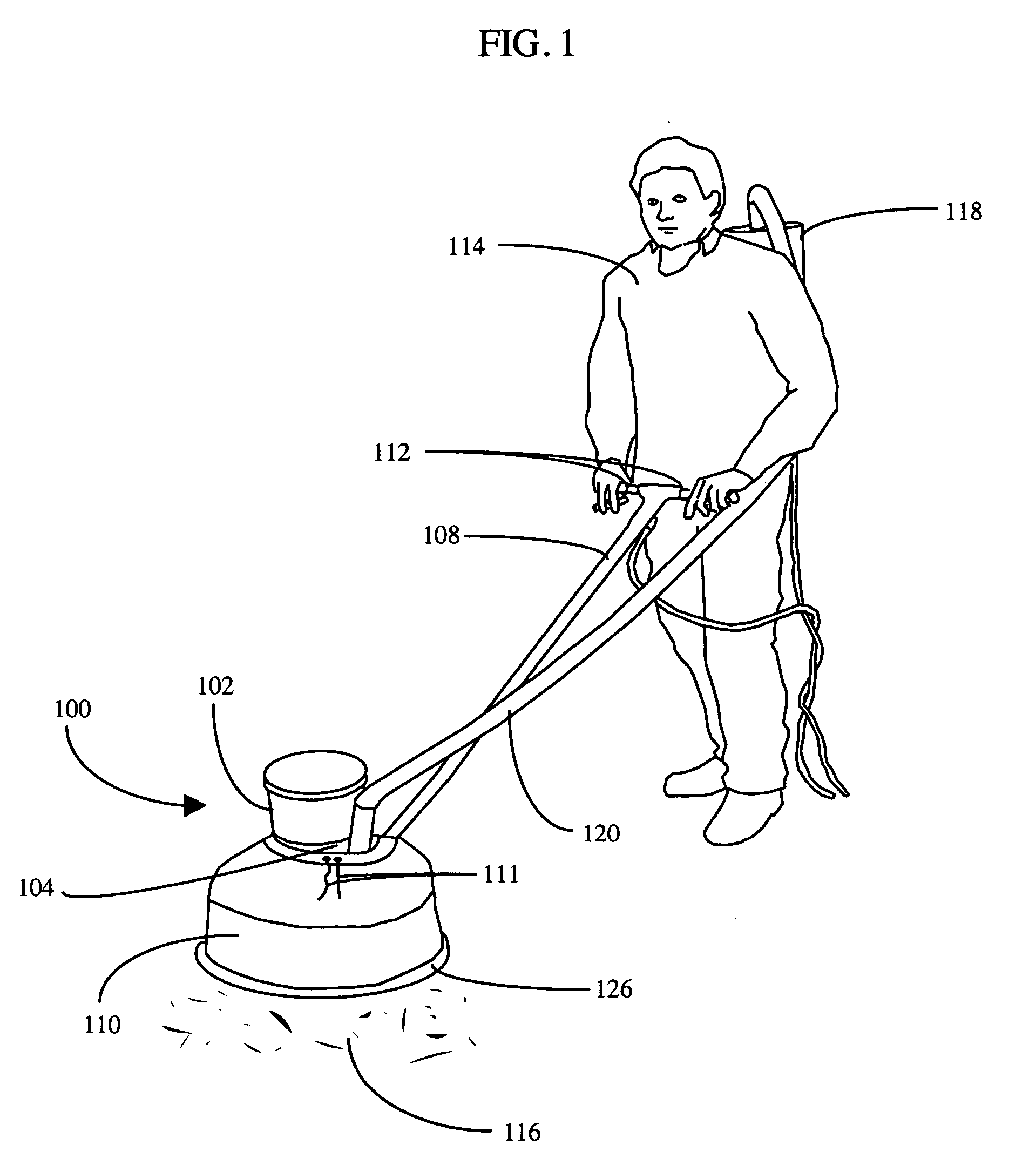

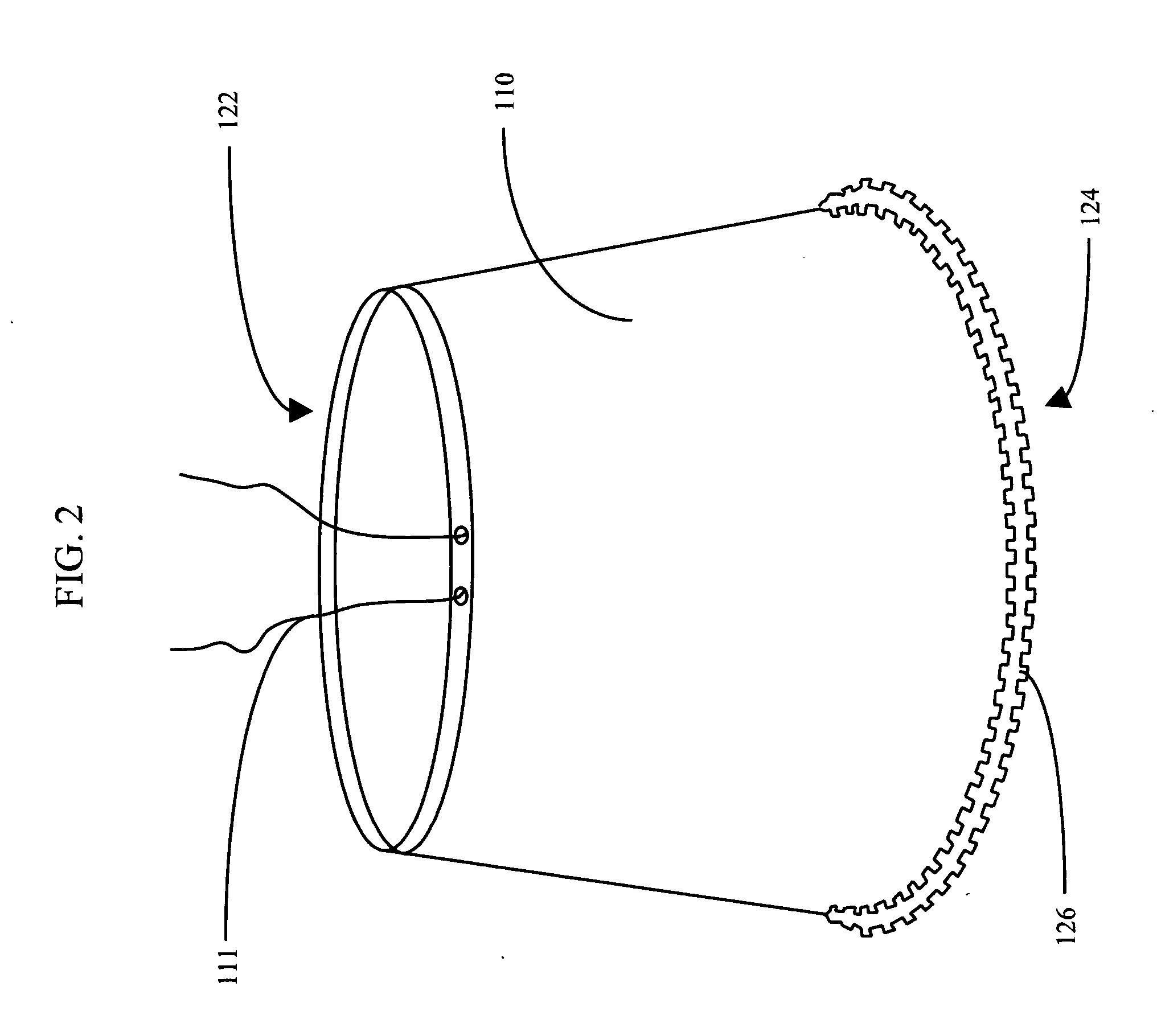

Dust containment device for surfacing machines

InactiveUS7056198B2Increase speedPrevent escapePortable grinding machinesPlane surface grinding machinesHigh velocityDust collection system

Owner:NHANCE

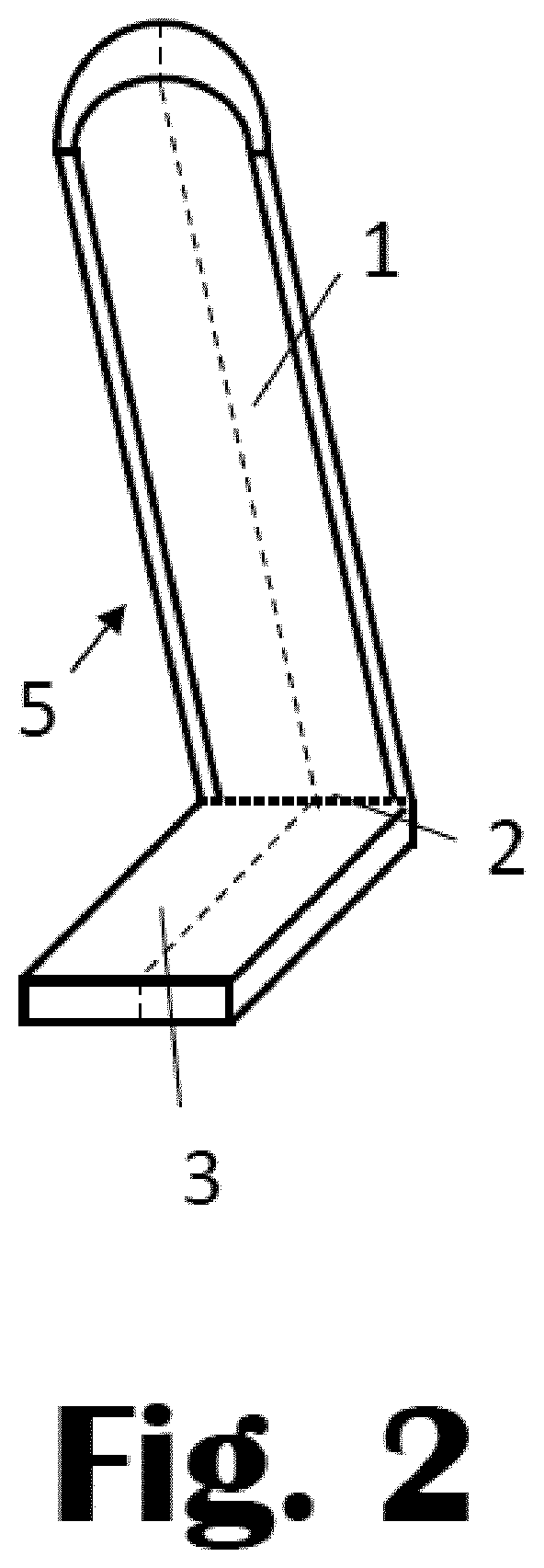

Nasal implant

ActiveUS20200155304A1DenseWell controlled macroporosityAdditive manufacturing apparatusNose implantsBiocompatibilityMechanical engineering

Nasal implant obtained by additive manufacturing, comprising a main portion and a return portion connected by an intermediate portion, the main and return portions forming an angle of between 25° and 90°,said implant is made from a biocompatible ceramic of synthetic origin;said implant has an average macroporosity characterized by:a density of material of between 20% and 95% by volume, said density of material being higher in said intermediate portion than in said main portion;cavities defining sections of cavities, said sections of cavities each having a diameter of between 0.3 mm and 1 mm;said sections of cavities each having an area and a form substantially equal over the entire implant.

Owner:CERHUM SA

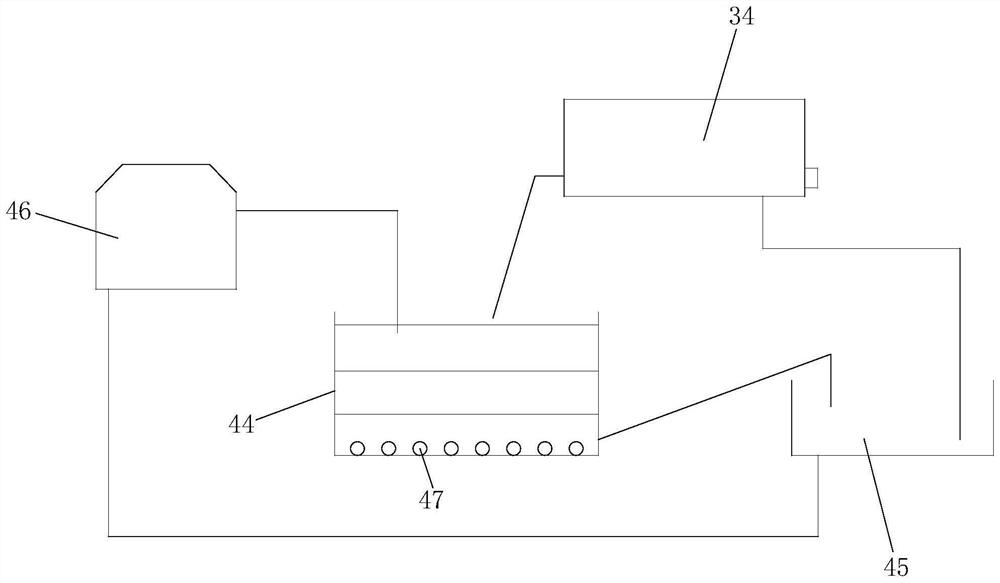

Pond engineering circulating water zero-discharge culture system

ActiveCN112335596AEasy to handleShort solution timeWater contaminantsWaste water treatment from animal husbandryWaste collectionSewage

The invention discloses a pond engineering circulating water zero-discharge culture system. The culture system comprises a culture area, a sewage collection area, a waste collection area, a solid-liquid separation device, a purification area I, a filter feeding area, a sedimentation area, a biochemical area and a purification area II. The sewage collection area is used for collecting sewage generated in the culture area, and the waste collection area is used for collecting sewage in the sewage collection area and conducting layering; the solid-liquid separation device is used for carrying outsolid-liquid separation on the bottom-layer sewage, and the purification area I is provided with an aquatic plant floating bed I; filter feeding organisms are cultured in the filter feeding area, andthe sedimentation area is used for settling the sewage; the biochemical area is used for receiving supernatant liquor and supernatant liquid and performing aeration treatment on mixed liquid; and thepurification area II is used for purifying and treating the mixed liquid treated by the biochemical area and conveying a purified water body to the culture area. According to the sewage collection area, a flow field in circulating water and a space of an outer pond are reasonably utilized, culture tail water treatment and production are organically combined together, 60%-90% of water body area canbe used for tail water treatment, and large-density culture can be realized.

Owner:FISHERIES RES INST ANHUI ACAD OF AGRI SCI

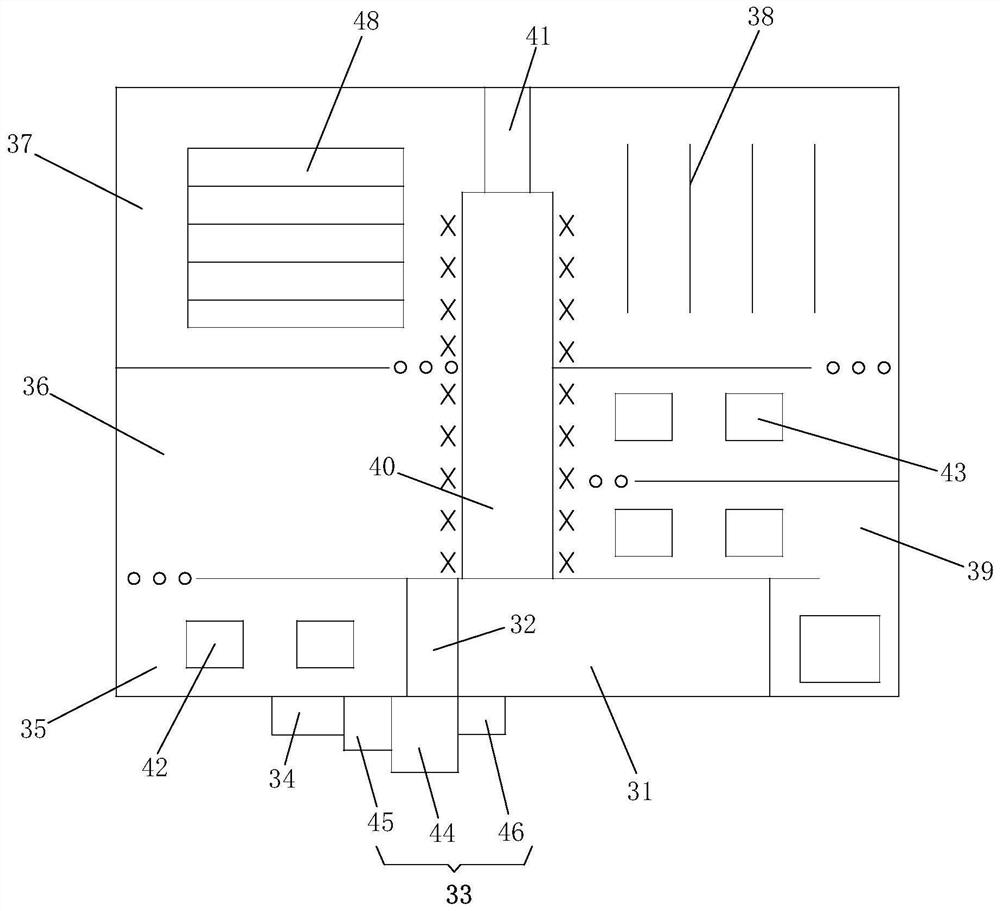

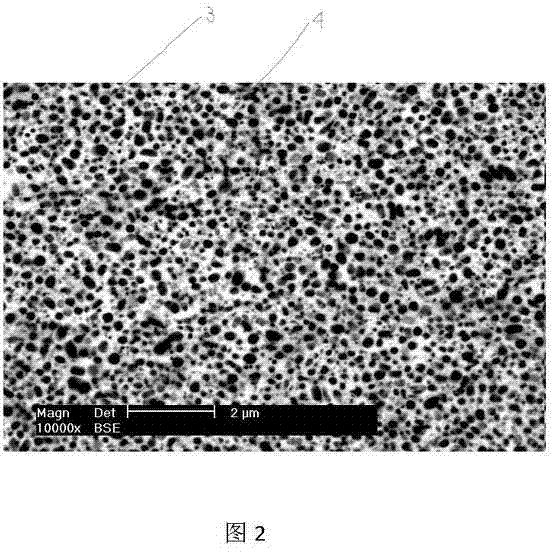

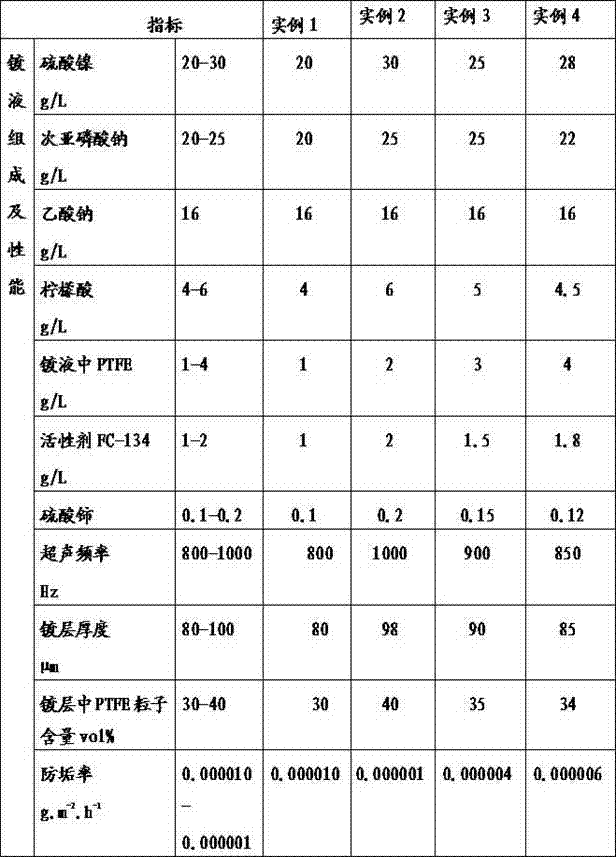

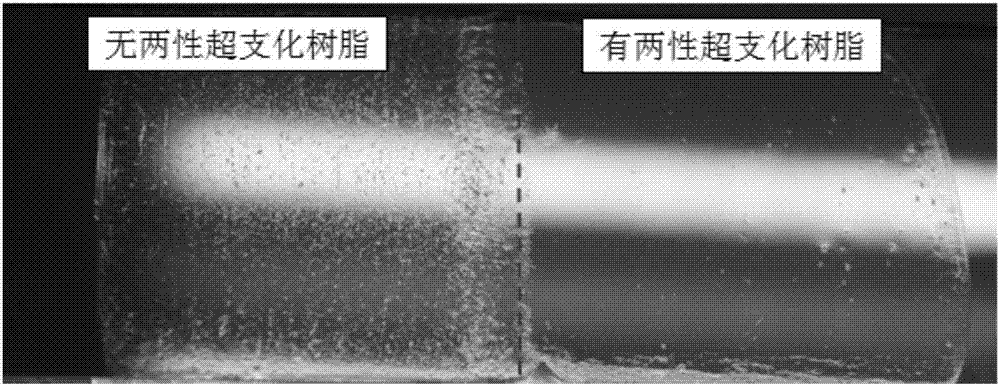

A Ni-P-PTFE anti-scale plating by rear earth cerium-induced ultrasonic chemical codeposition and a preparing process thereof

InactiveCN104120413AImprove antifouling performanceEvenly dispersedLiquid/solution decomposition chemical coatingEmulsionCerium

A Ni-P-PTFE anti-scale plating by rear earth cerium-induced ultrasonic chemical codeposition and a preparing process thereof are disclosed. The PTFE content in the plating is increased by rear earth cerium ultrasonic induced codeposition. The Ni-P-PTFE anti-scale plating (2) is prepared on a C45 steel plate (1) substrate. The content of PTFE particles in the plating (2) is 30-40 vol%, and the scaling rate is 0.000010-0.000001 g*m<-2>h<-1>. The preparing process comprises steps of: 1) preparing a sample and performing oil removing treatment and rust removing treatment; 2) dispersing PTFE emulsion by an activating agent; 3) preparing a plating solution; 4) mixing the PTFE activating solution and the plating solution; 5) activating the sample, and performing cerium-induced ultrasonic chemical codeposition; 6) drying; and 7) performing performance detection. The beneficial effects of the anti-scale plating and the preparing process are that: (1) the activating agent can uniformly disperse the PTFE particles; (2) the combination of rare earth-induced codeposition and ultrasonic wave plating allows the PTFE particles in the plating to be high in content and uniform in distribution; and (3) the prepared Ni-P-PTFE plating has a good anti-scale property.

Owner:DALIAN UNIVERSITY

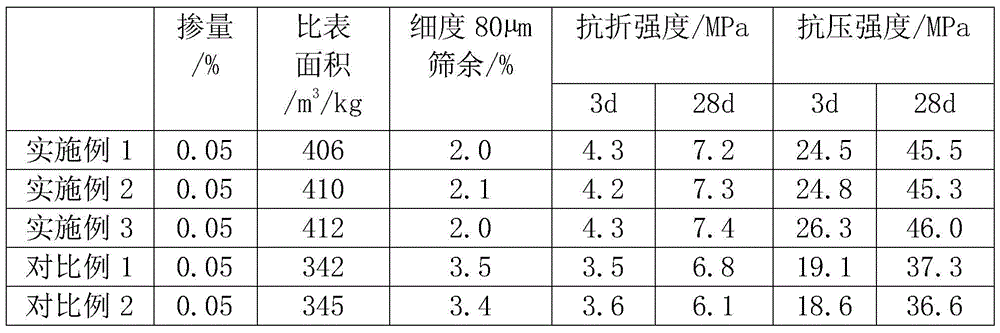

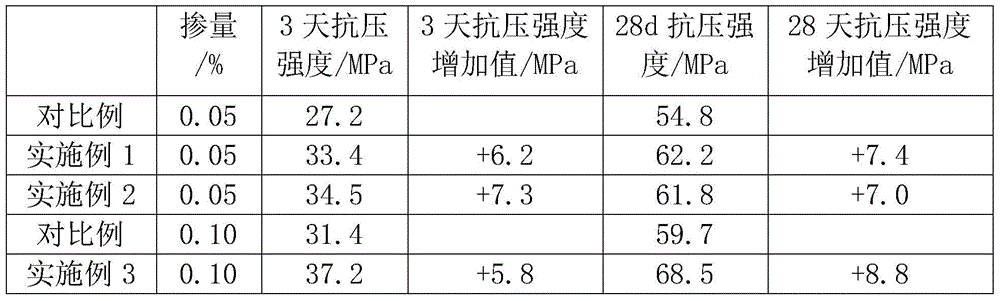

An enhanced cement grinding aid

The invention discloses a reinforced cement grinding aid which comprises the following ingredients in parts by weight: 10-15 parts of diethanolisopropanolamine, 3-5 parts of triethanolamine, 4-6 parts of sodium acetate, 6-10 parts of sodium thiosulfate, 10-12 parts of sodium chloride, 4-6 parts of sodium carboxymethylcellulose and 15-18 parts of papermaking black liquid. The reinforced cement grinding aid is low in mixing amount, good in reinforcement effect and low in cost.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

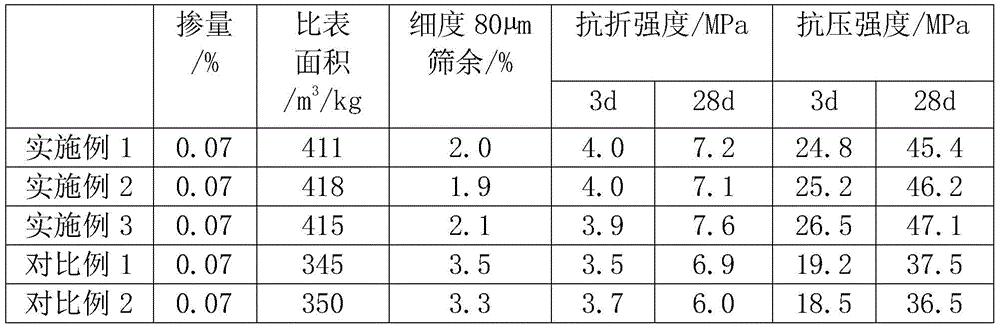

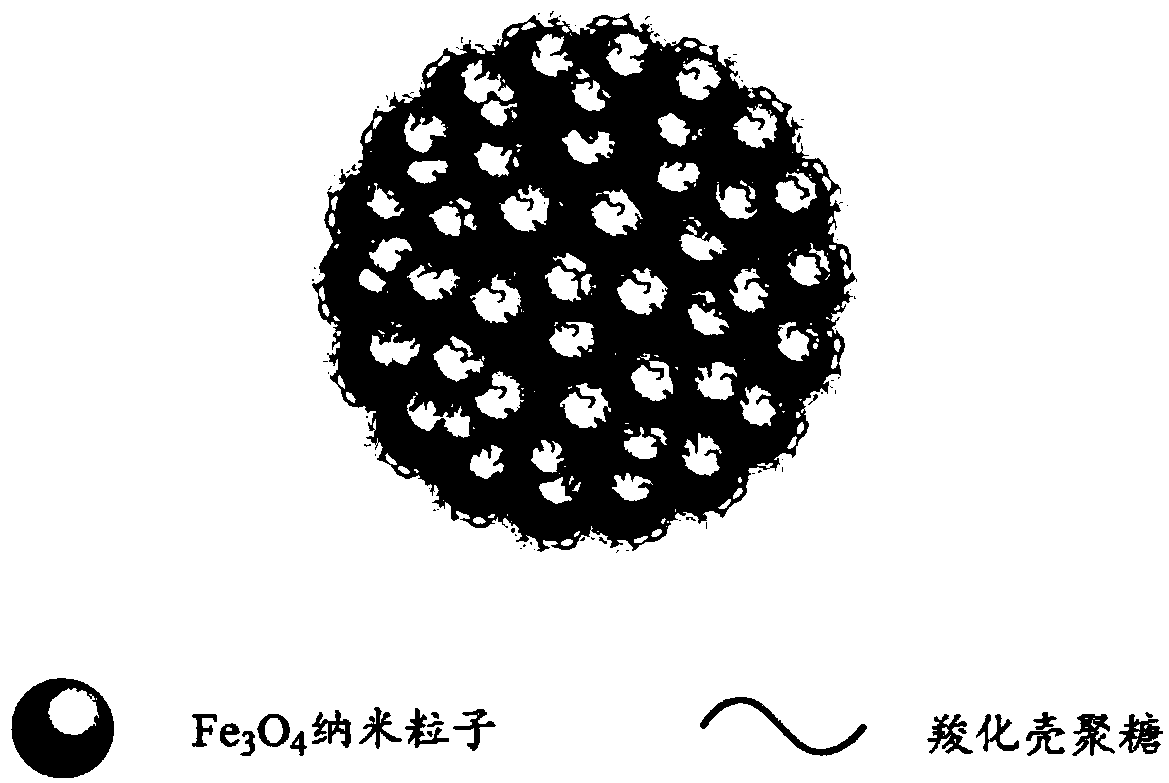

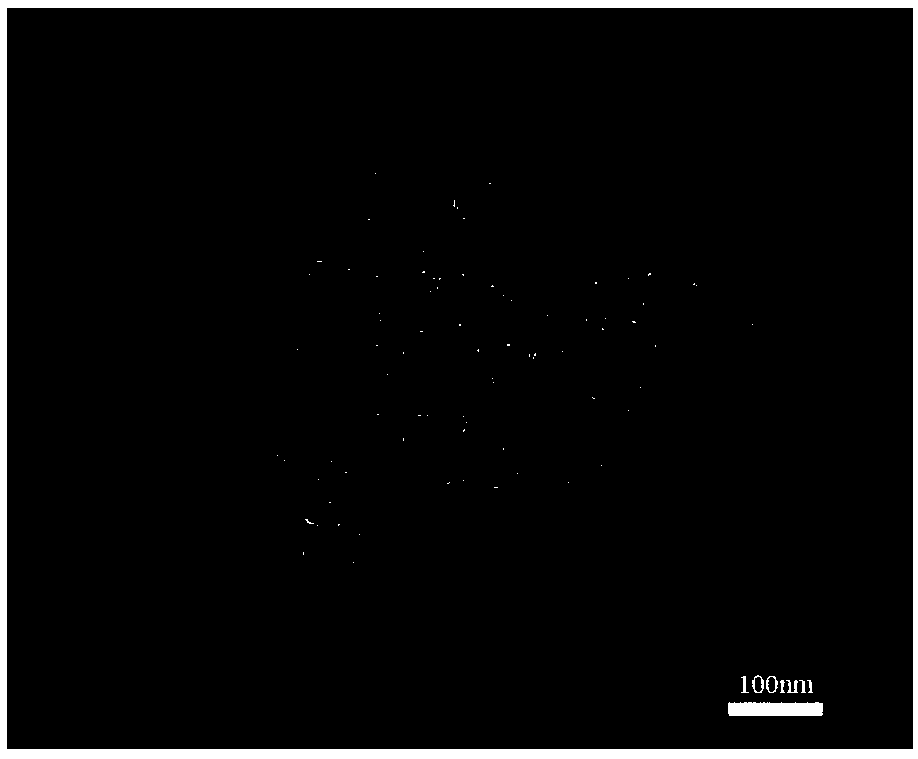

Preparation method of superparamagnetic carboxylated chitosan/Fe3O4 nanoparticle aggregate

ActiveCN108888780ASimple manufacturing processHigh particle contentEnergy modified materialsInorganic non-active ingredientsDispersityIce water

The invention provides a preparation method of superparamagnetic carboxylated chitosan / Fe3O4 nanoparticle aggregate. The method comprises the following steps: (1) preparing a stable superparamagneticFe3O4 nanoparticle water dispersion solution of carboxylated chitosan; (2) dissolving an emulsifier into a non-polar solvent to obtain an emulsifier solution; (3) dissolving hydrophilic metal salt orthe hydrophilic metal salt and the carboxylated chitosan into the superparamagnetic Fe3O4 nanoparticle water dispersion solution, so as to obtain a dispersion solution A; then adding the dispersion solution A into the emulsifier solution and stirring and pre-emulsifying to obtain crude emulsion; then putting a container filled with the crude emulsion into an ice water bath; carrying out ultrasonictreatment to obtain reverse-phase fine emulsion; and (4) directly dropwise adding a crosslinking agent into the reverse-phase fine emulsion, and enabling the crosslinking agent and the carboxylated chitosan to react to obtain the superparamagnetic carboxylated chitosan / Fe3O4 nanoparticle aggregate. The method provided by the invention is simple and efficient; and the prepared superparamagnetic nanoparticle aggregate has the advantages of good dispersity, high magnetic component content, strong magnetic responsibility, excellent biocompatibility and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Aqueous nanometer inorganic oxide-organic hybrid coating composition and its application

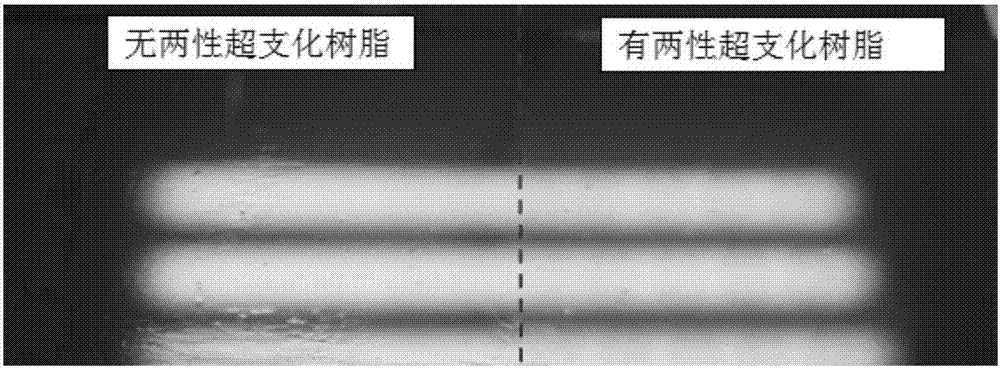

InactiveCN107083130AIncreased critical pigment volume concentrationHigh Nano Inorganic Oxide ContentAntifouling/underwater paintsPaints with biocidesCoated surfaceNanometre

The invention discloses an aqueous nanometer inorganic oxide-organic hybrid coating composition and its preparation method and application. The coating composition contains at least one aqueous film-forming organic high polymer, at least one nanometer inorganic oxide particle and at least one amphoteric hyperbranched resin. The invention provides a simple method for solving the problem of compatibility and stability of nanometer inorganic oxide-organic hybridization through an amphoteric hyperbranched polymer additive. Through introduction of the amphoteric hyperbranched resin in the coating composition, the compatibility of the nanometer inorganic oxide particles and the aqueous film-forming organic high polymer is improved so that the coating is not easily cracked at high nanometer inorganic oxide particle content. The surface morphology of the coating changes, the coating surface hydrophilicity is improved and the coating stain resistance is improved.

Owner:NIPPON PAINT CHINA +1

Four-step method for processing and recycling tin ore floatation wastewater

ActiveCN102030445BReduce productionIncrease the amount of purificationEnergy based wastewater treatmentMultistage water/sewage treatmentChemical treatmentPolyacrylamide

The invention discloses a four-step method for processing and recycling tin ore floatation wastewater, which comprises a new floatation technique, chemical treatment, physical treatment and biological treatment. The four-step method is characterized in that the principle of putting prevention first and providing prevention and control is adopted. The method is as follows: the new floatation technique and process are utilized to reduce the floatation wastewater and the microgranular particles from the headstream and reduce the usage amount of floatation reagents; because the chemical treatmentmethod is used, the concentration of polyacrylamide in the tin ore floatation wastewater is increased from 0.5 percent to 0.9-1.1 percent, and the settling rate of part of the wastewater is improved;the physical treatment method is adopted to increase the settling distance and the settling time, the settling distance is extended for another 600 to 800m on the basis of 200m, and the settling timeis increased for another 25 to 27 hours on the basis of 10 hours; aquatic organisms or plants, such as fish, frogs, aquatic weeds and the like are adopted to process the wastewater, the ecological reconstruction is realized, the agricultural irrigation standards are met, the utilization ratio of floatation return water is improved from 86 percent to above 97 percent, and peaceful and friendly coexistence of human and environment is realized.

Owner:广西华锡矿业有限公司铜坑矿业分公司

Cement grinding aid

The invention discloses a cement grinding aid. The cement grinding aid is prepared from, by weight, 20-30 parts of triethanolamine, 20-30 parts of calcium formate, 20-30 parts of maleic anhydride, 10-15 parts of sodium lignin sulfonate, 1-8 parts of sodium pyrophosphate, 1-10 parts of wood calcium, 1-5 parts of hydrochloric ether and 5-10 parts of carboxymethylcellulose. According to the cement grinding aid, as the carboxymethylcellulose is added into the cement grinding aid formula, the birdnesting phenomenon of powder is obviously solved, the gradation of particles is improved, the micro-powder particle content is increased, the mobility of cement powder is accelerated, the powder is fully subjected to powder grinding, and the fineness and the strength of cement can be improved.

Owner:北海金匠水泥制品有限责任公司

Dust containment device for surfacing machines

InactiveUS20050277374A1Increase speedPrevent escapePortable grinding machinesPlane surface grinding machinesHigh velocityFuselage

A floor machine comprising a motor, a body, and a dust collection system. The dust collection system comprises a skirt, which is coupled to the floor machine and forms a cavity over the body and a floor treatment pad. The skirt includes an air channel device secured to a bottom edge of the skirt. The air channel device encircles the floor treatment pad and comprises a multiplicity of slots between a floor and the skirt. Jointly, the skirt and air channel device confine particles within the cavity. A vacuum for sucking the particles from the cavity creates high velocity air flow through the air channel device. Negative pressure within the cavity prevents particles from escaping. The particles are removed from the cavity through a vacuum tube into the vacuum.

Owner:NHANCE

Novel cement grinding aid

InactiveCN106336143ASolve the phenomenon of powder agglomerationImprove gradingMaleic anhydrideSodium carboxymethylcellulose

The invention discloses a novel cement grinding aid, which comprises the following raw materials by weight: 20-30 parts of allyl alcohol, 20-30 parts of diethanolamine, 20-30 parts of maleic anhydride, 10-15 parts of sodium lignin sulfonate, 1-8 parts of sodium pyrophosphate, 1-10 parts of a magnesium lignin sulfonate salt, 1-5 parts of sodium dodecylsulfonate, and 5-10 parts of carboxymethylcellulose. The invention provides the novel cement grinding aid, wherein the carboxymethyl cellulose is added in the formula of the cement grinding aid, such that the powder agglomeration phenomenon is significantly solved, the gradation of the particles is improved, the particle content of the micro-powder is increased, the fluidity of the cement powder is accelerated, and the powder material is sufficiently grinded so as to improve the fineness and the strength of the cement.

Owner:北海金匠水泥制品有限责任公司

Hand-held portable sliding arc low-temperature plasma generation device

ActiveCN103997841BEasy to useSimple and flexible operationPlasma techniqueTreatment effectPlasma particle

The invention discloses a handheld portable generating device for sliding arc low-temperature plasma. According to the structure, a miniature air pump is connected with an insulating sleeve through a silica gel conduit, the insulating sleeve is located between a high-voltage electrode and a ground electrode, a high-voltage power source supplies power to the high-voltage electrode and the ground electrode, the high-voltage power source, the high-voltage electrode and the ground electrode are embedded in a handle, a hole is formed in the front end of the handle, so that the plasma is sprayed out, and a control switch is arranged on the handle so as to control the high-voltage power source to work. The generating device has the advantages that the length and the temperature of the plasma are changed through adjustment of the voltage, operation is simple and flexible, and the device can be used conveniently by an operator; the device is small in size, convenient to carry, attractive in appearance and low in cost; air or simple substance gas or a mixture of air and simple substance gas or a gaseous compound or gaseous organic matter serves as the working gas and various requirements can be met; other excitation devices are not needed, faults are reduced, and reliability of the device is improved; the generating device is different from a traditional plasma source, a sliding arc is more efficient, the activity of generated plasma particles is better, and the particles are more beneficial to the human body and the material treatment effect.

Owner:JIANGSU ROZENMED MEDICAL TECH CO LTD

A liquid cement grinding aid with low alcohol amine content

The invention discloses a liquid cement grinding aid with low alcohol amine content. The liquid cement grinding aid is prepared from the following ingredients in parts by weight: 10-15 parts of diacetal monoisopropanolamine, 3-5 parts of triethanolamine, 4-6 parts of sodium acetate, 4-6 parts of sodium chloride, 1-2 parts of sodium lignosulfonate, 6-8 parts of hydroxyethyl cellulose and 20-25 parts of papermaking black liquor. The cement grinding aid disclosed by the invention is low in consumption, good in enhancement effect and low in cost.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

A chlorine-free high-efficiency cement grinding aid

The invention discloses an efficient chloride-free cement grinding aid. The efficient chloride-free cement grinding aid is prepared from the following ingredients in parts by weight: 10-12 parts of polyether, 6-8 parts of diacetal monoisopropanolamine, 3-5 parts of triethanolamine, 2-4 parts of sodium carboxymethyl cellulose, 1-2 parts of sodium lignosulfonate and 8-12 parts of papermaking black liquor. Compared with the products in the prior art, the efficient chloride-free cement grinding aid has the advantage that the 3-day compressive strength and 28-day compressive strength can be obviously improved under the condition of different dosages.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

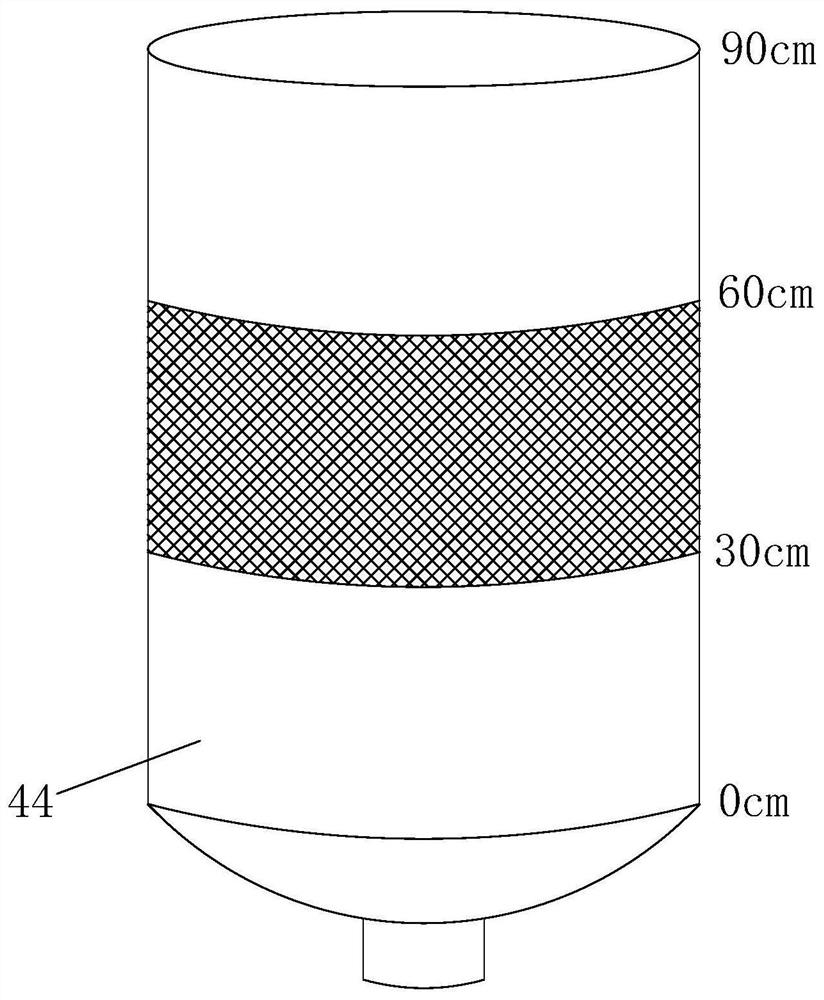

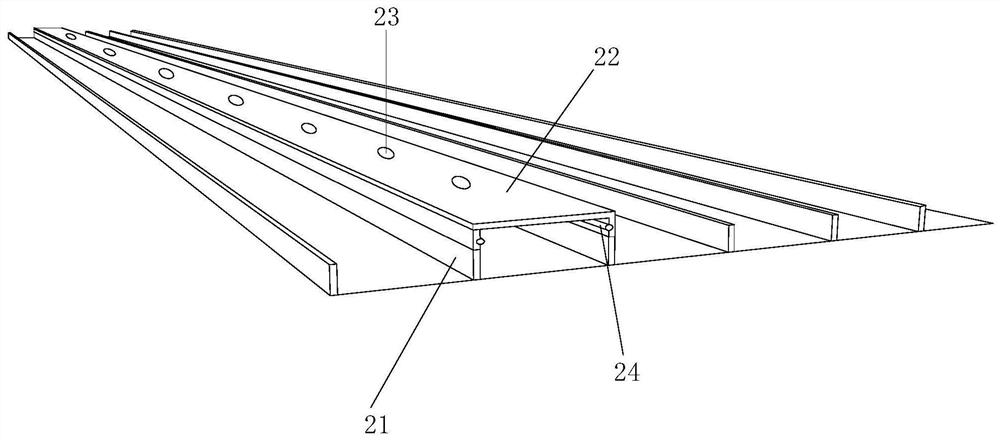

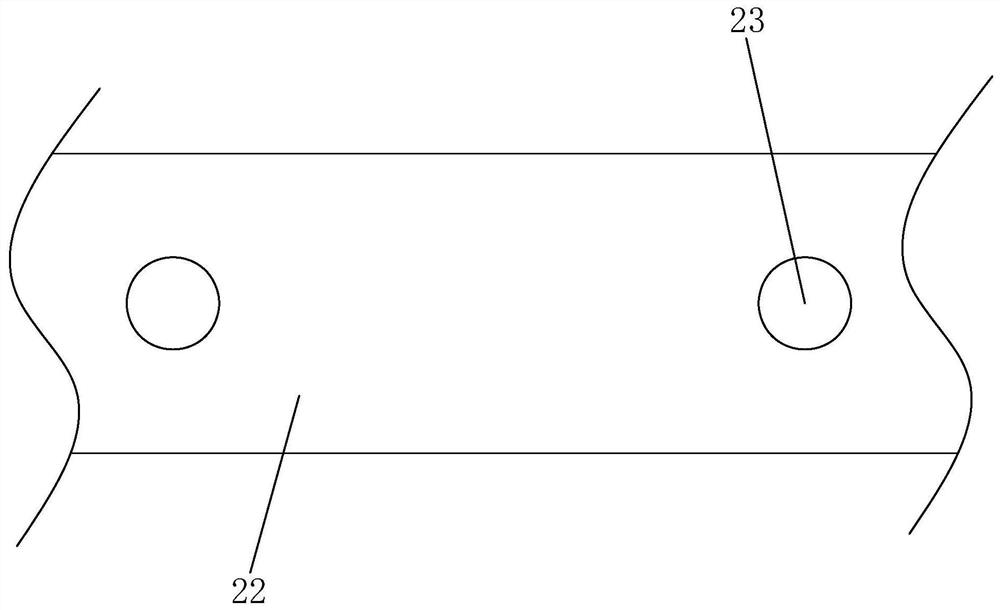

Efficient and automatic sewage suction device for pond engineering circulating water

ActiveCN112335602AAvoid smallHigh particle contentClimate change adaptationPisciculture and aquariaWater flowSewage

The invention discloses an efficient and automatic sewage suction device for pond engineering circulating water. The sewage suction device comprises a plurality of grids, a sewage suction cover, at least two water outlet pipes, a plurality of rows of ultraviolet fluorescence sensors, a plurality of sewage suction pipes, a sewage suction pump and a controller. The grids are parallel to one anotherand are arranged at the bottom of a sewage collecting area at equal intervals, and a plurality of water flow grooves are formed by the grids and the bottom wall of the sewage collecting area. The sewage suction cover is in an inverted U shape, covers the two adjacent grids and defines a water flow channel with the water flow grooves. The two water outlet pipes are arranged in parallel and fixed tothe inner walls of the two opposite sides of the sewage suction cover. A plurality of water outlets are formed in each water outlet pipe at equal intervals. The multiple rows of ultraviolet fluorescence sensors correspond to the multiple water flow grooves respectively, and each row of ultraviolet fluorescence sensors are installed on the bottom walls of the corresponding water flow grooves. Thedevice can automatically detect and suck deposited particles, operation is more convenient, the content of the particles in sucked sewage is higher, the sewage suction effect is better, and the sewagesuction efficiency and the sewage suction effect can be improved.

Owner:FISHERIES RES INST ANHUI ACAD OF AGRI SCI

Preparation method of composite cladding material and equipment

ActiveCN100390326CUniform thicknessHigh particle contentCellsElectrolytic coatingsComposite plateMetal

A process for preparing the composite plated layer on substrate includes putting substrate in the electrolyte of electrolyzer, and electroplating while making anode to rotate and stirring the electrolyte by air stirrer. Its apparatus is composed of electrolyzer, anode, rotating triangular anode, pump, air stirrer and filter for removing big particles.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

A kind of intragranular grain boundary distributed micro-nano composite particle reinforced aluminum matrix composite material and preparation method thereof

ActiveCN110229979BSpeed up the reaction processSmall particle sizeNano complexAluminum matrix composites

The invention discloses an aluminum-based composite material reinforced with micro-nano composite particles distributed in grain boundaries within a grain and a preparation method thereof. Firstly, K 2 TiF 6 powder into the pure aluminum melt, supplemented by ultrasonic stirring, to prepare Al‑Al with uniform structure 3 Ti master alloy, and the resulting Al‑Al 3 Al in Ti master alloy 3 The average particle size of Ti particles is less than 5 μm; then the K 2 TiF 6 Powder and KBF 4 The powder is mixed according to the molar ratio of 1:2, and then added to the pure aluminum melt, supplemented by ultrasonic stirring treatment, and the Al-TiB with uniform structure is prepared. 2 master alloy, and the resulting Al‑TiB 2 TiB in master alloy 2 The average particle size of the particles is less than 100nm; 3 Ti master alloys and Al‑TiB 2 Master alloys as raw materials, or Al, alloying elements, Al‑Al 3 Ti master alloys and Al‑TiB 2 The master alloy is used as the raw material, and the raw material is melted, supplemented by ultrasonic stirring to disperse the reinforced particles, and the double-reinforced aluminum matrix composite material within the grain boundary is obtained after casting.

Owner:咸阳瞪羚谷新材料科技有限公司

A kind of powder grinding aid, its preparation method and application

ActiveCN109467957BGood dispersionImprove grinding efficiencyPigment physical treatmentSODIUM METAPHOSPHATESodium phosphates

The invention discloses a novel environmentally-friendly powder grinding aid as well as a preparation method and application thereof, and belongs to the technical field of powder grinding. The grinding aid comprises the following raw materials in parts by weight: 40-50 parts of diethanol monoisopropanolamine, 30-40 parts of hexadecanol ester, 10-15 parts of calcium lignosulfonate, 5-10 parts of ethylene glycol, 4-8 parts of hydroxyethyl methylcellulose, 8-12 parts of sodium hexametaphosphate and 2-5 parts of sodium polyacrylate. The calcium lignosulfonate has good dispersibility, so that the grinding efficiency can be improved, the machine-hour output is increased, the electricity consumption is lowered, a synergistic effect of raw material components can be also promoted, and the adaptability of the grinding aid to calcium carbonate is improved. The hexadecanol ester is applied to fusion of polyol and a lignin derivative, and high-adsorption strength dispersing agents, namely the sodium hexametaphosphate and the sodium polyacrylate, are contained, so that a phenomenon of powder agglomeration can be obviously solved, gradation of calcium carbonate particles is improved and the content of micropowder particles is increased.

Owner:濮阳圣恺环保新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com