A liquid cement grinding aid with low alcohol amine content

A technology of cement grinding aids and alcohol amines, applied in the field of liquid cement grinding aids, can solve the problems of insufficient utilization, heterogeneity of macromolecular polydispersity, physical and chemical properties, structural complexity, etc., and achieve improvement The effect of reducing the output per hour, reducing the amount of direct addition, and increasing the fluidity of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

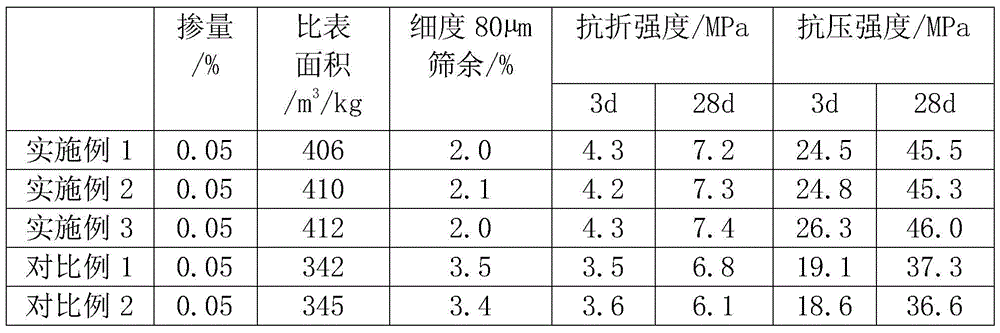

Embodiment 1

[0015] Weigh the following raw materials according to the weight ratio: 10kg of diethanol monoisopropanolamine, 5kg of triethanolamine, 4kg of sodium acetate, 6kg of sodium chloride, 1kg of sodium lignosulfonate, 8kg of hydroxyethyl cellulose, and 20kg of papermaking black liquor , mixed and stirred for 30 minutes to obtain the cement grinding aid product.

Embodiment 2

[0017] Weigh the following raw materials in proportion by weight: 15kg of diethanol monoisopropanolamine, 3kg of triethanolamine, 4kg of sodium acetate, 6kg of sodium chloride, 1kg of sodium lignosulfonate, 8kg of hydroxyethyl cellulose, and 25kg of papermaking black liquor , mixed and stirred for 30 minutes to obtain the cement grinding aid product.

Embodiment 3

[0019] Weigh the following raw materials by weight: 12 kg of diethanol monoisopropanolamine, 4 kg of triethanolamine, 5 kg of sodium acetate, 5 kg of sodium chloride, 1 kg of sodium lignosulfonate, 6 kg of hydroxyethyl cellulose, and 22 kg of papermaking black liquor , mixed and stirred for 30 minutes to obtain the cement grinding aid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com