A Ni-P-PTFE anti-scale plating by rear earth cerium-induced ultrasonic chemical codeposition and a preparing process thereof

A technology of sonochemistry and preparation technology, applied in the field of rare earth cerium-induced ultrasonic chemical co-deposition Ni-P-PTFE anti-scaling coating, which can solve the problems of poor anti-scaling performance and achieve the effect of improving the anti-scaling performance of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

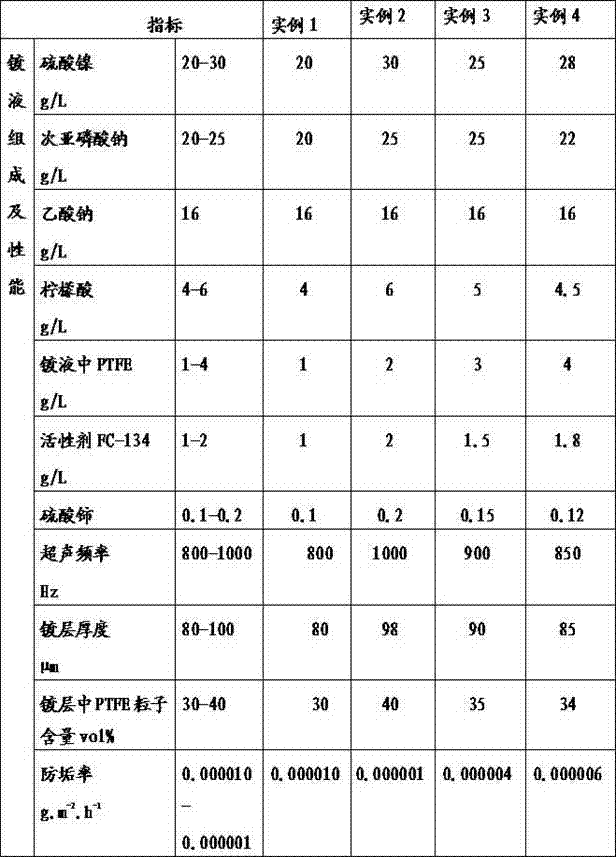

[0028] The second step, mechanical stirring (speed: 400r / min), active agent FC-134 (purity>90%): 1g / L and PTFE emulsion: 1g / L mixed solution for 1h;

[0029] In the third step, the composition content of the plating solution is: nickel sulfate: 20g / L; sodium hypophosphite: 20g / L; citric acid: 4g / L; sodium acetate: 16g / L; PTFE (particle size: 0.5μm): 1g / L L; active agent FC-134 (purity>90%): 1g / L; cerium sulfate: 0.1g / L;

[0030] The fifth step is to put the pre-treated sample and the activated mixture into an ultrasonic (ultrasonic frequency 800Hz) water bath for 3 hours of plating;

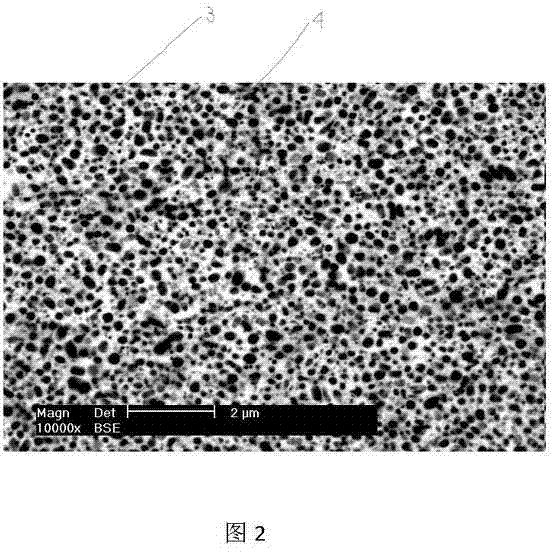

[0031] The seventh step, coating (2) (see figure 1 ) properties: the coating (2) is dense, with a thickness of 80 μm, and the content of PTFE particles (3) in the coating (2) is 30vol% (see figure 2 ), the anti-scaling rate is 0.000010g.m -2 .h -1 .

Embodiment 2

[0033] The second step, mechanical stirring (speed: 400r / min), active agent FC-134 (purity>90%): 2g / L and PTFE emulsion: 2g / L mixed solution for 2h;

[0034] In the third step, the composition content of the plating solution is: nickel sulfate: 30g / L; sodium hypophosphite: 25g / L; citric acid: 6g / L; sodium acetate: 16g / L; PTFE (particle size: 0.5μm): 4g / L L; active agent FC-134 (purity>90%): 2g / L; cerium sulfate: 0.2g / L;

[0035] The fifth step is to put the pretreated sample and the activated mixture into an ultrasonic (ultrasonic frequency of 1000Hz) water bath for 3 hours of plating;

[0036] The seventh step, coating (2) (see figure 1 ) properties: the coating (2) is dense, the thickness is 98μm, and the PTFE particles (3) in the coating (2) contain 40vol% (see figure 2 ), the anti-scaling rate is 0.000001g.m -2 .h -1 .

Embodiment 3

[0038] The second step, mechanical stirring (speed: 400r / min), active agent FC-134 (purity>90%): 1.5g / L and PTFE emulsion: 3g / L mixed solution for 1.5h;

[0039] In the third step, the composition content of the plating solution is: nickel sulfate: 25g / L; sodium hypophosphite: 25g / L; citric acid: 5g / L; sodium acetate: 16g / L; PTFE (particle size: 0.5μm): 2g / L L; active agent FC-134 (purity>90%): 1.5g / L; cerium sulfate: 0.15g / L;

[0040] The fifth step is to put the pretreated sample and the activated mixture into an ultrasonic (ultrasonic frequency of 900Hz) water bath for 3 hours;

[0041] The seventh step, coating (2) (see figure 1 ) properties: the coating (2) is dense, with a thickness of 90 μm, and the content of PTFE particles (3) in the coating (2) is 35vol% (see figure 2 ), the anti-scaling rate is 0.000004g.m -2 .h -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com