Preparation method of polyethylene glycol/ZnO/Ag nanoparticle composite fiber material

A polyethylene glycol and composite fiber technology, which is applied in fiber processing, fiber chemical characteristics, spinning solution preparation, etc., can solve the problems of difficulty in setting solvent spinning parameters, complicated coaxial electrospinning devices, etc., and achieves good results. Application prospects, low cost, and the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

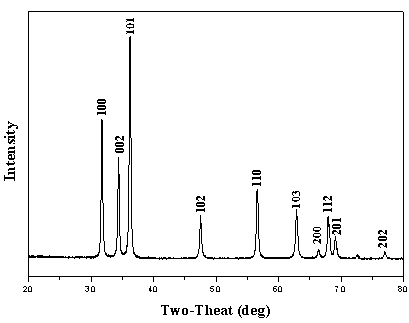

[0028] Example 1: Nanoparticle composite fiber with Ag content of 0atom %

[0029] 4g Zn(NO 3 ) 2 ·6H 2 Add 10ml deionized water and 10ml deionized ethanol to O and 1gPVP and stir evenly, then mix and stir for 30min, add 2gPEG to 20ml dehydrated ethanol and stir, add the above mixed solution, stir magnetically at room temperature for 6h and then let it stand for 4h to obtain Uniform, transparent and viscous [PEG+PVP] / Zn(NO 3 ) 2 Spinning solution; the weight ratio of each component of the spinning solution is: Zn(NO 3 ) 2 ·6H 2 O / [PEG+PVP] / absolute ethanol / deionized water=4:3:30:10; add the configured spinning solution to the existing electrospinning device of the spinning device for electrospinning, the nozzle The caliber is 0.6mm, the working voltage is 15kV; the curing distance from the syringe needle nozzle to the receiving screen is 13cm; the indoor temperature is 15 o C, with a relative humidity of 45%, [PEG+PVP] / Zn(NO 3 ) 2 Composite nanofibers; the prepared...

example 2

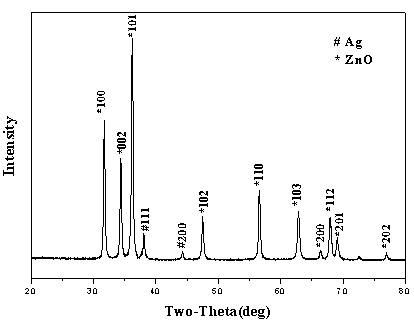

[0031] Example 2: Nanoparticle composite fiber with Ag content of 5atom %

[0032] 3.886g Zn(NO 3 ) 2 ·6H 2 O and 0.114g AgNO 3 Mix, add 10ml of deionized water and stir evenly, dissolve 1gPVP and 2gPEG with 10ml of absolute ethanol and 20ml of absolute ethanol respectively, then mix the above solutions, stir magnetically at room temperature for 6h and then let stand for 4h to obtain Uniform, gray and viscous [PEG+PVP] / [Zn(NO 3 ) 2 +AgNO 3 ] spinning solution; the weight ratio of each component of the spinning solution is: [Zn(NO 3 ) 2 ·6H 2 O+ AgNO 3 ] / [PEG+PVP) / absolute ethanol / deionized water=4:3:30:10, where AgNO 3 with Zn(NO 3 ) 2 ·6H 2 The substance ratio of O is 0.05:1; the configured spinning solution is added to the existing electrospinning device of the spinning device for electrospinning, the nozzle diameter is 0.6mm, and the working voltage is 15kV; the needle nozzle of the syringe The curing distance to the receiving screen is 13cm; the indoor temp...

example 3

[0036] Example 3: Nanoparticle composite fiber with Ag content of 10atom %

[0037] 3.772g Zn(NO 3 ) 2 ·6H 2 O and 0.228g AgNO 3 Mix, add 10ml of deionized water and stir evenly, dissolve 1gPVP and 2gPEG with 10ml of absolute ethanol and 20ml of absolute ethanol respectively, then mix the above solutions, stir magnetically at room temperature for 6h and then let stand for 4h to obtain Uniform, gray and viscous [PEG+PVP] / [Zn(NO 3 ) 2 +AgNO 3 ] spinning solution; the weight ratio of each component of the spinning solution is: [Zn(NO 3 ) 2 ·6H 2 O+ AgNO 3 ] / [PEG+PVP] / absolute ethanol / deionized water=4:3:30:10, where AgNO 3 with Zn(NO 3 ) 2 ·6H 2 The mass ratio of O is 0.1:1; the configured spinning solution is added to the existing electrospinning device of the spinning device for electrospinning, the nozzle diameter is 0.6mm, and the working voltage is 15kV; the needle nozzle of the syringe The curing distance to the receiving screen is 13cm; the indoor temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com