Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Guaranteed structural accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

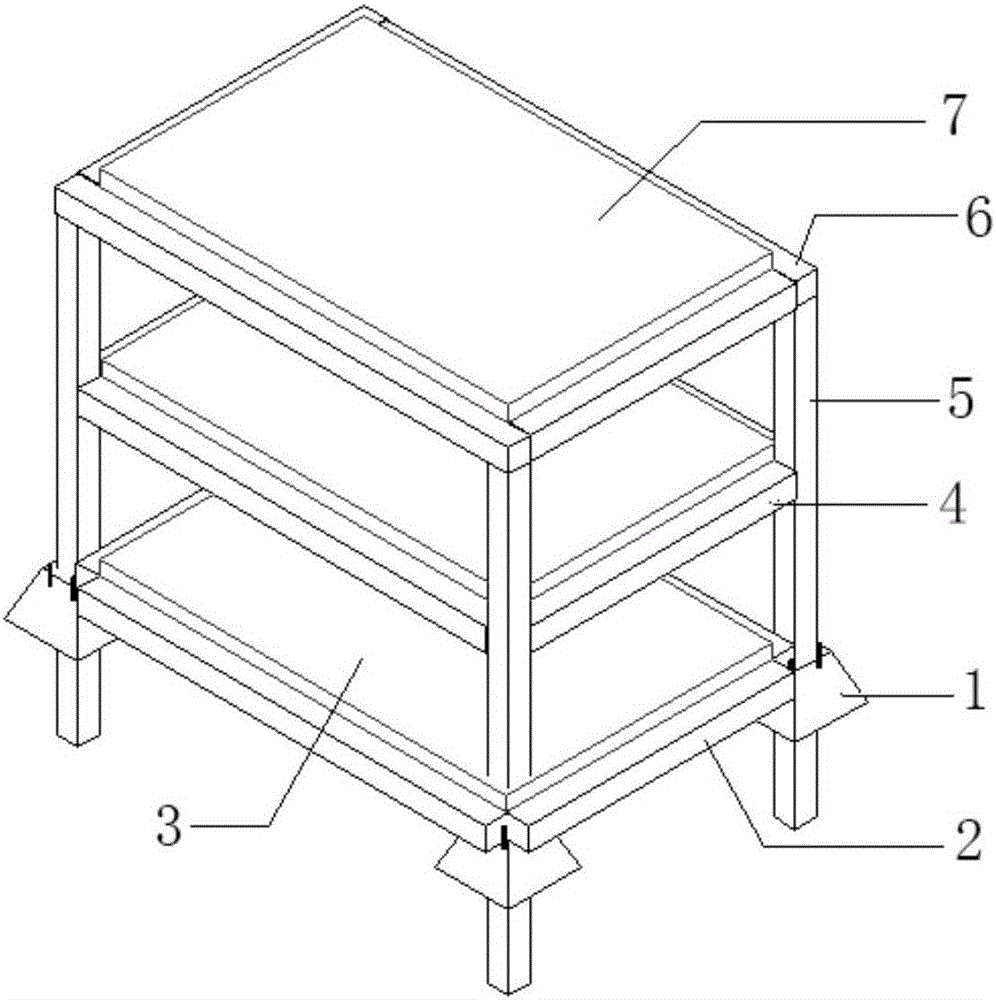

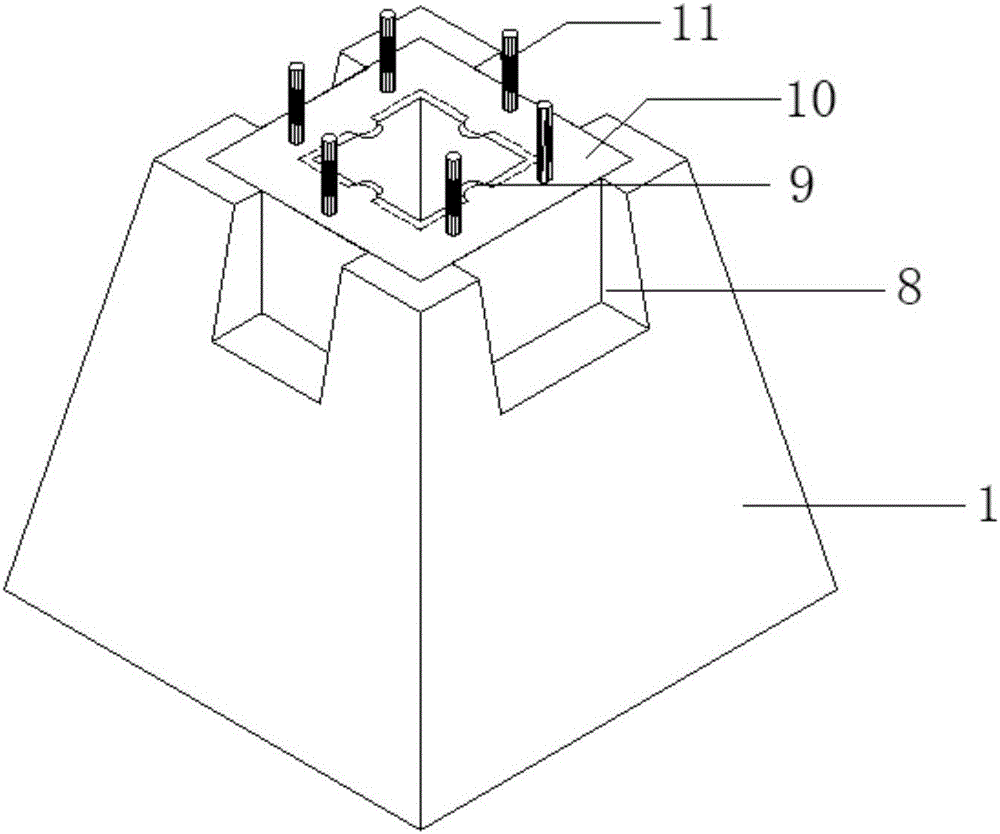

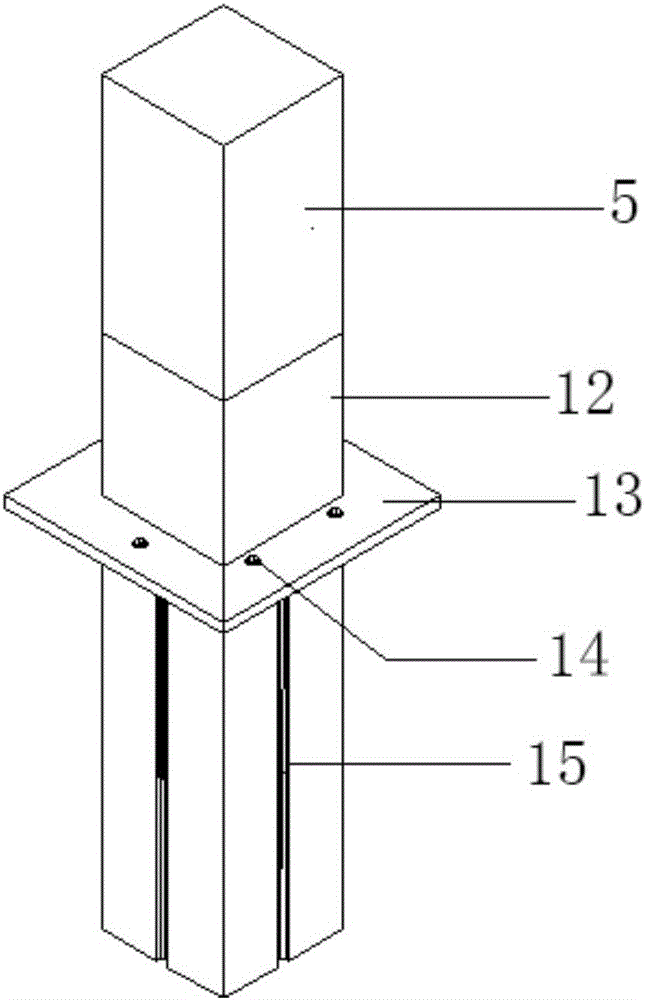

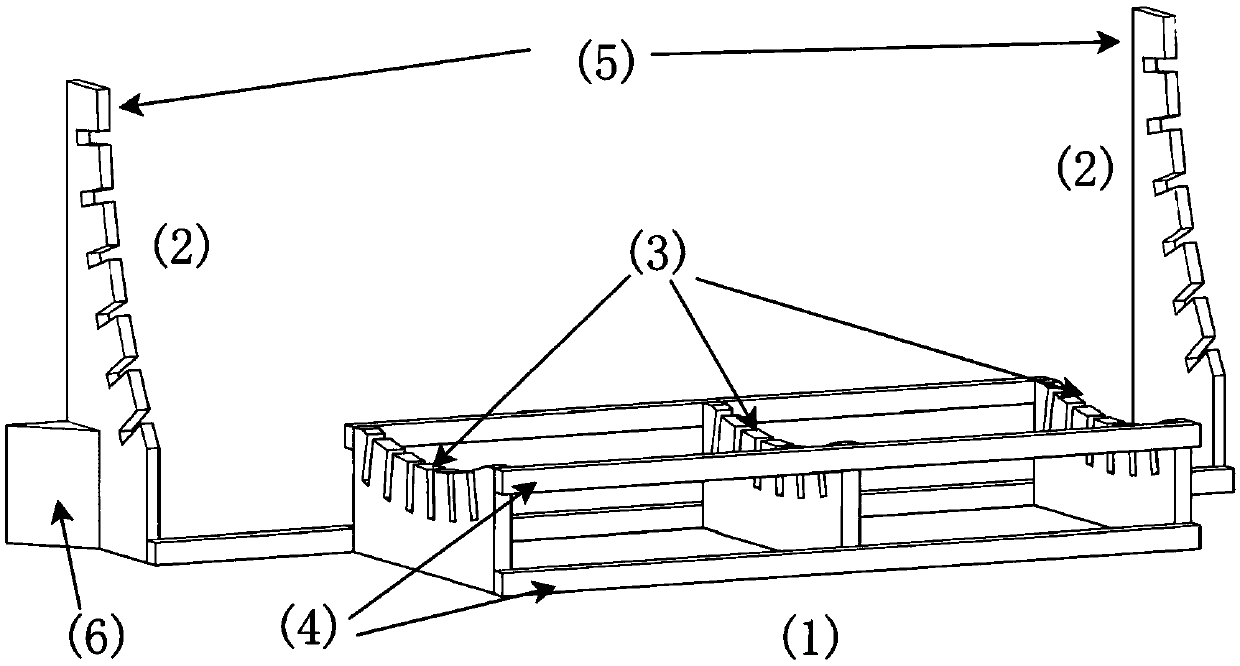

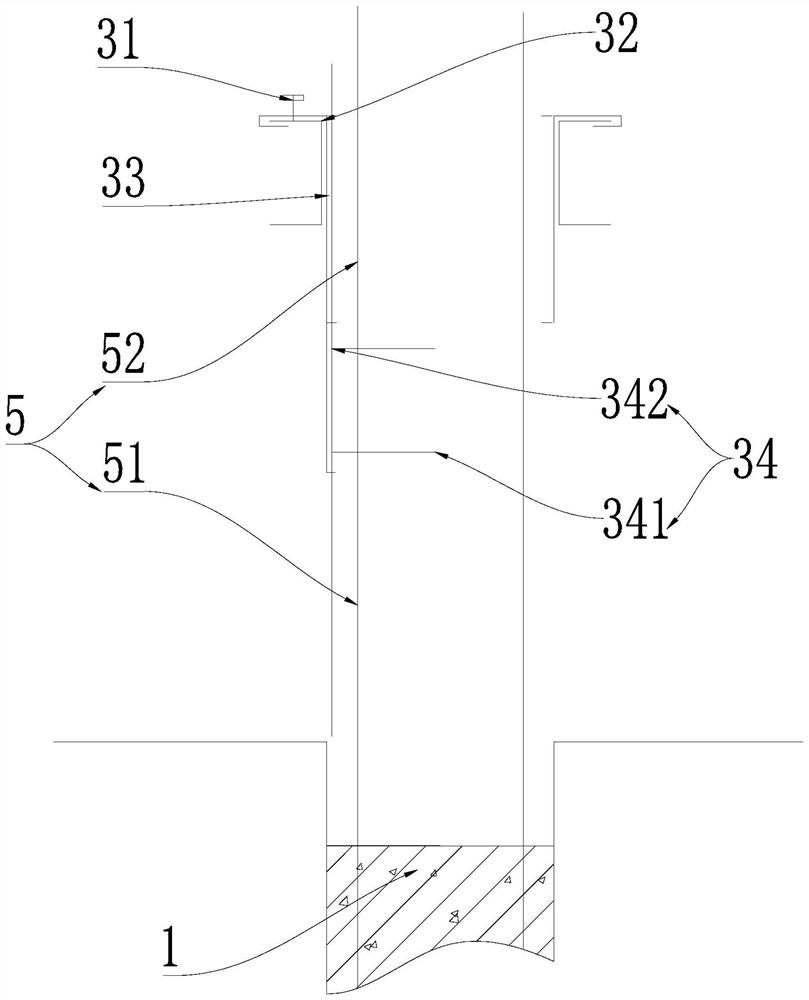

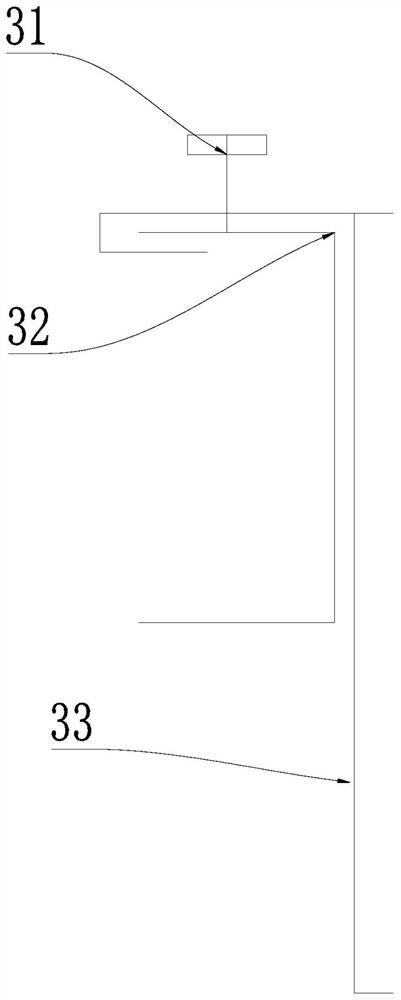

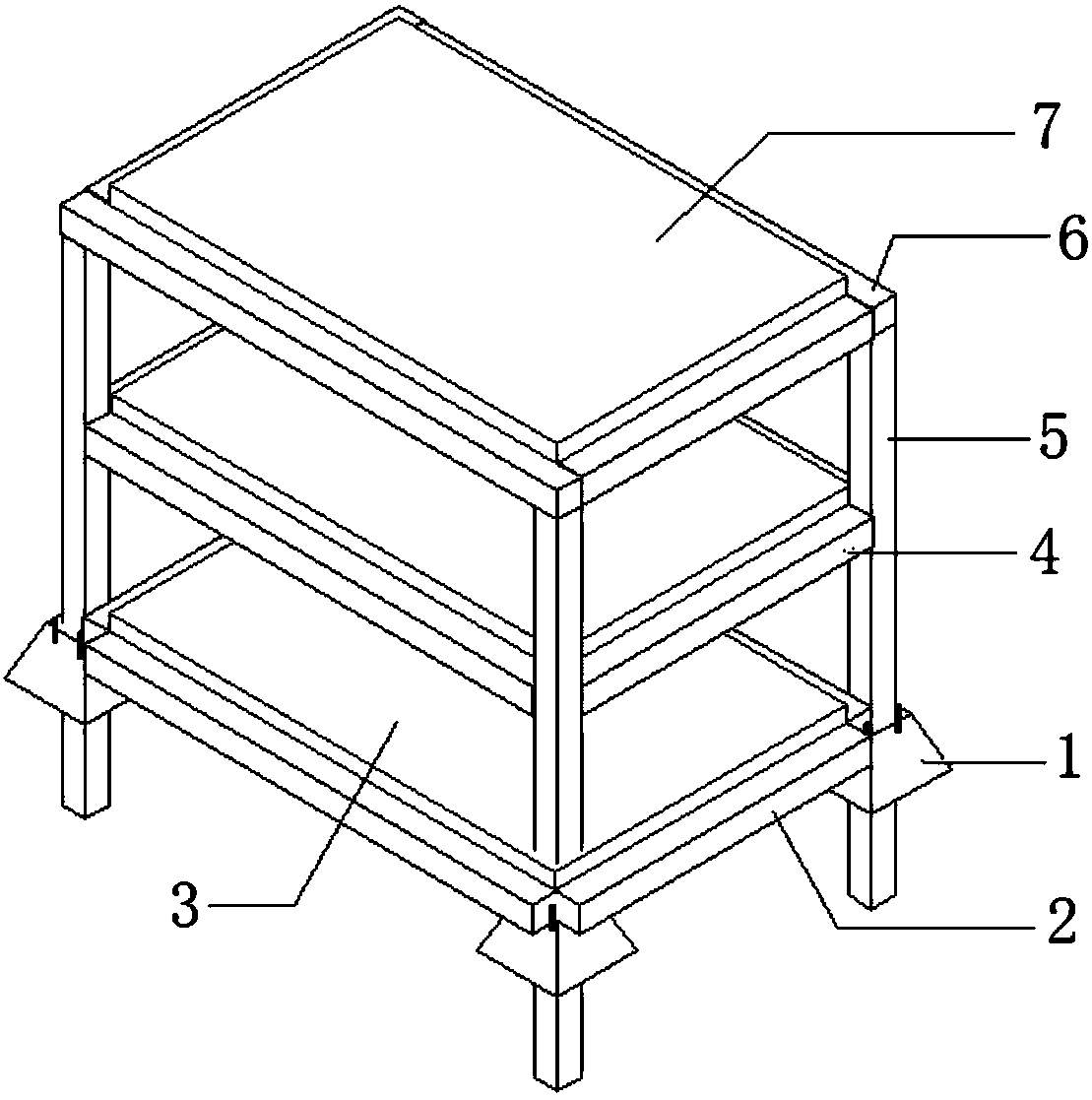

Assembled type garage structure system based on precast piles and method

ActiveCN105862900AEmission reductionGuaranteed verticalityArtificial islandsUnderwater structuresEngineeringVertical load

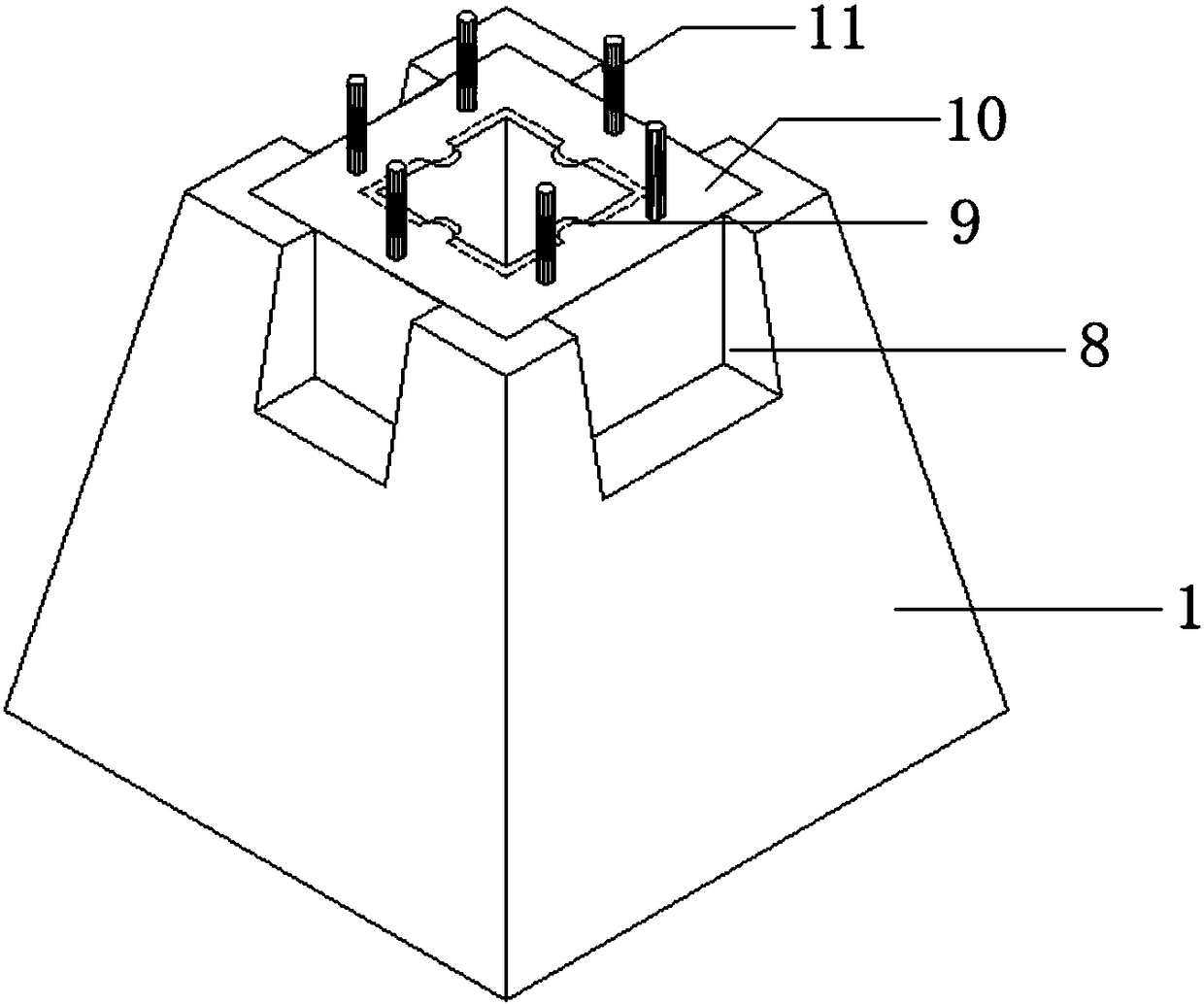

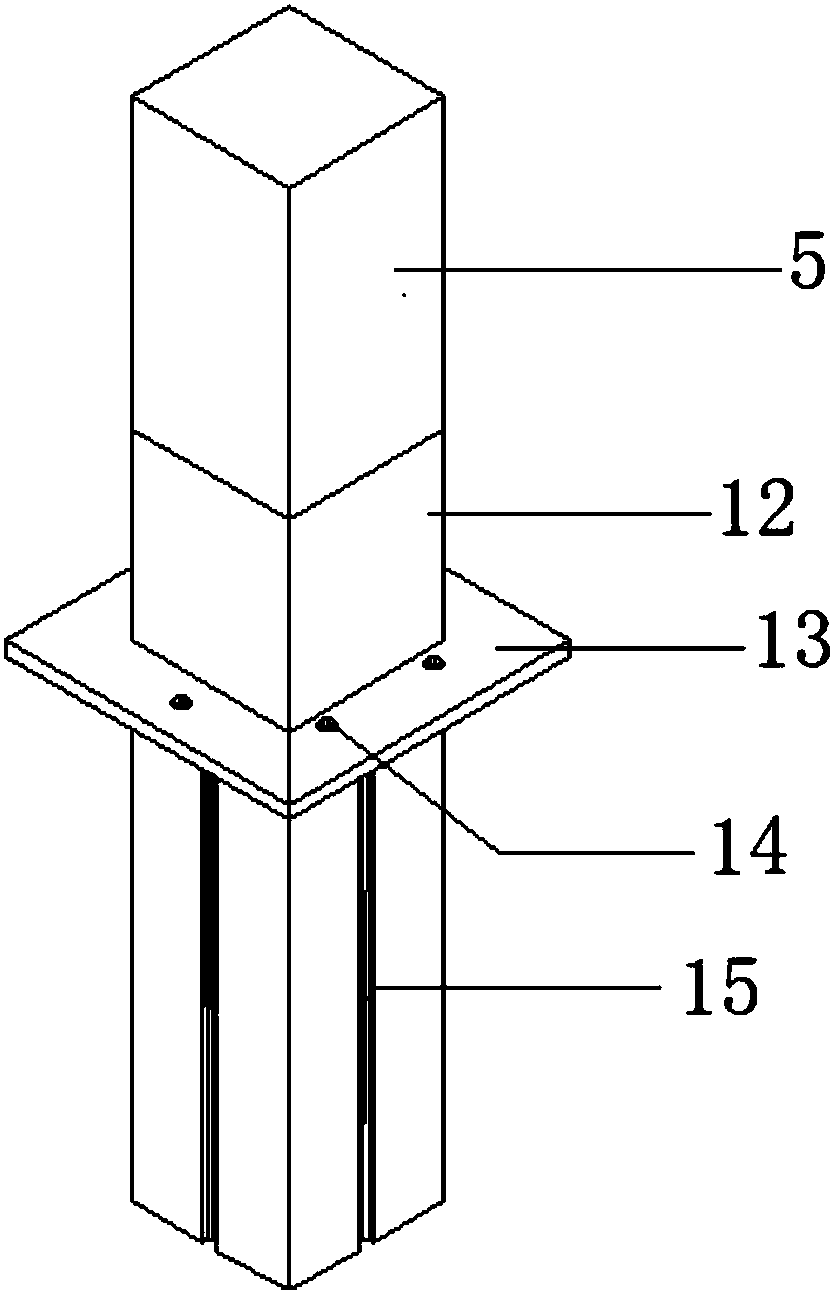

The invention discloses an assembled type garage structure system based on precast piles and a method. The assembled type garage structure system comprises the precast piles, horizontal supporting beams and independent foundations, wherein vertical load bearing parts of a garage structure are formed by the precast piles, and guide rails are arranged on the outer surfaces of the precast piles; the horizontal supporting beams comprise ground beams and superposed beams, the ground beams are arranged around the precast piles by one circle so as to support a bottom plate of a garage, and the superposed beams are arranged around the precast piles so as to support a garage floor plate or a garage top panel; the independent foundations are connected with the precast piles and the precast ground beams through designed grooves. All the structure members such as the precast piles and the independent foundations are machined in factories and can be assembled for construction, so that emission of pollutants at a construction site is reduced; through the guide rails and cooperation of the independent foundations and mounting flanges, the perpendicularity of the precast piles is guaranteed, the structure bearing capacity is well guaranteed, and structure precision is guaranteed; the precast piles and garage columns are integrated, so that not only is energy saved, but also construction efficiency of the underground garage is greatly improved.

Owner:SHANDONG UNIV

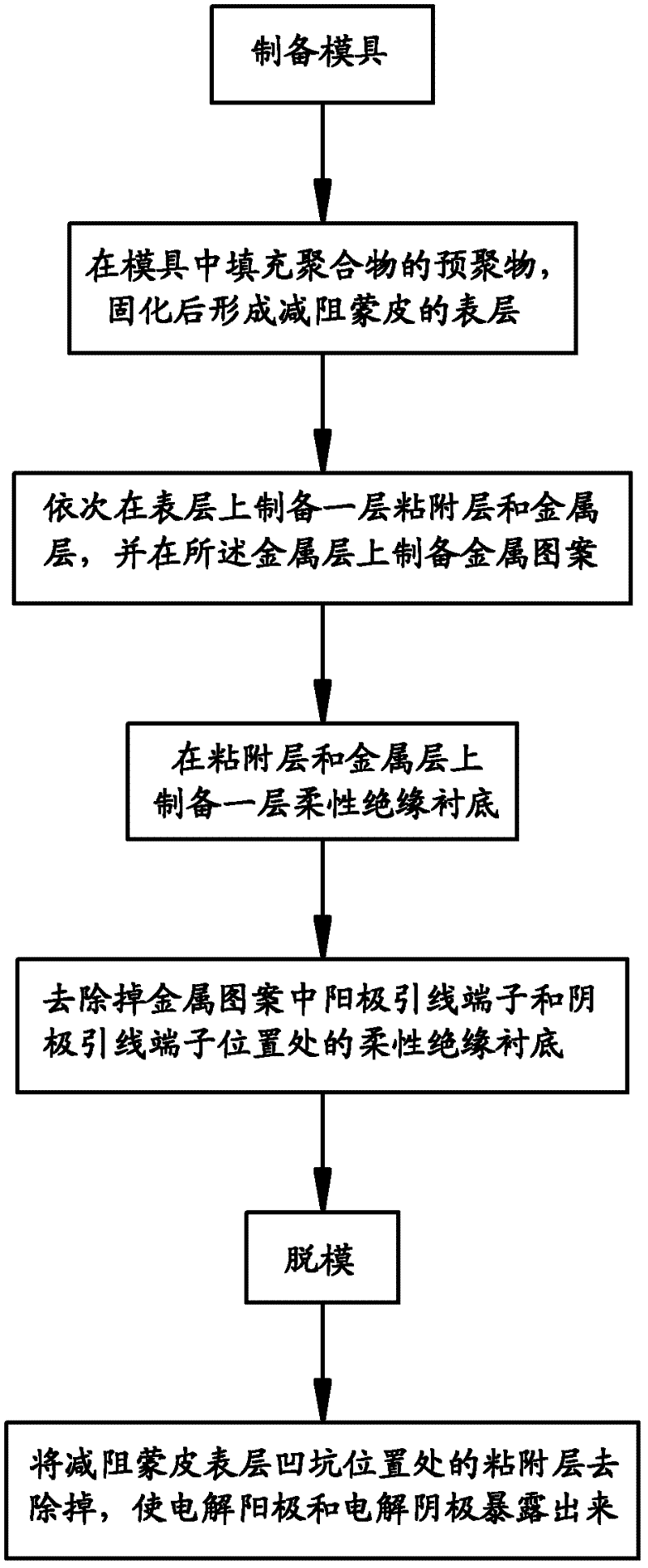

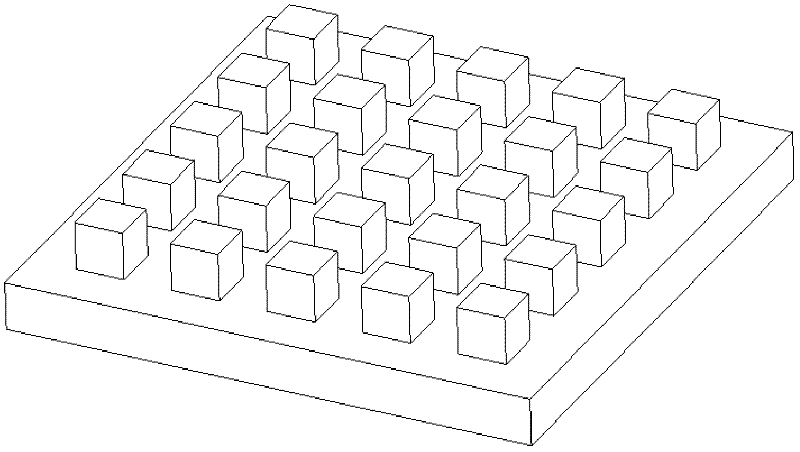

Manufacturing method of flexible mems drag-reducing skin

InactiveCN102295267ABroaden your optionsGuaranteed structural accuracyDecorative surface effectsChemical vapor deposition coatingSurface layerEngineering

The invention which discloses a manufacturing method of a flexible MEMS anti-drag skin belongs to the micromachining field, and the manufacturing method is designed to provide an improved manufacturing process. The manufacturing method of the invention comprises the following steps: preparing a die which contains a dimpling column array, wherein the shape of the dimpling column array is opposite to the shape of micro-pits on the surface layer of the skin; forming the surface layer of the anti-drag skin by filling the die with a prepolymer of a polymer, and curing; preparing an adhesive layer on the surface layer; preparing a metal layer on the adhesive layer, and forming an electrolytic anode, an electrolytic cathode, an anode lead terminal, a cathode lead terminal, and an internal connection lead with an MEMS plane fine technology; preparing a flexible insulation substrate on the adhesive layer and the metal layer; removing the flexible insulation substrate on a position corresponding to a lead terminal; demolding; and removing the adhesive layer on a position corresponding to micro-pits of the surface layer to expose metal electrodes. The manufacturing method of the present invention is suitable for manufacturing the flexible MEMS anti-drag skin which treats the polymer difficult to etch as a surface layer material.

Owner:TSINGHUA UNIV

Cable extrusion test run technology

InactiveCN104167260AImprove electrical performanceImprove mechanical propertiesInsulating conductors/cablesElectricityMaterials science

The invention discloses a cable extrusion test run technology. The technology comprises the steps that (1) a mold core and a mold sleeve are selected according to the cable extrusion thickness, a wedge-shaped ruler is inserted into the gap between the mold core and the mold sleeve for measurement after the mold core and the mold sleeve are installed, and meanwhile the coaxiality of the mold core and the mold sleeve are precisely adjusted; (2) technology traction and extension are achieved for the cable extrusion technology, concretely, optimal technological parameters are set for the cable type, cable materials and indoor temperature, in other words, glue output amount, the traction speed and indoor temperature are set as fixed values, the plastifying temperature which is a variable is adjusted, five kinds of finished products plastified at different temperatures are manufactured in a trial mode, insulation voltage, tensile strength, elongation at break and hot extending tests are carried out, test results are compared, the plastifying temperature value with the best electric performance and mechanical performance is taken as the optical parameter value for the processing technology of the cable type, and the standard technological process is formed. According to the cable extrusion test run technology, a mold is precisely adjusted before cable extrusion, the structural precision is ensured, using is easy and convenient, the maneuverability is high, and the rate of rejected products produced in the cable manufacturing process can be effectively lowered.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

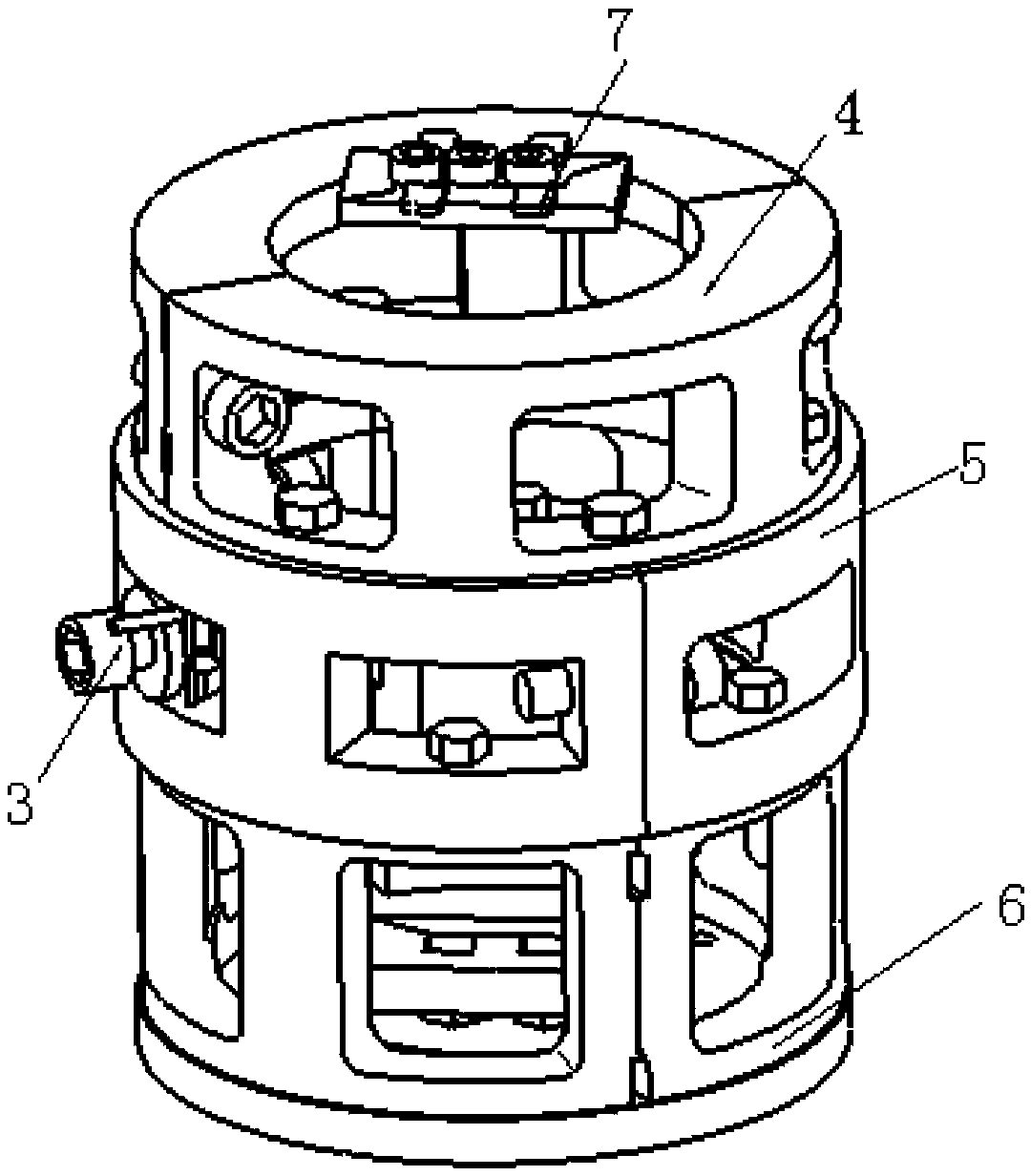

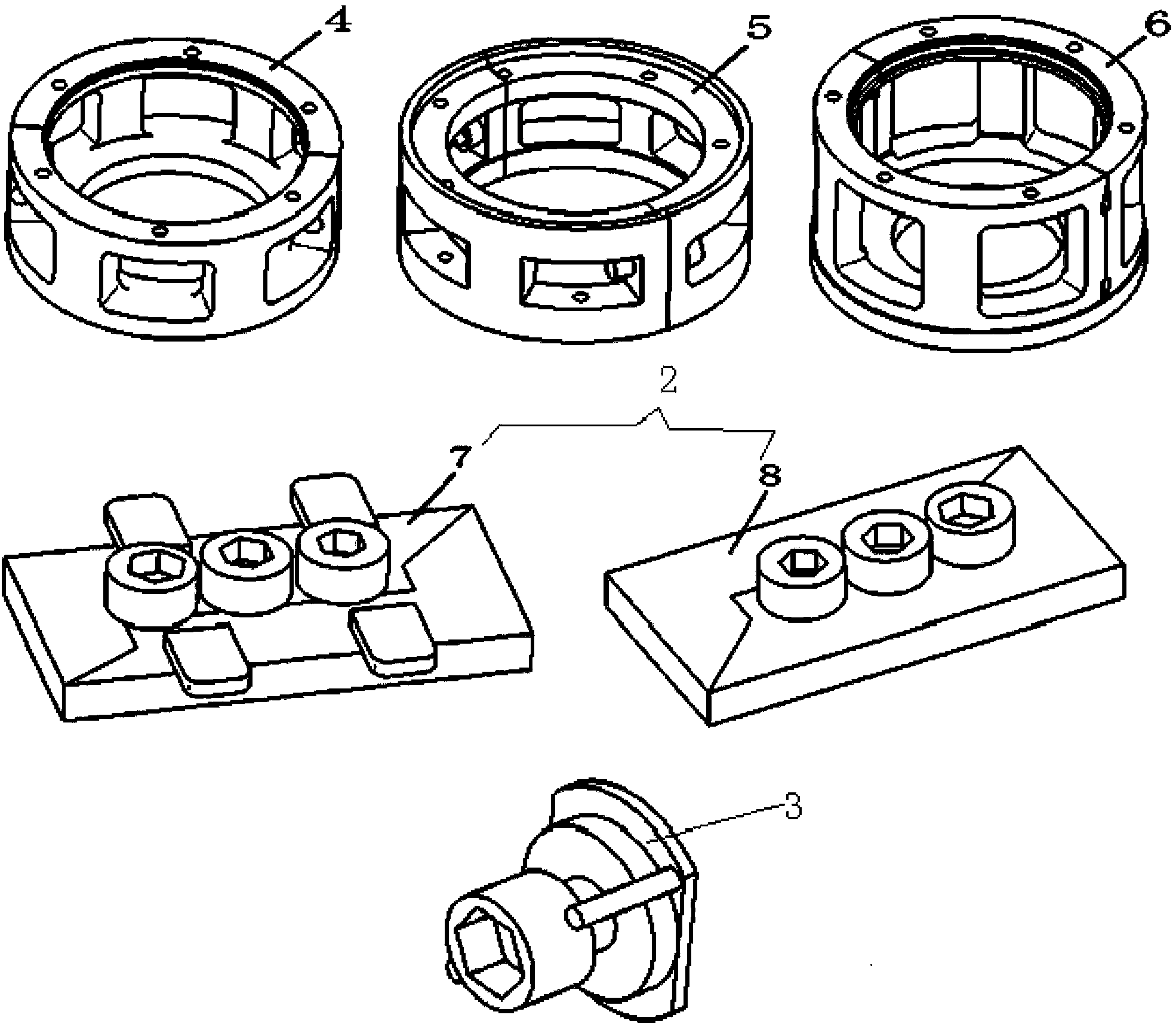

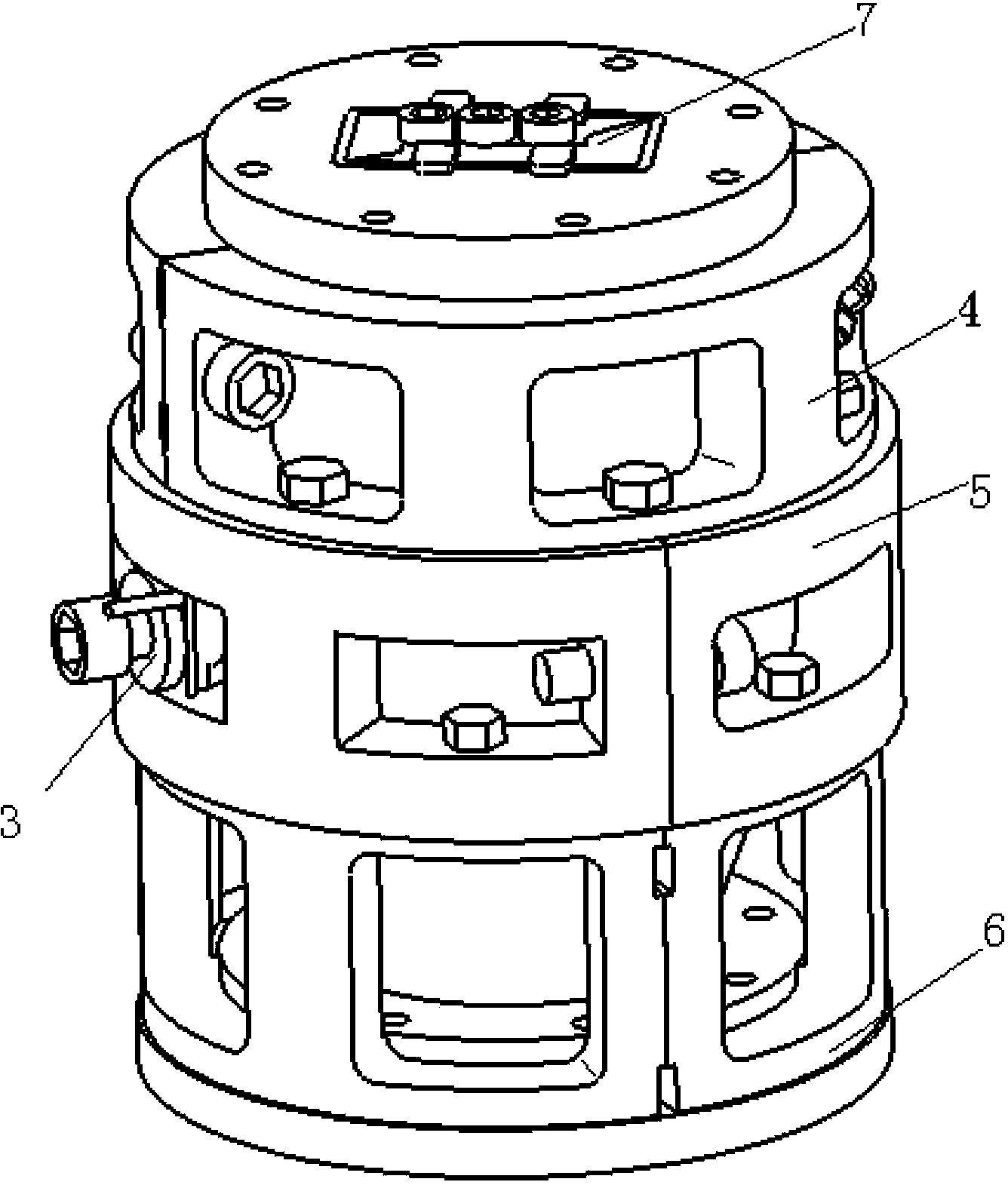

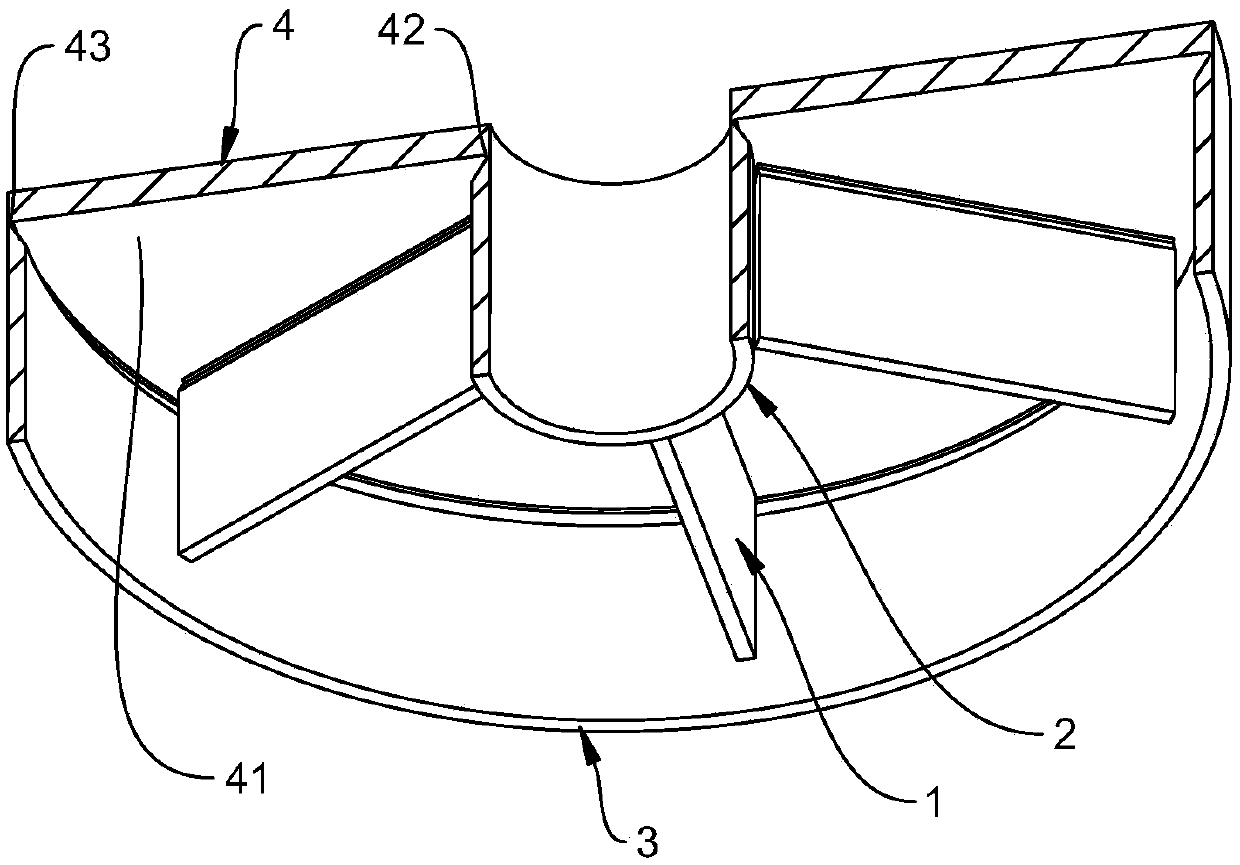

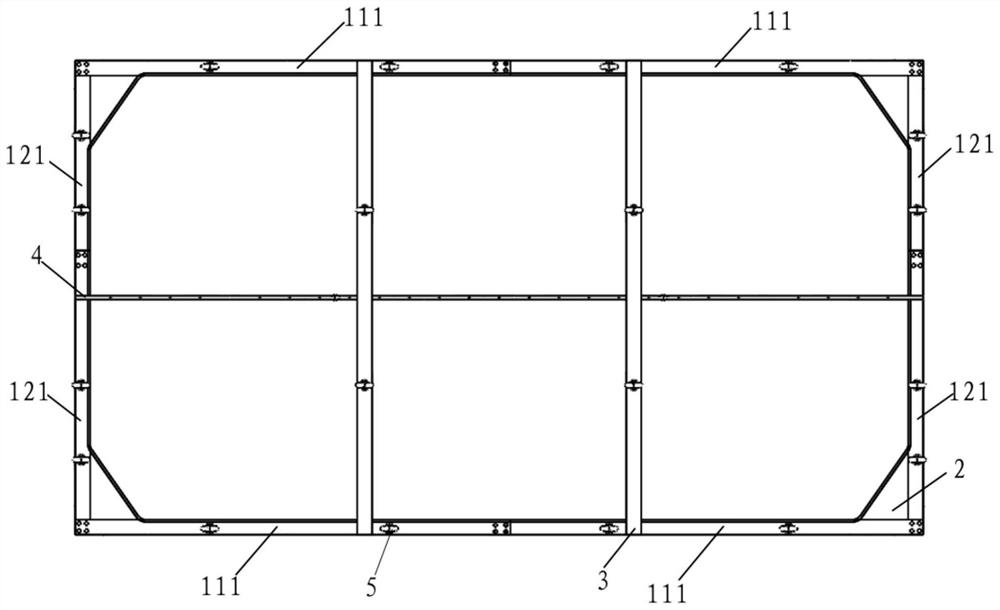

Splicing and lifting type sea-area cultivation net cage

ActiveCN107223619AReduce volumeLow costClimate change adaptationPisciculture and aquariaFisheryEdge structure

The invention provides a splicing and lifting type sea-area cultivation net cage. The splicing and lifting type sea-area cultivation net cage is characterized in that the whole outer frame of the cultivation net cage is of a cone frustum shape, and the bottom surface diameter of the outer frame of the cultivation net cage is larger than the top surface diameter of the outer frame of the cultivation net cage; the outer frame of the cultivation net cage is assembled by a plurality of trapezoid frames with narrow upper portions and wide lower portions, a net rack is mounted on the bottom surface of the cultivation net cage, adjacent trapezoid frames are mounted together through flanges and connectors, a float is arranged at the bottom of each trapezoid frame, each float is provided with an air inlet pipe and a draining outlet, and the floats are used for controlling the floating of the cultivation net cage; fish shelter anchors are hung to the cultivation net cage through anchor cables, and the middles of the anchor cables are connected with floater components suspended above through inhaul cables. Compared with a traditional deep-sea rigid net cage, the splicing and lifting type sea-area cultivation net cage has the advantages that the cone-frustum-shaped splicing structure of the net cage adopts a cone-frustum-shaped multi-edge structure, net cage strength is enhanced while modularized, standardized and miniaturized batch factory production is achieved, manufacturing precision is guaranteed, transportation is facilitated, and on-site assembling and net cage putting are achieved.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

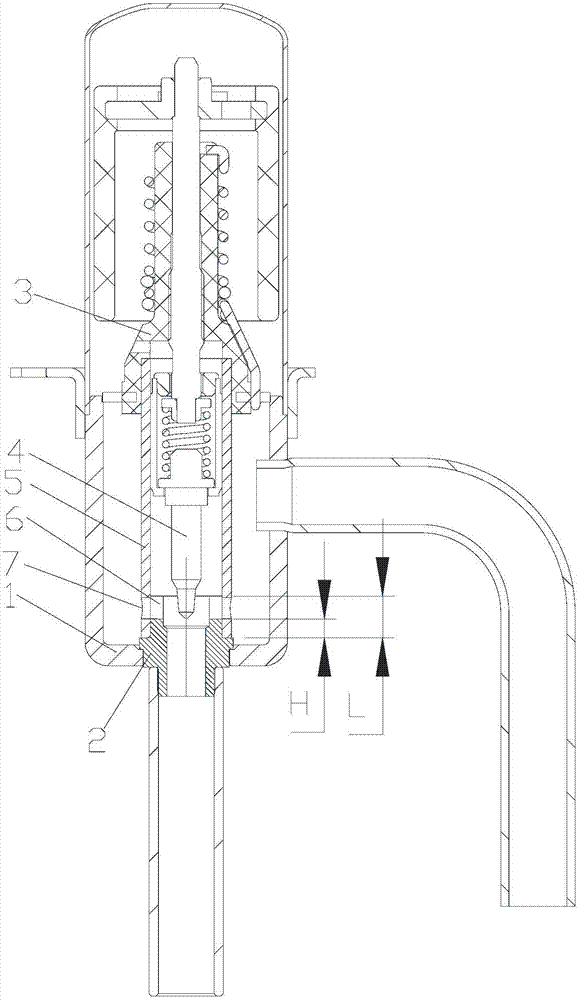

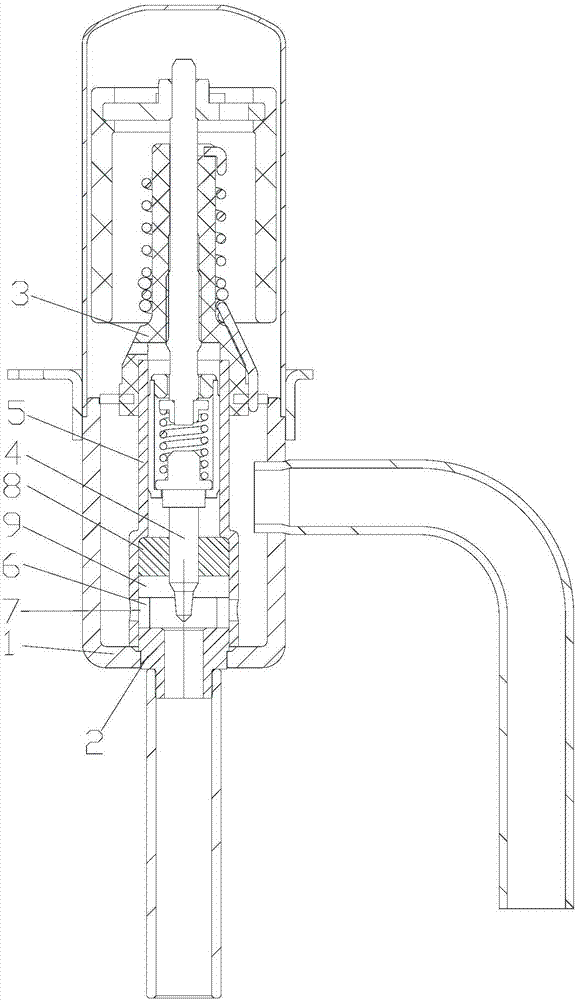

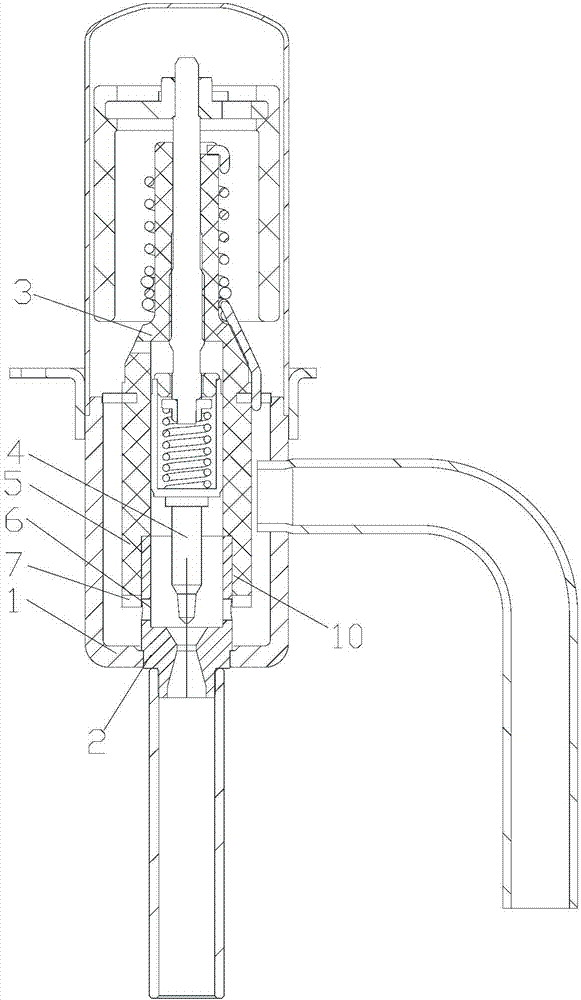

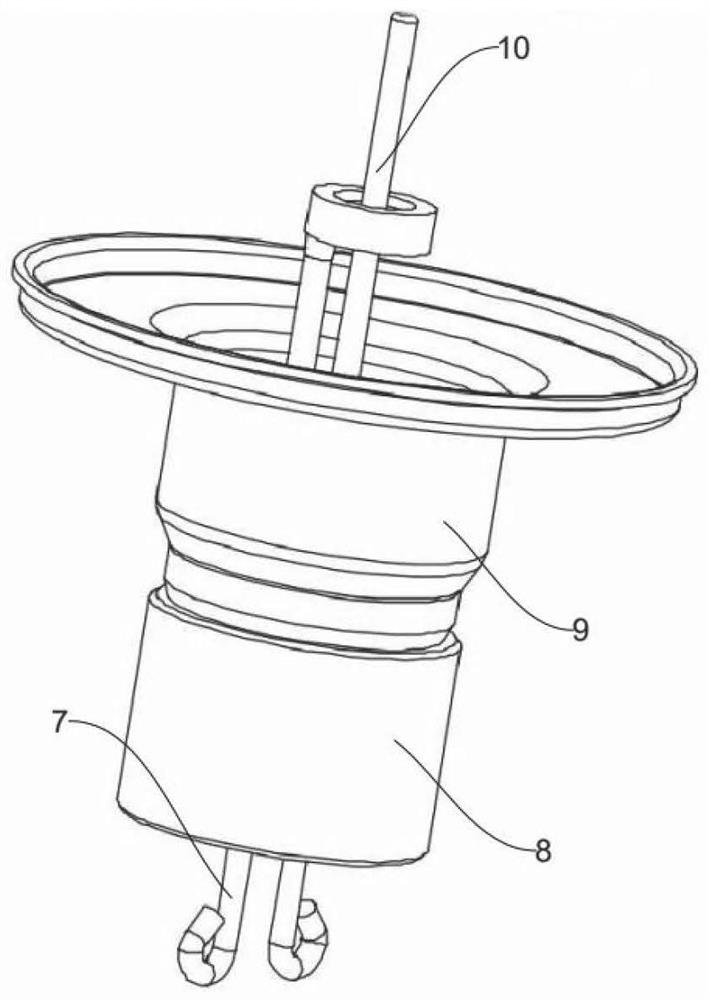

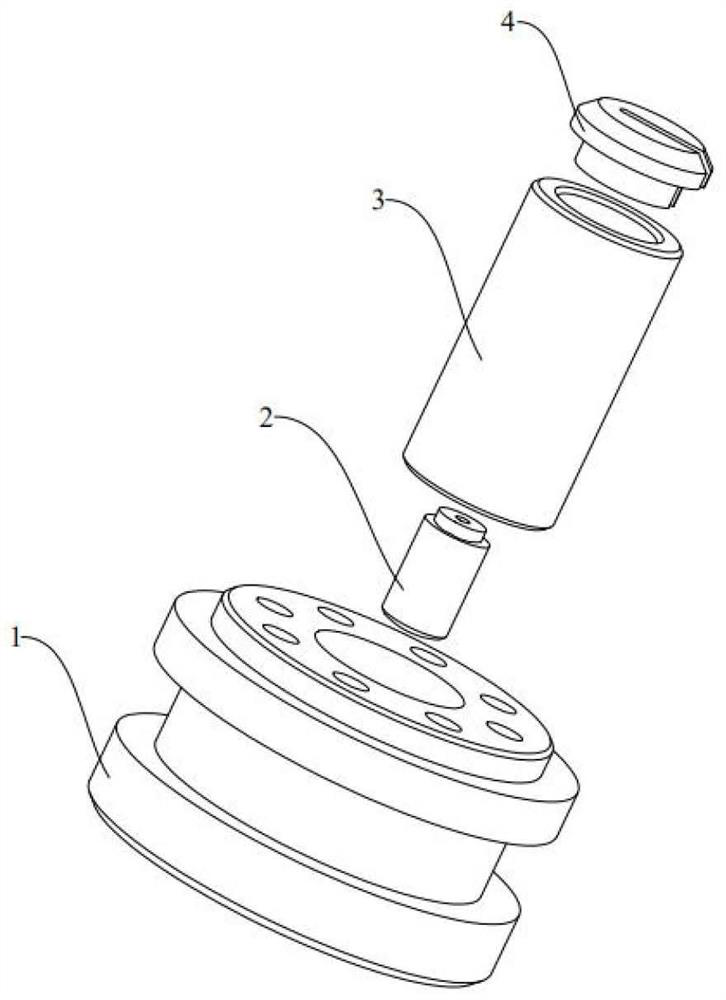

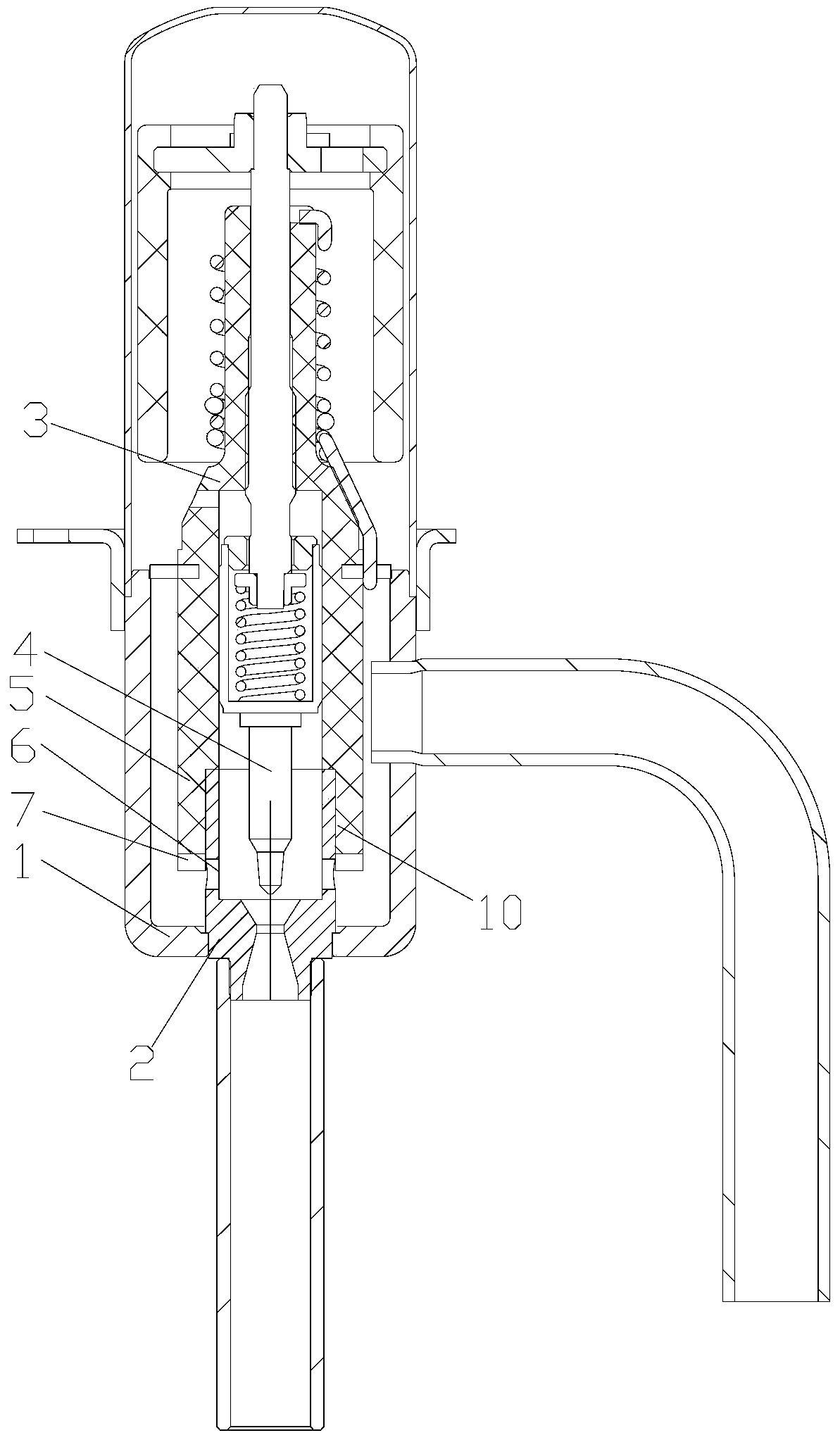

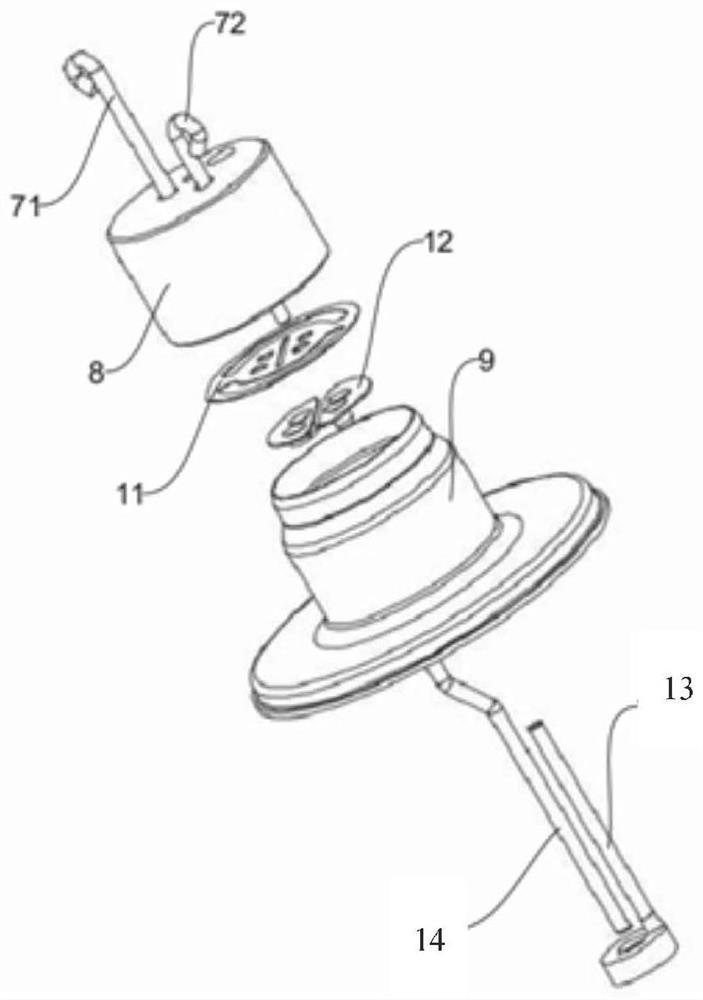

Electronic expansion valve

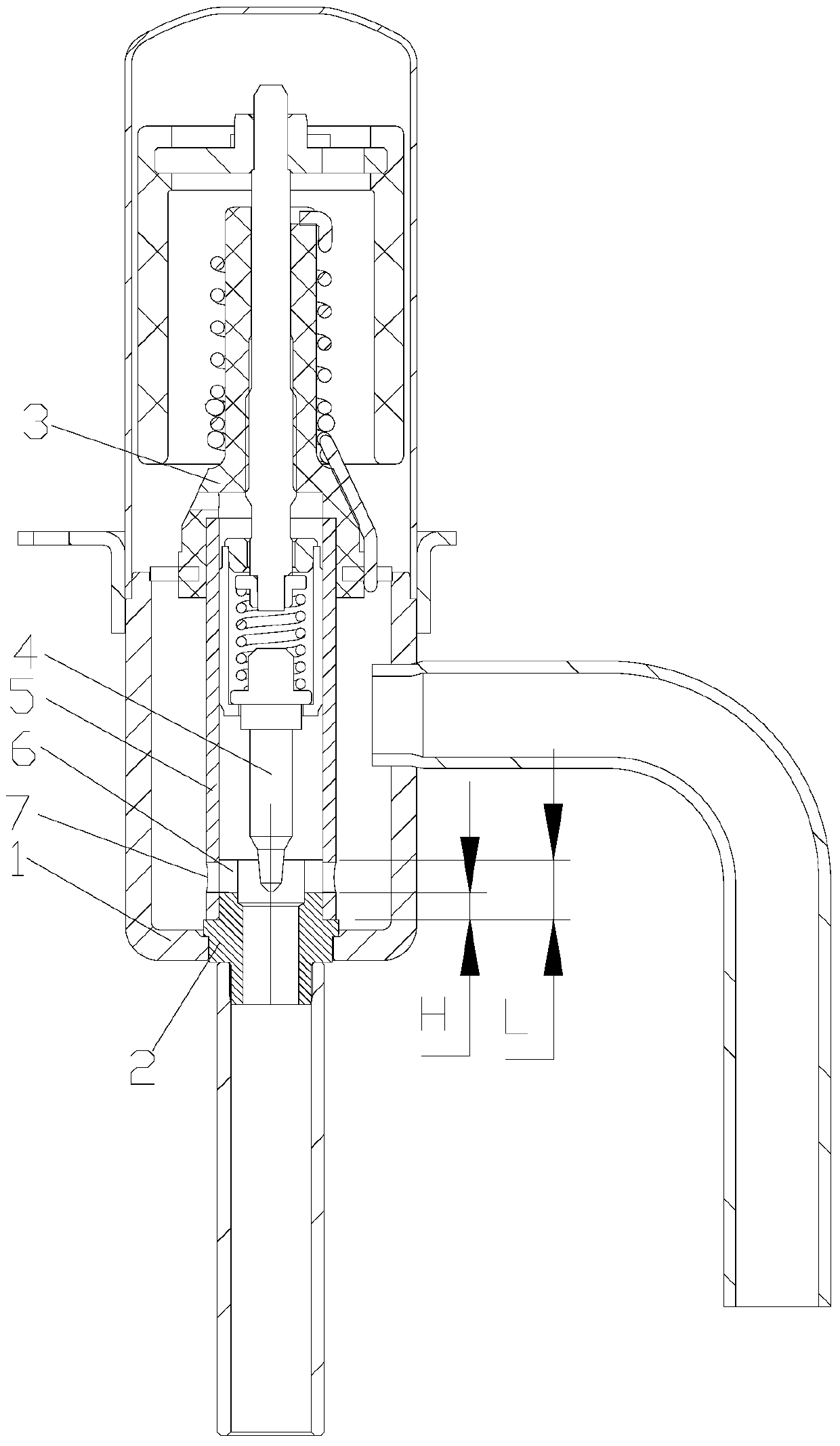

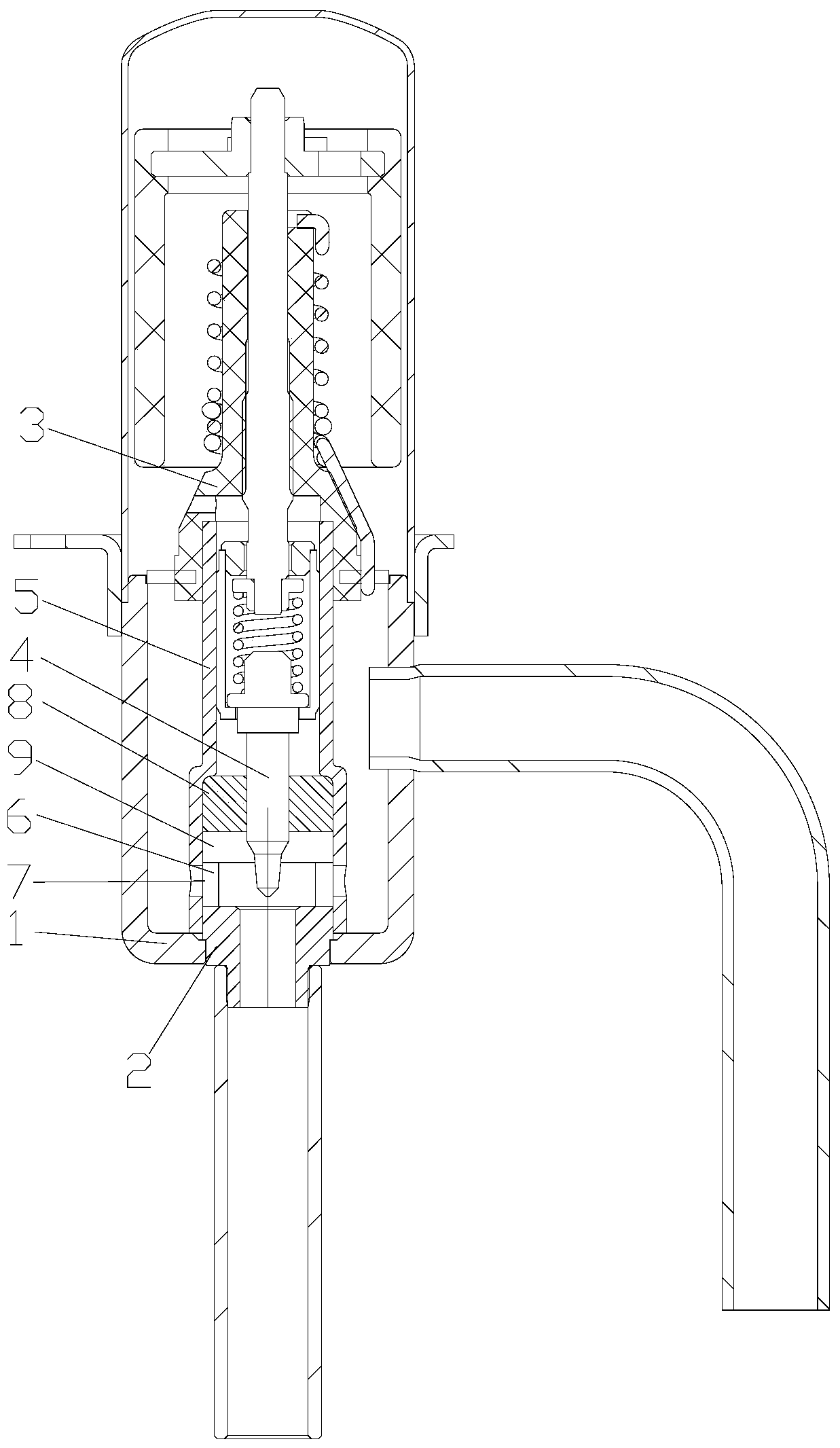

ActiveCN107289138AGuaranteed structural accuracyIncrease axial fit lengthEfficient regulation technologiesFluid circulation arrangementReciprocating motionEngineering

The invention provides an electronic expansion valve. The electronic expansion valve comprises a valve seat, a valve port seat, a nut assembly and a valve needle, the valve port seat is fixedly arranged on the valve seat, a guide sleeve is arranged between the valve seat and the nut assembly, and the valve needle capable of conducting reciprocating motion in the axial direction of the guide sleeve is arranged in the guide sleeve; and the valve port seat is concentrically connected with the guide sleeve in a sleeved mode, a first flow channel for communicating the valve cavity of the valve seat with the valve port of the valve port seat is formed in one end, close to the guide sleeve, of the valve port seat in the radial direction, and the matching length of the valve port seat and the guide sleeve is longer than the height from the bottom of the first flow channel of the valve port seat to a bottom axial stop face which is located outside the valve port seat and corresponds to the guide sleeve. According to the electronic expansion valve, the problem that, in the prior art, a valve seat does not conduct sufficient axial positioning on a guide sleeve, therefore the phenomenon of deflection of the guide sleeve is prone to happening, and thus the structural accuracy of the electronic expansion valve is affected can be solved.

Owner:ZHEJIANG DUNAN ARTIFICIAL ENVIRONMENT

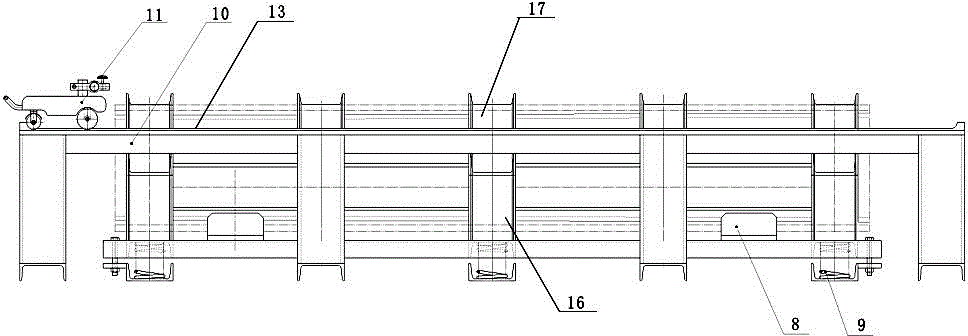

Vacuum self-consuming furnace crystallizer welded cylinder producing process and welding assistive device

ActiveCN103817530AGuaranteed structural strengthGuaranteed structural accuracyWelding/cutting auxillary devicesOther manufacturing equipments/toolsSmelting processProcess engineering

The invention relates to the technical field of vacuum self-consuming furnaces, in particular to a vacuum self-consuming furnace crystallizer welded cylinder producing process and a welding assistive device, and solves the problems that currently a cylinder is formed by spinning or forging, the process is complicated, production cost is high and price is high. The crystallizer cylinder is formed in a welded manner by the aid of the welding assistive device, the technical prejudice that the cylinder can only be formed by spinning or forging in the prior art is overcome, indicators of the produced cylinder meet the requirements of the vacuum self-consuming furnace during smelting, on the basis of guaranteeing structural strength and accuracy of a crystallizer, producing difficulty is reduced effectively, production cost of the crystallizer is reduced, and market competitiveness of equipment is improved.

Owner:太原市冶金机械厂

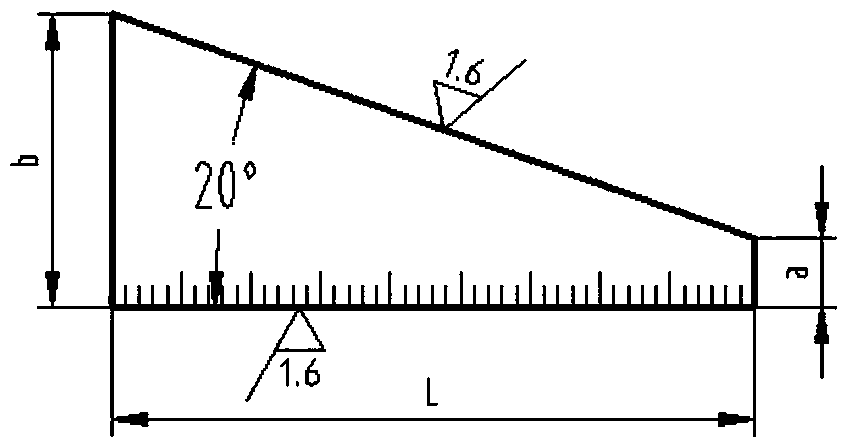

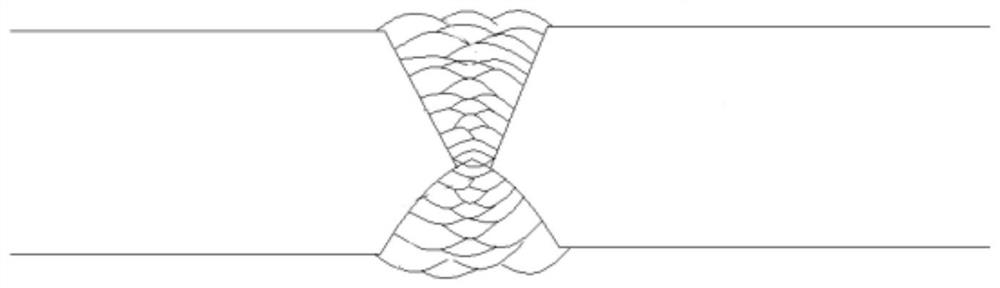

Large-pipe-diameter large-thickness high-strength steel cylinder welding process

PendingCN112296478AAvoid deformationGuaranteed accuracyArc welding apparatusWelding/soldering/cutting articlesStress concentrationMaterials science

The invention relates to the technical field of steel cylinder welding, and discloses a large-pipe-diameter large-thickness high-strength steel cylinder welding process. The large-pipe-diameter large-thickness high-strength steel cylinder welding process comprises the following steps: cutting the edge of a barrel section to form an inclined groove; forming a barrel body through at least two barrelsections, and carrying out positioned welding along the circular seam; and arranging an even number of welders at equal intervals in the circumferential direction of a weld joint, and carrying out segmented welding in the same direction. A multi-layer welding method is adopted in the welding manner, and staggered welding is conducted on weld bead welding heads in adjacent layers at preset intervals. According to the large-pipe-diameter large-thickness high-strength steel cylinder welding process in the embodiment, segmented welding is conducted on the weld joint, an even number of welders areadopted to be arranged in the circumferential direction of the weld joint at equal intervals and conduct welding in the same direction, barrel body deformation caused by stress concentration in the welding process is avoided, the structural precision is guaranteed, the flatness and perpendicularity of a barrel body flange can be effectively guaranteed, and the component precision is guaranteed.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

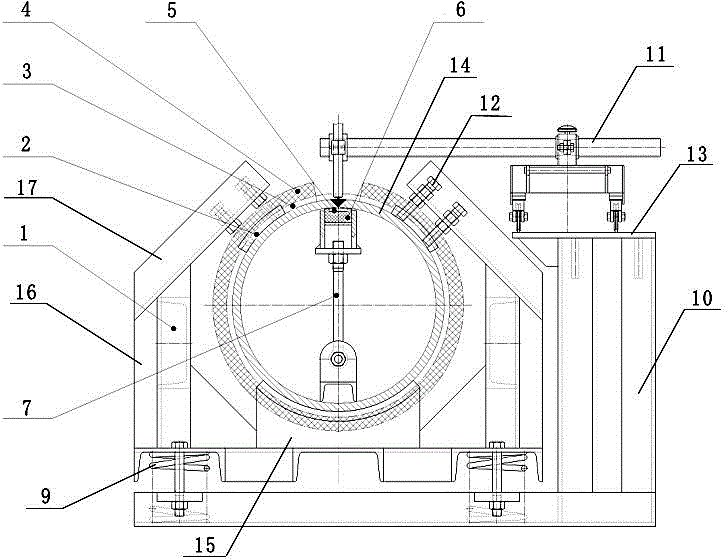

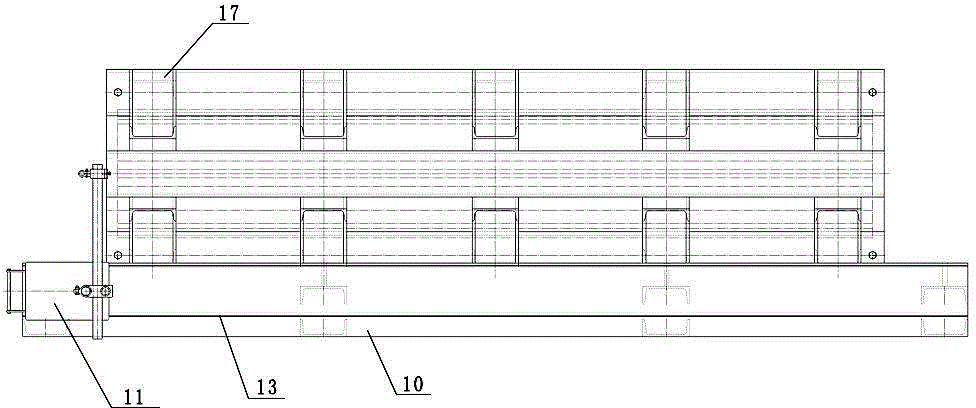

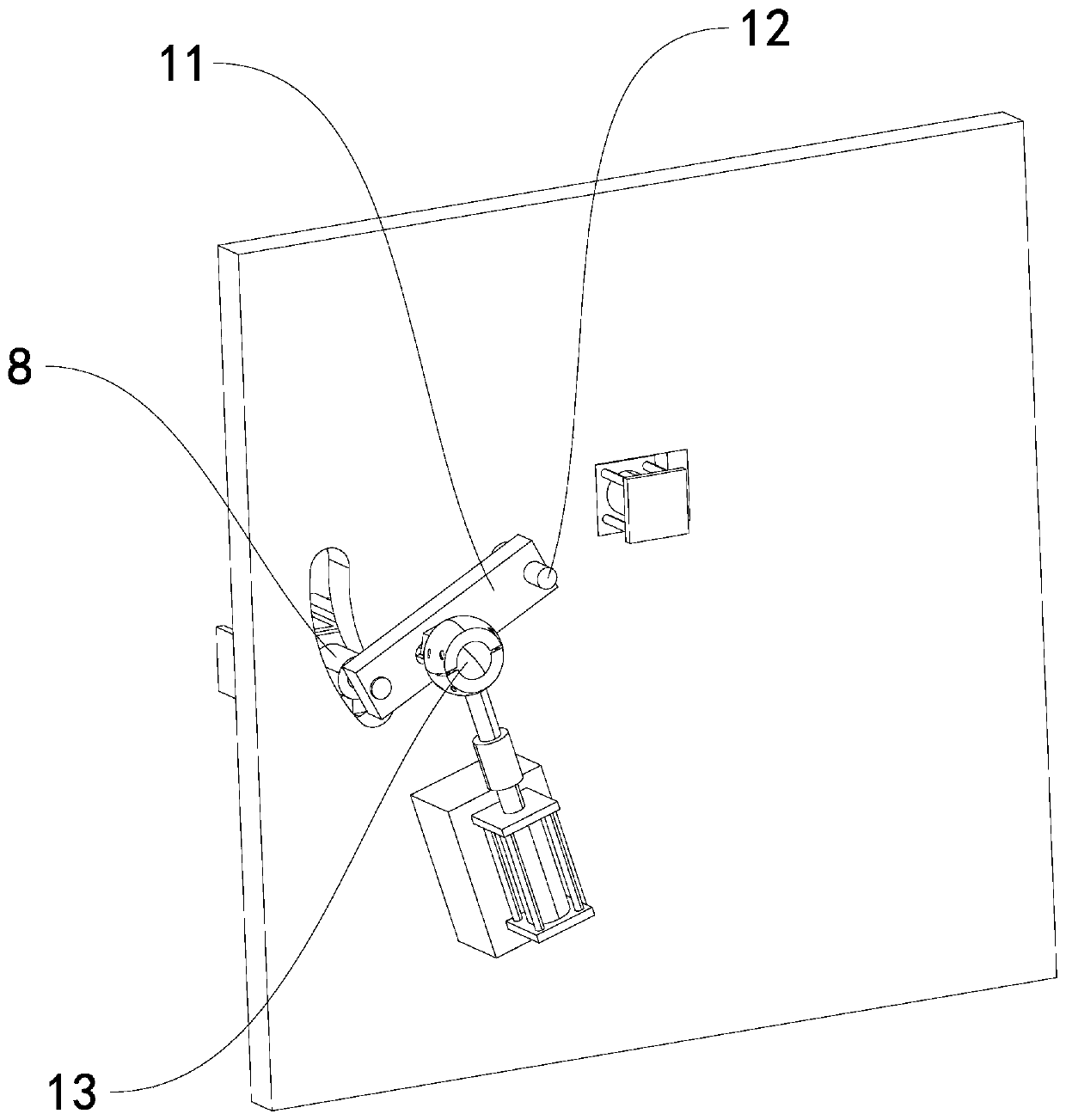

Electrical test device for simulating winding of large turbo-generator stator

InactiveCN108802560AGuaranteed structural accuracyGuaranteed accuracyElectric winding testingEngineeringElectrical performance

The invention relates to an electrical test device for simulating winding of a large turbo-generator stator. The test device is capable of efficiently bearing the simulating winding of the large turbo-generator stator, the accurate size, stable structure and appropriate angle are guaranteed and the safety operation of stator simulating winding high voltage electrical test is ensured. The test device is provided with a slot part fixing device and an end part fixing device of turbo-generator stator simulating winding, the specific structure and relationship between the fixing devices is determined for the first time. The test device is practical in structure, efficient in method, easy to design, process and mold, the device relates to the effective establishment of turbo-generator stator simulating winding electrical test integrated unit, which lays a good foundation for further research on the electrical performance of winding.

Owner:HARBIN ELECTRIC MASCH CO LTD

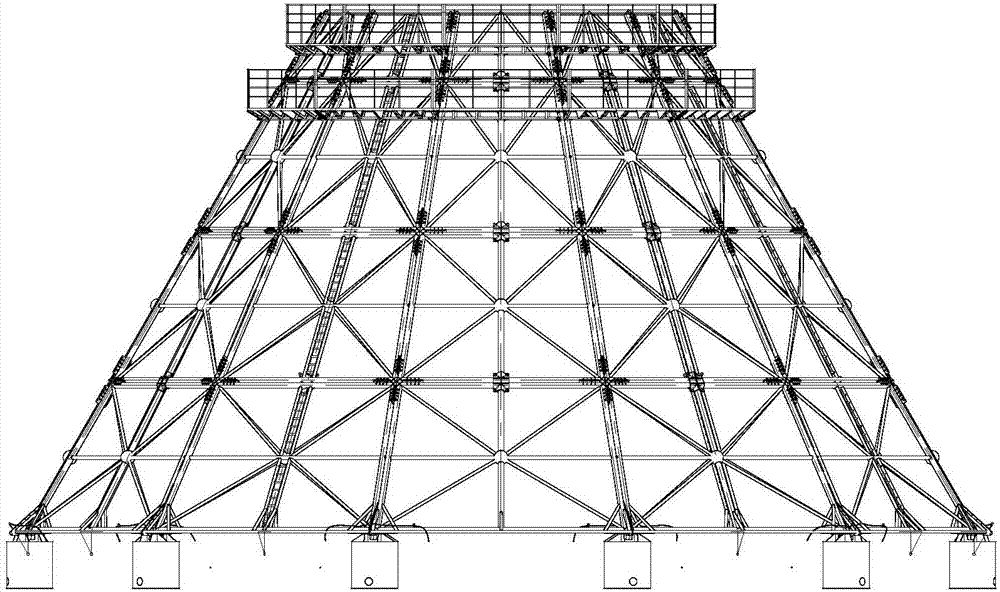

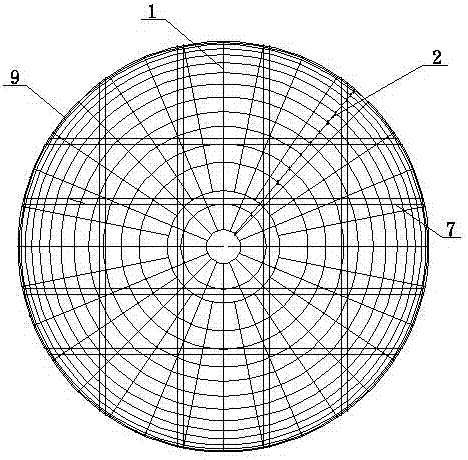

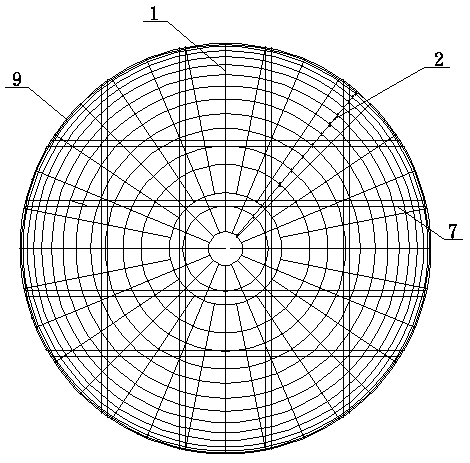

Support lattice shell of concrete spherical shell structure and construction method

ActiveCN107060094ASolve construction problemsReduce the difficulty of supportArched structuresVaulted structuresSupporting systemConcrete beams

The invention discloses a support lattice shell of a concrete spherical shell structure and a construction method. The support lattice shell of the concrete spherical shell structure comprises radial steel tubes, annular steel tubes, annular components of expansion bolts, annular components of built-in fittings, the expansion bolts, the built-in fittings, a concrete wall body, frameworks, spherical shell concrete beams, concrete shells, a support lattice shell, fragment lattice shells, through holes and fixing plates of the built-in fittings. In the construction process of the construction method, firstly the radical steel tubes and the annular steel tubes are mounted one segment by another, and are fixed to a concrete wall body structure through the annular components, and finally the frameworks are laid to form a support lattice shell of the spherical shell structure. By adoption of the construction method, the structure accuracy can be guaranteed, supporting and arranging difficulties of the frameworks can be reduced, and the construction efficiency and the construction quality can be improved. In addition, the support lattice shell of the spherical shell structure is a steel structure, can be recycled, not only can decrease wood consumption, but also is environmentally friendly; and the problems that the molding accuracy of the concrete wall body structure is low and the support system of the concrete wall body structure is difficult are solved, and the problem of framework construction of the concrete wall body structure is solved.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

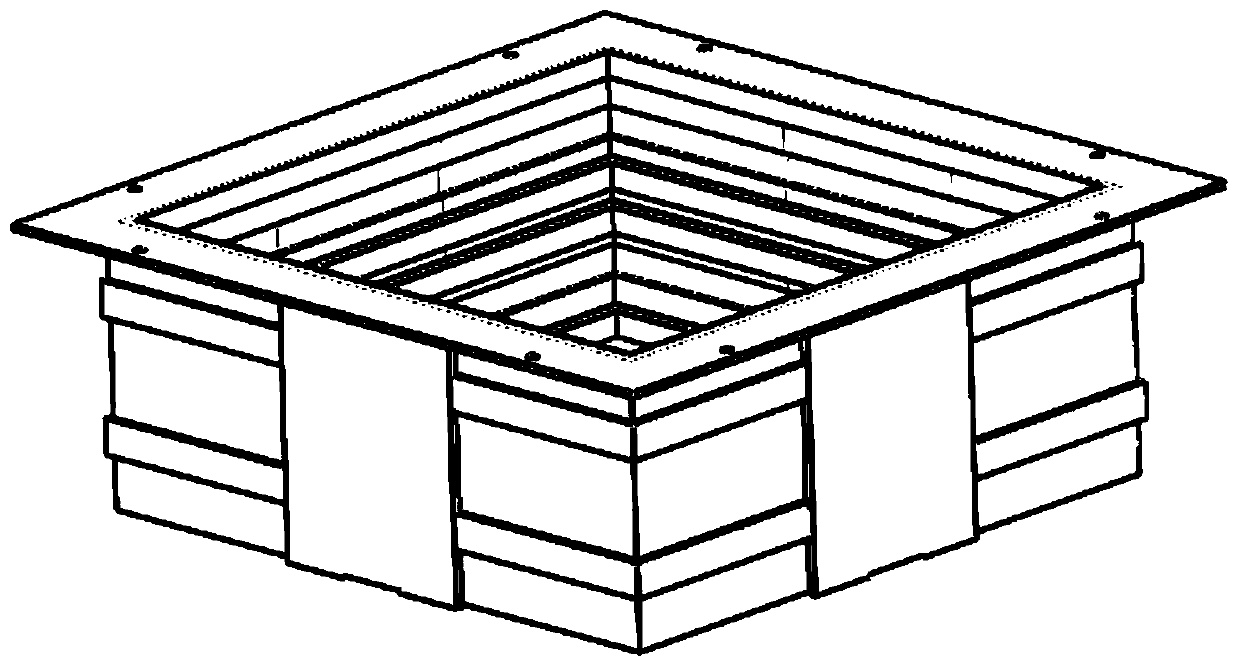

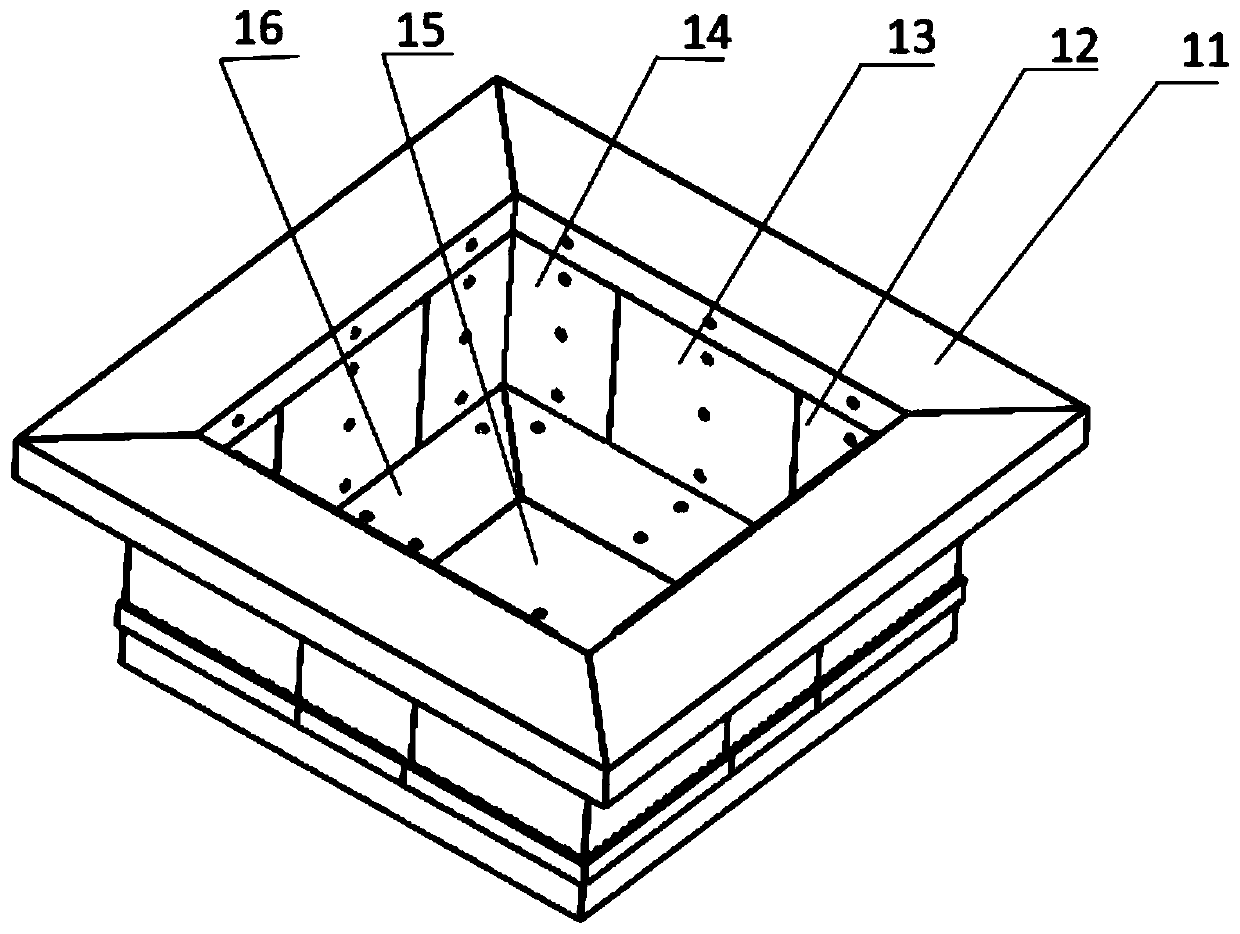

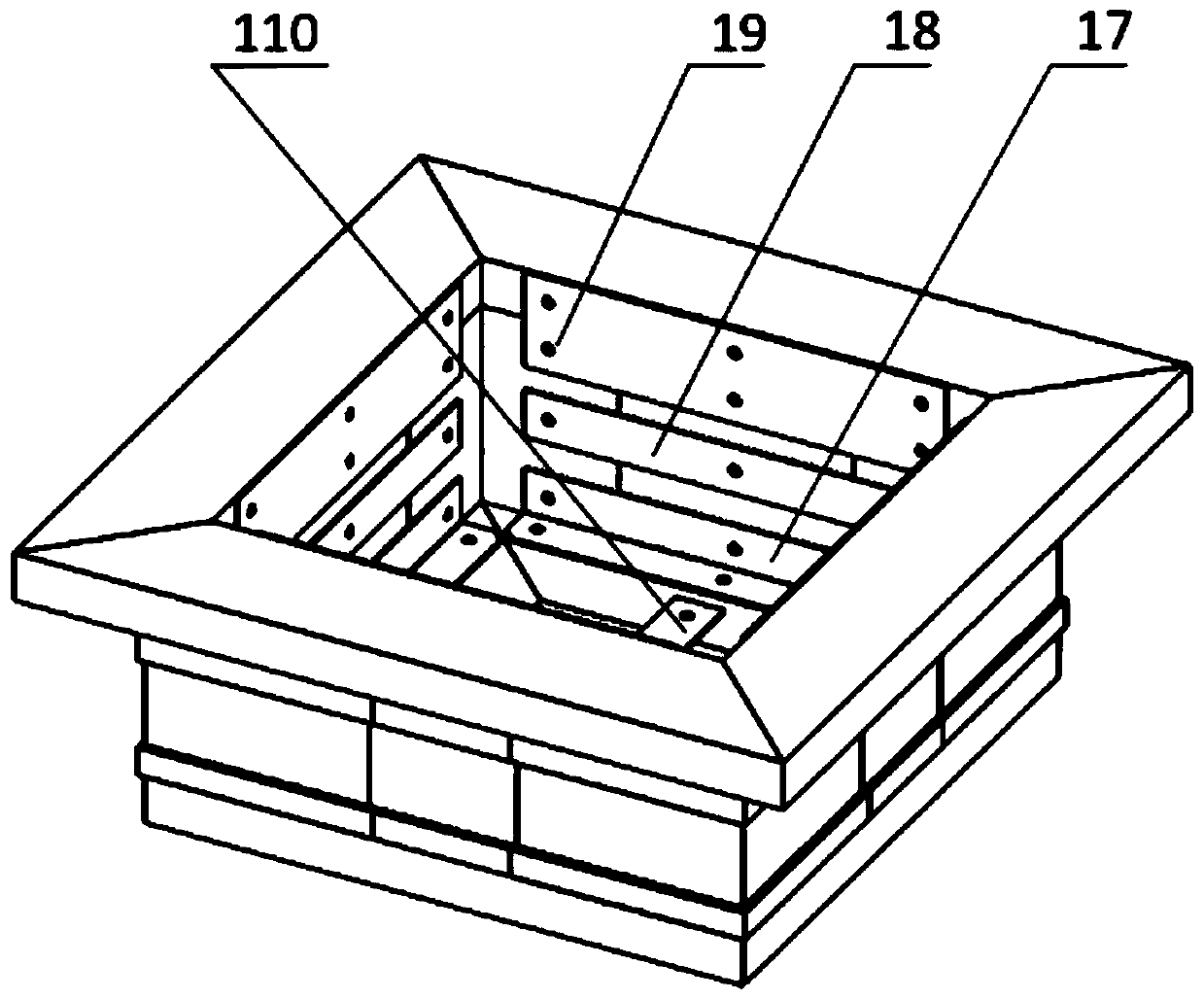

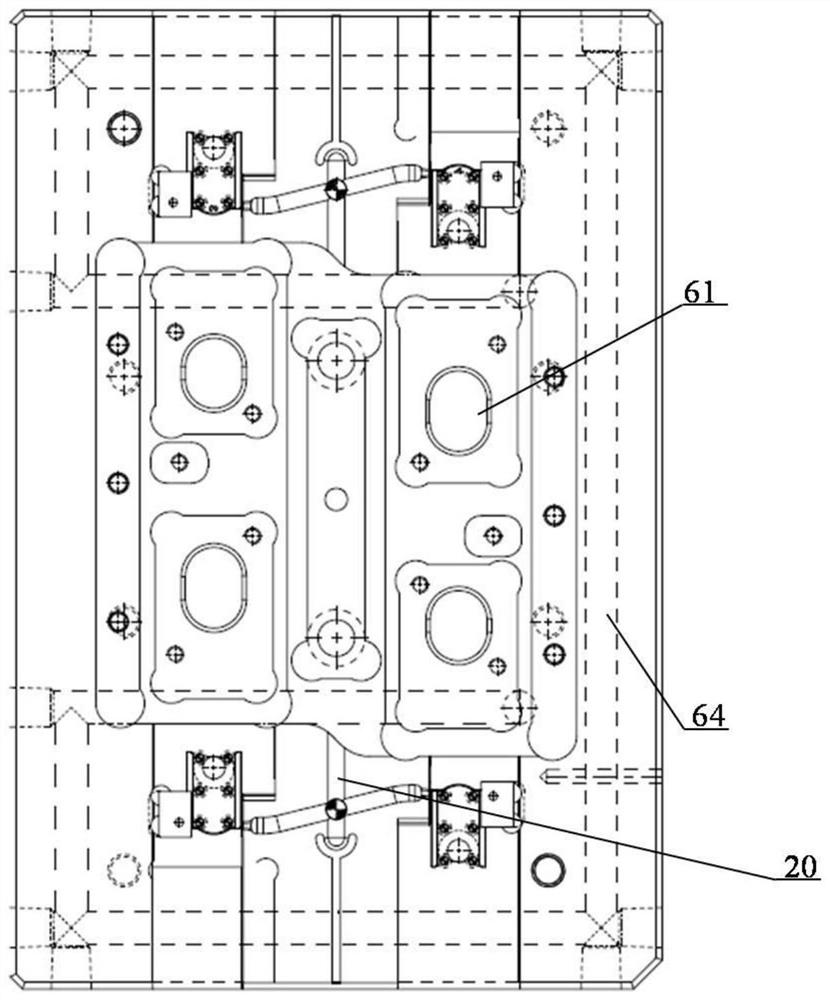

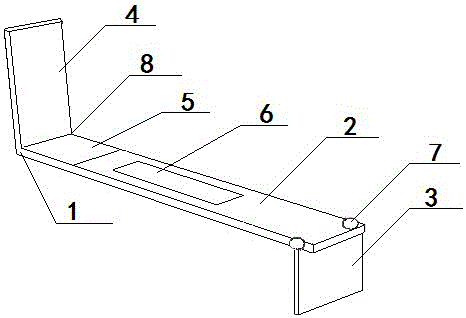

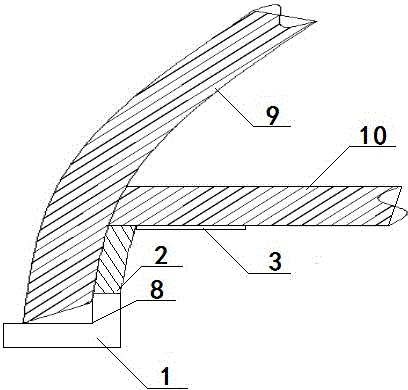

Laying forming mold for resin-matrix composite battery case of new-energy automobile

The invention discloses a laying forming mold for a resin-matrix composite battery case of a new-energy automobile. The laying forming mold for the resin-matrix composite battery case of the new-energy automobile comprises an inner mold body, an outer mold body and a fastening device. The inner mold body comprises an inner flange, a front inner side plate, a middle inner side plate, a rear inner side plate, an inner bottom central plate and four inner bottom corners. The outer mold body comprises a front outer side plate, a middle outer side plate, a middle outer side plate, a rear outer sideplate, and an outer bottom face. The mold comprising the inner mold body and the outer mold body can fully guarantee the geometric precision and structural precision; the detachable mold well overcomes the defect of complex and difficult demolding of resin-matrix composites; and the influence of concave and convex planes formed by a battery case reinforcing structure on the installation of the openable outer mold body is avoided.

Owner:DALIAN UNIV OF TECH

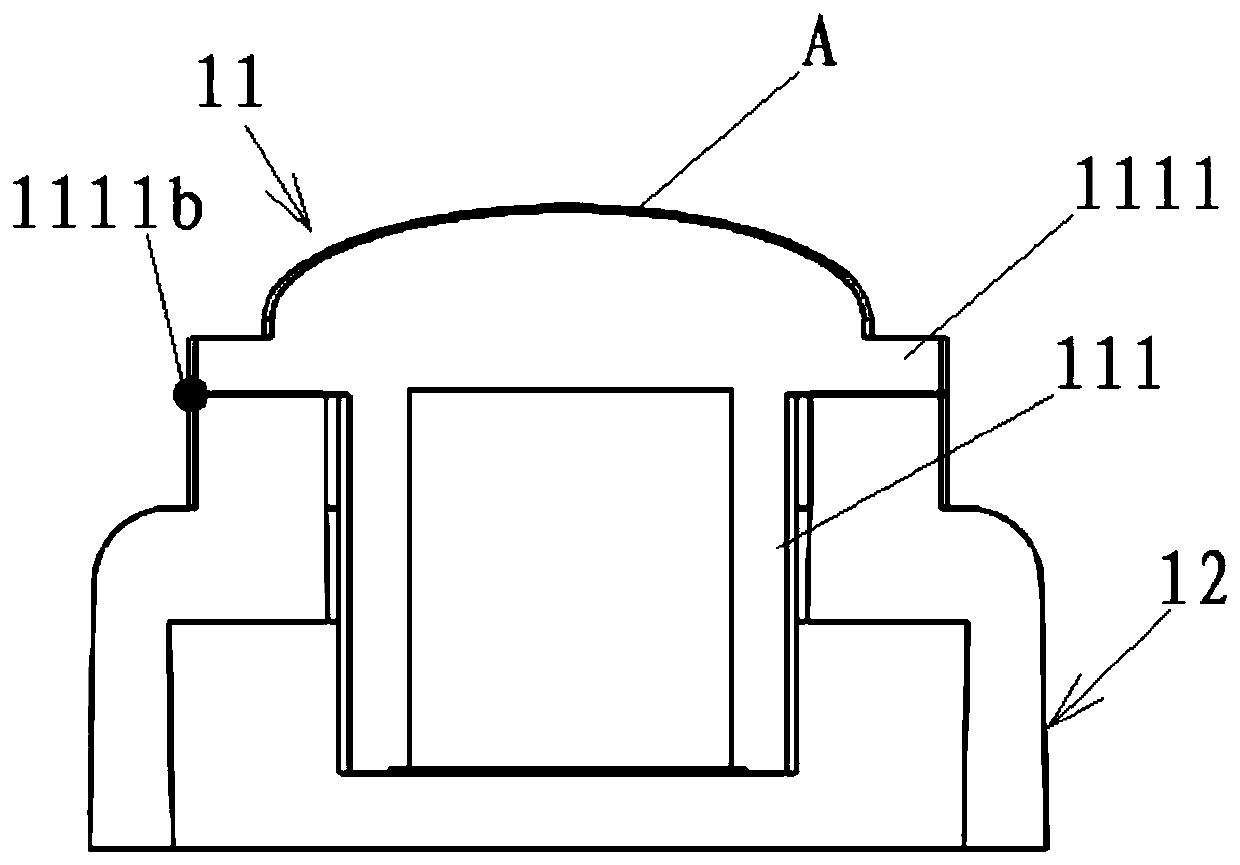

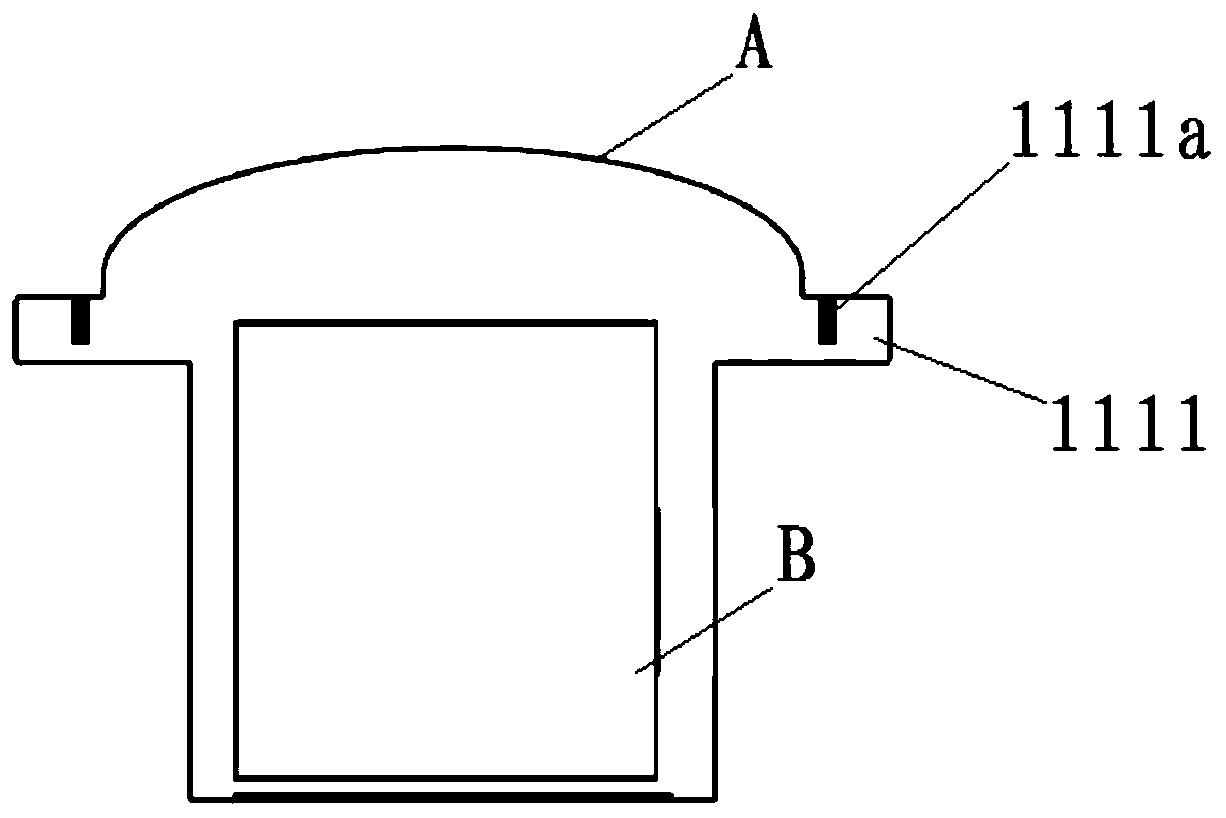

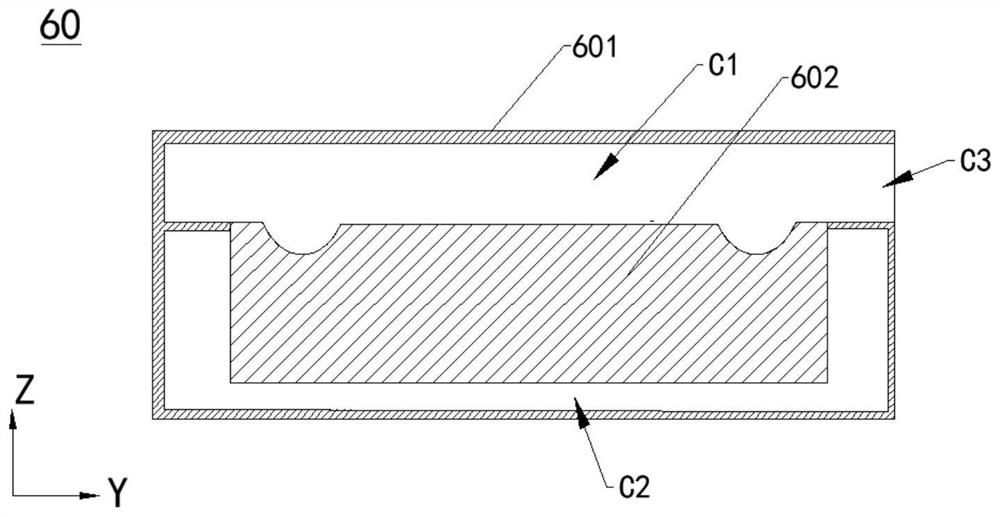

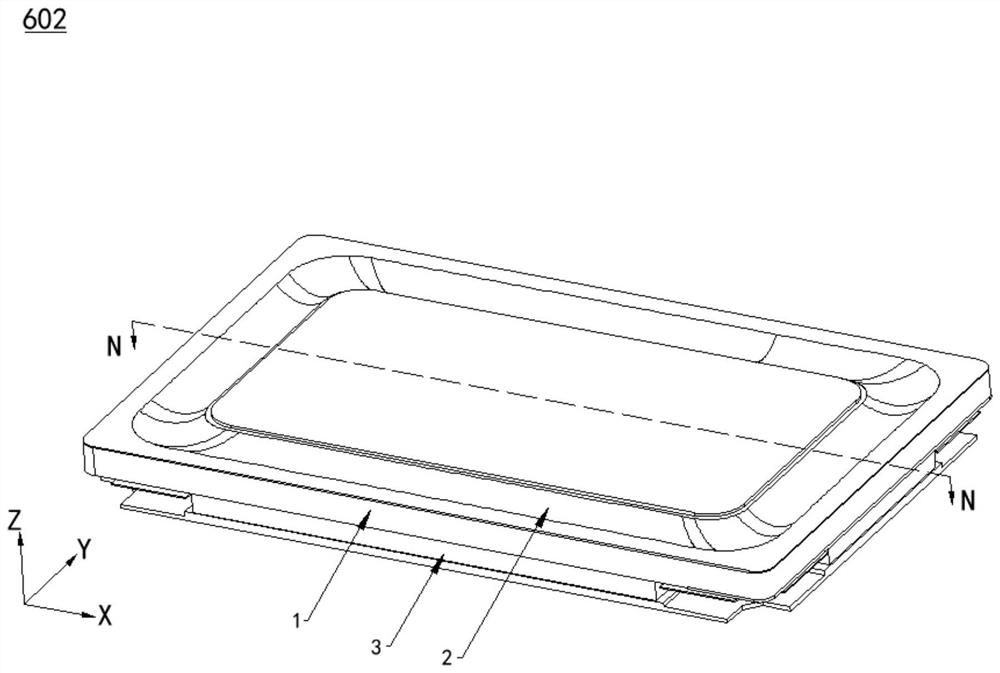

Lens module

InactiveCN110320631AProblems Affecting AccuracyGuaranteed structural accuracyMountingsCamera lensPhysics

The invention relates to a lens module. The lens module comprises a lens (11) and a lens base (12) fixedly connected with the lens (11); a lens barrel (111) of the lens (11) is provided with a connecting portion (1111) welded to the lens base (12); and an annular groove (1111a) is arranged on the side of the connecting portion (1111) along the axial direction of the lens (11). The connection between the lens and the lens base is achieved by means of welding, therefore, the problem of influence on the lens precision caused by glue shrink and the like generated by the curing process of the glueis avoided; especially when connected by laser welding, the welding spot area is small; and the generated internal stress is correspondingly reduced through the evenly distributed welding points, which benefits ensuring the structural precision and stability of the lens module disclosed by the invention.

Owner:ZHEJIANG SUNNY SMARTLEAD TECH CO LTD

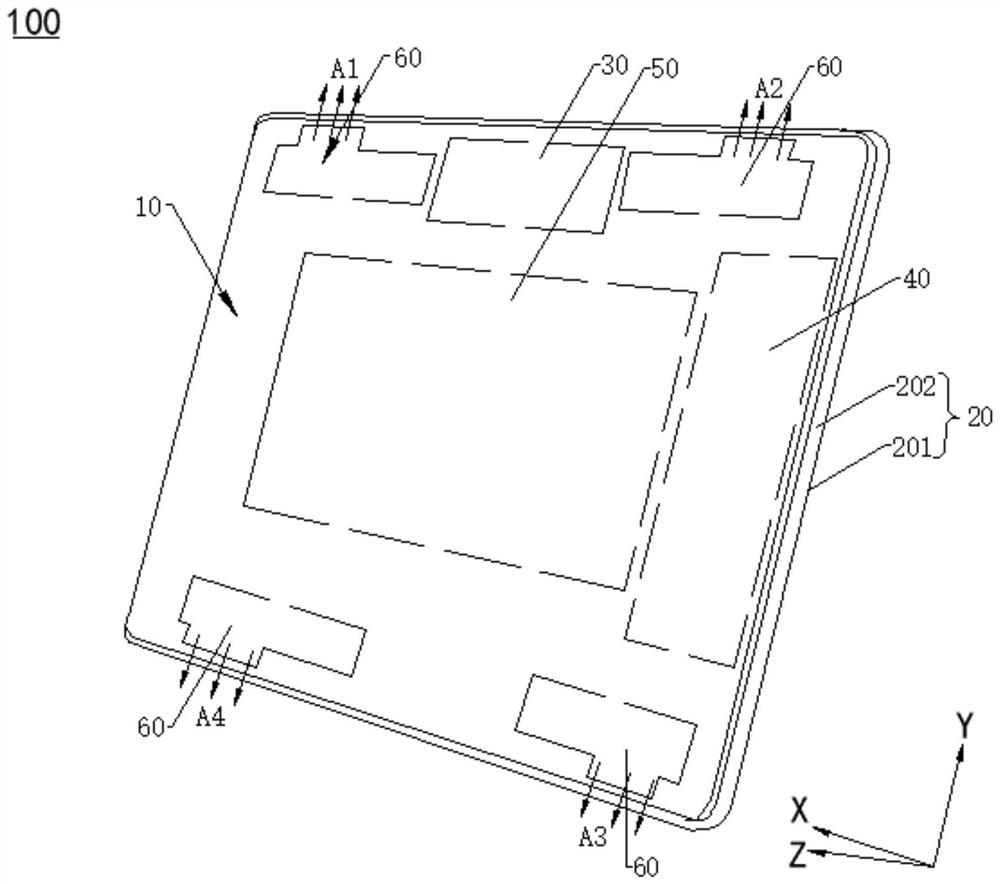

Inner core, loudspeaker module and electronic equipment

PendingCN114501260AImprove audio performanceConducive to thin designElectrical transducersLoudspeakerEngineering

The invention provides a core, a loudspeaker module and electronic equipment, relates to the technical field of electronic equipment, and can realize thinning of the electronic equipment and ensure the audio performance of the loudspeaker module and the coaxiality of a voice coil skeleton, a diaphragm group and a voice coil. The inner core of the loudspeaker module comprises a voice coil framework and a voice coil, and the voice coil framework comprises a main body part and a supporting part. The main body part is annular, and the supporting part is arranged on the outer edge of the main body part. The part of the main body part where the supporting part is located is provided with a first gap, and the first gap does not break the part of the voice coil skeleton composed of the supporting part and the part of the main body part. The voice coil is fixed on one axial side of the main body part; an inner side lead of the voice coil comprises a spanning section; the spanning section extends from the inner edge of the surface, close to the main body part, of the voice coil to the outer edge of the surface, and the spanning section is accommodated in the first gap. The kernel provided by the embodiment of the invention is used for converting an audio electric signal into sound.

Owner:北京荣耀终端有限公司

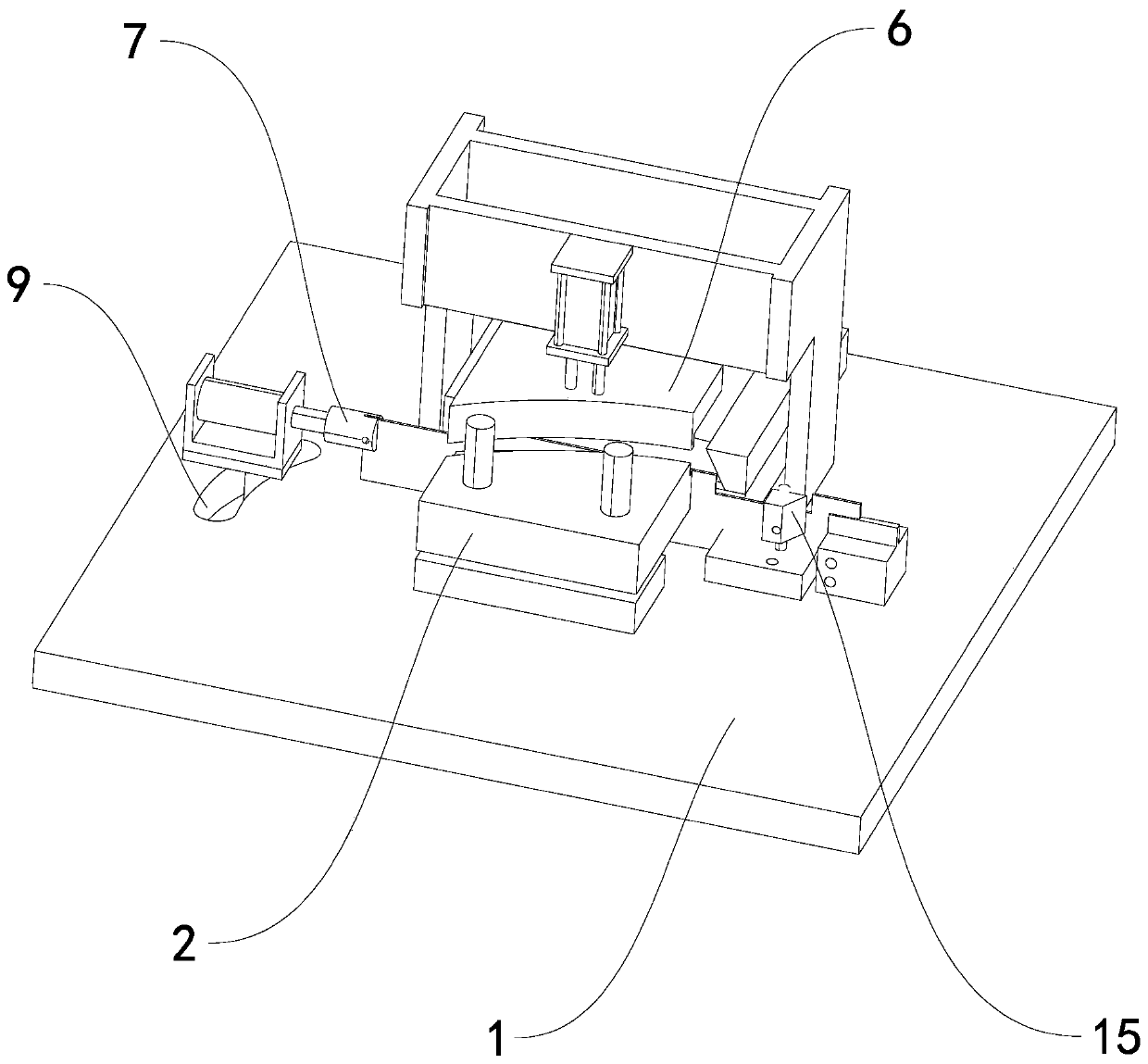

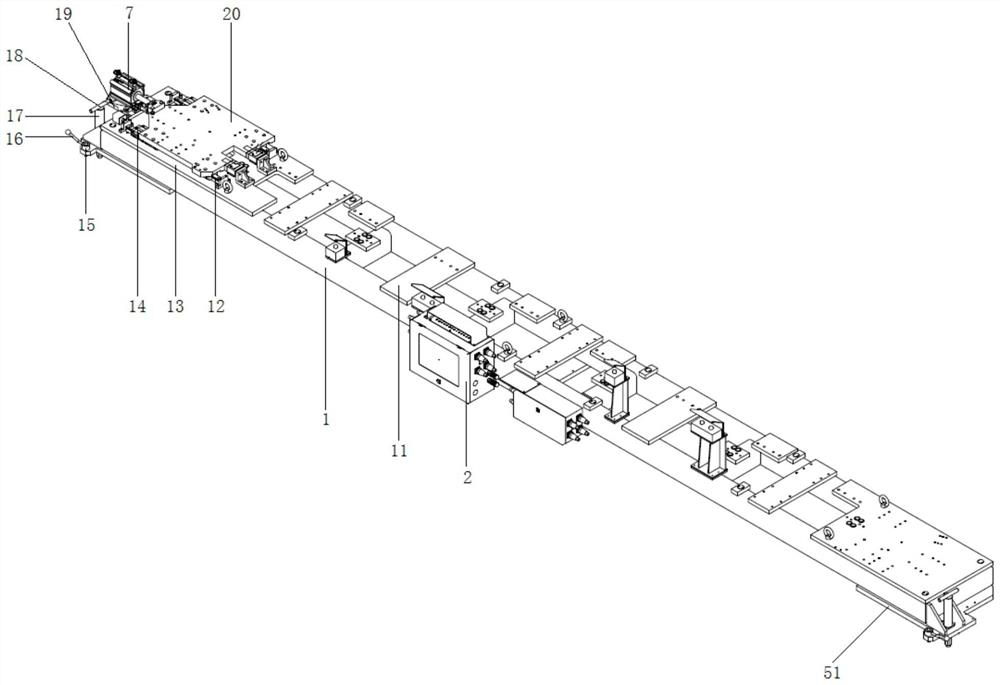

Bending equipment for automobile seal strip

PendingCN111113863AGuaranteed bending accuracyGuaranteed structural accuracyStructural engineeringPower apparatus

The invention discloses bending equipment for an automobile seal strip. The bending equipment comprises a base plate, a reference block and a first pressing block, and the reference block and the first pressing block are arranged on the base plate oppositely. The face, opposite to the first pressing block, of the reference block is a standard curved face. An elastic piece is arranged between the reference block and the pressing block. One end of the elastic piece is fixed to the base plate, and the other end of the elastic piece is connected with a power device. The seal strip is clamped to the elastic piece in the length direction of the elastic piece. The power device drives the elastic piece to be bent and to be completely attached to the standard curved face of the reference block. A second pressing block is further arranged on the reference block. The first pressing block and the second pressing block are connected with the power device. The power device drives the first pressingblock to move and press on the elastic piece attached to the standard curved face, and the power device drives the second pressing block to vertically downwards press and act on the elastic piece andthe standard curved face. Press-bending of the automobile seal strip is achieved through a simple mechanical structure, and the product obtained through bending is high in precision.

Owner:建新赵氏科技股份有限公司

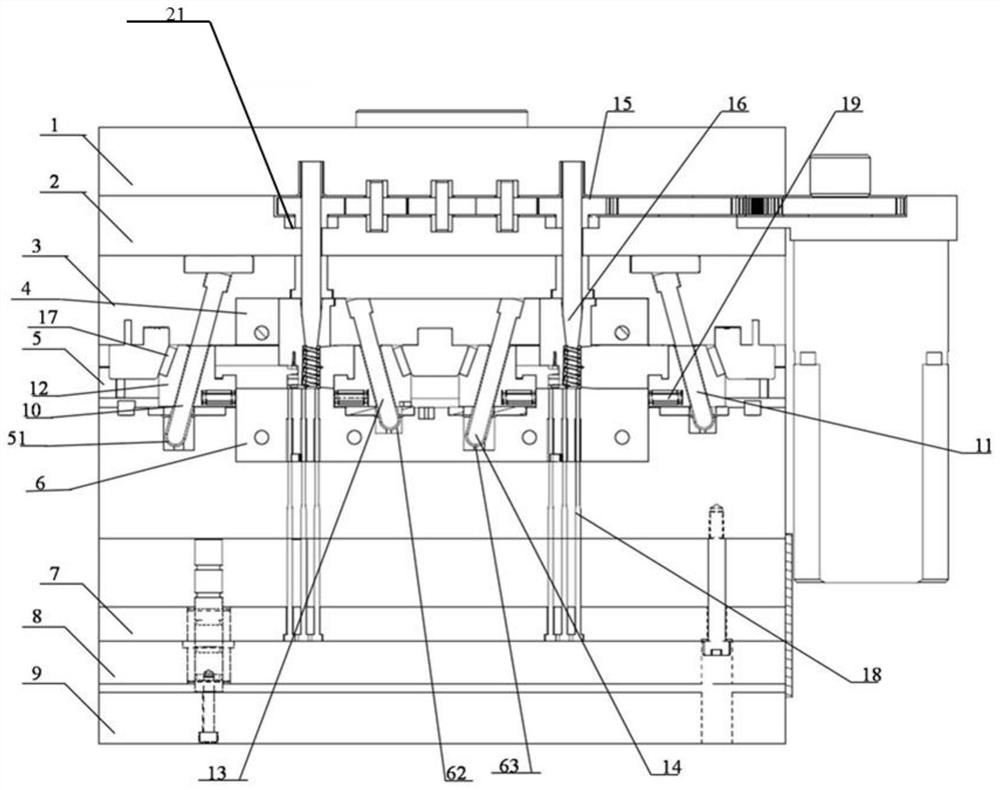

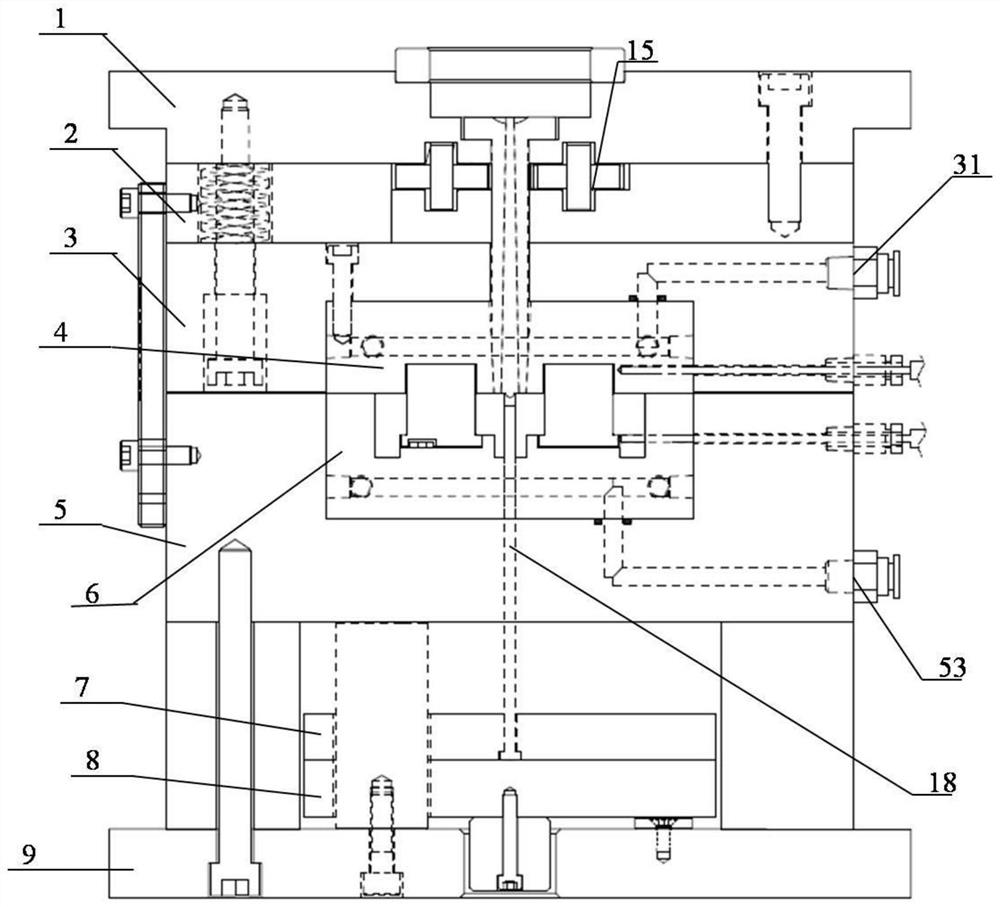

Fixator injection mold

Owner:昆山市欣百顺精密模具有限公司

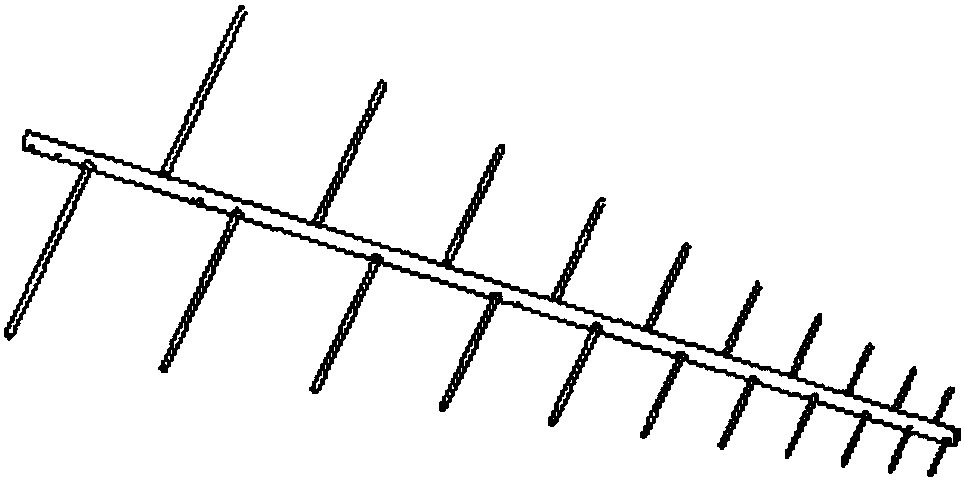

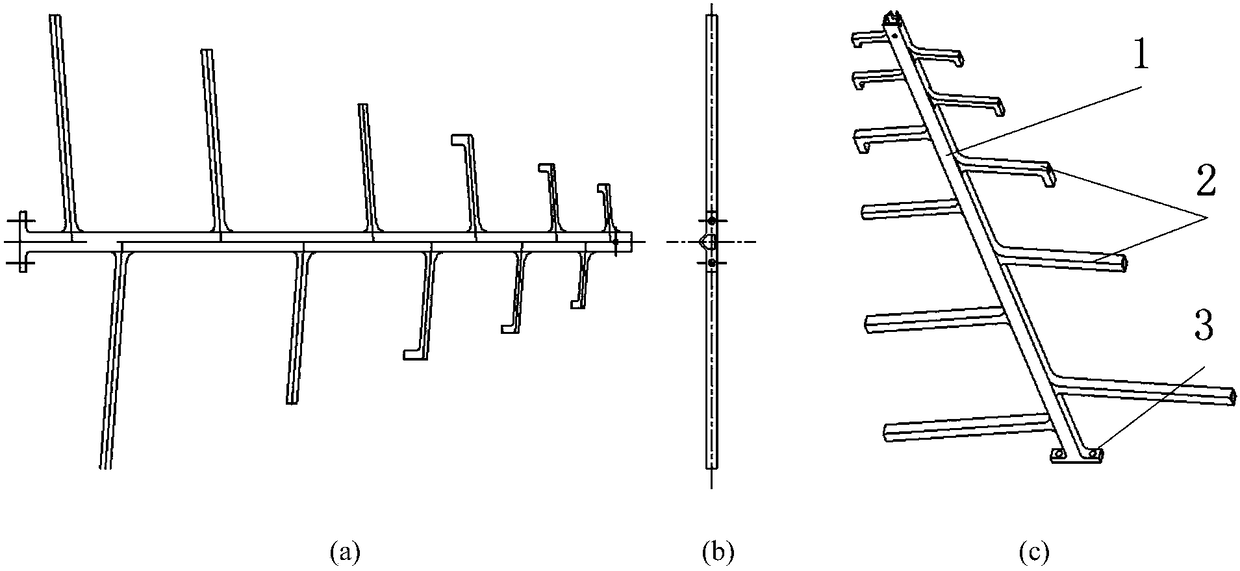

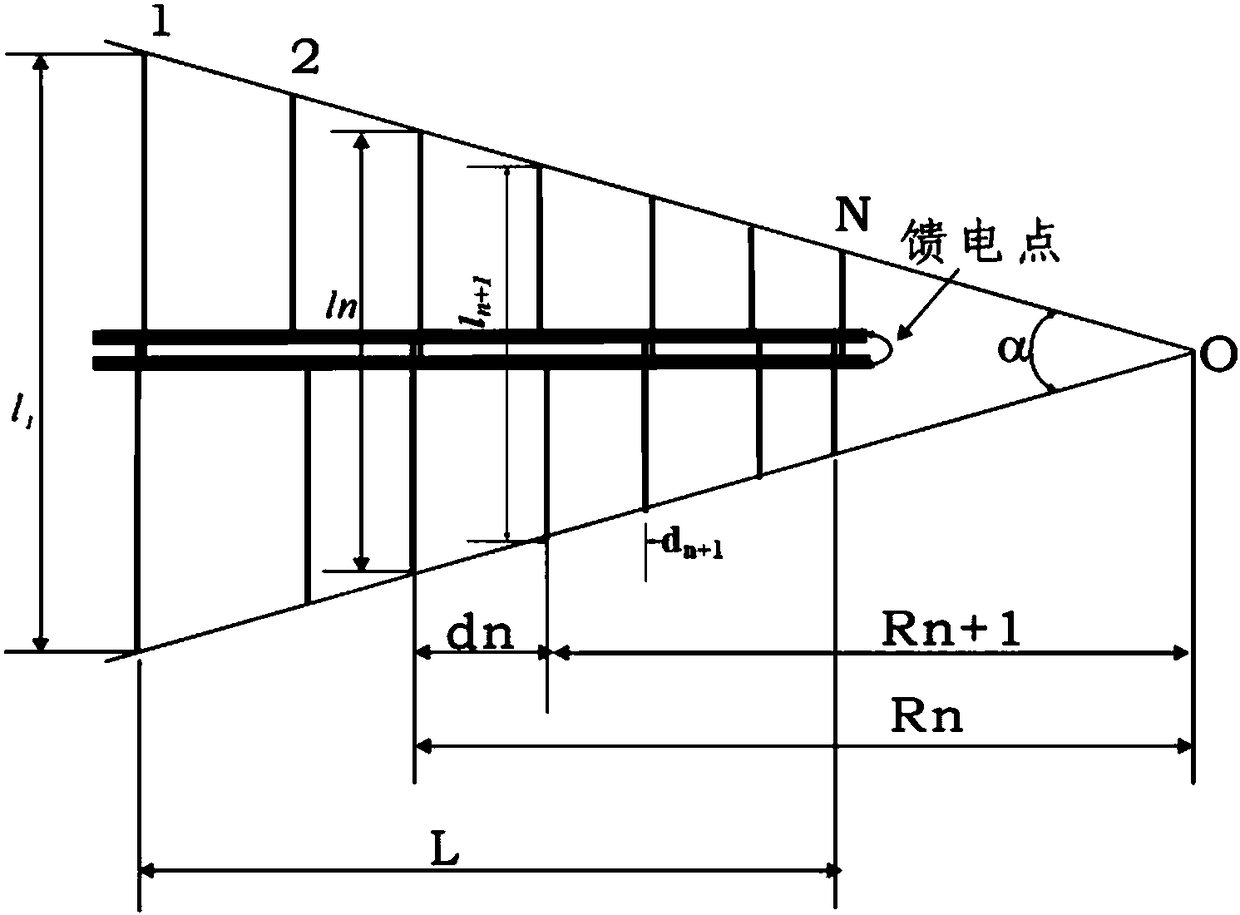

High-precision log-periodic dipole antenna integral forming method

InactiveCN108365319AGuaranteed structural accuracyImprove structural featuresAntenna supports/mountingsRadiating elements structural formsNumerical controlC banding

The invention provides a high-precision log-periodic dipole antenna integral forming method. The main structure of a high-precision log-periodic dipole antenna comprises an assembly line with a pentagonal cross section, and multi-layer radiation oscillators which are integrally designed and attached to the assembly line and have different lengths and different cross sections. According to productworking requirements, detailed structural design is carried out through theoretical calculation and simulation, materials meeting task requirements are selected, complex workpiece machining is carriedout by means of various combined machining processes such as numerical control machining, precision wire cutting and deep hole machining, a 3D laser scanner is adopted to perform effective precisionmonitoring on the complex shape of the high-precision log-periodic dipole antenna and screening qualified parts after the machining is completed, and the structural consistency between products is ensured to guarantee requirements for electrical performance of log-periodic antennas after assembly. The high-precision log-periodic dipole antenna integral forming method effectively solves the problems of guaranteeing high phase consistency, wide frequency band, wide directional diagram, high gain and the like between different log-periodic antennas in the L / S / C band, effectively reduces product weight, improves structural strength of products, broadens the application range of measurement and control type log-periodic antennas, and is adapted to different application fields of the products.

Owner:CHINA ELECTRONICS TECH GRP NO 39 RES INST

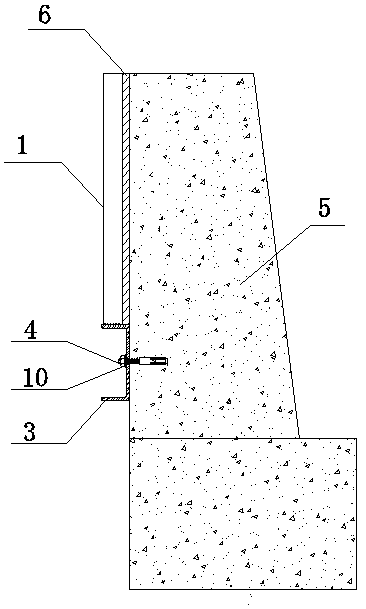

Auxiliary device and method used for controlling tongue-and-groove size manufacturing precision

InactiveCN106595426ALower difficulty requirementGuaranteed structural strengthMechanical measuring arrangementsEngineeringTongue and groove

The invention discloses an auxiliary device used for controlling tongue-and-groove size manufacturing precision. The auxiliary device comprises a magnetic angle iron (1), a calibrated scale (2), and an iron sheet (3). The magnetic angle iron (1) comprises a groove plate (4) and a scale plate (5), and the side edge of the scale plate (5) is provided with scales. The calibrated scale (2) is provided with a strong ferromagnetic device (6). The calibrated scale (2) is provided with the scales used to correspondingly extend the scales of the scale plate (5), and the calibrated scale is an elastic telescopic member. One surface of the calibrated scale (2) is provided with the iron sheet (3), which is a fixable movable member, and is disposed on the side of the magnetic angle iron (1) opposite to a bending direction, and is fixedly disposed on the calibrated scale (2) by a locking device (7). The invention also discloses a method used for controlling the tongue-and-groove size manufacturing precision. The auxiliary device and the method have advantages of simple structure, convenient use, and high measurement precision.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

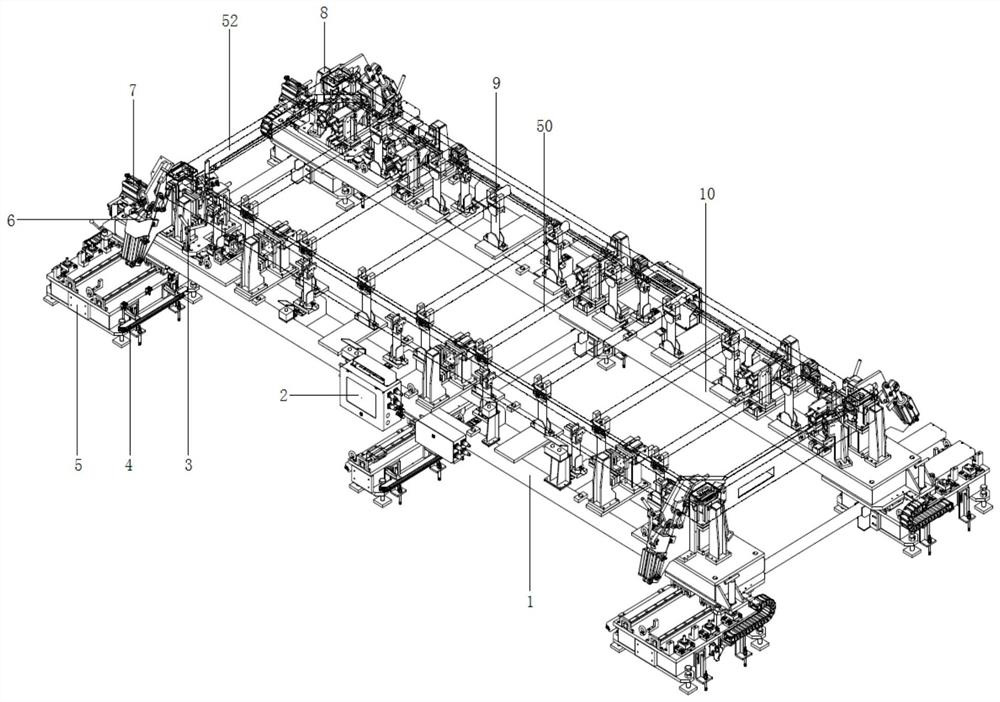

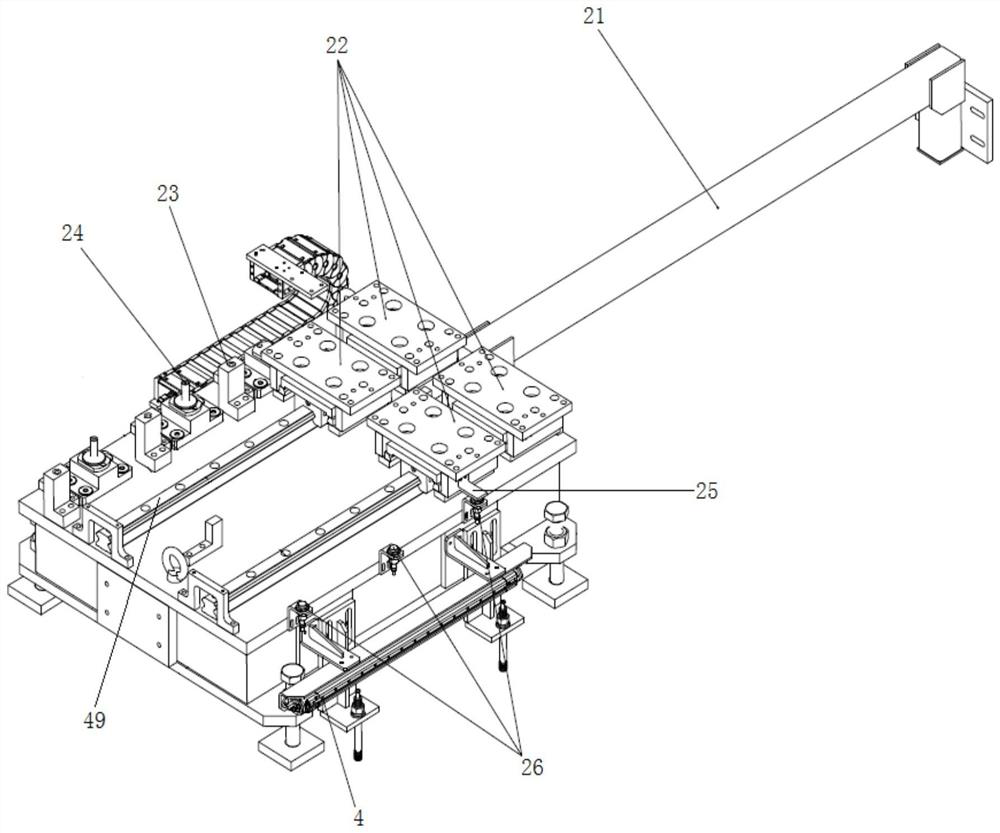

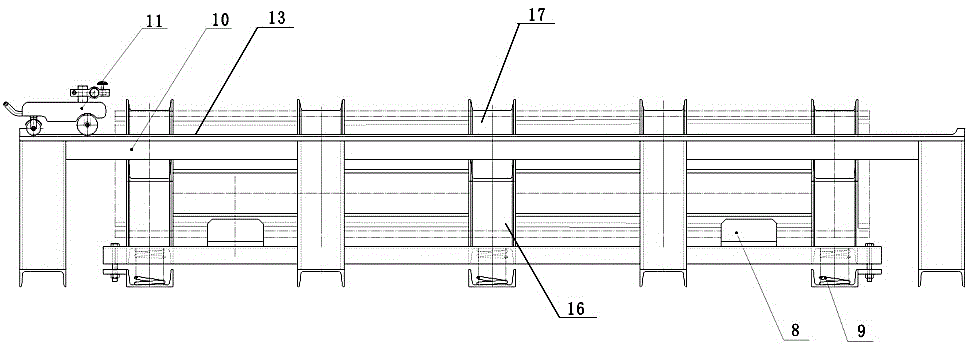

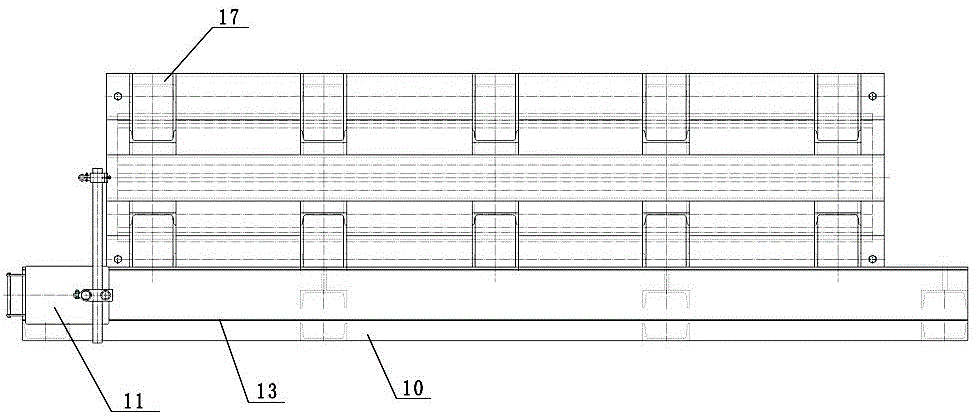

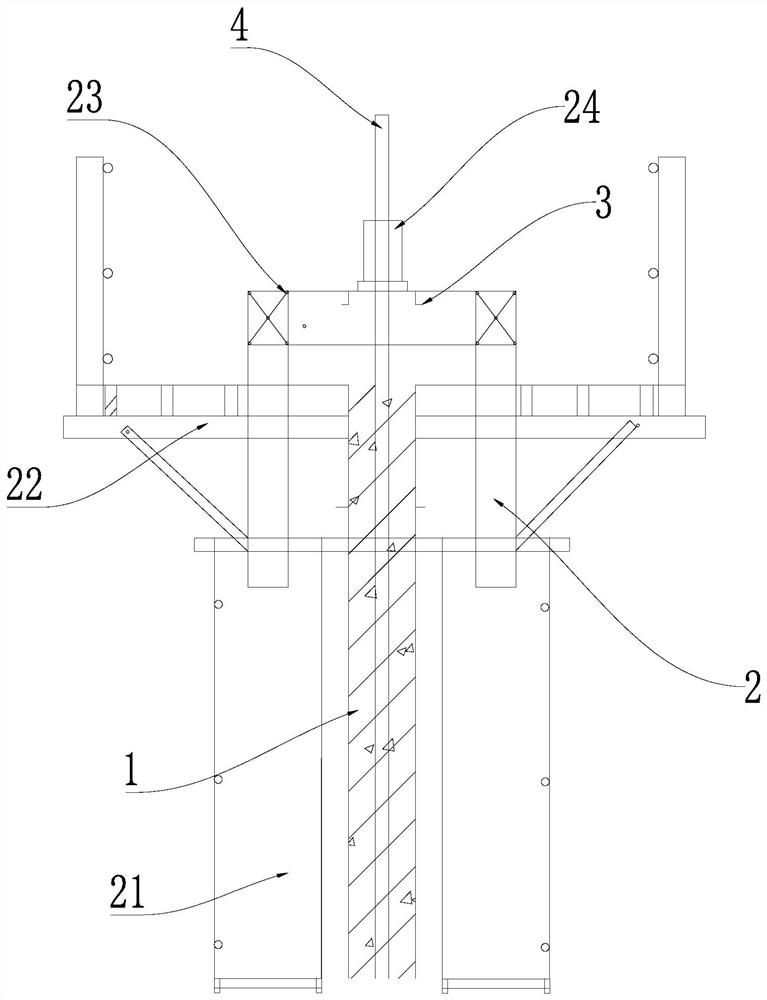

Top frame welding clamp

PendingCN114043144AAchieve clamping fasteningGuaranteed structural accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSlide plate

The invention discloses a top frame welding clamp, and belongs to the technical field of welding fixtures. The top frame welding clamp comprises a first truss beam and a second truss beam which is arranged horizontally with the first truss beam, the two ends of the bottom of the first truss beam and the two ends of the bottom of the second truss beam are connected with bases in a sliding mode, and positioning assemblies and locking assemblies are fixedly arranged on the bases. The positioning assemblies are used for positioning the sliding stroke of the first truss beam and the second truss beam and the locking assemblies are used for locking the first truss beam and the second truss beam after positioning. A sliding plate and a first driving mechanism for driving the sliding plate to slide on the first truss beam and the second truss beam are arranged at the corresponding ends of the first truss beam and the second truss beam, and a corner end pressing mechanism, a side top pressing mechanism and a side wall clamping mechanism are mounted on the sliding plate. The invention provides the top frame welding clamp which solves the technical problems that in the prior art, a top frame welding clamp is poor in universality, and clamping and fastening of a top frame cannot be truly achieved.

Owner:江苏鲁安特智能装备科技有限公司

Vacuum Consumable Furnace Crystallizer Welding Cylinder Preparation Technology and Welding Aids

ActiveCN103817530BGuaranteed structural strengthGuaranteed structural accuracyWelding/cutting auxillary devicesOther manufacturing equipments/toolsSmelting processCylinder mold

The invention relates to the technical field of vacuum self-consuming furnaces, in particular to a vacuum self-consuming furnace crystallizer welded cylinder producing process and a welding assistive device, and solves the problems that currently a cylinder is formed by spinning or forging, the process is complicated, production cost is high and price is high. The crystallizer cylinder is formed in a welded manner by the aid of the welding assistive device, the technical prejudice that the cylinder can only be formed by spinning or forging in the prior art is overcome, indicators of the produced cylinder meet the requirements of the vacuum self-consuming furnace during smelting, on the basis of guaranteeing structural strength and accuracy of a crystallizer, producing difficulty is reduced effectively, production cost of the crystallizer is reduced, and market competitiveness of equipment is improved.

Owner:太原市冶金机械厂

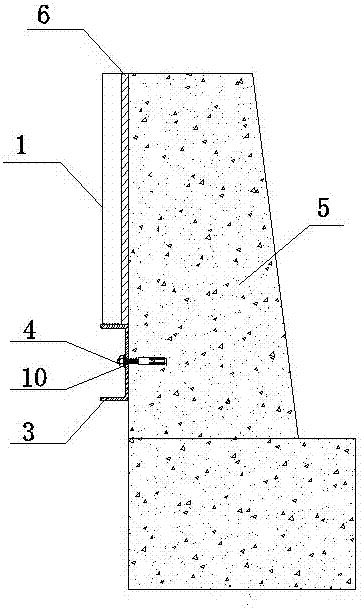

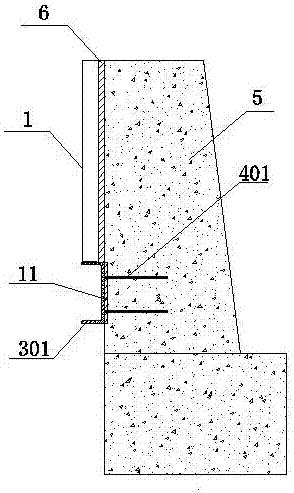

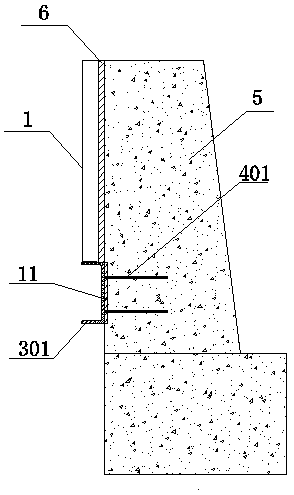

Rapid pre-embedded silo structure auxiliary steel structure silo wall

PendingCN112982961AGuaranteed structural accuracyEasy constructionForms/shuttering/falseworksBuilding material handlingRebarSilo

The invention discloses a rapid pre-embedded silo structure auxiliary steel structure silo wall. The rapid pre-embedded silo structure auxiliary steel structure silo wall comprises a sliding mold operation platform and a positioning assembly, wherein the positioning assembly is arranged above the sliding mold operation platform, the sliding mold operation platform is arranged on the silo wall, the silo wall comprises a lower concrete layer and an upper steel bar layer, the upper steel bar layer comprises a plurality of steel bars extending out of the lower concrete layer, and the positioning assembly is used for controlling the vertical distance between the plurality of steel bars; and the positioning assembly comprises transverse channel steel, a correcting device and a pre-embedded fixing piece, the transverse channel steel is arranged perpendicular to the silo wall, one end of the correcting device is fixed on the transverse channel steel, the other end of the correcting device is provided with the pre-embedded fixing piece, the pre-embedded fixing piece is embedded in the upper steel bar layer, and the distance between the adjacent steel bars is corrected. The position of the pre-embedded fixing piece is accurately positioned through the correcting device, so that the position of the upper steel bar layer can be accurately positioned according to the position of the pre-embedded fixing piece, and the correcting device can be used for multiple times after being disassembled.

Owner:CHINA MCC5 GROUP CORP

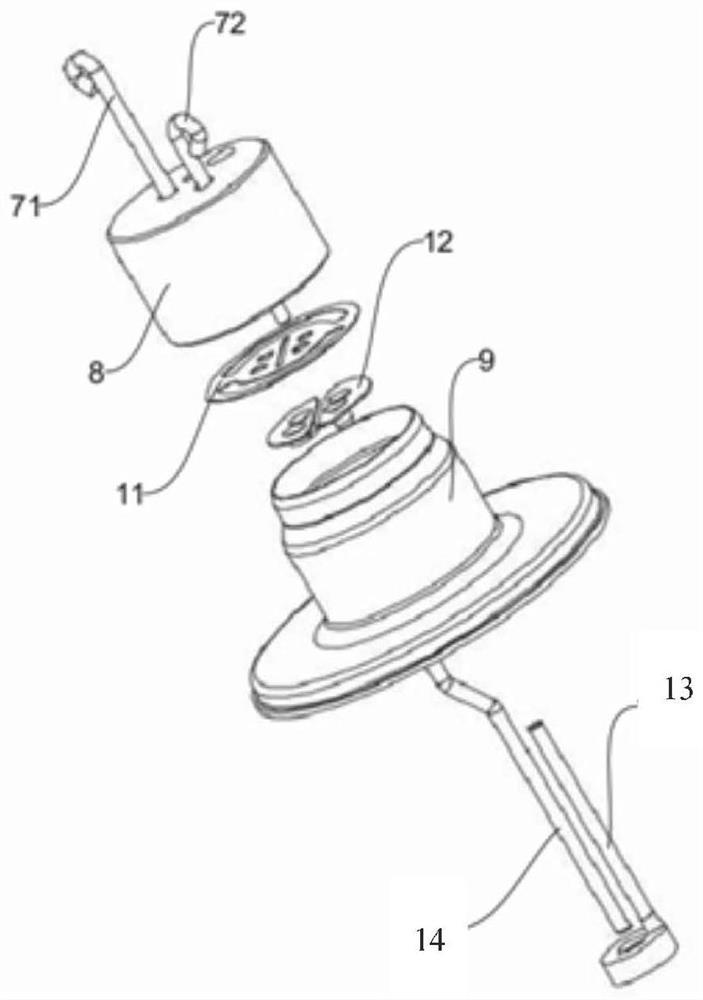

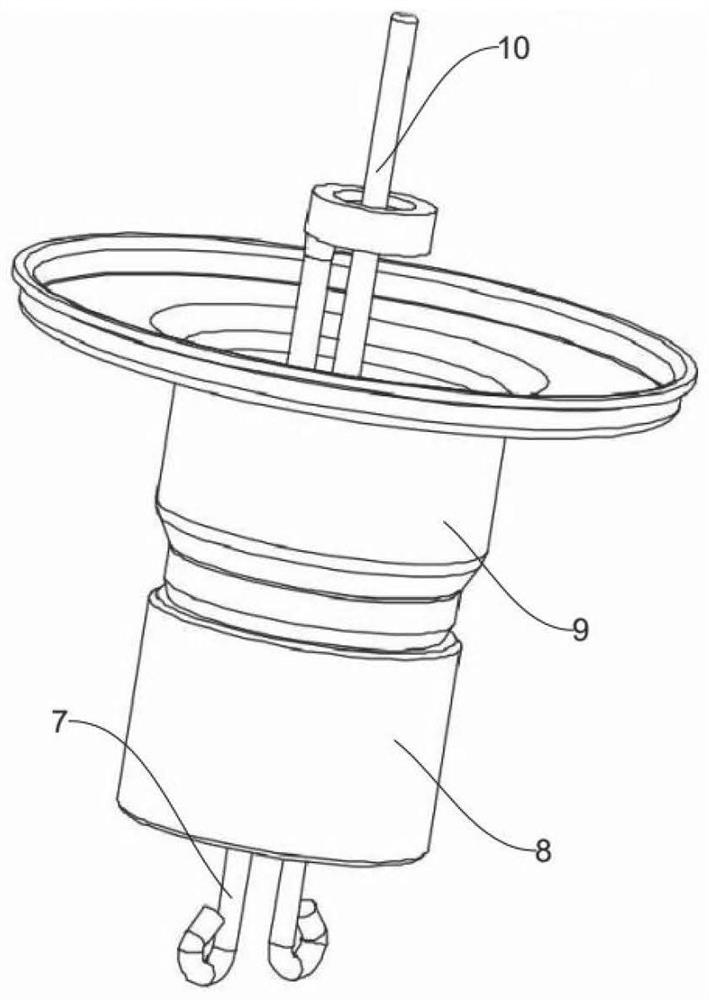

Assembling process of magnetron cathode assembly

ActiveCN112238274AImprove yield rateGuaranteed structural accuracySoldering auxillary devicesPhysicsPre-RC assembly

The invention provides an assembling process of a magnetron cathode assembly. The assembling process comprises the following steps of S1, pre-assembling a pre-assembled part and molds; S2, welding andmold removal; S3, leak detection; S4, installing a filament and an upper end cap, and welding and fixing the filament and the upper end cap; S5, filament carbonization; and S6, resistance detection and titanium powder coating; wherein the pre-assembled part comprises a lower end cap, a long lead, a reflecting plate, a K side tube, a solder plate, a support body and a terminal assembly, and the molds comprise an upper mold and a lower mold. By arranging the upper mold and the lower mold, the cathode assembly does not deform during welding, so that the structural precision of the cathode assembly is ensured, by arranging an upper clamp and a lower clamp of a leak detector, higher sensitivity and detection precision are achieved during the leak detection of the cathode assembly, by adoptinga cathode assembly assembling process formed by the molds, the assembling precision of the magnetron cathode assembly is ensured, and the product percent of pass is improved.

Owner:GUANGDONG GALANZ MICROWAVE OVEN & ELECTRICAL APPLIANCES MFG +1

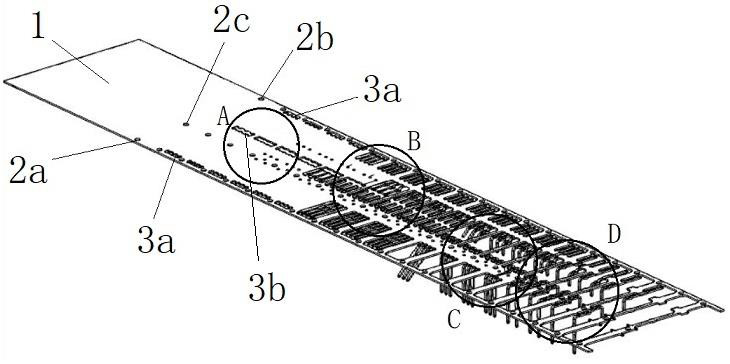

A continuous molding method for thin terminals

ActiveCN113560427BGuaranteed structural accuracyMeet the precision requirementsContact member manufacturingMetal-working feeding devicesConvex structurePunching

Owner:苏州铭峰精密机械有限公司

Assembling and welding tool for ceramic windows and application method for assembling and welding tool

InactiveCN103252602BThere is no phenomenon of sticking togetherEvenly distributedWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention discloses an assembling and welding tool for ceramic windows and an application method for the assembling and welding tool. The assembling and welding tool comprises a main tool mold, an inner cavity support structure and barriers. The periphery of a body of a ceramic window is fixed by the aid of the main tool mold, the upper end and the lower end of the body of the ceramic window are fixed by the aid of the inner cavity support structure, and a cooling water connector is fixed by the aid of the barriers. The application method includes steps of combining components of the main tool mold for assembling parts of the ceramic window with one another; assembling the inner cavity support structure and the barriers; integrally welding the ceramic window at one step; and disassembling the main tool mold, the inner cavity structure and the barriers to obtain a finished product. The assembling and welding tool and the application method have the advantages that three tool units with high concentricity and parallelism form the main tool mold to constrain the body of the ceramic window; the size of a waveguide inner cavity is fixed by the aid of the inner cavity support structure capable of moving in front, rear, left and right directions, and the waveguide inner cavity with the fixed size is prevented from deforming during welding; the cooling water connector is positioned by the barriers, and screws on the barriers are adjusted to be abutted to the water connector, so that the water connector cannot move; and owing to the method, all the parts are assembled at one step and are welded and molded at one step, so that the design precision of the ceramic window is effectively guaranteed, the production efficiency is greatly improved, and the ceramic window manufacturing cost is reduced.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI +1

Structural system and method of prefabricated garage based on prefabricated piles

ActiveCN105862900BEmission reductionGuaranteed verticalityArtificial islandsUnderwater structuresVertical loadStructure system

The invention discloses an assembled type garage structure system based on precast piles and a method. The assembled type garage structure system comprises the precast piles, horizontal supporting beams and independent foundations, wherein vertical load bearing parts of a garage structure are formed by the precast piles, and guide rails are arranged on the outer surfaces of the precast piles; the horizontal supporting beams comprise ground beams and superposed beams, the ground beams are arranged around the precast piles by one circle so as to support a bottom plate of a garage, and the superposed beams are arranged around the precast piles so as to support a garage floor plate or a garage top panel; the independent foundations are connected with the precast piles and the precast ground beams through designed grooves. All the structure members such as the precast piles and the independent foundations are machined in factories and can be assembled for construction, so that emission of pollutants at a construction site is reduced; through the guide rails and cooperation of the independent foundations and mounting flanges, the perpendicularity of the precast piles is guaranteed, the structure bearing capacity is well guaranteed, and structure precision is guaranteed; the precast piles and garage columns are integrated, so that not only is energy saved, but also construction efficiency of the underground garage is greatly improved.

Owner:SHANDONG UNIV

Electronic expansion valve

ActiveCN107289138BGuaranteed structural accuracyIncrease axial fit lengthEfficient regulation technologiesFluid circulation arrangementReciprocating motionStructural engineering

The invention provides an electronic expansion valve. The electronic expansion valve includes a valve seat, a valve port seat, a nut assembly and a valve needle. The valve port seat is fixedly arranged on the valve seat, and a guide sleeve is arranged between the valve seat and the nut assembly. Set in the guide sleeve, the valve port seat and the guide sleeve are concentrically socketed, and the end of the valve port seat close to the guide sleeve is radially provided with a first flow channel that connects the valve cavity of the valve seat with the valve port of the valve port seat, and the valve port seat and the guide sleeve The matching length is greater than the height from the bottom of the first flow channel of the valve port seat to the bottom axial stop surface outside the valve port seat corresponding to the guide sleeve. According to the electronic expansion valve of the present invention, it can solve the problems in the prior art that the axial positioning of the valve seat to the guide sleeve is insufficient, the deflection of the guide sleeve is prone to occur, and the structural accuracy of the electronic expansion valve is affected.

Owner:ZHEJIANG DUNAN ARTIFICIAL ENVIRONMENT

Supporting reticulated shell of a concrete spherical shell structure and its construction method

ActiveCN107060094BSolve construction problemsReduce the difficulty of supportArched structuresVaulted structuresSupporting systemConcrete beams

The invention discloses a support lattice shell of a concrete spherical shell structure and a construction method. The support lattice shell of the concrete spherical shell structure comprises radial steel tubes, annular steel tubes, annular components of expansion bolts, annular components of built-in fittings, the expansion bolts, the built-in fittings, a concrete wall body, frameworks, spherical shell concrete beams, concrete shells, a support lattice shell, fragment lattice shells, through holes and fixing plates of the built-in fittings. In the construction process of the construction method, firstly the radical steel tubes and the annular steel tubes are mounted one segment by another, and are fixed to a concrete wall body structure through the annular components, and finally the frameworks are laid to form a support lattice shell of the spherical shell structure. By adoption of the construction method, the structure accuracy can be guaranteed, supporting and arranging difficulties of the frameworks can be reduced, and the construction efficiency and the construction quality can be improved. In addition, the support lattice shell of the spherical shell structure is a steel structure, can be recycled, not only can decrease wood consumption, but also is environmentally friendly; and the problems that the molding accuracy of the concrete wall body structure is low and the support system of the concrete wall body structure is difficult are solved, and the problem of framework construction of the concrete wall body structure is solved.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

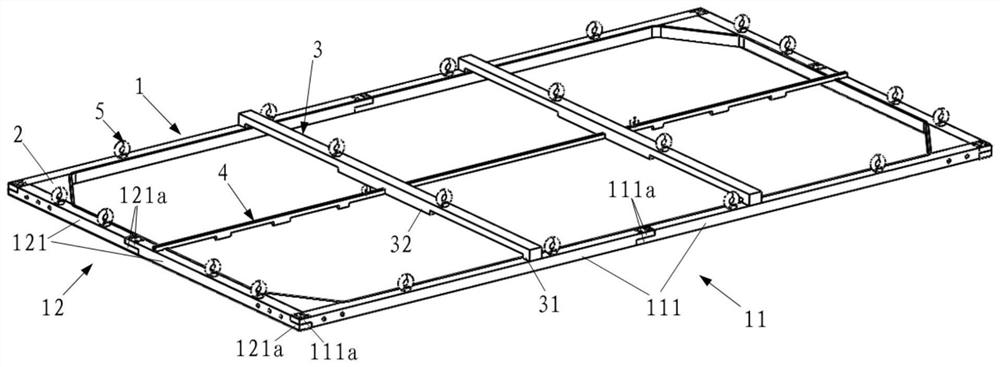

A resin-based composite material battery box laying mold for new energy vehicles

The invention discloses a resin-based composite material battery box laying mold for new energy vehicles. The mold includes an inner mold, an outer mold and a fastening device. The inner mold includes an inner flanging edge, an inner panel-front, an inner panel-middle, an inner panel-back, a center panel of the inner bottom surface and four corners of the inner bottom surface. The outer mold includes outer plate-front, outer plate-middle, outer plate-rear and outer bottom surface. The fastening device includes a side plate fastening device and an upper and lower fastening device, which are composed of bolts, nuts, side panels and upper and lower panels. The internal and external combination mold designed by the invention can fully guarantee the geometric accuracy and structural accuracy of the battery box; the detachable mold designed by the invention well overcomes the difficult problem of complex demoulding of resin-based composite materials; the openable mold designed by the invention The outer mold overcomes the influence of the concave-convex plane formed by the reinforcement structure of the battery box on the installation of the outer mold.

Owner:DALIAN UNIV OF TECH

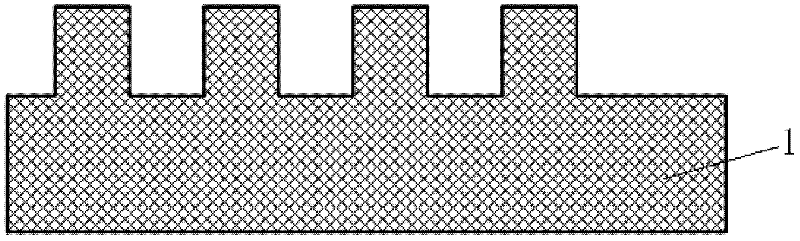

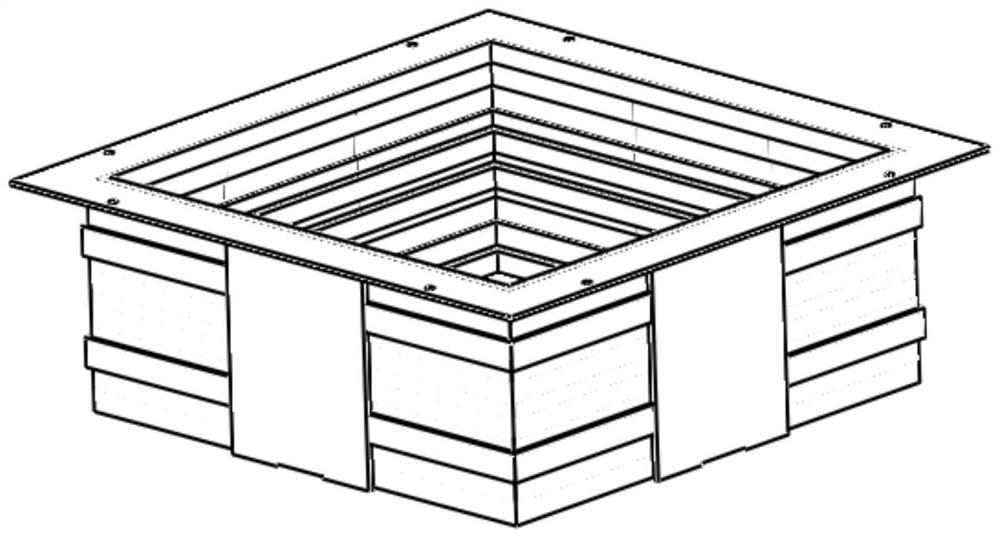

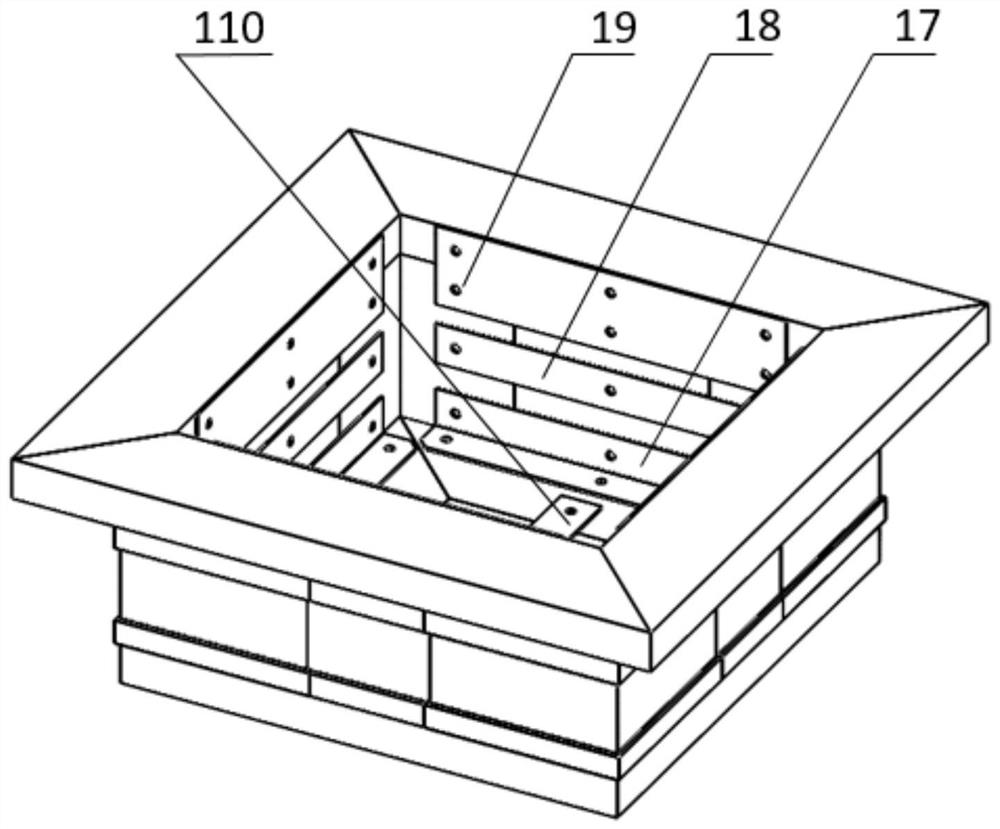

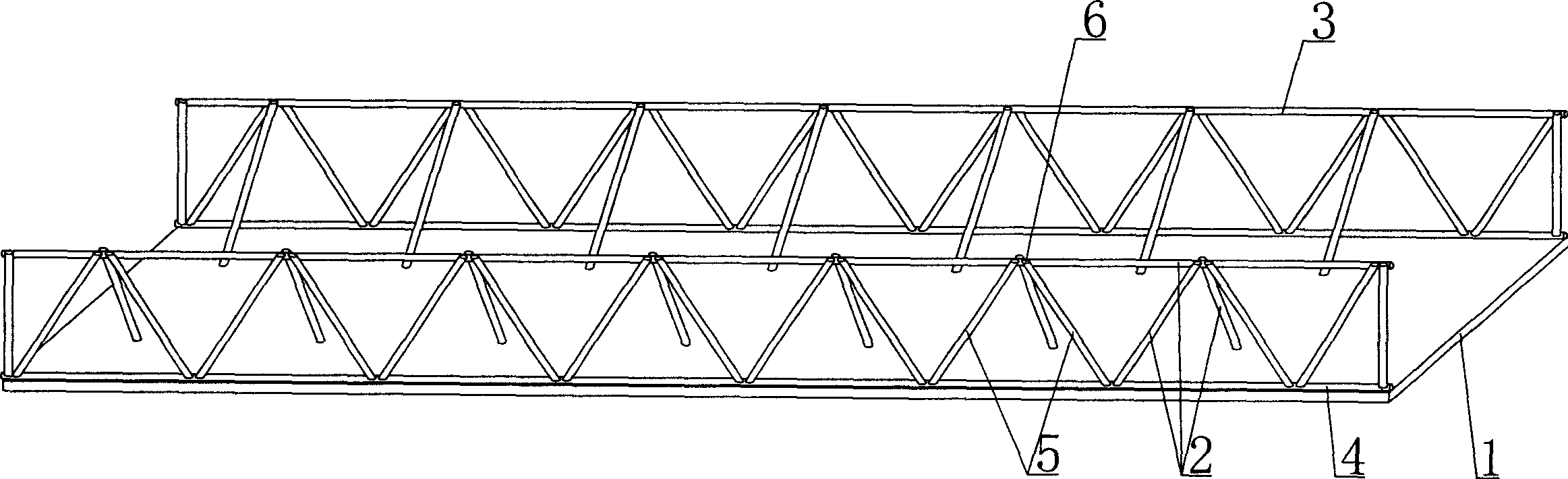

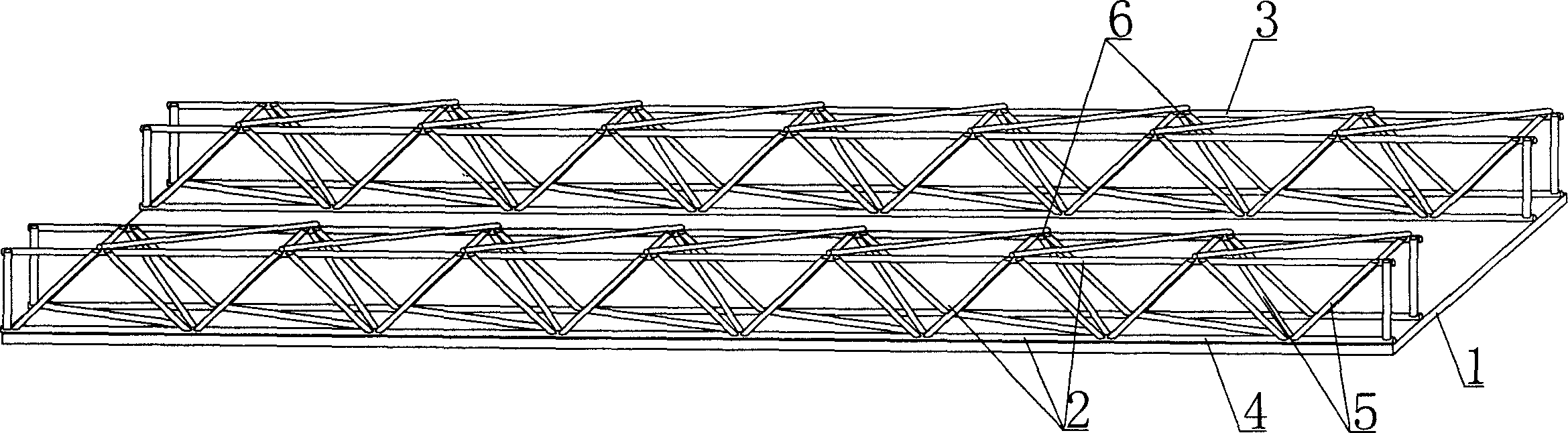

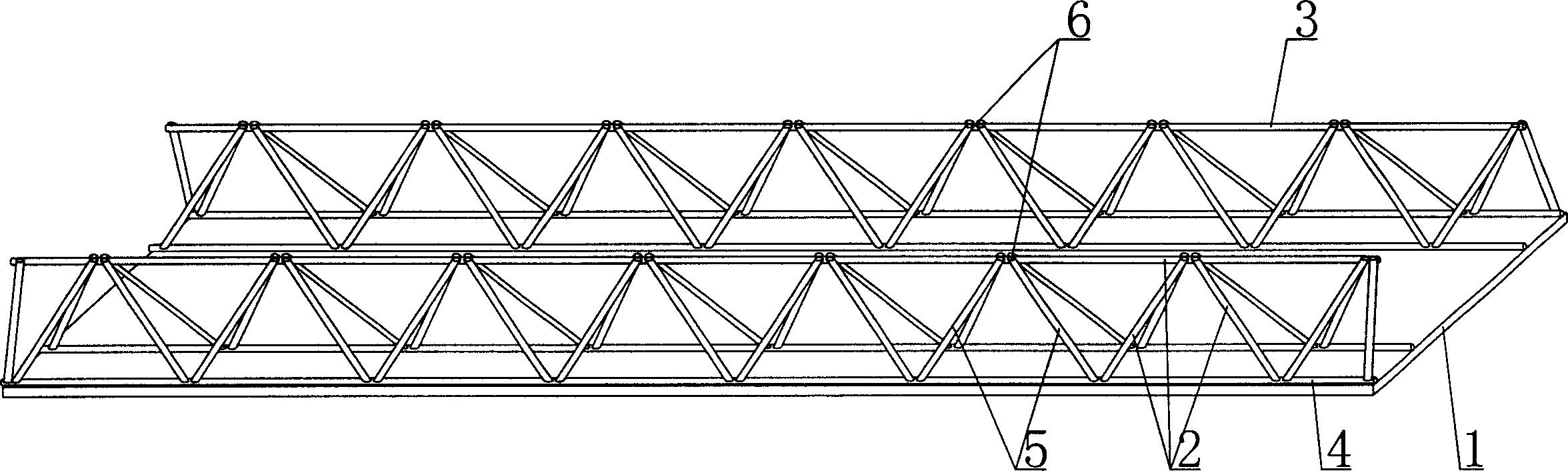

Structure force bearing type mould plate construction unit

A structural-load-carrying template component includes the template (1) and at least one web shelf (2) which is set on the template and connected to form the whole. The web shelf is installed with the upper chord (3), the lower chord (4) and the web member (5) which is connected with the (3) and the (4). At least three connected web members are in at least one node (6) to form the reticular three-dimensional member bar structure. So it is used for the hollow board, the floor, the roof, the base soleplate, the wall and the bridge of pouring reinforced concrete or the prestressed reinforced concrete, especially for the hollow floor with no girder.

Owner:邱则有

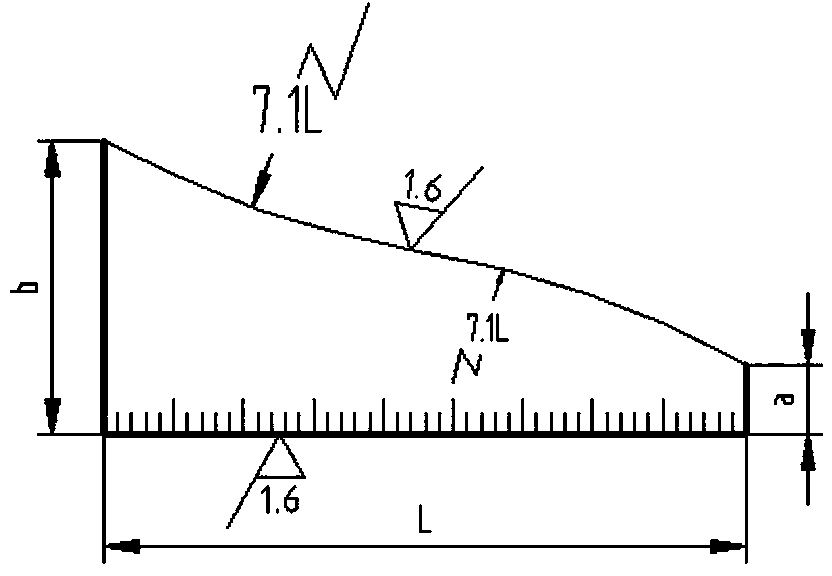

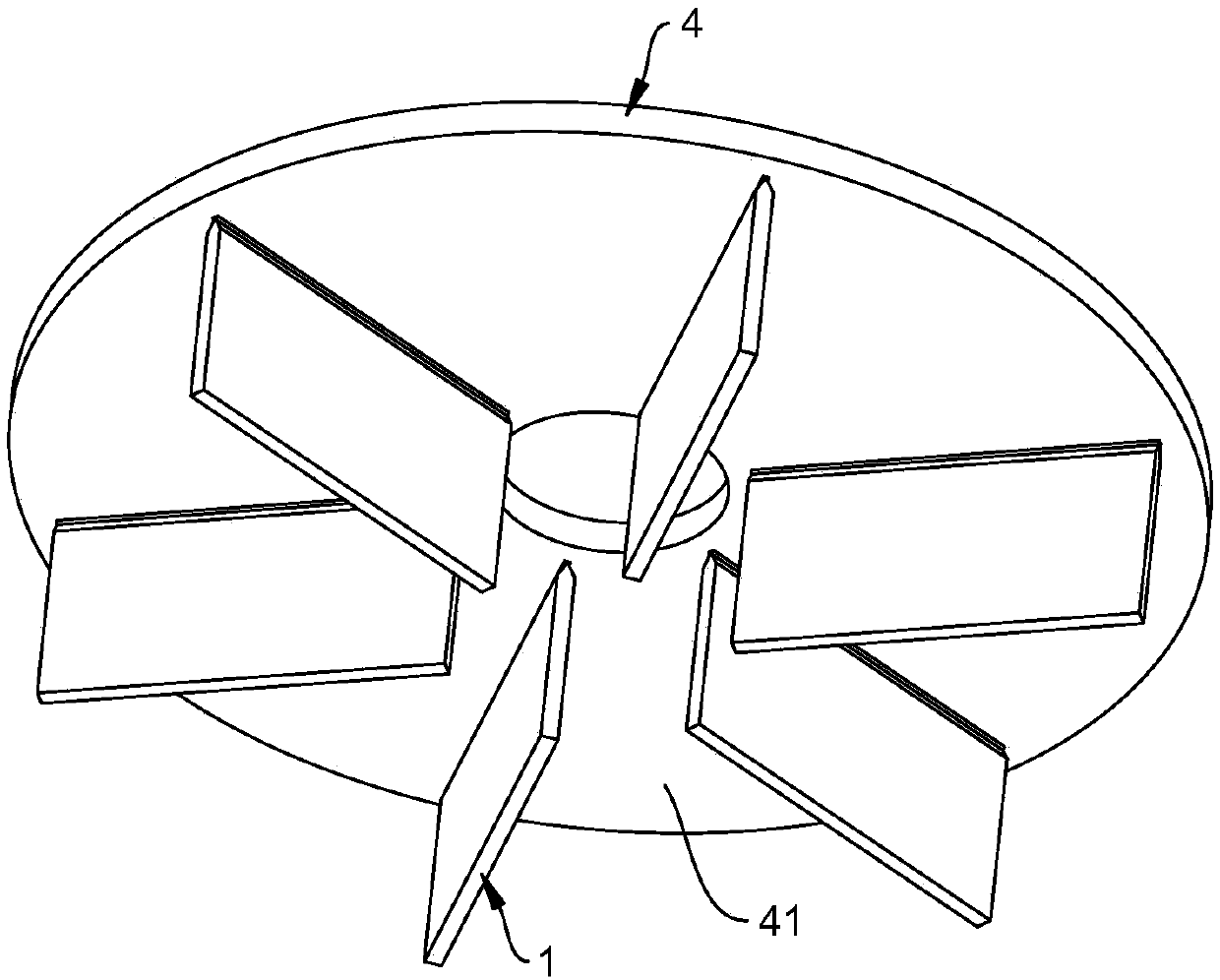

Support structure for three-dimensional (3D) printing platform part

PendingCN109605751ASignificant progressAvoid crackingManufacturing platforms/substratesHeat stressUltimate tensile strength

The invention relates to the technical field of three-dimensional (3D) printing, in particular to a support structure for a three-dimensional (3D) printing platform part. The support structure for the3D printing platform parts is arranged under the platform part, and comprises a platy support body, an inner edge annular support body and an outer edge annular support body, wherein the platy support body perpendicularly contacts the bottom surface of the platform part and is arranged along the radial direction of the bottom surface; the inner edge annular support body perpendicularly contacts the inner edge of the bottom surface of the platform part and is arranged along the circumferential direction of the inner edge; and the outer edge annular support body perpendicularly contacts the outer edge of the bottom surface of the platform part and is arranged along the circumferential direction of the outer edge. Through the platy support body, the platform part has high structural stiffness in the shrinkage trend direction, so that the heat shrinkage of a bottom layer of the platform part can be effectively controlled; and through the inner edge annular support body and the outer edgeannular support body, the thicknesses of the bottom layers of the platform part at the inner edge and the outer edge are increased, so that heat stress can be effectively dispersed. Therefore, the strength of the initially formed bottom layer structure can be effectively improved, the crack initiation is improved and restrained, and the bottom layer of the platform part is prevented from crackingduring the printing forming process.

Owner:上海汉邦联航激光科技有限公司

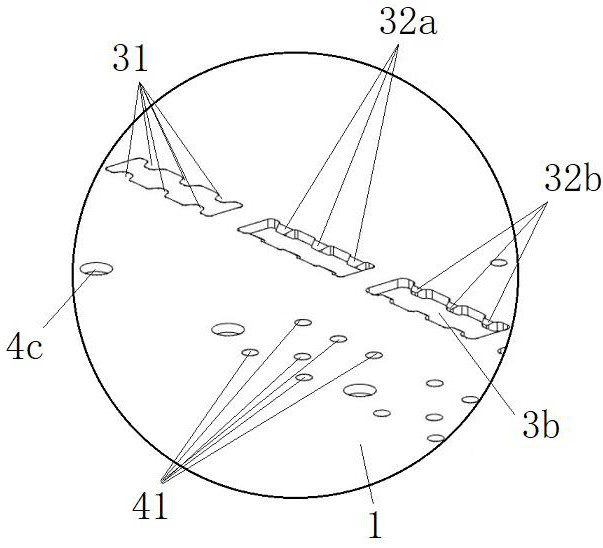

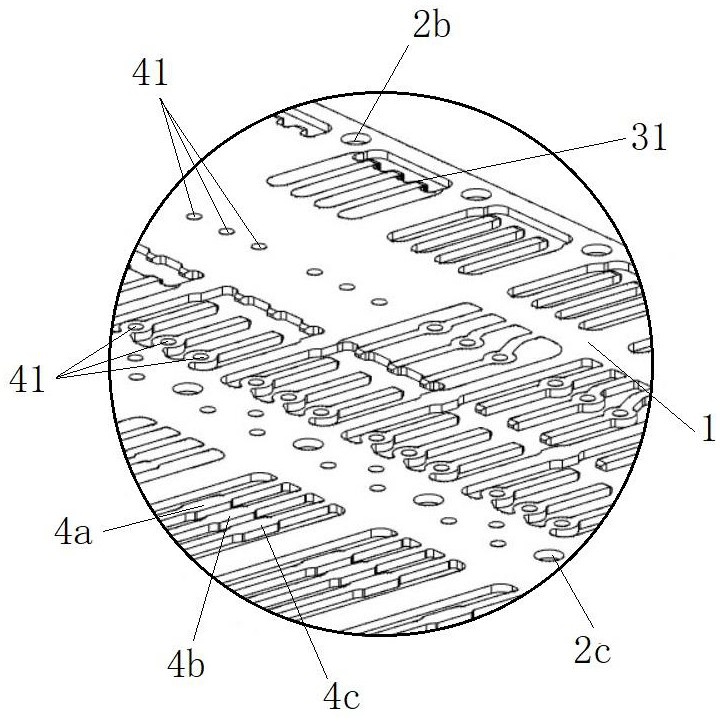

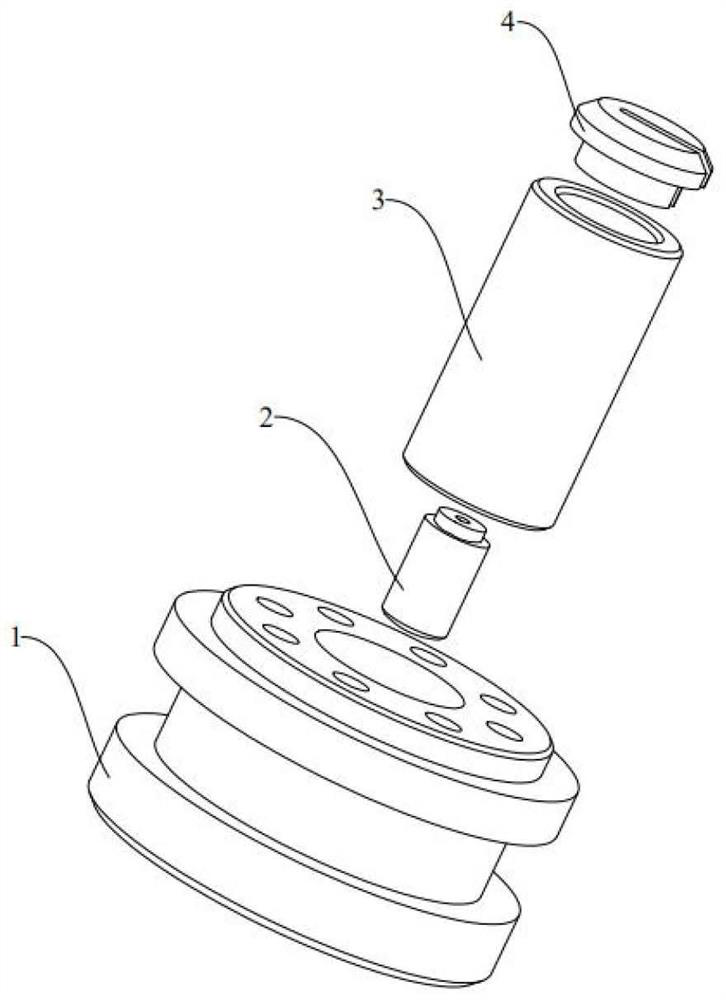

Large composite material product forming die

PendingCN114800958AEnsure structural stabilityGuaranteed structural accuracyPunchingMaterials science

The invention relates to a large composite material product forming die which comprises a die body (1), a connecting block (2), a correcting rod (3) and a punching tool rod (4). The mold main body (1) is of a regular annular structure; the multiple connecting blocks (2) are arranged at intervals in the circumferential direction of the mold body (1), and the connecting blocks (2) are located on the inner side of the mold body (1); a plurality of correcting rods (3) are arranged on the same side of the mold main body (1) at intervals; wherein two opposite ends of the correcting rod (3) are respectively connected with the mold main body (1); the punching tool rod (4) is perpendicular to the correcting rod (3), and the punching tool rod (4) and the correcting rod (3) are located on the same side of the die body (1); wherein two opposite ends of the punching tool rod (4) are respectively connected with the die main body (1).

Owner:NINGBO SHUXIANG NEW MATERIAL

A kind of assembly process of magnetron cathode assembly

ActiveCN112238274BImprove assembly efficiencyImprove yield rateSoldering auxillary devicesEngineeringPre-RC assembly

The invention provides a magnetron cathode assembly assembly process, including the following steps: S1: pre-assembly between pre-assembled parts and molds; S2: welding, demoulding; S3: leak detection; S4: installation of filaments, upper ends cap, and weld and fix the filament and upper end cap; S5: filament carbonization; S6: resistance detection, titanium powder coating; wherein, the pre-installed parts include lower end cap, long lead wire, reflector, K side tube, solder plate, support Body, terminal assembly; the mold includes an upper mold and a lower mold. The upper mold and the lower mold are set so that the cathode assembly will not be deformed during welding, thereby ensuring the structural accuracy of the cathode assembly, and then through the setting of the upper and lower fixtures of the leak detector, the cathode assembly can be inspected When leaking, it has higher sensitivity and detection accuracy. The cathode assembly assembly process formed by the above mold is used to ensure the assembly accuracy of the magnetron cathode assembly and improve the product qualification rate.

Owner:GUANGDONG GALANZ MICROWAVE OVEN & ELECTRICAL APPLIANCES MFG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com