Electronic expansion valve

An electronic expansion valve and valve port technology, which is applied to lift valves, valve devices, lighting and heating equipment, etc., can solve the problems affecting the structural accuracy of the electronic expansion valve, insufficient axial positioning of the guide sleeve, and deflection of the guide sleeve. Improve the neutrality, enhance the axial fit length, and ensure the effect of structural accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

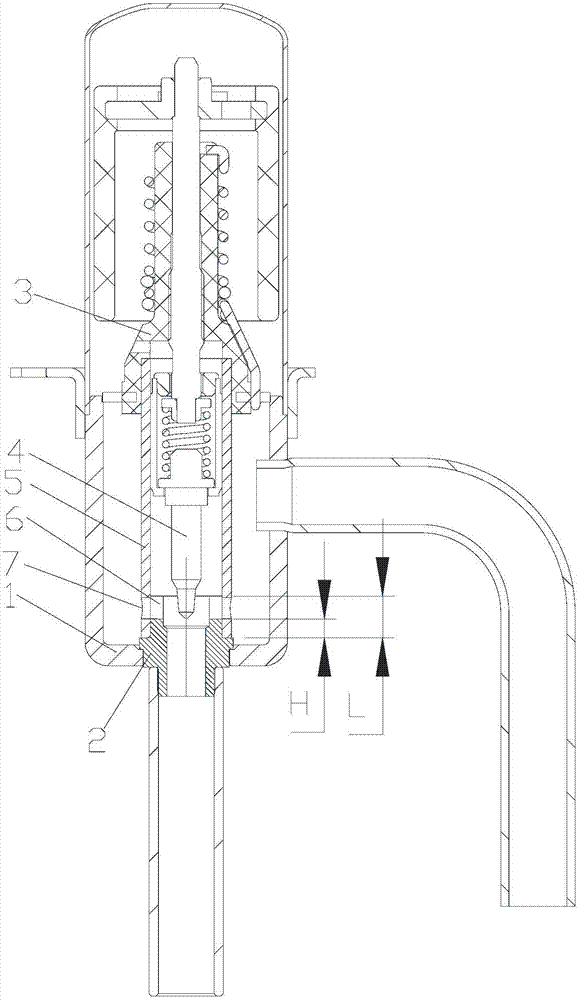

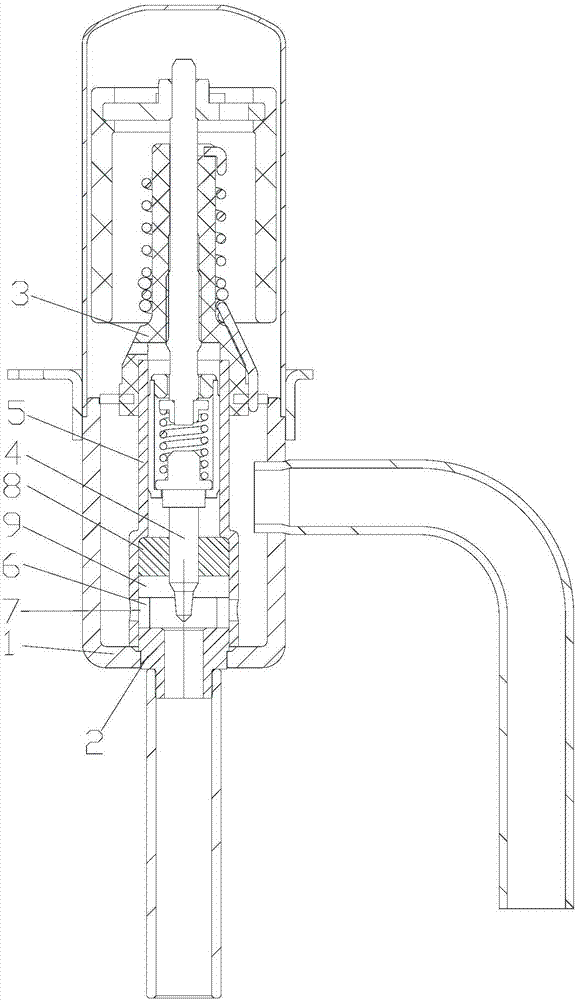

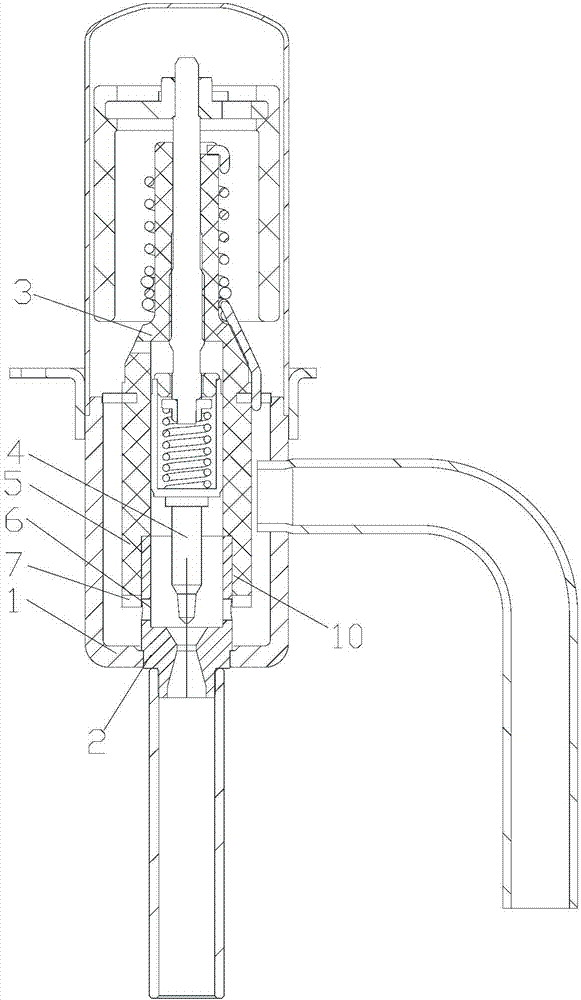

[0015] Please refer to Figures 1 to 4 , according to an embodiment of the present invention, the electronic expansion valve includes a valve seat 1, a valve port seat 2, a nut assembly 3 and a valve needle 4, the valve port seat 2 is fixedly arranged on the valve seat 1, and the valve seat 1 and the nut assembly 3 are provided with A guide sleeve 5, a valve core part is connected to the nut assembly, a magnetic rotor is connected to the valve core part, the valve core part includes a screw rod and a valve needle 4, the nut assembly guides the valve needle 4 through the guide sleeve, and the valve needle 4 guides the valve needle 4 along the guide sleeve. 5 is reciprocatingly arranged in the guide sleeve 5 in the axial direction, the valve port seat 2 is concentrically socketed with the guide sleeve 5, and the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com