Electrical test device for simulating winding of large turbo-generator stator

A steam turbine generator and electrical test technology, applied in the direction of electrical winding testing, measuring devices, measuring electricity, etc., can solve problems such as difficulty in realization, and achieve the effects of ensuring accuracy, ensuring structural accuracy, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The electrical performance of the simulated winding of the stator of the turbogenerator is the key element of the winding structure and the stability of the unit operation. After rigorous drawing practice and theoretical derivation, the inventors accurately established the slot fixing device and terminal of the simulated winding of the turbogenerator stator. Internal fixtures, the specific structure and mutual relationship of these devices are clarified for the first time. The specific implementation method is as follows:

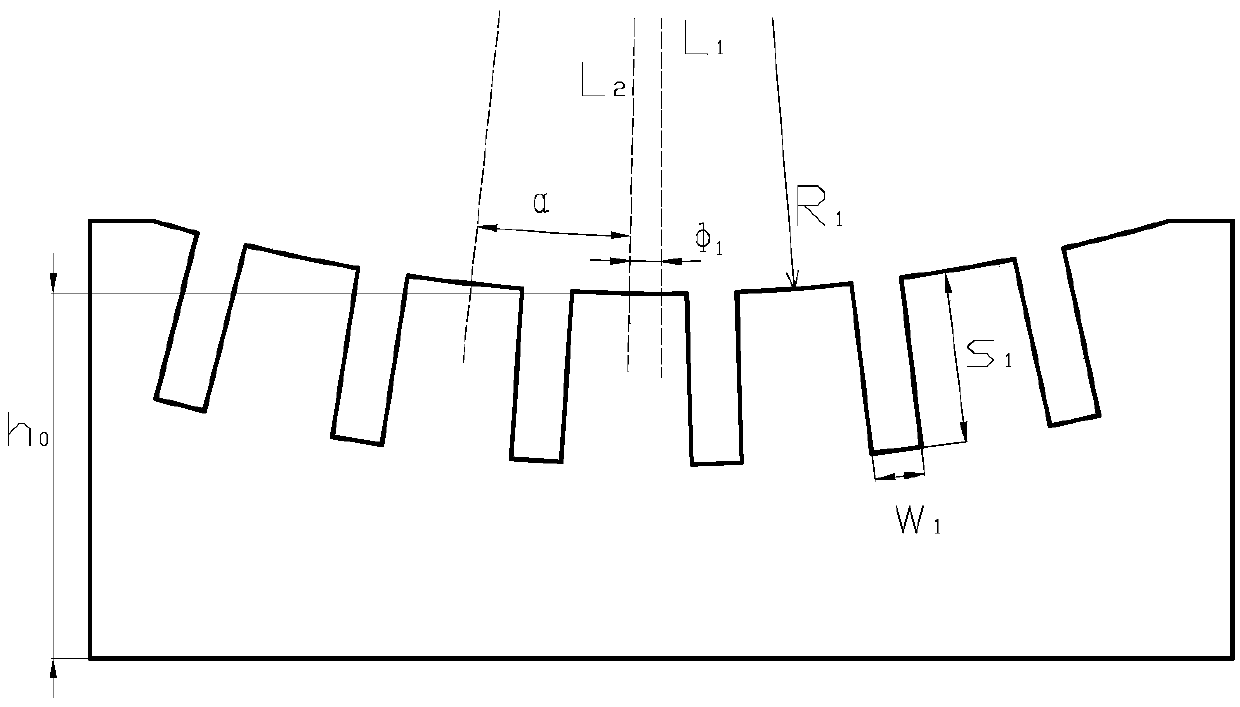

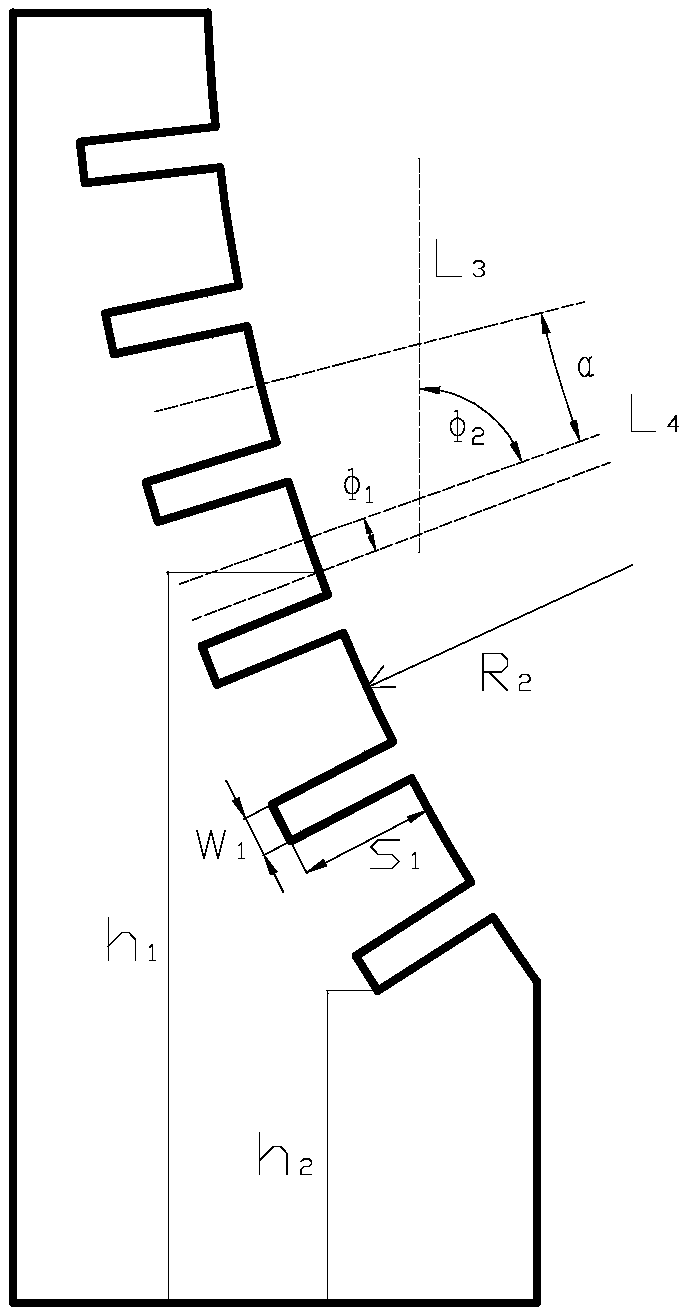

[0025] The basic parameters of the model include: the radius of the inner circle of the groove R 1 , end inner circle radius R 2 , angle between grooves α, groove angle end corner Groove width w 1 , slot height s 1 , the number of slots n, the bottom height of the inner circle of the slot h 0 , end and groove h 0 Point corresponds to position height h 1 , height h of the lowest point in the end slot 2 ;

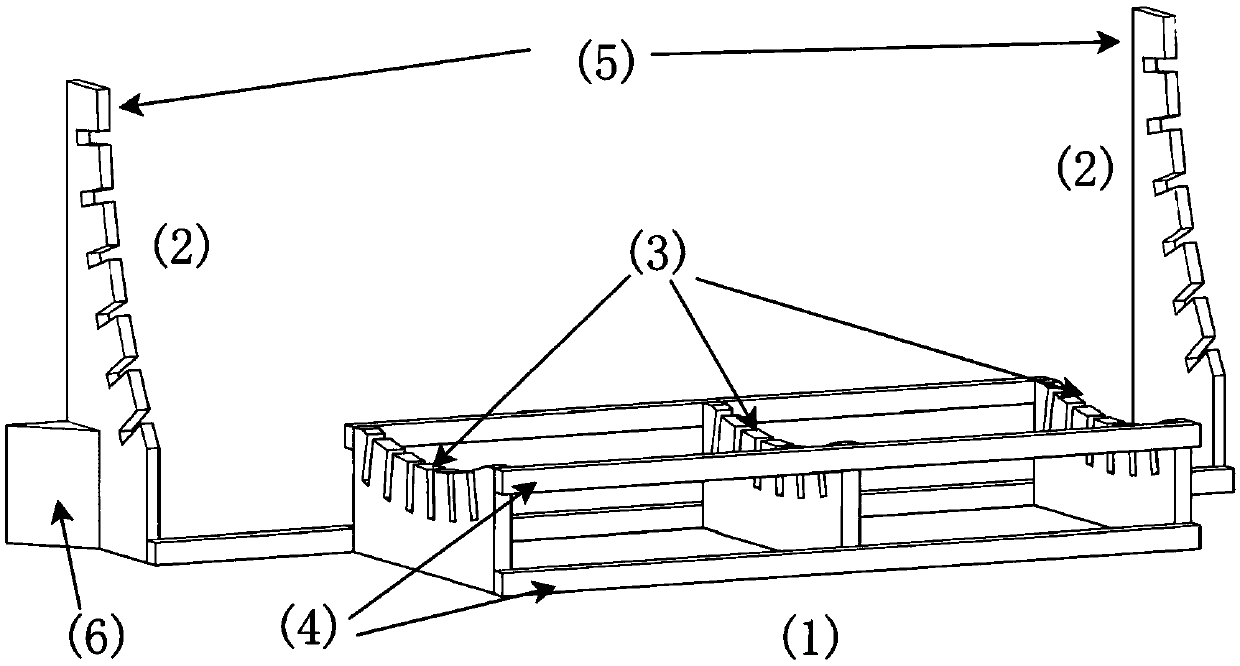

[0026] like image 3 As shown, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com