Rapid pre-embedded silo structure auxiliary steel structure silo wall

A pre-embedded and rapid technology, applied in building construction, on-site preparation of building components, formwork/formwork/working frame, etc., can solve problems such as unstable structures and poor concrete quality, and achieve the goal of ensuring structural accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

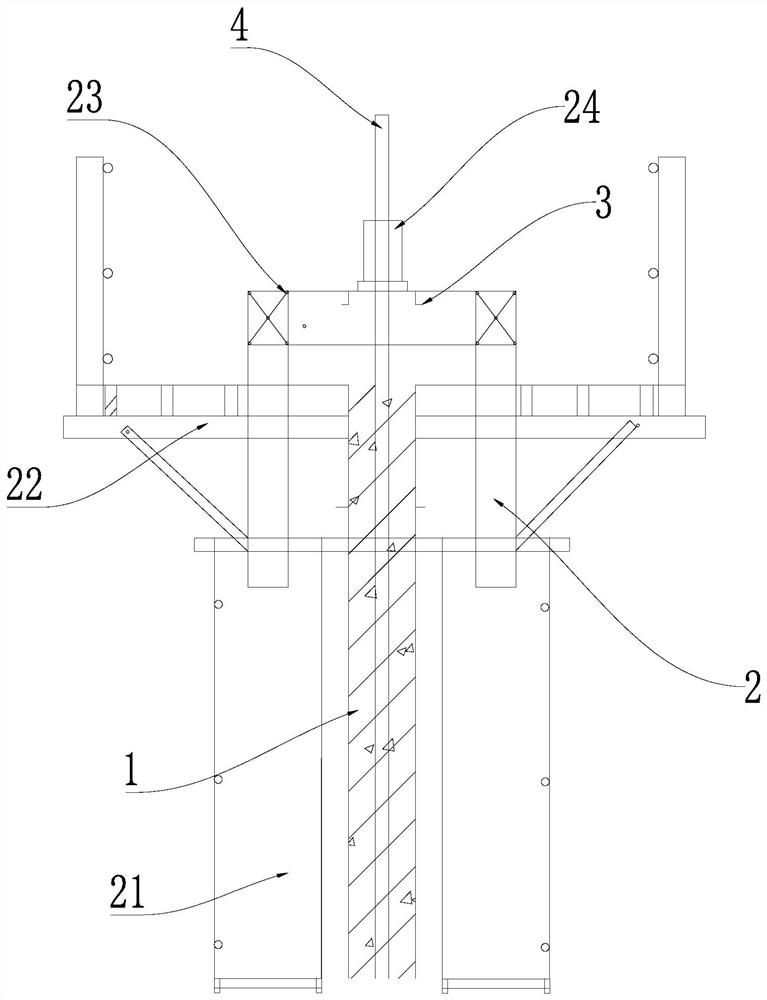

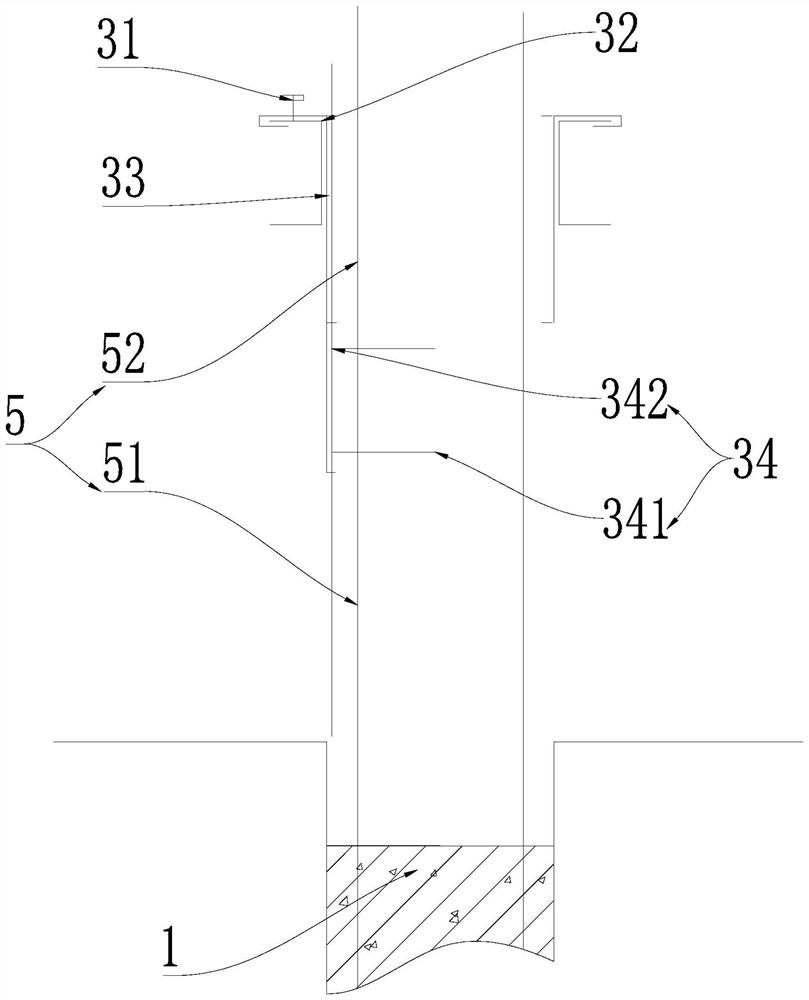

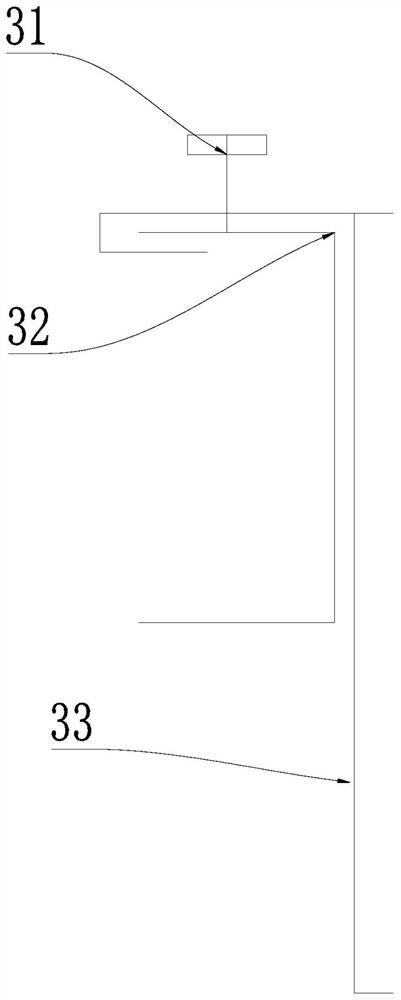

[0021] Example 1: See Figure 1 to 3 The wall wall of the rapid pre-buried silo structure of this embodiment, including the sliding mode operation platform 2 and the positioning assembly 3, the positioning assembly 3 is disposed above the sliding mode operation platform 2, the sliding mode operation platform 2 is disposed in the bin On the wall, and the wall wall includes the lower concrete layer 1 and the upper reinforced layer 5, and the upper reinforced layer 5 includes a plurality of steel bars extending from the lower concrete layer 1, and the positioning assembly 3 is used for vertical spacing between multiple steel bars. Control; the positioning assembly 3 includes a lateral groove 32, a correction device, and a pre-buried fixing member 34, and the lateral groove 32 is arranged perpendicular to the wall wall, and the correcting device is fixed to the lateral groove 32, and the other end is provided with a pre-buried fixture. 34. The embedded member 342 is embedded in the upp...

Embodiment 2

[0022] Example 2: The sliding mode operation platform 2 of the present embodiment includes a lifting frame 23 and a support platform 22, and the lifting frame 23 is fixed to the support platform 22, and the lateral groove 32 is fixed to the lifting frame 23. The present embodiment also includes a support rod 4 fixed to the lower concrete layer 1, and the top end of the support rod 4 extends the lift frame 23, and jack 23 is provided on the lifting frame 23, and the jack 24 is slidable with the support rod 4. The correction apparatus of the present embodiment includes a spiral clamp 31 and a guide member 33, and the guide member 33 is disposed perpendicular to the support platform 22, and one end is used to secure the embedded fixture 34, and the other end fixing the spiral clamp 31, the spiral clamp The device 31 adjustable is disposed on the lateral groove 32. The spiral clamp 31 can be used multiple times, and the embedded fixing member 34 is calibrated according to the transver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com