Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Guaranteed production accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process of large-diameter ultrathin quartz wafer

InactiveCN103847032AIncrease profitIncrease productivityLapping machinesFine working devicesLacquerQuartz

The invention belongs to the technical field of a quartz wafer tool, and particularly relates to a production process of a large-diameter ultrathin quartz wafer. The invention discloses a production process of a large-diameter ultrathin quartz wafer. The production process comprises the following steps of A, cutting quartz crystal lump by utilizing a fret saw; B, grinding the quartz crystal lump by adding green carbon silicon sand by utilizing a double-sided grinding machine; C, coating one surface of a wafer with protective paint by utilizing a spin coater; D, adhering the wafer onto an optical cement plate; E, grinding the optical cement plate with wafers being adhered on the upper surface and the lower surface; F, polishing the wafer with two sides being well ground by utilizing a double-sided polishing machine; G, placing the wafer into a wafer box after the wafer is qualified in inspection. By adopting the production process, the precision of a product of the processed quartz wafer is guaranteed, the mass production of the large-diameter ultrathin wafer is realized, the production efficiency is improved, and the production of the large-diameter quartz wafer is realized.

Owner:DEQING JINGHUI OPTOELECTRONICS TECH

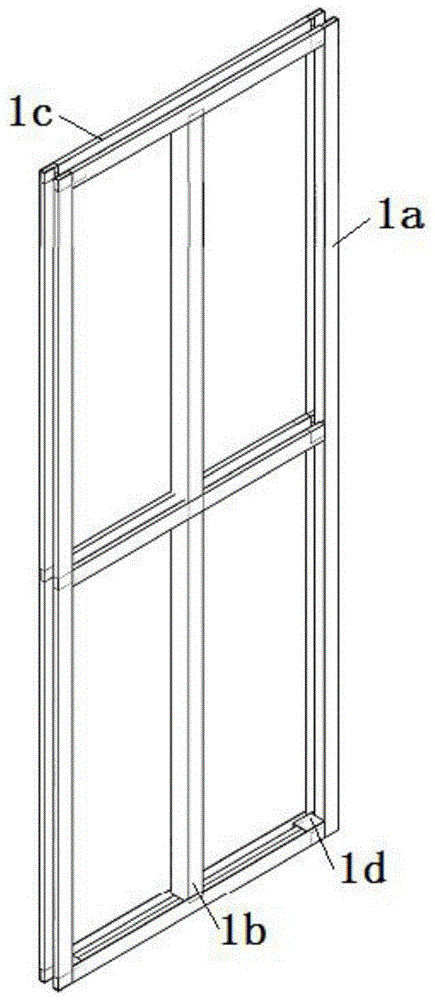

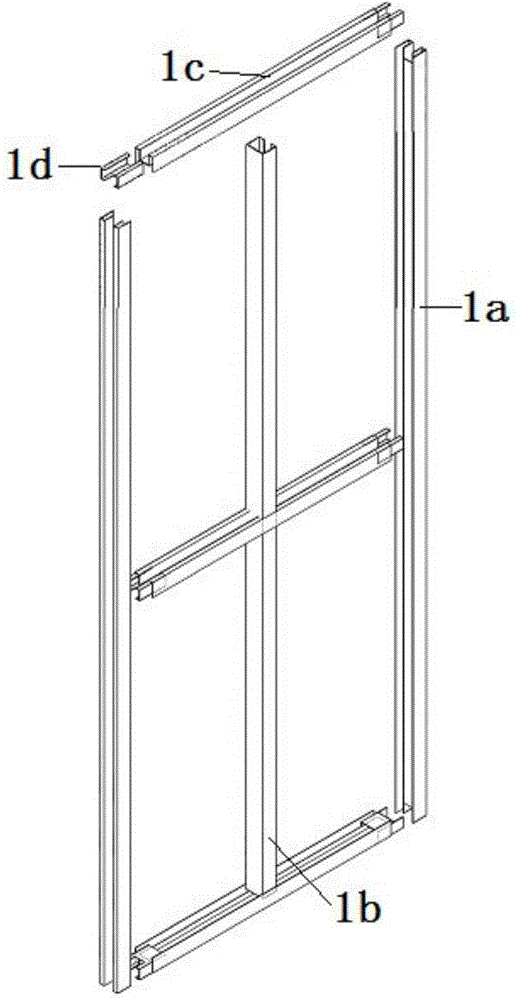

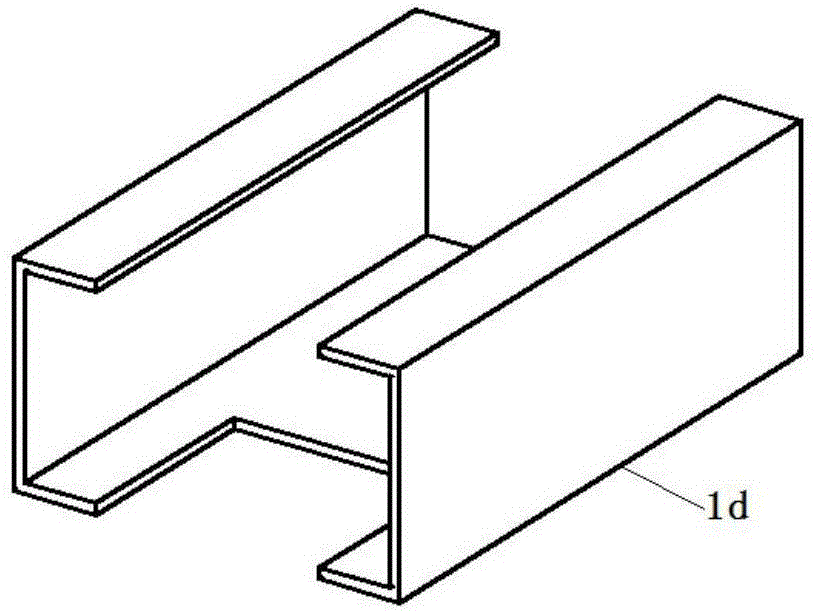

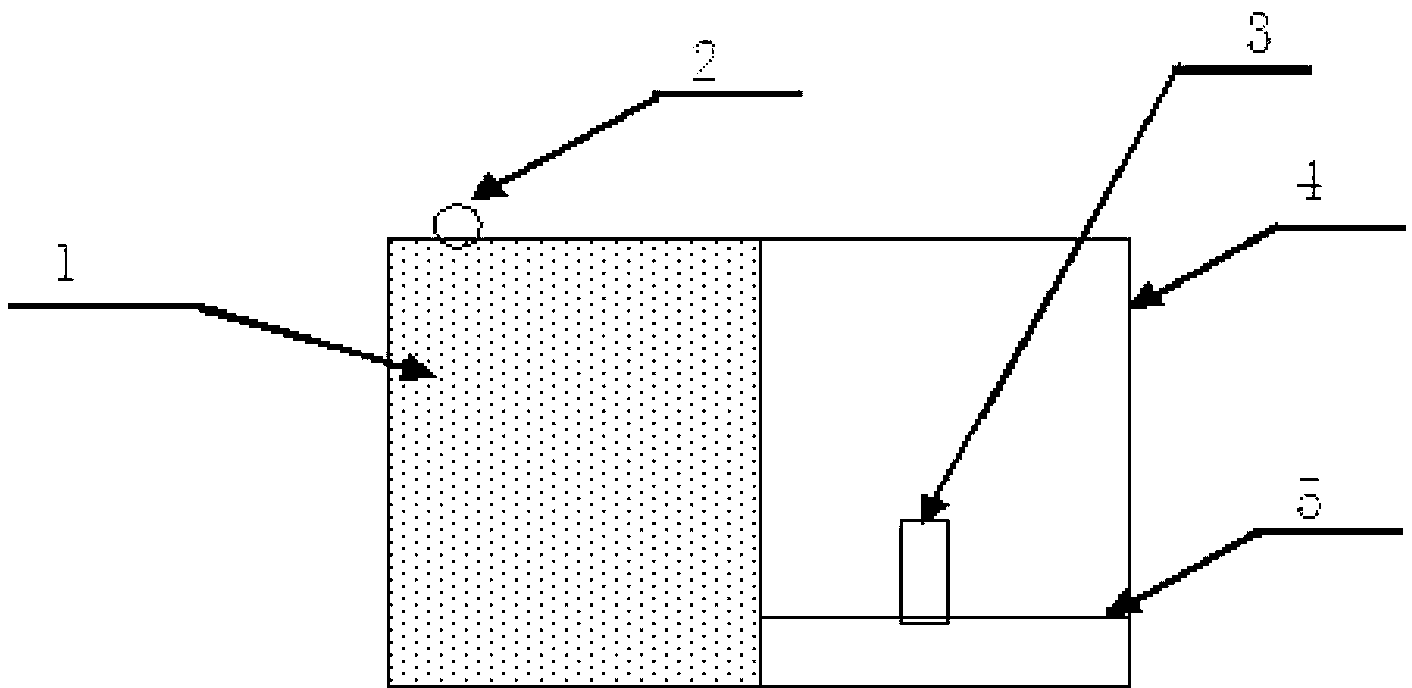

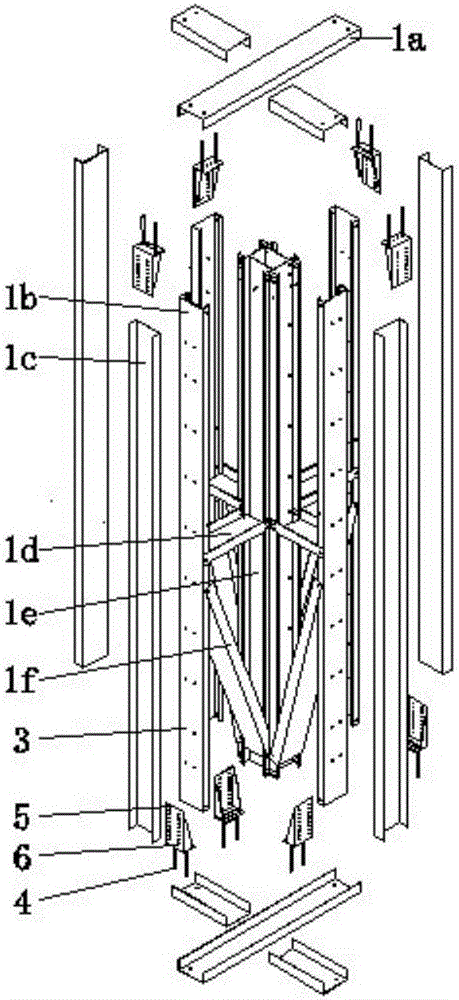

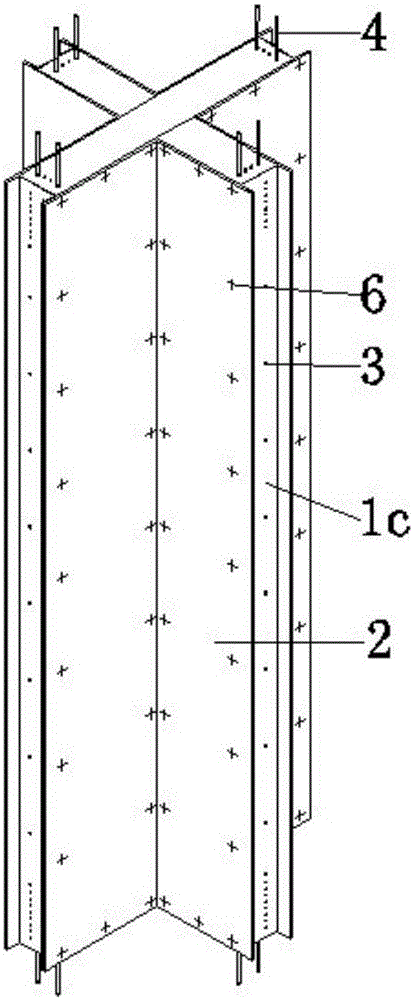

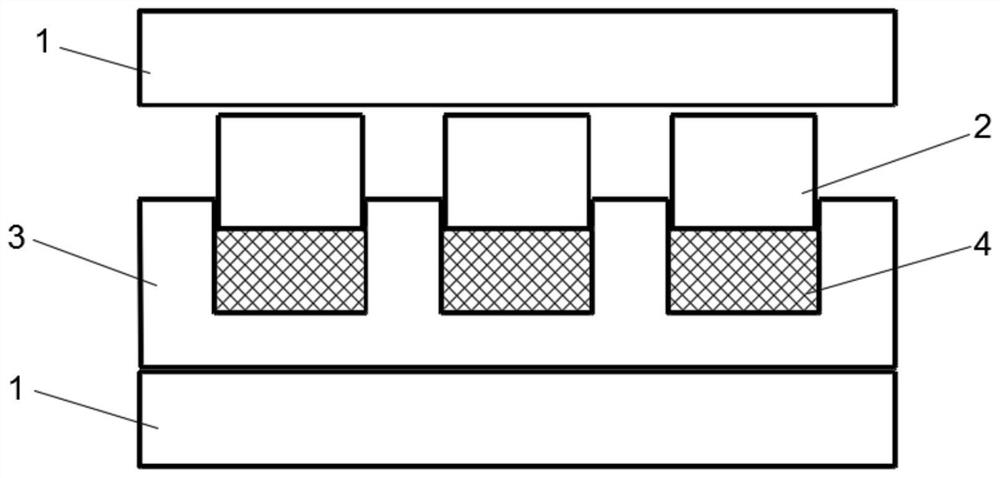

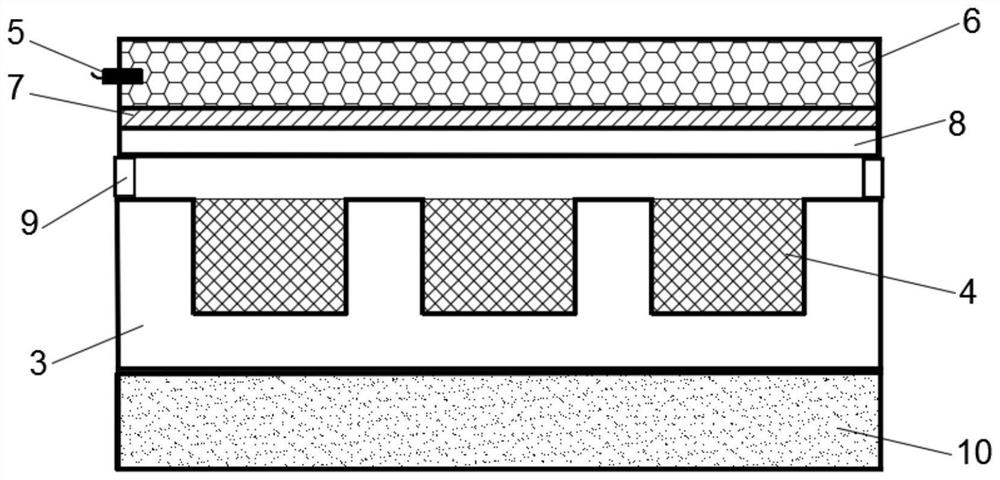

Modular assembly type composite wall and connecting mode thereof

The invention discloses a modular assembly type composite wall and a connecting mode thereof. A foamed cement core material is filled in the middle of a cold-formed thin-wall type steel framework; a self-leveling cement surface layer is bonded with the foamed cement core layer, and the self-leveling cement surface layer and the cold-formed thin-wall type steel framework are connected by a self-tapping bolt; and the cold-formed thin-wall type steel framework, the foamed cement core material and the self-leveling cement surface layer are connected to form the modular assembly type composite wall. Adjacent two modular assembly type composite walls are horizontally connected by a connector among wall modules. The modular assembly type composite wall and floor modules are vertically connected by a connector among the floor modules. The modular assembly type composite wall disclosed by the invention is a wall which is integrated with structural bearing, thermal insulation and decoration, is high in degree of integration and assembly, low in material cost, cheap in overall price and simple in configuration, and greatly saves labor cost.

Owner:BEIJING UNIV OF TECH

Novel cigarette production method applying 3D (3-dimensional) printing technology

The invention relates to the field of cigarette production, in particular to a novel cigarette production method applying a 3D (3-dimensional) printing technology. A novel cigarette comprises a cigarette stick and a filter tip stick, wherein the cigarette stick is formed by bonding tobacco powder ground by tobacco leaves through an adhesive. The production method of the novel cigarette provided by the invention comprises the following steps: producing the cigarette by utilizing the 3D printing technology, increasing the tobacco powder layer by layer in hierarchical processing and superstition solidification forming ways to generate a 3D entity cigarette, spraying the adhesive through a 3D printer according to the shape of each cross section designed in software, carrying out progression layer by layer and finally obtaining the cigarette stick which is formed by overlapping all the cross sections, so that the production precision is effectively ensured. Meanwhile, the treatment process of the tobacco leaves is simplified, the application scope of tobacco raw materials is broadened, the utilization rare of the tobacco raw materials is improved, and the wood gas of cigarette smoke is removed. The 3D printer used in the novel cigarette production method is smaller in size and is more economic, the relevant procedure of computer graphic data can be directly utilized to generate the cigarette, and the cost is saved while the production is convenient.

Owner:HUBEI CHINA TOBACCO IND +1

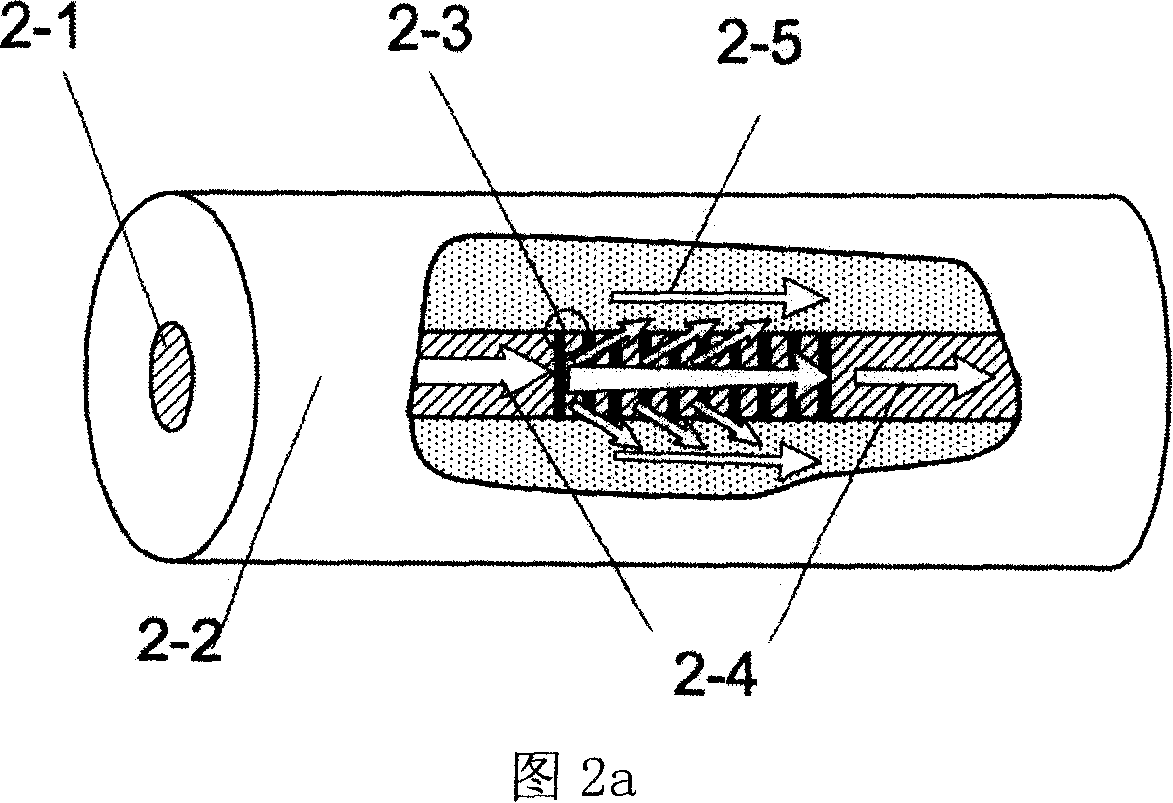

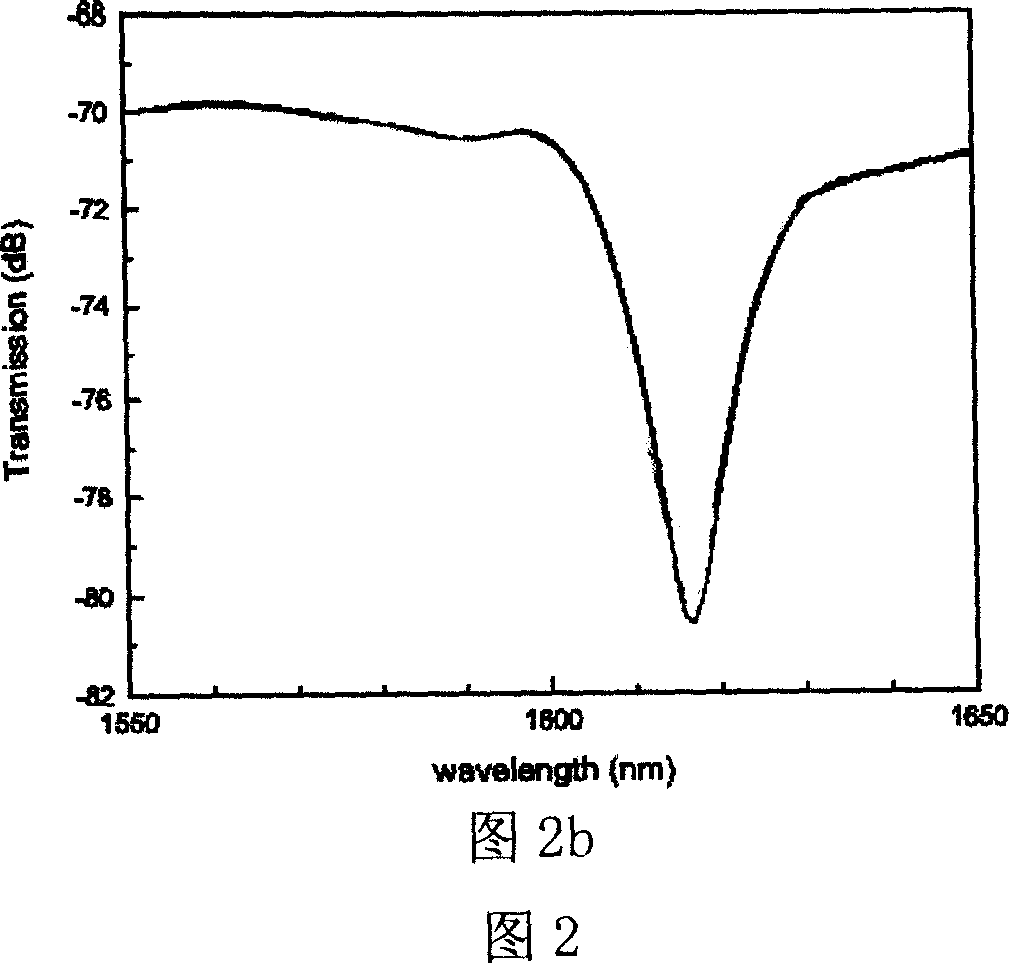

Long-period optical fiber grating band-pass filtering method and band-pass filter for realizing the same method

InactiveCN1975484AImprove performanceApplicable to a wide range of wavelengthsCoupling light guidesGratingLong-period fiber grating

This invention discloses a kind of long-periodic optical fiber grating band filtering method , it adopts two long-periodic optical fiber grating LPFG-I and LPFG-II which mate and connect together, making mandrel absorber in the core place in the back face of LPFG-I; The light is divided into core mode and cladding mode after passing LPFG-I , the core mode is absorbed by mandrel absorber, And the cladding mode pass through the interface of two gratings, be transferred to LPFG-II and coupling reversely to the core mode in its grating area, finally returning to the core mode of LPFG-II, outputting from the back face of LPFG-II. This method has removed the routine core mode in LPFG but has made use of the cladding mode, only the light which according with the phase match conditional can pass trough the grating pair of the long-periodic optical fiber, forming a band filter. This invention keeps merit of the exist LPFG filter that no back reflecting , tuning capability is good , making up its deficiency, changing the 'band stop'type spectrum to 'bandpass' type spectrum , realizing the real long-periodic optical fiber grating band filter.

Owner:CHONGQING UNIV

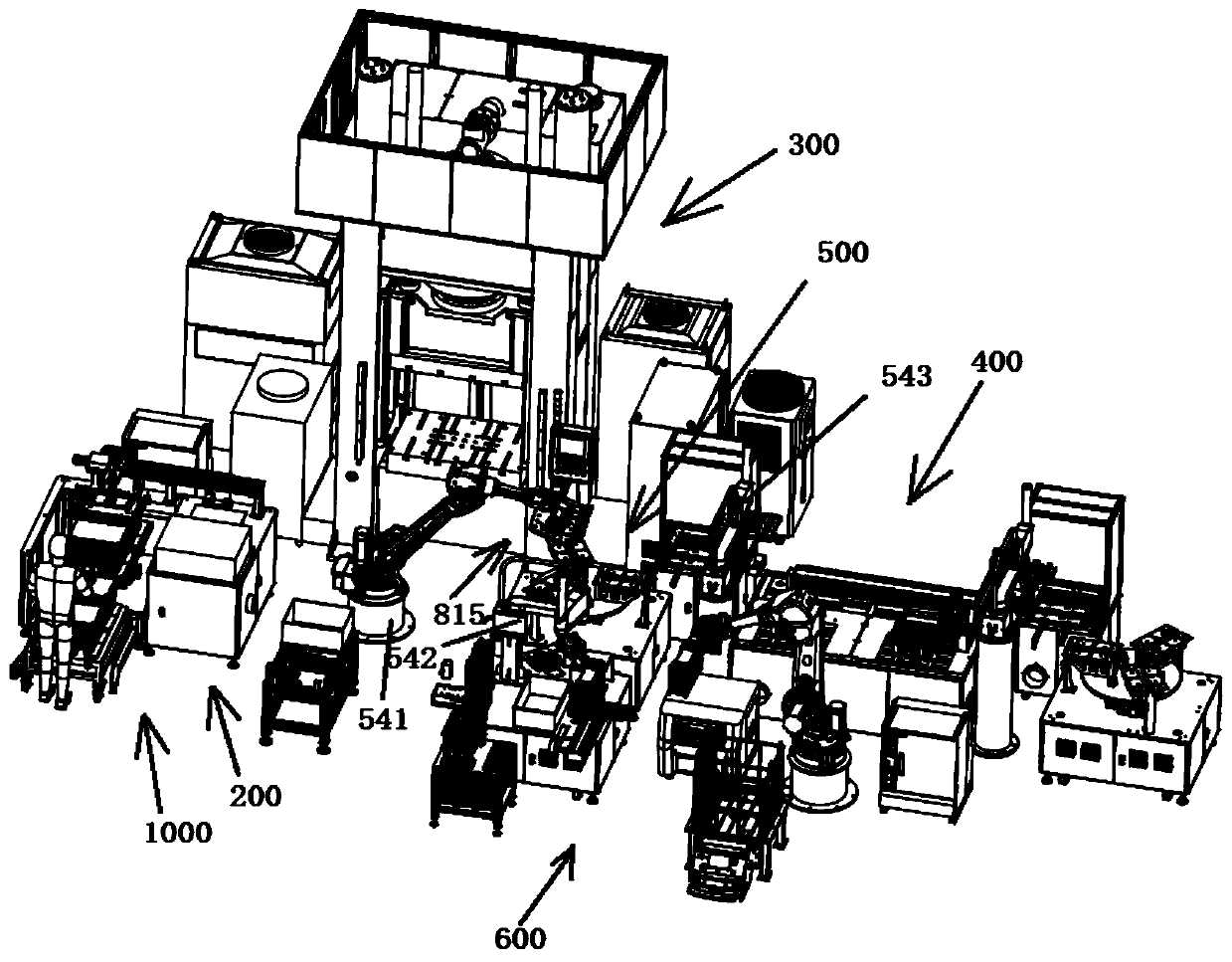

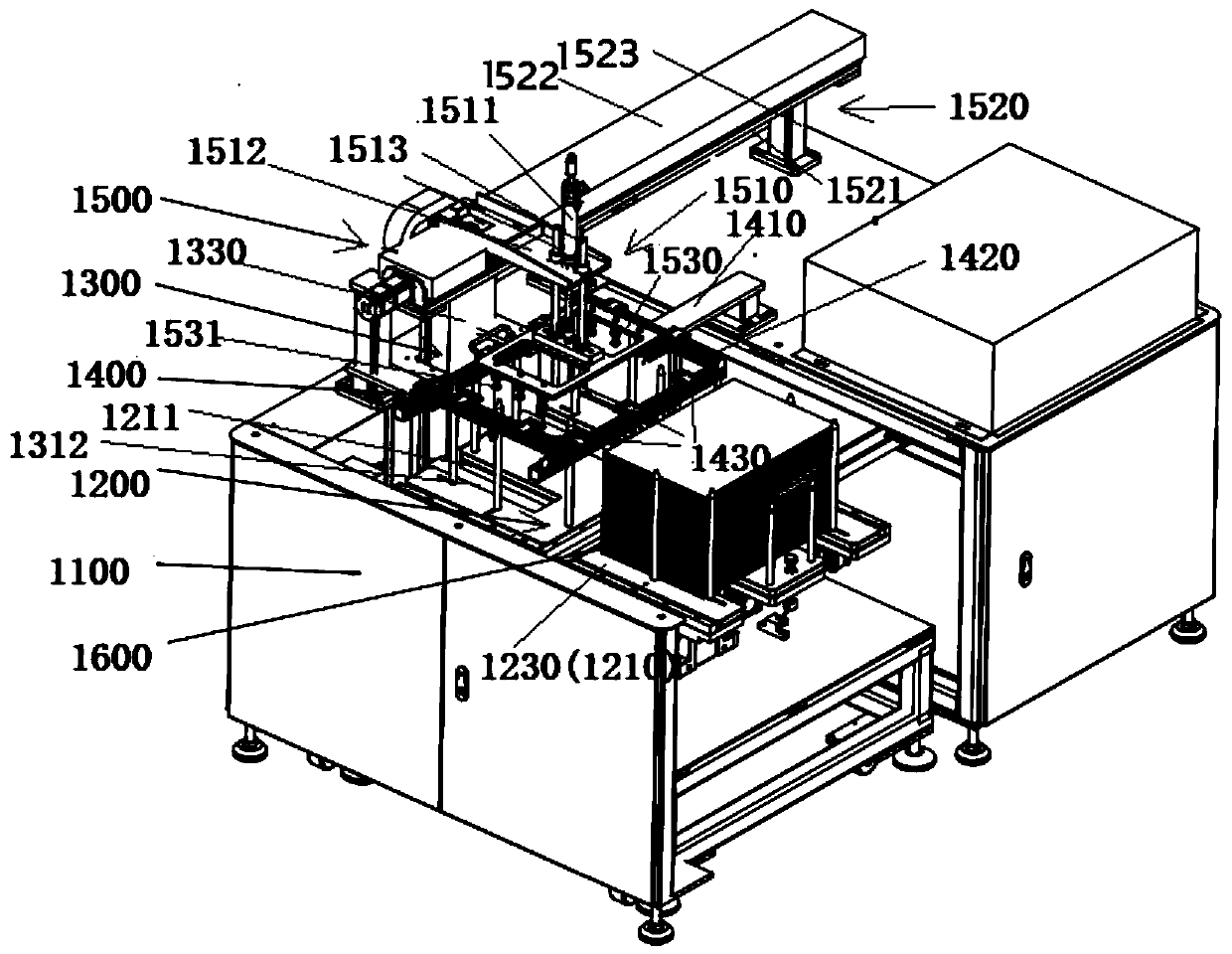

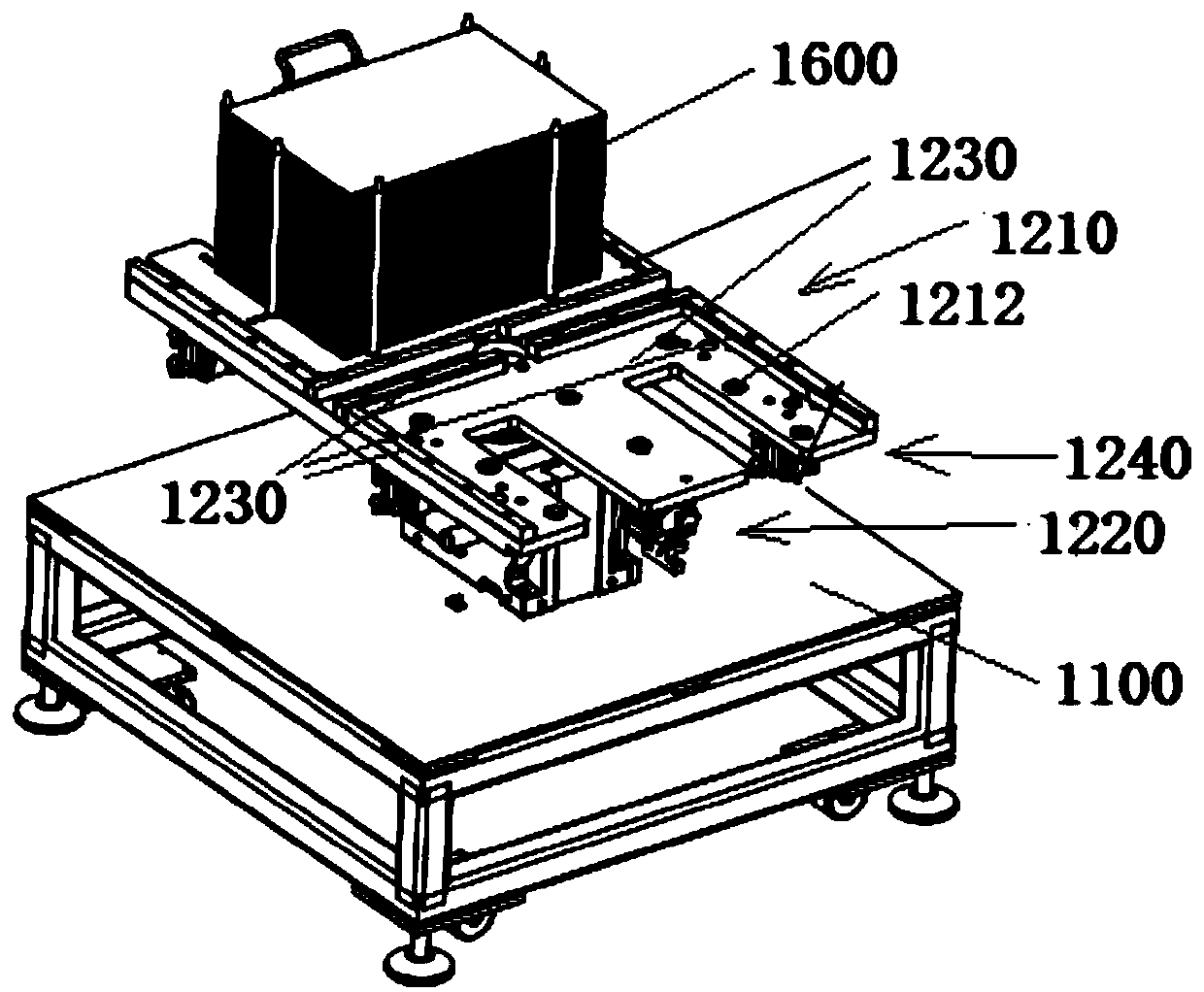

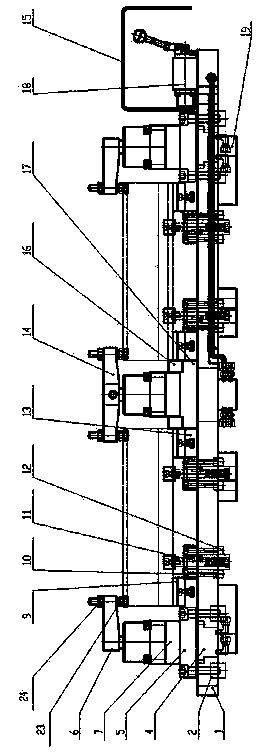

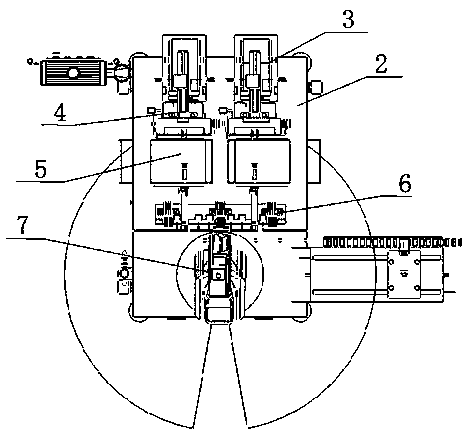

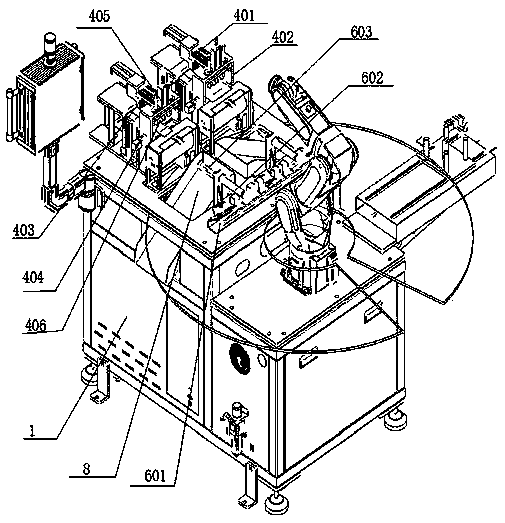

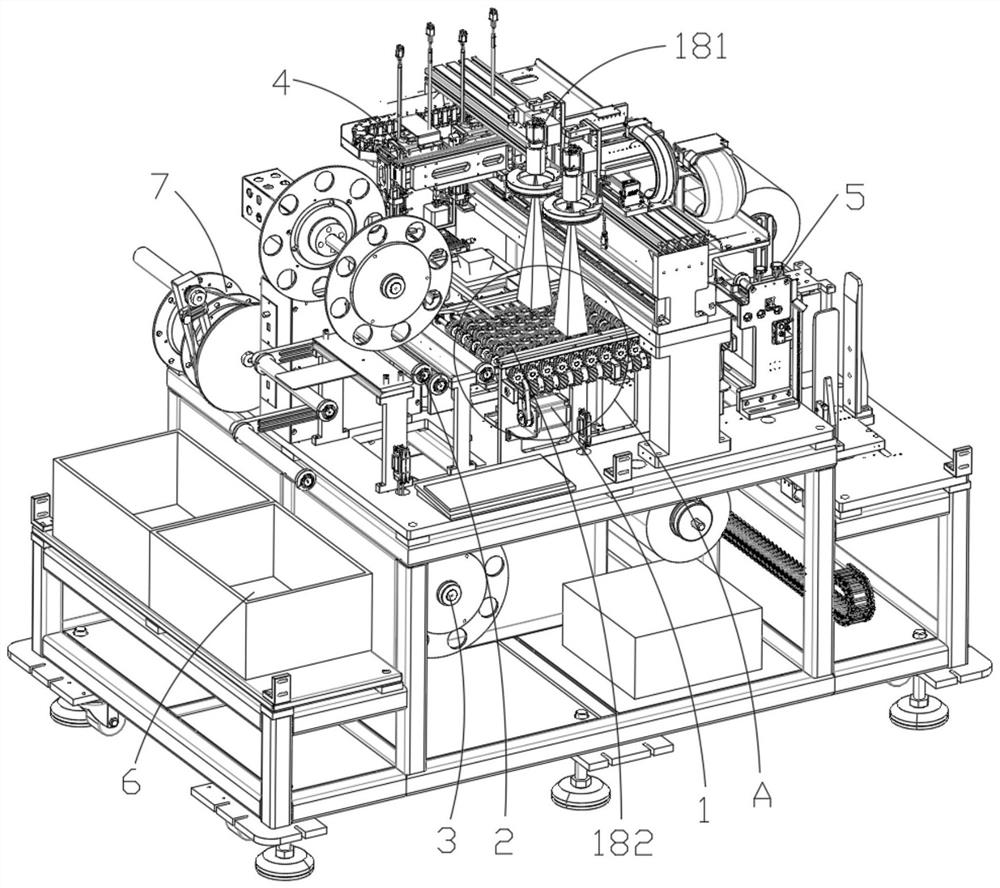

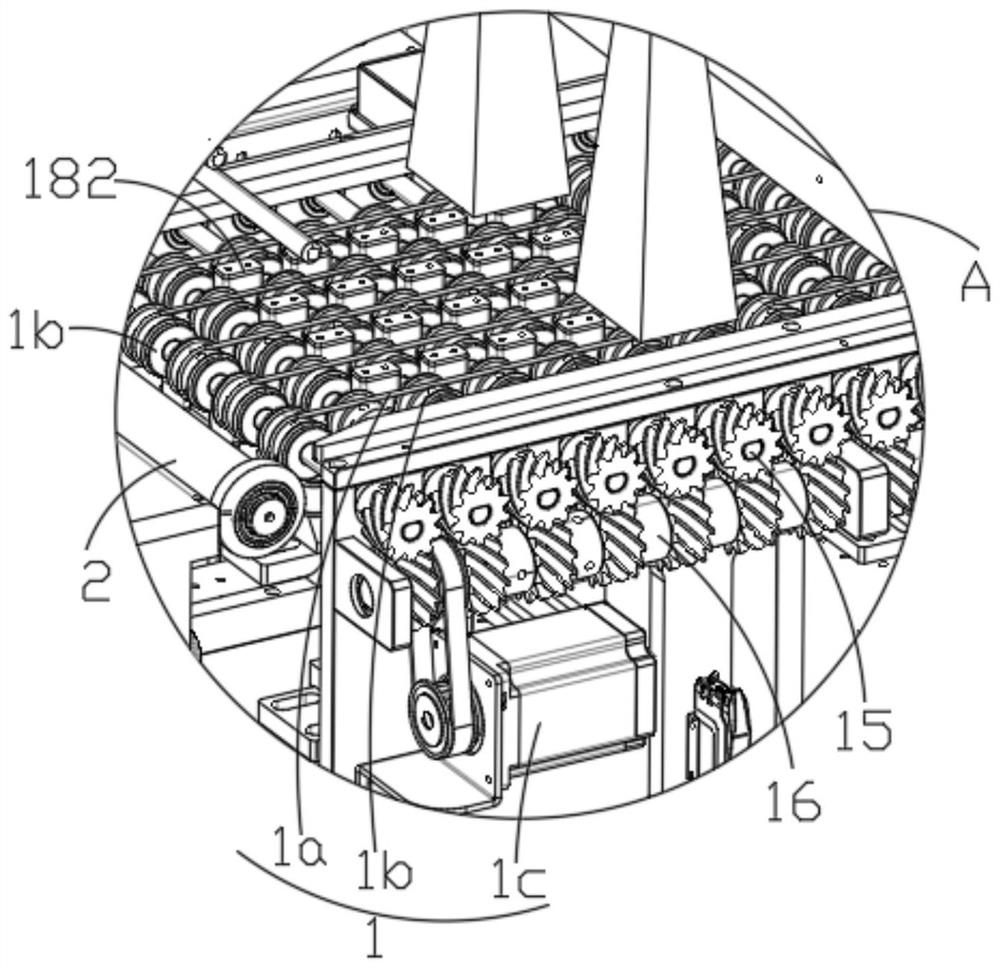

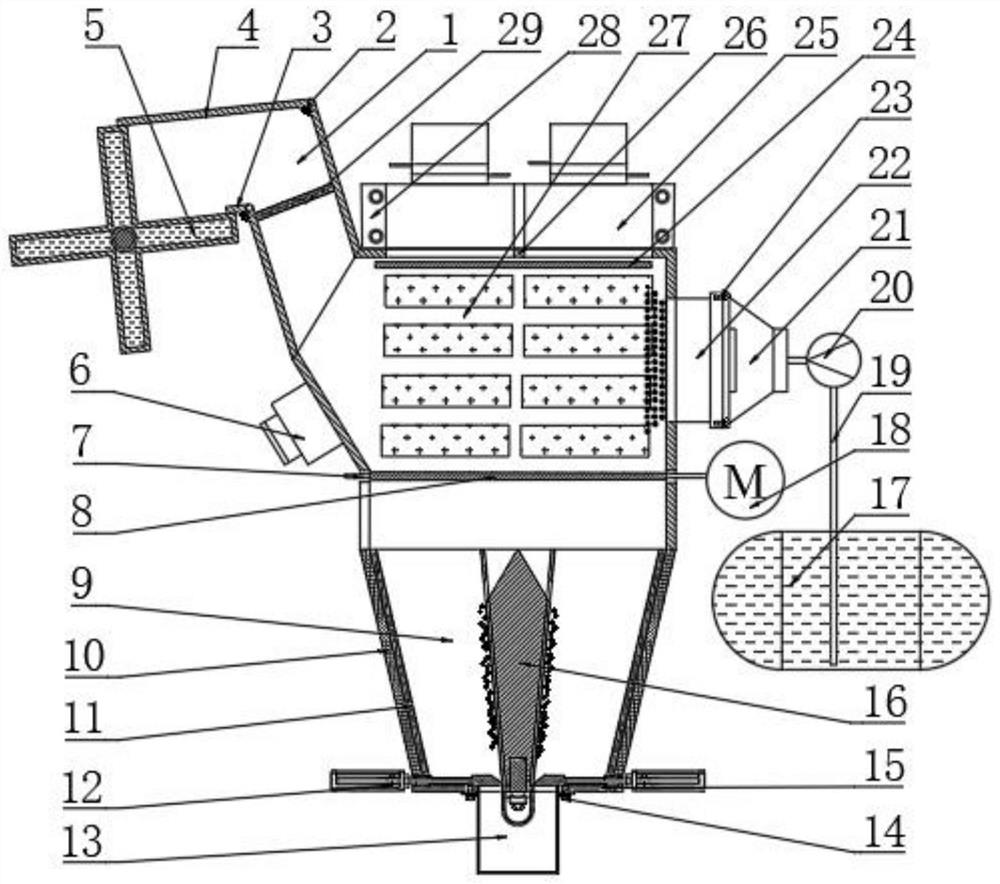

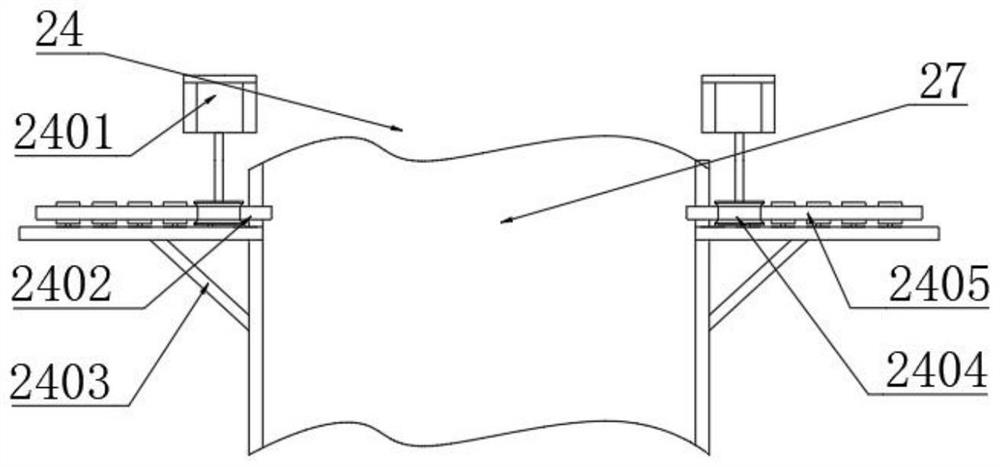

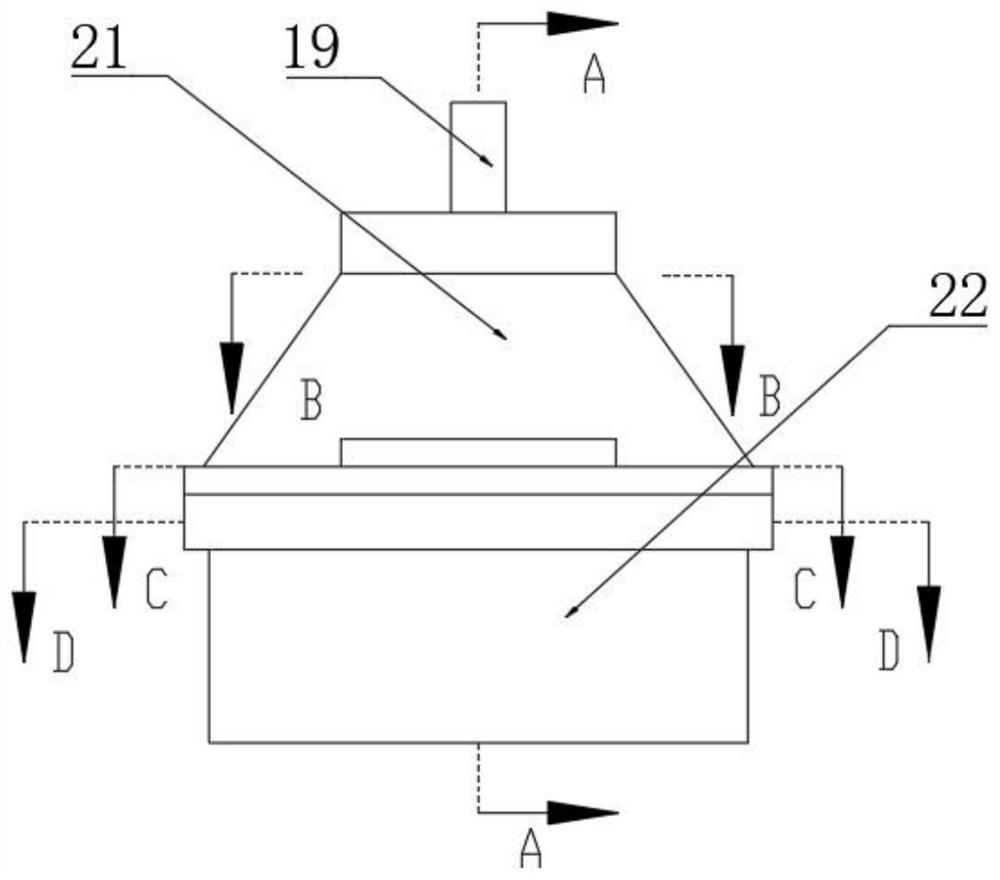

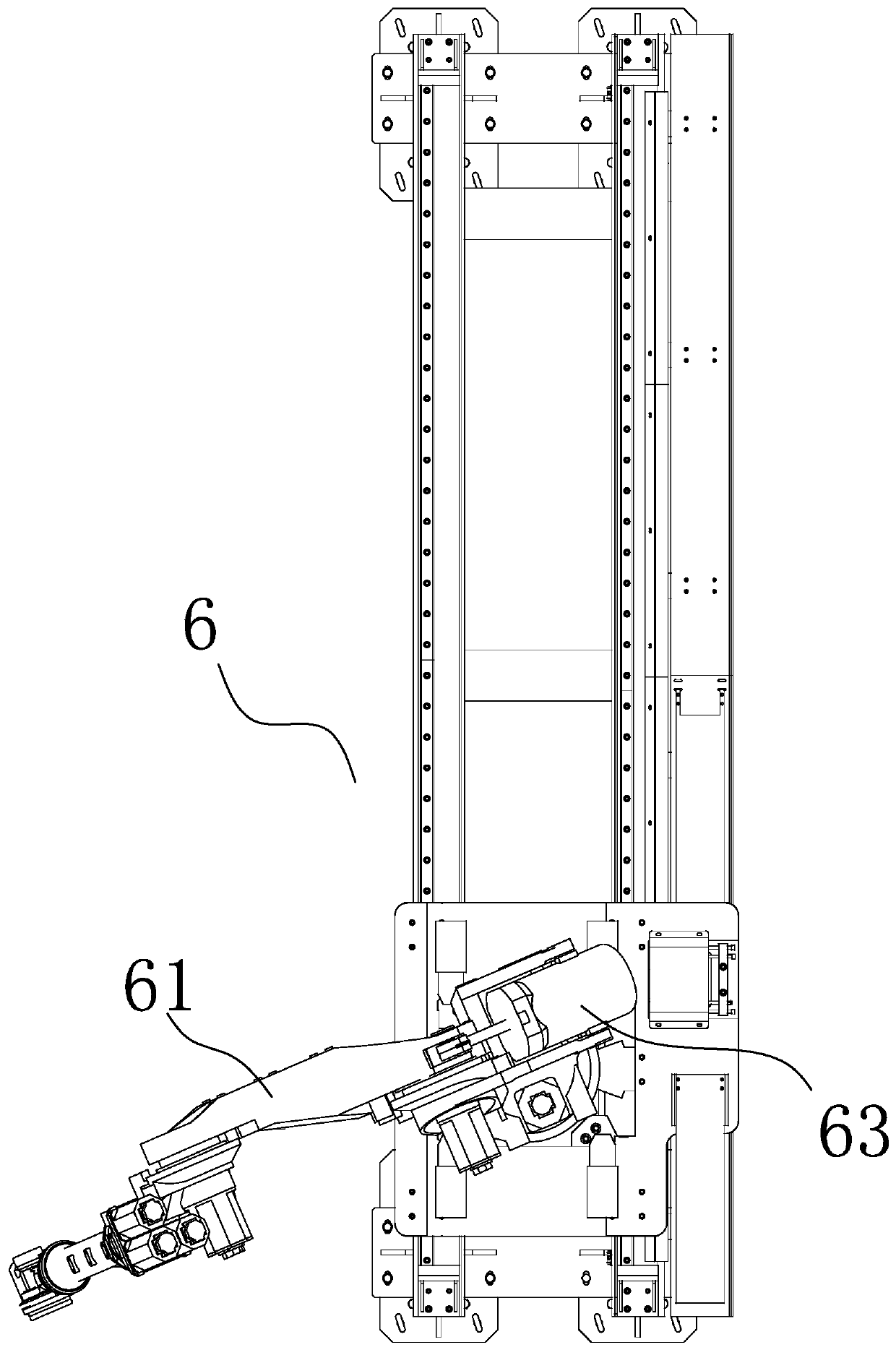

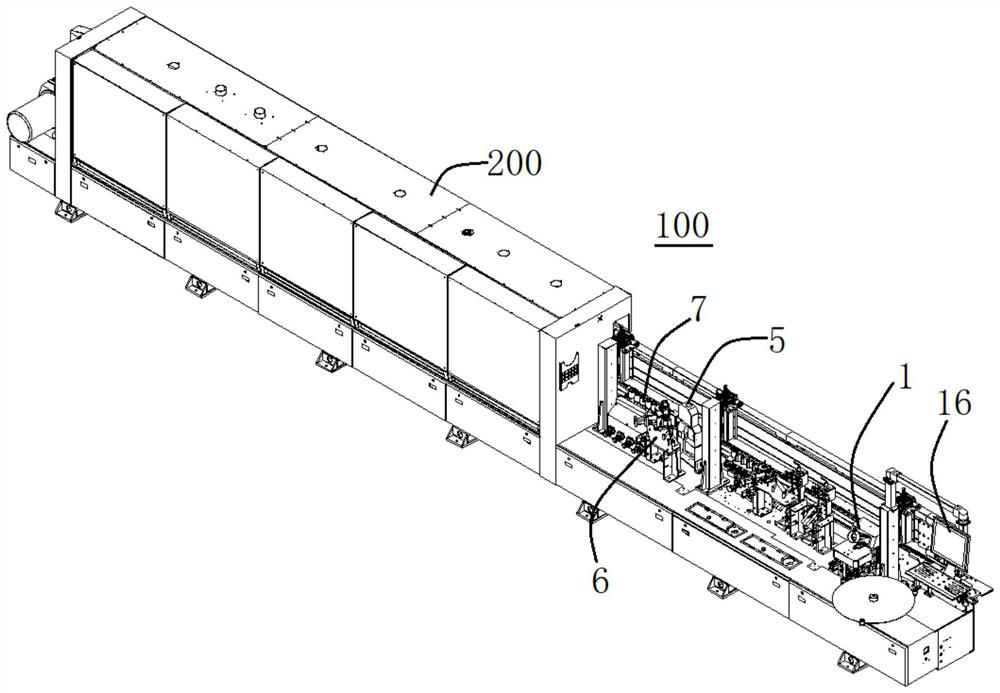

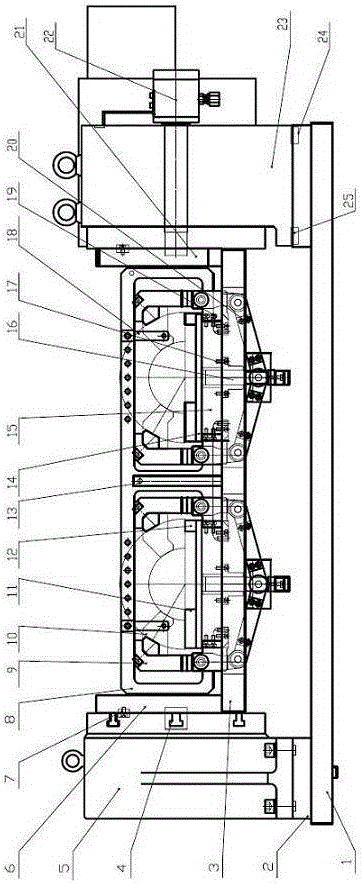

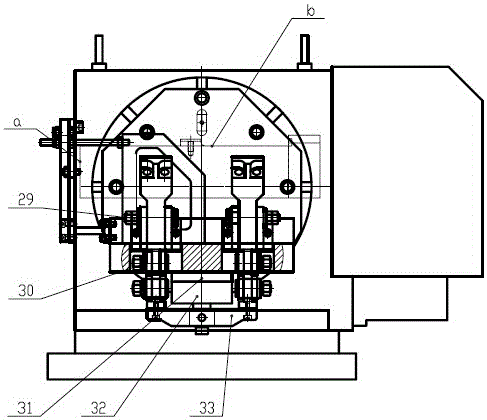

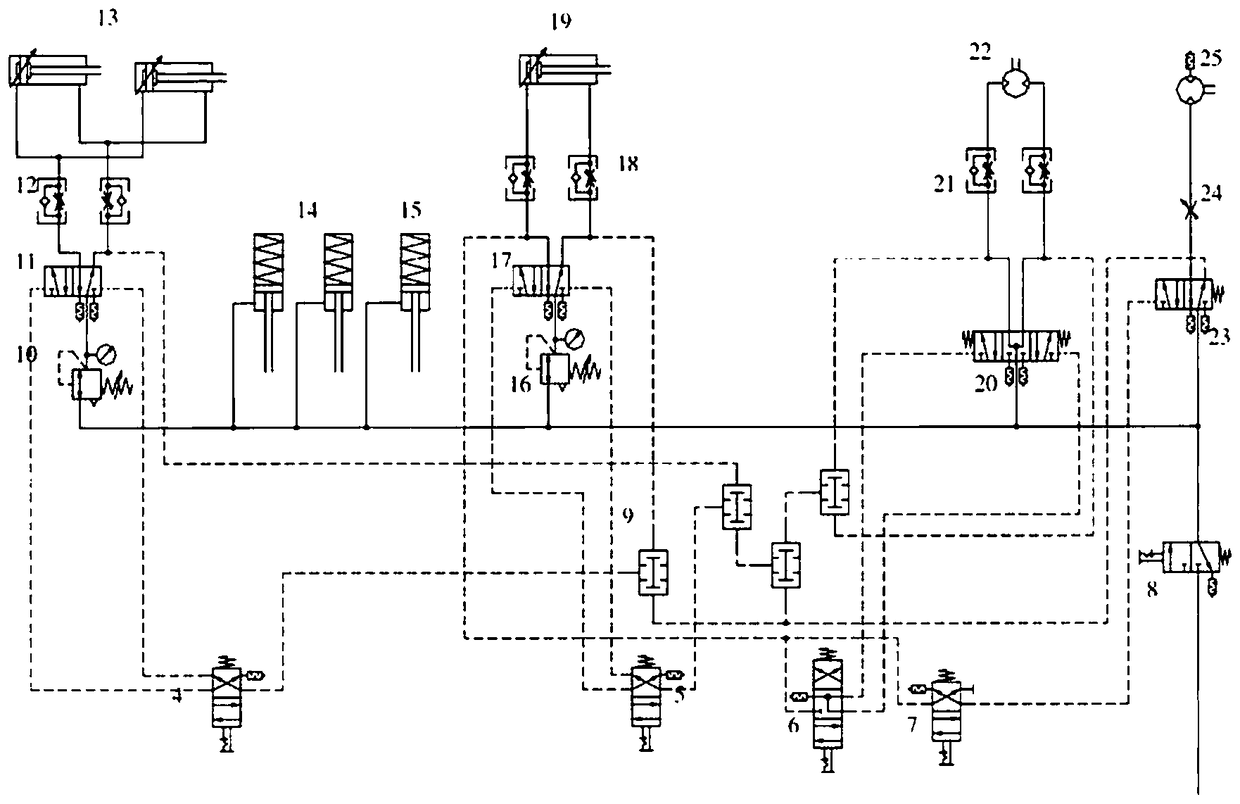

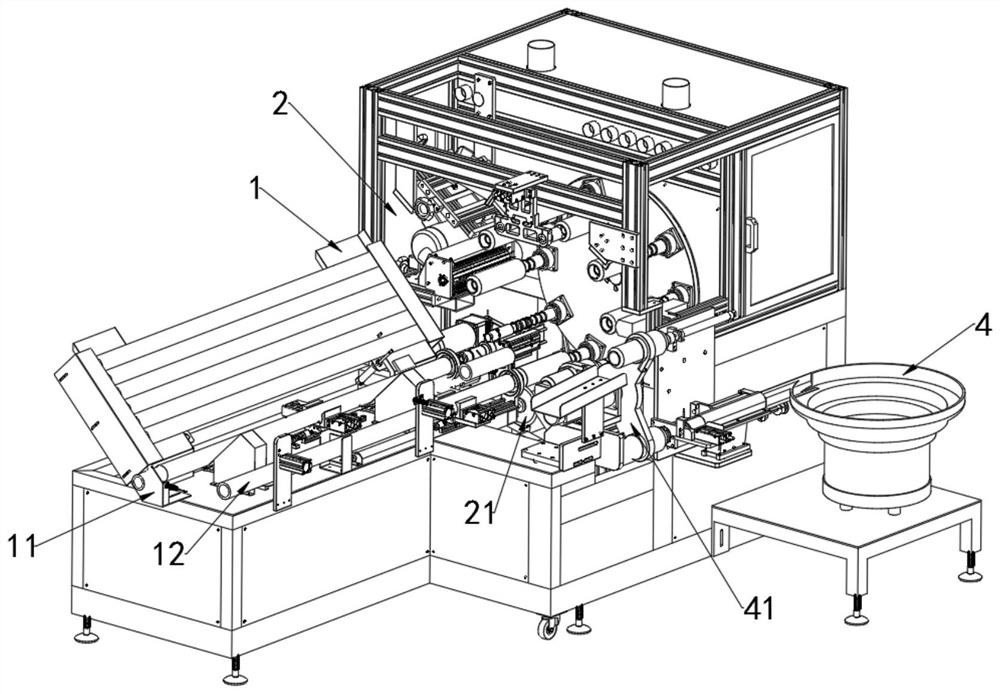

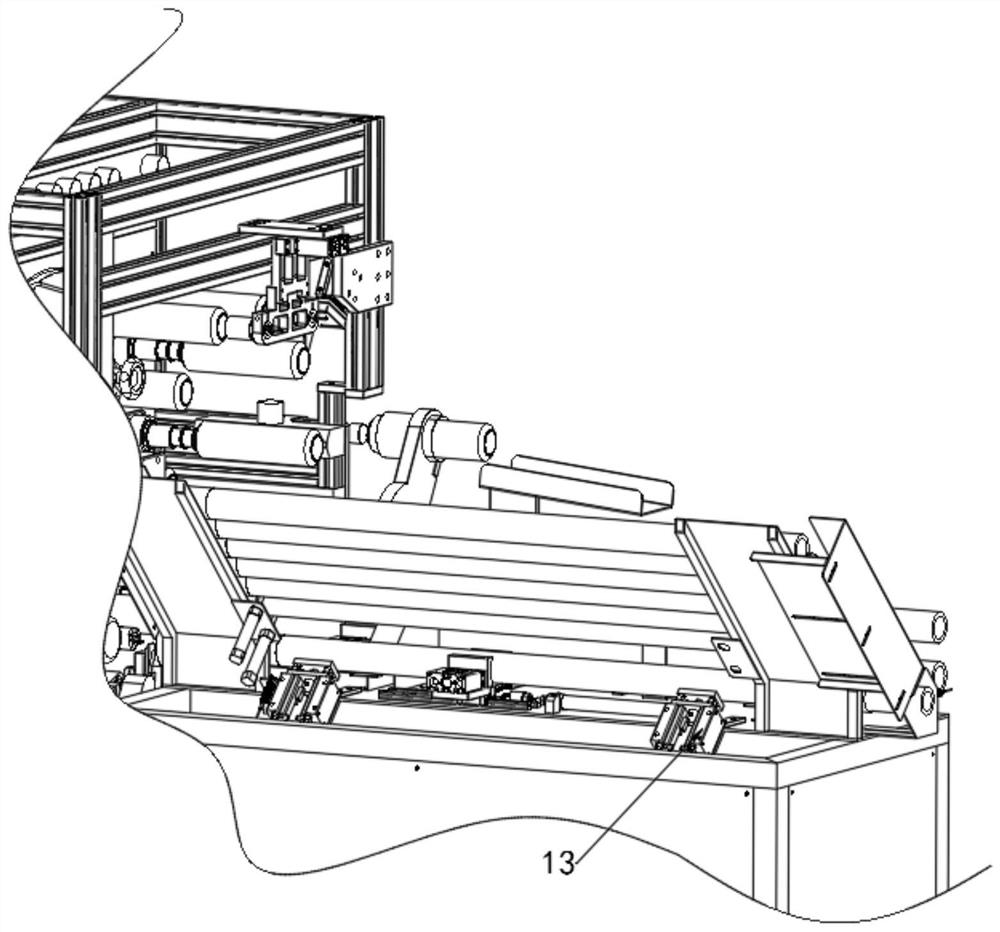

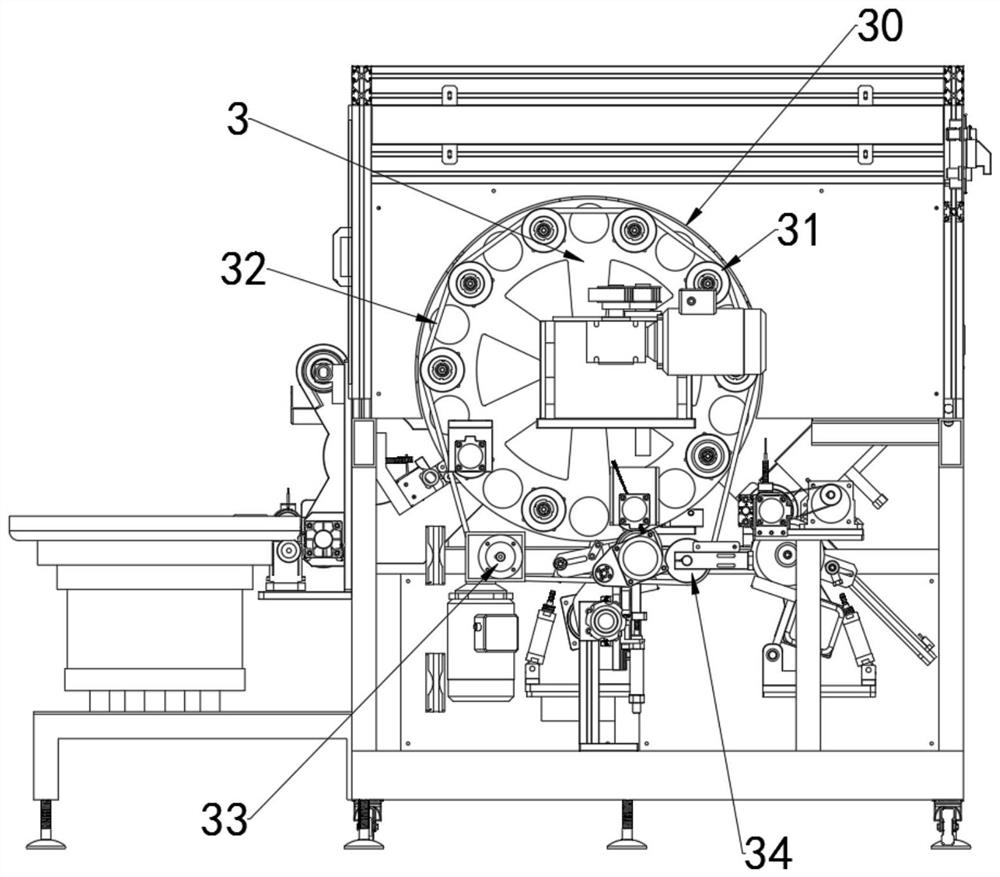

Graphite bipolar plate compression moulding forming system

ActiveCN110696416AGuaranteed production accuracyReduce manufacturing costDirt cleaningPackagingMonoboardGraphite

The invention discloses a graphite bipolar plate compression moulding forming system. The graphite bipolar plate compression moulding forming system comprises a loading device, a sweeping device, a mould pressing device, a deburring device, a conveying device, an automatic cage loading device and an electric control system. The loading device is used for loading a graphite plate to the sweeping device, the sweeping device is used for sweeping impurities on the surface of the graphite plate, the mould pressing device is used for carrying out mould pressing on the cleaned graphite plate to forma bipolar plate single board, the deburring device is used for cutting burrs on the periphery of the bipolar plate single board, the conveying device is used for transferring a graphite plate to the mould pressing device from the sweeping device, after mould pressing is finished, wastes are transferred to the recycling position, the finished bipolar plate single board is transferred to the deburring device, after the deburring procedure is finished, the bipolar plate single board is transferred to the automatic cage loading device, the automatic cage loading device transfers the bipolar platesingle board to other stations, and the electric control system is electrically connected with the loading device, the sweeping device, the mould pressing device, the deburring device, the conveying device and the automatic cage loading device and used for controlling the devices. The system effectively ensures production precision in the bipolar plate mould pressing forming process, the product yield is improved, and the bipolar plate production cost is reduced.

Owner:魔方氢能源科技(江苏)有限公司

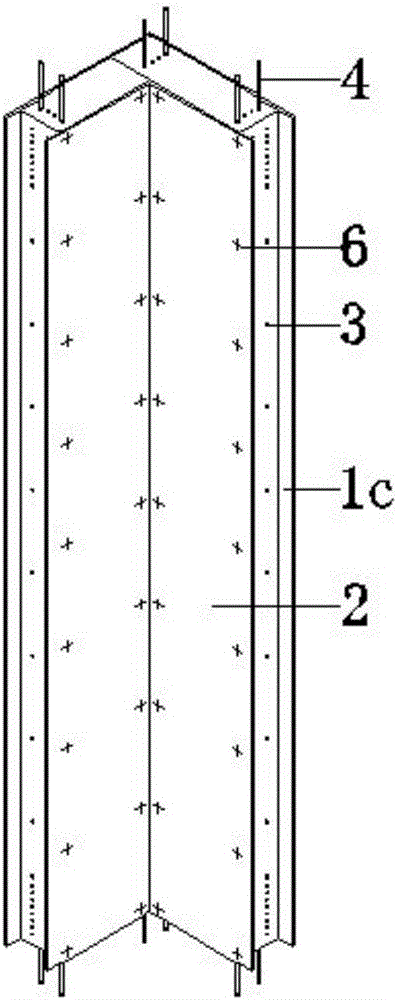

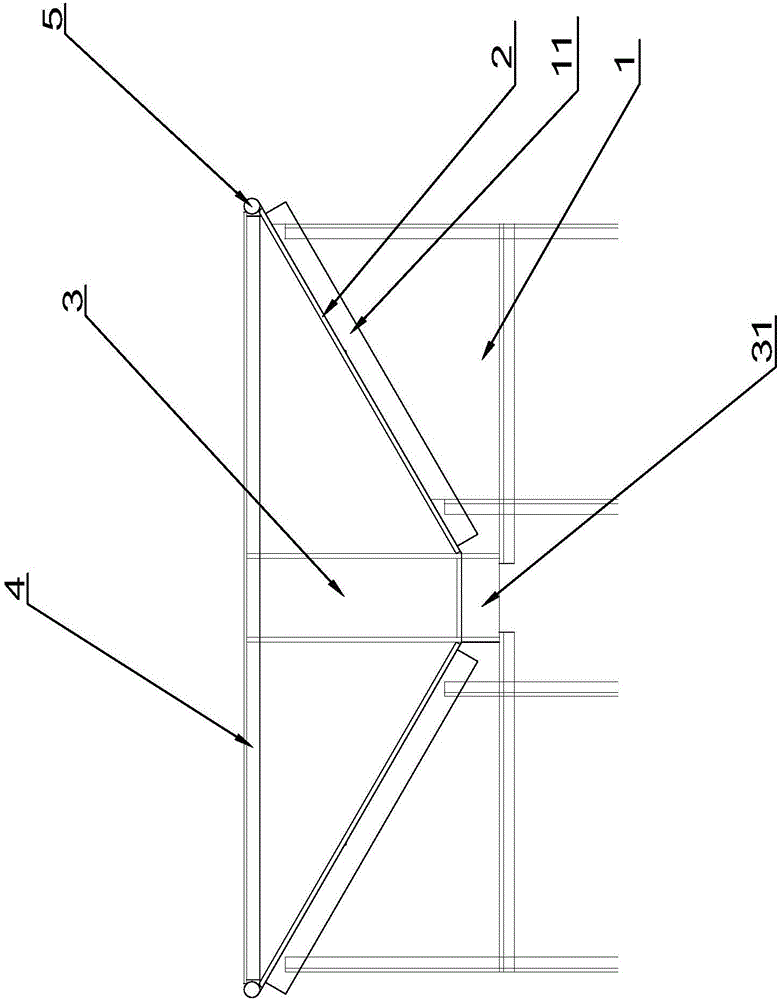

Modular assembly type L-shaped cold-formed thin-walled steel combined wall and connecting mode thereof

The invention discloses a modular assembly type L-shaped cold-formed thin-walled steel combined wall and a connecting mode of the modular assembly type L-shaped cold-formed thin-walled steel combined wall. The modular assembly type L-shaped cold-formed thin-walled steel combined wall is characterized in that the middle part of an L-shaped cold-formed thin-walled steel framework is filled with a heat preservation layer; a wall panel and the L-shaped cold-formed thin-walled steel framework are connected through self-tapping screws; the modular assembly type L-shaped cold-formed thin-walled steel combined wall is formed by the L-shaped cold-formed thin-walled steel framework, the heat preservation layer and the wall panel. Horizontal-direction connection between an L-shaped cold-formed thin-walled steel combined wall module and a common wall module is realized through a horizontal connecting mode between wall modules; vertical-direction connection between two adjacent L-shaped cold-formed thin-walled steel combined wall modules which are adjacent in the vertical direction is realized through a vertical connecting mode between the wall modules. The modular assembly type L-shaped cold-formed thin-walled steel combined wall disclosed by the invention integrates structural bearing and heat preservation, and has the advantages of high integration and assembly degrees, applicability in industrial production and the like, and the problems of weak connection between a longitudinal wall and a horizontal wall, high difficulty and difficulty in handling installation seams, and the like can be solved. The connecting mode of the modular assembly type L-shaped cold-formed thin-walled steel combined wall is simple in structure and is quick and efficient, and a large amount of labor cost can be reduced.

Owner:BEIJING UNIV OF TECH

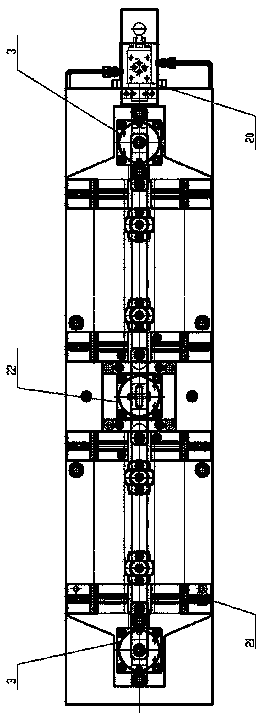

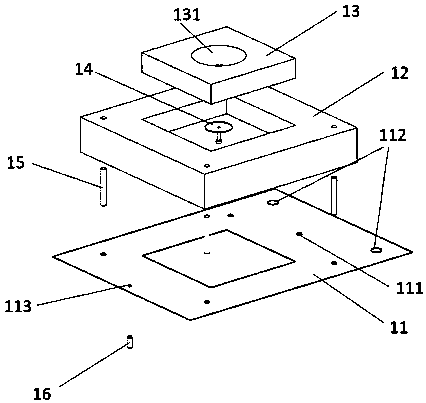

Two-sided milling fixture for blank forming molds

InactiveCN103817552ASimple and fast operationEasy to adjustWork clamping meansPositioning apparatusEngineeringWork time

The invention discloses a two-sided milling fixture for blank forming molds. The two-sided milling fixture comprises a base, movable support clamping mechanisms, a movable centering mechanism and a middle fixed support clamping mechanism. The middle fixed support clamping mechanism is mounted in the middle of the base, the movable support clamping mechanisms are mounted at two ends of the base, and the movable centering mechanism is mounted between a fixed mechanism and a movable mechanism on the base. The two-sided milling fixture for the blank forming molds has the advantages that operation in processing parts is facilitated, adjustment during mold changing is facilitated, work time is saved, positioning precision is high, production precision is guaranteed, and process yield is increased. Since the two-sided milling fixture is a double-station fixture capable of processing two parts each time and the two parts share the same middle positioning and clamping device, cost is saved while processing efficiency is improved.

Owner:WUXI RUIZHEN PRECISION MACHINERY

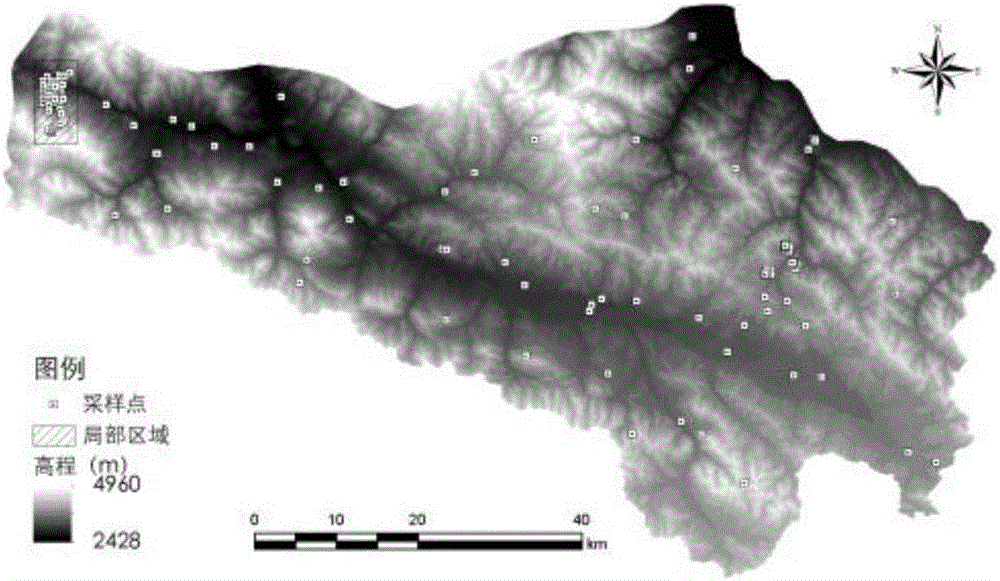

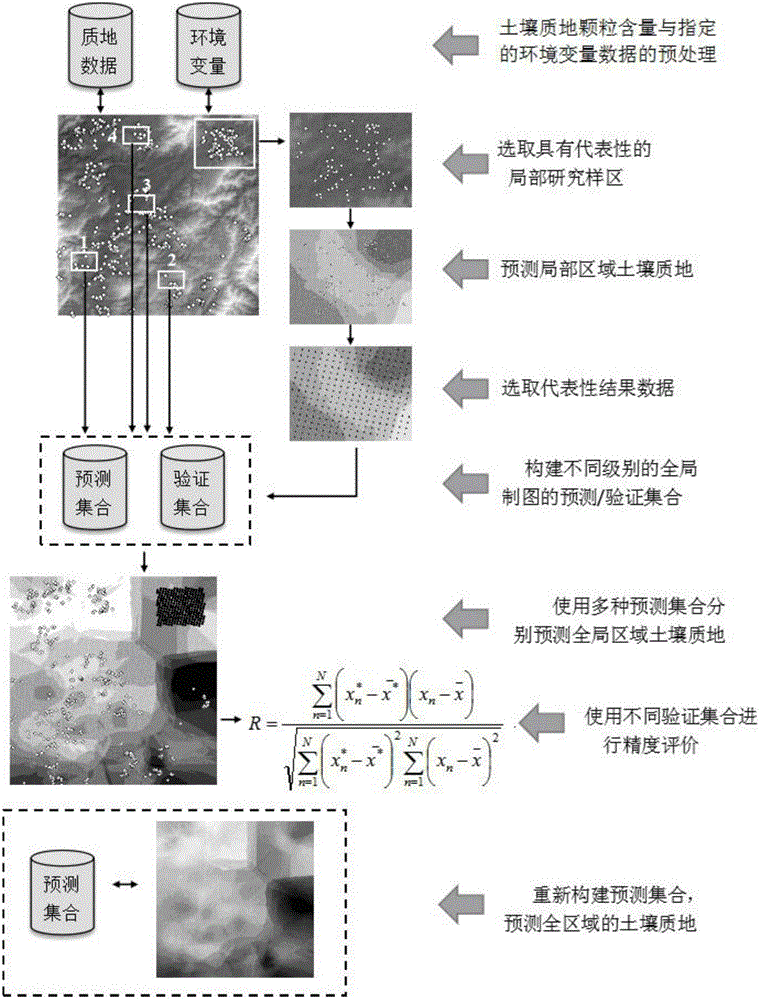

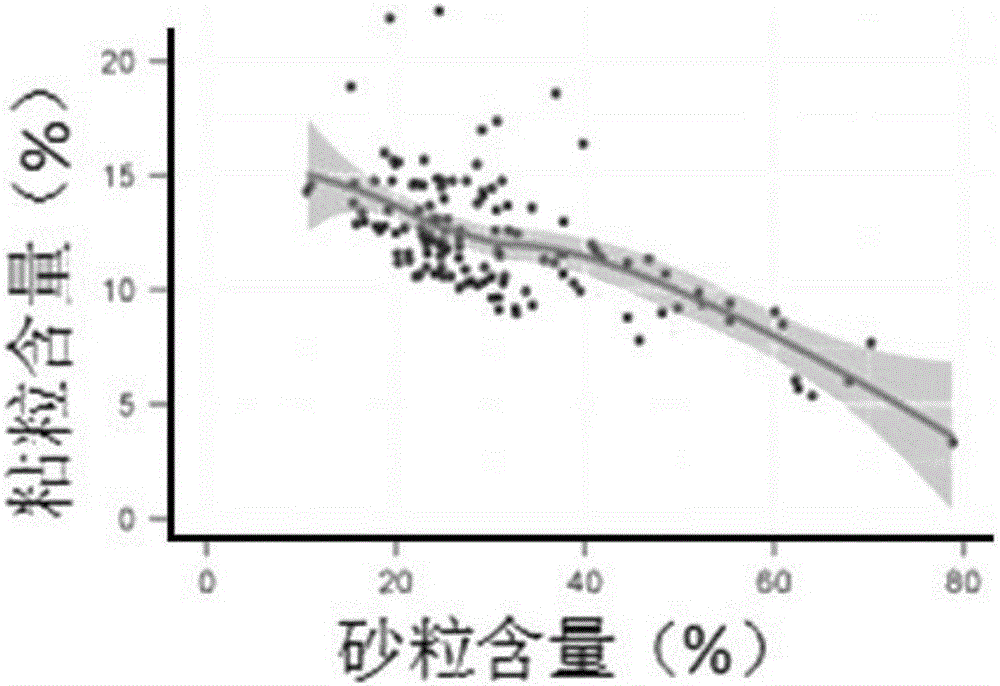

Soil texture particle content predicting method

ActiveCN105891442AImprove product qualityResolve uncertaintyEarth material testingPrediction methodsUncertainty analysis

The invention relates to a soil texture particle content predicting method, and provides a complete soil property predicting technical scheme based on extrapolation technology. The optimal prediction data set is selected through the combination of the local soil-landscape model extrapolation technology and the cross validation mechanism, the universal digital soil cartography technical scheme that an extrapolation frame is universal for different research sample regions, the optimal extrapolation area is determined according to different data properties and uncertainty is analyzed by evaluating a local model is achieved through the extrapolation soil expert knowledge and quantitative evaluation prediction precision technology, and the method has wide industrial application prospects.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

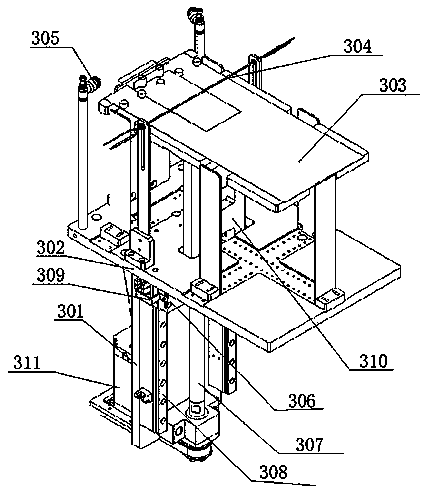

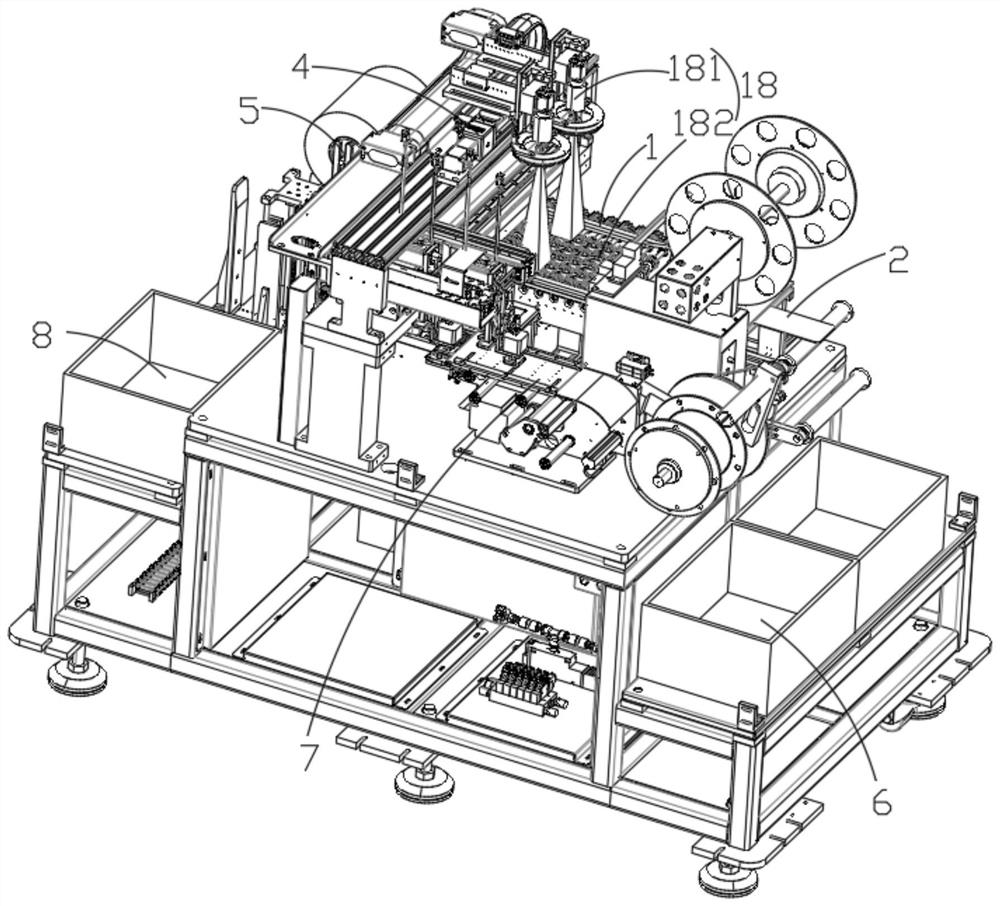

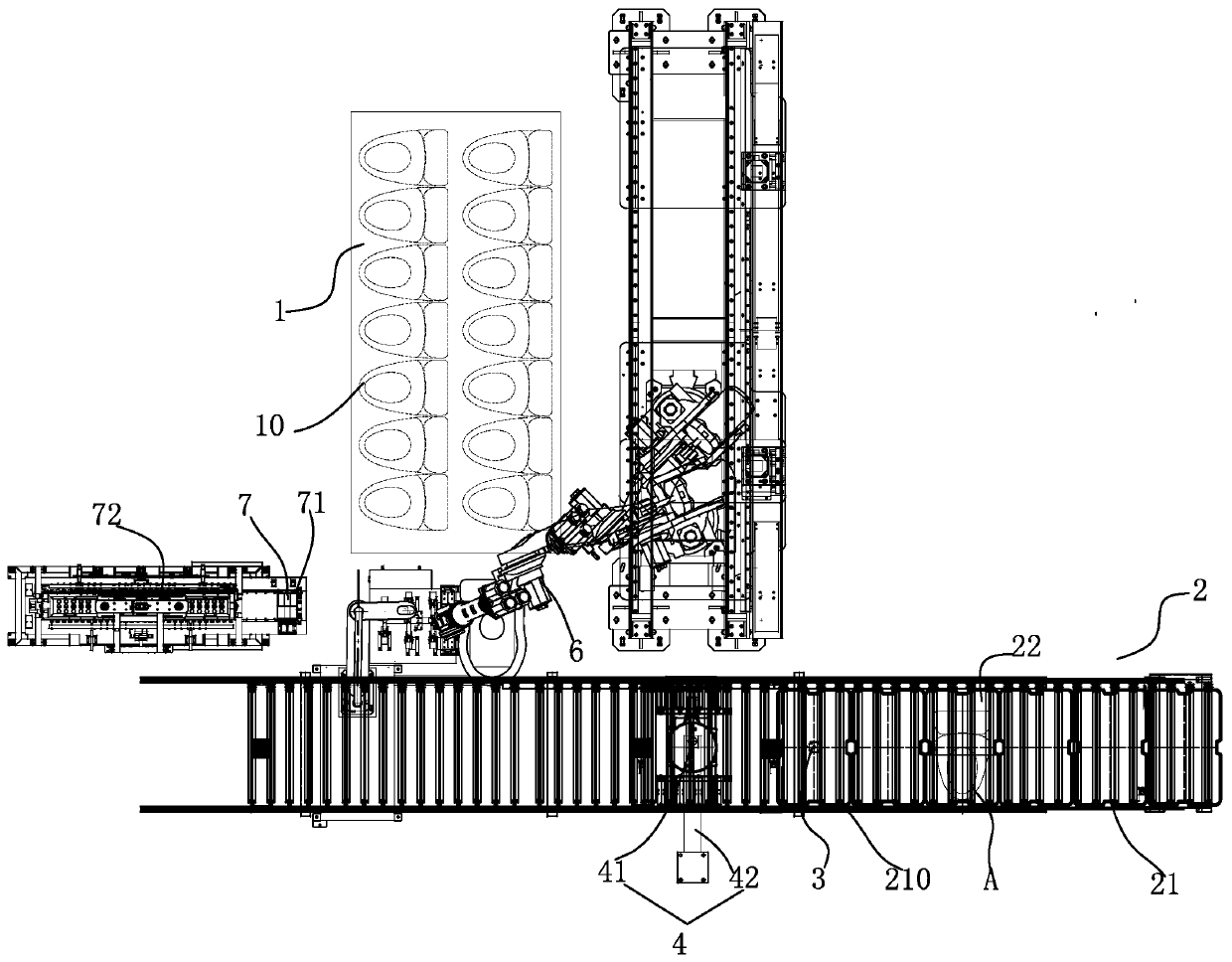

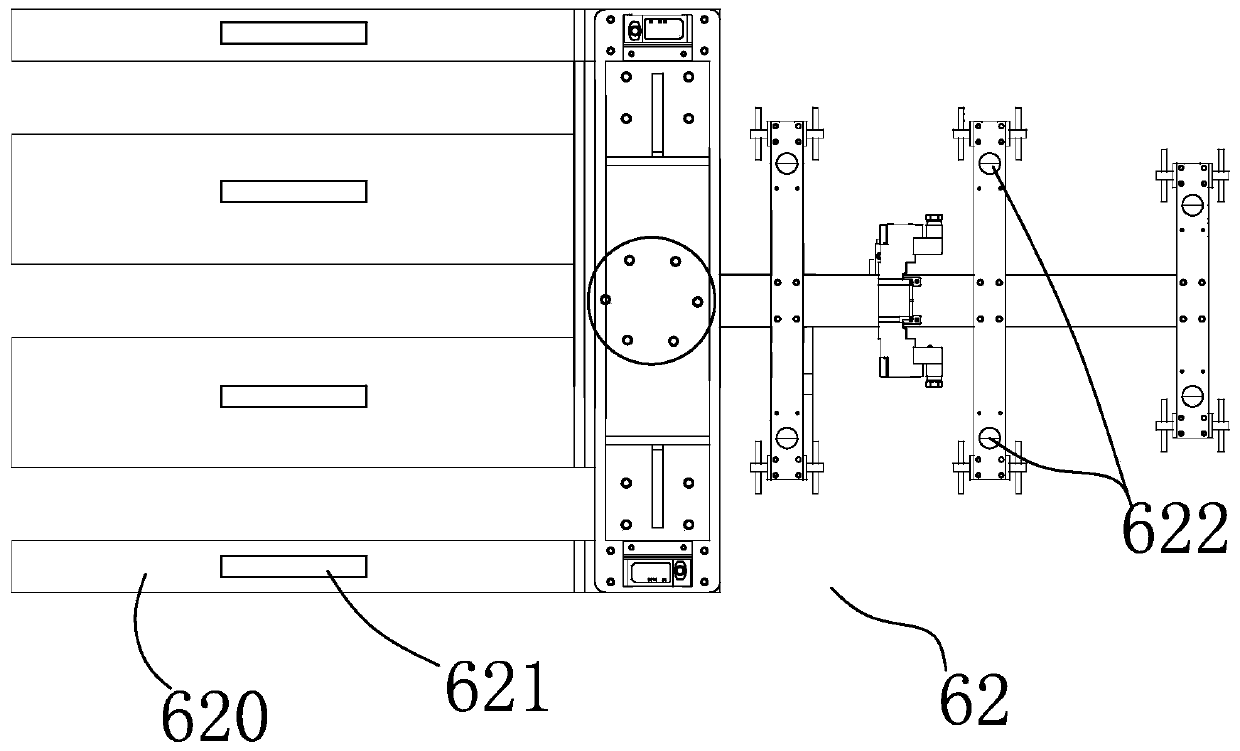

Sheet feeding machine

PendingCN110422657AGuaranteed accuracyHigh degree of automationLamination ancillary operationsLaminationEngineeringAutomation

The invention discloses a sheet feeding machine. The sheet feeding machine comprises a base, feeding units and a six-axis robot, and is characterized in that the base is provided with at least two sets of feeding units; the base is provided with a mounting plate; the feeding units are mounted on the mounting plate; each feeding unit comprises a supporting mechanism, a conveying mechanism, a peeling mechanism and a waste disposal mechanism; and the six-axis robot is matched with the peeling mechanism. Through cooperation between the supporting mechanism, the conveying mechanism, the peeling mechanism, the waste disposal mechanism and the six-axis robot, sheet release paper is peeled, and products are transferred, the automation degree is high, the production efficiency is high, and the product production accuracy is ensured.

Owner:禾准电子科技(昆山)有限公司

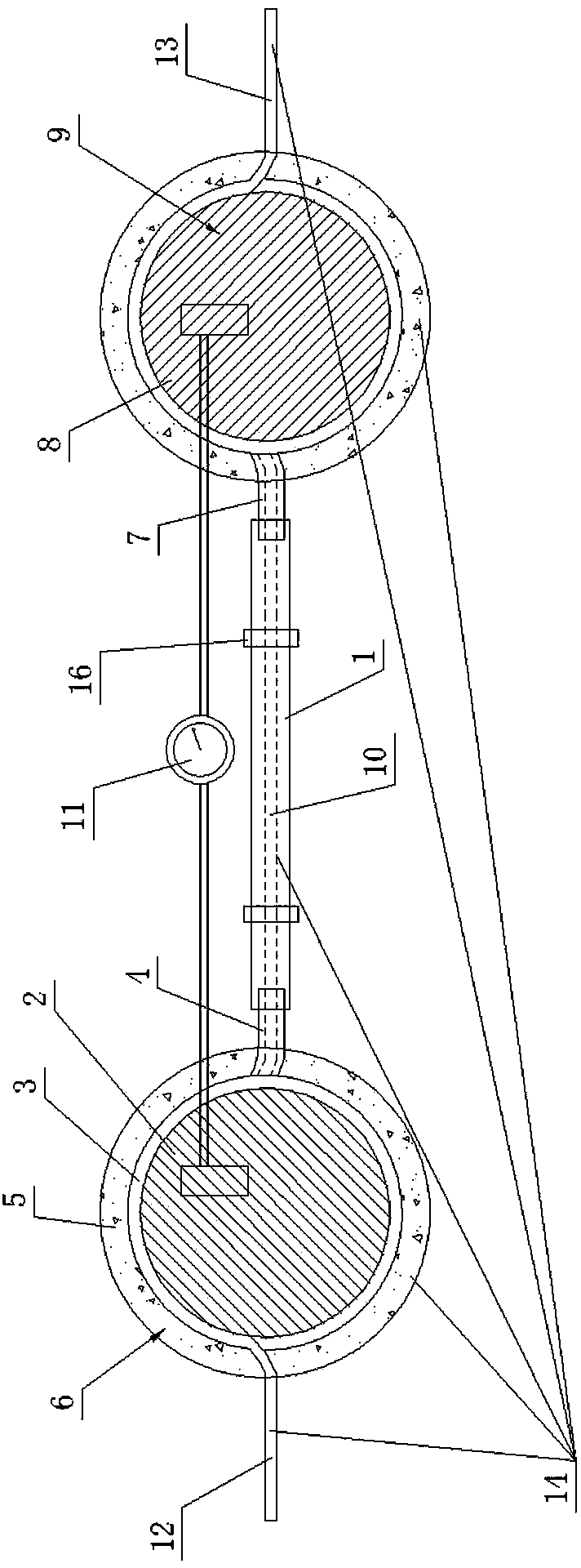

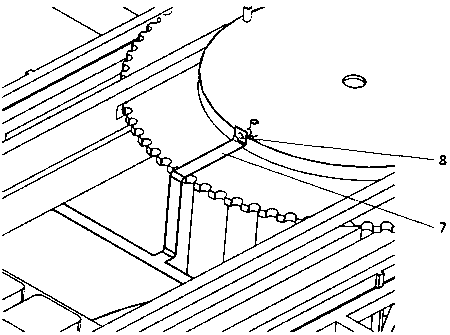

Method for installing distributed sensing optical fibers used for monitoring strain of steel structure

InactiveCN103376067AAccurate measurementGuaranteed production accuracyUsing optical meansOptical fiber connectorEngineering

The invention discloses a method for installing distributed sensing optical fibers used for monitoring strain of a steel structure. The method includes the following steps that a plurality of optical fiber distribution monomers (14) are manufactured, wherein each optical fiber distribution monomer (14) comprises two magnetic bonding ends, a strain monitoring optical fiber section (10), a front section signal transmission optical fiber section (12) and a rear section signal transmission optical fiber section (13); the optical fiber distribution monomers (14) are sequentially connected in series, and optical fiber connectors are welded at the front end of the front section signal transmission optical fiber section (12) of the headmost optical fiber distribution monomer (14) and the rear end of the rear section signal transmission optical fiber section (13) of the backmost optical fiber distribution monomer (14) respectively; then the optical fiber distribution monomers (14) which are connected in series are fixed on the steel structure to be monitored, and then the two optical fiber connectors of the optical fiber distribution monomers (14) which are connected in series are connected to a test instrument. The method for installing the distributed sensing optical fibers is rapid, comprehensive and accurate.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

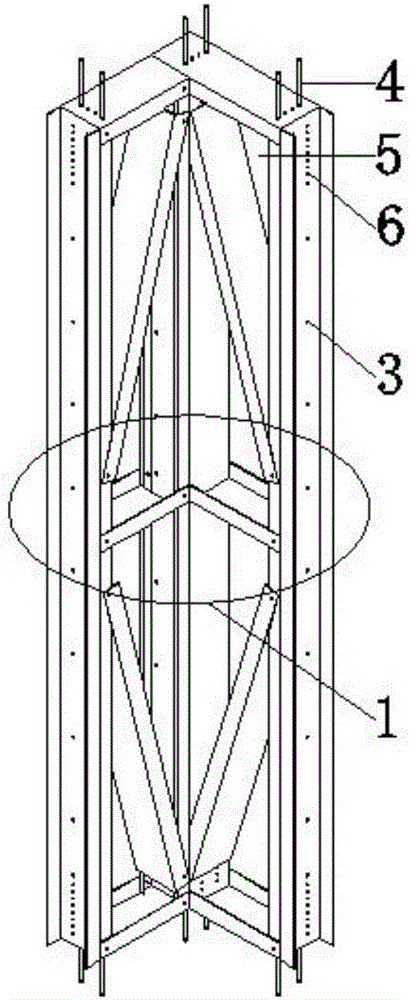

Modularized assembling-type cross-shaped cold-bending thin-wall profile steel combined wall and connection method thereof

InactiveCN105908855AImprove carrying capacityImprove torsion resistanceWallsHeat proofingThermal insulationKeel

The invention provides a modularized assembling-type cross-shaped cold-bending thin-wall profile steel combined wall and a connection method thereof. A cross-shaped cold bending thin-wall steel framework is filled with a thermal insulation layer. A wall face board and a cross-shaped cold bending thin-wall steel keel are connected together through tapping screws. The cross-shaped cold bending thin-wall steel framework, the thermal insulation layer and the wall face board form the modularized assembling-type cross-shaped cold-bending thin-wall profile steel combined wall. The cross-shaped cold-bending thin-wall profile steel combined wall and a common wall module are in horizontal connection realized through an inter-wall-module horizontal connection method. An upper cross-shaped cold-bending thin-wall profile steel combined wall and a lower cross-shaped cold-bending thin-wall profile steel combined wall are in vertical connection realized through an inter-wall-module vertical connection method. The modularized assembling-type cross-shaped cold-bending thin-wall profile steel combined wall integrates functions of structural load bearing and thermal insulation and has advantages of being high in integration and assembly degree and being suitable for industrial production and the like. Problems that field assembly and connection of joints of walls whose four faces are perpendicular to each other is poor in strength, high in difficulty and the mounting joints are difficult to process.

Owner:BEIJING UNIV OF TECH

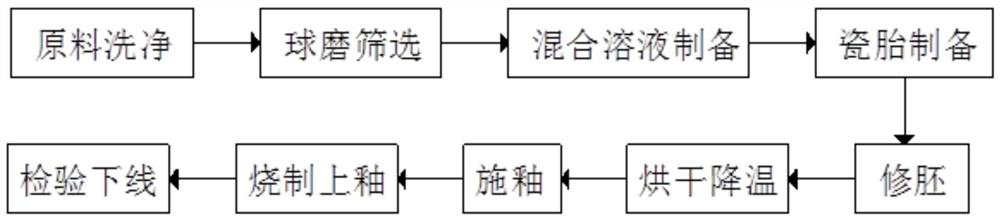

Preparation method of multi-layer glaze daily-use porcelain

The invention provides a preparation method of multi-glaze daily-use porcelain. The multi-glaze daily-use porcelain is prepared from the following raw materials of: aluminum oxide, silicon dioxide, ferric oxide, calcium oxide, magnesium oxide, potassium oxide, sodium oxide, titanium dioxide, chromium carbonate, diboron trioxide, barium oxide, pigment and deionized water. Through reasonable matching of the raw materials, the selection of the ceramic materials is changed, the chemical reaction sufficiency of the ceramic materials is improved, the reaction among the chemical components of the ceramic materials is more stable. The preparation method comprises the following steps of: raw material washing, ball-milling and screening, mixed solution preparation, porcelain body preparation, blanktrimming, drying and cooling, glazing, firing and glazing, and inspecting and discharging. Clean and standard raw materials are used, meanwhile, the manufacturing precision of each link is guaranteed;the thermal stability of a ceramic product is improved; the ceramic product is not prone to cracking in a high-temperature or low-temperature environment; the ceramic is sintered at the medium temperature, the sintering cost of the ceramic is greatly reduced, and the energy-saving and consumption-reducing functions are achieved.

Owner:GUANGDONG SITONG GROUP

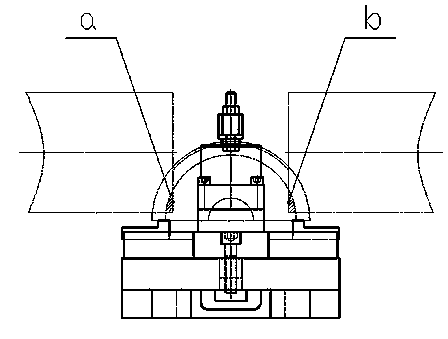

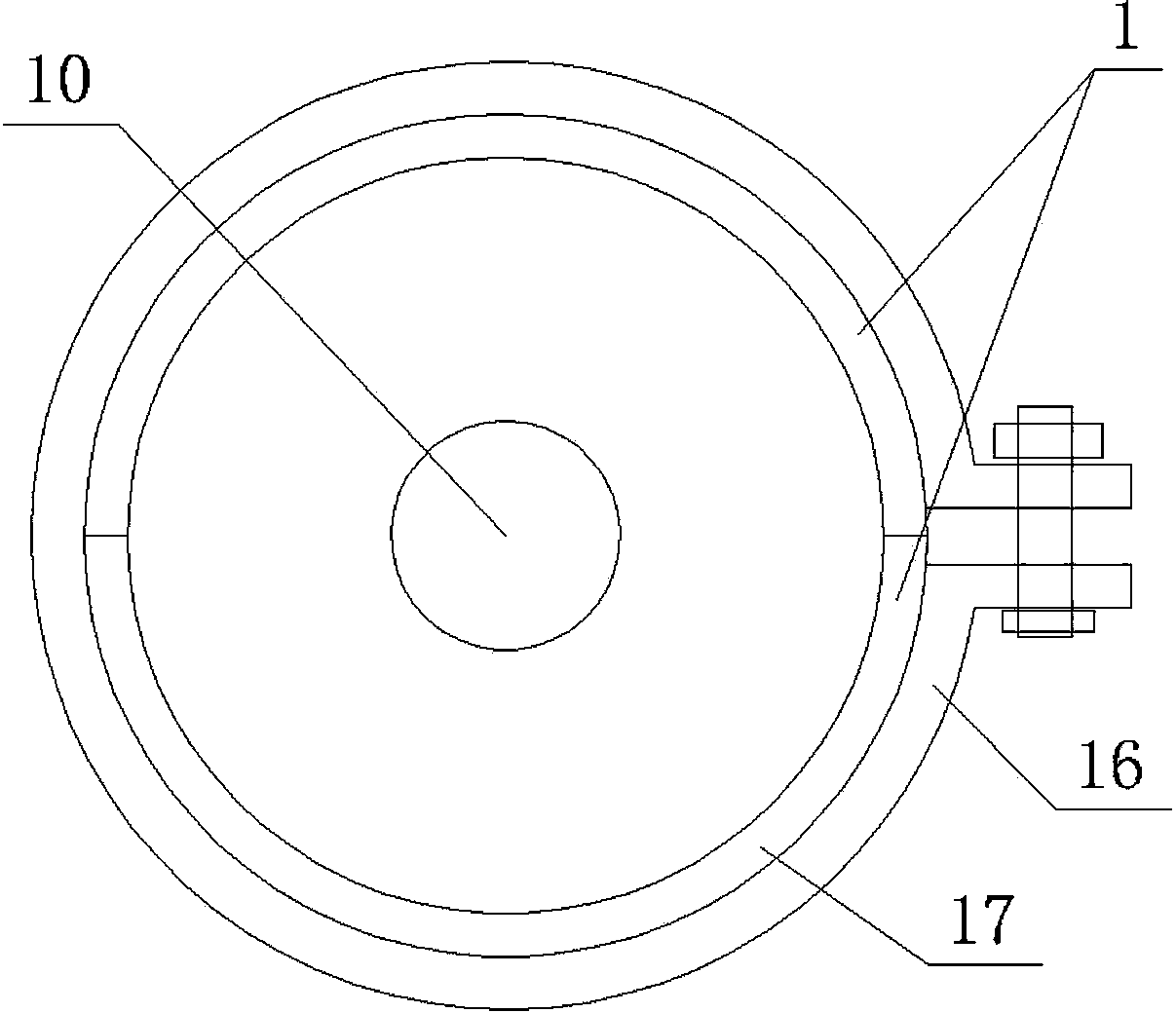

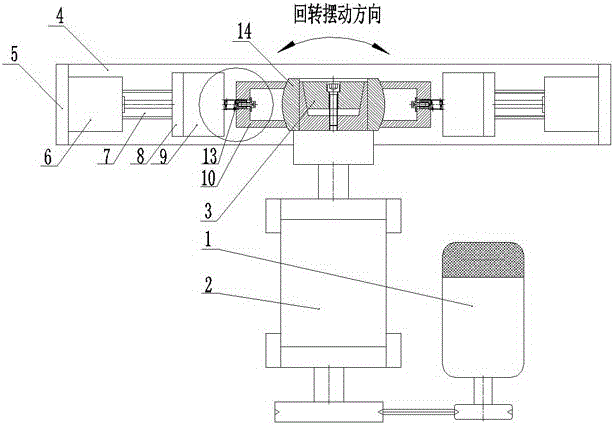

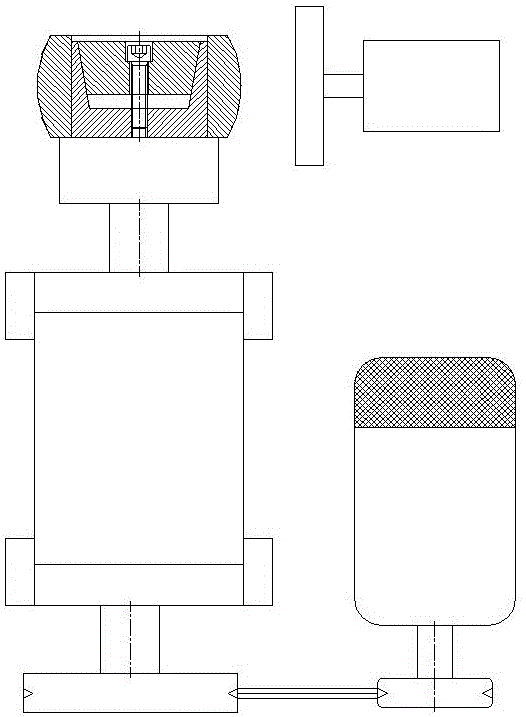

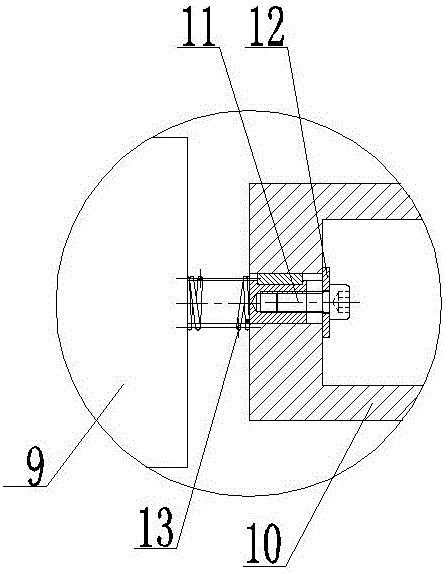

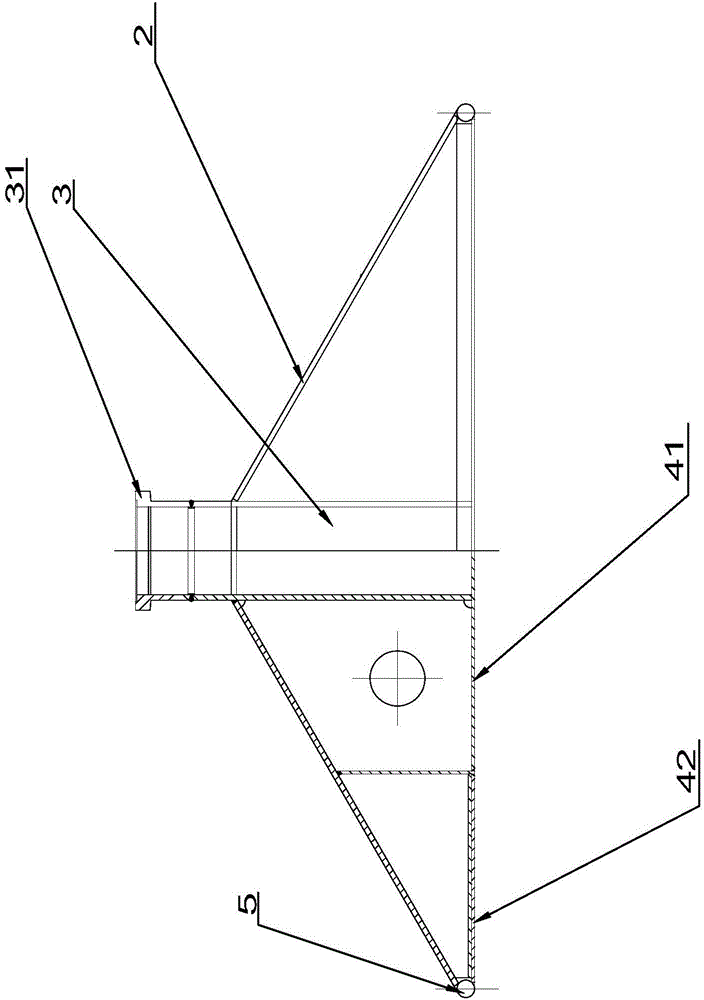

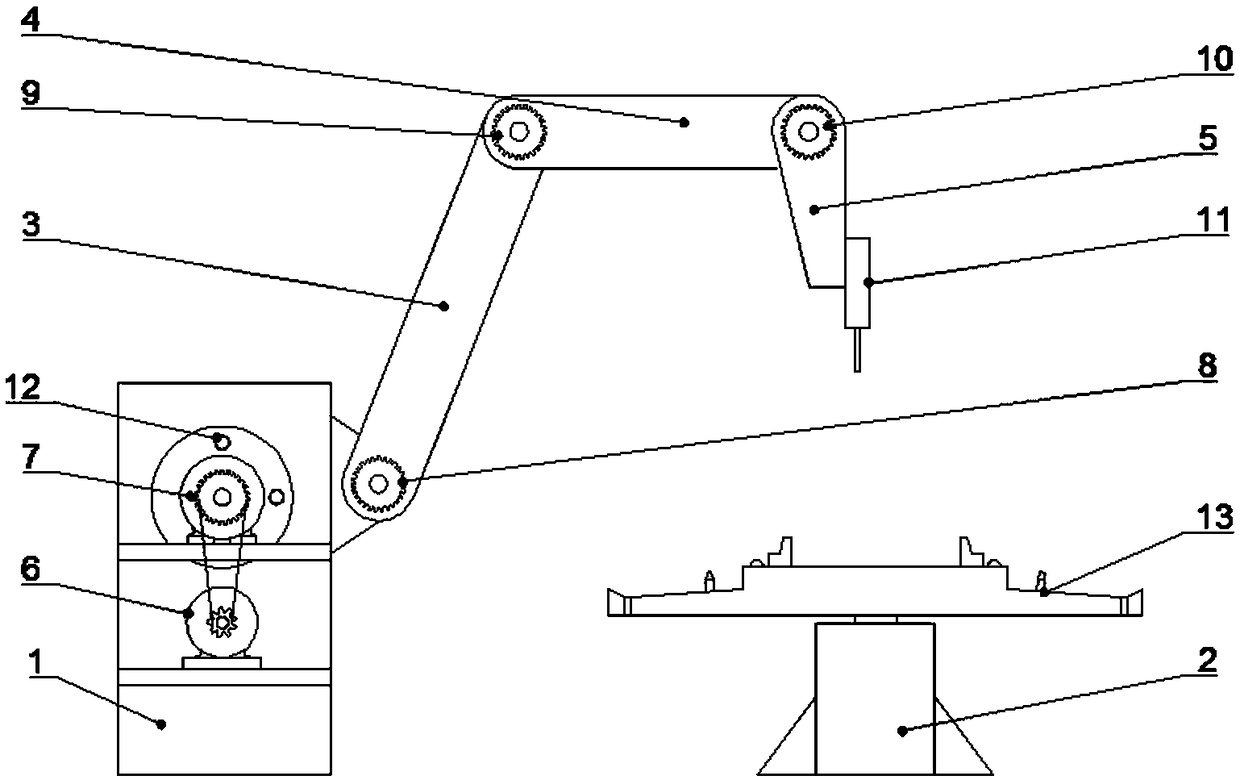

Grinding device for profile tolerance and roughness of large joint ball

InactiveCN106141897AIncrease productivityGuaranteed production accuracyLapping machinesGrinding machinesLarge jointBilateral symmetry

The invention relate to a grinding device for the profile tolerance and roughness of a large joint ball. The grinding device for the profile tolerance and roughness of the large joint ball is characterized in that the grinding device comprises a main motor (1), a spindle box (2), an internal swelling sleeve (3), a rotary swing support (4) and two grinding assemblies, the output end of the spindle box (2) is connected with the internal swelling sleeve (3), the rotary swing support (4) is arranged transversely, the two grinding assemblies are arranged on the rotary swing support (4) in a bilateral symmetry mode, and grinding sleeves (10) of the two grinding assemblies are located on the left side and the right side of the internal swelling sleeve (3) correspondingly. The grinding device for the profile tolerance and roughness of the large joint ball has the advantages that the production efficiency is improved, and the production precision is guaranteed.

Owner:WUXI YINGBEI PRECISION BEARING

Production process of conical mud door

ActiveCN104646960AImprove production efficiencyGuaranteed production accuracyManufacturing engineeringSurface plate

The invention discloses a production process of a conical mud door. According to the production process of the conical mud door, an inverted conical tooling platform is arranged in an inner cavity, so that a conical panel can be positioned and fixed through the tooling platform in the production process of the conical mud door, the problem that an existing conical panel is separately fixed is solved, the production efficiency of the conical mud door can be effectively improved, and the production precision of the conical mud door can be preferably guaranteed. The production process of the conical mud door is used in the production field of dredge mud doors.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

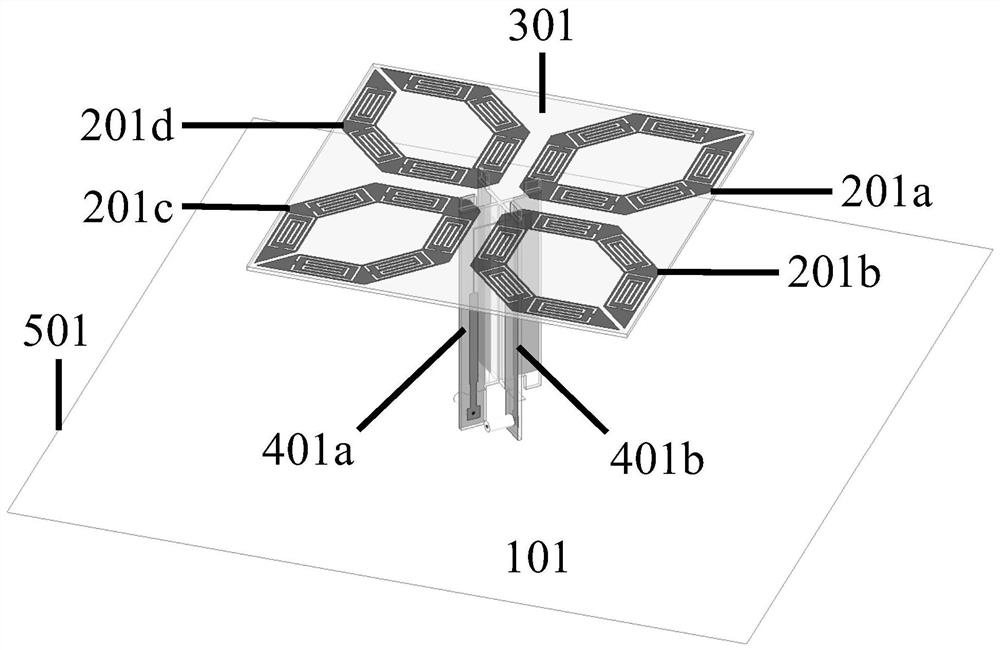

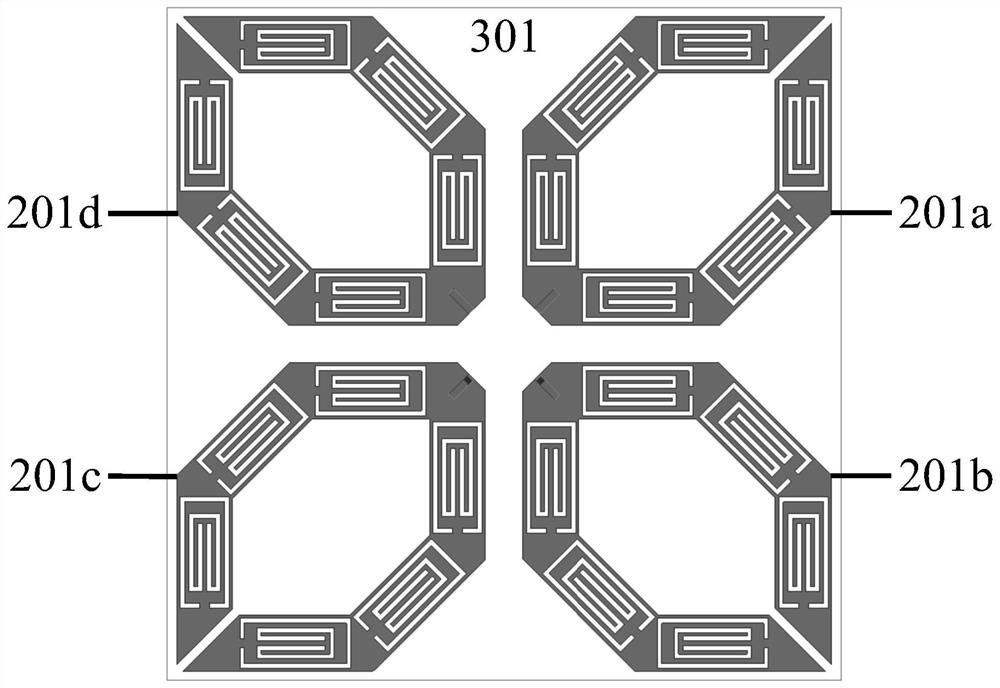

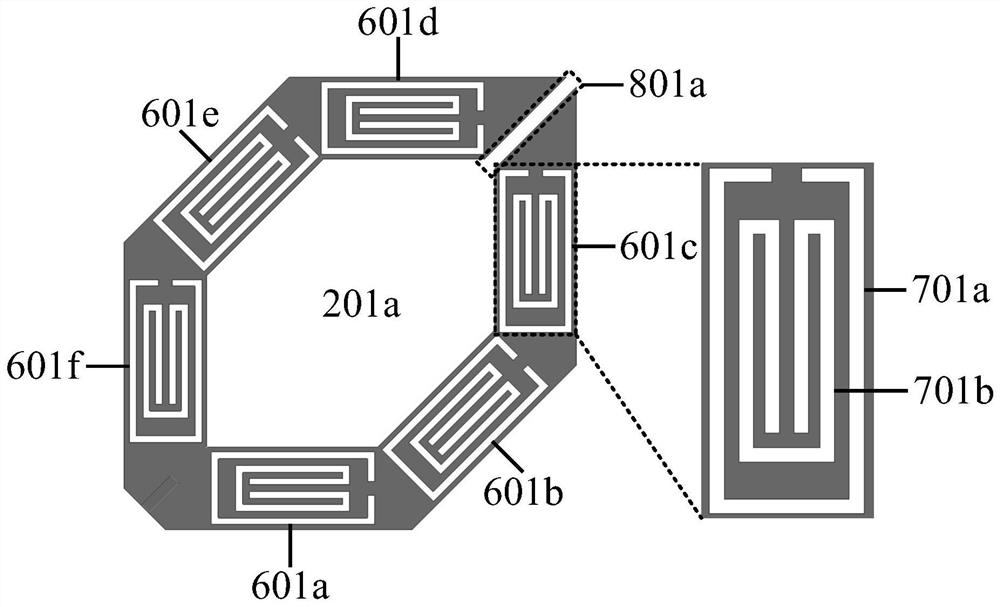

Broadband dual-polarized electromagnetic transparent antenna

ActiveCN113964490AObtaining Broadband Impedance Matching CharacteristicsSuppression of scattered interferenceParticular array feeding systemsRadiating elements structural formsSoftware engineeringDielectric substrate

The invention discloses a broadband dual-polarized electromagnetic transparent antenna which is used for suppressing cross-band scattering interference among multiband antennas. The antenna is mainly characterized in that four oscillator arms are designed on a dielectric substrate, at least one nested opening resonance groove is etched in each oscillator arm, each nested opening resonance groove is composed of an inner opening resonance groove and an outer opening resonance groove, and the scattering suppression frequency band of the antenna is determined according to the size of the nested opening resonance grooves. Two relatively narrow scattering suppression frequency bands can be combined into a wide scattering suppression frequency band by adjusting the sizes of the inner opening resonance groove and the outer opening resonance groove so that broadband scattering suppression is realized, and in the scattering suppression frequency band, and scattering currents on the oscillator arms are mainly distributed near the nested opening resonance grooves in opposite directions. And a scattering field generated by the reverse scattering current can be self-counteracted so that scattering interference generated by the broadband dual-polarization electromagnetic transparent antenna on an antenna working in an action frequency band of the broadband dual-polarization electromagnetic transparent antenna is effectively inhibited, and an electromagnetic transparent effect is further realized.

Owner:SOUTH CHINA UNIV OF TECH

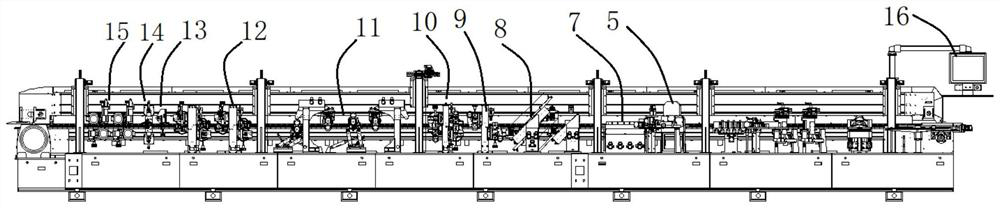

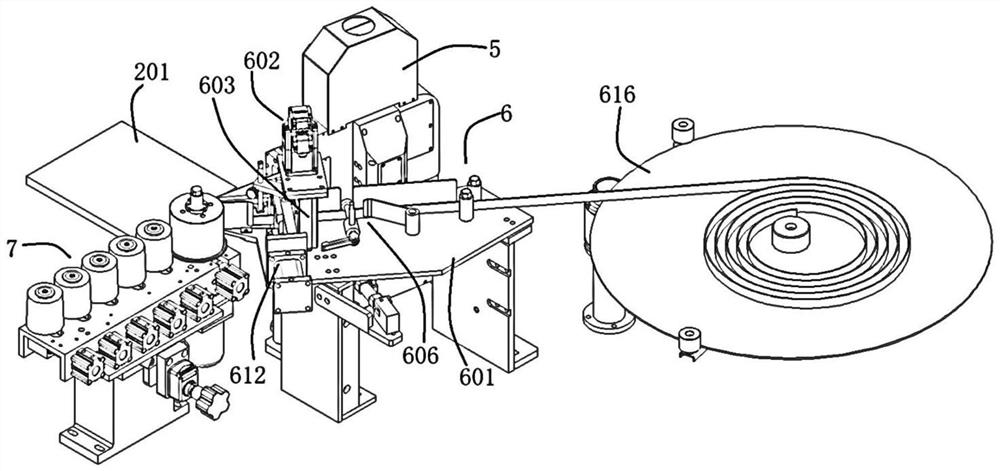

Multi-film-layer full-automatic synchronous continuous production film laminating equipment and processing method thereof

PendingCN114211850AClosely connectedExecution time difference is smallLamination ancillary operationsLaminationMechanical engineeringIndustrial engineering

The invention relates to multi-film-layer full-automatic synchronous continuous production film laminating equipment and a processing method thereof. The equipment comprises a product assembly, a driving mechanism, a film tearing mechanism, a film pasting mechanism, a film laminating mechanism, a first feeding mechanism, a second feeding mechanism and a receiving mechanism, the product assembly comprises a base band, a base band upper film and a base band new film, through mutual cooperation of the driving mechanism, the film tearing mechanism, the film pasting mechanism and the film covering mechanism and a specific layout mode, continuous film pasting can be conducted on workpieces to be pasted, flow steps corresponding to all the mechanisms are closely connected, the execution time difference is small, and the production efficiency is high. The production efficiency is greatly improved, the yield per hour can be improved from original 700 pice to 1000 pice or above, the efficiency and the production precision are guaranteed, and meanwhile the automation degree of equipment is further improved.

Owner:深圳双十科技股份有限公司

Novel cigarette production method applying 3D (3-dimensional) printing technology

The invention relates to the field of cigarette production, in particular to a novel cigarette production method applying a 3D (3-dimensional) printing technology. A novel cigarette comprises a cigarette stick and a filter tip stick, wherein the cigarette stick is formed by bonding tobacco powder ground by tobacco leaves through an adhesive. The production method of the novel cigarette provided by the invention comprises the following steps: producing the cigarette by utilizing the 3D printing technology, increasing the tobacco powder layer by layer in hierarchical processing and superstition solidification forming ways to generate a 3D entity cigarette, spraying the adhesive through a 3D printer according to the shape of each cross section designed in software, carrying out progression layer by layer and finally obtaining the cigarette stick which is formed by overlapping all the cross sections, so that the production precision is effectively ensured. Meanwhile, the treatment process of the tobacco leaves is simplified, the application scope of tobacco raw materials is broadened, the utilization rare of the tobacco raw materials is improved, and the wood gas of cigarette smoke is removed. The 3D printer used in the novel cigarette production method is smaller in size and is more economic, the relevant procedure of computer graphic data can be directly utilized to generate the cigarette, and the cost is saved while the production is convenient.

Owner:HUBEI CHINA TOBACCO IND +1

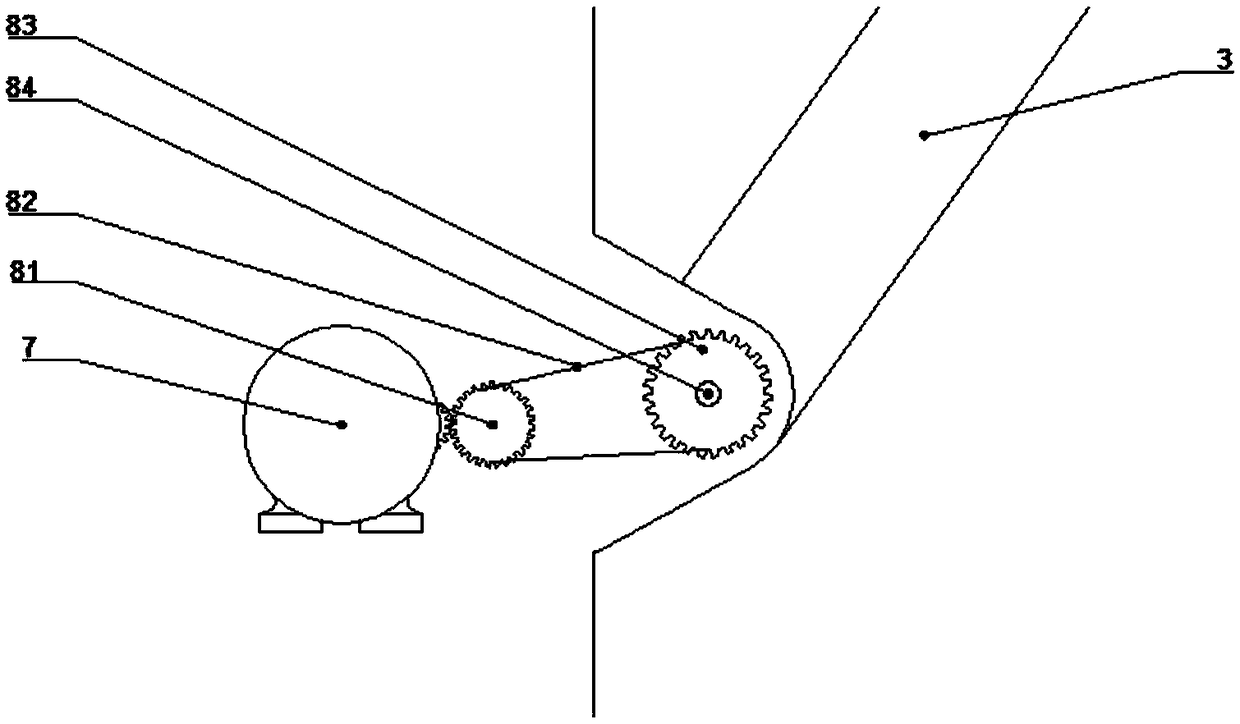

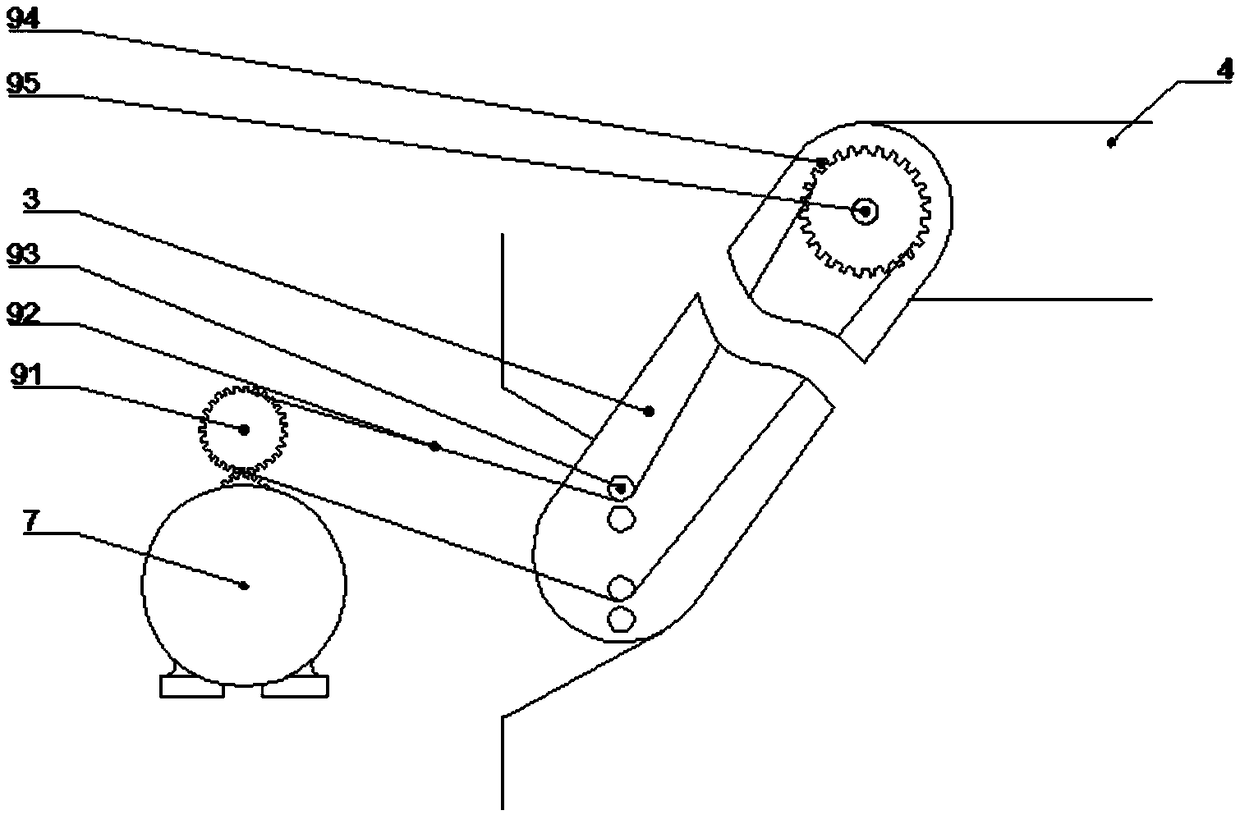

Welding mechanical arm capable of preventing sparks from splashing and working method of welding mechanical arm

PendingCN108857193ARealize multi-joint movementEnsure degrees of freedomWelding/cutting auxillary devicesAuxillary welding devicesMotor driveEngineering

The invention discloses a welding mechanical arm capable of preventing sparks from splashing. The welding mechanical arm comprises a base, a rotary workbench, mechanical arms, a drive motor, a transmission gear box, rotary chain wheel sets and a tail end welding gun. The rotary workbench is arranged on one side of the base. The mechanical arms are arranged at the upper end of the base, and the tail end welding gun is fixed to one end of one mechanical arm. The drive motor and the transmission gear box are arranged in the base. The rotary chain wheel sets are arranged at the hinged positions ofthe base and the mechanical arms. One end of the transmission gear box is connected with the rotary chain wheel sets. The invention further discloses a working method of the welding mechanical arm capable of preventing the sparks from splashing. The problem that personnel cannot approach to the mechanical arm due to the fact that sparks splash is solved; production problems can be found and handled in time in the work process; the work efficiency of the mechanical arm is improved; meanwhile, single motor drive is achieved; the space needed by a drive joint is reduced; the cost of a drive component is reduced; and the welding mechanical arm can adapt to the small-batch production environment and can be achieved in more fields.

Owner:薛敏强

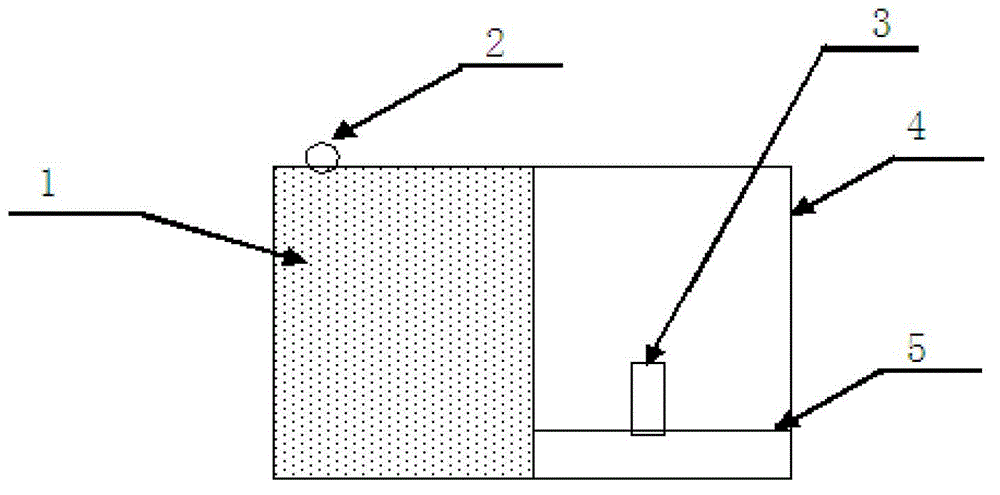

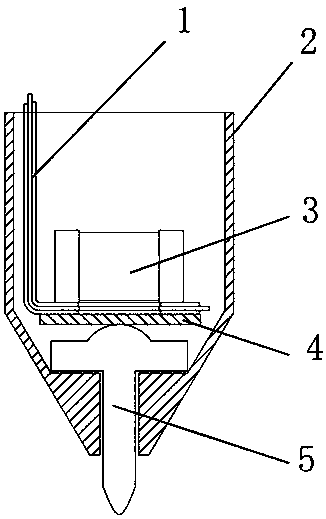

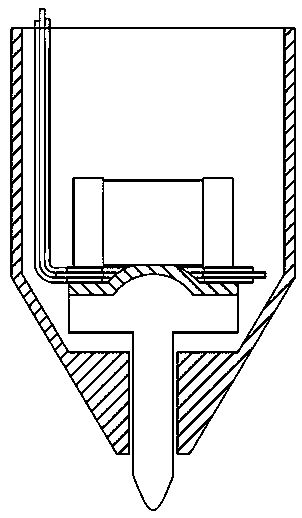

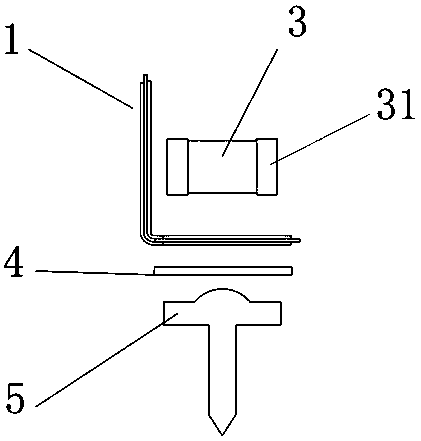

Variable-capacitance pressure sensor

The invention provides a variable-capacitance pressure sensor, which includes a double-layer flexible circuit board, a multi-layer ceramic capacitor and a soft conductive gasket. The multi-layer ceramic capacitor is arranged close to the soft conductive gasket. The double-layer flexible circuit board with a through hole or a gap is arranged between the multi-layer ceramic capacitor and the soft conductive gasket. The multi-layer ceramic capacitor is arranged above the through hole or the gap. The soft conductive gasket is arranged below the through hole or the gap. When the soft conductive gasket deforms under external pressure, the soft conductive gasket will pass through the through hole or the gap of the flexible circuit board and contact the ceramic medium of the multi-layer ceramic capacitor. When the external pressure changes, the contact area between the soft conductive gasket and the ceramic medium of the multi-layer ceramic capacitor will change, and the capacitance value between the soft conductive gasket and external electrodes connected into the multi-layer ceramic capacitor will change. The number of components is reduced, the production and assembly process is simplified, and the cost is reduced.

Owner:伍颖超 +2

Rapid drying and collecting device for micro nano powder

ActiveCN113945070AFast dryingNot easy to reuniteDrying solid materials with heatSteam/vapor condensersMicro nanoMetallurgy

The invention provides a rapid drying and collecting device for micro nano powder, and belongs to the field of powder drying. The device comprises a micro-droplet spraying device for forming nano powder slurry into a droplet state, a rapid drying device for drying nano powder droplets to form nano powder, a dehumidification device for removing water vapor generated in the drying process of the nano powder, and a powder collecting device for collecting the nano powder. According to the device, the microwave technology, the ultrasonic technology and the electrostatic technology are organically combined, nano powder is rapidly collected under the action of an electrostatic field after being suspended and dried in a drying chamber, the device has the advantages of being high in drying speed, not prone to agglomeration, controllable in drying time and suitable for drying the nano powder with different particle sizes, and meanwhile the device is compact in structure, suitable for small-batch preparation of nano powder in scientific research laboratories, and meets the requirement of taking and using at any time.

Owner:WUXI HOPE LIGHT IND EQUIP TECH +1

Automatic kiln-loading device and automatic kiln-loading method for sanitary ceramics

InactiveCN110260666ASimple structureReasonable designCharge composition/stateCharge supportsEngineeringHigh intensity

The invention discloses an automatic kiln-loading device and an automatic kiln-loading method for sanitary ceramics. The automatic kiln-loading device is arranged close to an inlet of a kiln, and comprises a bearing table, a conveying assembly, a bottom mat, and a carrying part, wherein the bearing table is flatly placed on a kiln car; ceramics to be sintered can be placed on the bearing table; the conveying assembly is used for transferring the ceramics to be sintered to the neighborhood of the bearing table; the bottom mat is placed on the bearing table and is used for bearing the ceramics to be sintered; and the carrying part is arranged between the conveying assembly and the bearing table, and is used for paving the bottom mat on the bearing table and carrying the ceramics to be sintered onto the upper surface of the bottom mat from the conveying assembly. The automatic kiln-loading device and the automatic kiln-loading method for the sanitary ceramics provided by the invention are simple in structure, reasonable in design and easy to implement; and workers have no need to carry out high-intensitive carrying and kiln-loading work under the harsh high-temperature environment, so that time and labor are saved, and the demand on mass production is achieved.

Owner:JOMOO KITCHEN & BATHROOM

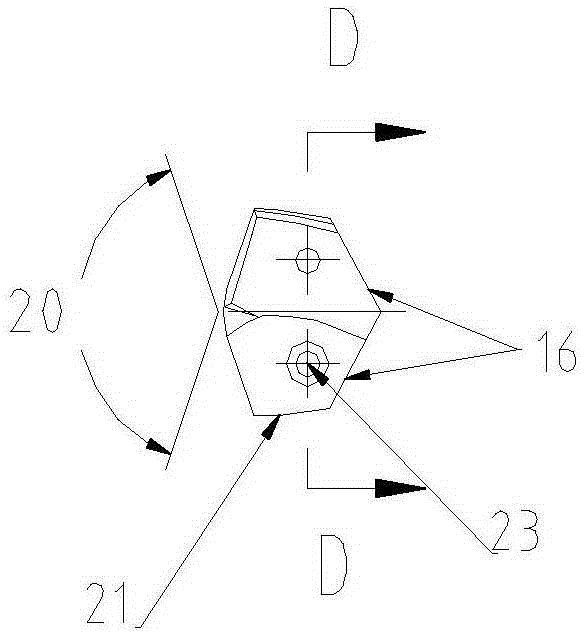

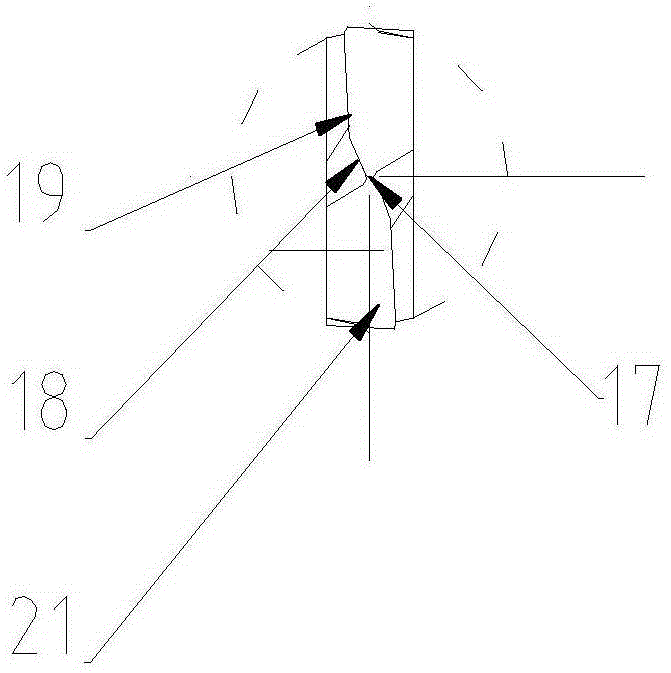

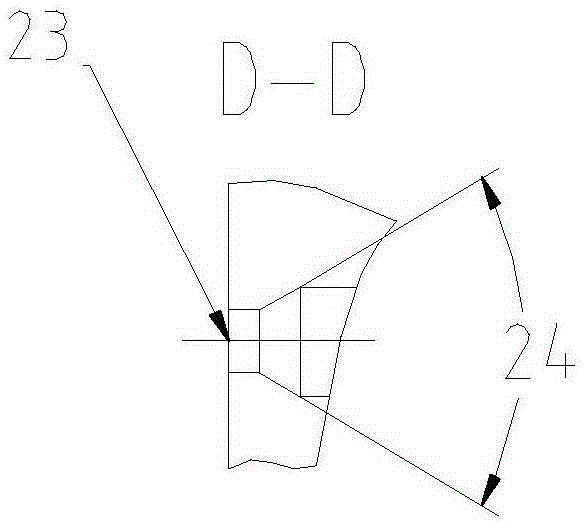

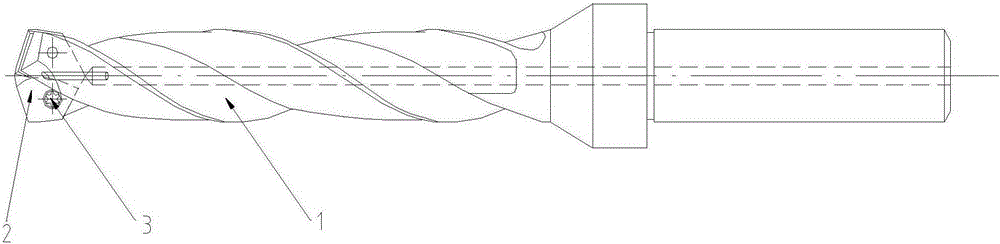

Tooth crown blade locked through double screws in V-shaped positioning groove

InactiveCN105171060AReduce manufacturing costIncrease contact areaTransportation and packagingTrepanning drillsEngineeringTransition edge

The invention relates to a tooth crown blade locked through double screws in a V-shaped positioning groove. A V-shaped positioning face matched with a positioning face of a working portion of a drilling rod is arranged at the right end of the tooth crown blade, and a cutting edge composed of a transverse edge, a transition edge and a main cutting edge is arranged at the left end of the tooth crown blade; the main cutting edge is formed by the crossing lines of a chip removal groove and rear cutter faces, and the transverse edge is formed on the crossing lines of the two rear cutter faces; and the transition edge is arranged between the main cutting edge and the transverse edge in a polishing manner. A tooth crown edge side is arranged on the tooth crown blade in the diameter direction and is spirally provided with a wide cylindrical face, and the tooth crown blade is provided with a ladder hole where a compressing screw is mounted; and the axis of the ladder hole is perpendicular to the mounting face of the blade, and the position of the ladder hole is opposite to the position of a fastening screw hole in a drilling rod; and the blade locked through the double screws in the V-shaped positioning groove is large in contact area, high in bearing force, good in clamping reliability and suitable for large feeding cutting.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

A modular assembled L-shaped cold-formed thin-walled steel composite wall and its connection method

The invention discloses a modular assembly type L-shaped cold-formed thin-walled steel combined wall and a connecting mode of the modular assembly type L-shaped cold-formed thin-walled steel combined wall. The modular assembly type L-shaped cold-formed thin-walled steel combined wall is characterized in that the middle part of an L-shaped cold-formed thin-walled steel framework is filled with a heat preservation layer; a wall panel and the L-shaped cold-formed thin-walled steel framework are connected through self-tapping screws; the modular assembly type L-shaped cold-formed thin-walled steel combined wall is formed by the L-shaped cold-formed thin-walled steel framework, the heat preservation layer and the wall panel. Horizontal-direction connection between an L-shaped cold-formed thin-walled steel combined wall module and a common wall module is realized through a horizontal connecting mode between wall modules; vertical-direction connection between two adjacent L-shaped cold-formed thin-walled steel combined wall modules which are adjacent in the vertical direction is realized through a vertical connecting mode between the wall modules. The modular assembly type L-shaped cold-formed thin-walled steel combined wall disclosed by the invention integrates structural bearing and heat preservation, and has the advantages of high integration and assembly degrees, applicability in industrial production and the like, and the problems of weak connection between a longitudinal wall and a horizontal wall, high difficulty and difficulty in handling installation seams, and the like can be solved. The connecting mode of the modular assembly type L-shaped cold-formed thin-walled steel combined wall is simple in structure and is quick and efficient, and a large amount of labor cost can be reduced.

Owner:BEIJING UNIV OF TECH

Device and method for producing runner-containing part of fusion reactor cladding by utilizing explosive cladding

PendingCN111889870AAvoid weld failureReduce the difference in wave impedanceNon-electric welding apparatusExplosive claddingDetonation

The invention discloses a device and a method for producing a runner-containing part of a fusion reactor cladding by utilizing explosive cladding. According to the device and the method, for a runnerpipe fitting and a covering plate before forming, certain salt powder of weak acids and weak bases is well mixed with certain low-melting-point metal particles according to a certain proportion, the resulting mixture is used for filling a runner, then the filler material is compacted with a jack to be flush with a runner opening. Compaction and filling of the runner eliminate huge acting force generated by detonation waves on the two sides of a composite interface due to wave impedance mutation, integrity of the shape and the microstructure of the runner-containing part is guaranteed, and theproblems of runner deformation and cracks generally existing in other methods are solved. The characteristic that salts of weak acids and weak bases are easy to decompose after being heated enables the whole filler to become loose during temperature rise, meanwhile, and reducing gas generated by decomposition of the filler can protect low-melting-point metal from being oxidized. It is guaranteed that the filler can be easily and thoroughly removed when the runner, especially a complex special-shaped runner, is heated, and no attachment exists in the obtained runner.

Owner:UNIV OF SCI & TECH OF CHINA

Intelligent laser edge bonding machine

ActiveCN114670306AAvoid harmRealize the purpose of edge bandingMulti-purpose machinesDomestic articlesHigh energyElectrical connection

The invention discloses an intelligent laser edge banding machine which comprises an edge banding machine body, an intelligent industrial control screen, a pre-milling mechanism, a laser edge banding mechanism and a six-wheel fixed belt pressing and pasting mechanism are installed on the edge banding machine body from right to left, and the pre-milling mechanism, the laser edge banding mechanism and the six-wheel fixed belt pressing and pasting mechanism are electrically connected with the intelligent industrial control screen. According to the intelligent laser edge bonding machine, high-energy laser generated by the laser edge bonding mechanism is used for carrying out glue melting on the laser edge bonding belt with a functional sol layer, a glue coating mechanism is omitted, hot melt glue does not need to be used, and the functional sol layer on the laser edge bonding belt is rapidly melted before the laser edge bonding belt makes contact with a workpiece; the laser edge sealing belt is pressed on the workpiece through the six-wheel fixed belt pressing and pasting mechanism, so that the laser edge sealing belt can be used immediately after being started, waiting is not needed, and heat preservation is not needed. And meanwhile, glue melting is conducted through the laser edge sealing mechanism, cleanliness, neatness, environmental protection and no peculiar smell are achieved, one-time edge sealing is completed, other additional protection is not needed, the reject ratio of products is reduced, production precision is guaranteed, the thickness of workpieces is ignored, high-speed edge sealing can be dealt with, production efficiency is improved, and production cost is reduced.

Owner:广东豪德数控装备股份有限公司

A fixture for the back and elevation of the blank mold

ActiveCN103817544BSimple and fast operationEasy to adjustLarge fixed membersPositioning apparatusEngineeringTailstock

The invention discloses a back elevation clamp of an initial die. The back elevation clamp comprises a turntable tailstock bridge plate structure, self-centering locating and clamping mechanisms and lateral locating mechanisms. A main board of the turntable tailstock bridge plate structure is provided with two sets of self-centering locating and clamping mechanisms, and the lateral locating mechanisms are arranged in front of the self-centering locating and clamping mechanisms. The back elevation clamp has the beneficial effects that one cylinder drives one mechanism, four pressing plates are controlled simultaneously, the die is compressed, and the centering effect is realized, so that the production precision is guaranteed, and the processing yield is improved; operation of processing parts is convenient, adjusting while remodeling is convenient, and the work time is saved; furthermore, the clamp is a double-station clamp, two parts can be processed at a time, processing contents on two faces can be processed at a time through the turntable tailstock bridge plate structure, the cost is reduced, and the processing efficiency is improved.

Owner:WUXI RUIZHEN PRECISION MACHINERY

Precision milling system for fuselage skin

InactiveCN108098030ARealize the function of cuttingEnsure safetyServomotor componentsServomotorsUltimate tensile strengthFuselage

The invention provides a precision milling system for fuselage skin. By means of installation, debugging and field application verification, the function of cutting the fuselage skin is realized whilesafety is guaranteed. With the adoption of the system, milling work of the fuselage skin can be completed efficiently and accurately, and manufacturing accuracy of an airplane product is guaranteed.Product precision requirements can be effectively met, product quality and stability are improved, labor intensity of an operator is reduced, and working efficiency is improved. Meanwhile, a supporting technology and experience are provided for allowance cropping of tube workpieces of the fuselage.

Owner:李福来

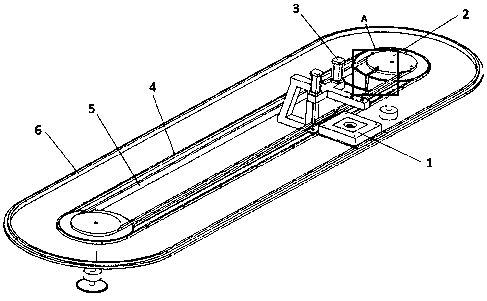

Mold locating device accurate in locating

ActiveCN108688226AReduce positional deviationGuaranteed production accuracyBox making operationsPaper-makingProduction lineProximity sensor

A mold locating device accurate in locating comprises a mold, locating wheels, a deviation correction device, a non-standard chain, an inner guide rail, an outer guide rail, a sensor support and a proximity sensor. According to the mold locating device, feedback signals are generated through the proximity sensor, a drive motor is controlled to be started and stopped to complete accurate locating of the mold, meanwhile, through combination with the design of a mechanical deviation correction mechanism, position deviation existing in a production line can be reduced to the largest degree, and the production precision of a packing box can be guaranteed.

Owner:汕头市顺容印刷工艺有限公司

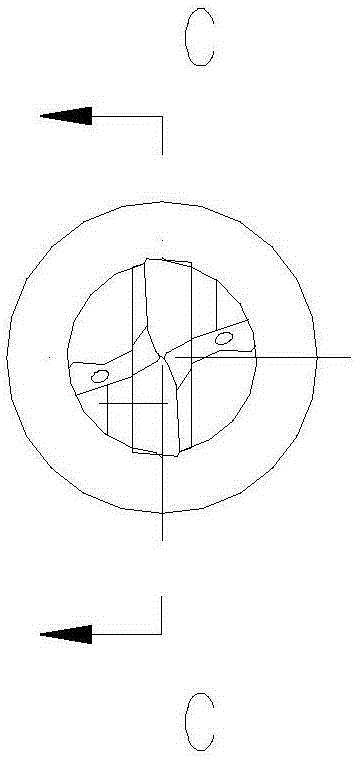

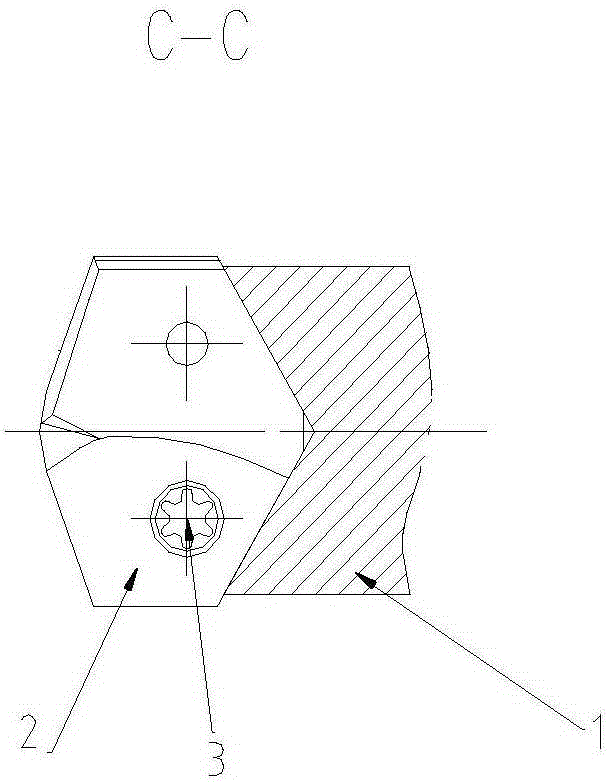

Tooth crown drill bit locked through two screws in V-shaped positioning groove

InactiveCN105171061AIncrease contact areaImprove bearing capacityTransportation and packagingTrepanning drillsEngineeringTooth crown

The invention relates to a tooth crown drill bit locked through two screws in a V-shaped positioning groove. The tooth crown drill bit comprises a drill rod, a tooth crown blade and the compression screws. A through main cooling hole is formed in the position of the axis of the drill rod. The left end of a working part is provided with two branch cooling holes. The main cooling hole and the two branch cooling holes form a Y-shaped internal cooling structure. The end face of the working part of the drill rod is provided with a blade mounting groove. The bottom of the blade mounting groove is provided with a V-shaped positioning surface used for positioning the tooth crown blade. The two sides of the blade mounting groove serve as blade mounting surfaces. A fastening screw hole used for being matched with the corresponding compression screw in a screwed mode is perpendicularly formed in each blade mounting surface. The right end of the tooth crown blade is provided with a V-shaped positioning surface matched with the positioning surface of the working part of the drill rod. The tooth crown blade is provided with stepped holes used for installation of the compression screws. The axis of each stepped hole is perpendicular to the corresponding blade mounting surface. The stepped holes are opposite to the fastening screw holes in position. The tooth crown blade is fastened onto the drill rod through the compression screws. The connection strength of the tooth crown blade and a cutter body is improved through in-groove locking.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

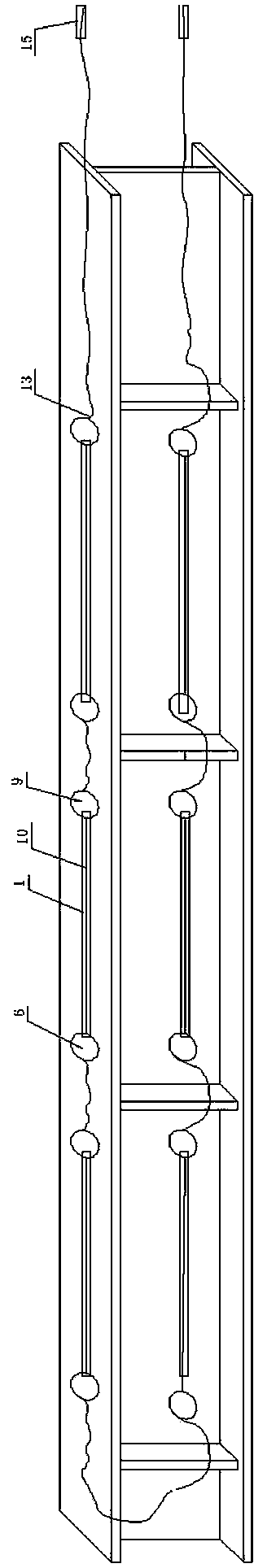

Inner core mounting structure of roller bristle sleeve machine

The invention discloses an inner core mounting structure of a roller bristle sleeve machine. The inner core mounting structure is characterized in that N supporting shafts are uniformly arranged on the circumference of a first rotary disc; a discharging mechanism conveys bristle sleeve rods to a first station supporting shaft of the first rotary disc; a first cutter cuts the bristle sleeve rods in a fixed length manner; a disc replacing device horizontally pushes bristle sleeves from the supporting shafts into sleeves of a second rotary disc; the second rotary disc is provided with a clamping station and an off-line station, and the second rotary disc is rotated to enable the bristle sleeves to complete clamping of inner cores; and a positioning plate is arranged on the front side of the clamping station, a vibration disc, a first core clamping groove and a second core clamping groove are arranged on the rear side of the clamping station, the first core clamping groove is connected with an inner core output rail of the vibration disc, displacement mechanisms are arranged beside the first core clamping groove and at the rear end of the second core clamping groove, the displacement mechanisms are used for enabling the inner cores to enter the second core clamping groove from the first core clamping groove and to be inserted into the bristle sleeves from the second core clamping groove, and the positioning plate is used for preventing the bristle sleeve from falling off from a cylinder sleeve. The structure is simple and effective and has low cost and compact and reasonable equipment layout.

Owner:SHUNDE POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com