Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Increased horizontal shear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

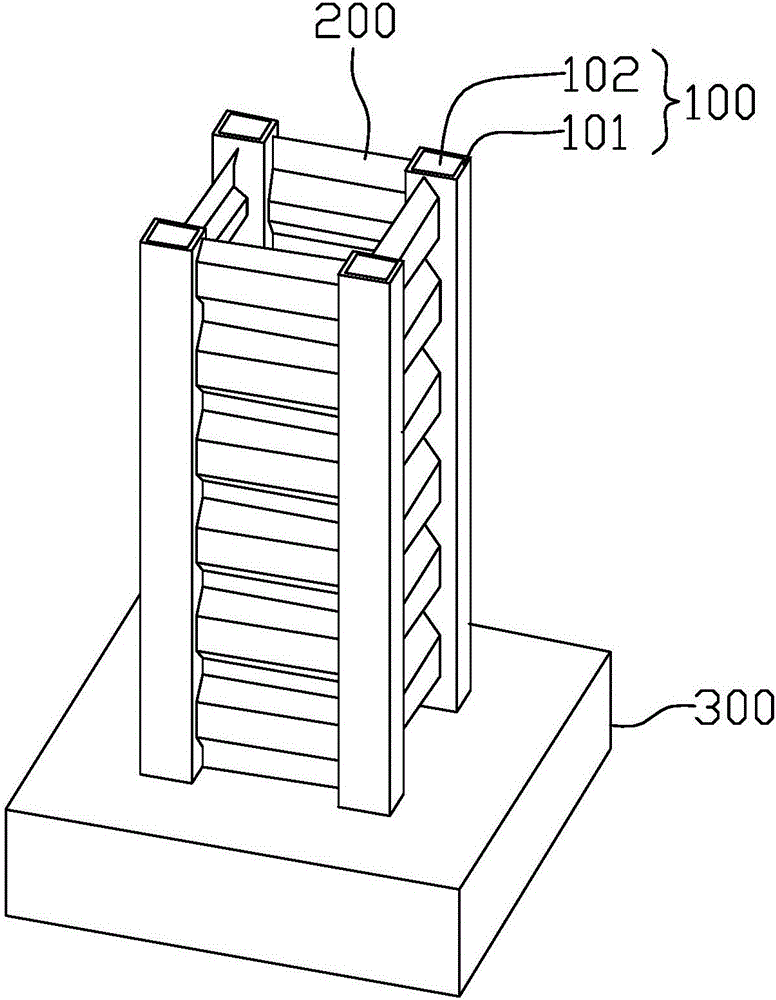

Modular assembling type cold-bent thin-wall type steel wall board structural system

Provided is a modular assembling type cold-bent thin-wall type steel wall board structural system. A vertical body structure of the cold-bent thin-wall type steel wall board structural system is formed by sequentially connecting a common wall body module, an opened wall body module, an L-shaped wall body module and a T-shaped wall body module. A horizontal body structure of the cold-bent thin-wall type steel wall board structural system is formed by sequentially splicing slab modules. The slab modules are spliced by being connected. The vertical body structure and the slab modules are connected in the mode that the wall body and the slab module are connected. By optimizing the wall body module connection mode, the slab module connection mode, and the wall body and slab module connection mode, the site assembly difficulty and site construction workload are reduced to a great extent, and the whole structural system can be safer and better in anti-seismic property. The modular assembling type cold-bent thin-wall type steel wall board structural system is low in mass, good in anti-seismic property, capable of preserving heat, insulating heat and saving energy, environmentally friendly, low in manufacturing cost, suitable for mid-rise buildings and low-rise buildings, and high in economic and social benefit.

Owner:BEIJING UNIV OF TECH

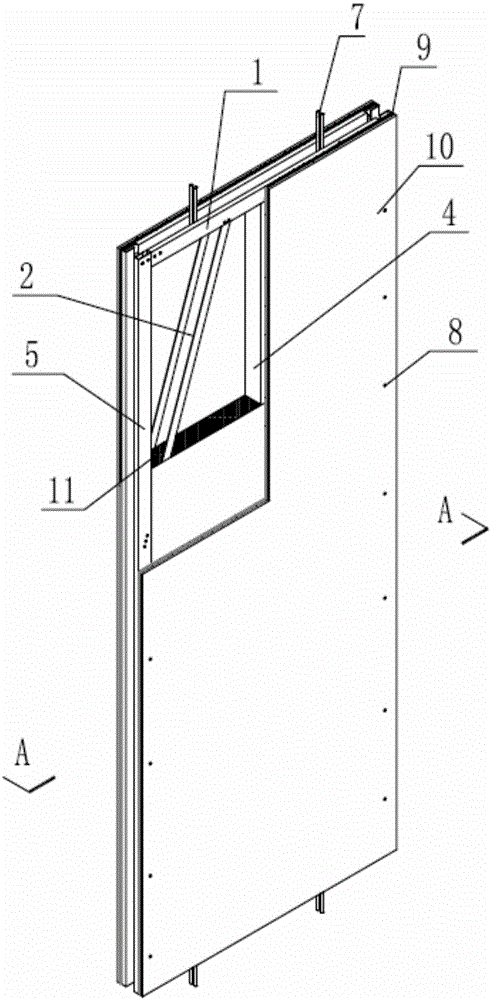

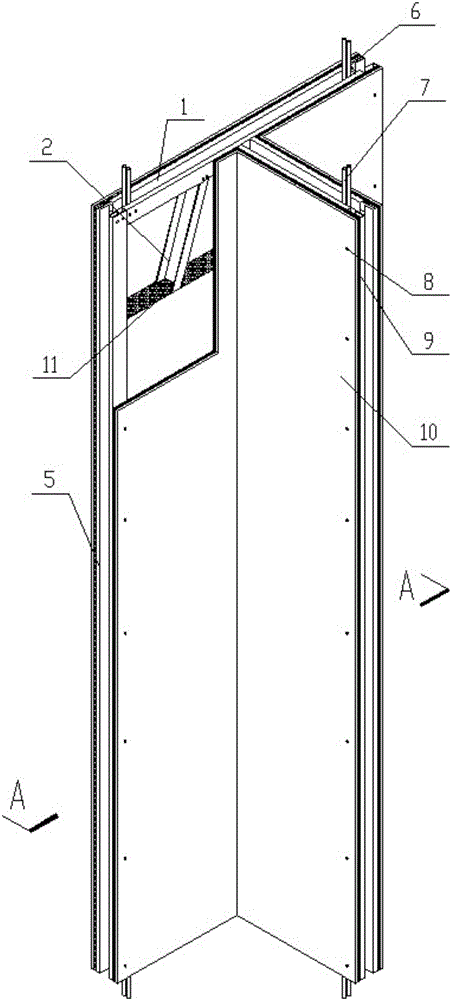

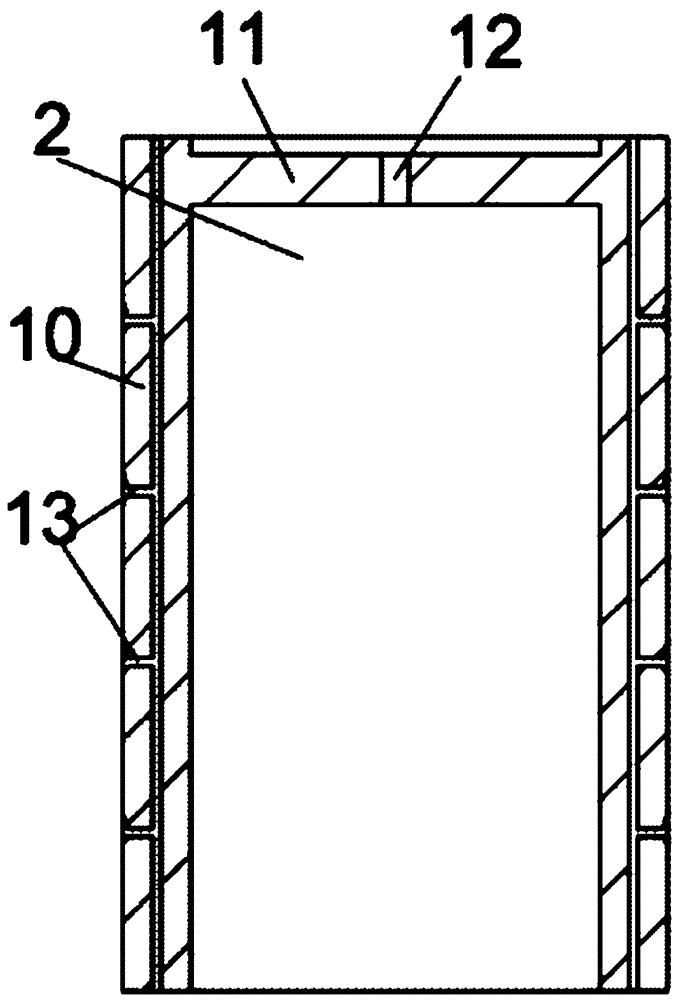

Prefabricated special-shaped light-steel composite wall board and mounting method thereof

ActiveCN104912257AResolve connectivityStructural solutionWallsBuilding material handlingSurface layerSteel frame

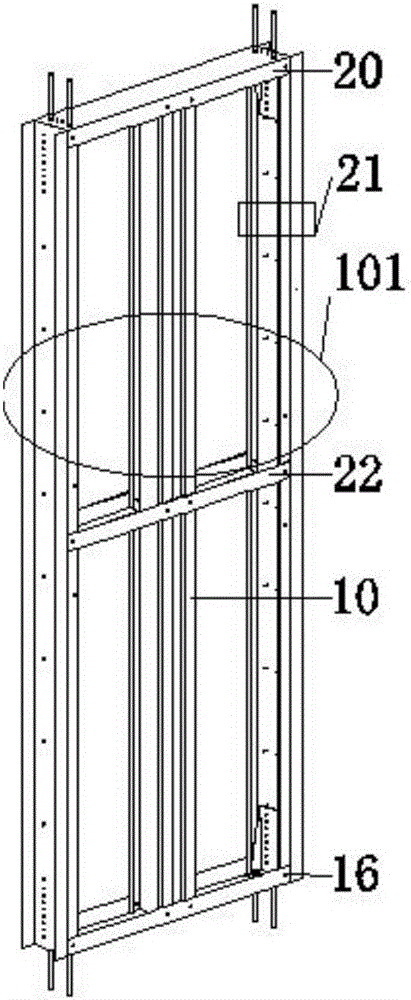

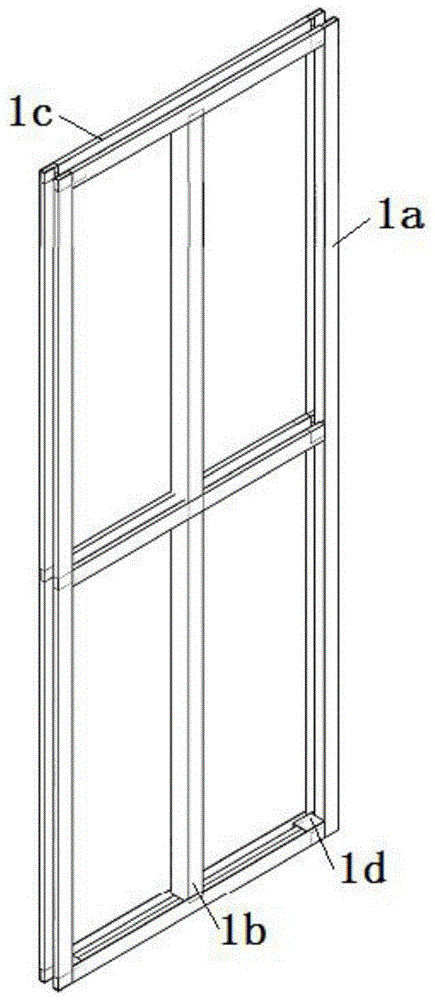

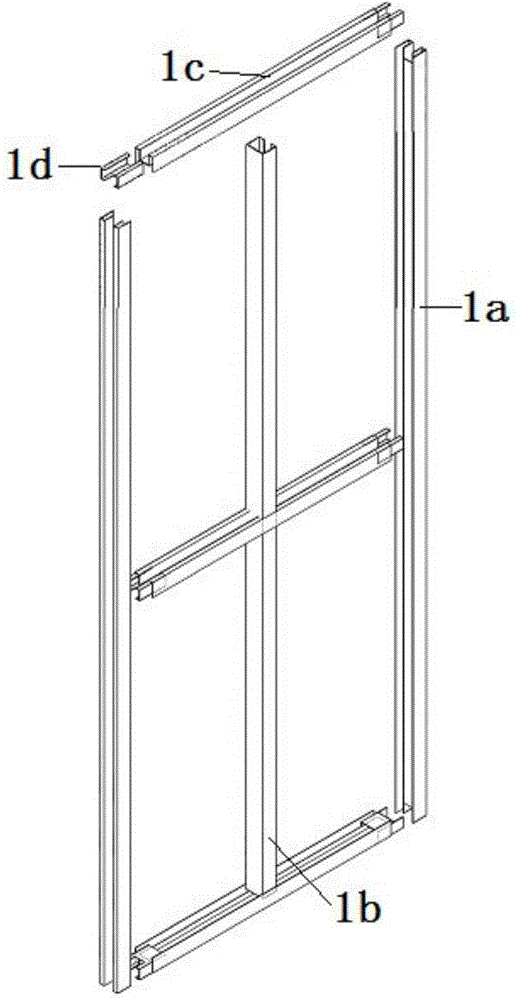

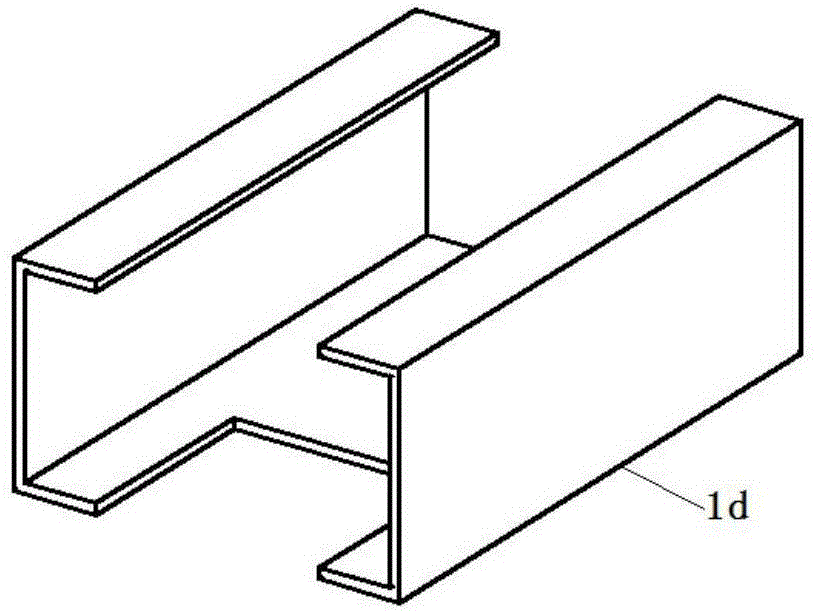

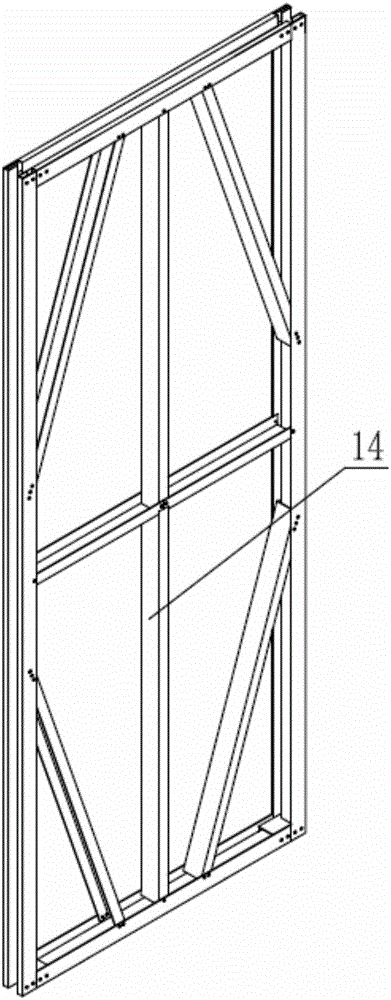

The invention discloses a prefabricated special-shaped light-steel composite wall board and a mounting method of the wall board. The middle of a light-steel frame is filled with a sandwich heat preservation material, and a steel wire mesh is welded with the outer surface of the light-steel frame; and a self-compaction cement surface layer is wrapped with the steel wire gauze and then is cast on the outer surface of the light-steel frame in an in-situ manner. The light-steel frame is pre-positioned on frame M-type steel, corner square steel, corner square steel and an inclined support which are manufactured in a factory according to the needed size; ends between the frame M-type steel are connected through U-shaped connecting parts via tapping screws; the corner square steel is connected with the frame M-type steel through bearing inserting heads on the upper portion of the corner square steel via a tapping screw; and the inclined support is connected with the frame M-type steel and the corner square steel through a tapping screw. In the actual mounting process of the wall board, a novel connecting manner between wall boards formed by M type steel in a wall and board connecting parts and a novel connecting manner between the wall boards and floors can provide more stable and safer connection, the mounting efficiency of the wall boards can be improved, the site assembly degree is greatly improved, and the construction period is shortened.

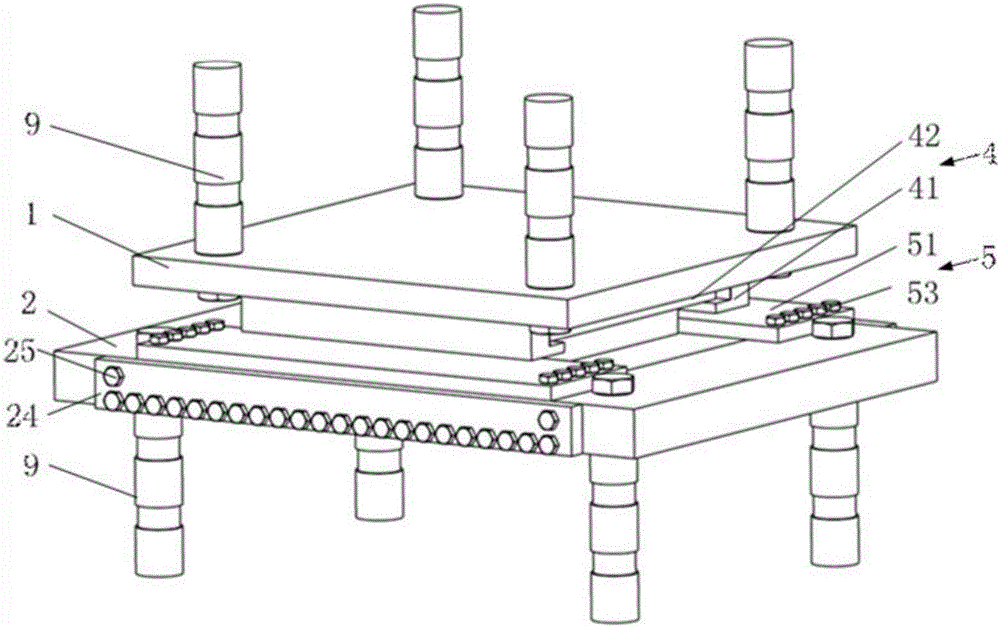

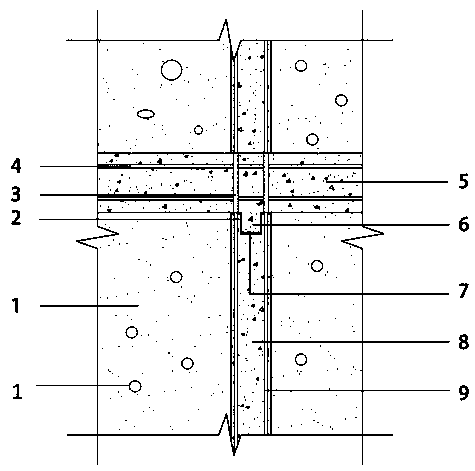

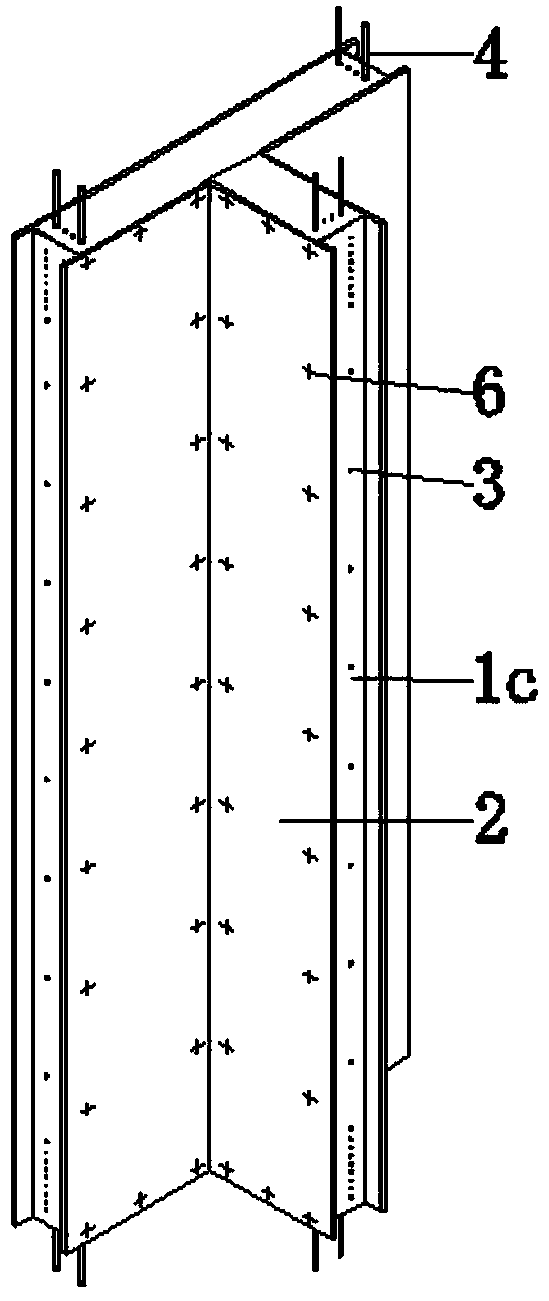

Modular assembly type composite wall and connecting mode thereof

The invention discloses a modular assembly type composite wall and a connecting mode thereof. A foamed cement core material is filled in the middle of a cold-formed thin-wall type steel framework; a self-leveling cement surface layer is bonded with the foamed cement core layer, and the self-leveling cement surface layer and the cold-formed thin-wall type steel framework are connected by a self-tapping bolt; and the cold-formed thin-wall type steel framework, the foamed cement core material and the self-leveling cement surface layer are connected to form the modular assembly type composite wall. Adjacent two modular assembly type composite walls are horizontally connected by a connector among wall modules. The modular assembly type composite wall and floor modules are vertically connected by a connector among the floor modules. The modular assembly type composite wall disclosed by the invention is a wall which is integrated with structural bearing, thermal insulation and decoration, is high in degree of integration and assembly, low in material cost, cheap in overall price and simple in configuration, and greatly saves labor cost.

Owner:BEIJING UNIV OF TECH

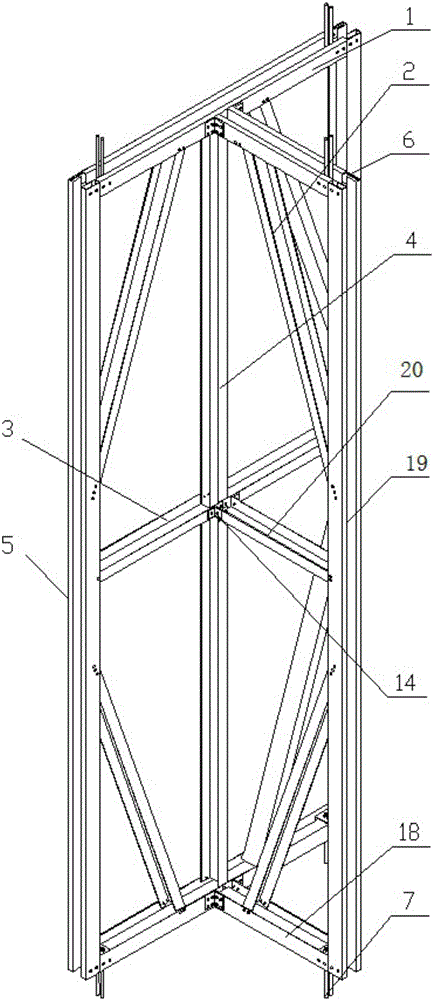

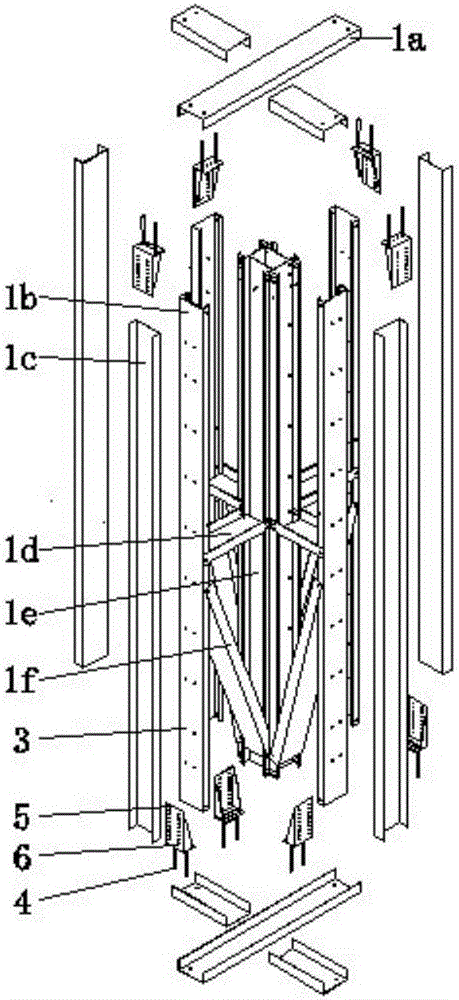

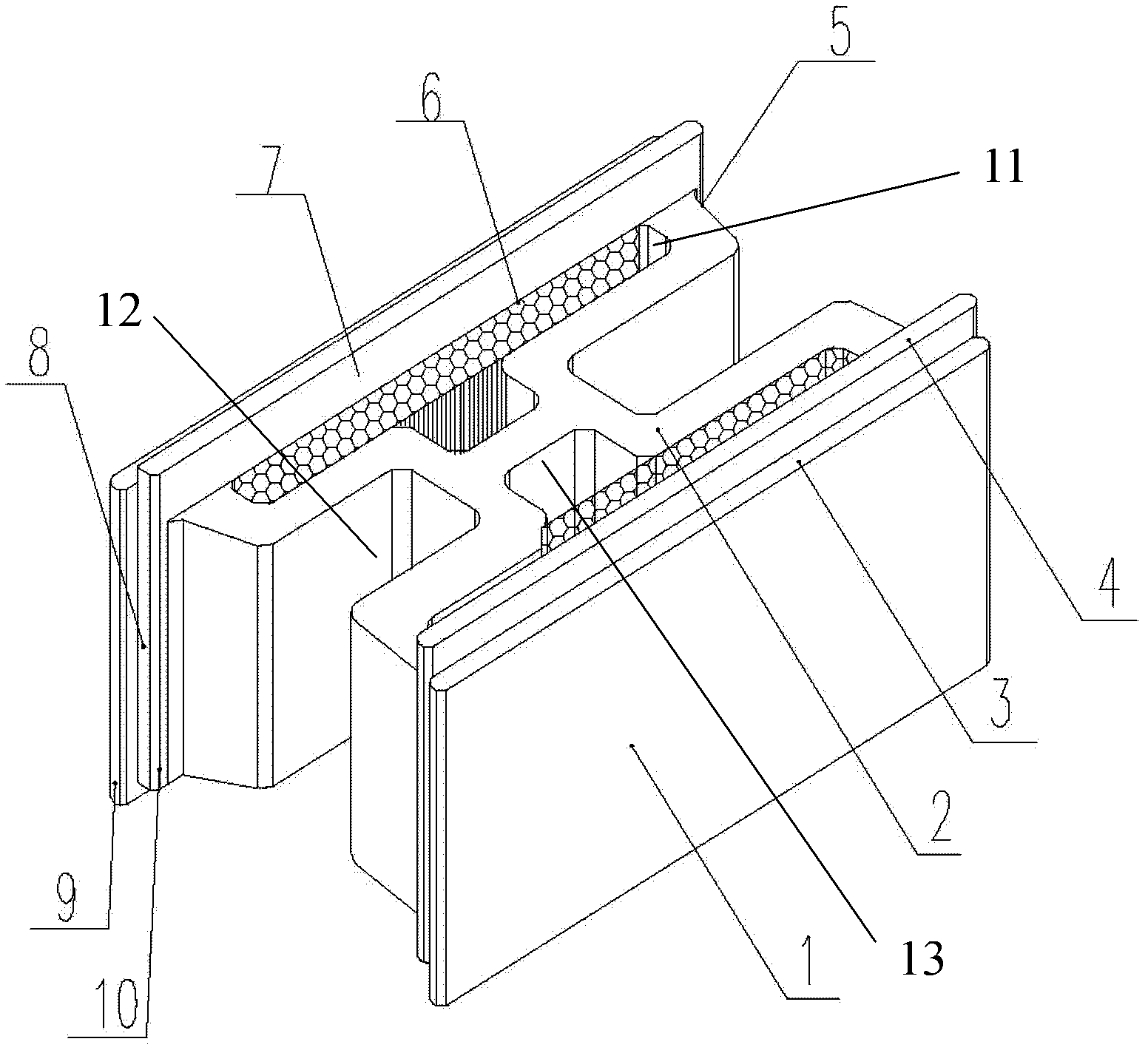

Light steel assembly type composite wall board, light steel framework, manufacturing method and installing method thereof

InactiveCN105804240AAvoid instabilityImprove stabilityWallsBuilding material handlingIsolation effectInsulation layer

The invention provides a light steel assembly type composite wall board, a light steel framework, a manufacturing method and an installing method thereof. An outer side frame of the light steel framework uses M-shaped steel; the inside uses C-shaped steel; the outer side frame is connected by C-shaped connecting elements through tapping screws; the vertical and horizontal bearing force is obviously improved; the anti-shearing and load bearing effects are good; a sandwich heat simulation layer is filled into the light steel framework; the heat simulation and light steel framework deformation limitation effects are achieved; the outer maintenance plate is attached to the outer side of the light steel framework; a heat insulation layer is arranged between the outer maintenance plate and the light steel framework; the outer maintenance plate and the light steel framework are connected through tapping screws; the horizontal anti-shearing capability, anti-cracking and anti-impacting performance of the wall body are further improved; the factory wet operation is reduced; the cold and heat bridge influence is reduced; the wall board and the main board are fixed through turnbuckles and sleeves; the connection is simple and reliable. The forming components of the composite wall board have the advantages that the types are few; the dead weight is light; steel consumption is low; heat insulation and sound isolation effects are achieved; the assembled degree is high; the fast full prefabricated assembled construction can be realized; the cost is low; the light steel assembly type composite wall board is applicable to low and multi-storey building load bearing wall systems.

Owner:江苏保力自动化科技有限公司

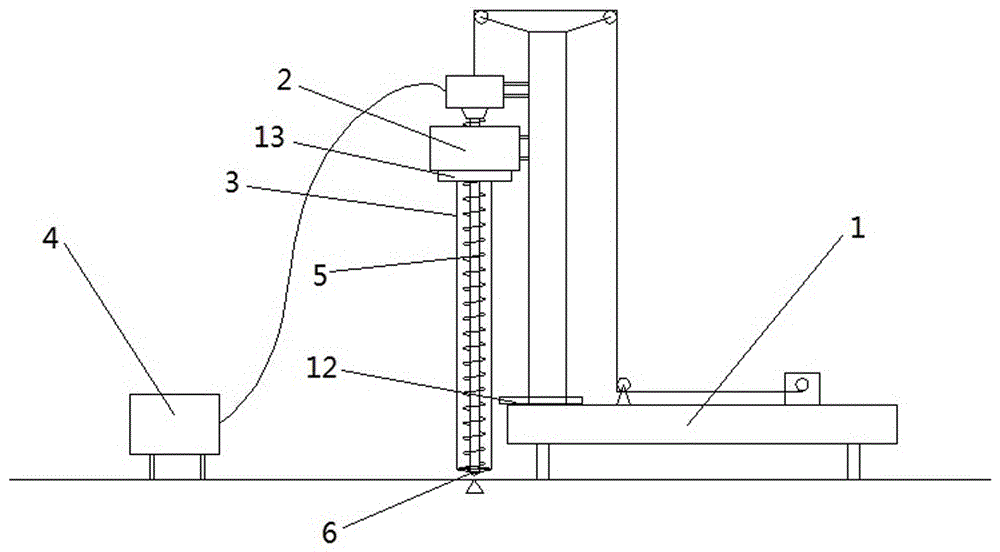

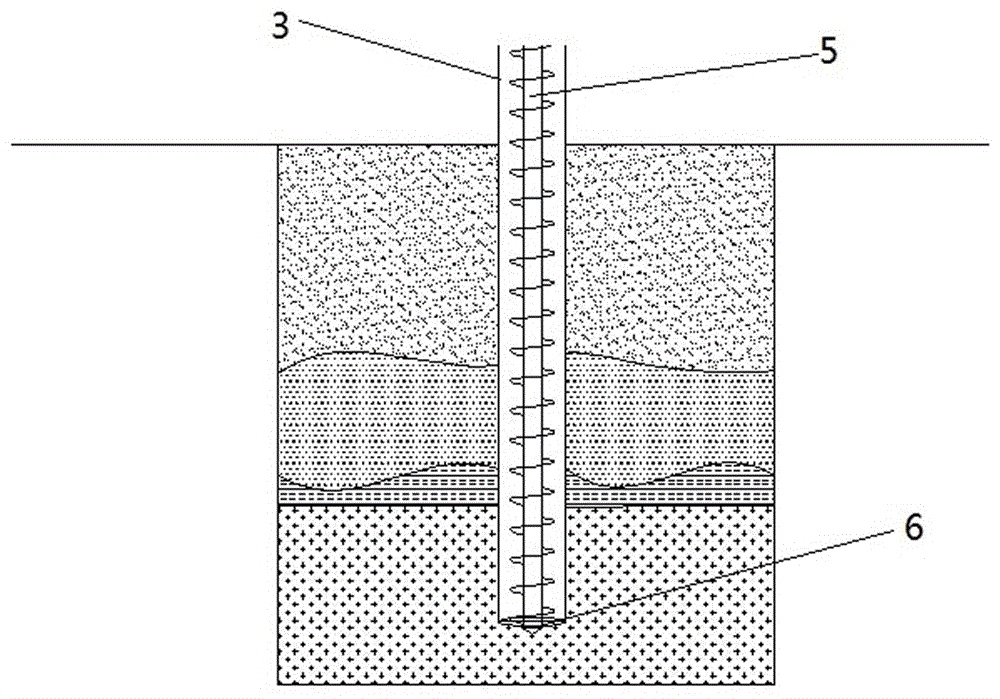

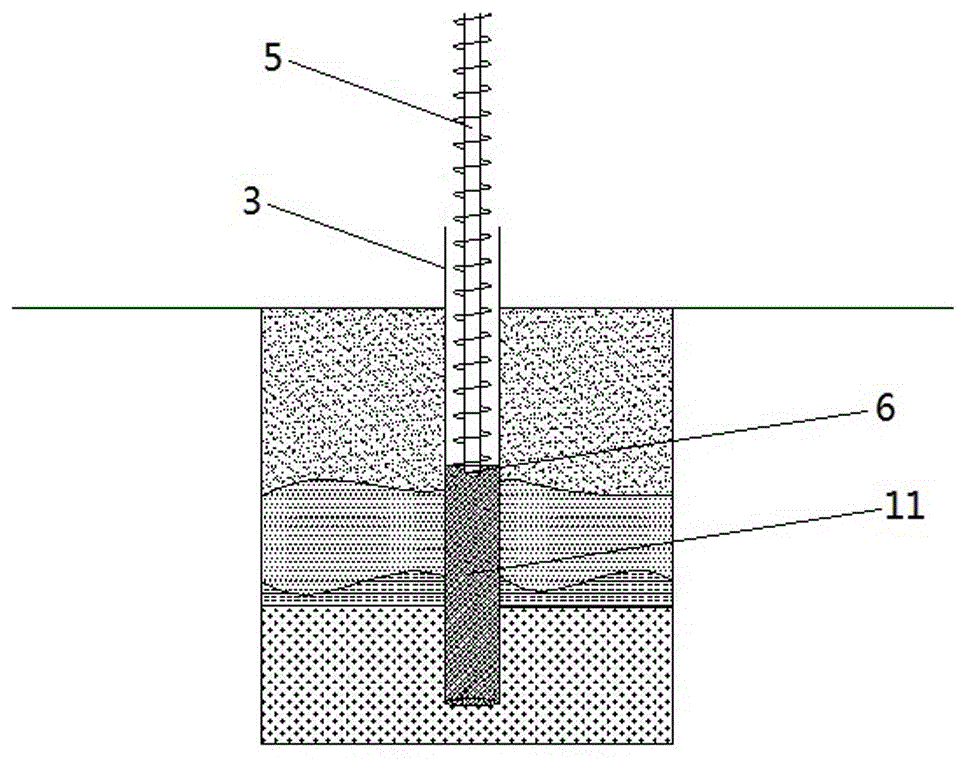

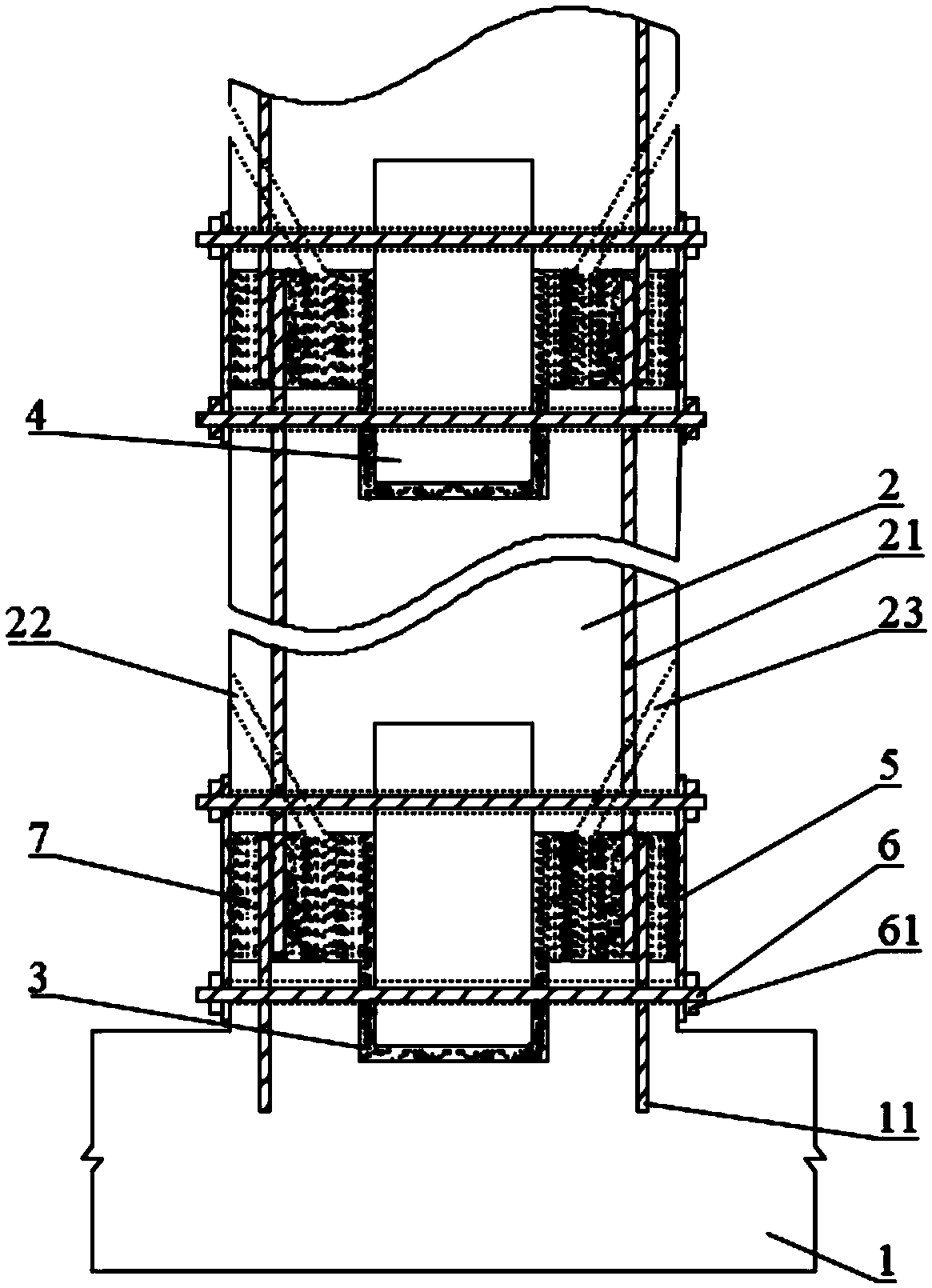

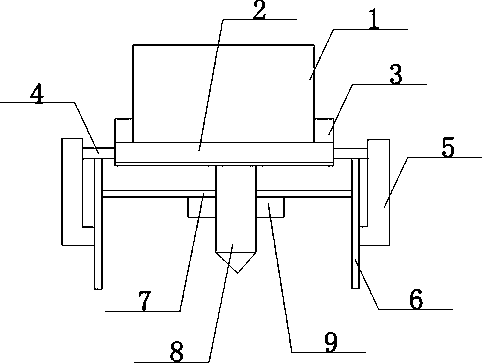

Construction method of medium-hole vibrating casing wall protection type long spiral cast-in-situ bored pile

The invention relates to a construction method of a medium-hole vibrating casing wall protection type long spiral cast-in-situ bored pile. The construction method comprises the steps that surveying and setting-out are conducted for determining a pile position, and a long spiral drilling machine is made to be aligned to the pile position; the long spiral drilling machine is started, and a spiral drill rod and a drill bit are driven to conduct rotary drilling vertically downwards; a medium-hole vibrating hammer is started at the same time to drive a pile casing to follow up vertically downwards to a preset pile end depth; the spiral drill rod idles, so that residue soil at the bottom is discharged; the drill rod is lifted, concrete is poured into a pile hole while the spiral drill rod is lifted, and concrete pouring is stopped after the spiral drill rod is lifted to a preset height; after concrete pouring is completed, the pile casing is left in the pile, the long spiral drilling machine is removed out of the pile hole, and a steel bar insertion device and a steel reinforcement cage are inserted into the poured concrete together by means of a crane while being vibrated; and after the steel reinforcement cage is inserted to a preset depth, the steel rib insertion device is pulled out, the pile casing is completely pulled out, and the cast-in-situ pile is solidified and formed. The construction method of the medium-hole vibrating casing wall protection type long spiral cast-in-situ bored pile has the advantages that the quality of the cast-in-site pile is high, construction is safe, the cost is low, the speed is high, environmental friendliness is achieved, and results are practical.

Owner:HENAN JINYUAN FOUND ENG CO LTD

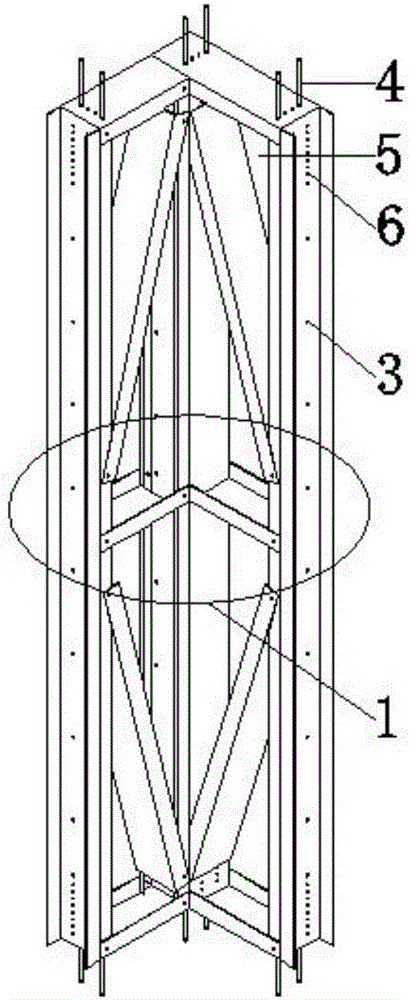

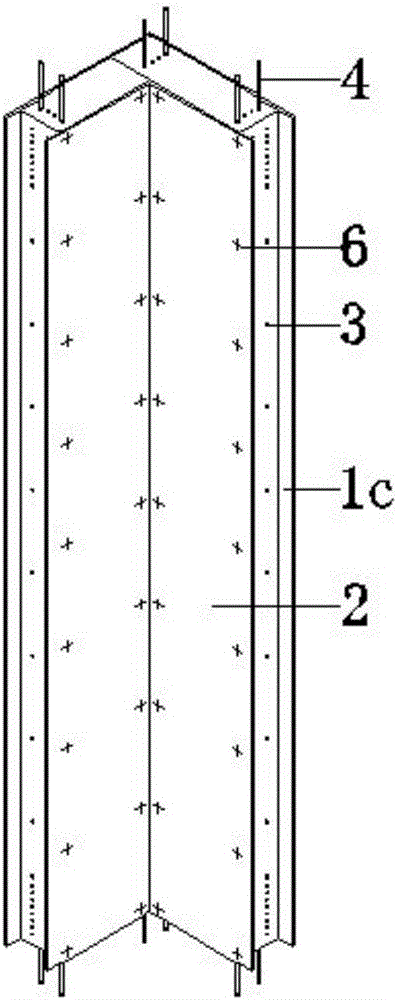

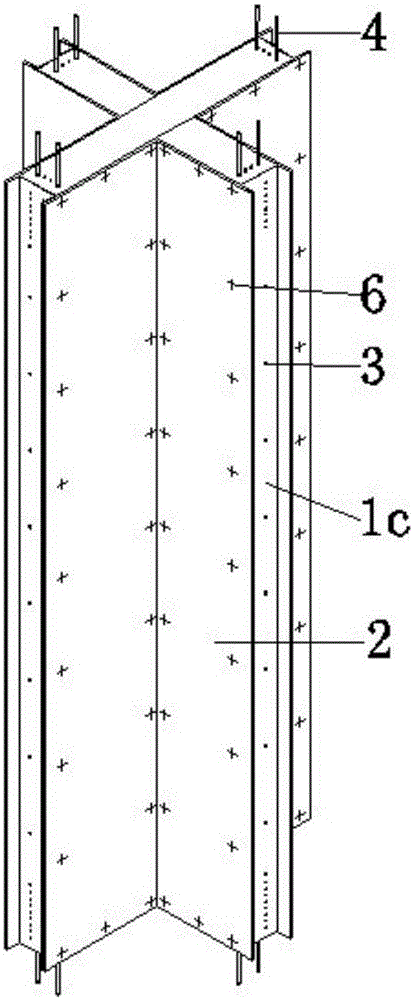

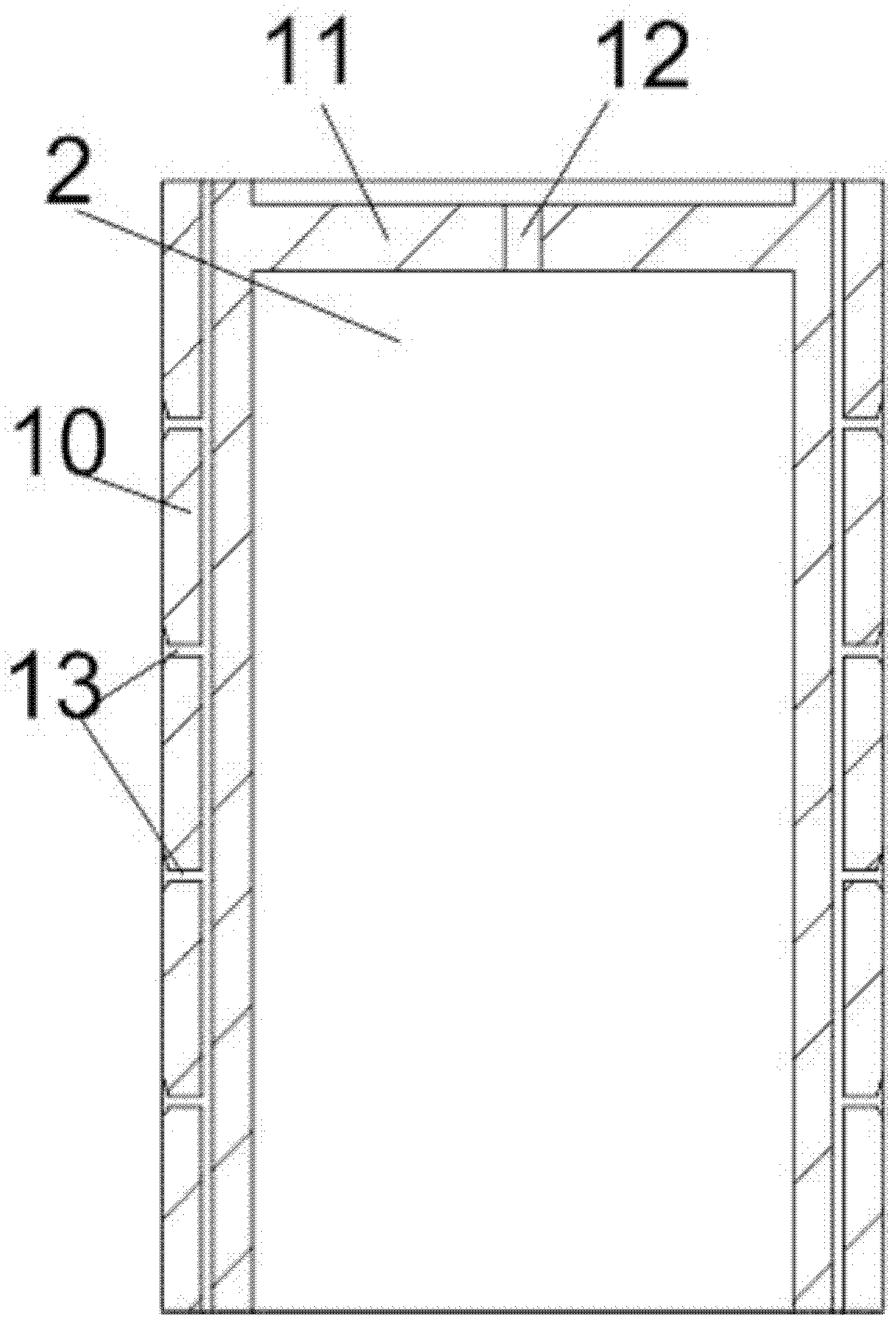

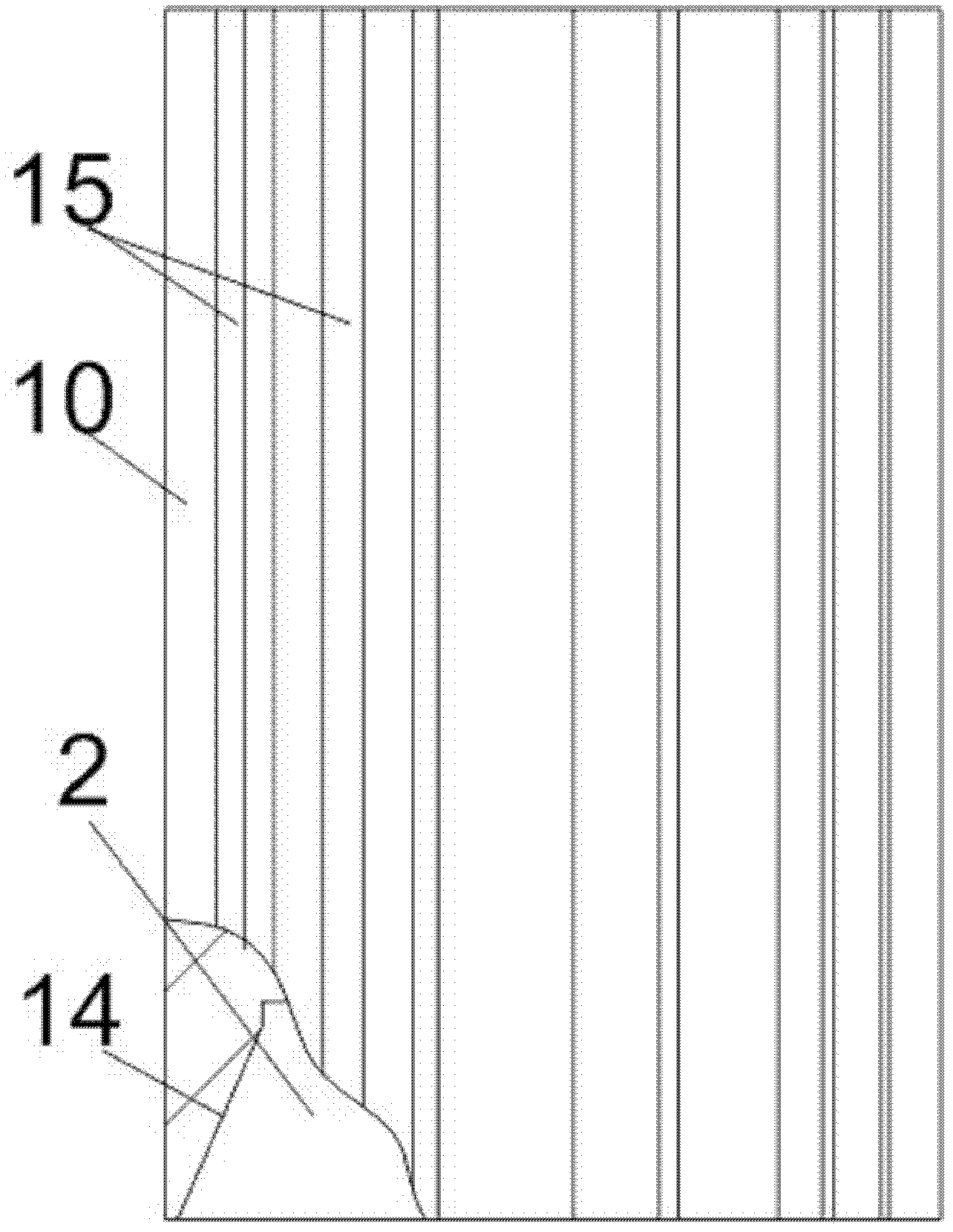

Modular assembly type L-shaped cold-formed thin-walled steel combined wall and connecting mode thereof

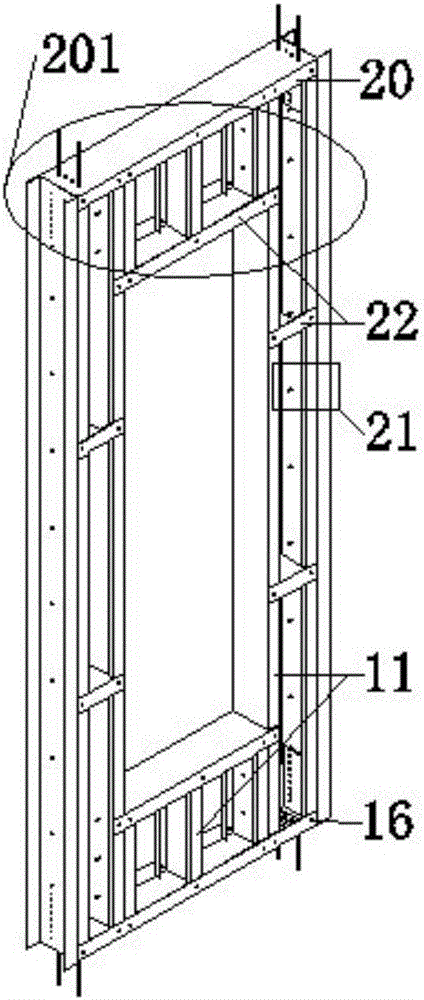

The invention discloses a modular assembly type L-shaped cold-formed thin-walled steel combined wall and a connecting mode of the modular assembly type L-shaped cold-formed thin-walled steel combined wall. The modular assembly type L-shaped cold-formed thin-walled steel combined wall is characterized in that the middle part of an L-shaped cold-formed thin-walled steel framework is filled with a heat preservation layer; a wall panel and the L-shaped cold-formed thin-walled steel framework are connected through self-tapping screws; the modular assembly type L-shaped cold-formed thin-walled steel combined wall is formed by the L-shaped cold-formed thin-walled steel framework, the heat preservation layer and the wall panel. Horizontal-direction connection between an L-shaped cold-formed thin-walled steel combined wall module and a common wall module is realized through a horizontal connecting mode between wall modules; vertical-direction connection between two adjacent L-shaped cold-formed thin-walled steel combined wall modules which are adjacent in the vertical direction is realized through a vertical connecting mode between the wall modules. The modular assembly type L-shaped cold-formed thin-walled steel combined wall disclosed by the invention integrates structural bearing and heat preservation, and has the advantages of high integration and assembly degrees, applicability in industrial production and the like, and the problems of weak connection between a longitudinal wall and a horizontal wall, high difficulty and difficulty in handling installation seams, and the like can be solved. The connecting mode of the modular assembly type L-shaped cold-formed thin-walled steel combined wall is simple in structure and is quick and efficient, and a large amount of labor cost can be reduced.

Owner:BEIJING UNIV OF TECH

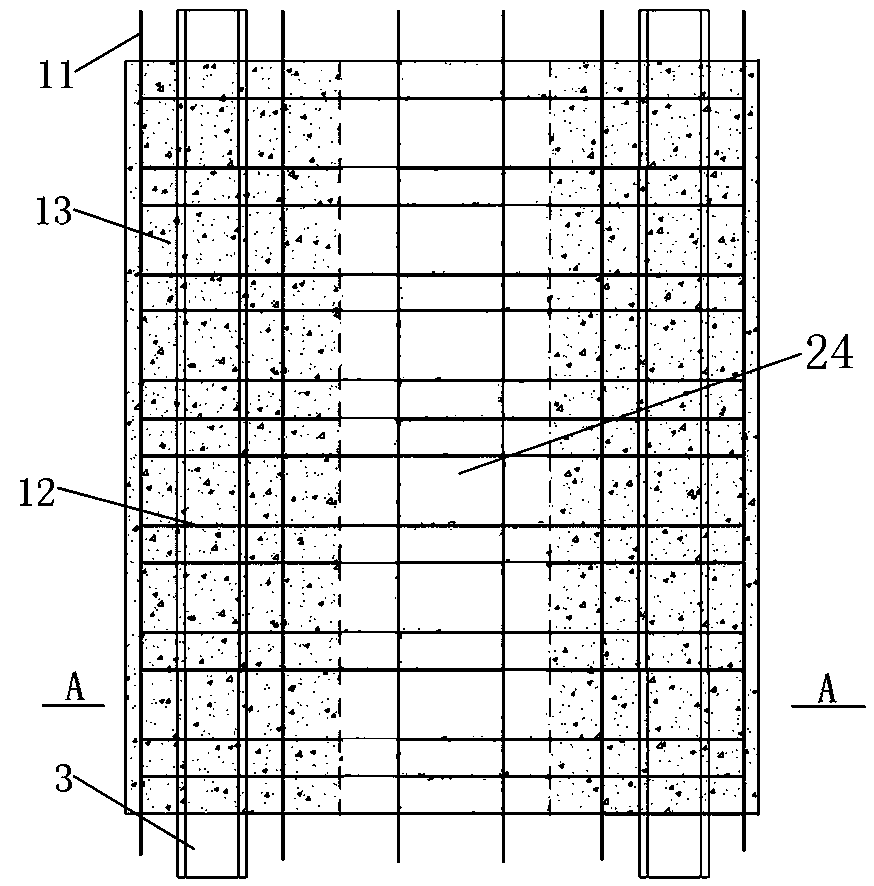

Prefabricated assembly type double-steel pipe concrete shear wall and assembly method thereof

ActiveCN107060140ARedundant elastic-plastic deformation ability is goodRedundant elastoplastic deformation ability fully utilizedWallsBuilding material handlingHigh strength concreteRelative motion

The invention discloses a prefabricated assembly type double-steel pipe concrete shear wall and an assembly method thereof. The double-steel pipe concrete shear wall comprises outer steel pipes buried in the concrete wall and a steel bar net buried inside the concrete wall and formed by interweaving of knot pulling steel bars, vertically-distributed steel bars and horizontally-distributed steel bars; the upper and lower ends of the outer steel pipes partially extend out of the upper portion and the lower portion of the concrete wall; inner steel pipes are sleeved with the outer steel pipes; the inner steel pipes are filled with high-strength concrete columns; and the parts, extending out of the concrete wall, of the outer steel pipes and the inner steel pipes are radially penetrated through and fixed through transverse bolts to prevent axial and circumferential relative motion between the parts, extending out of the concrete wall, of the outer steel pipes and the inner steel pipes. The double-steel pipe concrete shear wall has the advantages of being quick and reliable in vertical connection, simple in construction technology, high in horizontal shear resistance bearing capacity, good in integrity, high in out-plane stability, good in seismic performance and short in construction period, and most components can be subjected to standardized production.

Owner:SOUTH CHINA UNIV OF TECH

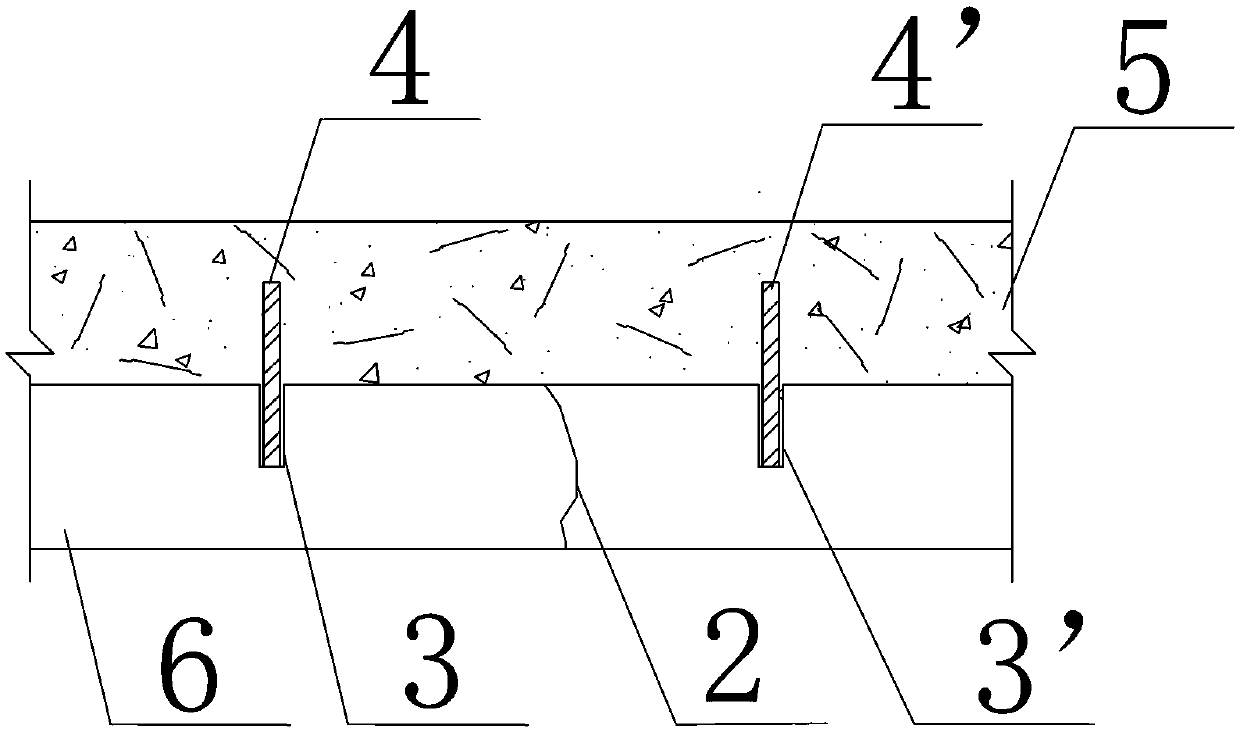

Damaged asphalt pavement repairing structure and seam sealant-pouring repairing method thereof

ActiveCN107604801AInhibit or even prevent extensionIncreased horizontal shear resistanceRoads maintainenceSurface layerNitrile rubber

The invention relates to a damaged asphalt pavement repairing structure and a seam sealant-pouring repairing method thereof. An asphalt pavement surface layer is included, slab-breaking seams are generated in the damaged asphalt pavement surface layer, multiple pairs of embedded steel bar holes are formed in the two sides of each slab-breaking seam in pairs, and the embedded steel bar holes are distributed in the extending direction of the slab-breaking seams. Steel bars are vertically inserted into the embedded steel bar holes, seam filling grooves are formed in the slab-breaking seams, and each seam filling groove is located between the corresponding embedded steel bar holes at the two sides. An asphalt repairing part with a rectangular cross section is arranged in each seam filling groove, the upper surface of each asphalt repairing part is covered with a sealing film, and the spaces between the slab-breaking seams and the asphalt repairing parts are filled with phenolic aldehyde-nitrile rubber adhesives. According to the key points of the technical scheme, in the repairing process, the durability of the repaired pavement is improved, the maintenance cost can be effectively lowered, the construction period is shortened, the slab-breaking seam repairing quality is guaranteed, and thus the road service life is prolonged.

Owner:苏州东振路桥工程有限公司

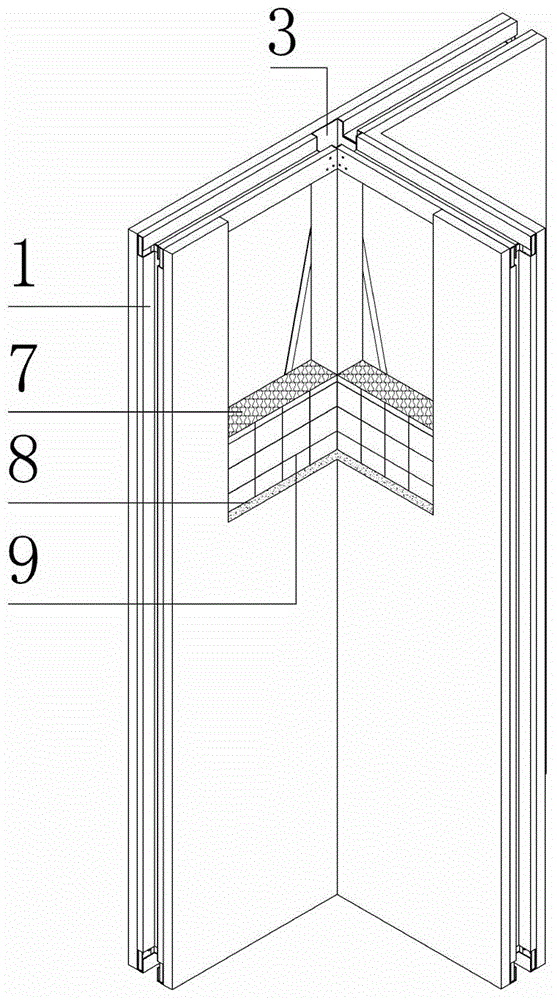

T-shaped light-weight steel frame, T-shaped light-weight steel assembling type compound wall plate and installation method thereof

InactiveCN105804324AImprove insulation effectAvoid pressure instabilityBuilding reinforcementsInsulation layerWhole body

The invention provides a T-shaped light-weight steel frame, a T-shaped light-weight steel assembling type compound wall plate and an installation method thereof. The T-shaped light-weight steel frame is used as a connection part of a wall body corner of an assembling type room in a connecting process, and connection construction and structure problems are solved very well. The T-shaped light-weight steel frame comprises a first framework and a second framework, which are vertical to each other; an outer edge frame is made of M-shaped steel and the interior is made of C-shaped steel; the outer edge frame is connected by a C-shaped connection part through a self-tapping screw; the wall plate is filled into the light-weight steel frame through a sandwiched heat insulation layer and is used for keeping heat and limiting the deformation of the light-weight steel frame; horizontal anti-shearing, anti-cracking and anti-impact performances of the wall body are improved through the light-weight steel frame and an external maintenance plate; vertical connection between the wall body and a main plate is realized through a turn buckle of the outer edge frame of the light-weight steel frame and a sleeve, so that the wall bodies of the upper and lower layers are connected to form a whole body, and the connection reliability of the wall body and the main plate is enhanced. The T-shaped light-weight steel frame is high in assembling degree, is suitable for industrial production, and integrates heat insulation and structure; the connection structure is safe and reliable, is easy to construct, mount and replace and is relatively low in cost.

Owner:江苏保力自动化科技有限公司

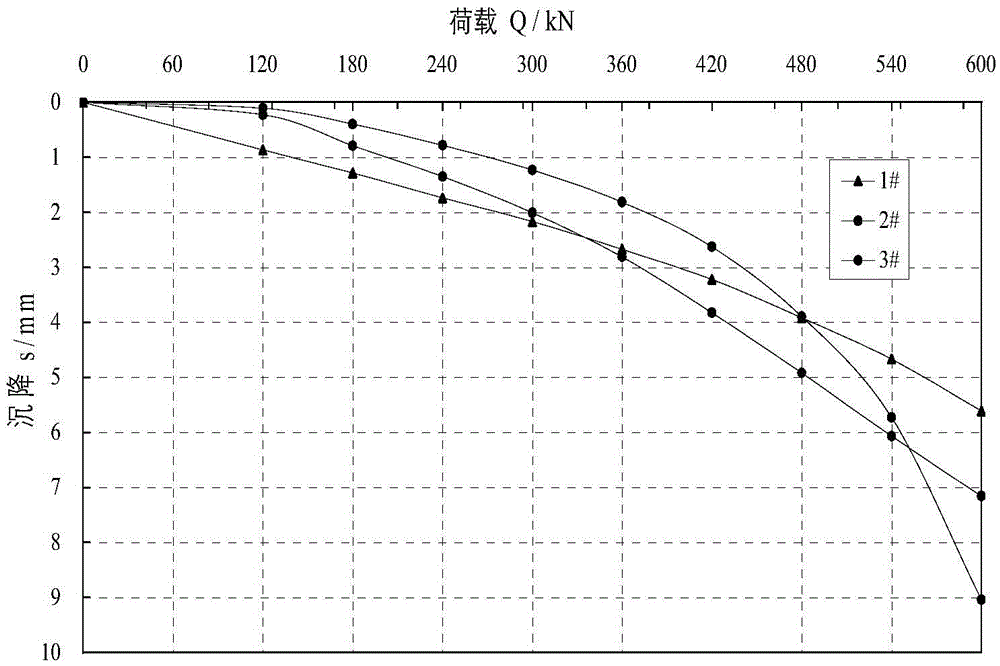

Back-insert steel reinforcement cage cement-flyash-gravel pile and pile-forming method thereof

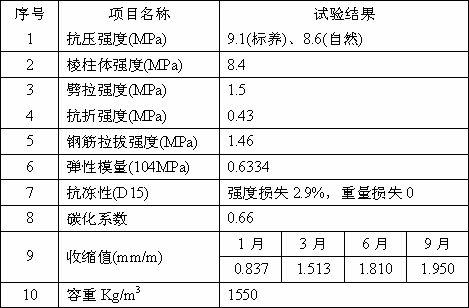

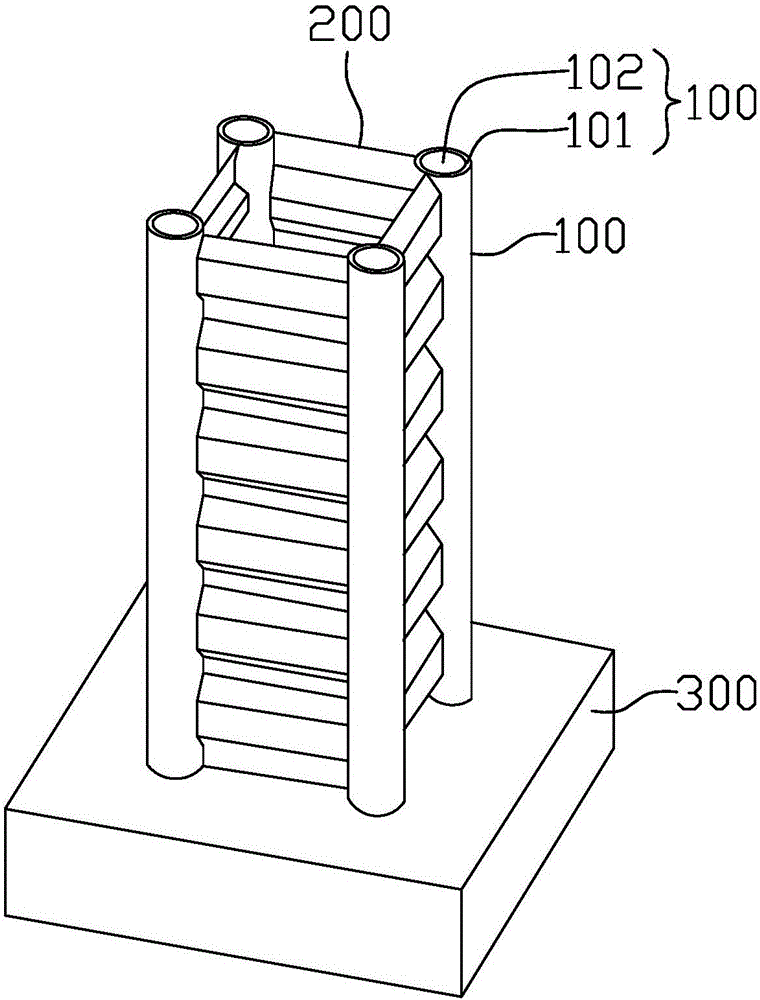

The invention discloses a back-insert steel reinforcement cage cement-flyash-gravel pile. The back-insert steel reinforcement cage cement-flyash-gravel pile comprises a cement-flyash-gravel mixture filled layer, and is characterized by comprising a cage-shaped framework which is mainly formed by fixedly connecting a plurality of main bars with hoopings, and the cement-flyash-gravel mixture filled layer is densely filled in the cage-shaped framework, extends and is covered on the periphery of the cage-shaped framework. According to the back-insert steel reinforcement cage cement-flyash-gravel pile disclosed by the invention, the cage-shaped framework is arranged in the cement-flyash-gravel mixture filled layer, so that the back-insert steel reinforcement cage cement-flyash-gravel pile disclosed by the invention can be used for reinforcement treatment of high-speed railway foundations, such as slope foundations, semi-filled and semi-excavated foundations, mucky soil layers and the like, which are easy to produce greater horizontal force and very strict to control sedimentation after working, greatly enhance the horizontal shearing strength of the cement-flyash-gravel pile composite foundations and ensure that the sedimentation and the stability of the high-speed railway foundations can meet the requirements. In addition, the back-insert steel reinforcement cage cement-flyash-gravel pile disclosed by the invention has obvious social effects and economic benefits. Compared with a small drilled pile (the diameter is 60cm), the cost of the back-insert steel reinforcement cage cement-flyash-gravel pile can be saved by nearly 1 / 3 under the same conditions.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Shear-resistant spherical steel bearing

ActiveCN107178029AEasy to get materialsEasy to processBridge structural detailsStructural engineeringEngineering

The invention provides a shear-resistant spherical steel bearing. The shear-resistant spherical steel bearing comprises an upper bearing plate assembly, a lower bearing plate assembly and a spherical cap liner, wherein the spherical cap liner is arranged between the upper bearing plate assembly and the lower bearing plate assembly in a sliding manner; the lower bearing plate assembly comprises a lower bearing plate, a bottom plate and damping springs; the lower bearing plate is arranged between the bottom plate and the spherical cap liner, and is in sliding fit with the bottom plate; and the damping springs are arranged along the sliding direction of the lower bearing plate. The shear-resistant spherical steel bearing disclosed by the invention is suitable for a large-span upper structure with high horizontal shear rigidity and has the advantage of high safety.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

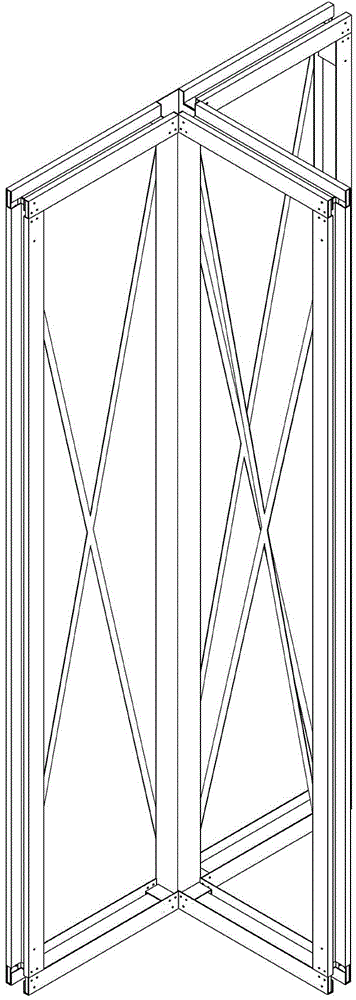

Modularized assembling-type cross-shaped cold-bending thin-wall profile steel combined wall and connection method thereof

InactiveCN105908855AImprove carrying capacityImprove torsion resistanceWallsHeat proofingThermal insulationKeel

The invention provides a modularized assembling-type cross-shaped cold-bending thin-wall profile steel combined wall and a connection method thereof. A cross-shaped cold bending thin-wall steel framework is filled with a thermal insulation layer. A wall face board and a cross-shaped cold bending thin-wall steel keel are connected together through tapping screws. The cross-shaped cold bending thin-wall steel framework, the thermal insulation layer and the wall face board form the modularized assembling-type cross-shaped cold-bending thin-wall profile steel combined wall. The cross-shaped cold-bending thin-wall profile steel combined wall and a common wall module are in horizontal connection realized through an inter-wall-module horizontal connection method. An upper cross-shaped cold-bending thin-wall profile steel combined wall and a lower cross-shaped cold-bending thin-wall profile steel combined wall are in vertical connection realized through an inter-wall-module vertical connection method. The modularized assembling-type cross-shaped cold-bending thin-wall profile steel combined wall integrates functions of structural load bearing and thermal insulation and has advantages of being high in integration and assembly degree and being suitable for industrial production and the like. Problems that field assembly and connection of joints of walls whose four faces are perpendicular to each other is poor in strength, high in difficulty and the mounting joints are difficult to process.

Owner:BEIJING UNIV OF TECH

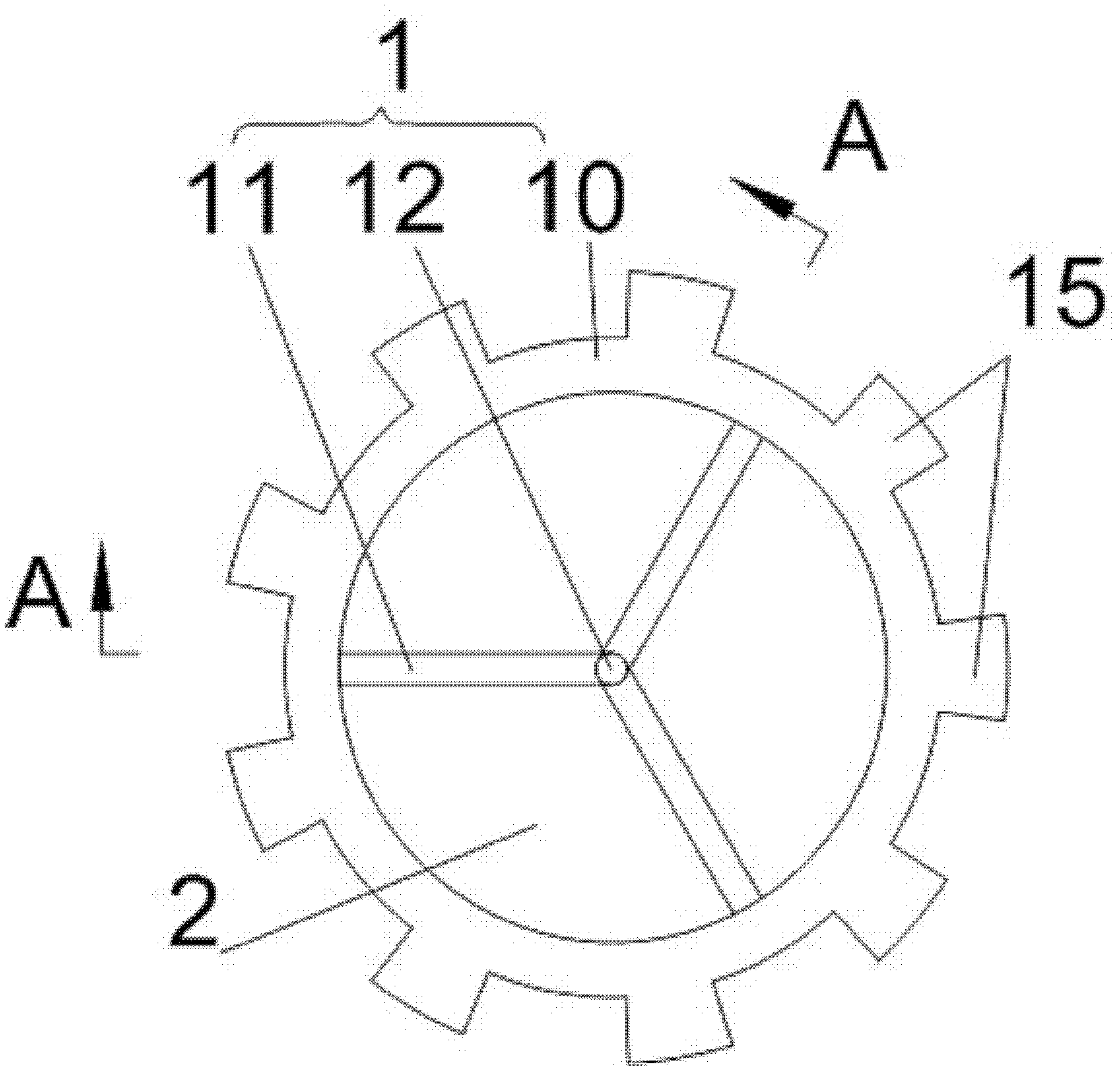

Gear-shaped precast concrete segment pile

ActiveCN102561335AReduce settlementIncreased horizontal shear resistanceBulkheads/pilesPrecast concreteBearing capacity

The invention discloses a gear-shaped precast concrete segment pile comprising a plurality of pile segments, wherein pile segments are sequentially and fixedly connected with each other; the cross-sections of the pile segments are gear-shaped, and the pile segments are in a hollow structure with communicated inner cavities; a soil-taking channel and a guide structure are arranged in the inner cavities of the pile segments, and the inner cavities are also used as the soil-taking channel; the guide structure comprises a branch arm and a guide hole used for allowing a guide rod to pass through; and a plurality of through holes for air or water ejection are also arranged on a side wall of the pile segment. Because of the above structural design, the obtained gear-shaped precast concrete segment pile has the beneficial effects of high single-pile bearing force and the like.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Restoration structure and method for damaged concrete pavement panel

InactiveCN105507111AImprove wear resistanceImprove bending resistanceIn situ pavingsPaving detailsRestoration methodRoad surface

The invention provides a restoration structure and method for a damaged concrete pavement panel. The restoration structure for the damaged concrete pavement panel comprises the concrete pavement panel with the planed surface, multiple pairs of rebar embedding holes, rebars and a steel fiber reinforced concrete cover. The rebar embedding holes are formed in the two sides of a broken slab crack in pairs and distributed in the extension direction of the broken slab crack. The rebars are vertically inserted and fixed into the rebar embedding holes in a binding mode. The steel fiber concrete cover is poured and fixed to the concrete pavement panel. The restoration method for the damaged concrete pavement panel includes the steps that 1, planing is conducted; 2, the multiple pairs of rebar embedding holes are drilled; 3, construction glue is poured into the rebar embedding holes, and the rebars are vertically embedded; 4, steel fiber reinforced concrete is poured to form the steel fiber reinforced concrete cover, and finally the restoration structure for the damaged concrete pavement panel is formed. According to the restoration structure and method for the damaged concrete pavement panel, the service life and the maintenance period of a road are prolonged, and meanwhile the long-term use cost is reduced.

Owner:ZHENGZHOU UNIV

Foundation pit supporting system and construction method thereof

PendingCN107165173AImprove the state of stressHigh material strengthExcavationsBulkheads/pilesSupporting systemPre stress

The invention discloses a foundation pit supporting system comprising a prestressed pipe pile cement soil wall, prestressed balance anchor rods, a ground cover plate and stiffening ribs. The prestressed pipe pile cement soil wall comprises prestressed pipe piles and three-axis cement soil stirring piles, and the prestressed pipe piles are inserted into the three-axis cement soil stirring piles. The prestressed pipe pile cement soil wall and the ground cover plate are in consolidation connection. The stiffening ribs are arranged at the junction corner of the prestressed pipe pile cement soil wall and the ground cover plate. The ends of the prestressed balance anchor rods are anchored in a hard soil layer, and the other ends of the prestressed balance anchor rods are fixed on the ground cover plate in a penetrating mode. The invention further discloses a construction method of the foundation pit supporting system. The foundation pit supporting system is simple in structure, convenient to operate, safe, reliable and low in cost, especially suitable for foundation pit supporting of an urban central zone which is narrow in construction space, close to an existing building (structure) and high in practicability.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

Metal connector for improving integrity of rammed-earth wall structure and rammed-earth wall structure

InactiveCN106677381AIncreased horizontal shear resistanceImprove shear resistanceWallsArray data structureEngineering

The invention provides a metal connector for improving the integrity of a rammed-earth wall structure and the rammed-earth wall structure. The metal connector comprises a plurality of groups of shear resisting units, wherein each group of shear resisting unit is composed of a steel plate, multiple upper-portion shear resisting steel columns and multiple lower-portion shear resisting steel columns, the multiple groups of shear resisting units form an integral connecting structure through connecting steel pieces welded among the steel plates and are L-shaped or T-shaped in the horizontal direction. The rammed-earth wall structure comprises a rammed-earth wall body, wherein the T-shaped metal connector is arranged at the T-shaped longitudinal and transverse wall connecting position of the rammed-earth wall body and located at the layering position of a rammed-earth layer. The upper-portion shear resisting steel columns on each metal connector are inserted into upper-layer rammed earth at the corresponding position, and the lower-portion shear resisting steel columns on each metal connector are inserted into lower-layer rammed earth. The metal connector can effectively improve the integrity and horizonal shear resistance of the rammed-earth wall structure, and the rammed-earth wall structure has good integrity and shear resistance.

Owner:TIANJIN CHENGJIAN UNIV

a socket-plug type structure of cast-in-situ UHPC material for prefabricating and assembling bridge piers

PendingCN109024249AImprove stabilityIncreased horizontal shear resistanceBridge structural detailsClimate change adaptationRebarBuilding construction

The invention relates to the technical field of bridge construction, in particular to a prefabricated bridge pier with cast-in-situ UHPC material socket-plug structure, comprising a prefabricated bearing cap and a prefabricated bridge pier, wherein the prefabricated bridge pier is installed on the prefabricated bearing cap, and a plurality of the prefabricated bridge piers are installed in a stackmanner; The top surface of the precast bearing cap and the top surface of the precast bridge pier are provided with tenons and grooves, the bottom of the precast bridge pier is provided with tenons and grooves, and the dimensions of the tenons and grooves are adapted to the tenons and grooves; Bridge pier reinforcement is embedded in the precast bridge pier. The invention has the beneficial effects that: through the design of the tenon and the tenon groove, when the precast bearing cap and the precast pier are spliced, dangerous accidents such as overturning and the like are prevented, and the stability of the structure in the construction process is increased; The setting of pier reinforcement and capping reinforcement can bind the pier reinforcement and capping reinforcement after inserting the tenon, so that the whole structure of the pier is more stable during the installation process.

Owner:FUJIAN UNIV OF TECH

Semi-assembled composite bridge pier and construction method thereof

PendingCN110685215AImprove corrosion resistanceStrong self-resetting abilityBridge structural detailsBridge erection/assemblyBridge engineeringArchitectural engineering

The invention belongs to the field of bridge engineering, and particularly relates to a semi-assembled composite bridge pier and a construction method thereof. The semi-assembled composite bridge piercomprises a prefabricated bearing platform and a plurality of prefabricated bridge pier segments, wherein the contact surfaces between the prefabricated bridge pier segments are connected by adoptingultra-high performance mortar; the ultra-high performance mortar has better corrosion resistance than mortar used in a traditional prefabricated assembly bridge pier joint; and the ultra-high-performance concrete inside a hollow steel tube of the bridge pier penetrates the entire bridge pier structure, so that the composite bridge pier has relatively strong deformation ability, good ductility andstrong self-resetting ability, and the residual deformation of the bridge pier under the action of earthquake can be reduced. According to the technical scheme, the semi-assembled composite bridge pier is convenient and fast to construct and has relatively high construction degree of safety.

Owner:FUJIAN UNIV OF TECH +1

Anti-seismic foundation

InactiveCN104164894AFirmly connectedDelay uneven settlementProtective foundationReinforced concreteEngineering

The invention discloses an anti-seismic foundation. The anti-seismic foundation comprises a limiting wall. The limiting wall is arranged on a pile group foundation body. The limiting wall and the pile group foundation body are fixedly connected through cement mortal. Baffles are installed on the two sides of the limiting wall. The outer side face of each baffle and the two ends of the pile group foundation body are located on the same horizontal line. Connecting pieces are arranged at the two ends of the pile group foundation body. Each connecting piece penetrates through the pile group foundation body transversely. A cast-in-place pile is arranged on each connecting piece. Each cast-in-place pile is of an L-shaped structure. Each connecting piece transversely penetrates through the end, on the long edge, of the corresponding cast-in-place pile. A jet grouting pile is arranged between the end, on the short edge, of each cast-in-place pile and the corresponding connecting piece. A reinforced concrete base is transversely connected between the two jet grouting piles. A main pile column is vertically installed between the reinforced concrete base and the pile group foundation body. According to the anti-seismic foundation, the better anti-seismic function can be achieved, connection is reliable, the overall connection performance is high, the vertical bearing capacity and the horizontal shearing resistance are both high, a pile body is not prone to damage, the stratum adaptability is high, differential settlement of the foundation can be reduced, and the anti-seismic foundation can be better used.

Owner:CHENGDU LYUDI TECH

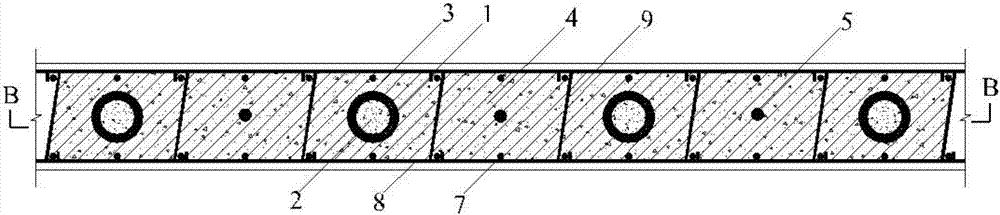

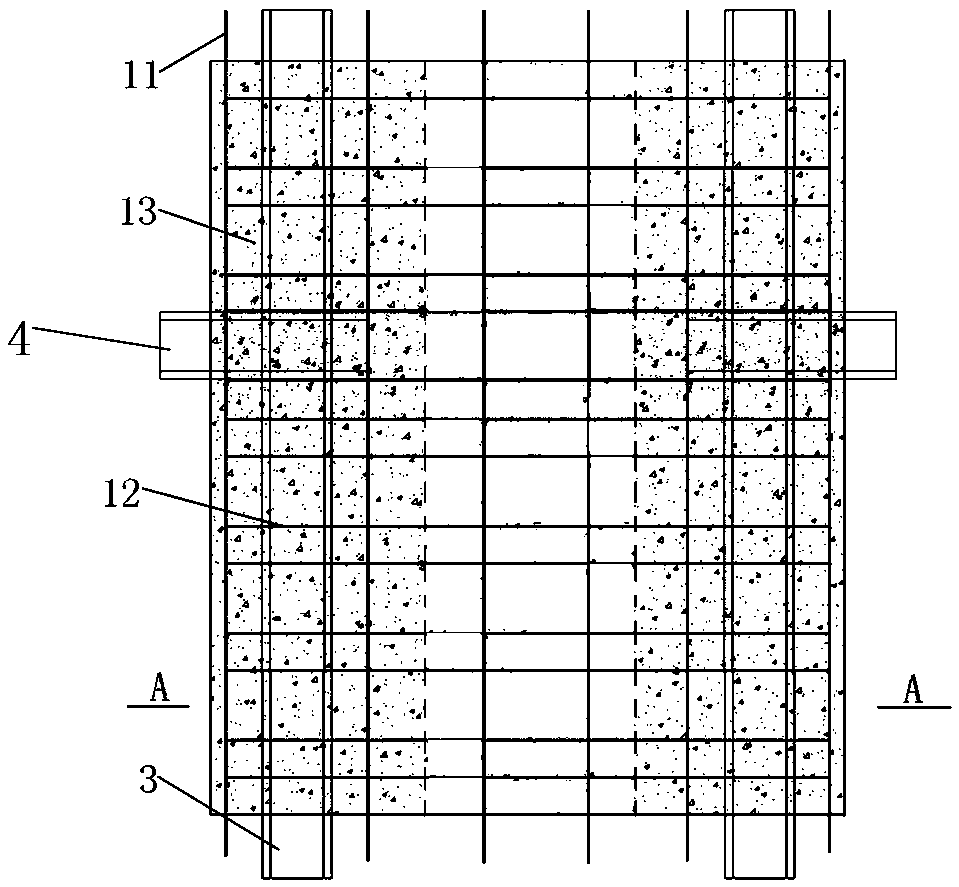

Double-plate-connected super-high-rise assembled building

InactiveCN106065662AIncreased horizontal shear resistanceReduce horizontal driftBuilding constructionsHigh riseHorizontal shear

The invention relates to a double-plate-connected super-high-rise assembled building, and belongs to the field of building construction. The double-plate-connected super-high-rise assembled building comprises wall shingles, a floor plate and a pillar body which are mutually connected to form a super-high-rise structure, wherein the side end surfaces of the wall shingles are connected with the pillar body; the side end surface of the floor plate is connected with the side end surfaces of the wall shingles; double-row steel plates containing a plurality of round holes are arranged on the side end surfaces of the wall shingles and the floor plate; a double-row steel plate containing a plurality of round holes is arranged on at least one side of the pillar body in the height direction; the steel plates are fixedly connected through bolts; nuts are welded at the round holes, in the opposite surfaces, in the double-row steel plates. Through the double-plate-connected manner of the pillar-shaped structure and precast slabs, a shear wall structure with a huge lattice column manner can be formed, the horizontal shear capacity of the super-high-rise assembled building can be improved, the horizontal displacement of the super-high-rise assembled building can be reduced, and the characteristics of convenience and quickness in mounting and high construction speed can be achieved; in addition, all assembly parts can be disassembled and recycled for many times, and the environmental protection and the energy conservation are achieved.

Owner:浙江越宫钢结构有限公司

A modular assembled L-shaped cold-formed thin-walled steel composite wall and its connection method

The invention discloses a modular assembly type L-shaped cold-formed thin-walled steel combined wall and a connecting mode of the modular assembly type L-shaped cold-formed thin-walled steel combined wall. The modular assembly type L-shaped cold-formed thin-walled steel combined wall is characterized in that the middle part of an L-shaped cold-formed thin-walled steel framework is filled with a heat preservation layer; a wall panel and the L-shaped cold-formed thin-walled steel framework are connected through self-tapping screws; the modular assembly type L-shaped cold-formed thin-walled steel combined wall is formed by the L-shaped cold-formed thin-walled steel framework, the heat preservation layer and the wall panel. Horizontal-direction connection between an L-shaped cold-formed thin-walled steel combined wall module and a common wall module is realized through a horizontal connecting mode between wall modules; vertical-direction connection between two adjacent L-shaped cold-formed thin-walled steel combined wall modules which are adjacent in the vertical direction is realized through a vertical connecting mode between the wall modules. The modular assembly type L-shaped cold-formed thin-walled steel combined wall disclosed by the invention integrates structural bearing and heat preservation, and has the advantages of high integration and assembly degrees, applicability in industrial production and the like, and the problems of weak connection between a longitudinal wall and a horizontal wall, high difficulty and difficulty in handling installation seams, and the like can be solved. The connecting mode of the modular assembly type L-shaped cold-formed thin-walled steel combined wall is simple in structure and is quick and efficient, and a large amount of labor cost can be reduced.

Owner:BEIJING UNIV OF TECH

Slurry for grouting for interlocking concrete block

InactiveCN102603242AImprove mechanical performanceIncreased horizontal shear resistanceLand resourcesSlag

The invention relates to the cement field containing slag, in particular to slurry for grouting an interlocking concrete block. The slurry for grouting the interlocking concrete block comprises 10-25 parts of concrete by weight and is characterized in that the slurry also comprises 50-70 parts of fine aggregate and 15-40 parts of mineral blend by weight, wherein the fine aggregate is obtained by mixing coal slag and aggregate chips uniformly according to any ratio; and the mineral blend is obtained by mixing coal ash and slag micro-powders uniformly according to any ratio. According to the slurry for grouting the interlocking concrete block, labor intensity is relieved; working efficiency is improved; construction cost is reduced; and the land resource is saved.

Owner:上海钟宏科技发展有限公司

Shock absorption combined type pier

InactiveCN106638279AImproved bending stabilityIncreased horizontal shear resistanceBridge structural detailsBridge materialsAxial pressureEnvironmentally friendly

The invention relates to the field of bridge buildings, and discloses a shock absorption combined type pier. The shock absorption combined type pier comprises pillar legs and corrugated steel sheets. The number of the pillar legs is at least two, and the adjacent pillar legs are connected into a whole through the corrugated steel sheets to form a box-shaped pier body. The corrugation direction of the corrugated steel sheets is the axial direction of the pier body. The pillar legs are used for bearing axial pressure and bending moment, the corrugated steel sheets are used for bearing horizontal shearing force, the press bending stability of the pillar legs and the overall horizontal anti-shearing performance and deformation capacity of the pier are improved in a matched mode, and the shock absorption combined type pier is suitable for pier deign of various heights. The corrugated steel sheets and the pillar legs have clear difference responsibilities, and the use efficiency of materials can be improved. The pier body is hollow, the use amount of concrete can be reduced, and the self-weight of the structure is reduced. The shock absorption combined type pier has the advantages of being convenient and fast to construct, saving in energy, environmentally friendly, good in economy and the like.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST +1

Gear-shaped precast concrete segment pile

ActiveCN102561335BReduce settlementIncreased horizontal shear resistanceBulkheads/pilesPrecast concreteBearing capacity

The invention discloses a gear-shaped precast concrete segment pile comprising a plurality of pile segments, wherein pile segments are sequentially and fixedly connected with each other; the cross-sections of the pile segments are gear-shaped, and the pile segments are in a hollow structure with communicated inner cavities; a soil-taking channel and a guide structure are arranged in the inner cavities of the pile segments, and the inner cavities are also used as the soil-taking channel; the guide structure comprises a branch arm and a guide hole used for allowing a guide rod to pass through; and a plurality of through holes for air or water ejection are also arranged on a side wall of the pile segment. Because of the above structural design, the obtained gear-shaped precast concrete segment pile has the beneficial effects of high single-pile bearing force and the like.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Concrete self-insulation mould-locking block

InactiveCN102644355ANo pollutionImprove mechanical performanceConstruction materialSolid componentSolid mass

The invention relates to a concrete self-insulation mould-locking block which comprises a solid component. Two first thermal insulation grooves are arranged in parallel in the solid component; the first thermal insulation grooves vertically run through the solid component; two second thermal insulation grooves are respectively arranged in two end faces of the solid component; the second thermal insulation grooves are positioned between the two first thermal insulation grooves; bayonet steps are respectively arranged in the top surface, the bottom surface, the left end face and the right end face; the shapes of the bayonet steps in the top surface and the bottom surface are matched in a yin and yang mode; the shapes of the bayonet steps in the left end face and the right end face are matched in a yin and yang mode; heat insulating materials are arranged in the first thermal insulation grooves and the second thermal insulation grooves; a vertically through placing hole is arranged at the middle part of the solid component; and a plurality of solid components are arranged along the horizontal direction and are overlapped along the vertical direction to form a wall body. According to the invention, the concrete self-insulation mould-locking block does not occupy a cultivated land, has low energy consumption and does not pollute the environment; and the wall body constructed by the concrete self-insulation mould-locking blocks is vertical and flat, has anti-seepage property, high integral rigidity, anti-cracking and anti-seismic properties and thermal insulation and has fireproof limit of 4 hours.

Owner:上海市房屋建筑设计院有限公司 +2

Inner-casting reinforced precast concrete wall panel, concrete wall, structure system and construction method

PendingCN110424566AIncreased horizontal shear resistanceReduce secondary pouringWallsCeramic shaping apparatusRebarWall plate

The invention relates to an inner-casting reinforced precast wall panel, a concrete wall, a structure system and a construction method. The wall panel comprises a precast part, wherein the precast part comprises precast part vertical reinforcing steel bars, precast part horizontal reinforcing steel bars and precast part concretes; vertical connecting pieces are arranged at the vertical connectingends of the precast part; vertical shear connectors are partially embedded into the precast part; at least one concrete inner-casting hole passage is arranged at the position, between the vertical connecting pieces, in the precast part; and the concrete inner-casting hole passages are continuously arranged along the vertical direction of the precast part. According to the inner-casting reinforcedprecast wall panel, the concrete wall, the structure system and the construction method provided by the invention, the concrete inner-casting hole passages are arranged, and at least one hole passageis located between the vertical shear connectors, so that the concretes between the vertical shear connectors are ensured to be poured densely, the concrete pouring quality between the vertical shearconnectors at a horizontal connecting area of the precast concrete wall panel is effectively improved, and the construction speed is fast.

Owner:姚攀峰

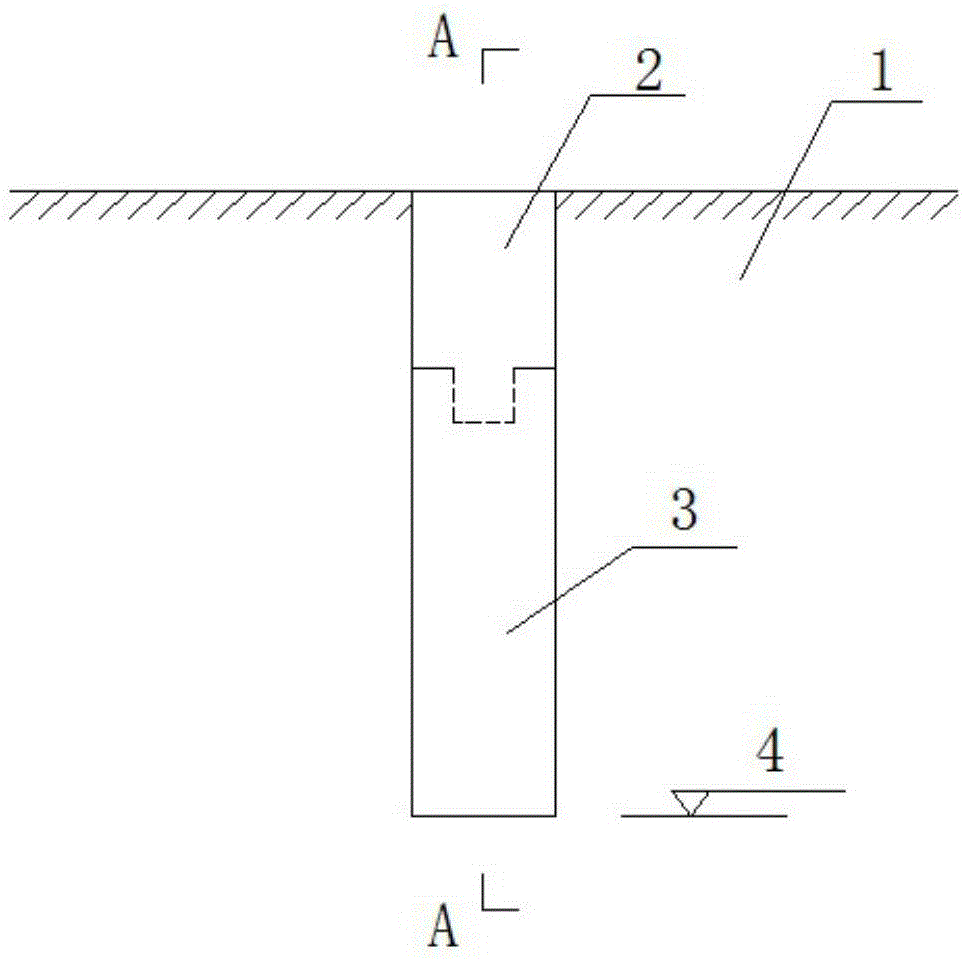

A kind of construction method of cement-soil and concrete composite material pile

The invention discloses a cemented soil and concrete composite pile and a construction method thereof. The construction method comprises the following steps: S1, performing setting out positioning according to a designed pile layout; S2, drilling; S3, inserting a spray pipe into a hole to the predetermined depth of the stratum; S4, performing jet grouting; S5, pulling out the pipe and washing to finish jet grouting pile construction; S6, performing cast-in-place concrete pile pore forming on the soil body above the top part of each jet grouting pile after the jet grouting pile construction is finished for 3-5 days; S7, digging the top part of each jet grouting pile to form a mortise; S8, filling plain concrete to the designed elevation of the top of each pile, vibrating and compacting to finish cemented soil and concrete composite pile construction. The composite pile body disclosed by the invention has the advantages that the connection is reliable, the integrality is strong, the vertical bearing capacity and the horizontal shearing resistance are higher, the pile body is not easy to damage under pressure, the adaptability to the stratum is strong, meanwhile, the construction is easy, the environmental pollution is small, the cost is low, and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

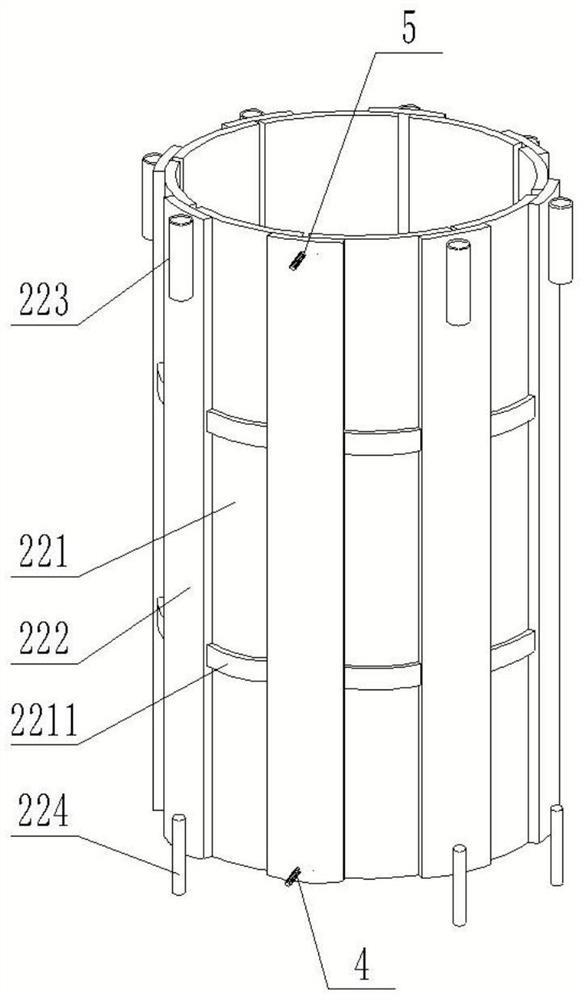

Splicing variable-diameter rigid pile casing compaction pile and construction method thereof

ActiveCN114673148AAvoid twisting and breakingImprove integrityBulkheads/pilesSoil preservationArchitectural engineeringStructural engineering

The compaction pile comprises a pile body and the pile casing arranged outside the pile body in a sleeving mode, the pile casing comprises a bottom cylinder, a middle cylinder and a top cylinder which are coaxially connected in sequence, and bottom cylinder fixing bolts are evenly distributed on the outer wall of the end, close to the middle cylinder, of the bottom cylinder in the annular direction; first middle cylinder fixing bolts are evenly distributed on the outer wall of the end, close to the bottom cylinder, of the middle cylinder in the annular direction, second middle cylinder fixing bolts are evenly distributed on the outer wall of the end, close to the top cylinder, of the middle cylinder in the annular direction, top cylinder fixing bolts are evenly distributed on the outer wall of the end, close to the middle cylinder, of the top cylinder in the annular direction, and the bottom cylinder fixing bolts and the first middle cylinder fixing bolts are connected through first connecting plates. And the middle cylinder second fixing bolt and the top cylinder fixing bolt are connected through a second connecting plate, the bottom cylinder, the middle cylinder and the top cylinder are all composed of a plurality of arc-shaped plates which are spliced with one another, and the purposes of preventing the compaction pile body from being twisted and broken, improving the integrity of the pile body, improving the compaction effect and effectively reducing negative friction can be achieved.

Owner:LANZHOU PETROCHEM COLLEGE OF VOCATIONAL TECH

Construction method for coordinated settlement of ring beam, structural column and rammed earth wall

InactiveCN110847444AAvoid crackingImprove performanceWallsShock proofingReinforced concreteInsulation layer

The invention relates to a construction method for coordinated settlement of a ring beam, a structural column and a rammed earth wall, and belongs to the technical field of construction engineering. The rammed earth wall, the reinforced concrete structural column and the reinforced concrete ring beam are included; 5%-30% of volume-compressible resilient aggregate is added to the rammed earth wall,and the rammed earth wall is tamped; a groove is formed in a column head of the reinforced concrete structural column of the rammed earth wall, a foam cushion layer is placed at the bottom of the groove, and an asphalt insulation layer is painted on the side wall of the groove; when concrete is poured in the reinforced concrete ring beam, the concrete flows into the groove and forms a protrusionon the bottom surface of the reinforced concrete ring beam, and the horizontal displacement of the reinforced concrete ring beam is limited during an earthquake; and sleeves sleeve reinforced sectionsat the overlap positions of reinforced concrete structural column vertical reinforcing steel bars and the reinforced concrete ring beam, and then concrete is poured in the reinforced concrete ring beam. The cracking of the reinforced concrete ring beam caused by the shrinkage of the rammed earth wall can be avoided, the shrinkage deformation of the rammed earth wall can be reduced, and the overall performance of the rammed earth wall can be significantly improved.

Owner:KUNMING UNIV OF SCI & TECH

A modular assembly type T-shaped cold-formed thin-walled steel composite wall connection method

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com