Slurry for grouting for interlocking concrete block

A technology of concrete and formwork, applied in the field of cement containing slag, can solve the problems of not being able to adapt to the sustainable development strategy, occupying large cultivated land resources, and high energy consumption, so as to improve the horizontal shear resistance, improve comprehensive economic benefits and save energy The effect of land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

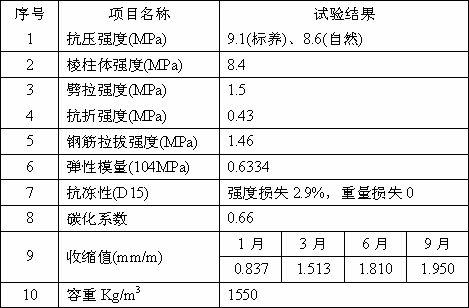

Examples

Embodiment 1

[0028] A kind of grout for grouting concrete formwork blocks, including cement, fine aggregate and mineral admixture, the fine aggregate is uniformly mixed with cinder and stone chips in any ratio, and the mineral admixture is composed of fly ash and slag The micropowder is uniformly mixed in any ratio, and the mass parts of each component are as follows:

[0029] Component Mass parts (%)

[0030] cement 10

[0031] Cinder 5

[0032] Stone Chips 45

[0033] fly ash 4

[0034] Slag fine powder 36

[0035] Among them, the particle size of coal slag in the fine aggregate is not greater than 15mm; the fly ash in the mineral admixture is grade II fly ash, that is, the fineness of fly ash is between 12 and 25; the cement is selected from "GB 175- Ordinary Portland cement with a strength grade of 42.5 as defined in 1999 Portland Cement, Ordinary Portland Cement, that is, the compressive strength and flexural strength of each age of cement are: the 3-day compressive strength is n...

Embodiment 2

[0039] A kind of grout for grouting concrete formwork blocks, including cement, fine aggregate and mineral admixture, the fine aggregate is uniformly mixed with cinder and stone chips in any ratio, and the mineral admixture is composed of fly ash and slag The micropowder is uniformly mixed in any ratio, and the mass parts of each component are as follows:

[0040] Component Mass parts (%)

[0041] cement 17

[0042] Cinder 30

[0043] Stone Chips 30

[0044] fly ash 14

[0045] Slag fine powder 14

[0046] Other components and method of use are all the same as in Example 1.

Embodiment 3

[0048] A kind of grout for grouting concrete formwork blocks, including cement, fine aggregate and mineral admixture, the fine aggregate is uniformly mixed with cinder and stone chips in any ratio, and the mineral admixture is composed of fly ash and slag The micropowder is uniformly mixed in any ratio, and the mass parts of each component are as follows:

[0049] Component Mass parts (%)

[0050] cement 25

[0051] Cinder 63

[0052] stone chips 7

[0053] fly ash 14

[0054] Slag fine powder 1

[0055] Other components and method of use are all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com