Precision milling system for fuselage skin

A fuselage skinning and milling technology, which is applied in the mechanical field, can solve problems such as large size, skewed skin incision, and mismatched joint surface size, so as to improve quality and stability, ensure product accuracy requirements, and ensure accurate manufacturing degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

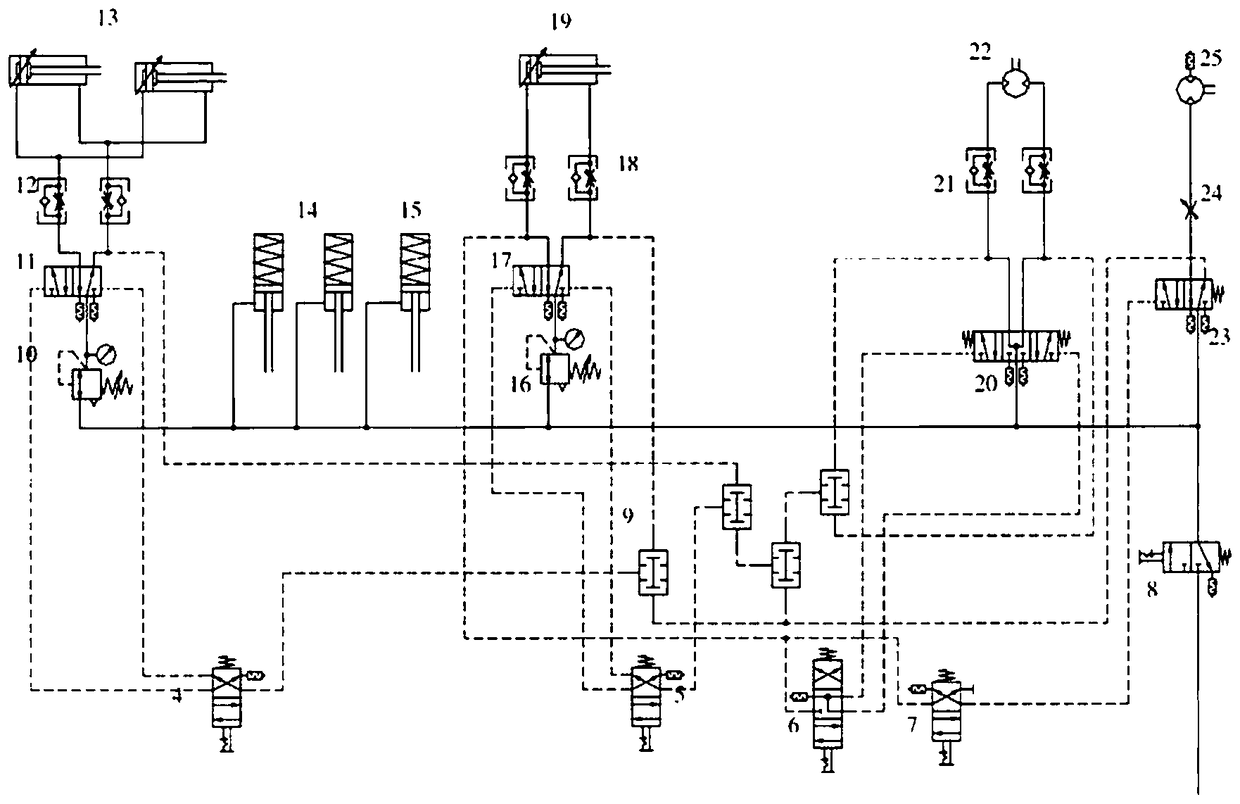

[0014] like figure 1 , The milling system guide rail module and the milling end effector are composed of pneumatic control. The aircraft fuselage passes through the center of the guide rail horizontally, and the milling end effector feeds along the guide rail for one week to complete the skin cutting.

[0015] The guide rail module is placed vertically on the ground through the frame plate, and the whole is circular. It mainly includes double V-shaped guide rails and chain drive guide rails. The cutting end effector performs milling work along the normal direction of the fuselage skin. Ensure that each section of double V-shaped guide rail is within the required range through CNC machining, and at the same time set multiple OPT detection points on the upper surface of each double V-shaped guide rail. During installation, each OPT point is measured one by one by laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com