Novel cigarette production method applying 3D (3-dimensional) printing technology

A technology of 3D printing and manufacturing method, applied in the field of cigarette manufacturing, can solve problems such as high cost, achieve the effects of improving utilization rate, simplifying processing procedures, and ensuring production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

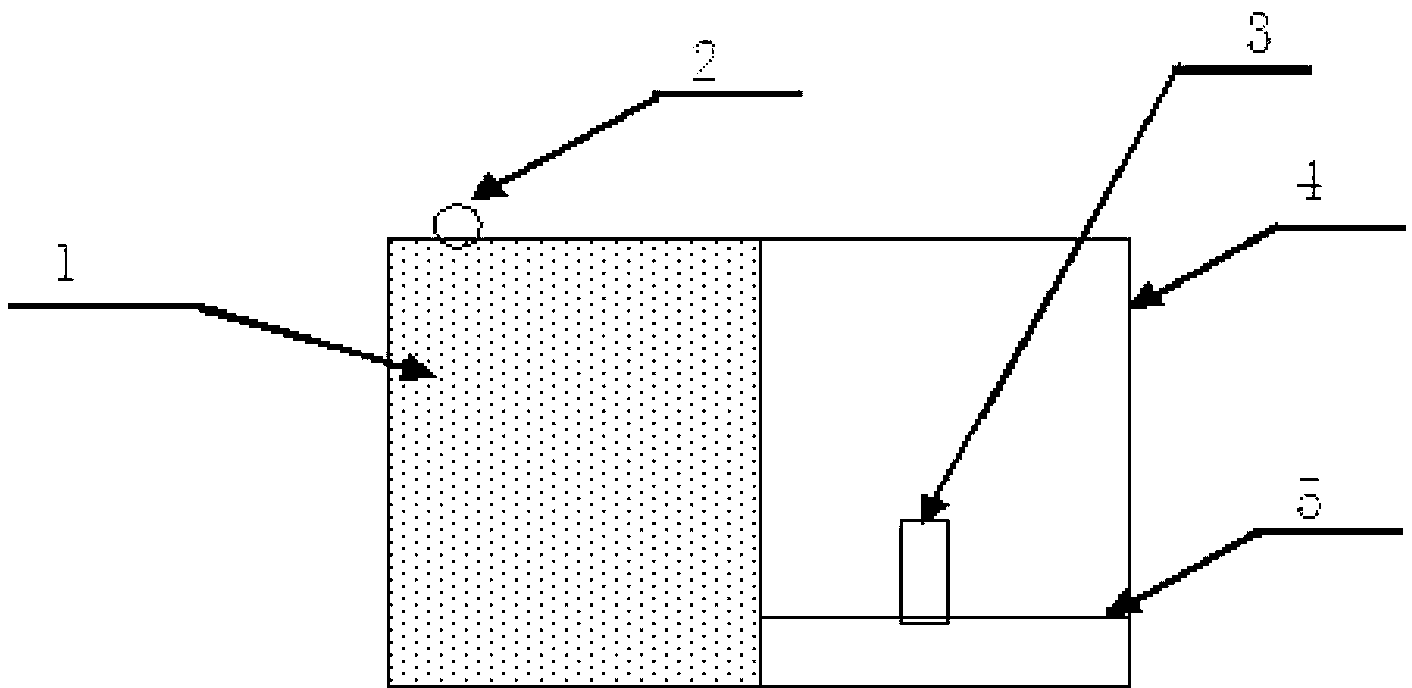

[0023] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

[0024] The invention provides a novel cigarette manufacturing method using 3D printing technology, comprising the following steps:

[0025] a. Grinding the tobacco leaves into powder in a pulverizer and passing through a screen to obtain smoke powder, which is added to the powder supply cylinder 1 of the 3D printer;

[0026] b. Operate the relevant software in the computer to design the shape model of the cigarette stick;

[0027] c. The powder spreading roller 2 on the powder supply cylinder 1 moves from left to right, so that the smoke powder in the powder supply cylinder 1 enters the forming cylinder 4, and forms a layer of smoke powder layer on the forming cylinder platform 5;

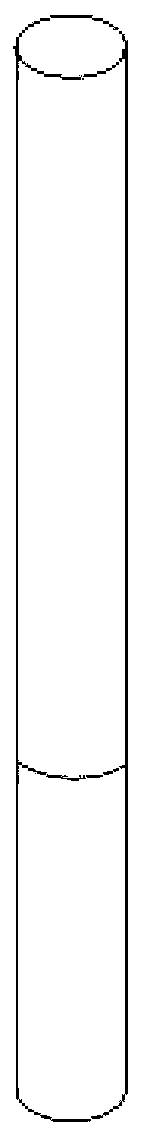

[0028] d. The print head 3 sprays the adhesive on the smoke powder layer on the forming cylinder platform 5. The shape of the attachment position of the adhesive is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com