Tooth crown drill bit locked through two screws in V-shaped positioning groove

A technology of positioning grooves and locking teeth, which is applied in the direction of drill repair, drilling tool accessories, drilling/drilling equipment, etc., can solve the problems of high production cost and complex structure, and achieve low production cost, large contact area, and improved The effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, technical solution of the present invention will be further described:

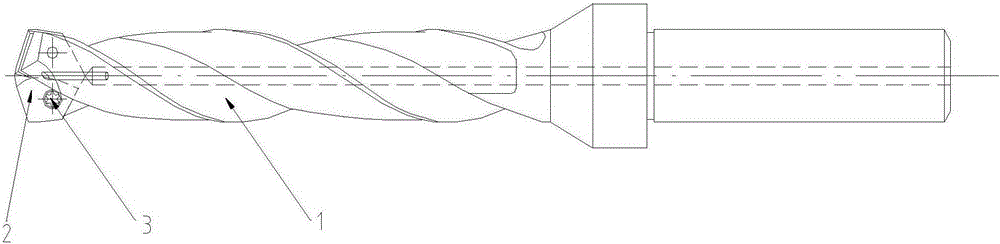

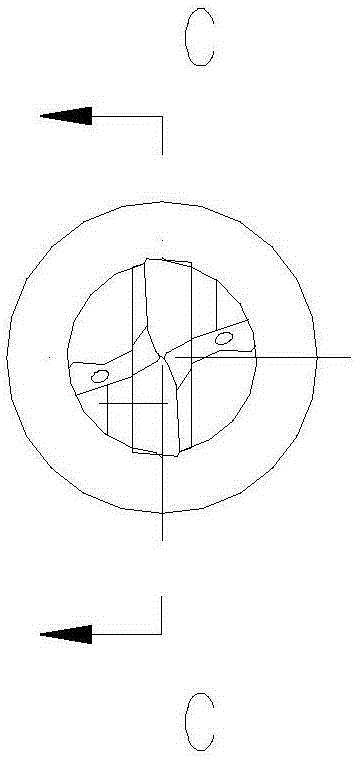

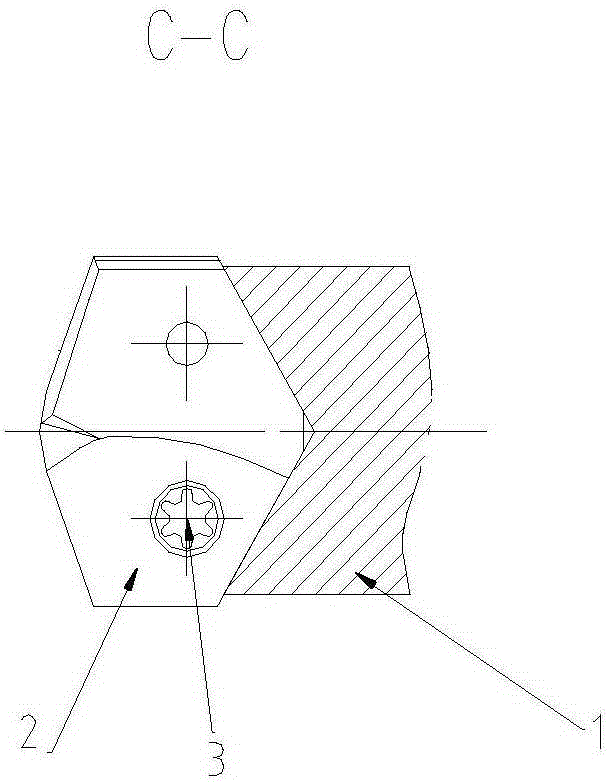

[0030] Such as Figure 1~4 As shown, the double-screw locking crown drill bit in the V-shaped positioning groove includes a drill rod 1, a crown blade 2, and a compression screw 3. The drill rod 1 includes a working part 5 and a neck that are successively connected around the same central axis. part 6 and shank 7, the working part is provided with a spiral chip flute 8, the solid part outside the chip flute 8 is the back 9, and the edge 4 is formed near the chip flute, and the edge 4 is one with the chip removal The helical surface with the same lead of the groove; the shank 7 is in the shape of a cylinder; the neck 6 is a combination of a cone and a cylinder.

[0031] Such as Figure 4~7 As shown, the axial position of the drill pipe is provided with a straight-through main cooling hole 10, and two sub-cooling holes 11 are provided at the left end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com