Graphite bipolar plate compression moulding forming system

A compression molding, bipolar plate technology, applied in the direction of presses, dust removal, cleaning methods and appliances, etc., can solve the problems of affecting surface hydrophilicity and hydrophobicity, affecting the next process, and damage to the plate sealing area, so as to improve labor production efficiency , Improve the product quality rate and ensure the effect of production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

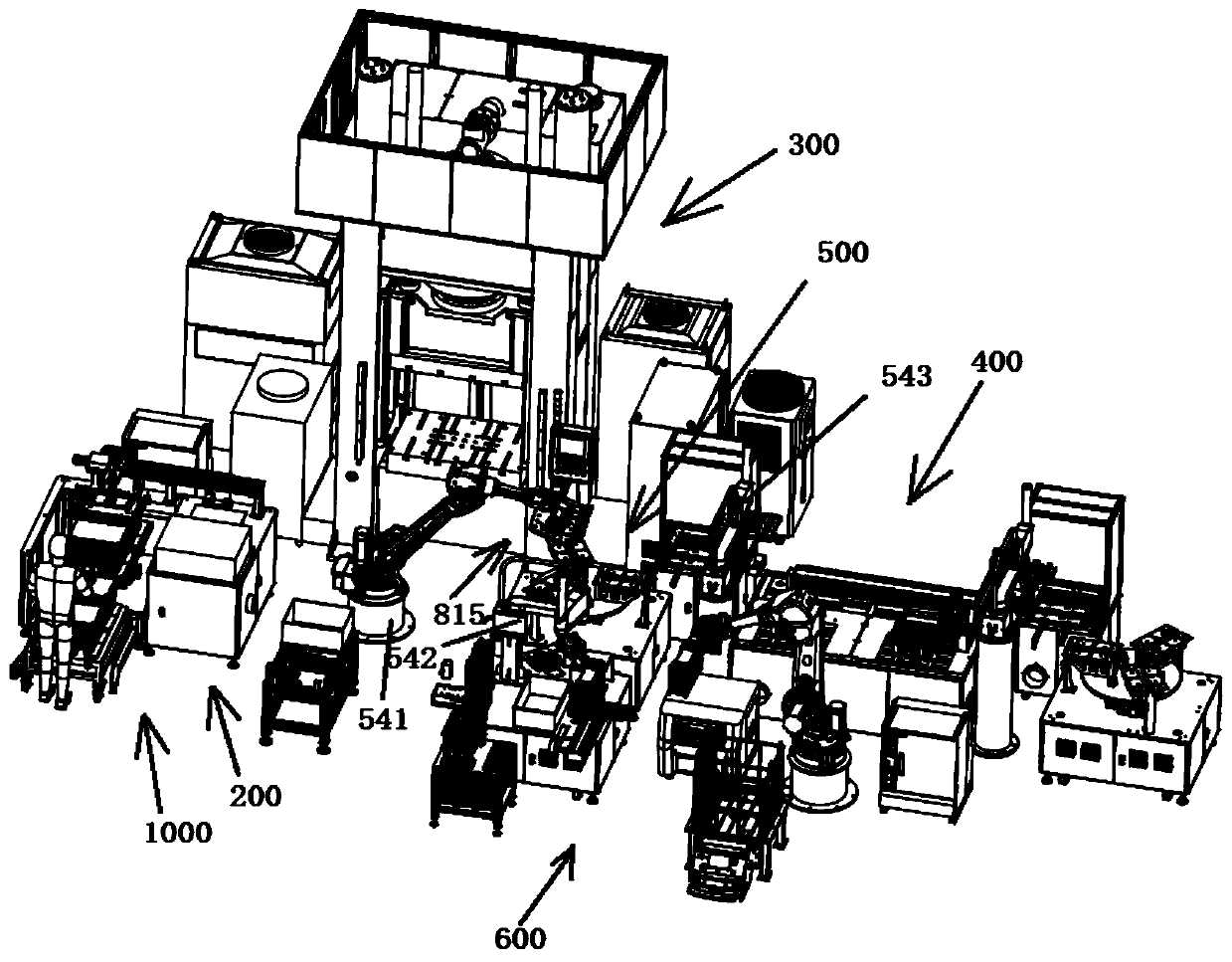

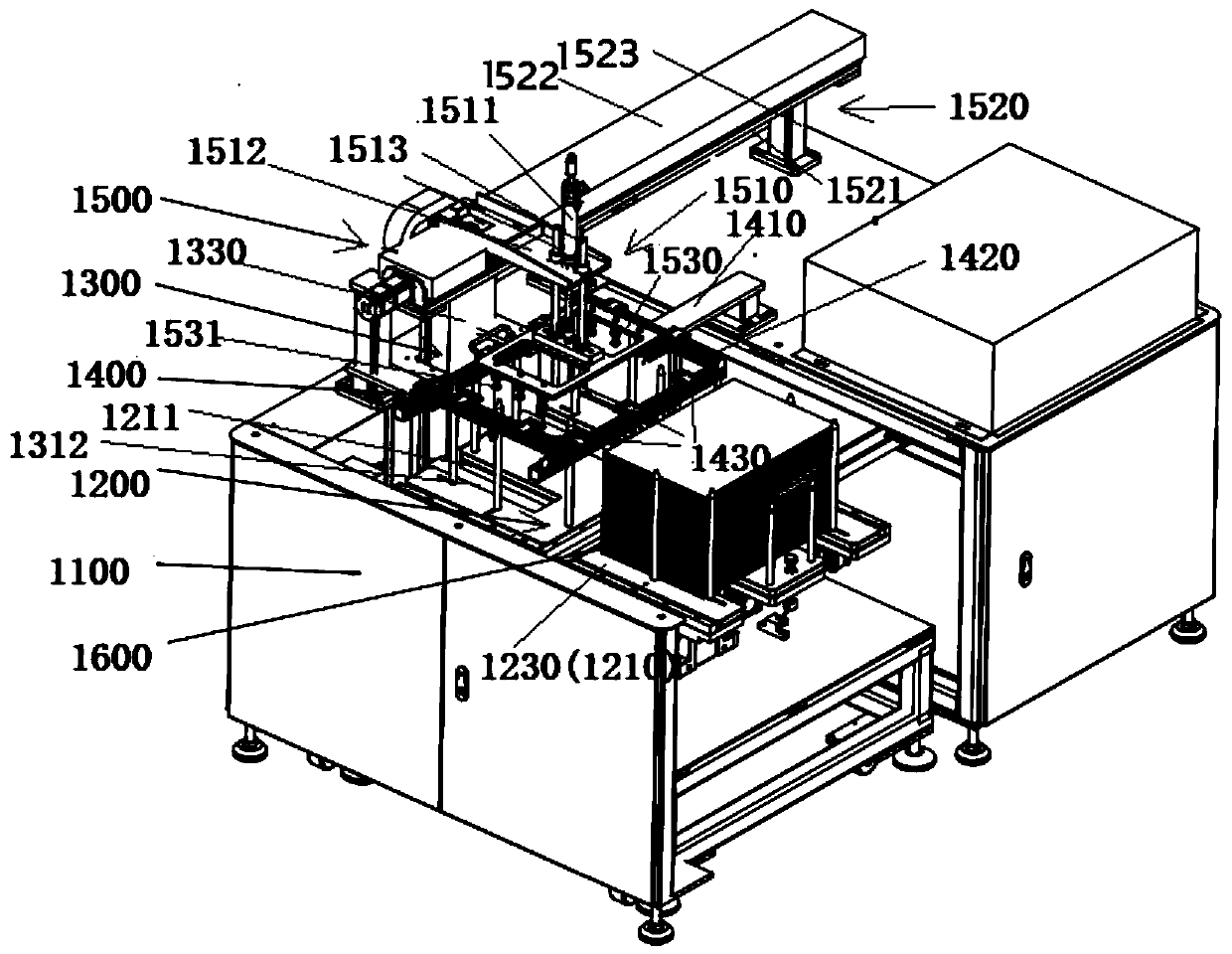

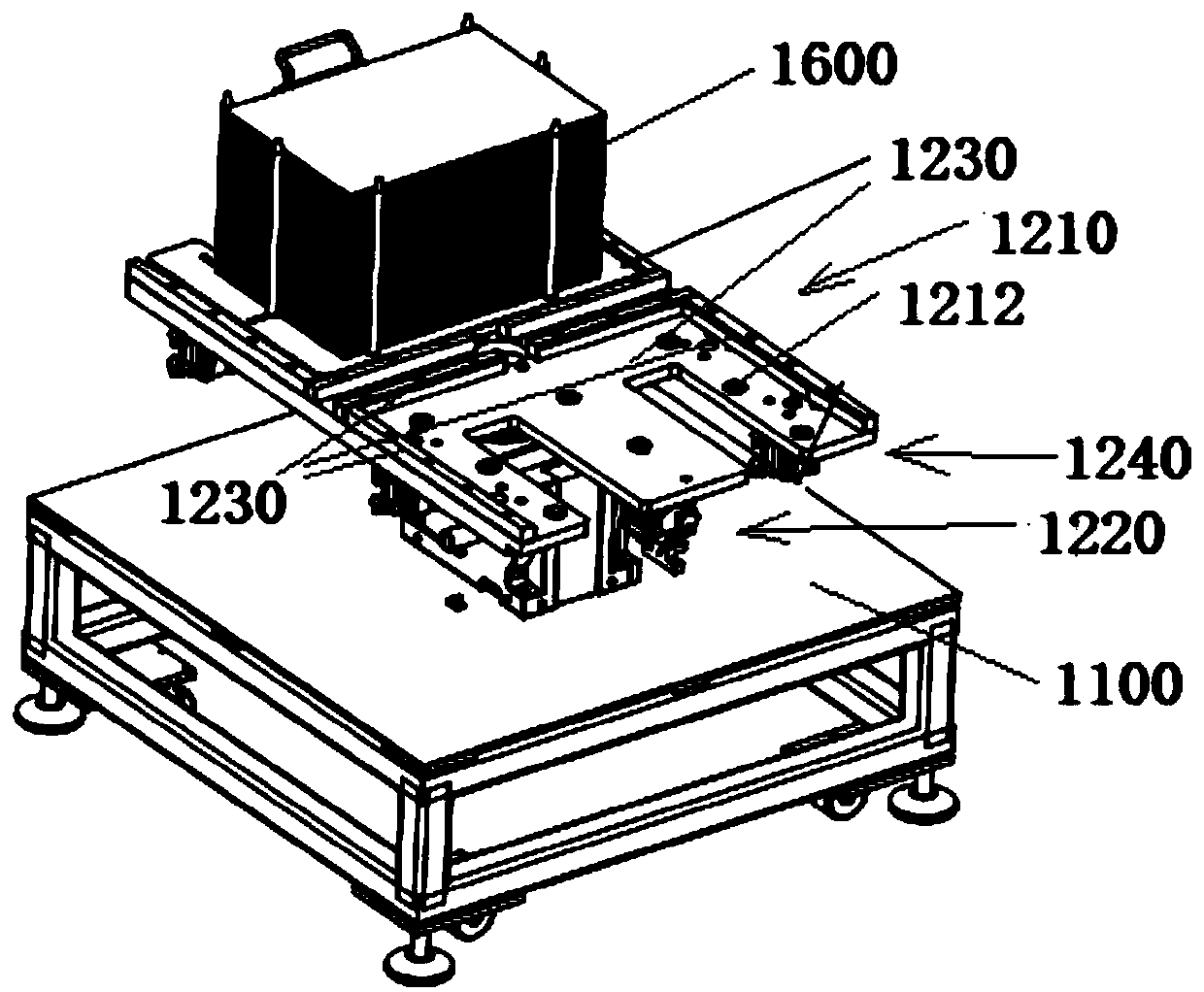

[0065] Such as figure 1 As shown, a graphite bipolar plate molding system invented includes: a feeding device 100, a cleaning device 200, a molding device 300, a conveying device 400, a deburring device 500, an automatic cage loading device 600 and an electric control system;

[0066] The feeding device 100 is used to feed the graphite plate onto the cleaning device;

[0067] Cleaning device 200, used to clean impurities on the surface of the graphite plate;

[0068] The molding device 300 is used to mold the cleaned graphite plate into a single bipolar plate;

[0069] The deburring device 500 is used for cutting the burrs around the single plate of the bipolar plate;

[0070] The conveying device 400 is used to transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com