Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Guaranteed effective length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

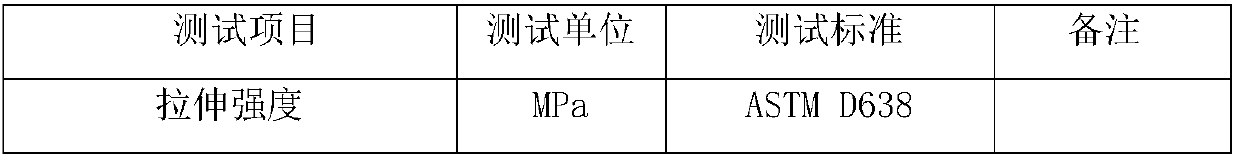

Continuous long fiber reinforced thermoplastic polyurethane material and preparation method thereof

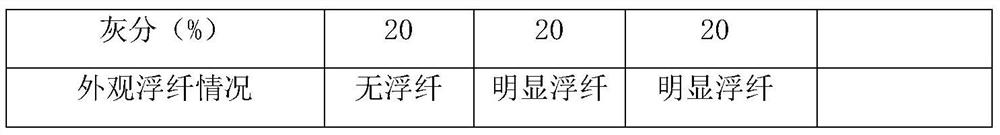

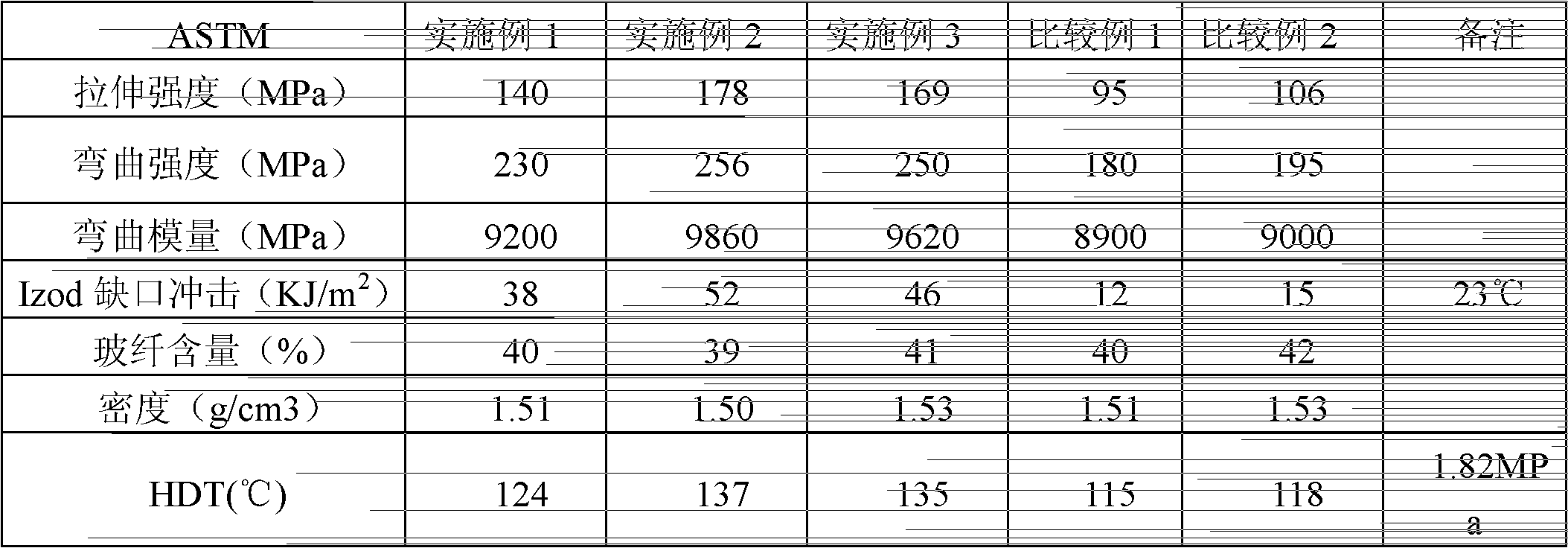

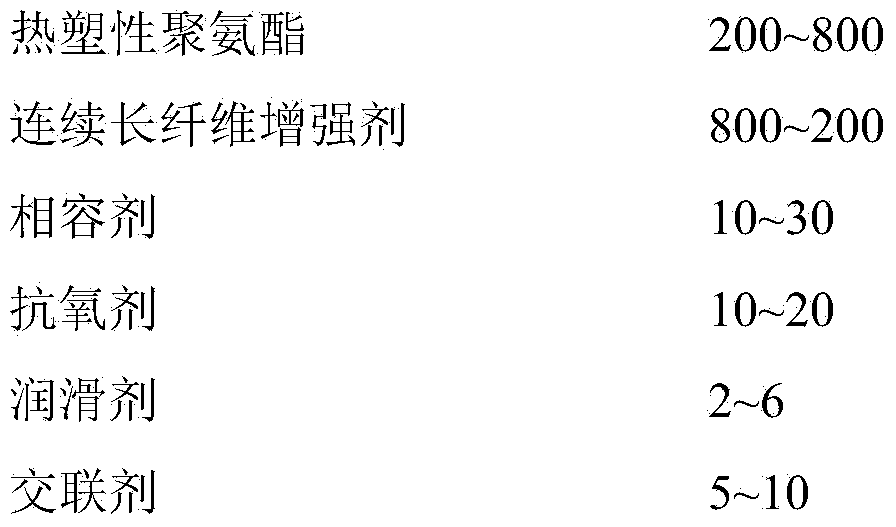

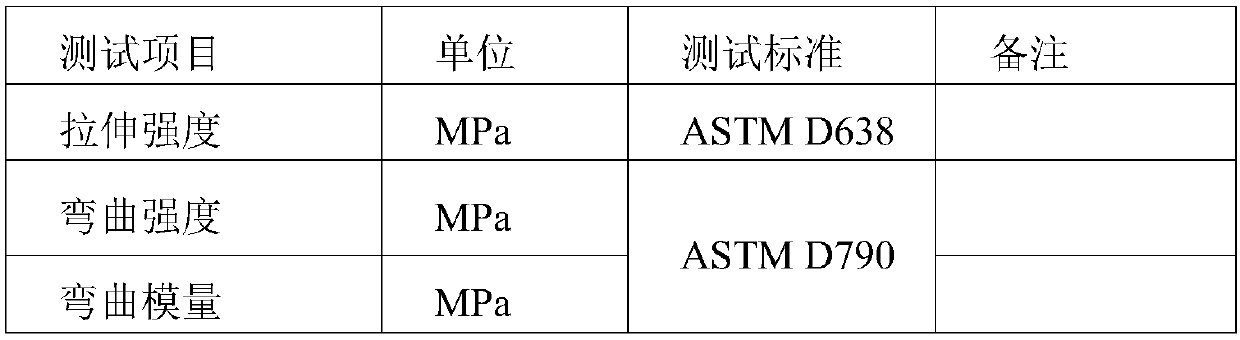

The invention belongs to the technical field of high polymer materials and discloses a continuous long fiber reinforced thermoplastic polyurethane material and a preparation method thereof. The continuous long fiber reinforced thermoplastic polyurethane material disclosed by the invention comprises the following components in parts by weight: 200-800 parts of thermoplastic polyurethane, 800-200 parts of continuous long fiber reinforcing agent, 10-30 parts of compatilizer, 10-20 parts of antioxidant, 2-6 parts of lubricating agent and 5-10 parts of crosslinking agent. Compared with the prior art, the continuous long fiber reinforced thermoplastic polyurethane material disclosed by the invention is simple in structure, reasonable in design and strong in practicability; and a long glass fiber reinforced thermoplastic polyurethane material is adopted, thereby greatly improving the rigidity and strength of the material and obviously improving the anti-impact property and heat-resistant property of the material.

Owner:HEFEI GENIUS NEW MATERIALS

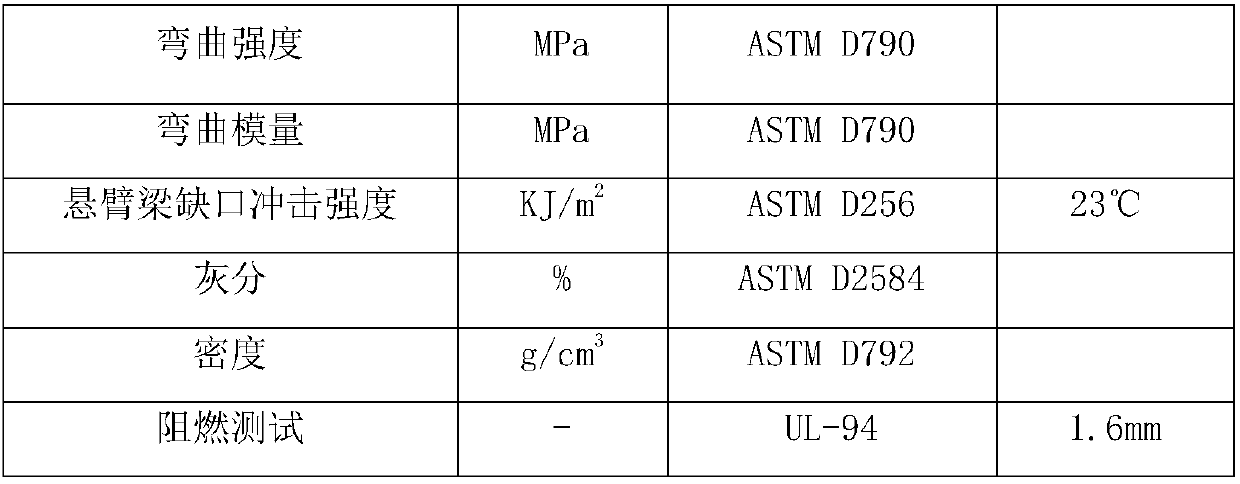

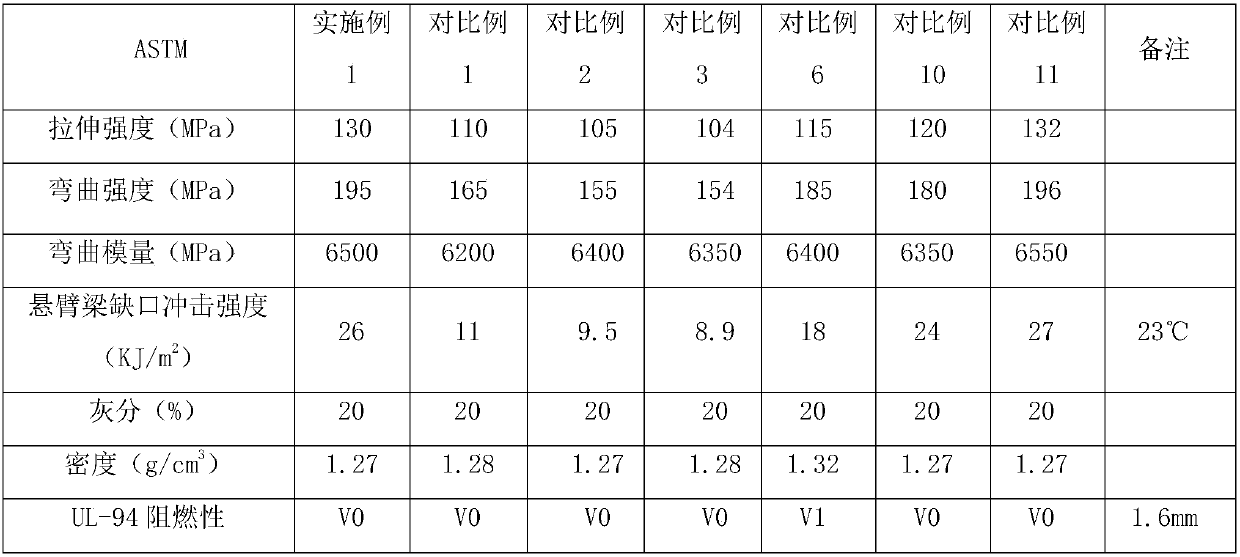

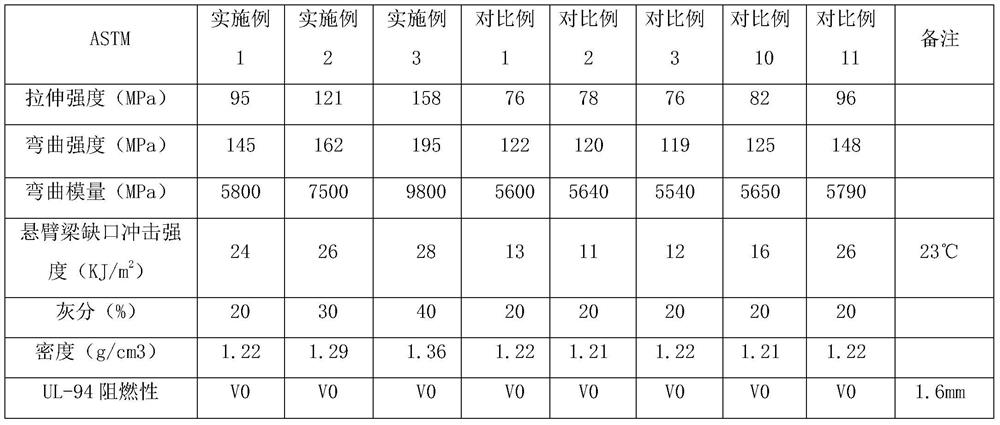

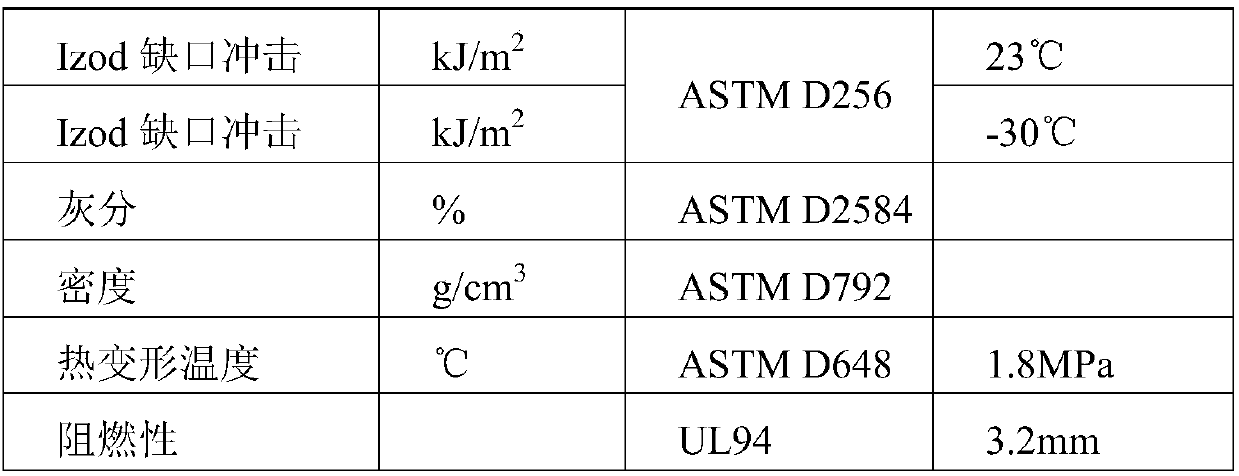

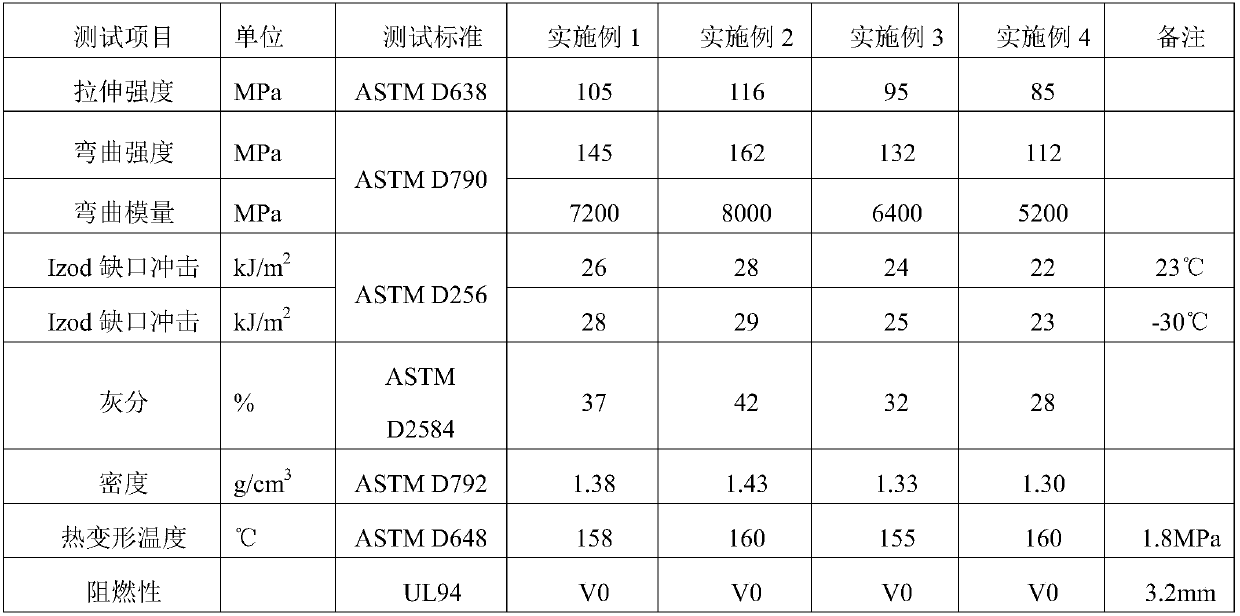

Lithium battery case flame-retardant material based on long-glass-fiber-reinforced polypropylene and preparation method thereof

The invention discloses a lithium battery case flame-retardant material based on long-glass-fiber-reinforced polypropylene and a preparation method thereof. The lithium battery case flame-retardant material is prepared from the following components in parts by weight: polypropylene, continuous glass fiber, coupling agent, main antioxidant, auxiliary antioxidant, lubricant, compatilizer, composite flame retardant and black master batch. The preparation method comprises the following steps: adding all the components expect the continuous glass fiber into a high-speed mixer, uniformly mixing, sending into an extruding machine, carrying out melt extrusion on the material into an impregnator, and meanwhile, sending the continuous glass fiber into the impregnator to carry out disperse impregnation with the molten material; and finally, carrying out die drawing at a setting port of the impregnator, cooling, carrying out blow-dry, and granulating to obtain the finished product. The lithium battery case flame-retardant material disclosed by the invention has higher strength and toughness, can not be easily combusted in naked fire, can effectively lower the possibility of battery combustion accidents, and ensures the case to have high plasticity and compressive strength.

Owner:HEFEI GENIUS NEW MATERIALS

Graphene coordinated continuous glass fiber reinforced halogen-free flame-retardant weather-resistant PPO/HIPS alloy material and preparation method thereof

The invention discloses a graphene coordinated continuous glass fiber reinforced halogen-free flame-retardant weather-resistant PPO / HIPS alloy material. The material is prepared from the following components in parts by weight: 360 to 480 parts of PPO, 240 to 320 parts of HIPS, 200 to 400 parts of continuous glass fiber, 5 to 15 parts of graphene, 10 to 20 parts of a compatibilizing agent, 50 to 80 parts of a toughening agent, 80 to 120 parts of a flame retardant, 6 to 10 parts of an antioxidant, 3 to 5 parts of a composite light stabilizer, 4 to 8 parts of a lubricant and 5 to 15 parts of metal oxide. According to the invention, through addition of predispersed graphene coordinated continuous glass fiber reinforced PPO / HIPS alloy, and compounding with a variety of functional additives, the material provided by the invention has excellent rigidity, impact toughness, weather resistance and flame-retardant performance; meanwhile, no glass fiber is exposed on the surface of an injection-molded workpiece, so application of glass fiber reinforced PPO / HIPS alloy in different fields can be satisfied; the material can be directly molded through injection molding, so the production efficiency is high; and a used workpiece can be recycled after crushing.

Owner:HEFEI GENIUS NEW MATERIALS

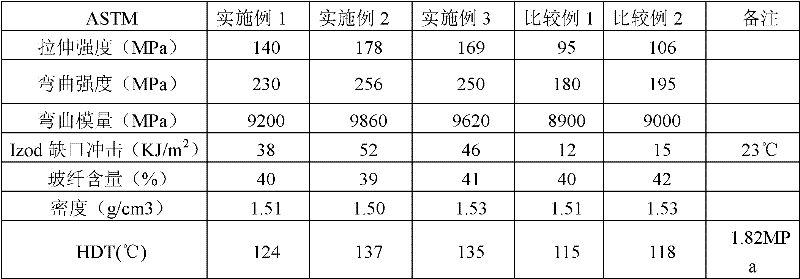

High-flowability long glass fiber reinforced nylon 6 material and preparation method thereof

The invention discloses a high-flowability long glass fiber reinforced nylon 6 material. The high-flowability long glass fiber reinforced nylon 6 material is prepared by the following ingredients in parts by weight: 500-700 parts of high-flowability nylon 6, 300-500 parts of continuous glass fiber, 6-10 parts of antioxidant, 4-8 parts of lubricant, and 3-6 parts of compatilizer. The high-flowability long glass fiber reinforced nylon 6 material has higher rigidity and strength, as well as excellent impact resistance property, the surface appearance of injection-moulded parts is good, the material can be directly formed by injection moulding, the production efficiency is high, and the used parts can be recycled after being ground.

Owner:HEFEI GENIUS NEW MATERIALS

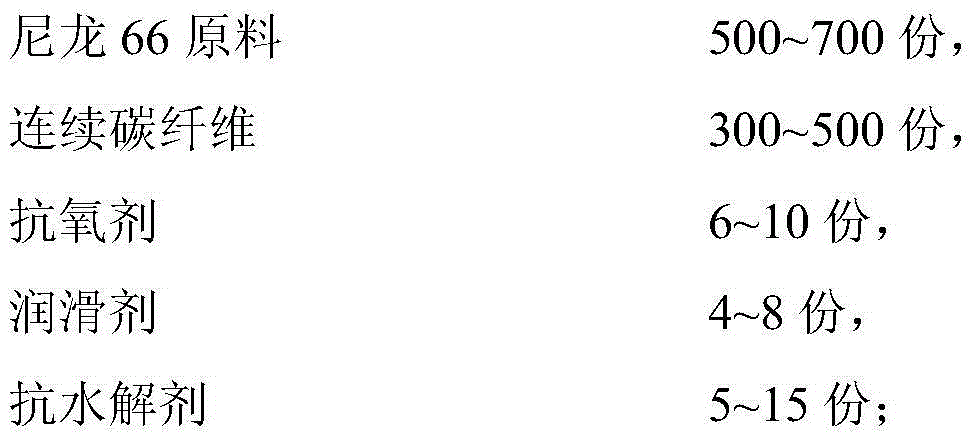

Nylon 66 material and preparation method thereof

The invention falls into the technical field of polymer material, and discloses Nylon 66 material and a preparation method thereof. The material comprises (by weight parts) Nylon 66 raw material 500-700, continuous carbon fibers 300-500, an antioxidant 6-10, a lubricant 4-8 and an anti-hydrolysis agent 5-15. Compared with prior art, the invention has reasonable design, simple operation and strong practicability; the adoption of continuous carbon fibers for reinforcing the Nylon 66 material results in that the length of carbon fibers in products can be kept at 3-6 mm, and as a result, the rigidity and the strength of the material are improved greatly, the impact resistance and the heat resistance of the material are improved remarkably, and the material possesses a long-term hydrolytic stability and a resistance to chemical corrosion.

Owner:上海事升新材料有限公司

A kind of anti-hydrolysis continuous carbon fiber reinforced nylon 6 material and preparation method thereof

The invention belongs to the technical field of a high polymer material and discloses a hydrolysis resistant continuous carbon fiber reinforced nylon 6 material and a preparation method thereof. The material disclosed by the invention comprises the following components in percentage by weight: 500-700 parts of nylon 6, 300-500 parts of continuous carbon fiber, 6-10 parts of oxidation inhibitor, 4-8 parts of lubricating agent and 5-15 parts of hydrolysis resistant agent. The invention also discloses the preparation method of the hydrolysis resistant continuous carbon fiber reinforced nylon 6 material. Compared with the prior art, the preparation method is reasonable in design, simple in operation and strong in practicability and adopts the continuous carbon fiber reinforced nylon 6 material so that the length of carbon fibers in a workpiece can be remained at 3-6mm, thereby the rigidity and the strength of the material are increased, the shock resistance and heat resistance of the material are obviously improved, and the material has long-term hydrolysis resistant stability and anti-chemical corrosion performance.

Owner:HEFEI GENIUS NEW MATERIALS

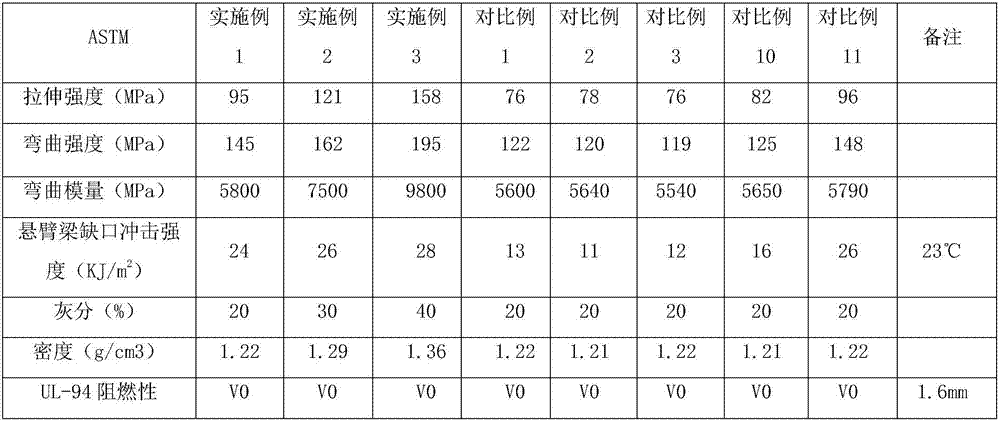

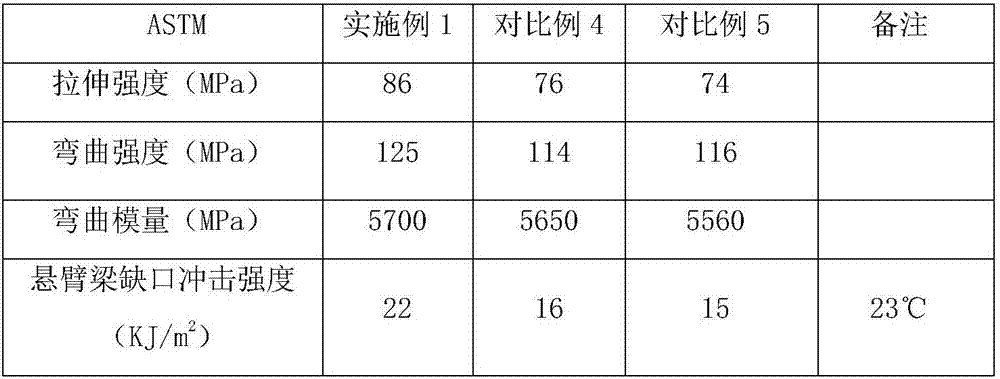

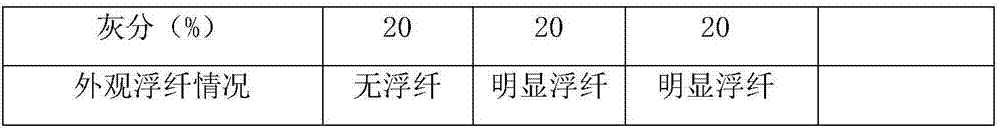

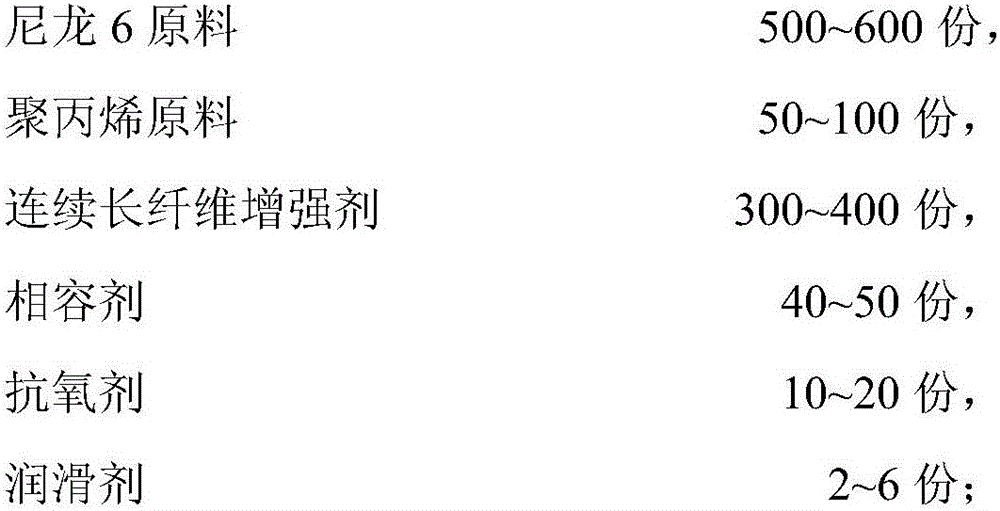

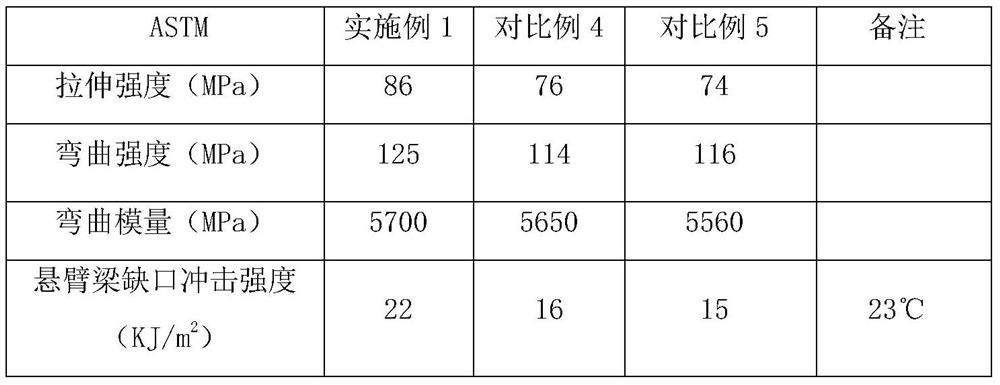

A kind of nylon 6/polypropylene composite material and preparation method thereof

The invention falls into the technical field of polymer material, and relates to nylon 6 / polypropylene composite material and a preparation method thereof. The composite material comprises (by weight parts) nylon 6 500-600, polypropylene 50-100, continuous filament reinforcement 300-400, a compatilizer 40-50, an antioxidant 10-20 and a lubricant 2-6. Compared with prior art, the inventive product ensures the effective length of glass fibers, and as a result, the rigidity and the strength of the material are improved greatly, and the hydrolysis resistance and the heat resistance of the material are improved remarkably at the same time, with the fibers of the material being dispersed uniformly and the weight of the product being stable. In addition, the inventive material can be injection-molded directly with high production efficiency, and the product can be recycled by crushing after the product is used.

Owner:HEFEI GENIUS NEW MATERIALS

Nylon 66 material and preparation method thereof

The invention falls into the technical field of polymer material, and discloses Nylon 66 material and a preparation method thereof. The material comprises (by weight parts) Nylon 66 raw material 500-700, continuous carbon fibers 300-500, an antioxidant 6-10, a lubricant 4-8 and an anti-hydrolysis agent 5-15. Compared with prior art, the invention has reasonable design, simple operation and strong practicability; the adoption of continuous carbon fibers for reinforcing the Nylon 66 material results in that the length of carbon fibers in products can be kept at 3-6 mm, and as a result, the rigidity and the strength of the material are improved greatly, the impact resistance and the heat resistance of the material are improved remarkably, and the material possesses a long-term hydrolytic stability and a resistance to chemical corrosion.

Owner:上海事升新材料有限公司

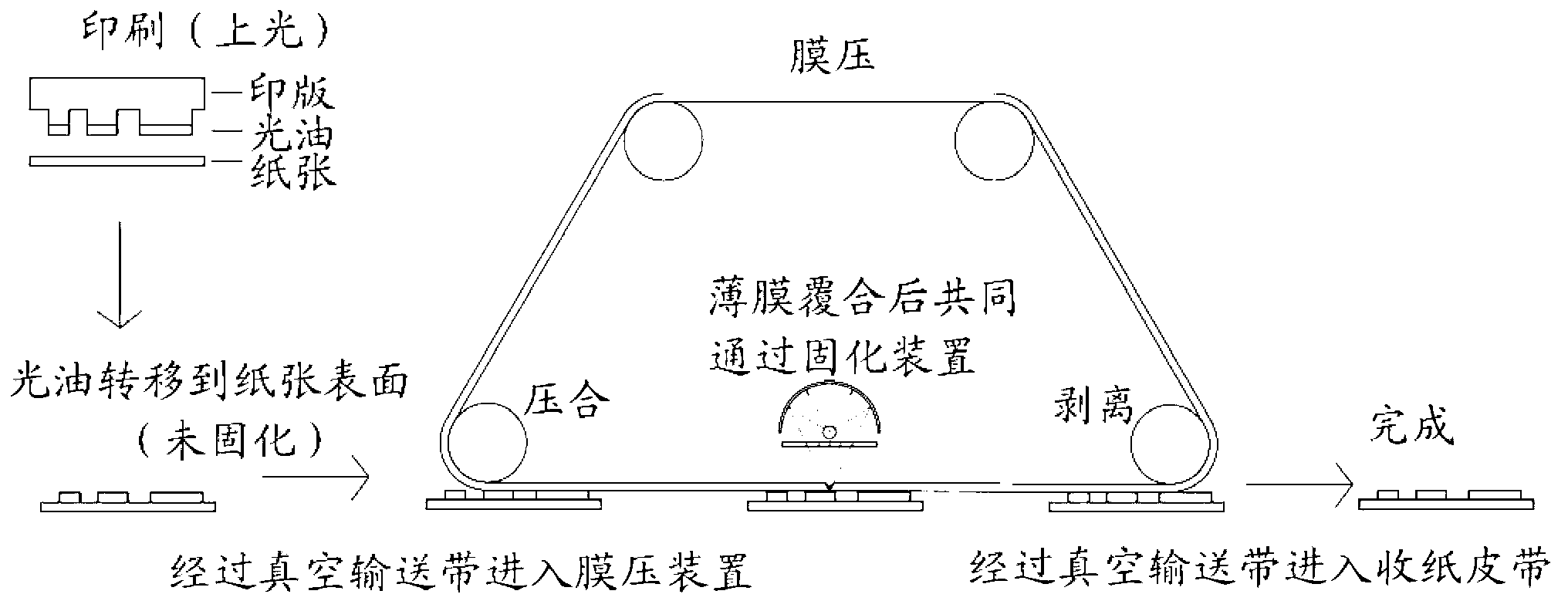

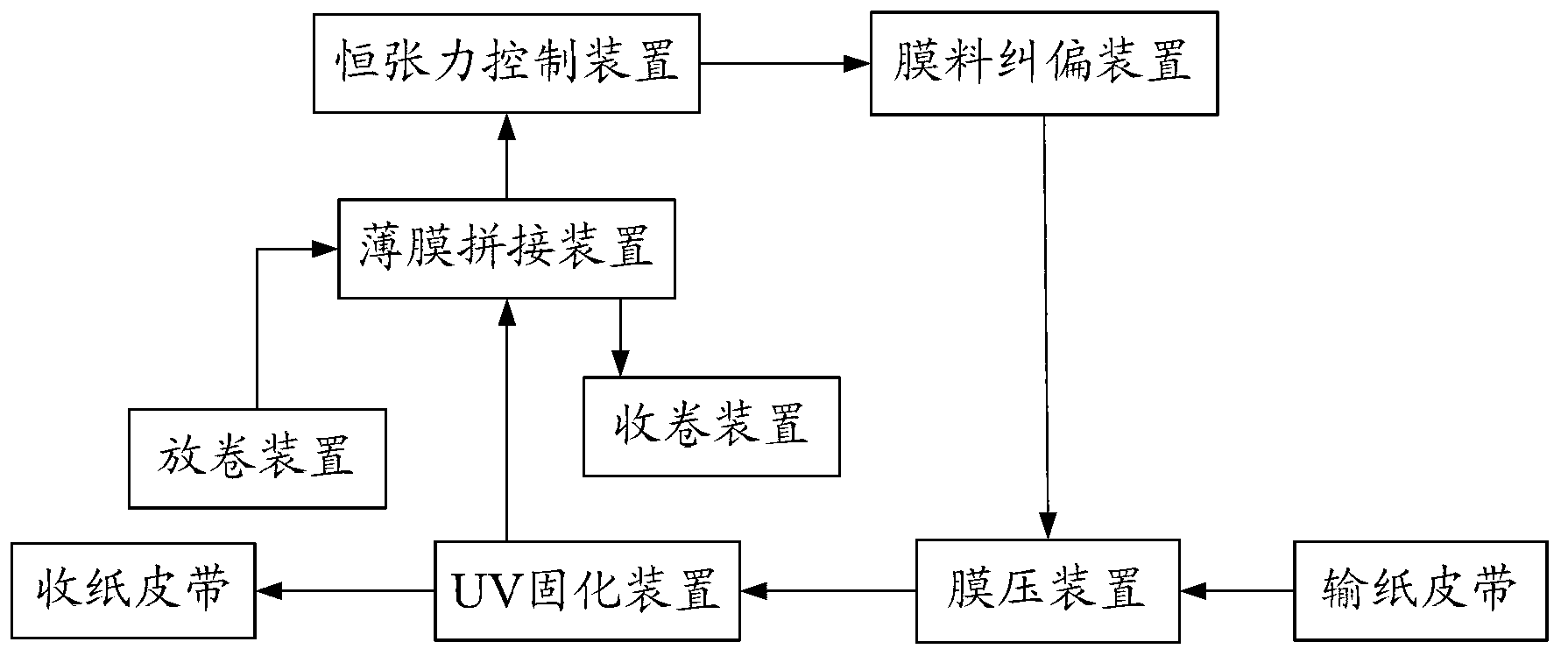

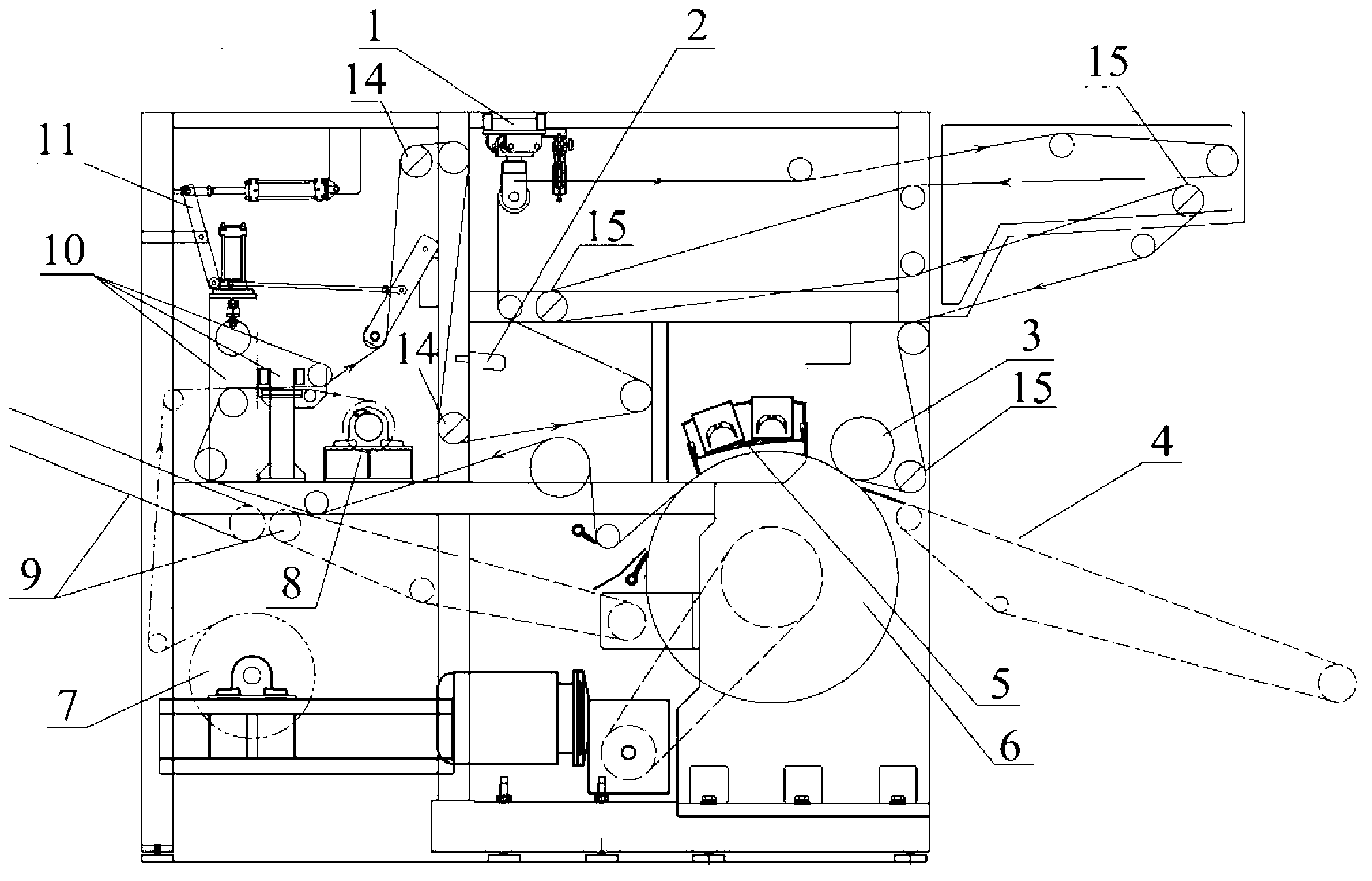

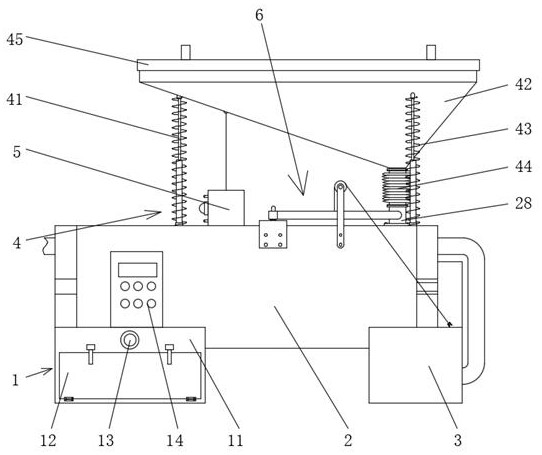

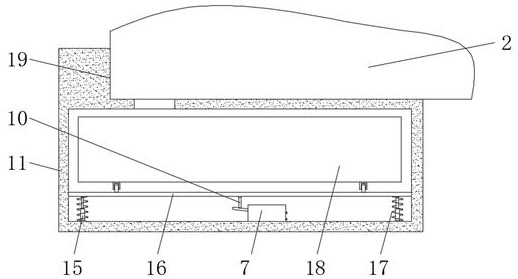

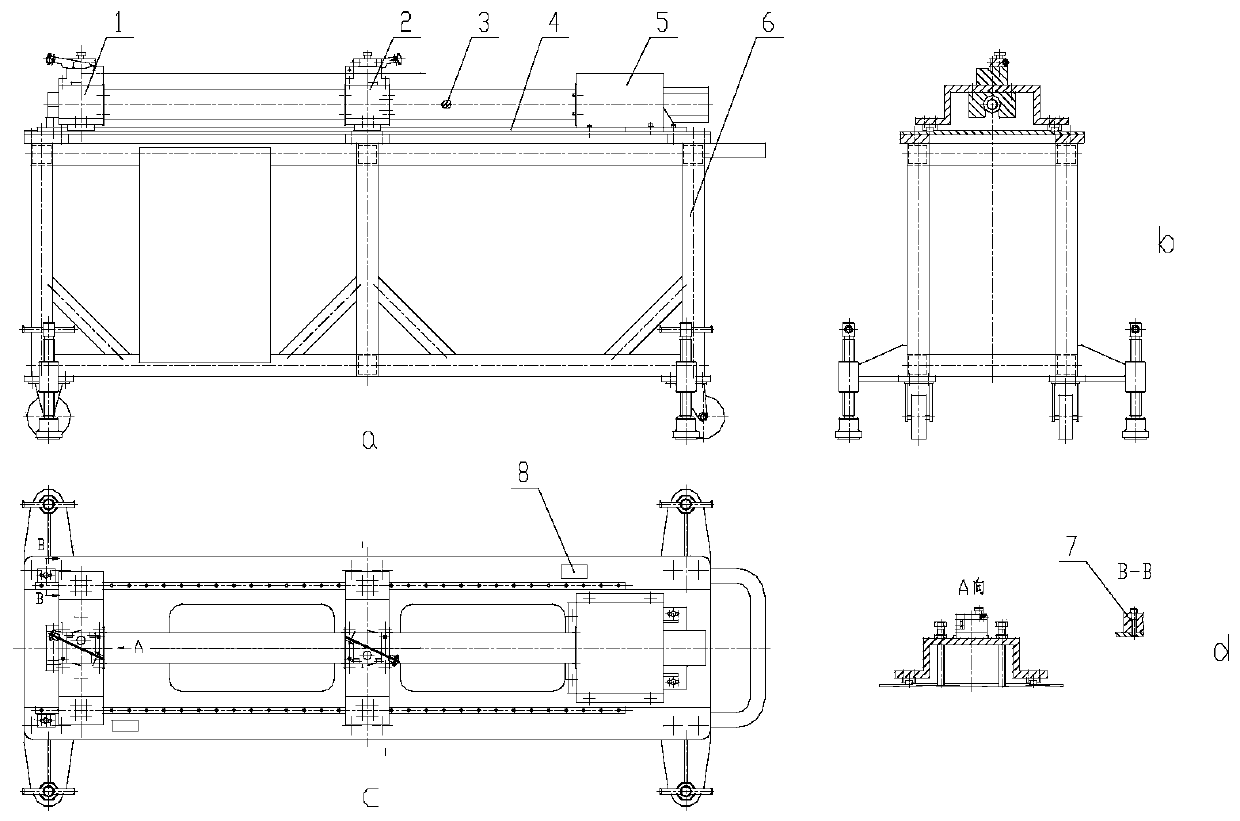

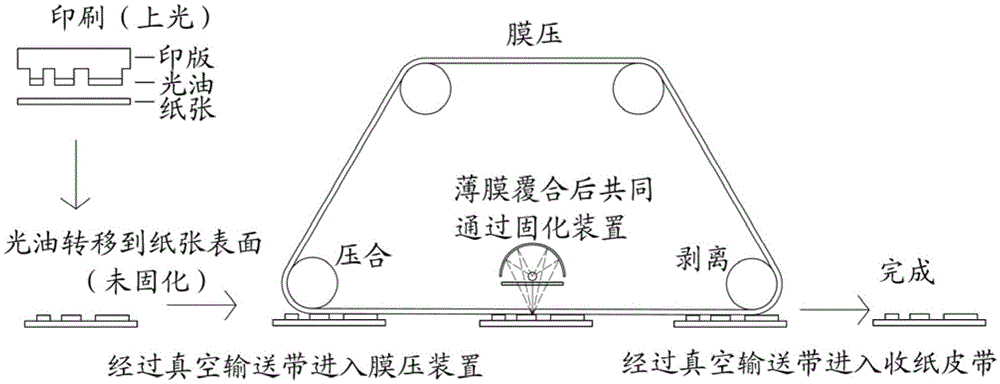

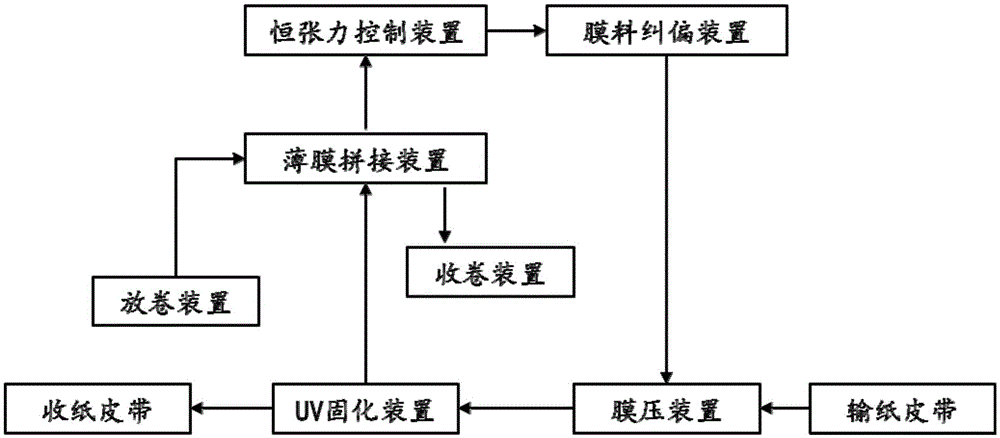

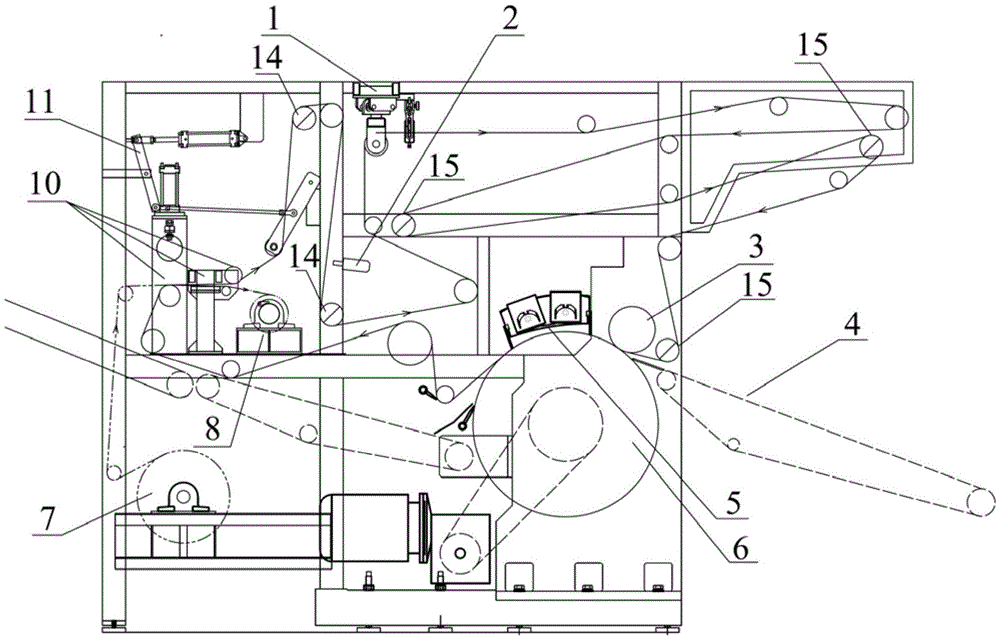

Laser transfer printing press

The invention relates to a laser transfer printing press. The laser transfer printing press comprises a paper conveyor belt, a film pressing device, a UV (Ultraviolet) solidification device and a paper collection belt. An object to be printed is input from the paper conveyor belt and output from the paper collection belt via the film pressing device and the UV solidification device. The laser transfer printing press further comprises a thin film splicing device, a rolling device and an unrolling device, wherein the thin film splicing device is used for changing an old pre-treated thin film into a new pre-treated thin film when a pre-treated thin film is needed to be changed, and the operative pre-treated thin film is laid on a closed loop formed by the thin film splicing device, the film pressing device and the UV solidification device. With the adoption of the structure, the laser transfer printing press can achieve that a thin film is reused by the film pressing device in an internal circulation way, prevents external dust from reaching the thin film and affecting the service life of the thin film, reduces the loss of the thin film, lowers the risk factor for workers, and is simple in structure and wider in application range.

Owner:SHANGHAI QIANYAN MACHINERY CO LTD

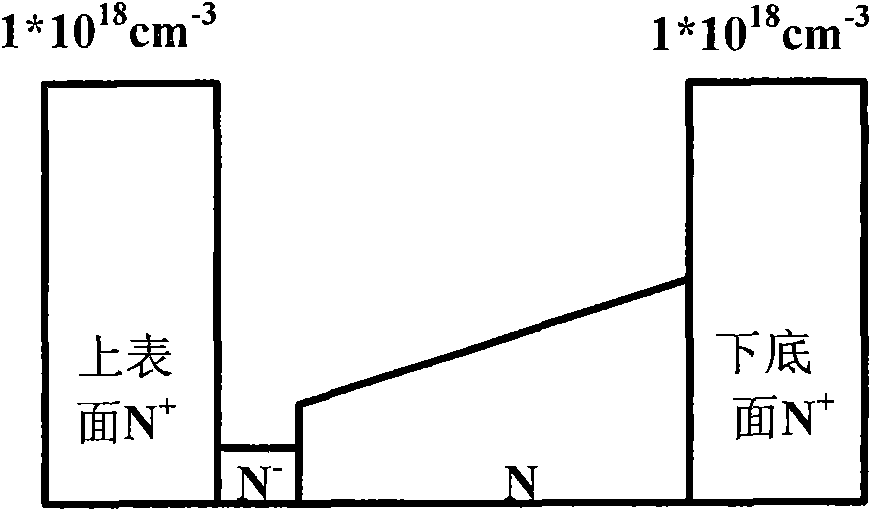

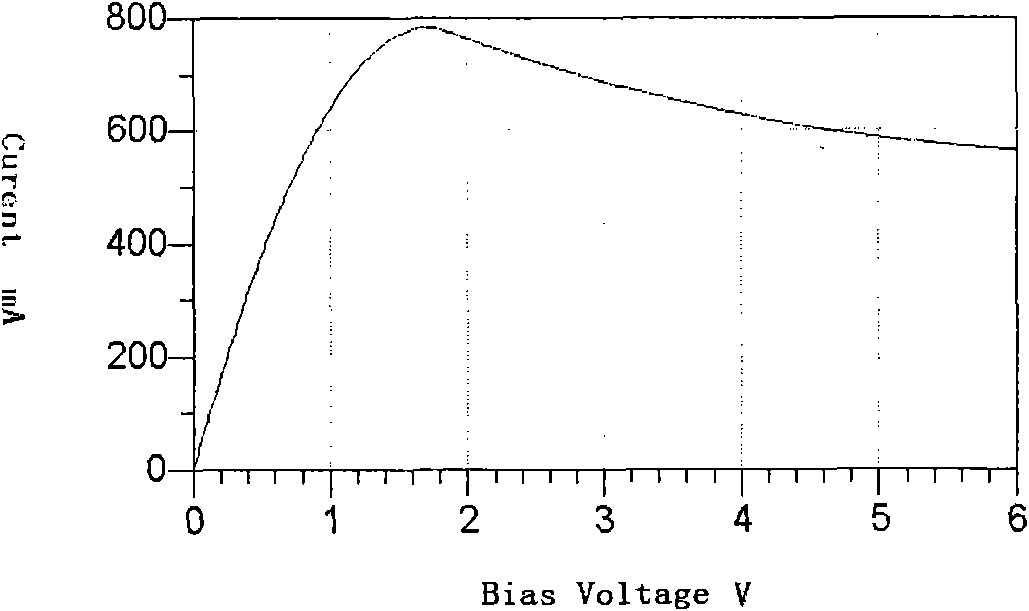

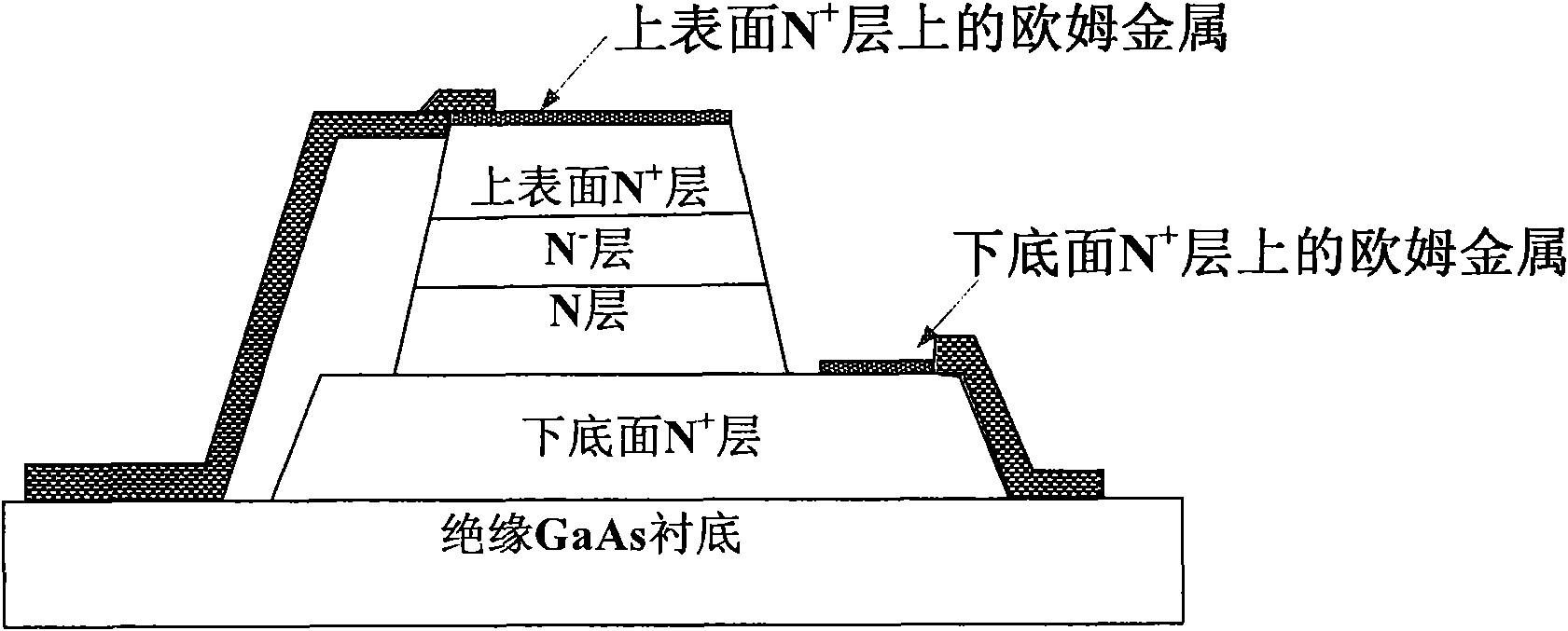

Reinforced linear gradient doped GaAs planar Gunn diode and manufacturing method thereof

InactiveCN102074651AGuaranteed effective lengthImprove power efficiencyBulk negative resistance effect devicesOhmic contactRadio frequency signal

The invention discloses a reinforced linear gradient doped GaAs planar Gunn diode, which comprises a semiconductor insulated substrate, a high doped bottom N+ layer, a linear gradient doped N layer, an N- layer, a high doped upper surface N+ layer, a table top structure, an upper electrode and a lower electrode, wherein the semiconductor insulated substrate is used for supporting the whole GaAs planar Gunn diode; the high doped bottom N+ layer is epitaxially grown on the semiconductor insulated substrate; the linear gradient doped N layer is continuously epitaxially grown on the bottom N+ layer; the N- layer is epitaxially grown on the linear gradient doped N layer; the high doped upper surface N+ layer is epitaxially grown on the N- layer; the table top structure is formed on the bottom N+ layer and the upper surface N+ layer by two processes of digging and isolating; the upper electrode of ohmic contact is formed by evaporating metal on the upper surface N+ layer; and the lower electrode of ohmic contact is formed by evaporating metal on the bottom N+ layer. The invention discloses a manufacturing method for the reinforced linear gradient doped GaAs planar Gunn diode at the same time. By using the diode, the working frequency of an oscillating circuit in a millimeter wave or sub millimeter wave range is improved, and the conversion efficiency of direct current-to-radio frequency signals is enhanced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

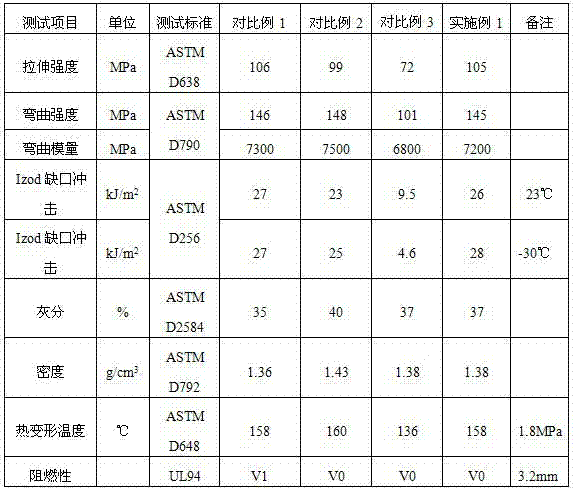

Graphene collaborative continuous glass fiber reinforced halogen-free flame-retardant weather-proof PPO/PA alloy material and preparation method thereof

The invention discloses a graphene collaborative continuous glass fiber reinforced halogen-free flame-retardant weather-proof PPO / PA alloy material, wherein the material is prepared from the followingcomponents in parts by weight: 360-480 parts of PPO, 240-320 parts of PA, 200-400 parts of continuous glass fibers, 5-15 parts of graphene, 10-20 parts of a compatilizer, 50-80 parts of a tougheningagent, 80-120 parts of a flame retardant, 6-10 parts of an antioxidant, 3-5 parts of a composite light stabilizer, 4-8 parts of a lubricant, and 5-15 parts of a metal oxide. By addition of a graphenecollaborative continuous glass fiber reinforced PPO / PA alloy subjected to pre-dispersion treatment, and with combination of various functional auxiliary agents, the material not only has excellent rigidity and impact toughness but also has excellent weather resistance and flame retardant performance, the surface of an injection molded preparation part has no glass fibers exposed, the application of the glass fiber reinforced PPO / PA alloy in different fields can be satisfied, the material can be directly molded through injection molding, the production efficiency is high, and the used preparation part after pulverization can be recycled.

Owner:HEFEI GENIUS NEW MATERIALS

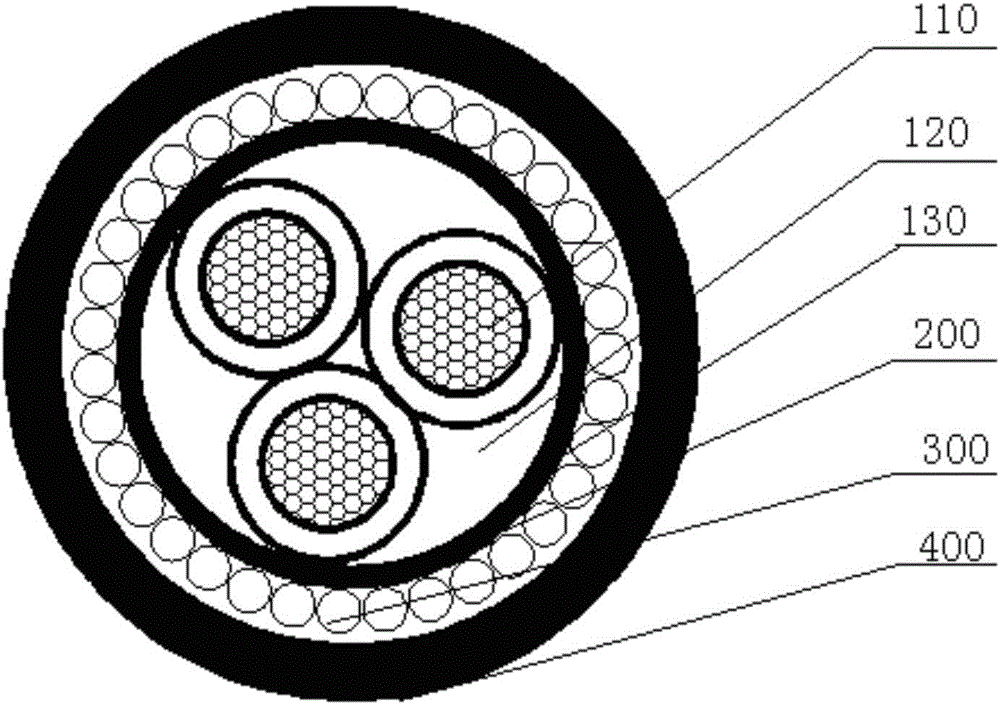

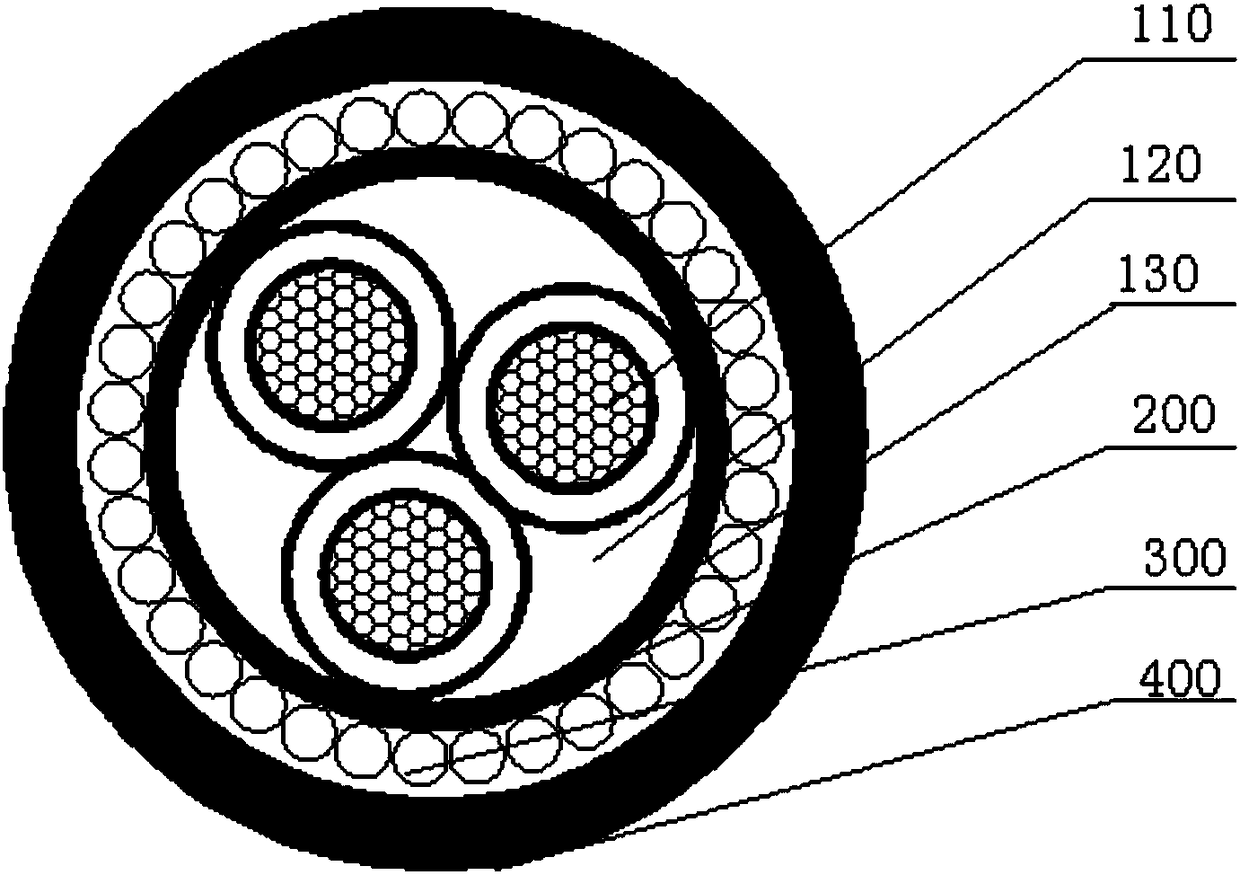

Steel wire armored power cable and processing method thereof

ActiveCN106653193AImprove protection strengthEliminate internal stressInsulated cablesCable/conductor manufacturePower cableEffective length

The invention discloses a steel wire armored power cable and a processing method thereof. The steel wire armored power cable comprises a cable core. The cable core is provided with an inner lining layer, a steel wire armored layer and an outer sheath layer. The processing method of the steel wire armored power cable comprises the following steps of (1), firstly intertwisting 3-5 insulated wire cores and a filler for forming a cable core through cladding; (2), then wrapping the cable core by the inner lining layer through squeezing; (3), performing armoring, namely performing pre-armoring to the head end of the cable core, and performing supplementary armoring on the back end; and (4), performing pre-twisting of rotating by 3-4 cycles in a steel wire armoring direction when the head end of the outer sheath layer is pulled, keeping a certain tension on the back end and fixing the cable core for preventing untwisting. The steel wire armored power cable performs functions of totally eliminating twisting generated on the steel wire, and eliminating an inner stress of the armored steel wire. After armoring of the steel wire, deformation, loosening and irregularity caused by the inner stress after armoring of the steel wire are prevented. The front end and the back end of the wire core of the finished cable is not limited by an external force, and the effective length of the cable core is ensured through pre-armoring and supplementary armoring.

Owner:SHANGHAI NANDA GROUP

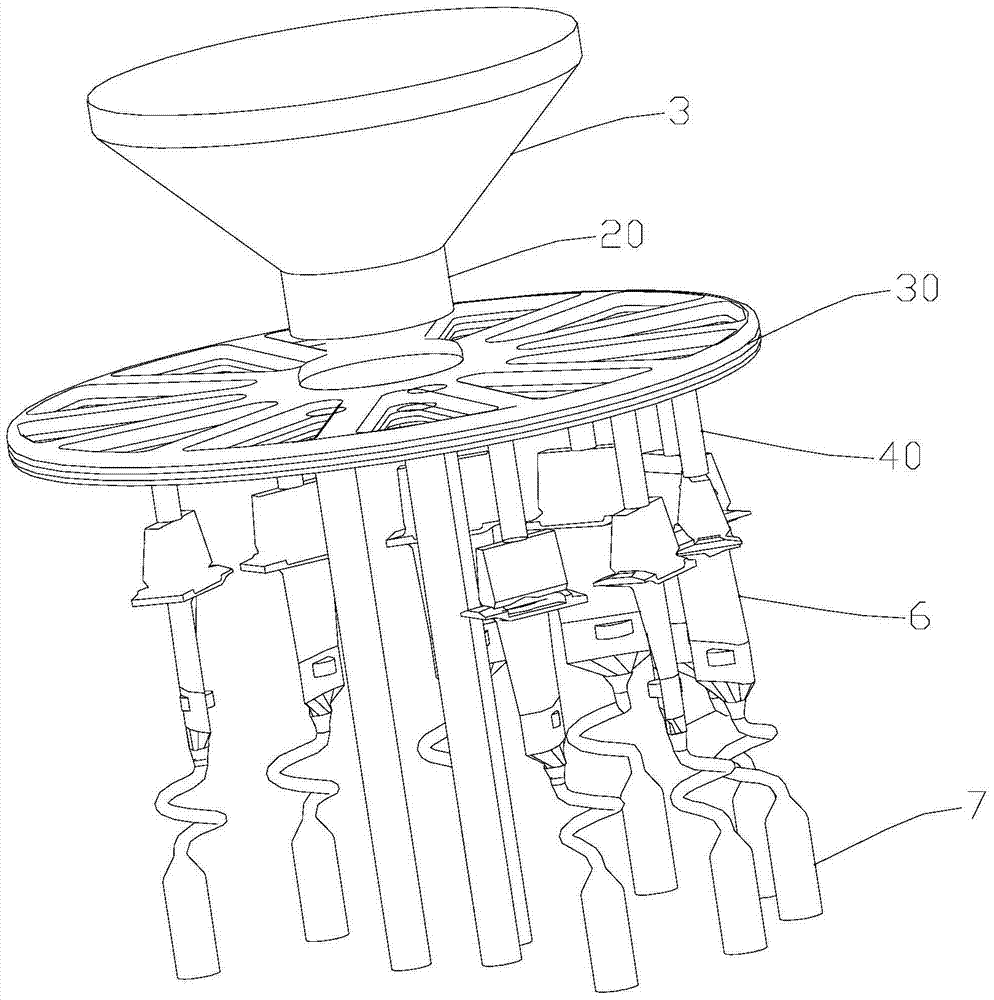

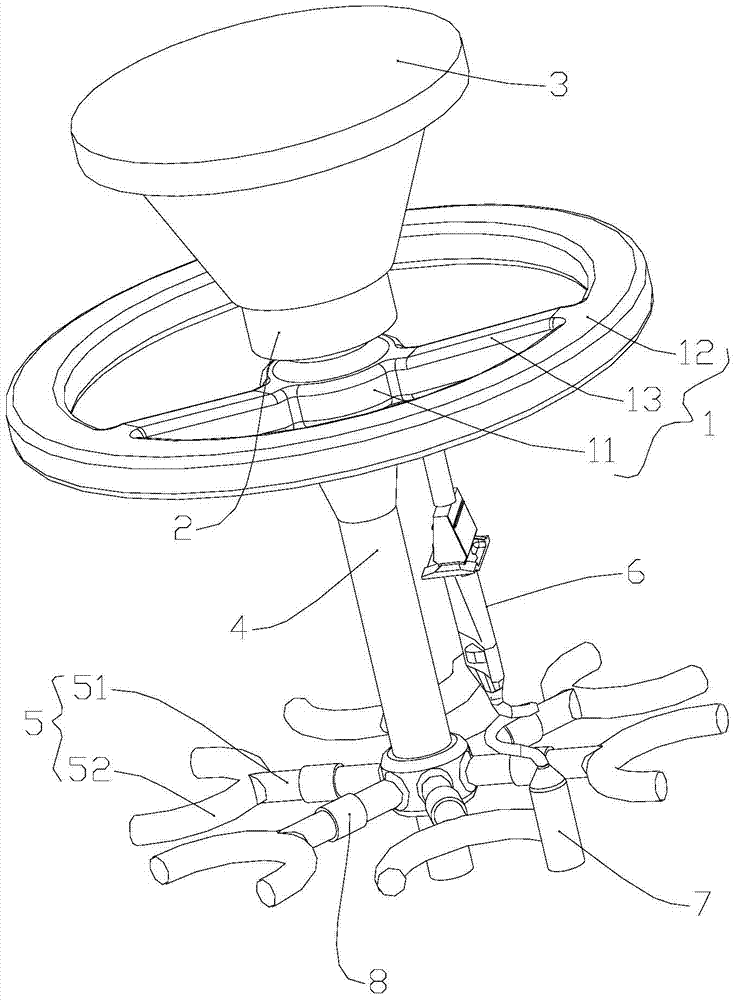

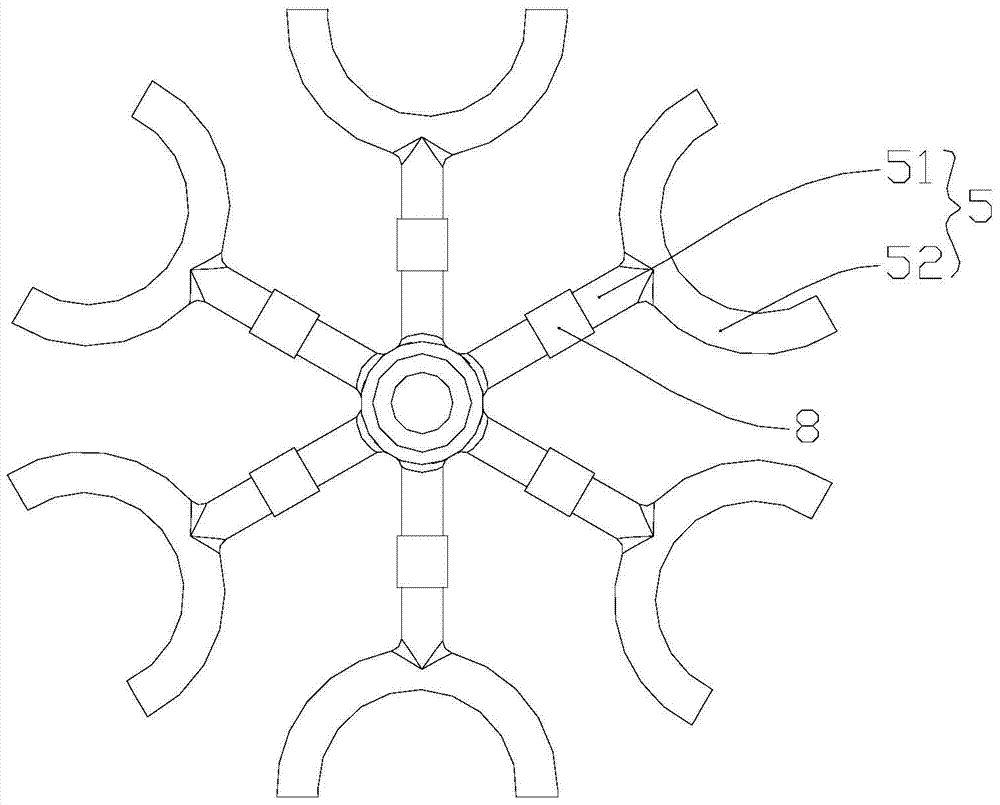

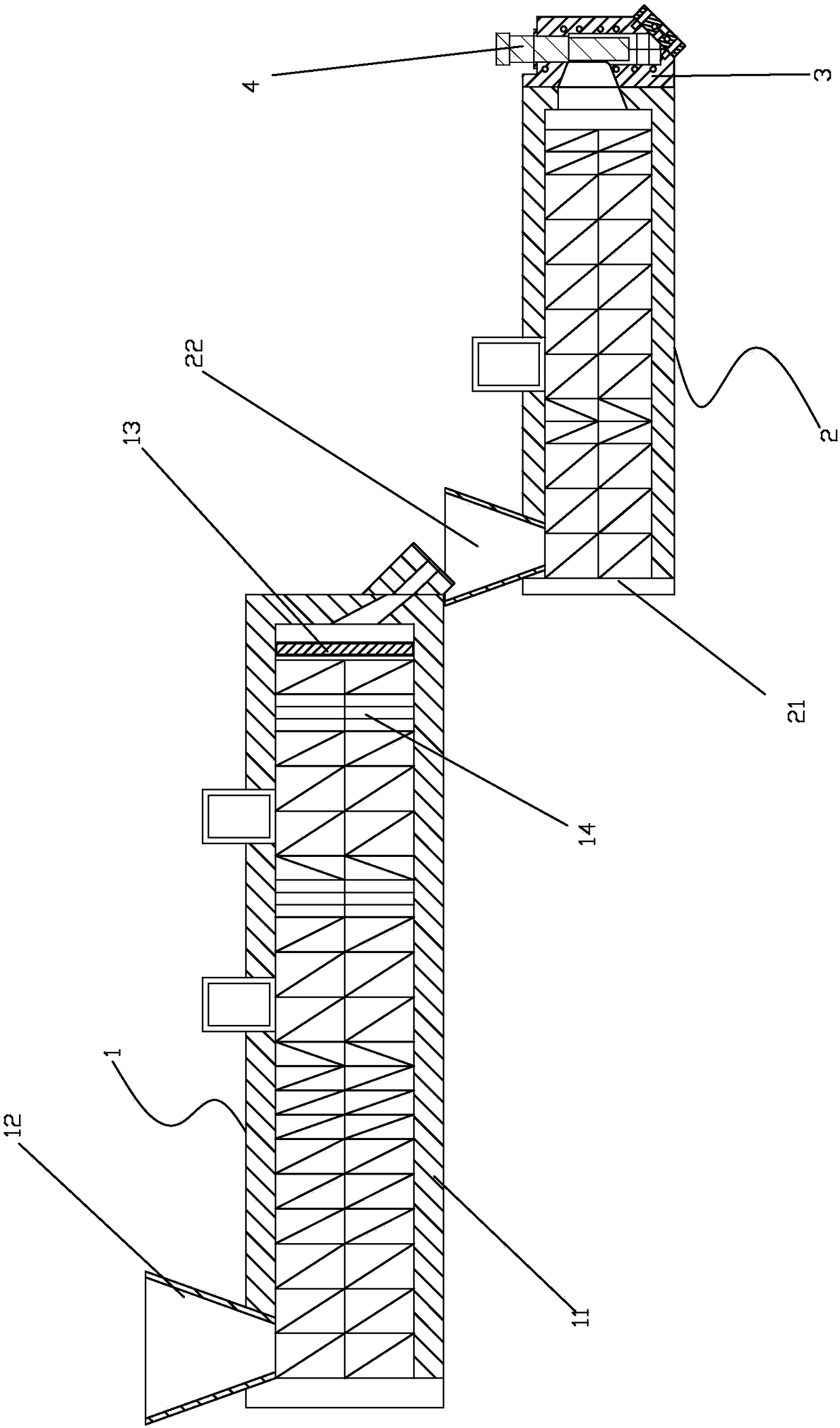

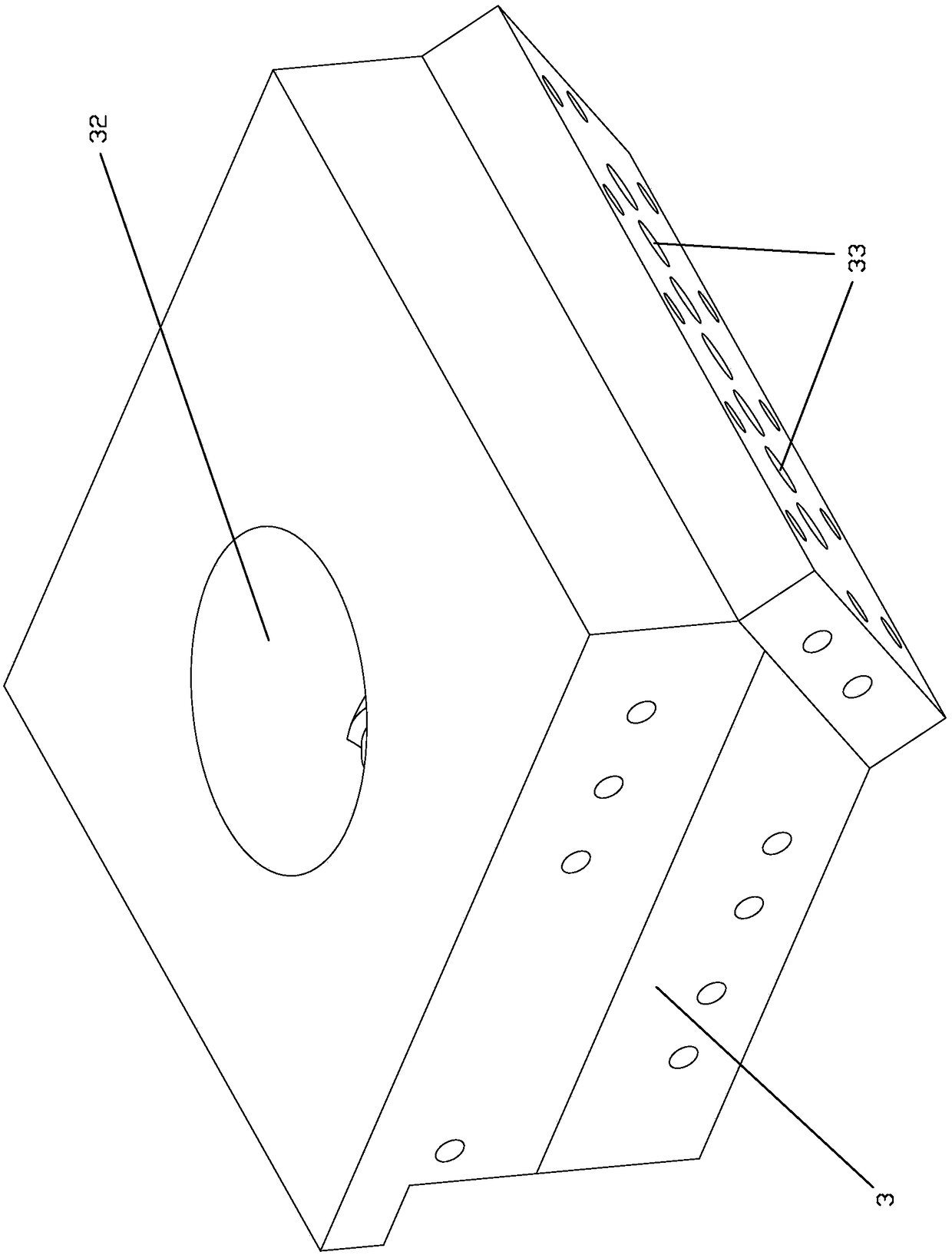

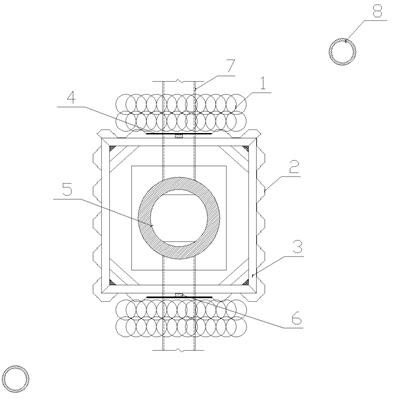

Bottom pouring system

ActiveCN105290333BGuaranteed effective lengthImprove grain orientation pass rateFoundry mouldsFoundry coresMold fillingCrystal orientation

The invention discloses a bottom pouring type pouring system. The bottom pouring type pouring system comprises a disc pouring gate which comprises a main disc pouring pipe allowing pouring liquid to pass through, a first filtering net used for filtering the pouring liquid is connected to the upper end of the main disc pouring pipe, and a pouring cup used for leading in the pouring liquid is connected to the upper end of the first filtering net; a vertically-arranged middle column pouring gate is connected to the lower end of the main disc pouring pipe, and a bottom pouring gate is connected to the bottom end of the middle column pouring gate; and a blade is connected to the disc pouring gate, a spiral crystal selecting device for molding the blade into a single crystal blade is connected to the bottom end of the blade, and the bottom end of the spiral crystal selecting device is communicated with the bottom pouring gate so as to enable the pouring liquid to enter the spiral crystal selecting device from the bottom end of the spiral crystal selecting device. In the bottom pouring type pouring system, the effective length of the spiral crystal selecting device is effectively guaranteed, the crystal orientation acceptability of the single crystal blade is improved, mold filling is stable, impact of the high-temperature pouring liquid to a ceramic core of the blade is reduced, the bottom pouring type pouring system is simple in structure, and assembling of all components of a module is easy and convenient.

Owner:CHINA HANGFA SOUTH IND CO LTD

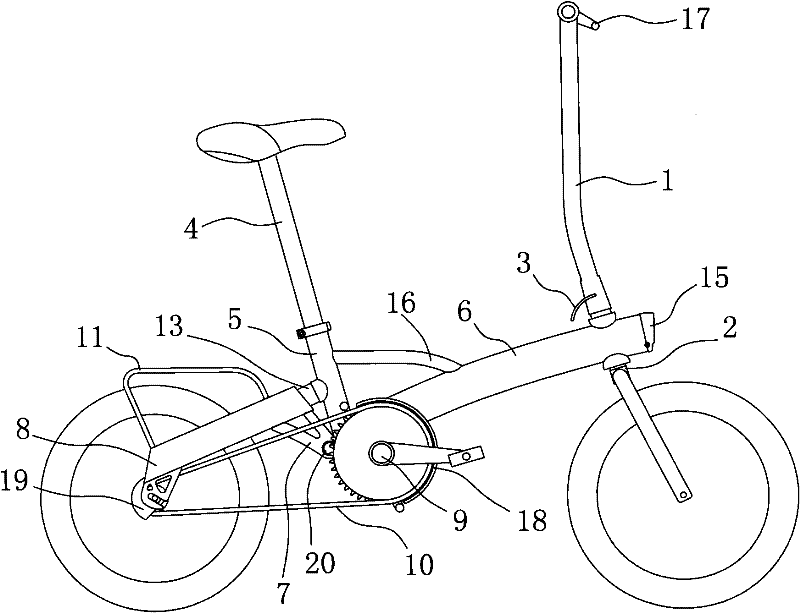

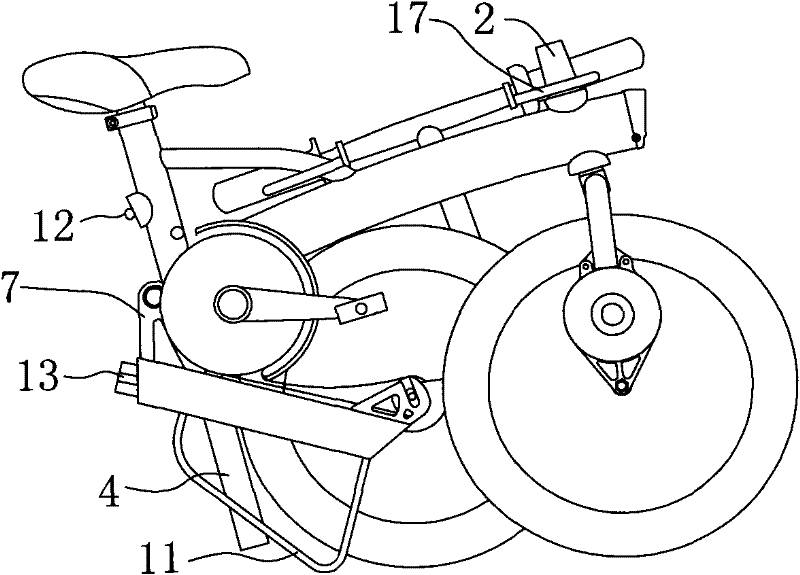

Folding bicycle

Owner:苏州诺雅电动车有限公司 +1

A primary and secondary combination medical stretcher

Owner:铃木电梯(中国)有限公司

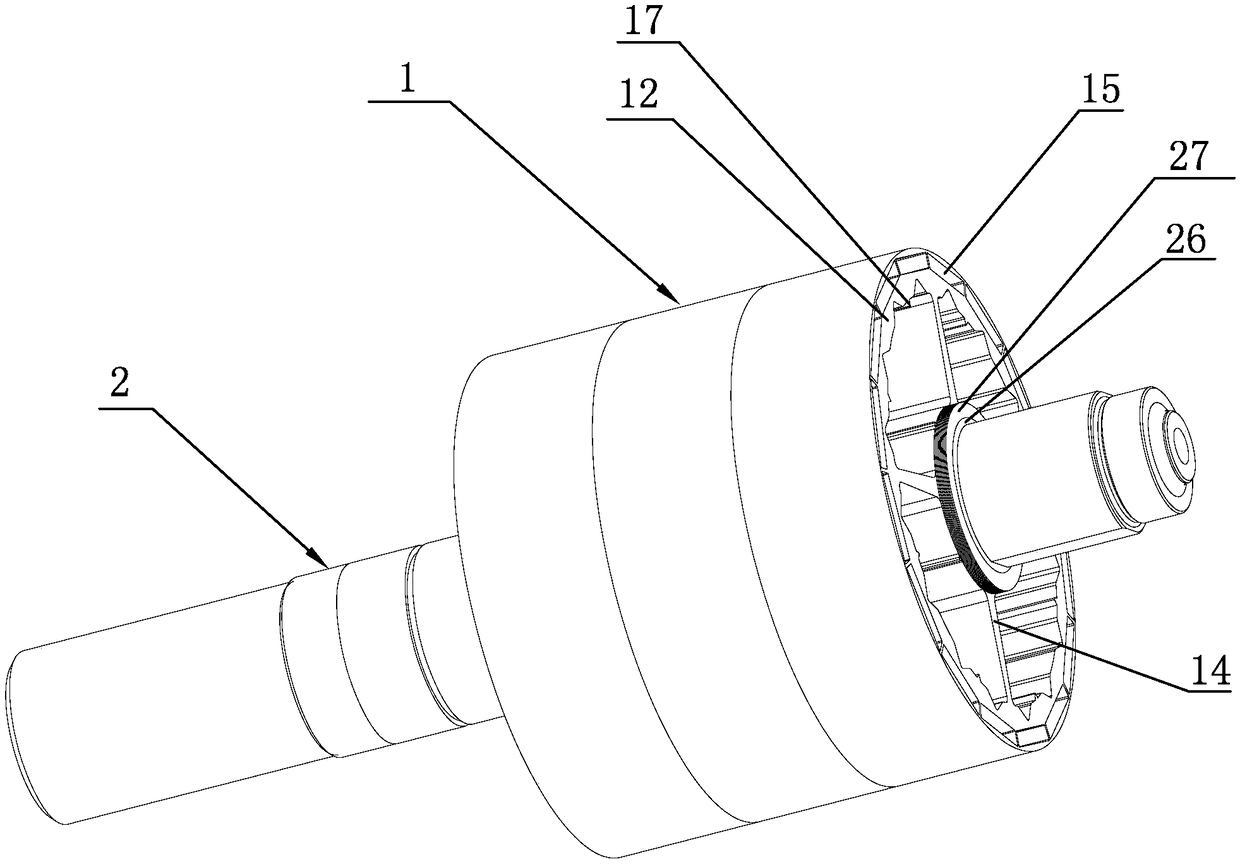

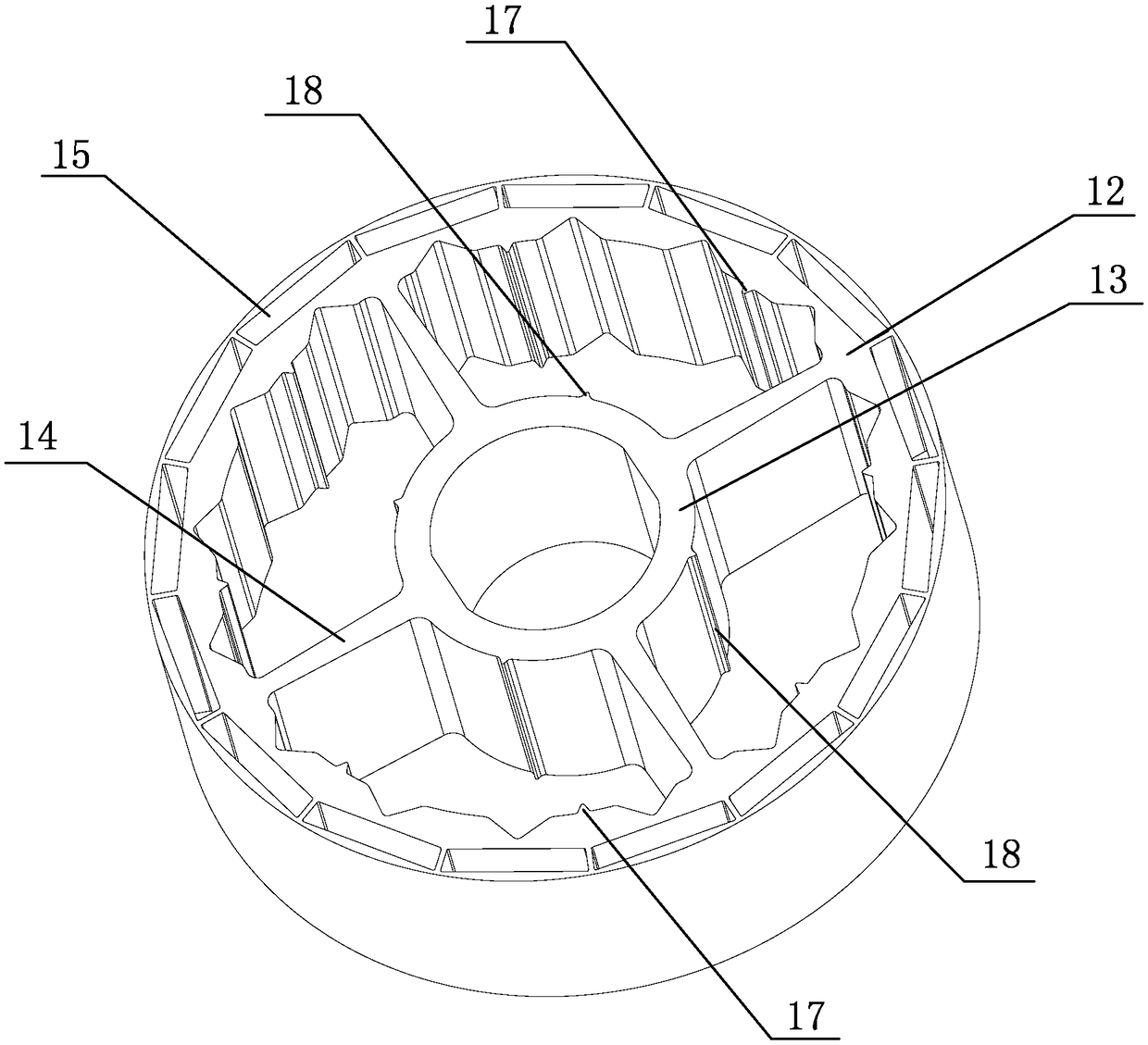

Low-inertia rotor of permanent magnet motor

PendingCN108183566AReduce consumptionMeet strength requirementsMagnetic circuit rotating partsPunchingEffective length

The invention discloses a low-inertia rotor of a permanent magnet motor, and the rotor is formed in a way that a plurality of rotor core modules are connected in series to a rotating shaft and are compressed together with the rotating shaft. Each iron core module is formed by the stacked welding of a plurality of rotor punching sheets. The rotor is advantageous in that the plurality of rotor punching sheets form one iron core module, which means that the plurality of rotor punching sheets forming one iron core module are welded together, but not riveted together through rivets, thereby avoiding a condition that the head of a rivet or a rivet connector is higher than an end plane of the rotor core module during the riveting. Therefore, the plurality of rotor core modules can be closely attached without gaps after stacking, thereby guaranteeing the effective length of the rotor core, improving the effective utilization rate of the rotor core, and improving the performances of the permanent magnet motor. Meanwhile, the rotor saves lining spacer rings between the adjacent iron core modules, and reduces the cost.

Owner:NINGBO ANXIN CNC TECH

A kind of recycling glass fiber reinforced plastic melt granulation extrusion equipment and its extrusion method

The invention discloses extrusion equipment for fusion and granulation of recovered glass fiber-reinforced plastic. According to the technical scheme, the extrusion equipment for fusion and granulation of recovered glass fiber-reinforced plastic comprises a double-screw extruder and a single-screw extruder which are connected in sequence; the double-screw extruder comprises a first-order cylinder with a heating function, a first-order feeding port used for feeding is formed in the front portion of the first-order cylinder, a filter screen is arranged on the rear portion of the first-order cylinder and used for filtering fused polymers, and a mixing unit is further arranged in the position, close to the filter screen, of the interior of the first-order cylinder; and the single-screw extruder comprises a second-order cylinder with a heating function, a second-order feeding port is formed in the front portion of the second-order cylinder and used for collecting short glass fibers and the polymers filtered by the filter screen, an extruder head is arranged on the rear portion of the second-order cylinder, and an ultrasonic vibration mechanism used for promoting the glass fibers and the polymers to be mixed is arranged on the extruder head. According to the extrusion equipment for fusion and granulation of recovered glass fiber-reinforced plastic, the cut short glass fibers are effectively protected, and the physical index of products is effectively increased.

Owner:中山市联科泰贸易有限公司

A kind of steel wire armored power cable and its processing method

ActiveCN106653193BImprove protection strengthEliminate internal stressInsulated cablesCable/conductor manufacturePower cableEffective length

The invention discloses a steel wire armored power cable and a processing method thereof. The steel wire armored power cable comprises a cable core. The cable core is provided with an inner lining layer, a steel wire armored layer and an outer sheath layer. The processing method of the steel wire armored power cable comprises the following steps of (1), firstly intertwisting 3-5 insulated wire cores and a filler for forming a cable core through cladding; (2), then wrapping the cable core by the inner lining layer through squeezing; (3), performing armoring, namely performing pre-armoring to the head end of the cable core, and performing supplementary armoring on the back end; and (4), performing pre-twisting of rotating by 3-4 cycles in a steel wire armoring direction when the head end of the outer sheath layer is pulled, keeping a certain tension on the back end and fixing the cable core for preventing untwisting. The steel wire armored power cable performs functions of totally eliminating twisting generated on the steel wire, and eliminating an inner stress of the armored steel wire. After armoring of the steel wire, deformation, loosening and irregularity caused by the inner stress after armoring of the steel wire are prevented. The front end and the back end of the wire core of the finished cable is not limited by an external force, and the effective length of the cable core is ensured through pre-armoring and supplementary armoring.

Owner:SHANGHAI NANDA GROUP

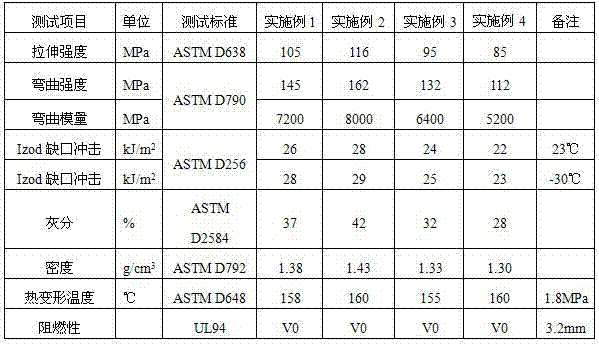

Weather-resistant and hydrolysis-resistant continuous glass fiber reinforced polyamide composite material and preparation method thereof

The invention discloses a weather-proof and hydrolysis-resistant continuous glass fiber reinforced polyamide composite material, which is prepared from the following components by weight: 400-560 parts of PA66, 100-140 parts of PA6, 300-500 parts of continuous glass fiber, 6-10 parts of an antioxidant, 1-6 parts of a composite anti-hydrolysis agent, 2-5 parts of a composite light stabilizer, 4-8 parts of a lubricant, and 5-15 parts of a carbon black masterbatch. The weather-proof and hydrolysis-resistant continuous glass fiber reinforced polyamide composite material provided in the invention has excellent weatherability and good hydrolysis resistance, and at the same time has excellent rigidity and impact toughness. An injection molding piece made of the composite material has a good surface appearance. Besides, the material can be directly shaped through injection molding, the production efficiency is high, and the used piece can be recycled after smashing.

Owner:HEFEI GENIUS NEW MATERIALS

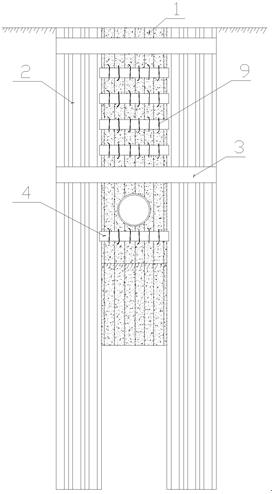

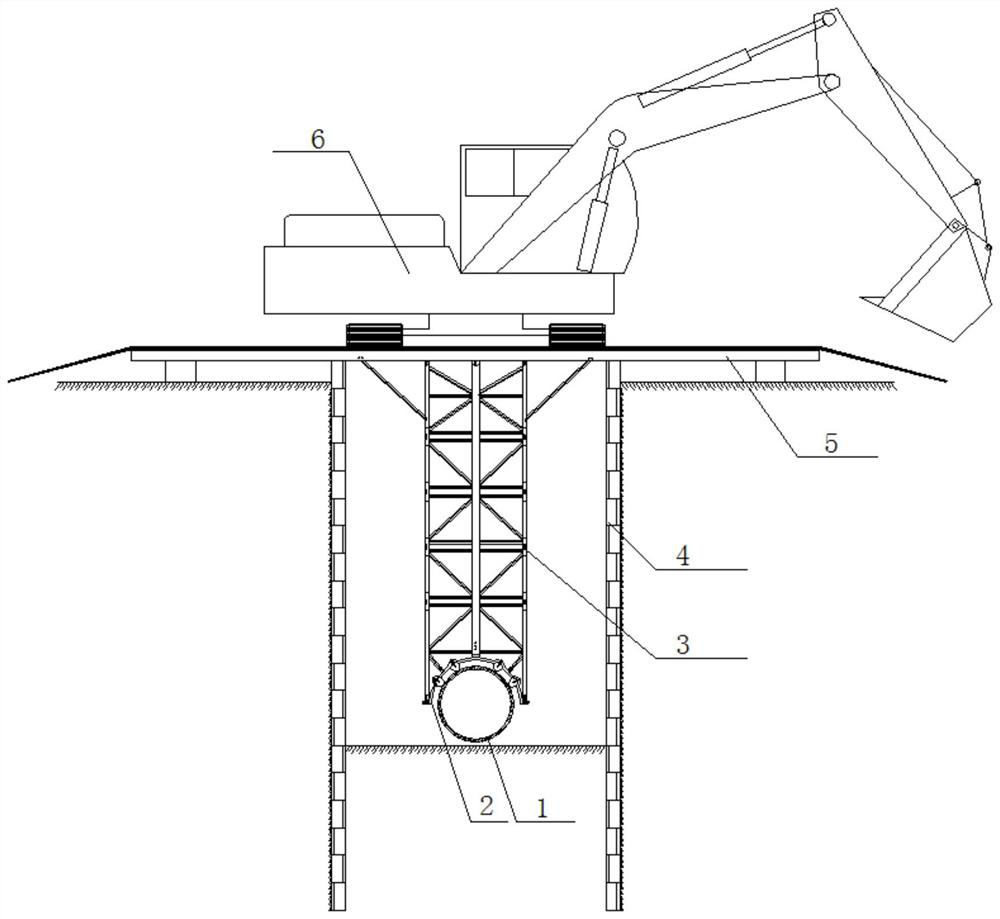

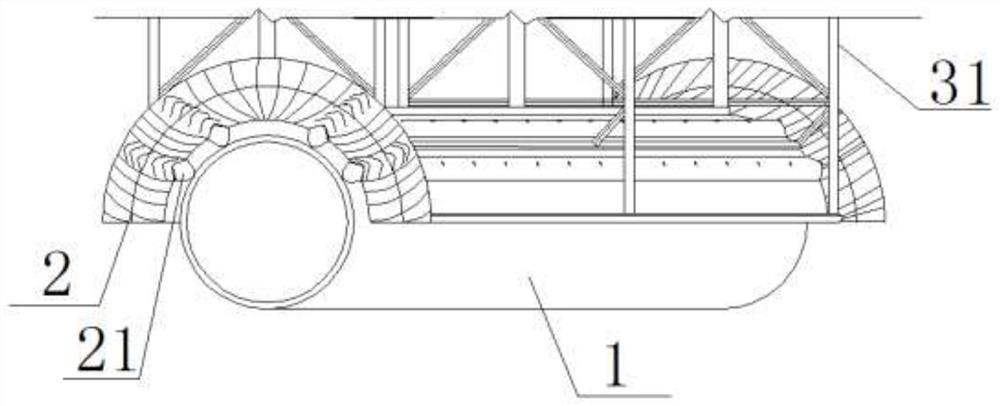

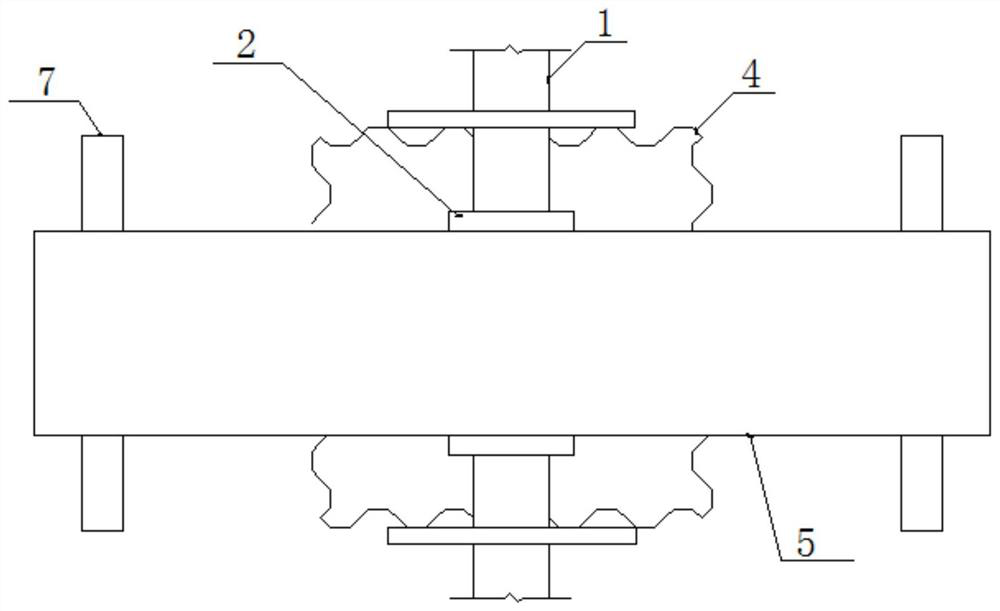

A support structure and construction method for foundation pit of dragged tube well chamber

ActiveCN110629763BPrevent floatingSolve the problem that cannot be fully closedSewerage structuresExcavationsArchitectural engineeringSheet pile

Owner:CHINA FIRST METALLURGICAL GROUP

Pipeline elevation control device and method

ActiveCN110657280BQuality assuranceEasy to dragPipe laying and repairMarine engineeringArchitectural engineering

The application provides a pipeline elevation control device and method, which belong to the technical field of pipeline construction. The pipeline elevation control device includes: a pipeline limiting plate, which is set on the underground dragging pipeline, and is used to limit the dragging track of the pipeline; a support frame, the lower end of which is connected to the pipeline limiting plate, and the upper end is fixed on the ground. A pipeline elevation control method, the steps include: step 1, obtaining construction data and at least two construction well positions; step 2, excavating a foundation pit at the construction well position, and setting a protective structure in the foundation pit; step 3, drilling , and clean up the mud; Step 4, hoist the two pipeline elevation control devices into two construction well positions respectively, adjust the elevation of the pipeline elevation control devices and fix their positions; Step 5, drag the pipeline for construction. In this application, the pipeline elevation control device is used to control and limit the elevation of the pipeline, so as to ensure the effective length of the pipeline underground and avoid the bending problem of the pipeline.

Owner:CHINA FIRST METALLURGICAL GROUP

A method for cultivating artificial quartz crystal seed crystals with low corrosion tunnel density

ActiveCN112176408BGuaranteed effective lengthQuality improvementAfter-treatment apparatusPolycrystalline material growthPhysical chemistryCrystal growth

The invention discloses a method for cultivating artificial quartz crystal seed crystals with low corrosion tunnel density. Crystal blocks; high-quality quartz raw materials are broken into blocks, washed with water, alkali washed, diluted with water, dried, and put into the dissolution zone at the lower part of the autoclave; On the side and bottom, the opening of the U-shaped groove hangs downwards on the crystal growth rack, and the crystal growth rack is placed in the upper growth area of the autoclave; the U-shaped groove is filled to form a complete shape of the artificial quartz crystal. After the growth is stopped, the seeds are removed The original U-shaped part of the crystal is extracted, and the newly filled part of the quartz crystal in the U-shaped groove is extracted to obtain an artificial quartz crystal seed crystal with a low corrosion tunnel density. The invention can solve the seed crystal requirement for the growth of artificial quartz crystal with low corrosion tunnel density, and meet the miniaturization and high-frequency QMEMS manufacturing process application of the crystal oscillator element.

Owner:SINOMA SYNTHETIC CRYSTALS CO LTD +1

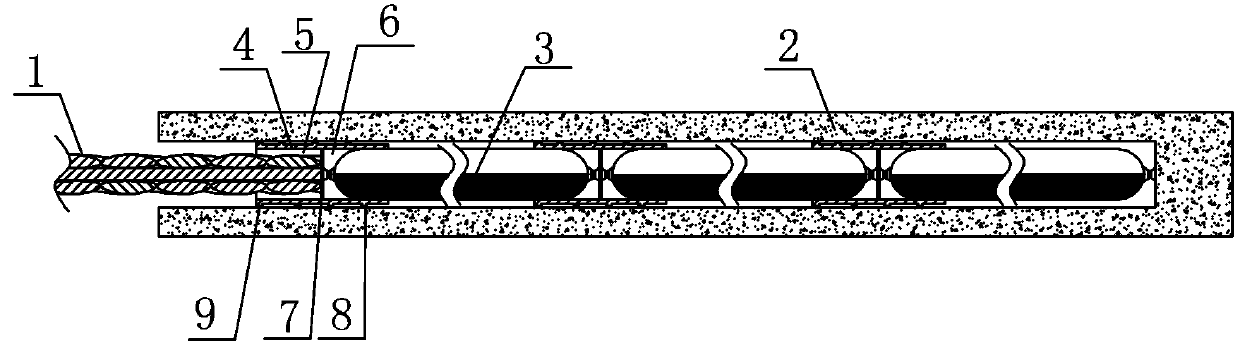

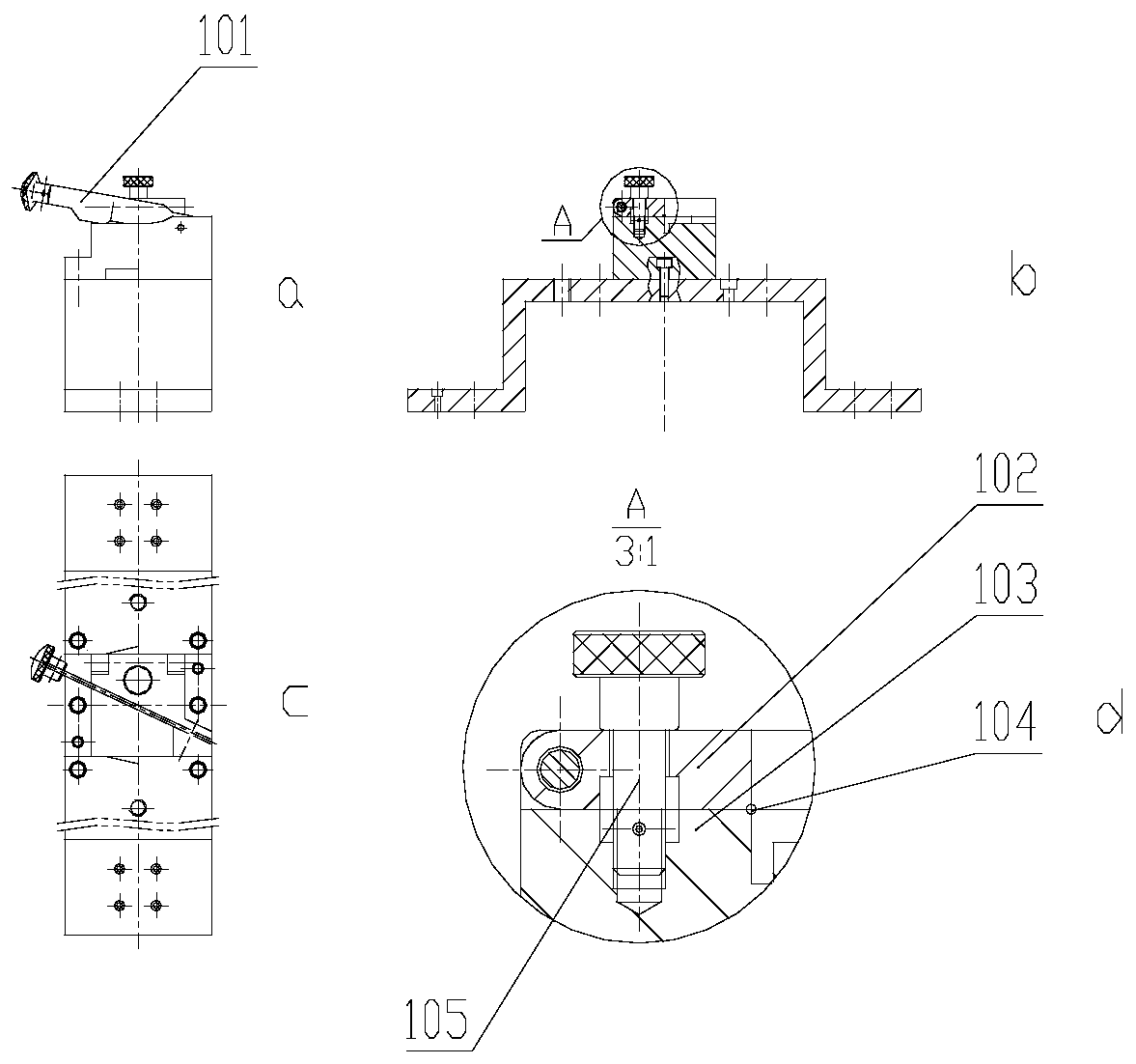

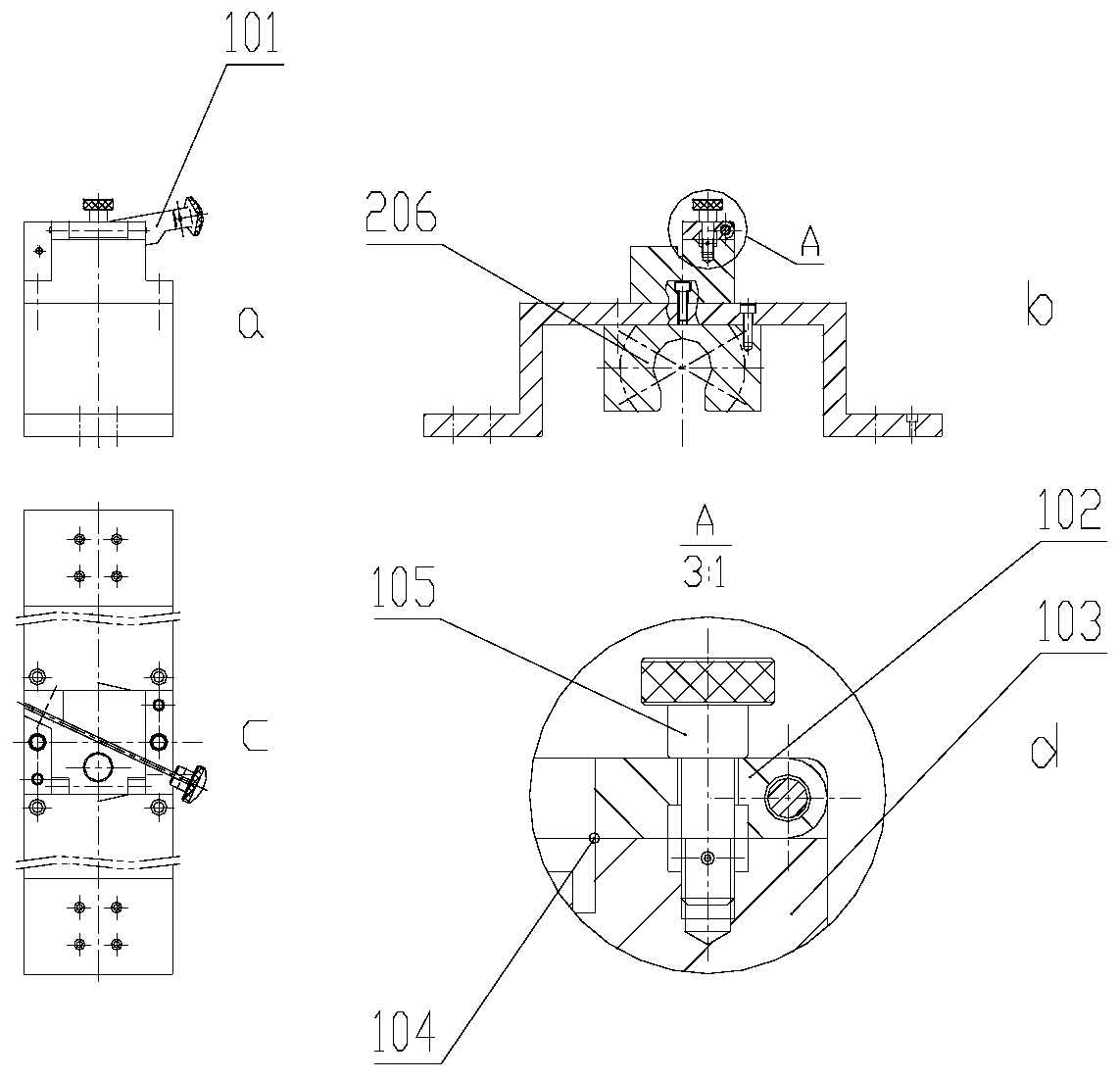

An anchoring agent leak-proof orientation method

ActiveCN108035753BGuaranteed effective lengthPrevent outflowAnchoring boltsClosed chamberEngineering

The invention discloses an anti-leakage orientation method for anchoring agents. After anchoring holes are constructed, the anchoring agents are inserted into anchoring agent installation components,the anchoring agent installation components include anchoring agent installation cylinders and anti-leakage blades, the anti-leakage blades are distributed in the outer walls of the anchoring agent installation cylinders, the interiors of the anchoring agent installation cylinders are divided into two upper and lower anchoring agent installation holes by partitioning pieces, and the anchoring agents are inserted into the anchoring agent installation holes; the anchoring agents are installed, an anchor rod is inserted into the lowest anchoring agent installation hole, and the anchor rod and theanchoring agents are integrally pushed to the bottoms of the anchoring holes; the anchor rod is rotated to break the partitioning pieces, so that the anchoring agents are stirred, gaps between the anchor rod (cable) and the inner walls of the anchoring agent installation holes are filled with the broken anchoring agents, an oriented blade can ensure that multi-volume anchoring agents are alignedwith the anchoring holes to prevent the outflow of the anchoring agents in each protection segment, and a relatively closed chamber is formed between the adjacent two anchoring agent installation components, so that the closed chamber is evenly filled with the anchoring agent.

Owner:HENAN POLYTECHNIC UNIV

A graphene synergistic continuous glass fiber reinforced halogen-free flame-retardant and weather-resistant PPO/hips alloy material and preparation method thereof

ActiveCN107541049BImprove mechanical propertiesImprove interface compatibilityFiberWeather resistance

The invention discloses a graphene-coordinated continuous glass fiber reinforced halogen-free flame-retardant and weather-resistant PPO / HIPS alloy material. The material is prepared from the following components in parts by weight: PPO: 360-480 parts, HIPS: 240-320 parts parts, continuous glass fiber: 200-400 parts, graphene 5-15 parts, compatibilizer 10-20 parts, toughening agent 50-80 parts, flame retardant 80-120 parts, antioxidant 6-10 parts, 3-5 parts of composite light stabilizer, 4-8 parts of lubricant, metal oxide: 5-15 parts. In the present invention, the PPO / HIPS alloy is reinforced by adding pre-dispersed graphene in coordination with continuous glass fiber, and compounding various functional additives, so that the material not only has excellent rigidity and impact toughness, but also has excellent weather resistance and flame retardant. It can meet the application of glass fiber reinforced PPO / HIPS alloy in different fields. The material can be directly molded by injection molding, and the production efficiency is high. The used parts can be recycled after being crushed. .

Owner:HEFEI GENIUS NEW MATERIALS

Continuous long fiber reinforced thermoplastic polyurethane material and preparation method thereof

The invention belongs to the technical field of high polymer materials and discloses a continuous long fiber reinforced thermoplastic polyurethane material and a preparation method thereof. The continuous long fiber reinforced thermoplastic polyurethane material disclosed by the invention comprises the following components in parts by weight: 200-800 parts of thermoplastic polyurethane, 800-200 parts of continuous long fiber reinforcing agent, 10-30 parts of compatilizer, 10-20 parts of antioxidant, 2-6 parts of lubricating agent and 5-10 parts of crosslinking agent. Compared with the prior art, the continuous long fiber reinforced thermoplastic polyurethane material disclosed by the invention is simple in structure, reasonable in design and strong in practicability; and a long glass fiber reinforced thermoplastic polyurethane material is adopted, thereby greatly improving the rigidity and strength of the material and obviously improving the anti-impact property and heat-resistant property of the material.

Owner:HEFEI GENIUS NEW MATERIALS

A flame retardant material for lithium battery shell based on long glass fiber reinforced polypropylene and its preparation method

The invention discloses a lithium battery shell flame-retardant material based on long glass fiber reinforced polypropylene and a preparation method thereof. The lithium battery shell flame-retardant material is prepared from the following components in parts by weight: polypropylene, continuous glass fiber , coupling agent, main antioxidant, auxiliary antioxidant, lubricant, compatibilizer, composite flame retardant and black masterbatch. The preparation method is to put the above components except the continuous glass fiber into the high mixer and mix them evenly before entering the extruder, and then the extruder melts and extrudes the above materials into the impregnation equipment, and at the same time the continuous glass fiber enters the impregnation equipment It is dispersed and impregnated with the molten material, and finally pulled out from the shaping die of the impregnation equipment, cooled, dried, and pelletized to obtain the finished product. The invention has more excellent strength and toughness, is not easy to burn under an open flame, can effectively reduce the occurrence of battery burning accidents, and ensures that the shell has good plasticity and compressive strength.

Owner:HEFEI GENIUS NEW MATERIALS

Laboratory VOCs treatment device and treatment method thereof

InactiveCN112426846AImprove practicalitySmooth entryGas treatmentDispersed particle separationActivated carbonPollution

The invention discloses a laboratory VOCs treatment device which comprises a collecting device, and an isolating device is arranged at the top of the collecting device. through cooperation of the collecting device, the isolating device, a transmission device, a feeding device and an adsorption device, the laboratory VOCs treatment device can automatically replace preferentially saturated activatedcarbon on the air source side, it is ensured that the effective length of an activated carbon column is within a safe range, the retention time of waste gas in the activated carbon is long enough, itis ensured that the waste gas is fully purified, purified air can reach the standard, and environmental pollution cannot be caused. People can supplement activated carbon into the feeding device in time through a warning device, the activated carbon can enter the adsorption device more smoothly through cooperation of the transmission device and a rapping device, and the activated carbon can enterthe adsorption device more smoothly. Through a prompt device, people can timely and intensively treat saturated activated carbon in the collecting device, so that the practicability of the laboratoryVOCs treatment device is improved.

Owner:安徽净工坊环保科技有限公司

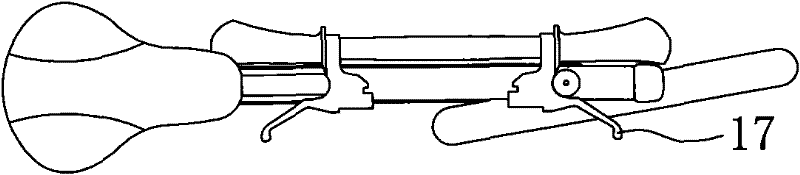

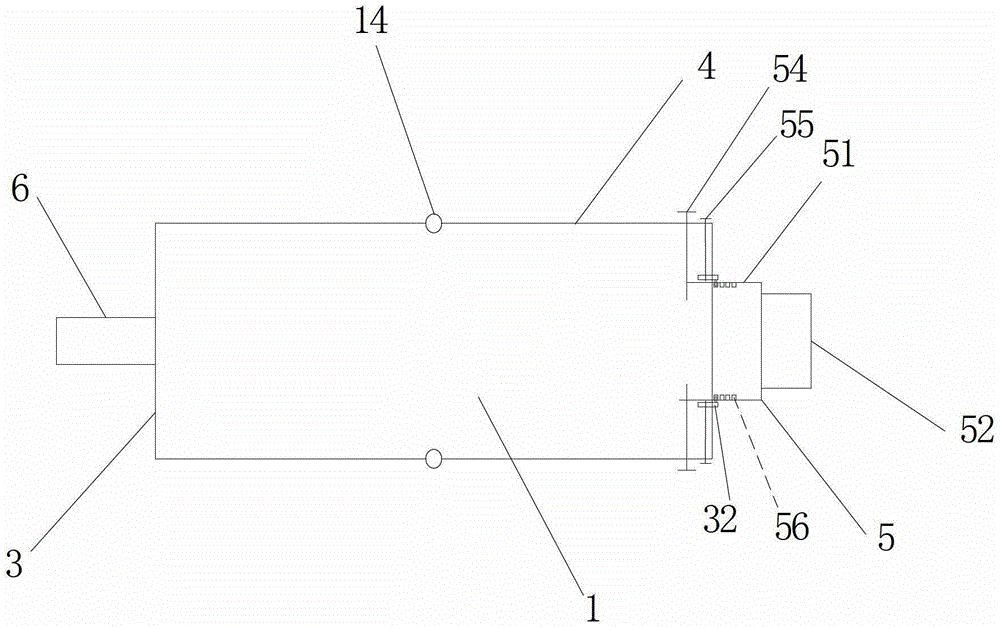

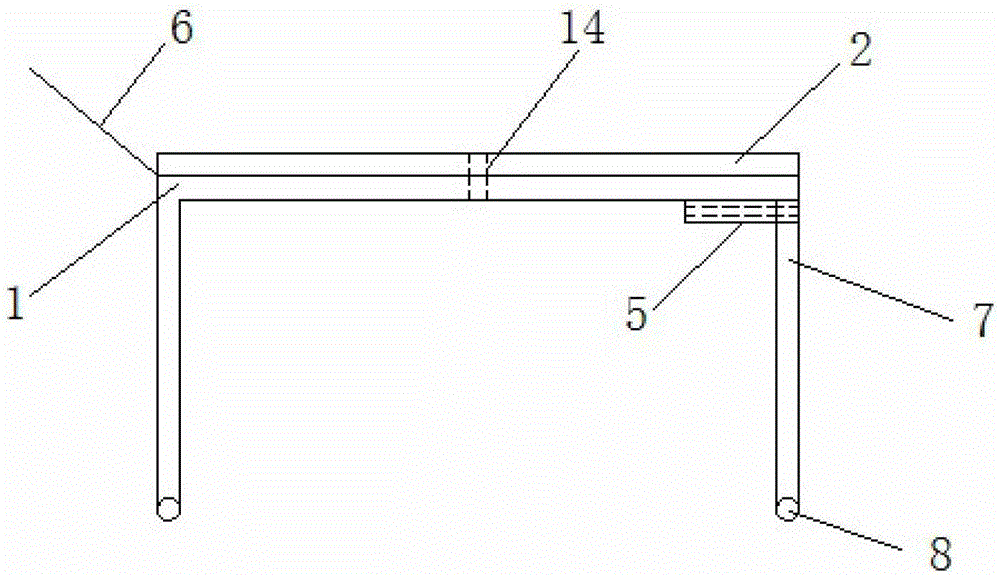

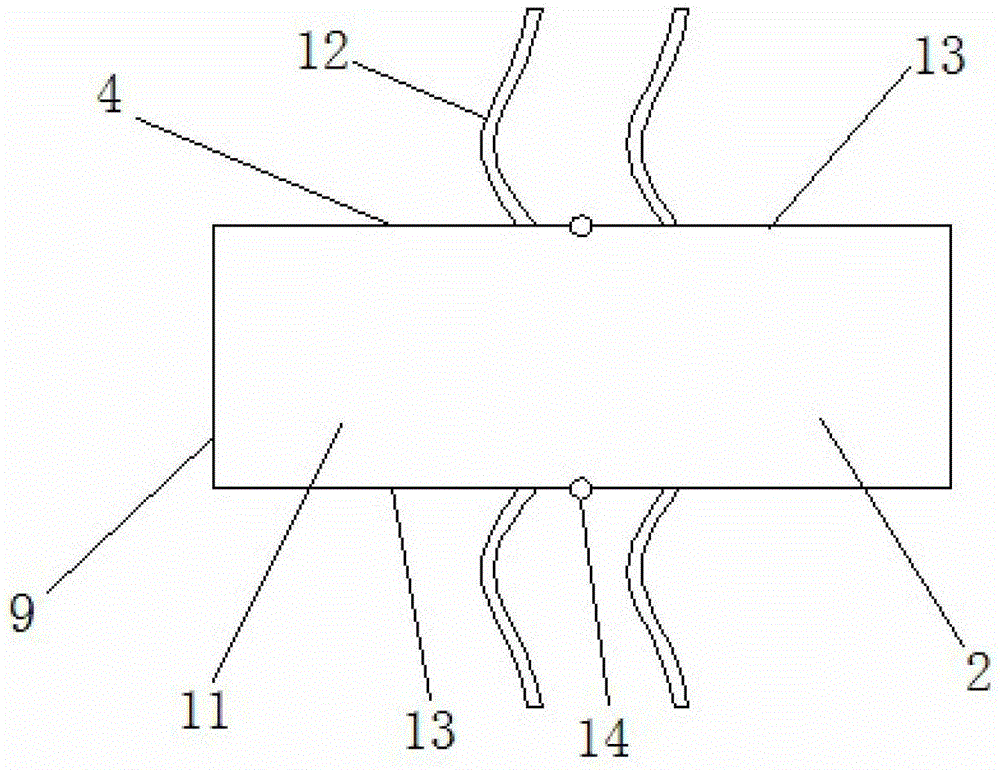

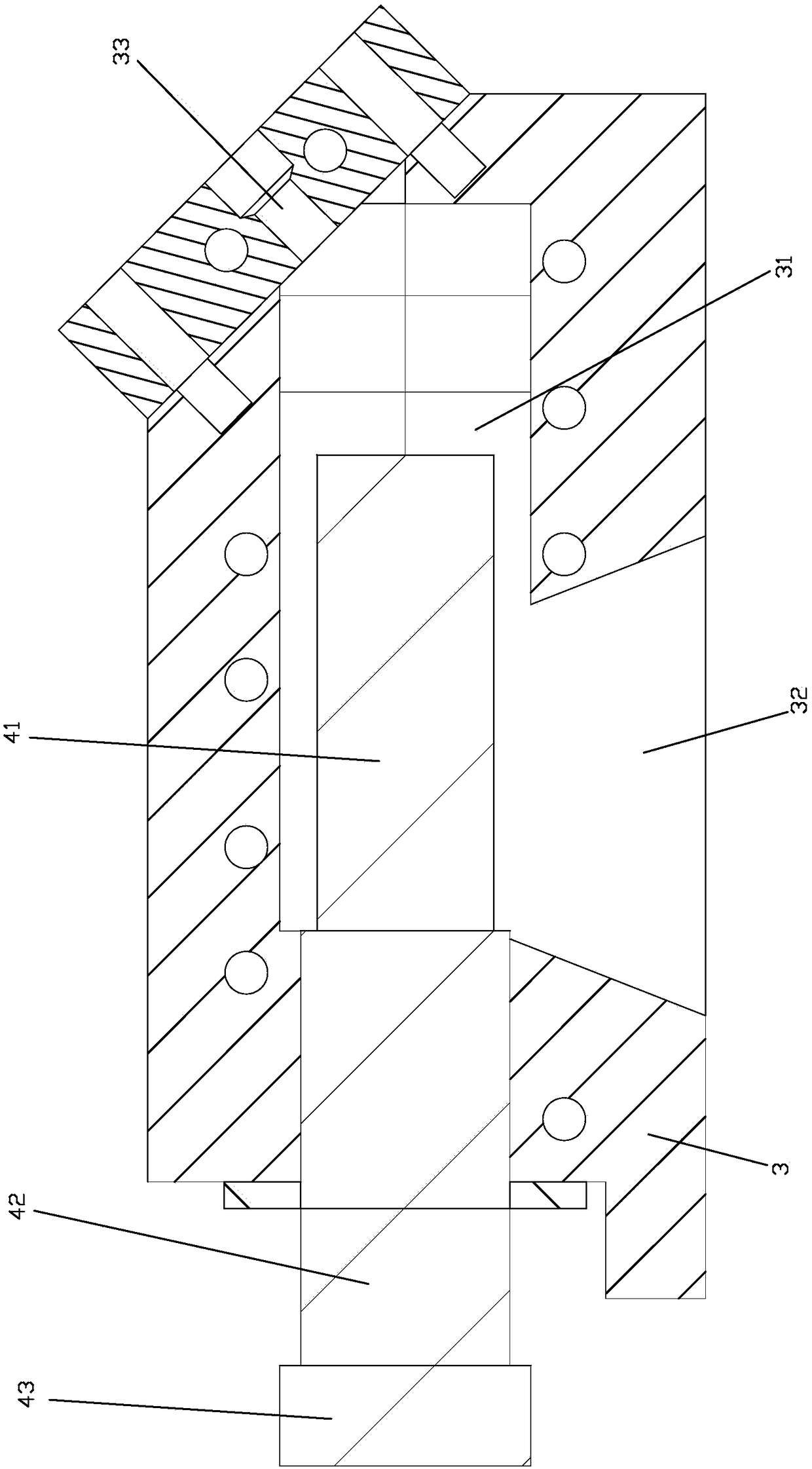

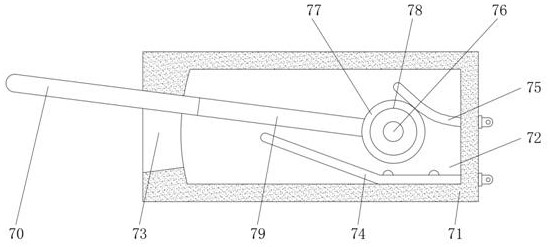

An Indium Wire Cutting Device Used for Sealing of Low Temperature Accumulator

The invention provides a cutting-off device of an indium wire for sealing a low-temperature pressure accumulator. The cutting-off device is used for cutting the indium wire with specific length, and overcomes the problems that in the prior air, in regard to special material cutting, the length and the angle of the cut indium wire cannot meet the technical requirements of the drawing, and the section of the cut indium wire is not flat and is large in deformation. A transmission assembly can be controlled through an electrical system, so that a movable cutter rest assembly can carry out accuratepositioning according to the length of the indium wire needing to be cut off; and the section of the indium wire is flatly pressed and cut off according to the length and the angle required to be cutoff through a cutting-off mechanism with a pressing structure.

Owner:CAPITAL AEROSPACE MACHINERY +1

Laser laser transfer printing machine

The invention relates to a laser transfer printing press. The laser transfer printing press comprises a paper conveyor belt, a film pressing device, a UV (Ultraviolet) solidification device and a paper collection belt. An object to be printed is input from the paper conveyor belt and output from the paper collection belt via the film pressing device and the UV solidification device. The laser transfer printing press further comprises a thin film splicing device, a rolling device and an unrolling device, wherein the thin film splicing device is used for changing an old pre-treated thin film into a new pre-treated thin film when a pre-treated thin film is needed to be changed, and the operative pre-treated thin film is laid on a closed loop formed by the thin film splicing device, the film pressing device and the UV solidification device. With the adoption of the structure, the laser transfer printing press can achieve that a thin film is reused by the film pressing device in an internal circulation way, prevents external dust from reaching the thin film and affecting the service life of the thin film, reduces the loss of the thin film, lowers the risk factor for workers, and is simple in structure and wider in application range.

Owner:SHANGHAI QIANYAN MACHINERY CO LTD

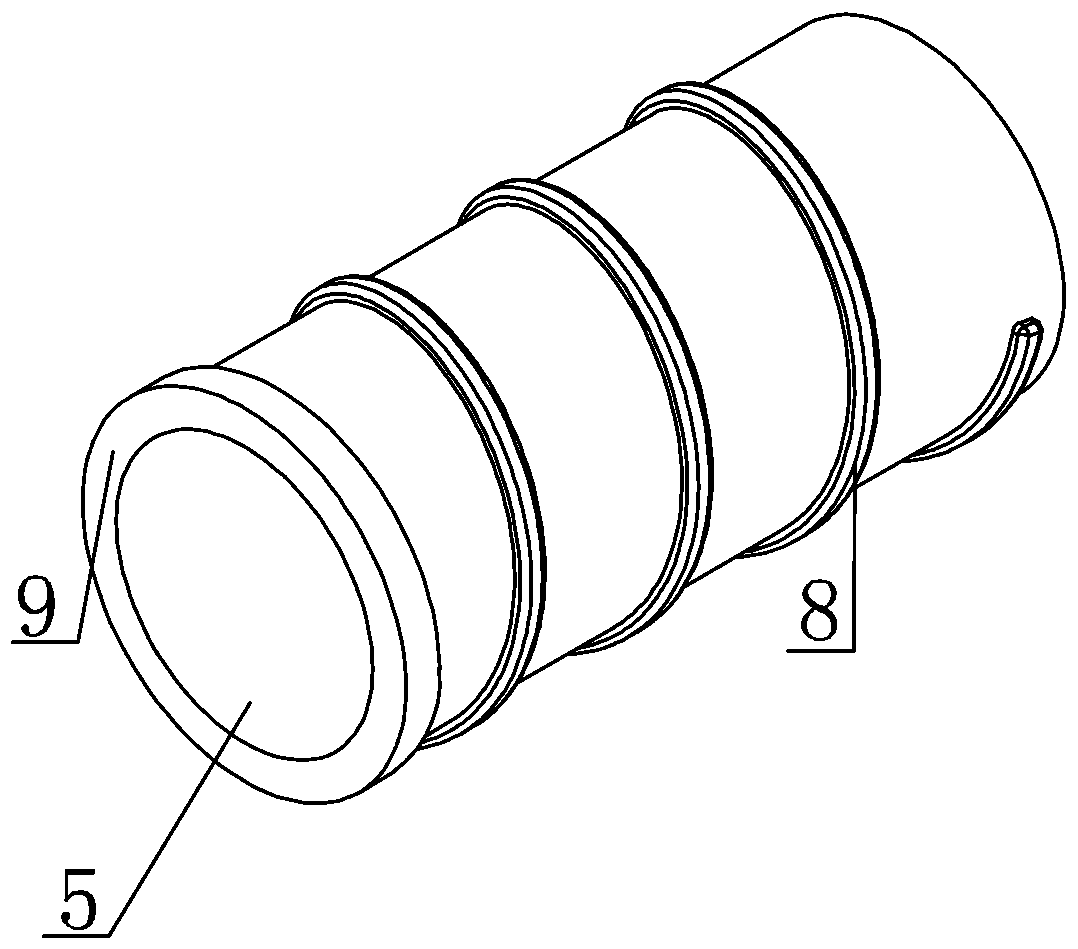

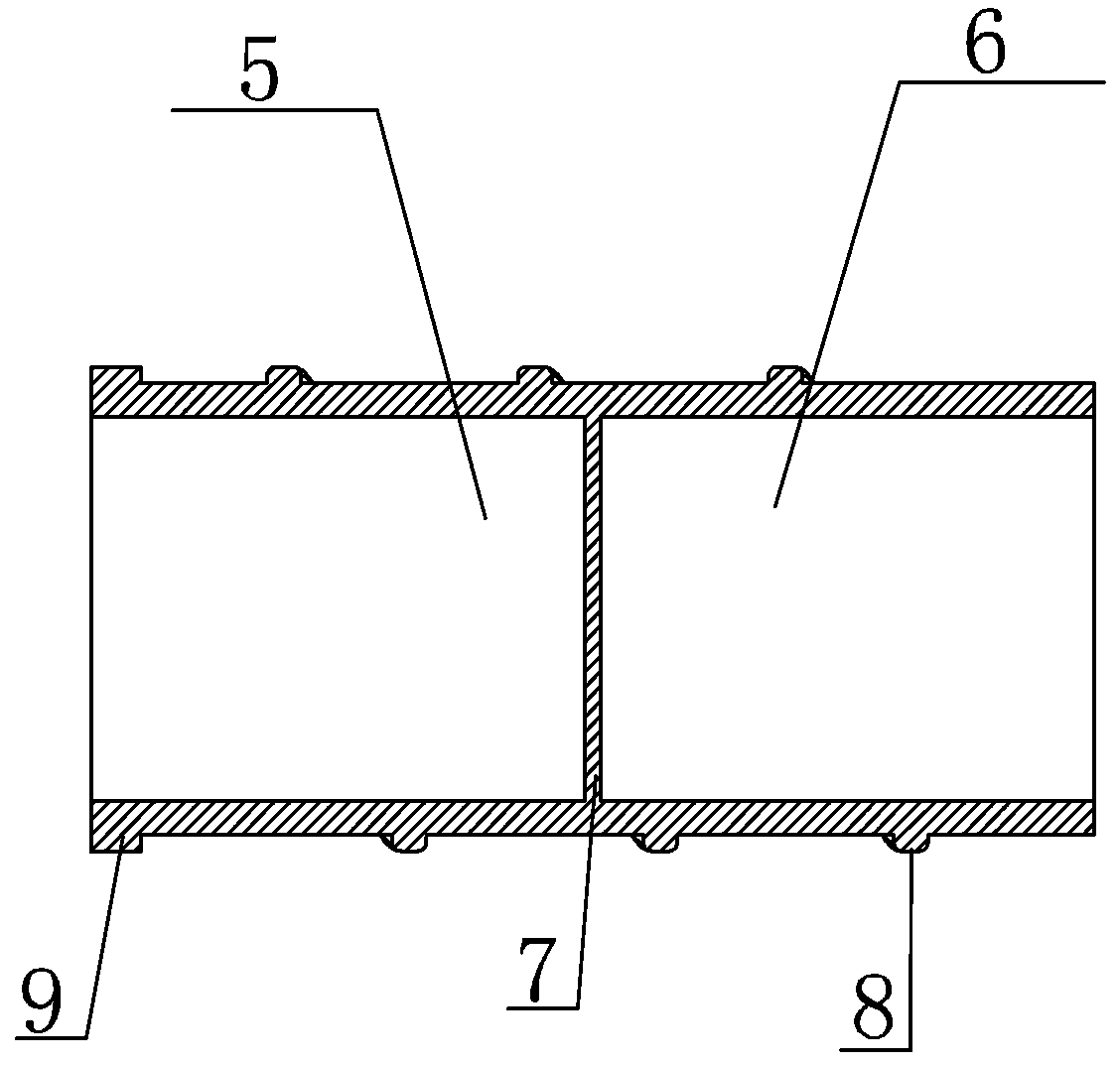

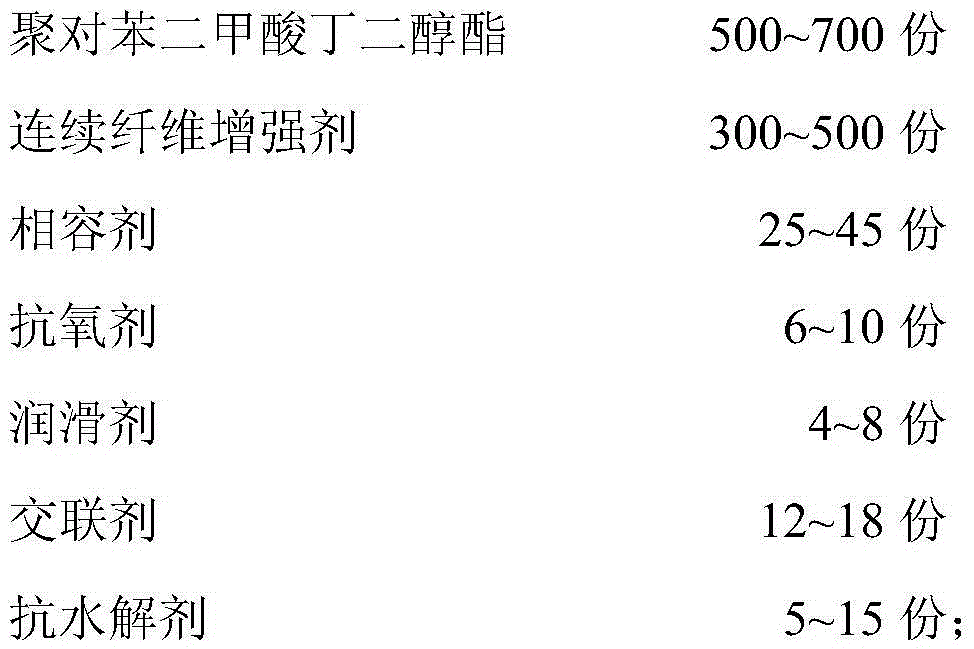

Continuous fiber reinforcement polybutylene terephthalate material and preparation method

ActiveCN102585454BGuaranteed effective lengthImprove interface performancePolytetramethylene terephthalatePolyethylene terephthalate

The invention relates to a continuous fiber reinforcement polybutylene terephthalate material and a preparation method. The material comprises the following components in parts by weight: 500-700 parts of polybutylene terephthalate, 300-500 parts of continuous fiber reinforcer, 25-45 parts of compatilizer, 6-10 parts of antioxygen, 4-8 parts of lubricant, 12-18 parts of coupling agent and 5-15 parts of anti-hydrolytic agent. Compared with the prior art, the preparation method is reasonable in design, is simple in operation and is strong in practical applicability. The continuous fiber reinforcement polybutylene terephthalate material is adopted, so that the length of fibers in prepared part can be kept to be 3-6mm, and thereby, the rigidity and the strength of the material are greatly increased, and meanwhile, the shock resistance and the heat resistance of the material are obviously improved. Moreover, the continuous fiber reinforcement polybutylene terephthalate material has long-term anti-hydrolytic stability and chemical corrosion resistance.

Owner:HEFEI GENIUS NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com