Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Guarantee production needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of large-size titanium alloy intermediate rod material

ActiveCN1657197ASolve technical problems that are prone to cracksAvoid formingMetal-working apparatusSurface cleaningIngot

Owner:宝武特冶钛金科技有限公司

Lentinus edodes strain culture medium containing coconut powder and preparation method thereof

InactiveCN106591151AEnsure transparencyModerate viscosityFungiMicroorganism based processesShiitake mushroomsRhizome

The invention belongs to the field of an edible fungus culture medium and particularly relates to a lentinus edodes strain culture medium containing coconut powder and a preparation method thereof. The lentinus edodes strain culture medium containing coconut powder is a lentinus edodes mother strain culture medium containing coconut powder or a lentinus edodes liquid strain culture medium containing coconut powder, wherein the lentinus edodes mother strain culture medium containing coconut powder comprises the following raw materials: wood dust, corn cobs, common yam rhizomes, taros, sweet potatoes, coconut powder, lentinus edodes powder, walnut powder, red bean powder, coix seed powder, agar powder and water; and the lentinus edodes liquid strain culture medium containing coconut powder comprises the following raw materials: peanuts, kernels, wood dust, corn cobs, common yam rhizomes, taros, sweet potatoes, coconut powder, walnut powder, red bean powder, coix seed powder and water. According to the formula of the culture medium provided by the invention, on the basis of improving the type of the formula of the culture medium suitable for growth of lentinus edodes mycelia, the requirements of actual production of the lentinus edodes strain are ensured.

Owner:LIAONING ACAD OF AGRI SCI

Purification process of raw material gas for production of synthetic ammonia or methanol production

InactiveCN1962414AMeet production requirementsGuarantee production needsProductsHydrogen separationTowerAmmonia

The invention discloses a purifying technology of raw material of synthetic ammonia or carbinol, which comprises the following steps: setting the pressure of transforming gas from transforming system at 3.4-3.6Mpa; transmitting into the bottom of desulfurizing tower to contact with reflow steric hindrance amine desulfurizing liquid from top of tower; making H2S and partial CO2 adsorbed by solution; decarburizing; entering transforming gas with pressure at 3.3-3.5Mpa from desulfurizing segment into adsorbing tower from the bottom; contacting with reflow MDEA in the tower.

Owner:SHANXI YANGMEI FENGXI FERTILIZER IND GRPCO

Vegetable cleaning device

A vegetable cleaning device comprises a base plate, a motor device, an external frame body device and a cylinder device. The base plate is provided with first supports, first oblique rods, a fixed frame, first support rods and first fixed blocks, the motor device comprises a motor, a first rotating shaft, second oblique rods, an internal frame body, a sealing ring and second support rods, the external frame body device comprises an external frame body, a material discharging ring and a fixed ring, the cylinder device comprises a first fixed frame, a second fixed frame, a cylinder, a pushing rod, a pressing plate and a splash-proof frame, the cross section of the external frame body is shaped like a Chinese character 'ao', a circular hole is formed in the lower surface of the external frame body, the lower end of the internal frame body is contained in the circular hole and connected with the external frame body in a sliding mode, the upper end of the first support is fixedly connected with the lower surface of the external frame body, the upper surface of the sealing ring is connected with the lower surface of the internal frame body in a sliding mode, the upper surface of the material discharging ring is in an inclined mode, and the outer surface of the fixed ring is fixedly connected with the inner surface of the external frame body. According to the vegetable cleaning device, effective cleaning can be conducted on vegetables, the cleaning efficiency is high, and manual use is reduced.

Owner:张佳训

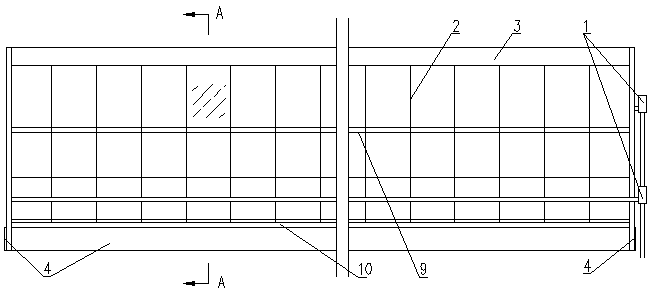

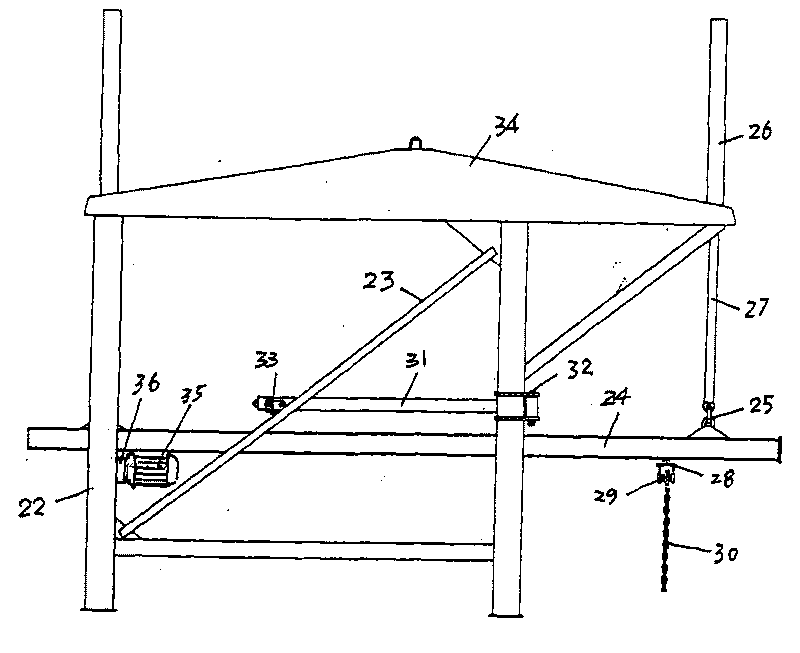

Sunlight greenhouse with heat-storage heat-insulation wall and building method thereof

ActiveCN104303895AIncrease temperatureGuarantee production needsClimate change adaptationGreenhouse cultivationWinding machineGreenhouse

A sunlight greenhouse with a heat-storage heat-insulation wall comprises a transmitting plastic greenhouse film and a heat-insulation quilt. The sunlight greenhouse is characterized by further comprising a foundation pad. The foundation pad is a solidified concrete body, a rear sleeper beam is fixedly connected with the foundation pad, the two ends of each arch frame are inserted and fixedly connected with a front ground beam and the rear sleeper beam respectively, and a plurality of arch frames are fixedly connected to be a whole through a longitudinal beam. Gables on the two sides are fixedly connected with a gable ground beam, and rear walls are placed on the rear sleeper beam and the arch frames and are fixedly connected. The transmitting plastic greenhouse film is externally laid on the arch frames and fixedly connected with the arch frames, the heat-insulation quilt covers the outer portion of the transmitting plastic greenhouse film, and heat-insulation plates are arranged on the outer sides of the foundation pad, the gable ground beam and the front ground beam along the circumference. A building method comprises the steps of leveling the ground, laying the rear sleeper beam, installing the arch frames, installing the gables on the two sides, installing the longitudinal beam, installing the wall, laying the transmitting plastic greenhouse film, laying the heat-insulation quilt, installing a film winder, installing a curtain winding machine, arranging the heat-insulation plates along the circumference, and performing earth filling and compaction. The sunlight greenhouse has the advantages of being simple in structure, low in cost, balanced in temperature, economical, environmentally friendly and favorable for second ploughing.

Owner:吉林市东北生态农业发展有限责任公司

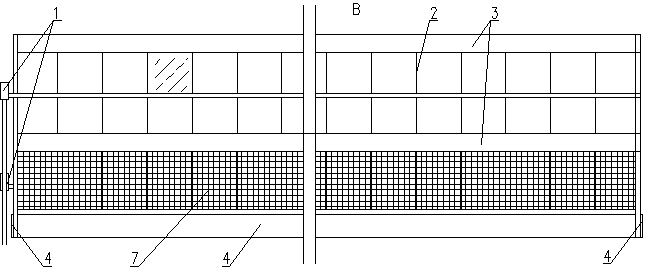

Fischer-Tropsch synthesis reaction product separation equipment

PendingCN108525613ASimple structureEasy to separateLiquid hydrocarbon mixture productionChemical/physical processesSlurry reactorReaction product

The invention relates to Fischer-Tropsch synthesis reaction product separation equipment. The equipment comprises a shell, a feed inlet, a feed pipe, a separator, a first discharge hole and a second discharge hole, wherein the top of the shell is provided with the feed inlet, one side of the middle upper part of the shell is provided with the first discharge hole, the bottom of the shell is provided with the second discharge hole, and the feed inlet, the feed pipe and the separator are coaxially arranged inside the shell and are communicated sequentially; the side walls of the separator are formed by surrounding four or more than four filtering and separating units which are vertically arranged, and the middle is provided with a cavity; the upper end of the separator is closely connected and communicated with the feed pipe through a top plate; a closed bottom plate is arranged at the lower part of the separator; and a filtering tray is arranged at the lower end of each filtering and separating unit, and a down pipe is arranged in each filter disk. The Fischer-Tropsch synthesis reaction product separation equipment provided by the invention realizes efficient separation of slurry reactor reaction products, and a Fischer-Tropsch synthesis reaction device can stably operate for a long period.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

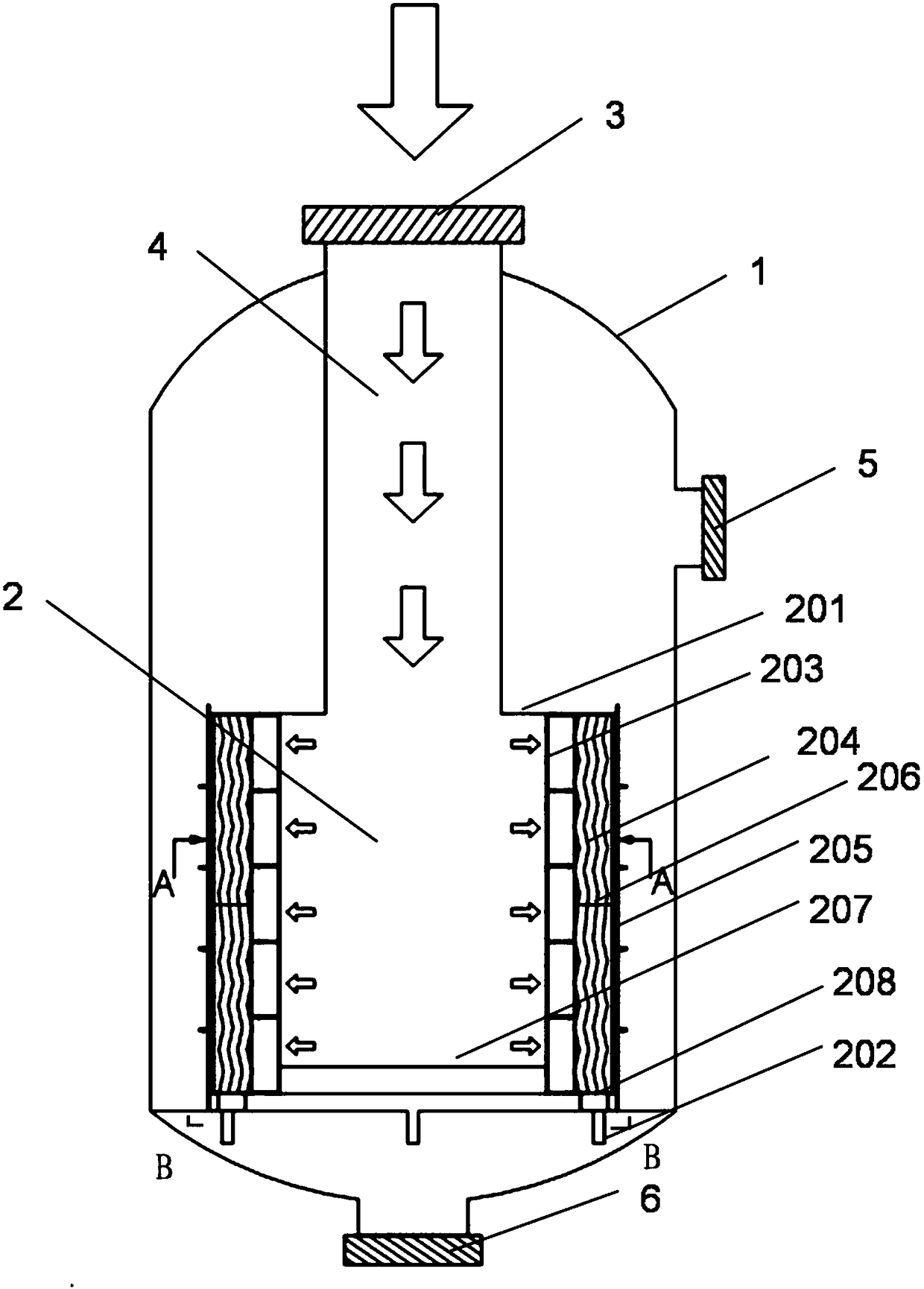

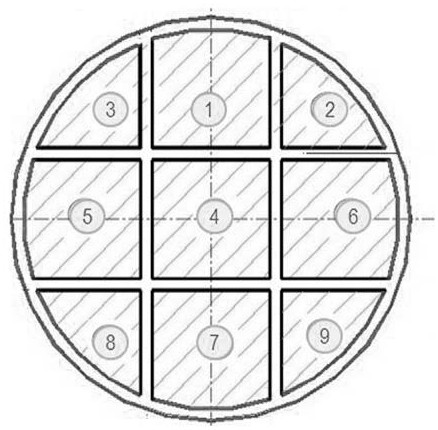

Reduction reaction furnace for polysilicon

InactiveCN101463498AGuarantee production needsExpand production scalePolycrystalline material growthSiliconEngineeringPolycrystalline silicon

The invention provides a polysilicon reduction reaction furnace, which comprises a furnace body, an electrode arranged in the furnace body and a silicon core connected with the electrode, an air inlet, an air outlet, an active furnace door arranged on the opening of the furnace body, and an electrode tray which is separated with the furnace body but moves or are fixed. The central axis of the furnace body is arranged along the horizontal direction. The reduction reaction furnace is used for producing polysilicon, which can easily expand the scale of production, shortens the production period, saves production cost, and increases the yield and productivity effect.

Owner:袁建中

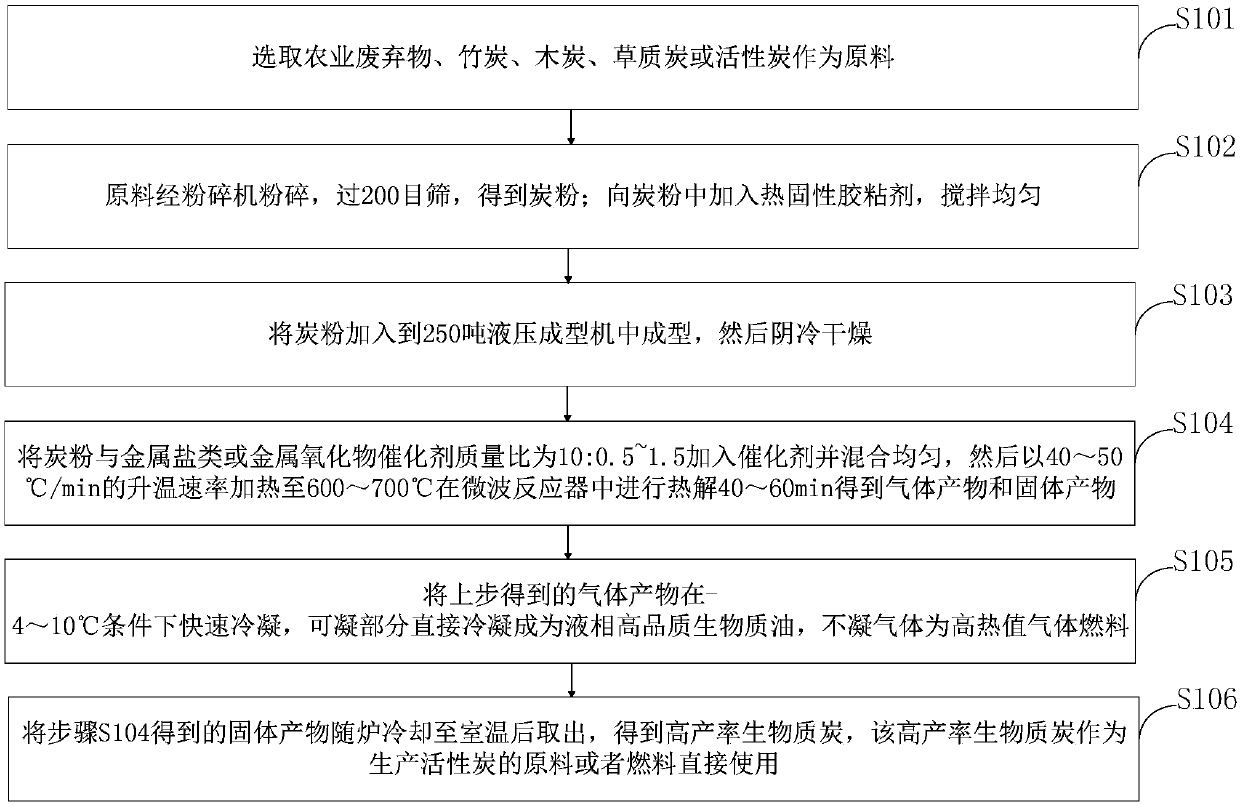

Method for directionally producing biomass charcoal by microwave catalytic pyrolysis of biomass

InactiveCN108251140AReduce usageReduce corrosionBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisAdhesive

The invention belongs to the technical field of biomass charcoal, and discloses a method for directionally producing biomass charcoal by the microwave catalytic pyrolysis of biomass. The method comprises the following steps: selecting agricultural wastes, bamboo charcoal, wood charcoal, grass charcoal or activated carbon as raw materials; smashing the raw materials by a pulverizer, and sieving toobtain powdered carbon; adding thermosetting adhesive into the powdered carbon, and evenly mixing; then, carrying out cold drying; evenly mixing the powdered carbon, metal salt or metal oxide catalyst, then, heating, carrying out pyrolysis for 40-60min in a microwave reactor to obtain a gas product and a solid product; quickly condensing the obtained gas product under a condition of -4 to 10DEG C,directly condensing a coagulable part into liquid-phase high-quality biomass oil, and taking non-condensing gas as high calorific value gas fuel. According to the method, the agricultural wastes aretaken as the raw material so as to be favorable for environment protection and the reuse of agricultural wastes. A preparation process of the biomass charcoal materials does not generate tar.

Owner:HUAIYIN TEACHERS COLLEGE

Method for efficiently preheating coke oven gas

InactiveCN102944129AEasy to handleRaise the preheat temperatureStationary tubular conduit assembliesAutomatic controlDecomposition

The invention discloses a method for efficiently preheating coke oven gas. The coke oven gas is subjected to preheating treatment by flue gas or waste gas with the temperature of above 1,150 DEG C, and the flue gas or the waste gas and the coke oven gas are subjected to countercurrent heat exchange, wherein the preheating treatment comprises convection preheating treatment and radiation preheating treatment which are performed sequentially; after the convection preheating treatment, the coke oven gas is preheated to 500 to 600 DEG C; and after the radiation preheating treatment the coke oven gas is continuously preheated to 800 to 950 DEG C. The coke oven gas is preheated by completely utilizing the sensible heat of high-temperature flue gas or tail gas, so that the preheating time is short, the preheating temperature is high, the automatic control can be realized basically, the heat efficiency is high, and operation safety and reliability are achieved. High-temperature decomposition of hydrocarbon in the coke oven gas and carbon deposition can be effectively prevented by adding a trace amount of a carbon deposition inhibitor and a decarbonizer, and the application range is wide.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Dropping pill for treating throat disease and preparing method thereof

ActiveCN1850156ASignificant effectGood curative effectHydroxy compound active ingredientsPill deliveryDiseaseSide effect

The present invention relates to a kind of dripping pills for curing pharyngolaryngeal diseases and its preparation method. It is made up by using 20-30 portions of argyi leaf, 10-15 portions of sesame oil, 10-20 portions of peppermint oil, 5-10 portions of menthanol, 10-20 portions of monoammonium glycyrrhizinate and 160-180 portions of polyethylene glycol 6000 through a certain preparation process. Said dripping pills preparation can be used for curing the diseases of acute and chronic pharyngitis, sore-throat, dryness of throat and hematoma of pharynx.

Owner:贵州黄果树立爽药业有限公司

Automatic liquid adding and material mixing machine

InactiveCN109569393AAvoid damageWell mixedTransportation and packagingMixersAutomatic controlEngineering

The invention discloses an automatic liquid adding and material mixing machine. The machine includes a mixing tank and a liquid adding tank. The bottom of the mixing tank is higher than the liquid adding tank; the side wall of the mixing tank and the side wall of the liquid adding tank are provided with spirally arranged compressed air tubes; the bottom of the mixing tank is provided with a waterpipe connecting the liquid adding tank, and the water pipe is provided with an electromagnetic valve; a floating ball liquid level switch is disposed on the upper portion of the liquid adding tank, and the floating ball liquid level switch controls opening and closing of the electromagnetic valve; the spirally arranged compressed air tubes can make a mixed liquid spirally rotate to ensure sufficient mixing and not easy to precipitate; the compressed air tubes are provided with dense circular air holes; the circular air holes on the compressed air tubes orient to the center of a container; andan air inlet of each of the compressed air tubes is at the lower end, and an air outlet is at the upper end. The machine is advantageous in that an automatic control device is adopted, operation of manual patrol and water adding is eliminated, and production need is ensured.

Owner:由治斌

Pressure and oxygen control system for fixed bed aeration gasification process

InactiveCN108264939AReduce supplyReduce wind pressureGasification processes detailsCombustible gas productionControl systemControl signal

The invention discloses a pressure and oxygen control system for a fixed bed aeration gasification process. An outlet of a blast blower is connected with an air output pipe, and an oxygen output pipeis connected with an aeration air main after converging and communicating with the air output pipe; the pressure and oxygen control system comprises an escape pipe and a pressure and oxygen control PLC, one end of the escape pipe communicates with the aeration air main, the other end of the escape pipe is connected to an inlet of the blast blower, and a pipeline of the escape pipe is provided withan escape regulating valve; the aeration air main is provided with an air pressure transmitter and an oxygen analyzer; the air pressure transmitter and the oxygen analyzer are respectively connectedto an input interface of the pressure and oxygen control PLC, and an output interface of the pressure and oxygen control PLC is respectively connected to the escape regulating valve and an aeration gasification PLC; and the pressure and oxygen control PLC controls the opening of the escape regulating valve according to the air pressure and oxygen concentration of the aeration air main and outputsan aeration control signal to the aeration gasification PLC, and the aeration gasification PLC controls an aeration regulating valve, so that the air pressure and oxygen concentration of the aerationair main are kept stable.

Owner:ANHUI JINGHE IND

Temperature control greenhouse for planting shiitake mushrooms

InactiveCN108633630ASimple structureEasy to operateCultivating equipmentsMushroom cultivationTemperature controlGreenhouse

The utility model relates to a temperature control greenhouse for planting shiitake mushrooms. The temperature control greenhouse comprises a greenhouse body, a thermal insulating wall is disposed inthe greenhouse body in the length direction, a chamber of the greenhouse body is divided into a left cultivation chamber and a right cultivation chamber by the thermal insulating wall, a boiler and ahot water pipe are disposed in the thermal insulating wall, and the left wall surface and the right wall surface of the thermal insulating wall are provided with radiators. The boiler, the hot water pipe and the radiators form a circulating loop. A cold water pipe is disposed in the thermal insulating wall, the left wall surface and the right wall surface of the thermal insulating wall are provided with atomizers, and the cold water pipe and the atomizers form a circulating loop. The temperature control greenhouse has the advantages of being free from the influence of the weather and capable of yielding mushrooms all year round, and is suitable for large-scale promotion.

Owner:竹溪县群鑫生态林牧家庭农场

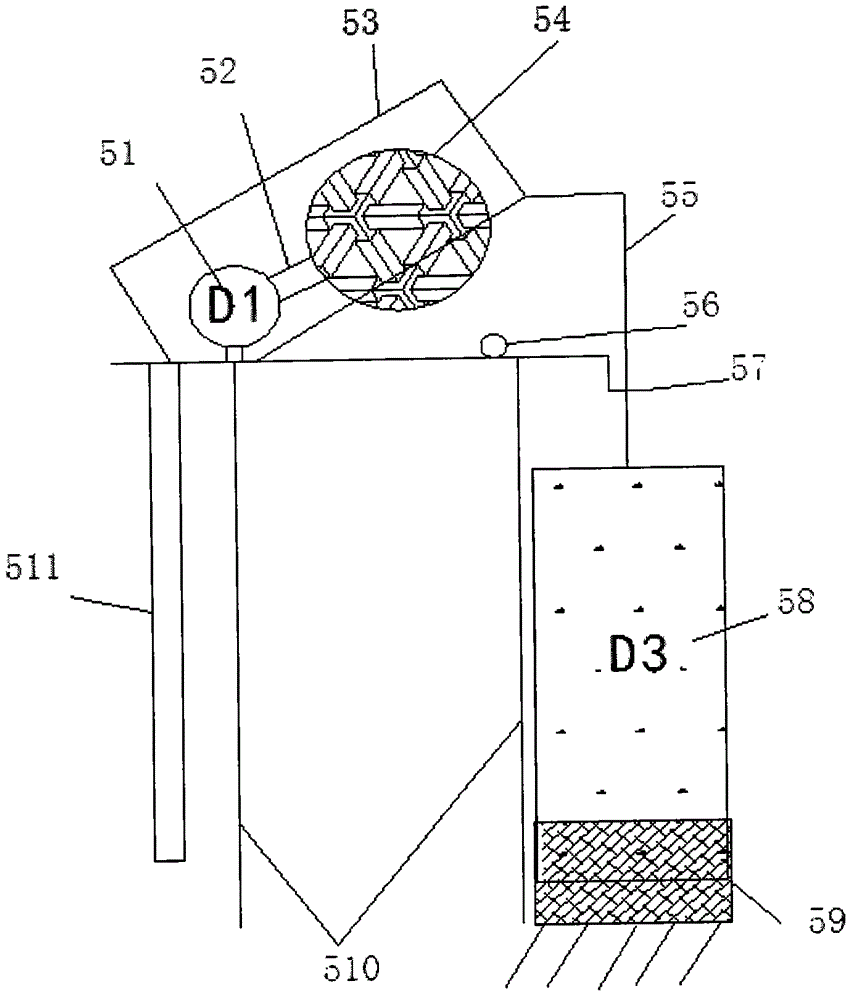

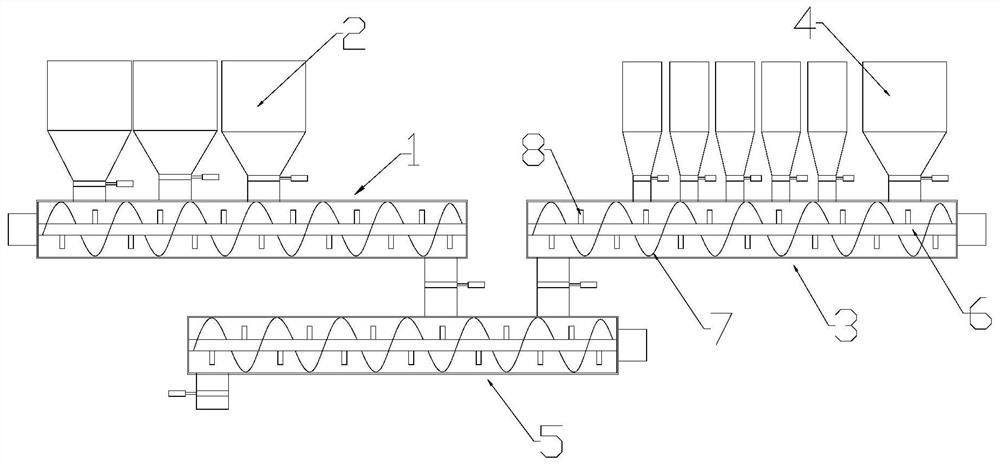

Parallel connection screw conveyer bin discharging conveying machine

InactiveCN104444436AArch fastGuarantee production needsLarge containersLoading/unloadingEngineeringMechanical engineering

The invention discloses a parallel connection screw conveyer bin discharging conveying machine which comprises a storage bin. A tapered hopper with a discharging opening is arranged below the storage bin. Supporting frames are arranged on the position, around the tapered hopper, of the storage bin. The discharging opening of the tapered hopper is provided with a parallel connection screw conveyer. The parallel connection screw conveyer comprises at least two screw shafts arranged side by side and screw blades on the screw shafts. The parallel connection screw conveyer is connected with a transmission device. The ends of the screw shafts are provided with a bin discharging opening. When materials are discharged out of the bin, the parallel connection screw conveyer is started directly, the screw blades rotate to destroy arch of the materials to push the materials to be discharged out of the bin, then the materials are conveyed to the bin discharging opening through the parallel connection screw conveyer, and the production requirement is guaranteed. Compared with a screw bin emptying machine, the parallel connection screw conveyer can destroy arch of the materials quickly, the conveying efficiency is improved greatly, and the bin emptying speed is increased greatly.

Owner:天津中外建输送机械有限公司

Full-automatic steel strand cutter

The invention discloses a full-automatic steel strand cutter. The full-automatic steel strand cutter comprises a supporting frame, a protection device, a steel strand containing frame, an output protecting bush, a feeding device, an automatic lifting cutting device, a size positioning device, an automatic finished-product discharging device and an electric control device. The full-automatic steel strand cutter is simple in structure, convenient to install, reliable in operation, low in investment and high in yield; manual operation is replaced by production automation operation, at least three persons are saved, a forty-steel-strand machining task which originally needs four persons to cooperatively work can be completed in one hour, more than thirty steel strands can be cut per hour, and the labor cost can be saved by 600 yuan every day. By means of the full-automatic steel strand cutter, manual operation is completely changed into automation operation, and the full-automatic steel strand cutter is a great trend of the current social development; in addition, no automatic special equipment for cutting the steel strands in the aspect exists in the society, and the large social popularization potential is achieved; the maintenance cost is quite low, the manufacturing cost is low, operation is convenient, the quality of finished products is high, size positioning is reliable, and the production requirement can be met.

Owner:XUCHANG UNIV

Method for fermenting temperature-sensitive strains by phosphoric acid to produce glutamic acid

The invention relates to a method for fermenting temperature-sensitive strains by phosphoric acid to produce glutamic acid. In a fermentation production process, the phosphoric acid is used for replacing phosphate in a process for fermenting the temperature-sensitive strains to produce the glutamic acid to prepare a fermentation culture medium; the glutamic acid is produced through fermentation. In the fermentation process of the method provided by the invention, the equal mol equivalent of the phosphoric acid is used for replacing the phosphate of the fermentation culture medium, and then a pH (Potential of Hydrogen) value of fermentation culture is neutralized by utilizing an alkaline substance; on one hand, the disadvantages that the time for completely dissolving the phosphate into water is long so that the fermentation culture medium is not uniformly mixed easily can be overcome, the preparation time of the fermentation culture medium is shortened and the production efficiency is improved; on the other hand, the acid production speed can be improved, a fermentation period is shortened and acid production of thalli is facilitated, so that the production cost is reduced; the acid production ratio and the saccharic acid invert ratio are improved; finally, the acid production level is also remarkably improved and can be improved by about 15 percent; the yield of the glutamic acid and the saccharic acid invert ratio are improved; the method has a wide industrial application prospect.

Owner:COFCO BIO CHEM ENERGY LONGJIANG CO LTD

Planker overturning device

The invention relates to a planker overturning device which comprises the following five parts: a bracket part, a rain cover frame, a hydraulic system, an overturning part and a maintenance part. The lifting and landing operation of a planker can be realized by the vertical displacement change of a hydraulic cylinder of the hydraulic system; the overturning part consists of an overturning beam, a speed reducer, a chain wheel and a chain wheel system, the planker is positioned by hookers and chains; 0-180 degree overturning of the planker can be realized by the overturning of the overturning beam; the maintenance part is formed and implemented by a rotating beam, a displacement part of the rotating beam and a hand-drive block; and the rain-proof part is undertaken by a rain cover. The planker overturning device can realize safe, fast and stable overturning of the planker, and can be operated simply and easily so that the planker overturning device can be controlled by only one person in a remote way and maintenance workers can overhaul the planker safely and conveniently, thereby reducing expenses on planker overhauling and greatly improving the safety and convenience of the workers in maintenance operation.

Owner:天津港第五港埠有限公司 +2

Method for efficiently preheating coke oven gas

InactiveCN102944129BEasy to handleRaise the preheat temperatureStationary tubular conduit assembliesAutomatic controlDecomposition

The invention discloses a method for efficiently preheating coke oven gas. The coke oven gas is subjected to preheating treatment by flue gas or waste gas with the temperature of above 1,150 DEG C, and the flue gas or the waste gas and the coke oven gas are subjected to countercurrent heat exchange, wherein the preheating treatment comprises convection preheating treatment and radiation preheating treatment which are performed sequentially; after the convection preheating treatment, the coke oven gas is preheated to 500 to 600 DEG C; and after the radiation preheating treatment the coke oven gas is continuously preheated to 800 to 950 DEG C. The coke oven gas is preheated by completely utilizing the sensible heat of high-temperature flue gas or tail gas, so that the preheating time is short, the preheating temperature is high, the automatic control can be realized basically, the heat efficiency is high, and operation safety and reliability are achieved. High-temperature decomposition of hydrocarbon in the coke oven gas and carbon deposition can be effectively prevented by adding a trace amount of a carbon deposition inhibitor and a decarbonizer, and the application range is wide.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

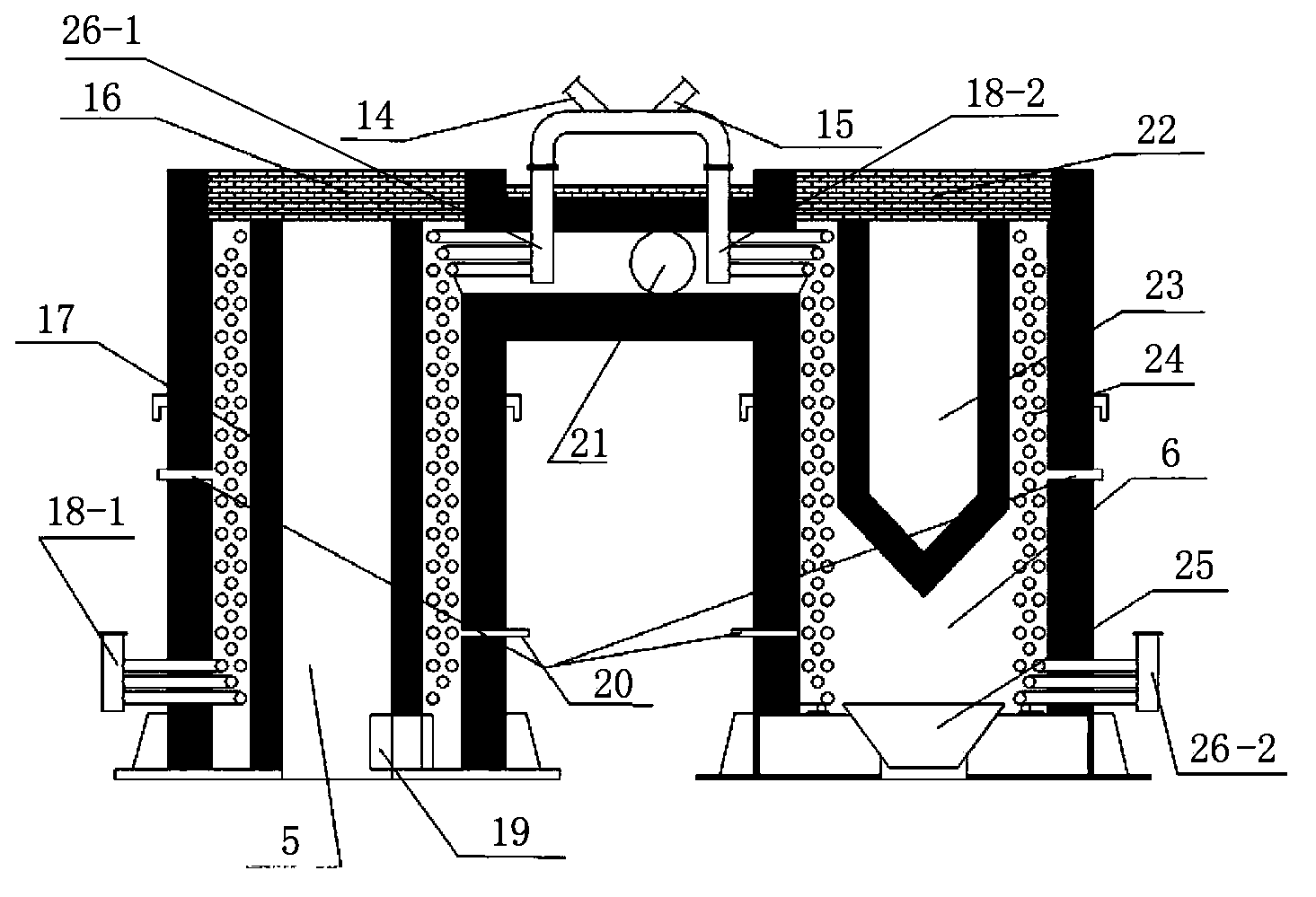

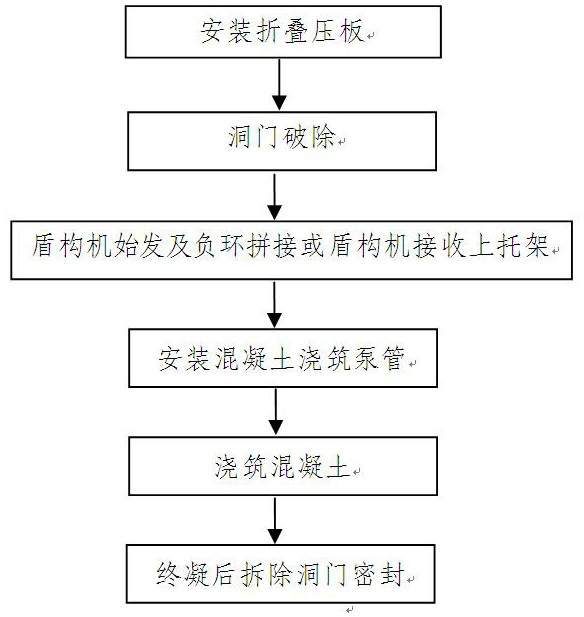

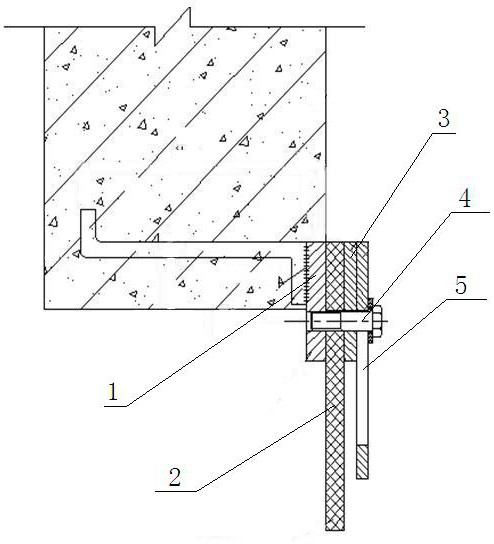

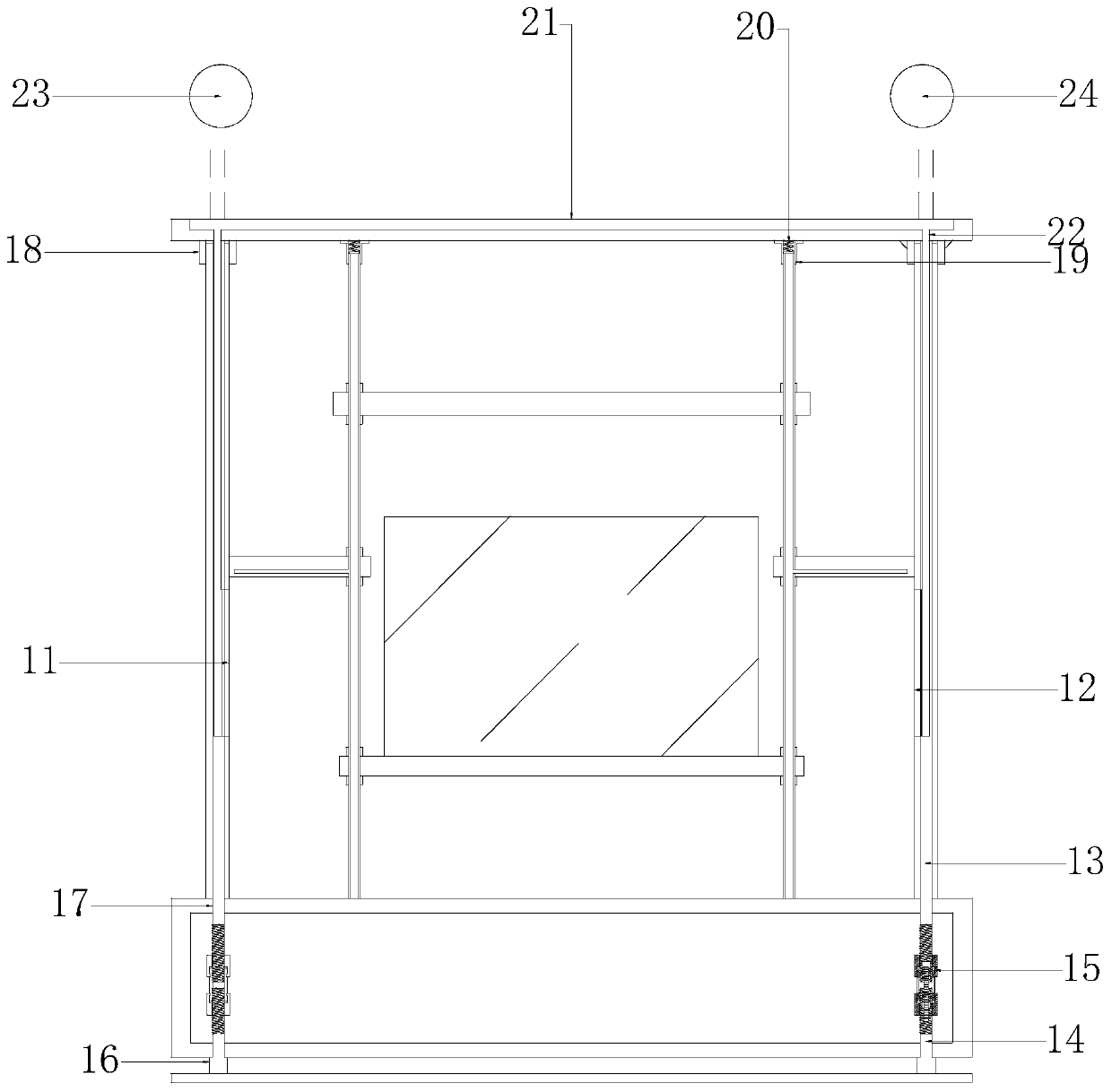

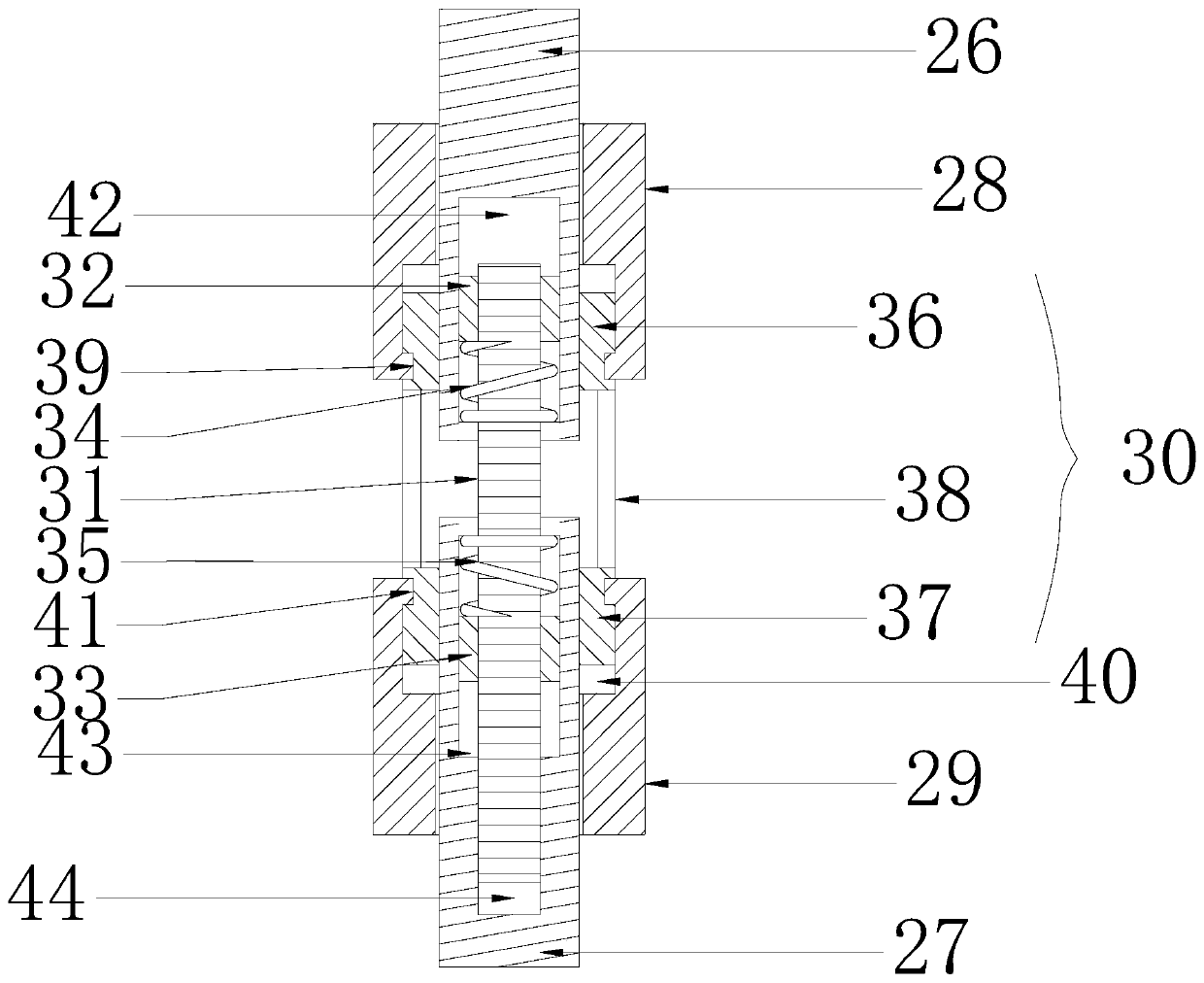

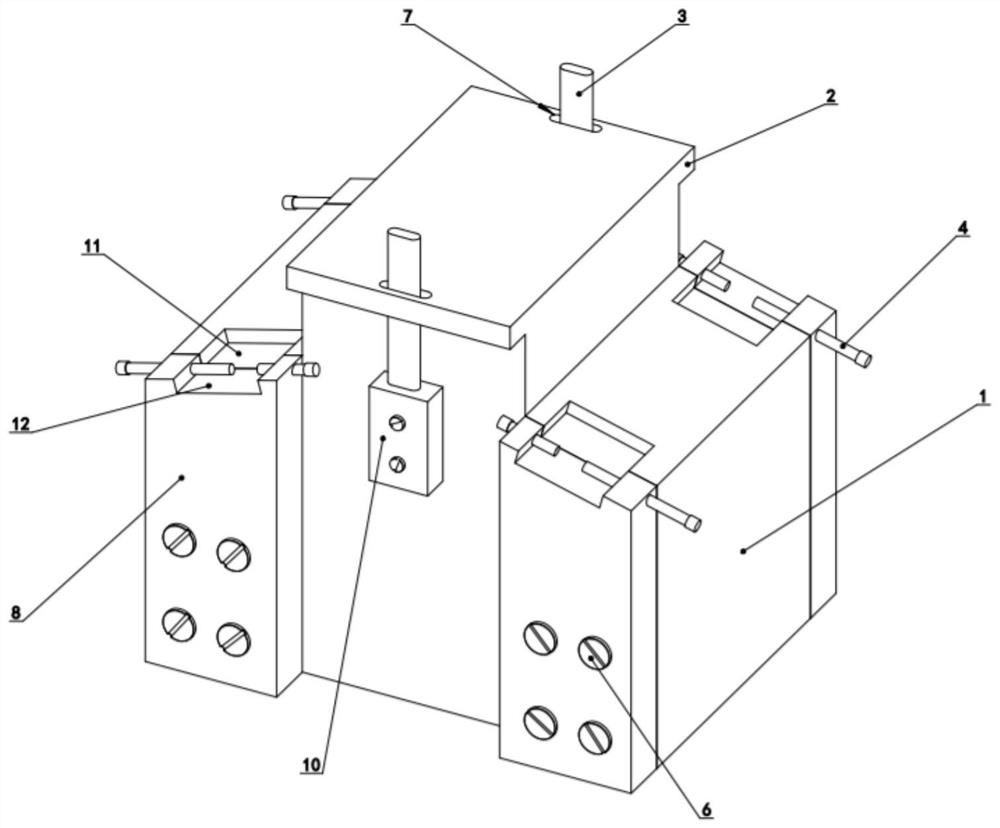

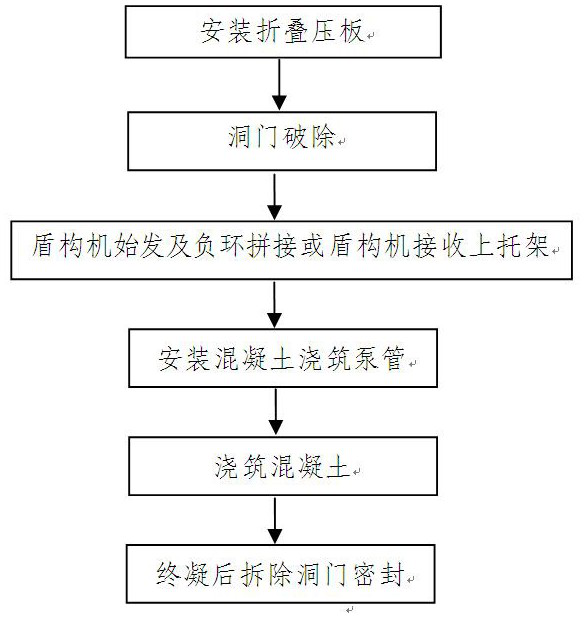

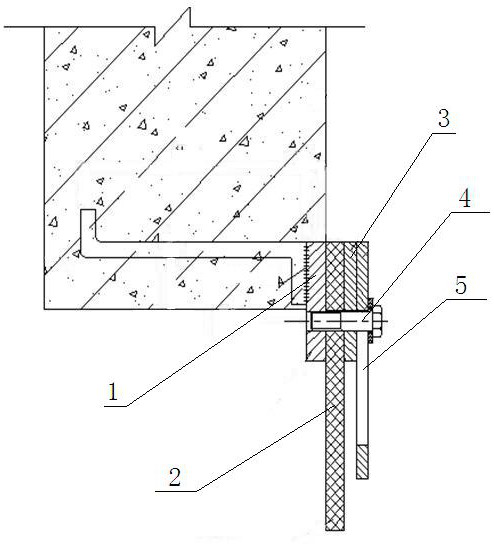

A new method for sealing the gap between subway shield excavation portals

ActiveCN111779496BReduce pollutionShorten the setting timeUnderground chambersTunnel liningClassical mechanicsEconomic benefits

The invention belongs to the technical field of shield tunneling, and in particular relates to a novel method for sealing a gap between a tunnel door of a shield tunnel. The present invention provides a new method for blocking the tunnel door of shield tunneling, comprising the following steps: S100~installation of the tunnel door sealing device; S200~destruction of the tunnel door; S300~calculation of concrete volume for the tunnel sealing tunnel; S400~installation Pour the pump pipe; S500~concrete pouring; S600~After the concrete has finally set, remove the door seal. The invention has the advantages of simple operation procedure and high plugging efficiency. Less labor, less consumption, significant economic benefits, and better sealing compactness.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

Rapid repair mortar and preparation method thereof

The invention provides rapid repair mortar and a preparation method thereof. The rapid repair mortar is prepared from the following raw materials in parts by weight: 25 parts of PO42.5 cement, 21 parts of sulphoaluminate cement, 3 parts of gypsum, 50 parts of 20-80-mesh quartz sand, 0.2-0.3 part of a water reducing agent, 0.1-0.2 part of 6mm short fibers, 0.1-0.2 part of a defoaming agent, 0.5-1 part of rubber powder and 0.03-0.05 part of lithium carbonate. According to the preparation method, in the raw material conveying process, other different raw materials can be added, stirred and mixed, the whole process is in a continuous state, it can be guaranteed that all the raw materials are evenly mixed, and the production requirement can be met. The repair mortar has the advantages of high early strength, good fluidity, convenient construction, no shrinkage and no cracking, simplifies the work flow, and improves the production efficiency.

Owner:XINYANG LINGSHI TECH CO LTD

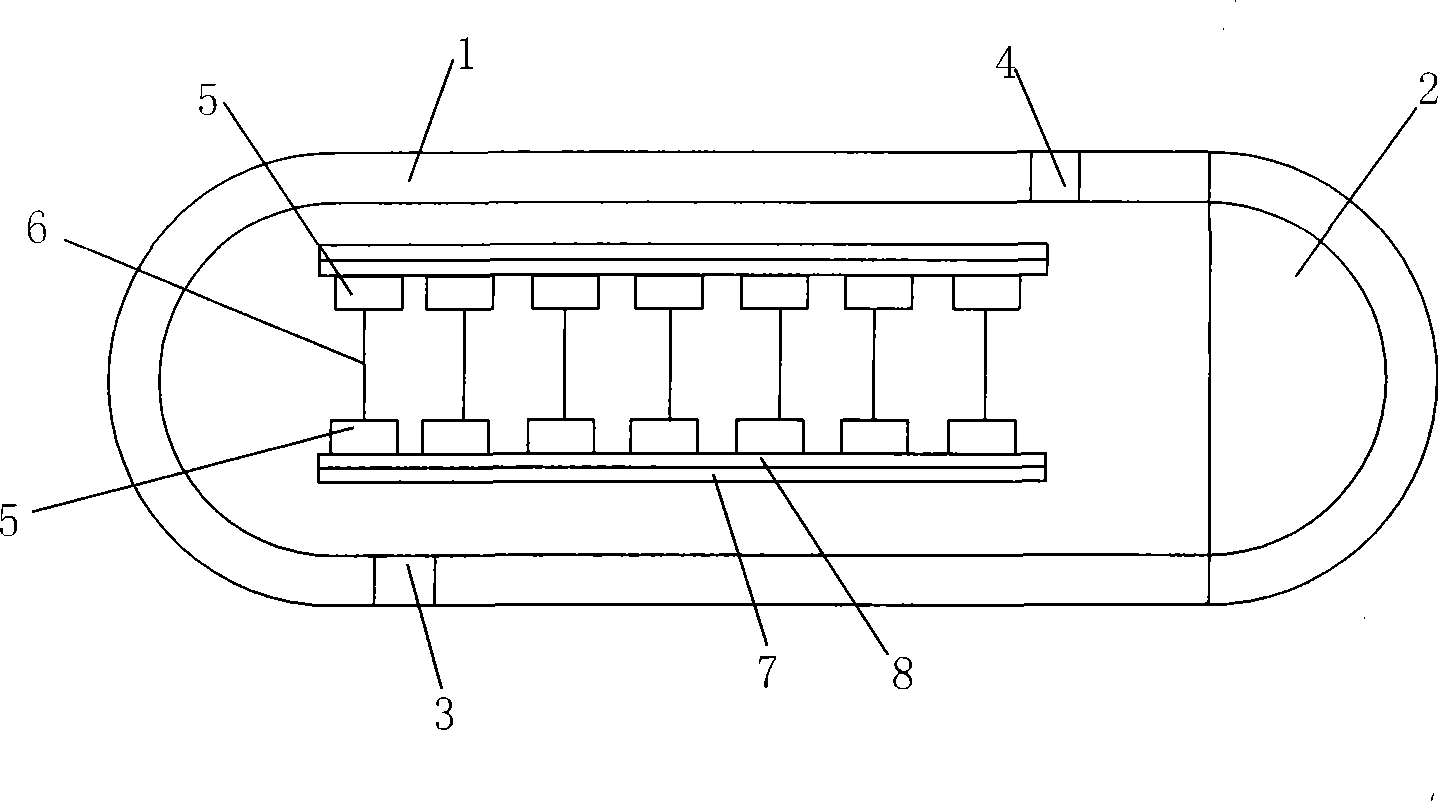

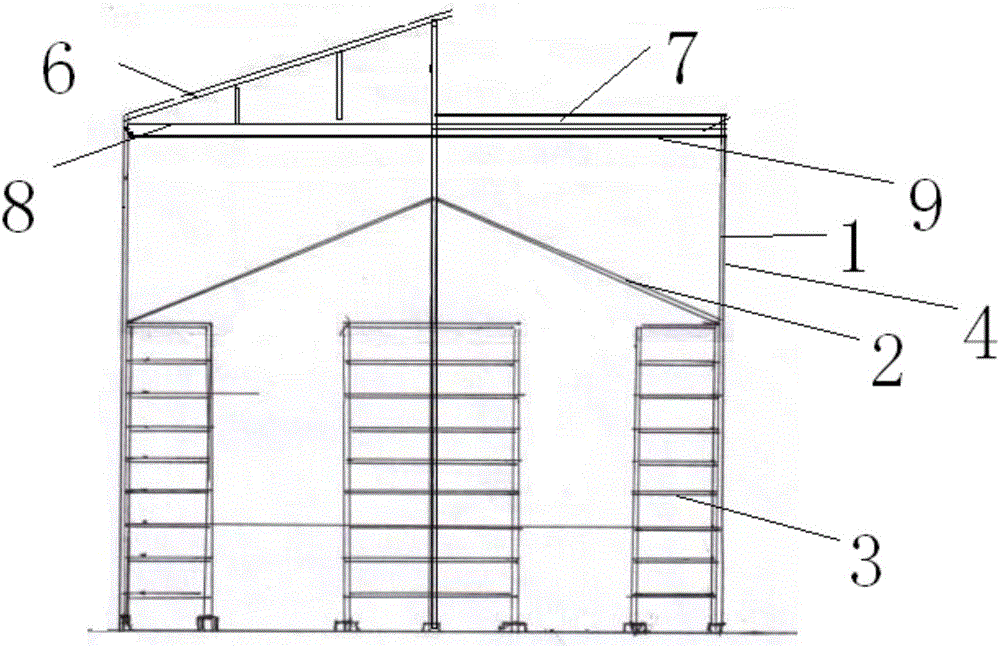

Annual mushroom producing greenhouse

InactiveCN106069201AGuarantee production needsAffect quality problemsCultivating equipmentsMushroom cultivationGreenhouseAgricultural engineering

The invention discloses an annual mushroom producing greenhouse. The greenhouse comprises a greenhouse external frame, a greenhouse body, mushroom shelves, sunshade nets and mushroom stick dishes, wherein the top of the greenhouse external frame is flat in the front and oblique in the back; an oblique top part is covered by glass steel tiles; a flat front part comprises a movable glass steel tile covered layer and a movable sunshade net layer; the movable glass steel tile covered layer is erected on an upper cross beam; the movable sunshade net layer is erected on a lower cross beam; the greenhouse body is fully covered by plastic films capable of extending and retracting up and down; the mushroom shelves are arranged according to the width of the greenhouse body; the mushroom stick dishes are oblong; 2-3cm high frames are arranged around the mushroom stick dishes; the bottom planes of the mushroom stick dishes are grids; the mushroom stick dishes are put on the mushroom shelves; plastic films are spread in the mushroom stick dishes; a layer of moisturizing material is spread on each film. The annual mushroom producing greenhouse has the advantages that the greenhouse is not affected by weather and can produce mushroom all year round, and is suitable for large-scale popularization.

Owner:绩溪县中巧食用菌种植专业合作社

Screening method for petroleum coke used for industrial silicon, carbonaceous reducing agent and smelting method for industrial silicon

ActiveCN109279610AImprove selection efficiencyRaise the gradeSilicon compoundsNew energyScreening method

The invention relates to the technical field of industrial silicon smelting and new energy, and discloses a screening method for petroleum coke used for industrial silicon, a carbonaceous reducing agent and a smelting method for the industrial silicon. The screening method includes the following steps: a performance parameter of the petroleum coke is determined, and the petroleum coke is screenedwhich simultaneously satisfies the following conditions: (1) the volatile matter content is not less than 13% by weight, (2) sintering processing is performed on the petroleum coke, and the obtained sintered product is a cake, and a Hardgrove grindability index of the cake is not more than 100. According to the screening method, the petroleum coke which satisfies a specific performance index is selected, the petroleum coke suitable as the carbonaceous reducing agent for the industrial silicon smelting can be obtained, thereby improving the selection efficiency of the petroleum coke in actual industrial silicon smelting production; and the carbonaceous reducing agent does not require or requires only a small amount of charcoal, production requirements can be ensured, the production cost isgreatly reduced, and the obtained silicon is high in grade and high in yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

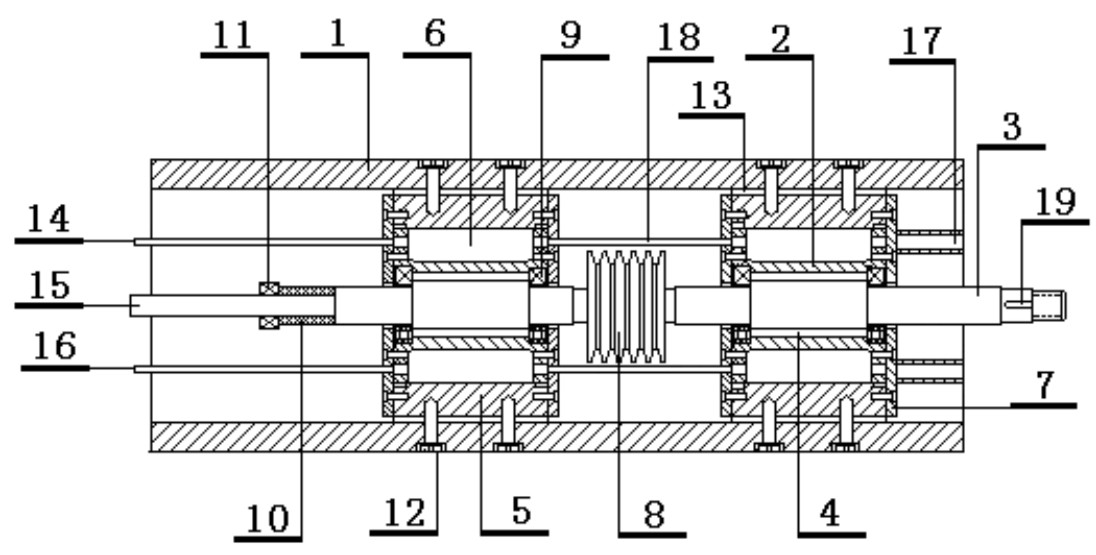

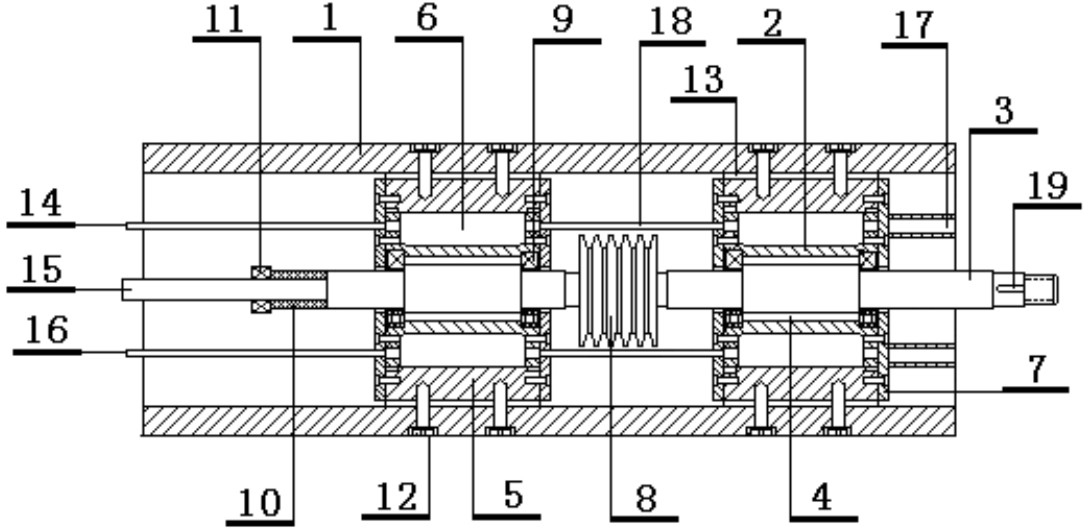

Axial-flow thick paste material temperature control conveying device

ActiveCN102657957AGuarantee production needsRealize temperature controlLiquid separation auxillary apparatusTemperature controlDrive wheel

The invention discloses an axial-flow thick paste material temperature control conveying device, which comprises an axial-flow barrel, a lubricating-cooling device and a material conveying mandrel, wherein the lubricating-cooling device and the material conveying mandrel are arranged coaxially in the axial-flow barrel; the lubricating-cooling device comprises a water cavity jacket and a lubricating shaft sleeve; after the lubricating shaft sleeve and the water cavity jacket are hermetically matched through a hermetic fixing plate, so that a cooling water cavity is formed; the lubricating shaft sleeve is in movable hermetic fit with the material conveying mandrel through a bearing; a lubricating oil cavity is formed between the lubricating shaft sleeve and the material conveying mandrel; the cooling water cavity is communicated with a cooling water inlet pipe and a cooling water return pipe respectively; and the material conveying mandrel is provided with a driving wheel. The principle of water jacket cooling is utilized skillfully, so that integral temperature control of the bearing and a conveyed material is realized. The axial-flow thick paste material temperature control conveying device is compact in structure, and works stably and reliably. According to the axial-flow thick paste material temperature control conveying device, a relatively constant temperature can be kept during material conveying, and the material production requirement is ensured; and furthermore, the temperature of the bearing can be controlled, so that overheat is avoided, and the service life of the bearing is prolonged.

Owner:YUNNAN MOER GARDEN BIOLOGICAL SCI & TECH DEV

Novel gas storage tank

InactiveCN104514978AGuaranteed drynessQuality assurancePressure vesselsActivated carbonProcess engineering

A novel gas storage tank comprises a gas inlet, a tank body and a gas outlet, the gas outlet is arranged at the bottom of the tank body, the gas inlet is arranged at the top of the tank body, a filler adsorption layer is arranged below the gas inlet, and the filler adsorption layer is an activated carbon adsorption layer. The novel gas storage tank has a simple structure; and the activated carbon adsorption layer is arranged at the gas inlet and can absorb moisture in air, so the dryness of a gas in the gas storage tank is ensured, the content of moisture in the gas in the gas storage tank is greatly reduced, the quality of the gas in the gas storage tank is guaranteed, enterprises' needs of the dry gas in production are met, the content of impurities in the gas is reduced, the purity of the gas is guaranteed, the enterprises' normal production needs are guaranteed, the enterprises' machine safety is guaranteed, and the use performance of the gas storage tank is optimized.

Owner:扬州三方电器有限公司

Dropping pill for treating throat disease and preparing method thereof

ActiveCN100349584CSignificant effectGood curative effectHydroxy compound active ingredientsPill deliveryDiseaseSide effect

The present invention relates to a kind of dripping pills for curing pharyngolaryngeal diseases and its preparation method. It is made up by using 20-30 portions of argyi leaf, 10-15 portions of sesame oil, 10-20 portions of peppermint oil, 5-10 portions of menthanol, 10-20 portions of monoammonium glycyrrhizinate and 160-180 portions of polyethylene glycol 6000 through a certain preparation process. Said dripping pills preparation can be used for curing the diseases of acute and chronic pharyngitis, sore-throat, dryness of throat and hematoma of pharynx.

Owner:贵州黄果树立爽药业有限公司

Smart home interior design porch partition

The invention discloses a smart home interior design porch partition. The partition comprises a building fresh air system, transverse plates, left and right main vertical plates, auxiliary vertical plates, a top plate, a bottom plate, a storage cabinet, air pipes, supporting structures and sealing lantern rings. Air passages and mounting channels are formed in the left and right main vertical plates correspondingly. A first opening and a second opening are formed in the positions, in the opposite side surfaces of the left and right main vertical plates, of the air passages correspondingly. Moreover, upper openings of the air passages are located in the top surfaces of the left and right main vertical plates correspondingly. The mounting channels penetrate through the top surfaces and the bottom surfaces of the left and right main vertical plates correspondingly. The section of each mounting channel is rectangular. Each supporting structure comprises a first stand column, a second standcolumn and a connecting structure, wherein the cross section of the first stand column is rectangular, a supporting step is arranged in the position close to the bottom of the second stand column, and the first stand column can be mounted in the corresponding mounting channel in an up-down sliding mode. In addition, the two ends of the first stand columns stretch out of the left and right main vertical plates correspondingly. The smart home interior design porch partition is convenient to use.

Owner:HEIHE UNIV

Axial-flow thick paste material temperature control conveying device

ActiveCN102657957BGuarantee production needsRealize temperature controlLiquid separation auxillary apparatusTemperature controlDrive wheel

The invention discloses an axial-flow thick paste material temperature control conveying device, which comprises an axial-flow barrel, a lubricating-cooling device and a material conveying mandrel, wherein the lubricating-cooling device and the material conveying mandrel are arranged coaxially in the axial-flow barrel; the lubricating-cooling device comprises a water cavity jacket and a lubricating shaft sleeve; after the lubricating shaft sleeve and the water cavity jacket are hermetically matched through a hermetic fixing plate, so that a cooling water cavity is formed; the lubricating shaft sleeve is in movable hermetic fit with the material conveying mandrel through a bearing; a lubricating oil cavity is formed between the lubricating shaft sleeve and the material conveying mandrel; the cooling water cavity is communicated with a cooling water inlet pipe and a cooling water return pipe respectively; and the material conveying mandrel is provided with a driving wheel. The principle of water jacket cooling is utilized skillfully, so that integral temperature control of the bearing and a conveyed material is realized. The axial-flow thick paste material temperature control conveying device is compact in structure, and works stably and reliably. According to the axial-flow thick paste material temperature control conveying device, a relatively constant temperature can be kept during material conveying, and the material production requirement is ensured; and furthermore, the temperature of the bearing can be controlled, so that overheat is avoided, and the service life of the bearing is prolonged.

Owner:YUNNAN MOER GARDEN BIOLOGICAL SCI & TECH DEV

Motor brush welding device

InactiveCN114102039AImprove welding productivityHigh reuse rateWelding/cutting auxillary devicesAuxillary welding devicesTorque motorElectric machinery

The invention belongs to the field of motors, and discloses a motor brush welding device which comprises a base. One end of the base is provided with a first tool unit, and the first tool unit comprises two electric brush positioning plates, a reed supporting seat and a reed pressing rod; the two electric brush positioning plates are respectively connected with two sides of the end part of the base, electric brush grooves for accommodating electric brushes are formed in the tops of the electric brush positioning plates, threaded holes are formed in two sides of each electric brush groove, electric brush ejector rods in threaded connection are arranged in the threaded holes, and the electric brush ejector rods are used for ejecting the electric brushes accommodated in the electric brush grooves; the reed supporting seat is movably connected with the base and is positioned between the two electric brush positioning plates; a protrusion is arranged at the end of the base, a mounting hole is formed in the protrusion, one end of the reed pressing rod penetrates through the protrusion and is located above the reed supporting seat, and a gap between the reed pressing rod and the reed supporting seat is used for containing the reed. The production requirements of torque motors of different models are met, the electric brush welding production efficiency and the tool repeated utilization rate are greatly improved, and the tool cost is saved.

Owner:SHAANXI UNIV OF SCI & TECH

Method for modifying petroleum coke, modified petroleum coke obtained therefrom, carbonaceous reducing agent and smelting method for industrial silicon

The invention relates to the technical field of industrial silicon smelting and new energy, and discloses a modification method for petroleum coke and modified petroleum coke obtained by the same, a carbonaceous reducing agent, and a smelting method for industrial silicon. The modification method includes the following steps: a modifier is mixed with the petroleum coke, and then a mixture is subjected to drying and molding, wherein the modifier is asphalt and / or heavy oil. The modified petroleum coke obtained by the modification method of the invention can replace charcoal as a component of the carbonaceous reducing agent of the industrial silicon, and so, the deficiency can be solved that the reaction reactivity is low and a volatile matter is low when the petroleum coke is utilized as the component of the carbonaceous reducing agent used for the industrial silicon smelting, and the adaptability is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel subway tunneling advancing hole opening gap blocking method

ActiveCN111779496AReduce pollutionShorten the setting timeUnderground chambersTunnel liningEconomic benefitsEngineering

The invention belongs to the technical field of tunneling construction, and particularly provides a novel subway tunneling advancing hole opening gap blocking method. The provided novel subway tunneling advancing hole opening gap blocking method comprises the following steps of: S100-installing a hole opening blocking device; S200-breaking a hole opening; S300-calculating hole opening blocking concrete volume; S400-installing a pouring pump pipe; S500-pouring concrete; and S600-dismantling hole opening sealing after final set of the concrete. The method has the advantages of simple and convenient operation procedures, high blocking efficiency, low manpower, low consumption, significant economic benefit, and better blocking compactness.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com