Annual mushroom producing greenhouse

A technology of shiitake mushrooms and greenhouses, which is applied in the fields of mushroom cultivation, horticulture, botanical equipment and methods, etc. It can solve problems such as unsuitable production and impact on shiitake mushroom production, and achieve the effect of reducing labor intensity and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

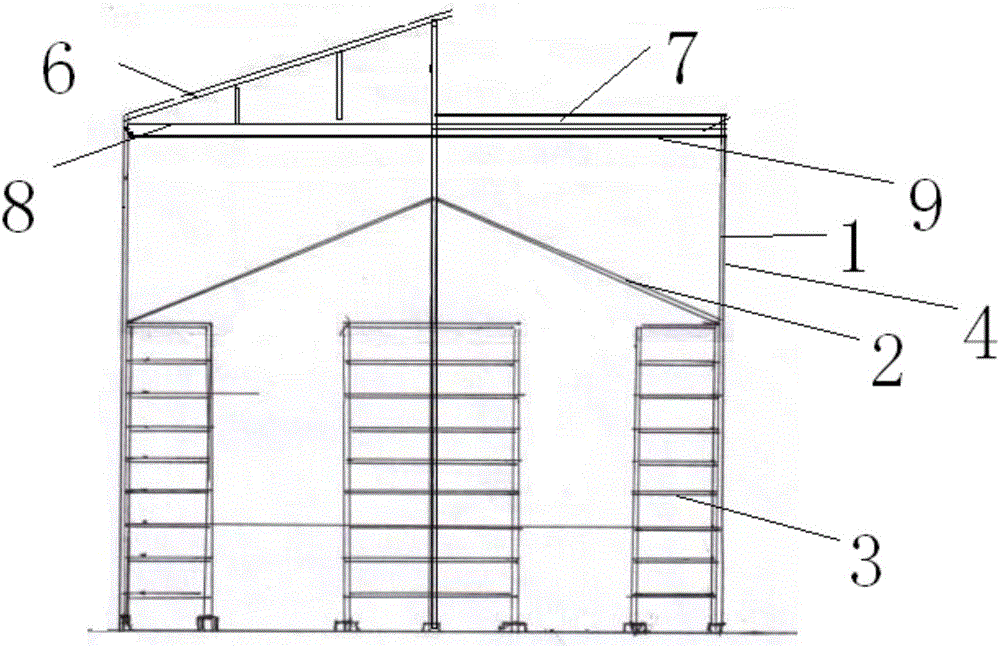

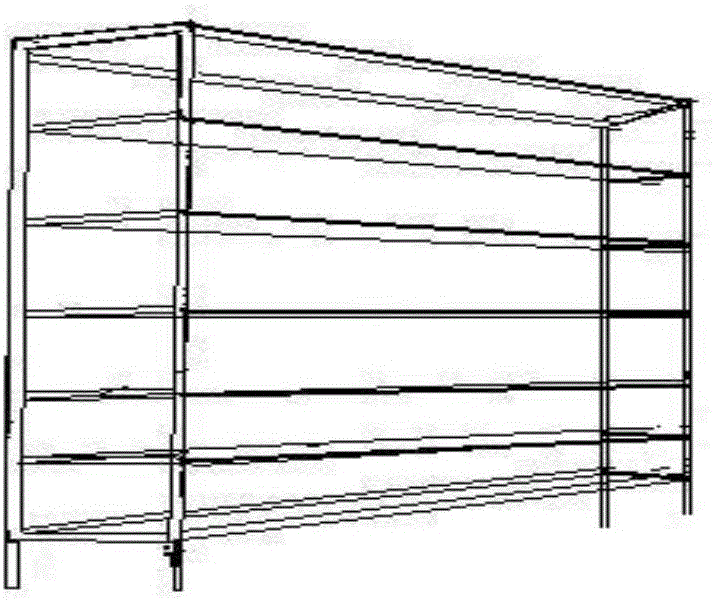

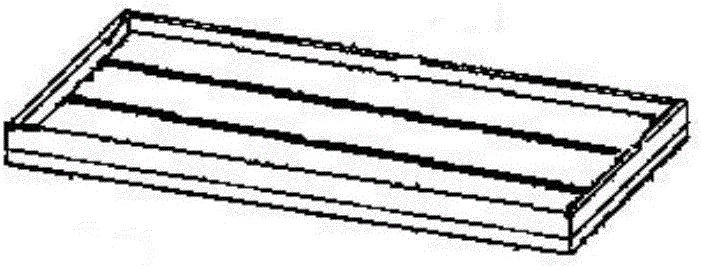

[0020] see Figure 1-3 , the present invention provides a technical solution: including the outer frame of the greenhouse (1), the shed body (2), the mushroom rack (3) and the sunshade net (4), and also includes the mushroom stick plate (5), the outer frame of the greenhouse (1) The width is 3.8m, the height of the falling edge is 3.2m, the top height of the middle part is 4m, and the length is 5m. This embodiment adopts a greenhouse outer frame (1) and a greenhouse body (2). Setting, the oblique angle of the slanted roof part (6) is 10 °, the upper cover glass steel tile of the slanted roof part (6); The size of movable cover glass-steel tile layer is 2m * 8m, and is framed on the upper beam (8), and the size of movable sunshade net layer is 2m * 5m, and is framed on the lower beam (9), in the snowy weather of winter, can put the upper layer Pull up the glass fiber reinforced plastic tile layer, this setting can effectively prevent heavy snow from crushing the plastic shed i...

Embodiment 2

[0022] see Figure 1-3 , the present invention provides a technical solution: including the outer frame of the greenhouse (1), the shed body (2), the mushroom rack (3) and the sunshade net (4), and also includes the mushroom stick plate (5), the outer frame of the greenhouse (1) The width is 4.5m, the height of the falling edge is 3.8m, the top height of the middle part is 4.6m, and the length is 6m. Multiple greenhouse outer frames (1) can be connected according to the terrain. The top of the greenhouse outer frame (1) is set with a front flat and a rear slope. Part (6) has an inclination angle of 20° and is covered with glass steel tiles; the front flat part (7) is a movable device structure, including a movable cover glass steel tile layer and a movable sunshade net layer, and the size of the movable cover glass steel tile layer is 2m×8m , framed on the upper beam (8), the size of the movable sunshade net layer is 2m * 6m, framed on the lower beam (9), in the snowy weather ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com