Automatic liquid adding and material mixing machine

A mixer, automatic technology, applied in mixers, dissolution, chemical instruments and methods, etc., can solve problems such as incompatibility, and achieve the effect of ensuring production needs, fully mixing, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

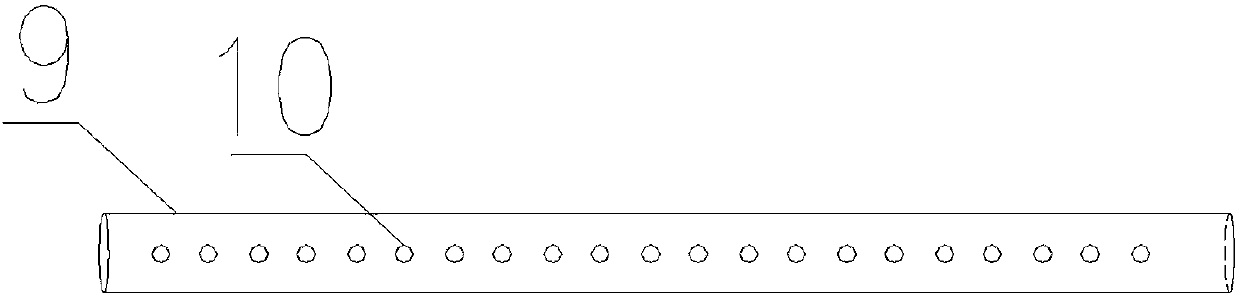

[0010] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 3 As shown, the present invention comprises a mixing tank 2 and a liquid addition tank 5, and the bottom of the mixing tank 2 is higher than the liquid addition tank 5; the side walls of the mixing tank 2 and the liquid addition tank 5 are provided with compressed air pipes 9; A water pipe 4 is arranged at the bottom of the tank 2 to connect to the filling tank 5, and a solenoid valve 3 is arranged on the water pipe 4; Opening and closing.

[0011] Dense circular air holes 10 are arranged on the compressed air pipe 9 .

[0012] The compressed air pipe 9 is spirally arranged on the side walls of the liquid addition tank 5 and the mixing tank 2 . The advantage of this method is that the mixed liquid is driven by the compressed air tube, and it also rotates in a spiral, so that the graphite and water are fully mixed, and it is not easy to precipitate.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com