Reduction reaction furnace for polysilicon

A reaction furnace and polysilicon technology, applied in the growth of polycrystalline materials, silicon, single crystal growth, etc., can solve the problems of lengthening the production of silicon rods, difficulty in expanding the production scale, time-consuming and labor-consuming, etc., to improve the yield and production efficiency , avoid shaking and breaking, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

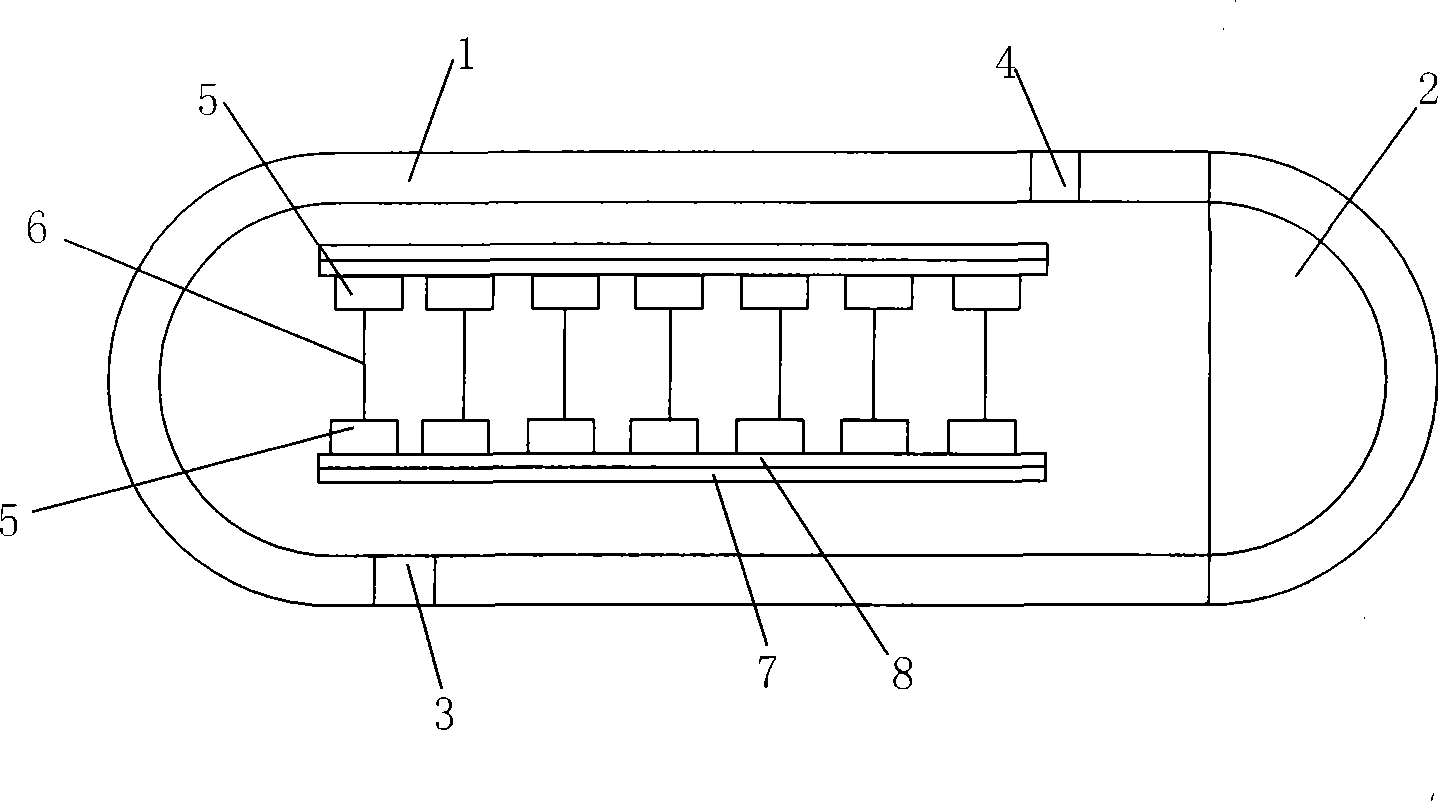

[0017] The features of the polysilicon reduction reaction furnace of the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

[0018] Such as figure 2 , 3 , 4, and 5, including furnace body 1, electrode 5 placed in furnace body 1 and silicon core 6 connected to the electrode, air inlet 3, exhaust port 4, movable furnace placed at the opening of furnace body 1 The door 2 and the movable or fixed electrode plate 7 separated from the furnace body 1, the central axis of the furnace body 1 is placed along the horizontal direction.

[0019] The electrode 5 is fixed at one end or at both ends on the electrode disc 7 , and there is an insulating layer 8 between the electrode 5 and the electrode disc 7 . In this embodiment, both ends of the electrode 5 are fixed on the electrode disk 7 .

[0020] The air inlet 3 and the air outlet 4 are placed on the furnace body 1 or the movable furnace door 2 . In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com