Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Good structural symmetry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

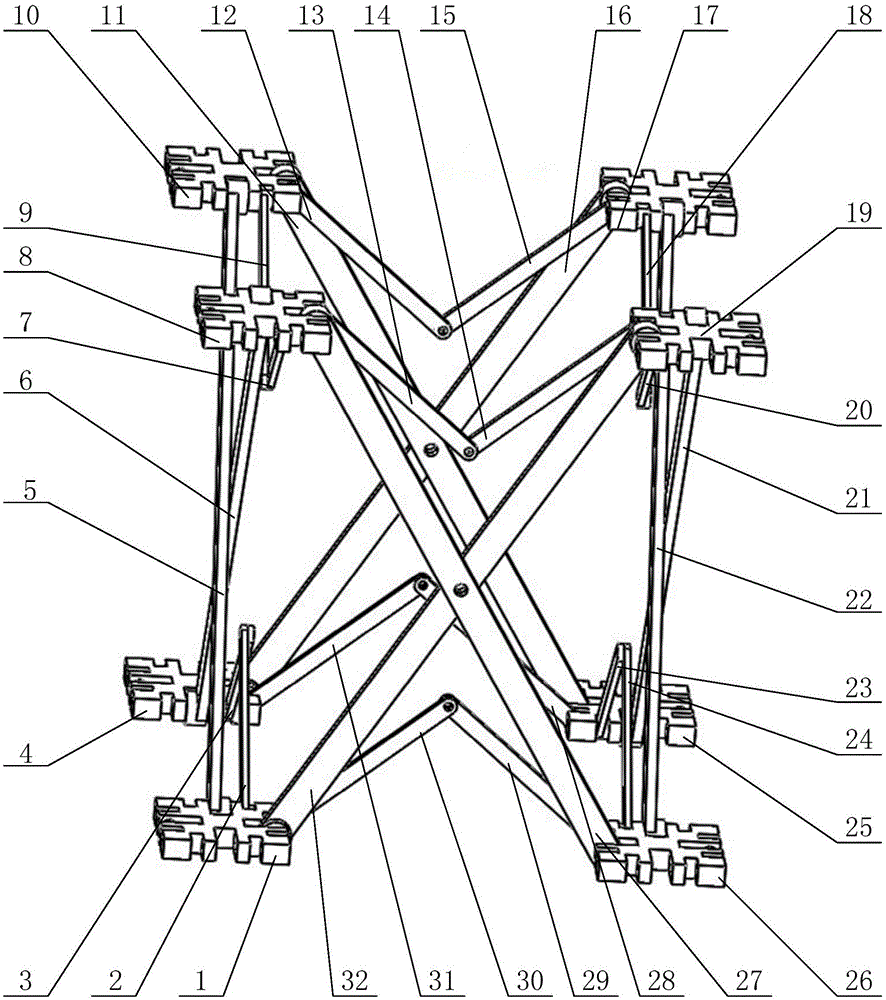

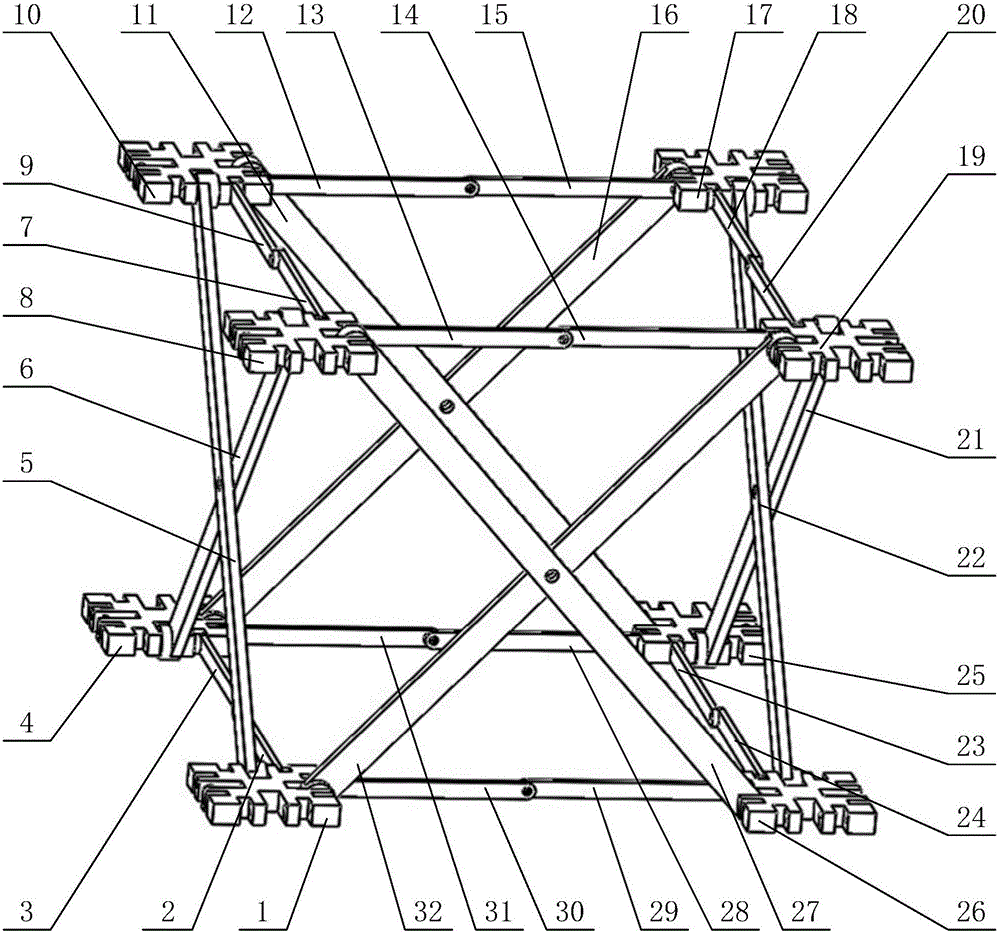

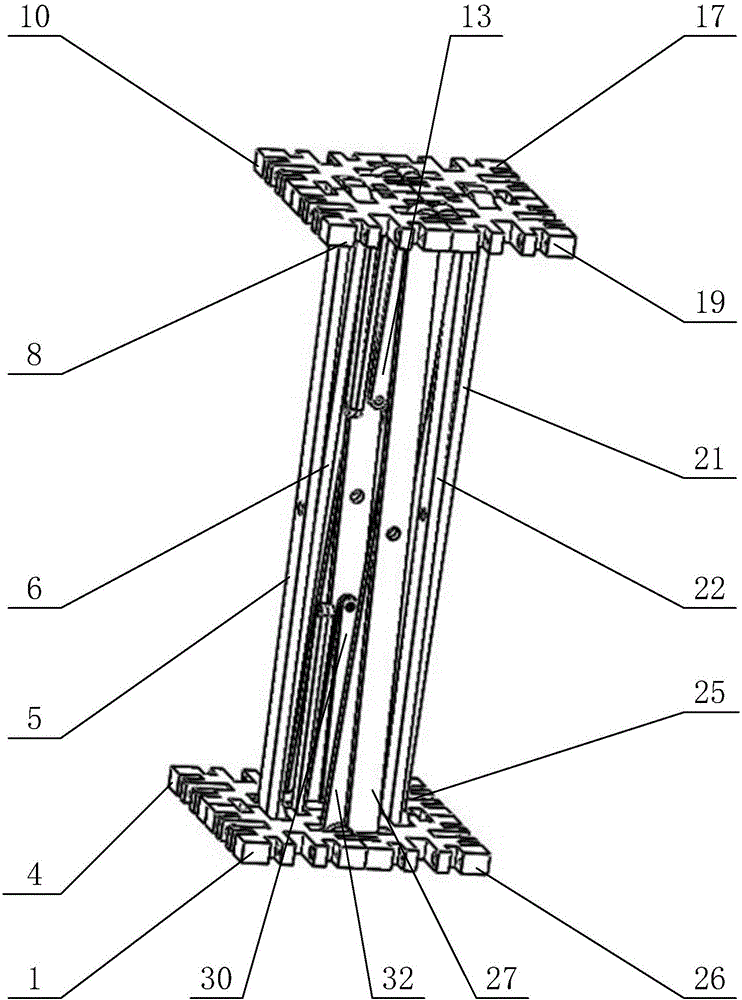

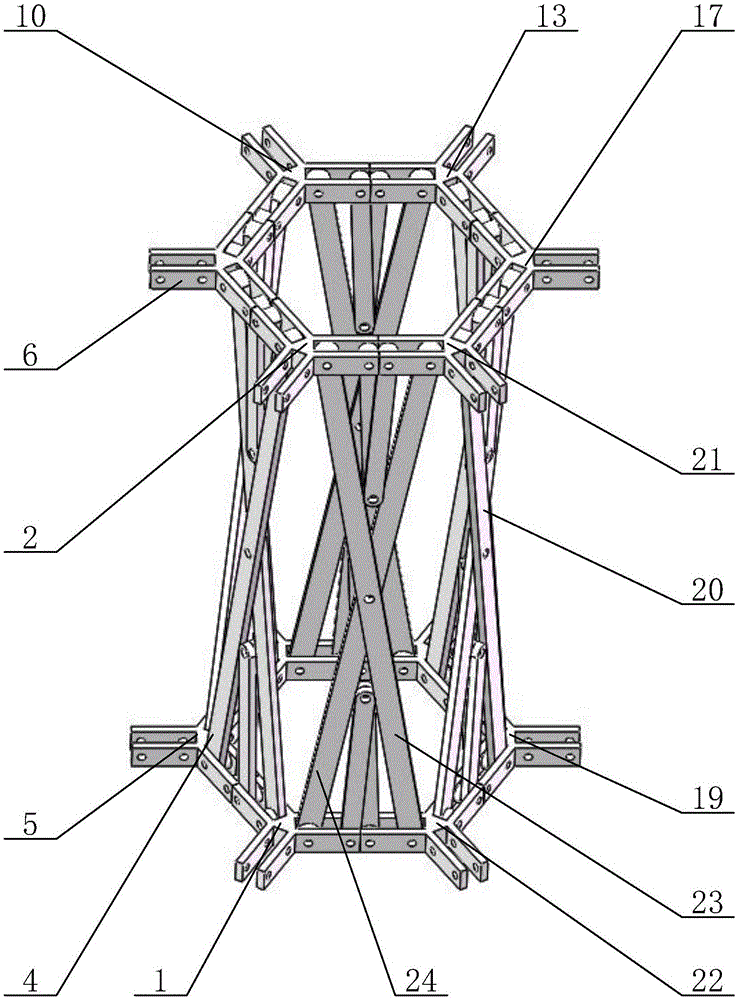

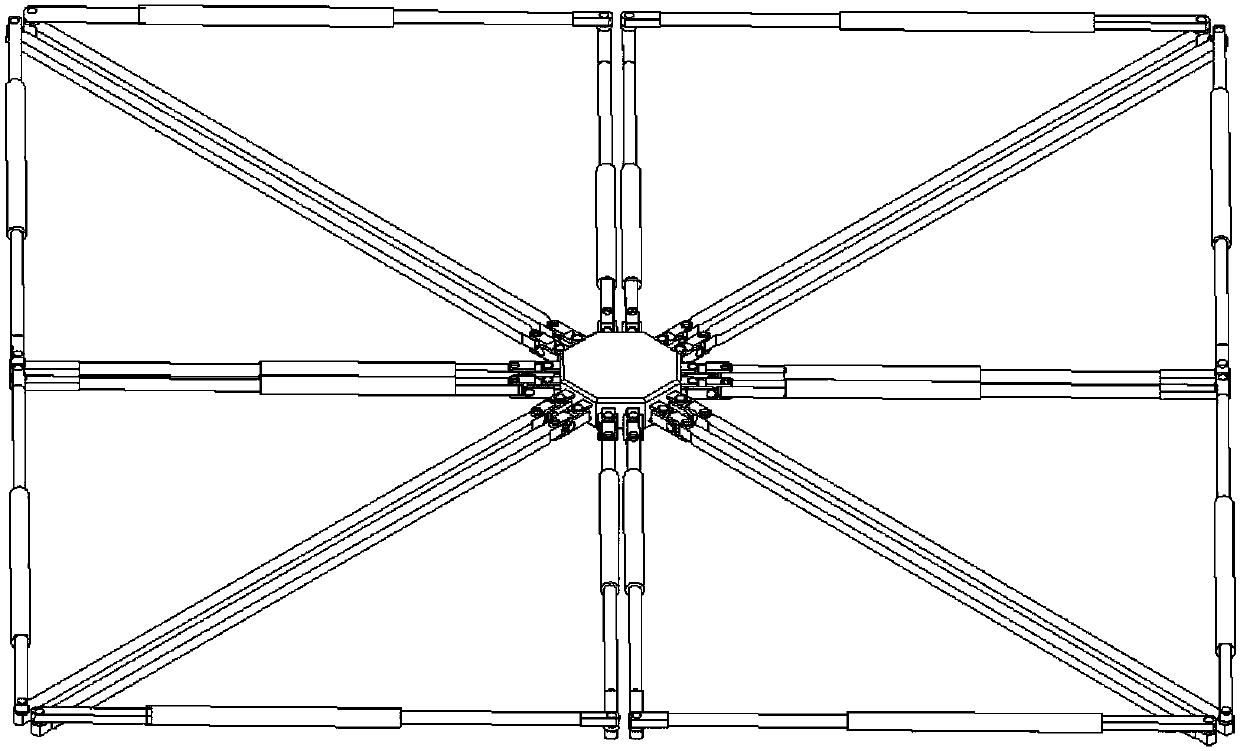

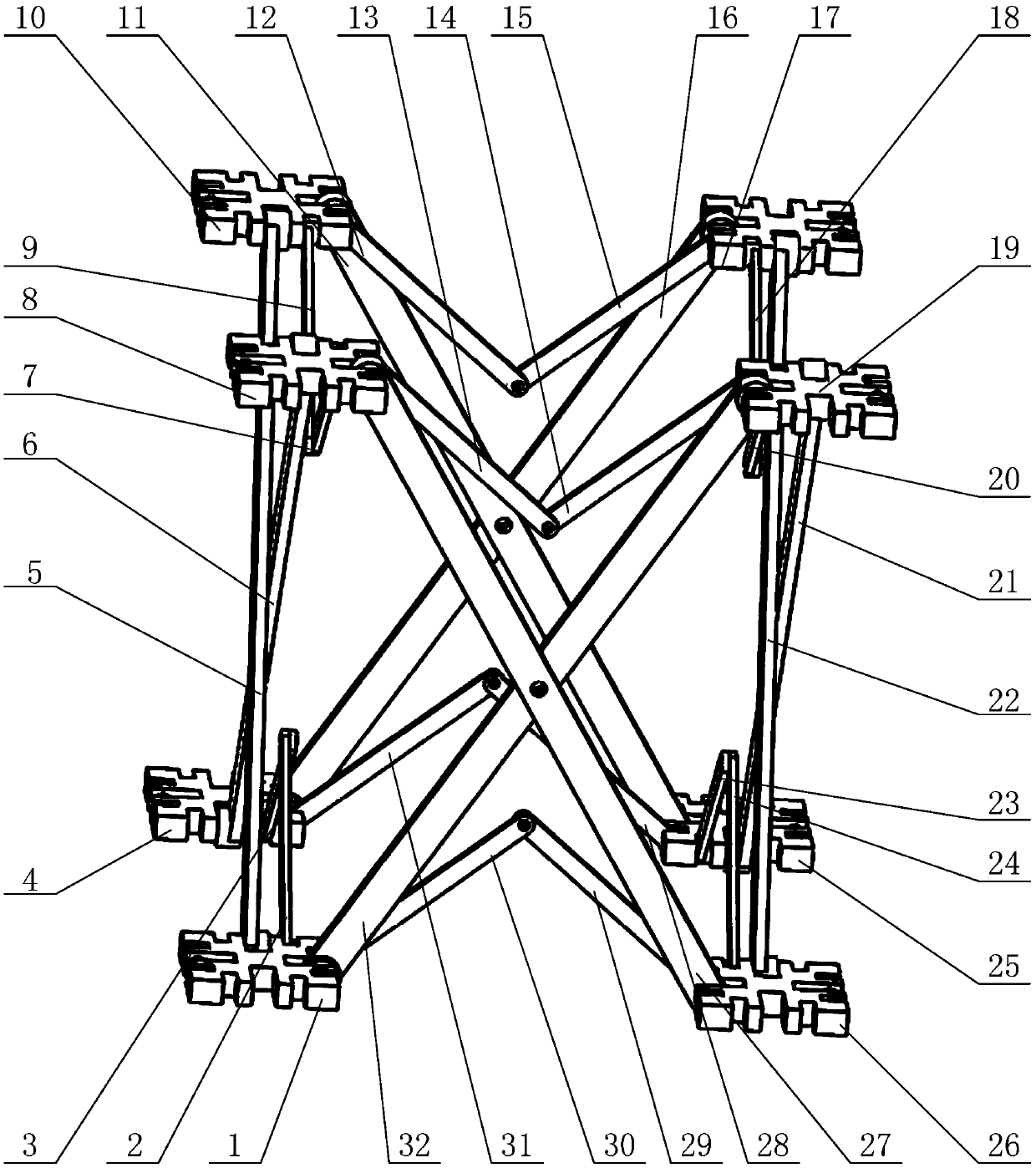

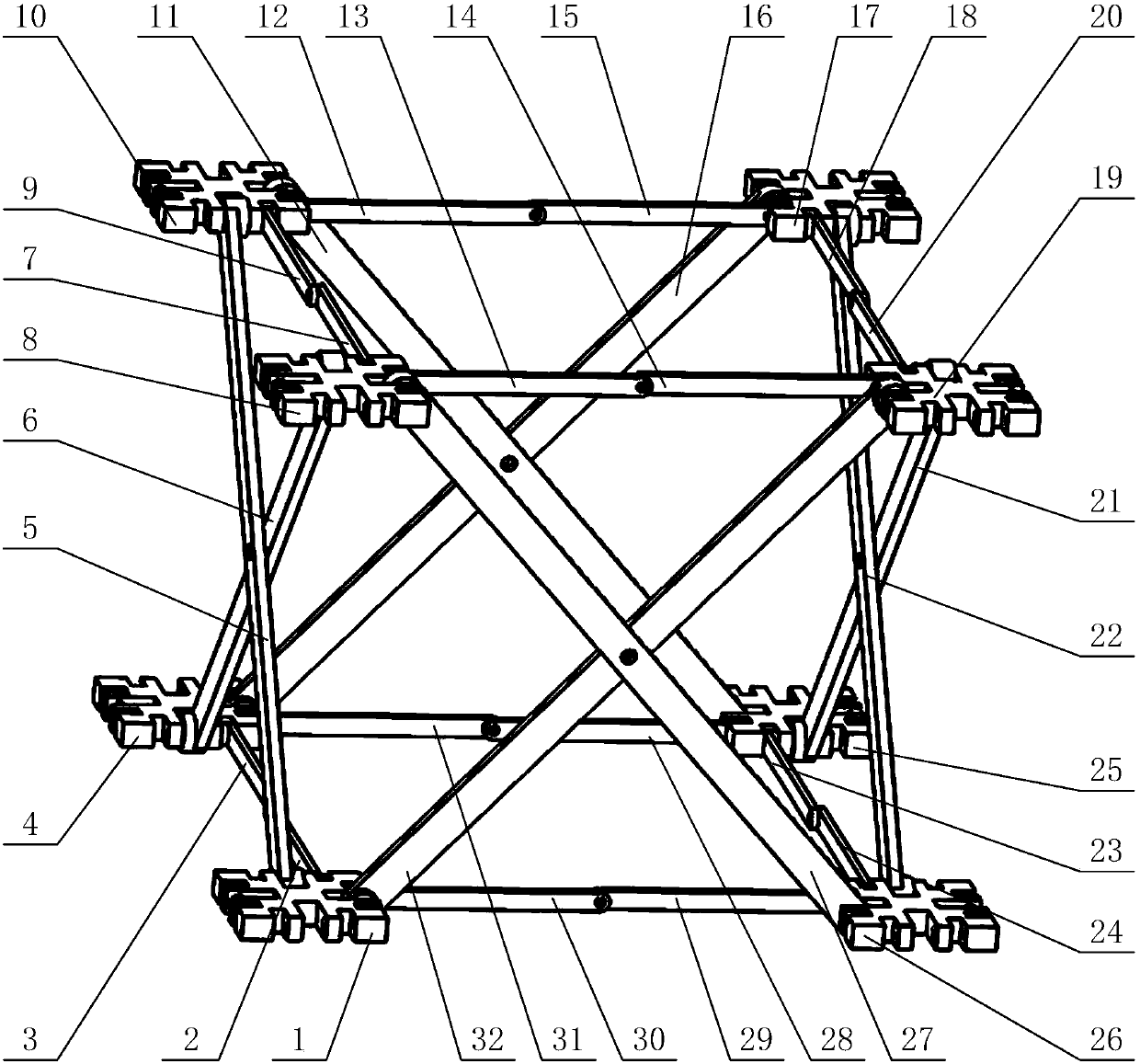

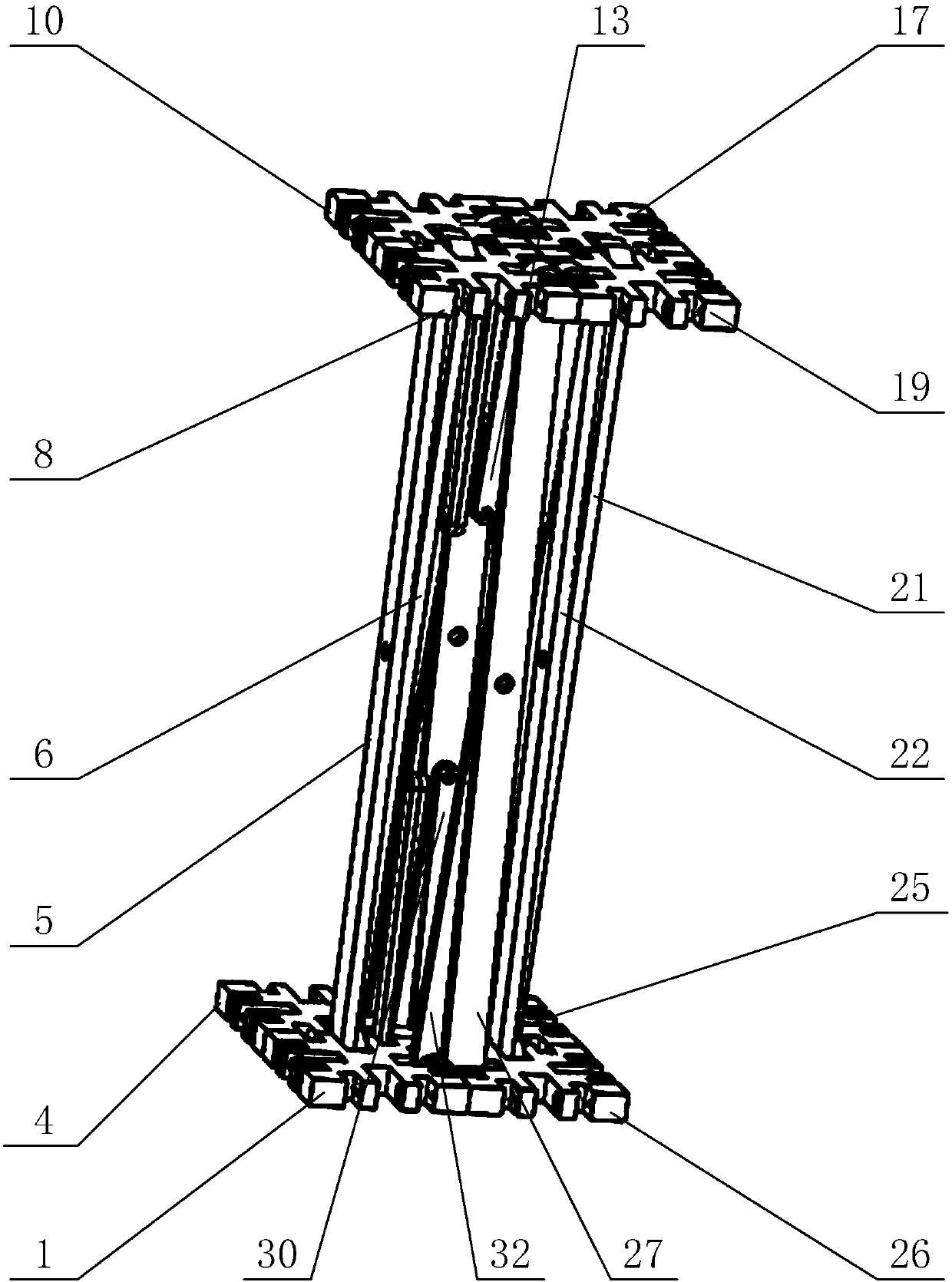

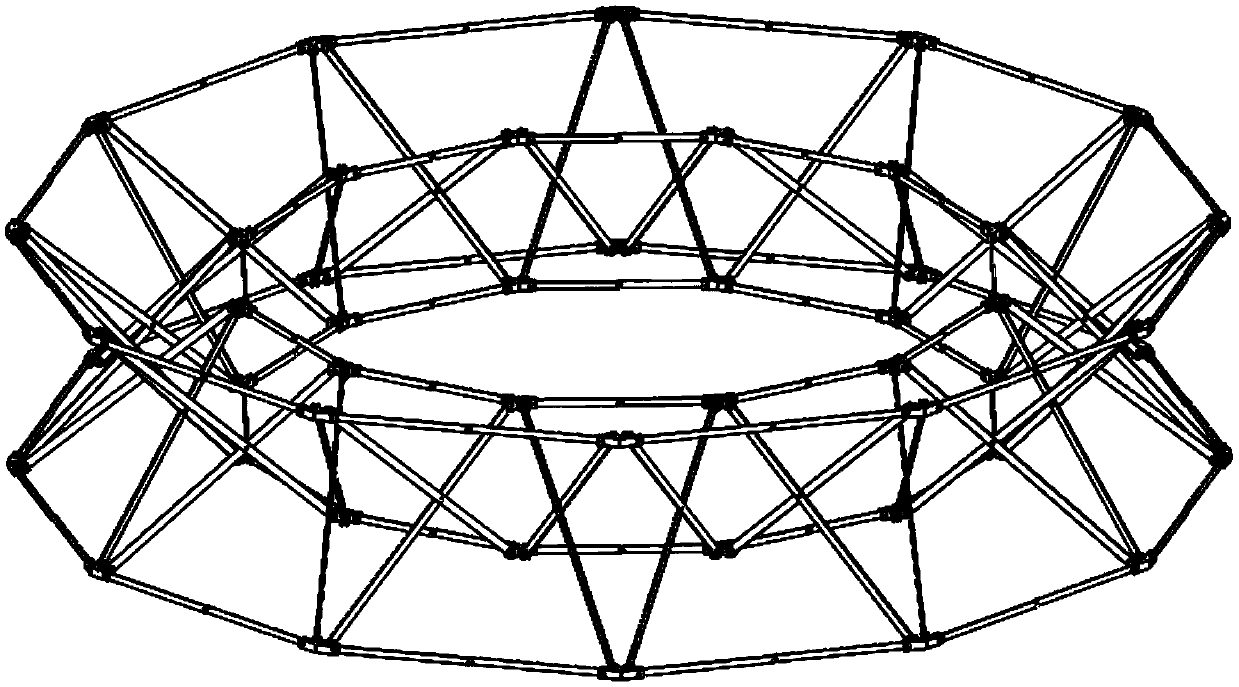

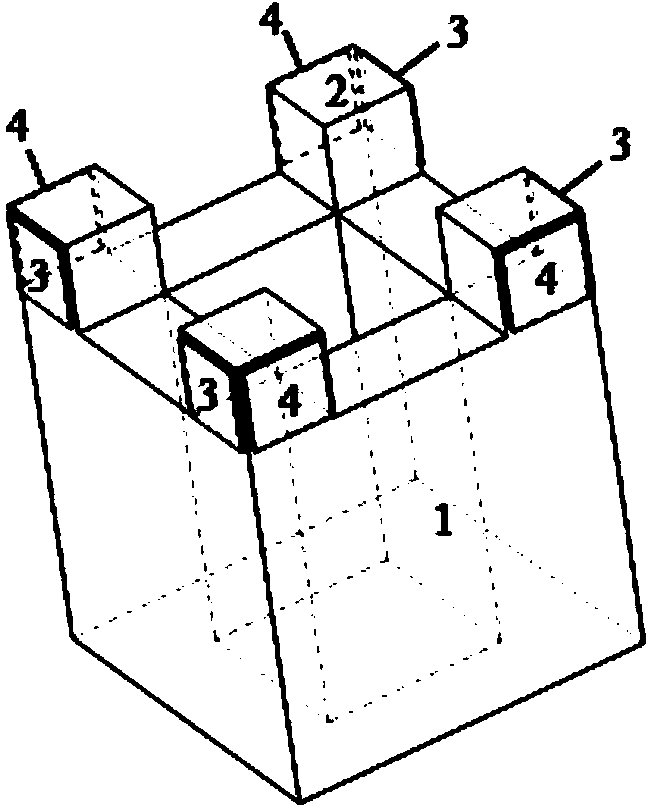

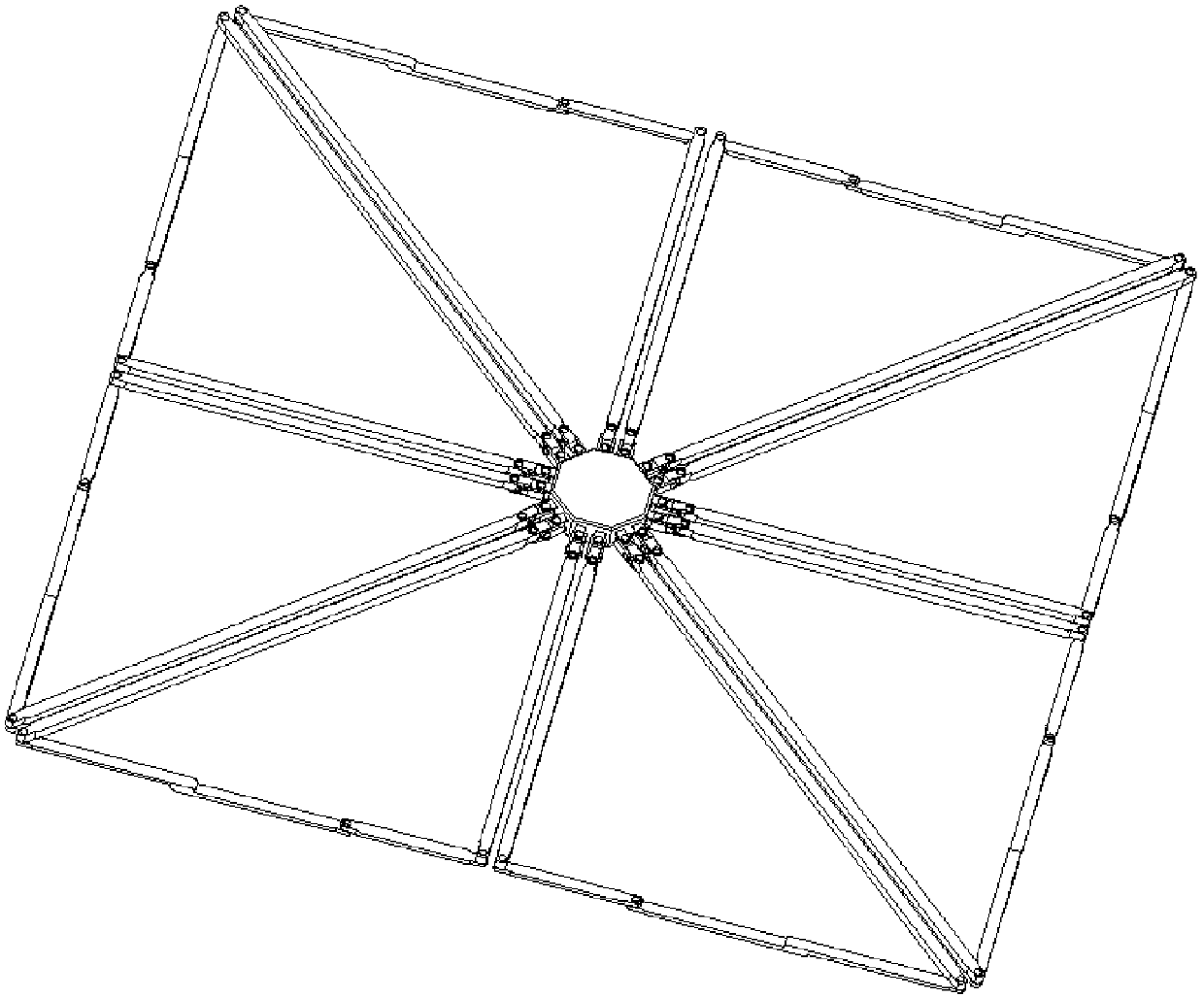

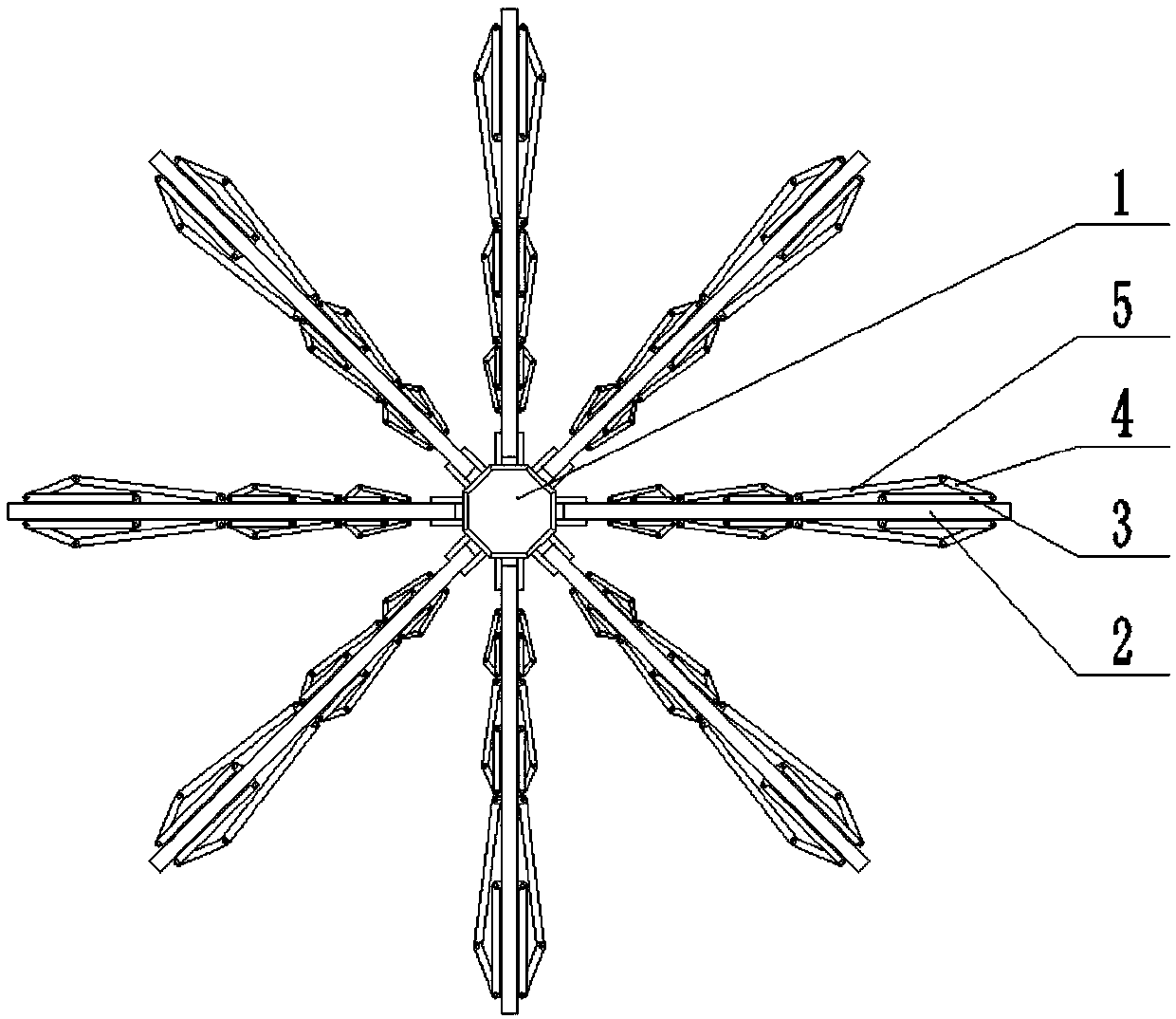

Single-degree-of-freedom overconstrained shear-type deployable unit and space deployable mechanisms composed of same

ActiveCN105799950ALarge folding ratioIncrease stiffnessCosmonautic vehiclesCosmonautic partsStructural symmetrySingle degree of freedom

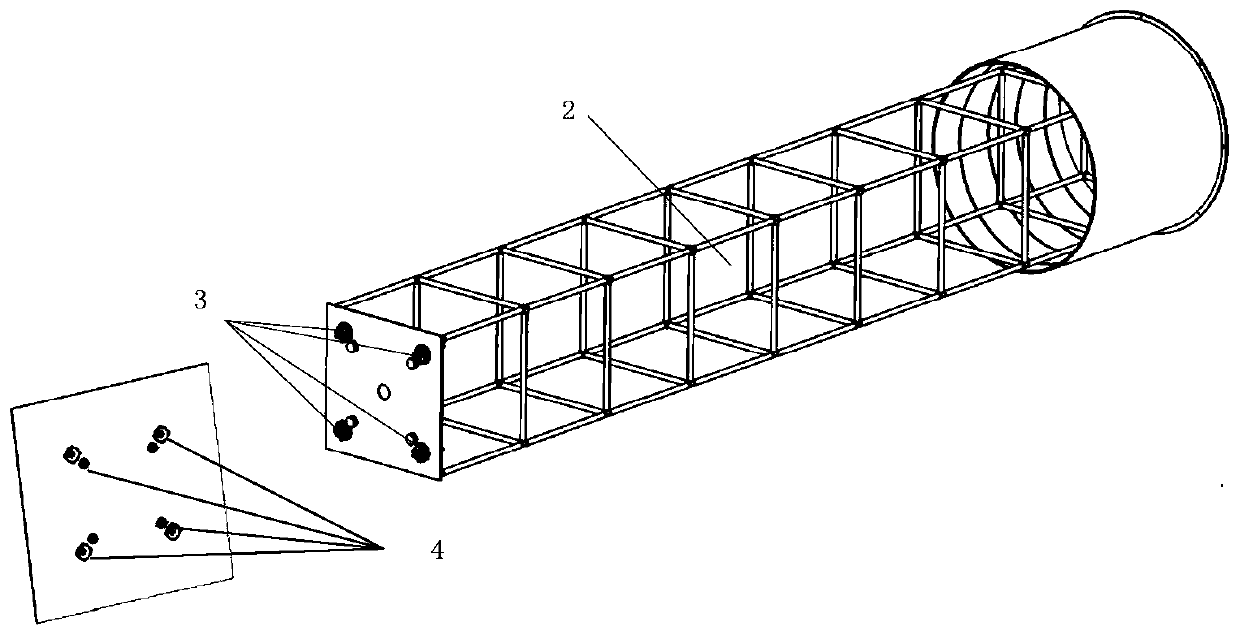

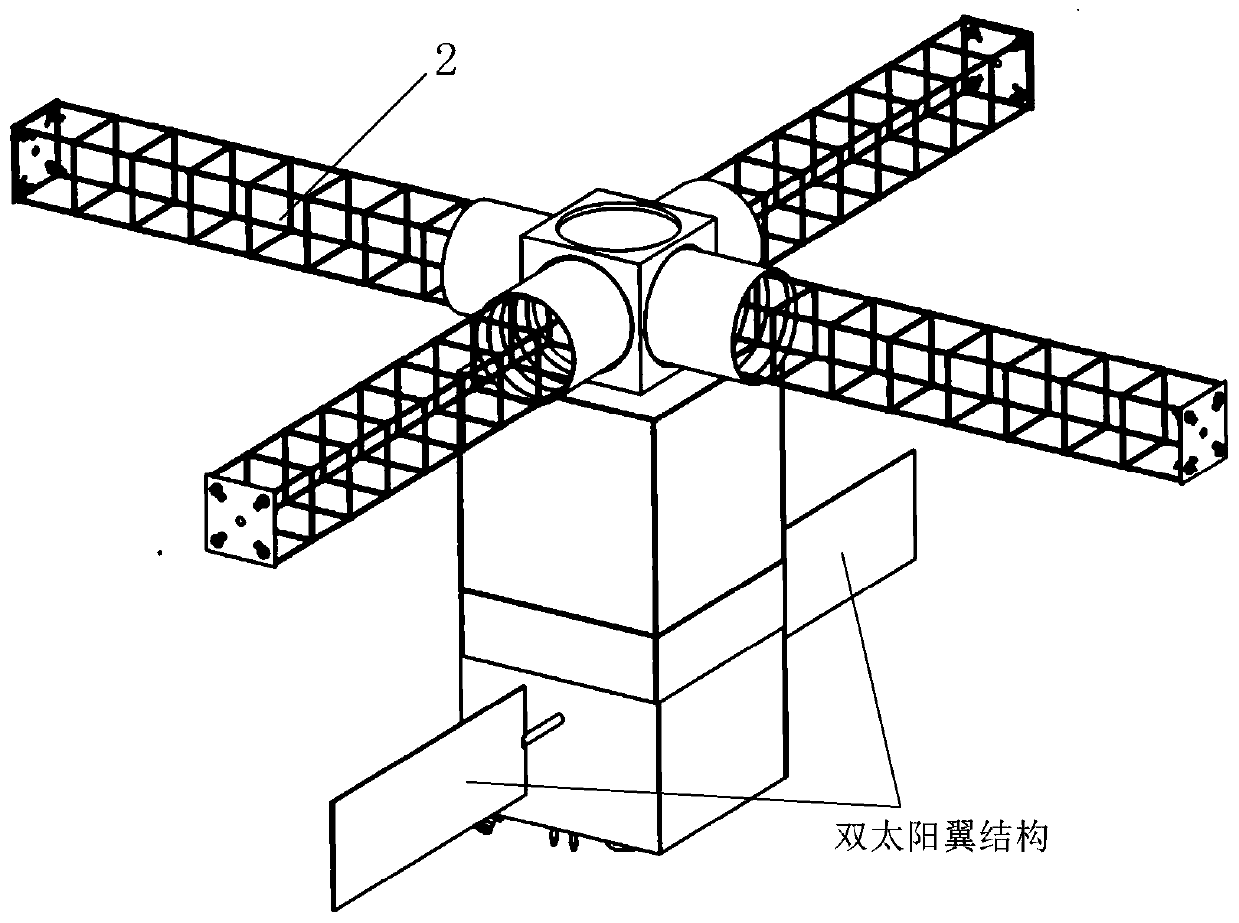

The invention discloses a single-degree-of-freedom overconstrained shear-type deployable unit and space deployable mechanisms composed of the same. The single-degree-of-freedom overconstrained shear-type deployable unit comprises eight disc chucks, four sets of shear fork folding rods and eight sets of folding connecting rods; one set of the folding connecting rods limit the deployable degree of the basic deployable units by depending on the length of the connecting rods, the other seven sets of the folding connecting rods are all overconstrained connecting rods, and the overconstrained connecting rods can effectively improve the rigidity of the basic deployable units. Accordingly, the basic deployable units can be sequentially arranged in order, every two adjacent deployable units can form the first space deployable mechanism and the second space deployable mechanism by sharing four of the disc chucks and one set of the shear fork folding rods, and the length of the first space deployable mechanism and the size of the second space deployable mechanism can be changed by changing the quantity of the basic deployable units. The single-degree-of-freedom overconstrained shear-type deployable unit is simple in structure, has the high structural symmetry and is suitable for constructing an extendable space mast, a solar battery array support and a satellite plane reflecting antenna.

Owner:YANSHAN UNIV

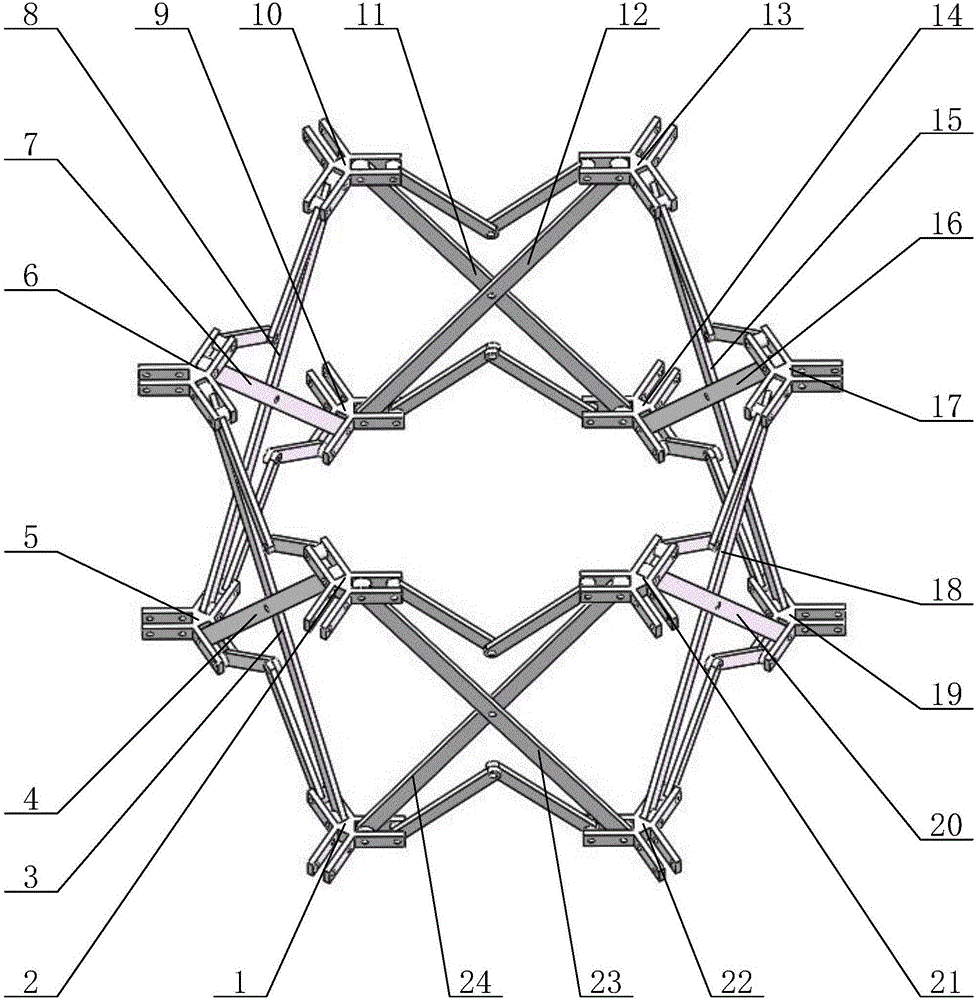

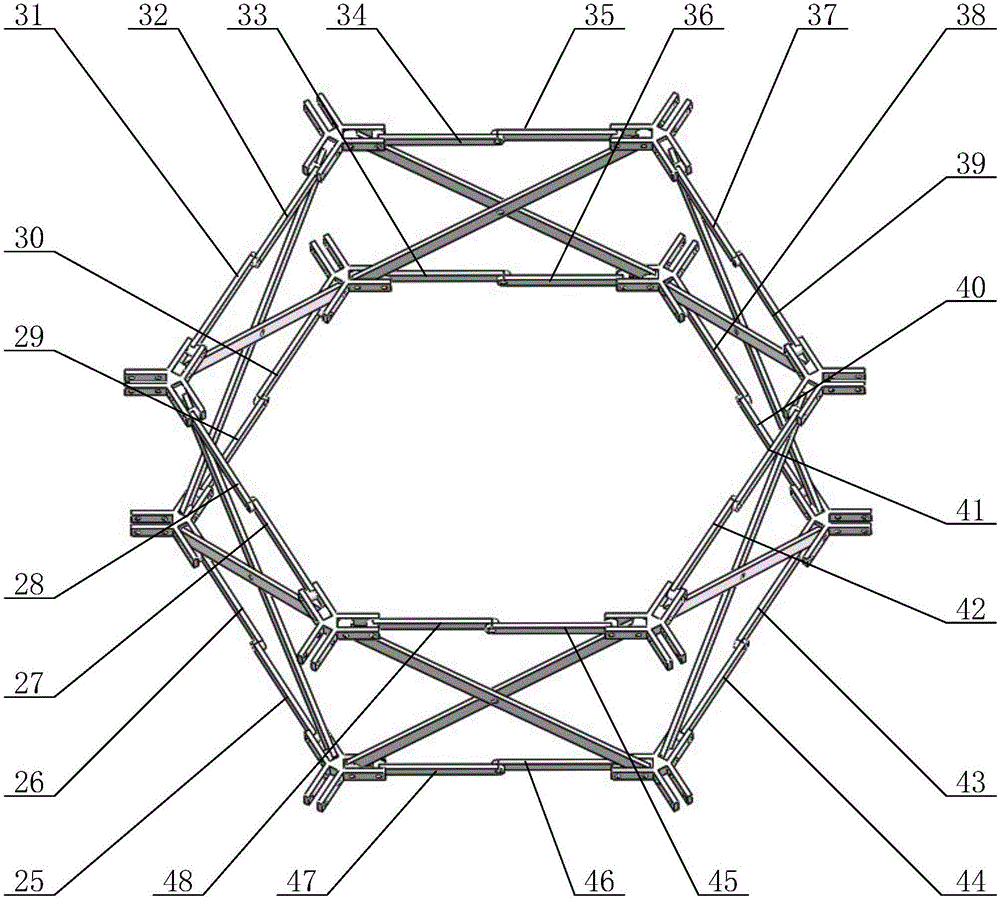

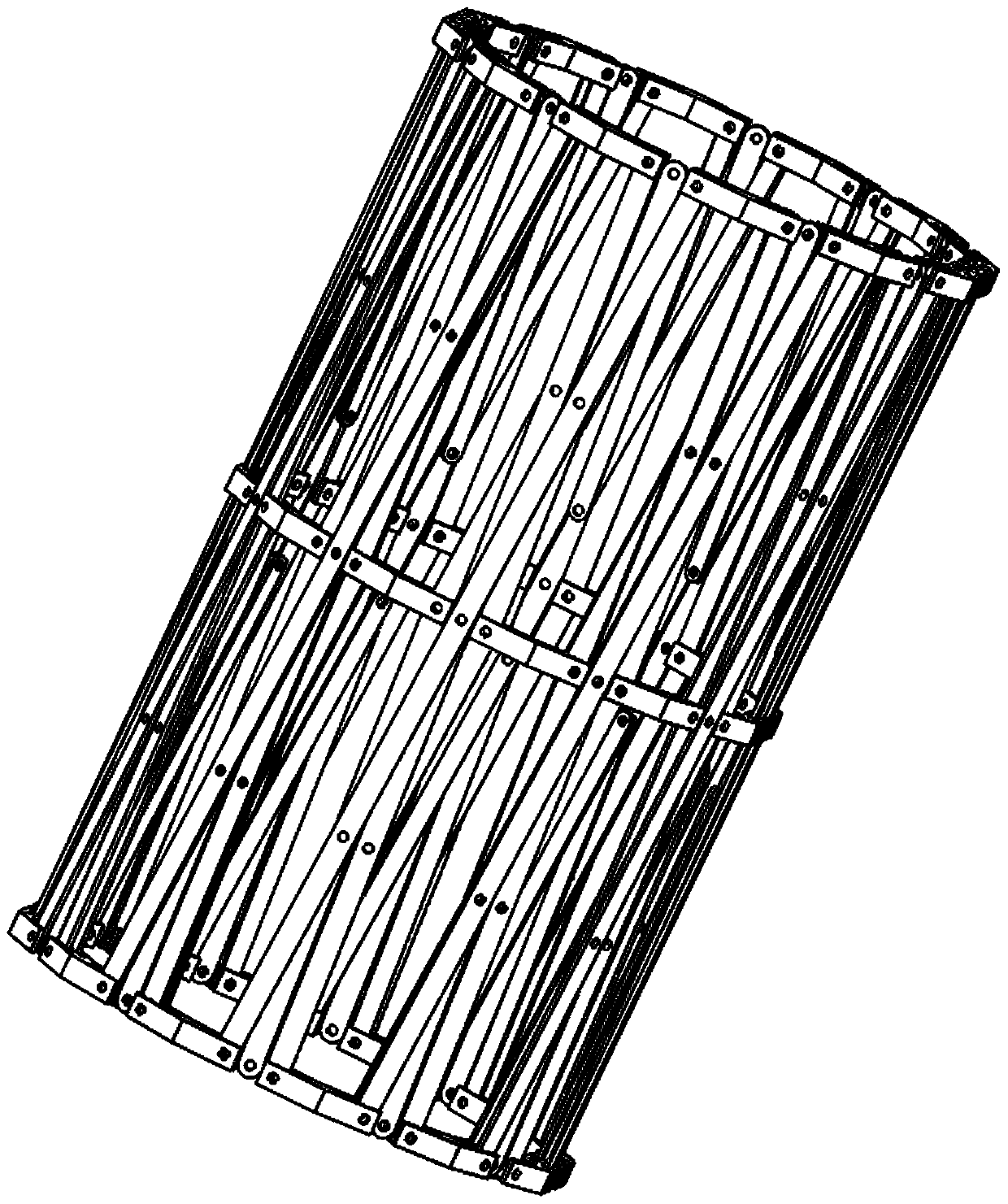

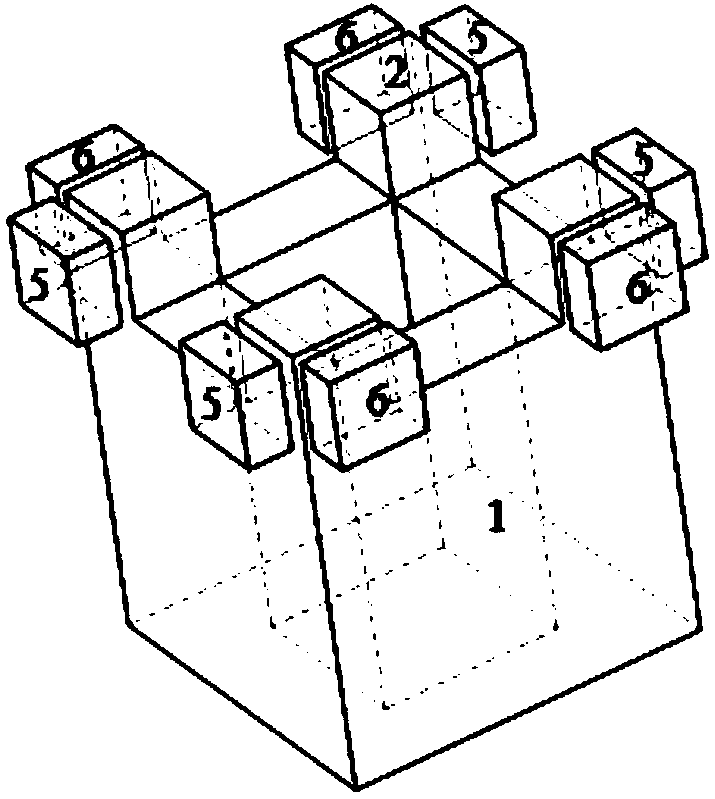

Scissors type hexagonal-prism-shaped extensible unit and space extensible mechanism formed by the same

InactiveCN106058415ALarge shrink rateIncrease stiffnessPhotovoltaic supportsCollapsable antennas meansStructural symmetryEngineering

The invention relates to a scissors type hexagonal-prism-shaped extensible unit and a space extensible mechanism formed by the same. The scissors type hexagonal-prism-shaped extensible unit being a single-freedom-degree over-constrained hexagonal-prism-shaped basic extensible unit comprises twelve floral discs, six groups of scissors type folding rods, and twelve groups of folding connecting rods. One group of folding connecting rods limits the extending degree of the basic extensible unit based on the connecting rod lengths and the rest of eleven groups of folding connecting rods are over-constrained folding connecting rod, so that the rigidity of the basic extensible unit is improved effectively. Multiple basic extensible unit are arranged closely and the adjacent basic extensible units can form a space extensible mechanism by sharing four floral discs, one group of scissors type folding rods and two groups of folding connecting rods; and the size of the pace extensible mechanism can be changed by changing the number of the space extensible units. The provided scissors type hexagonal-prism-shaped extensible unit has high structural symmetry; and different large-dimension space extensible mechanisms can be formed based on assembling of multiple extensible units. Therefore, the scissors type hexagonal-prism-shaped extensible unit and the space extensible mechanism are suitable for constructing a space solar battery array bracket and a satellite planar reflecting antenna.

Owner:YANSHAN UNIV

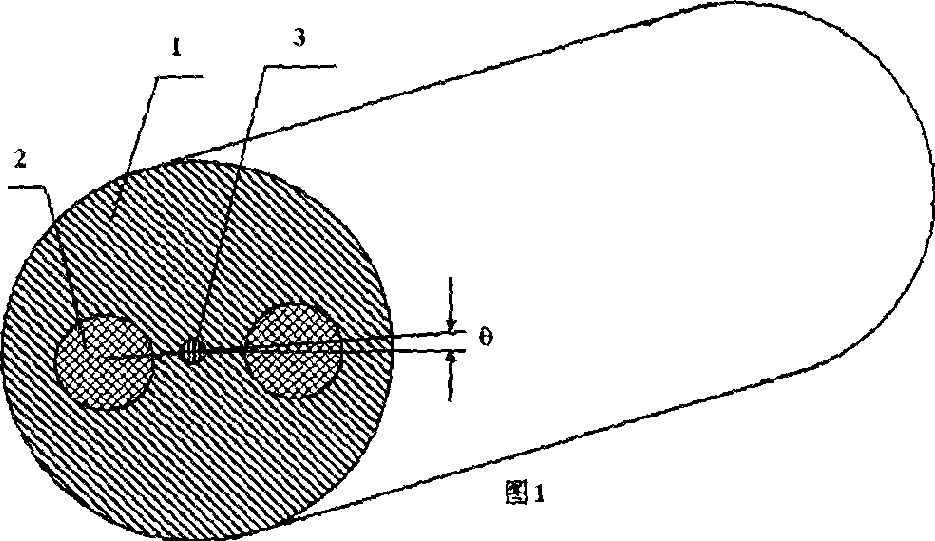

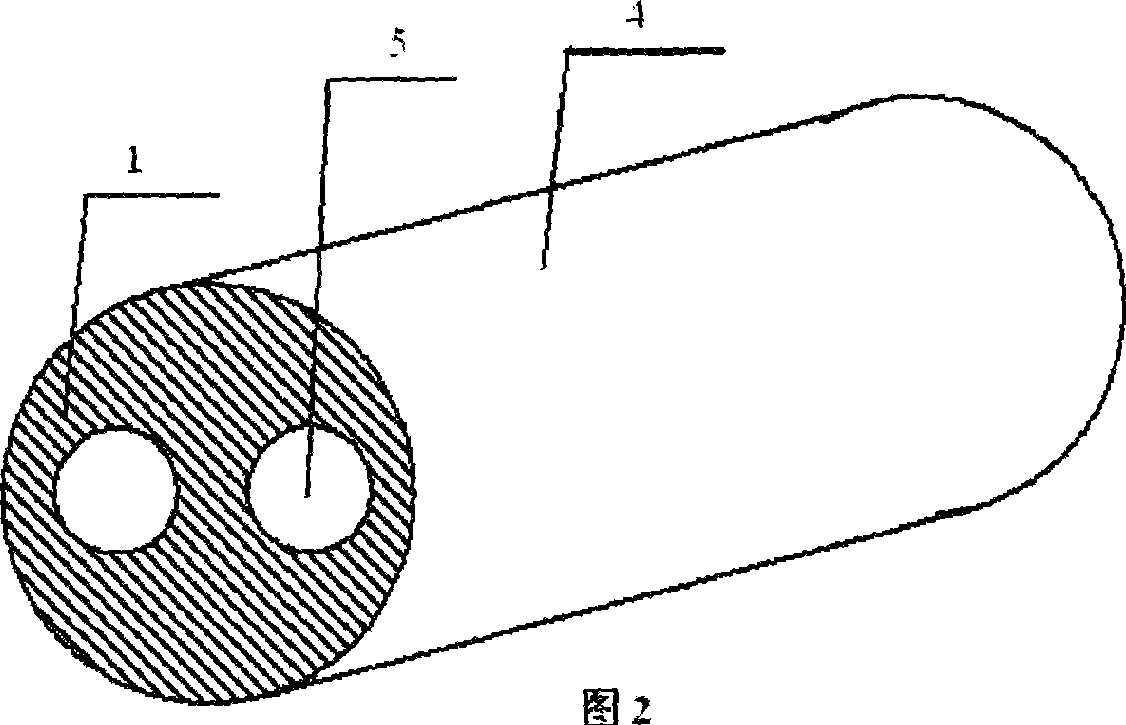

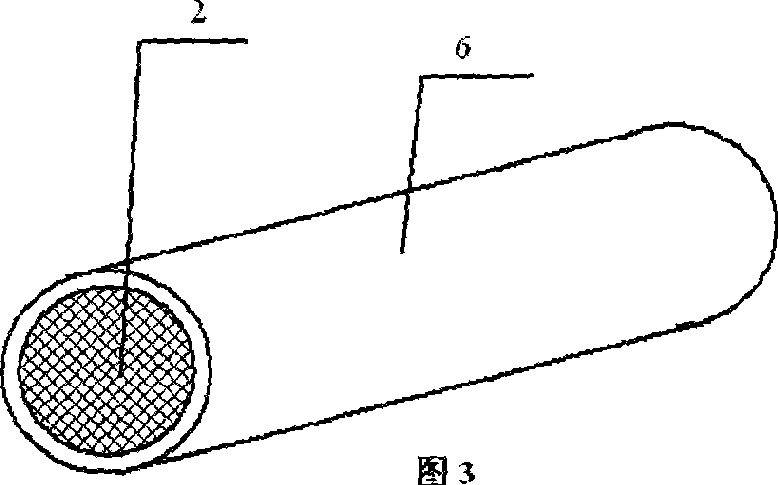

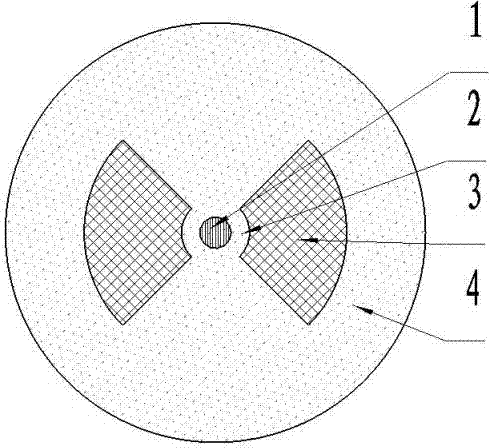

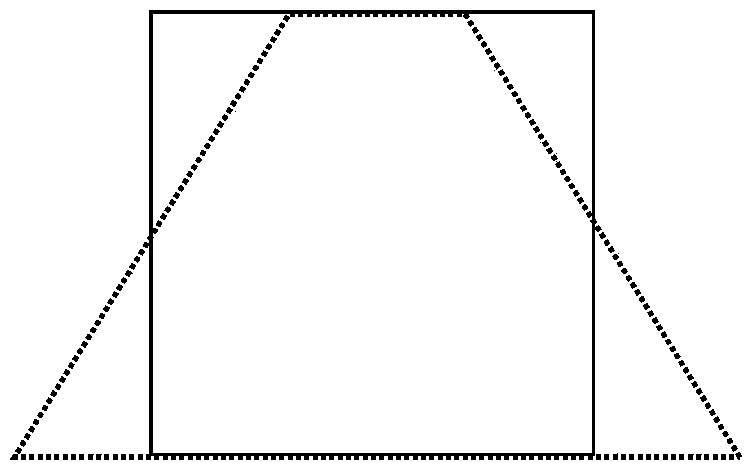

Large size combined optical fibre perform of polarization maintaining fiber and production method thereof

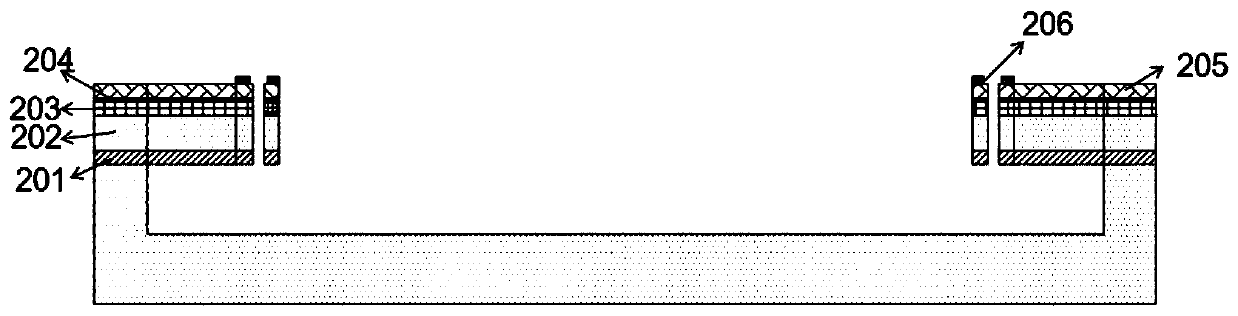

ActiveCN101391861AEasy to moveEvenly heatedGlass making apparatusGlass fibre productsStructural symmetryPolarization-maintaining optical fiber

The invention relates to a polarization maintaining optical fibre large-size composite optical fibre preform and a preparation technological method, and comprises the optical fibre preform with a fibre core and cladding layers; the areas of the cladding layers of the two sides of the fibre core of the optical fibre perform are provided with two holes which run through lengthways and are parallel to the fibre core; the two holes are provided with stress rods so as to form the composite optical fibre preform; the invention is characterized in that the optical fibre preform has the diameter of 30 to 80mm and the length of 200 to 800mm, the diameter range of the two side holes is 12 to 27mm and the diameter range of the stress area of the stress rod is 10 to 25mm. The polarization maintaining optical fibre large-size composite optical fibre preform and the preparation technological method lead the wire-drawing condition to be stable and controllable, and the drawn polarization maintaining optical fibre has excellent mechanical property and can pass the tension screening of 1 percent, even 2 percent; the preform with large diameter and large length is used for producing the polarization maintaining optical fibre; the wire-drawing length of a single preform reaches to be more than 200km, even more than 100km; and the production efficiency of the optical fibre is high. The drawn optical fibre structure has good symmetry and lengthwise uniformity and is easy to control.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

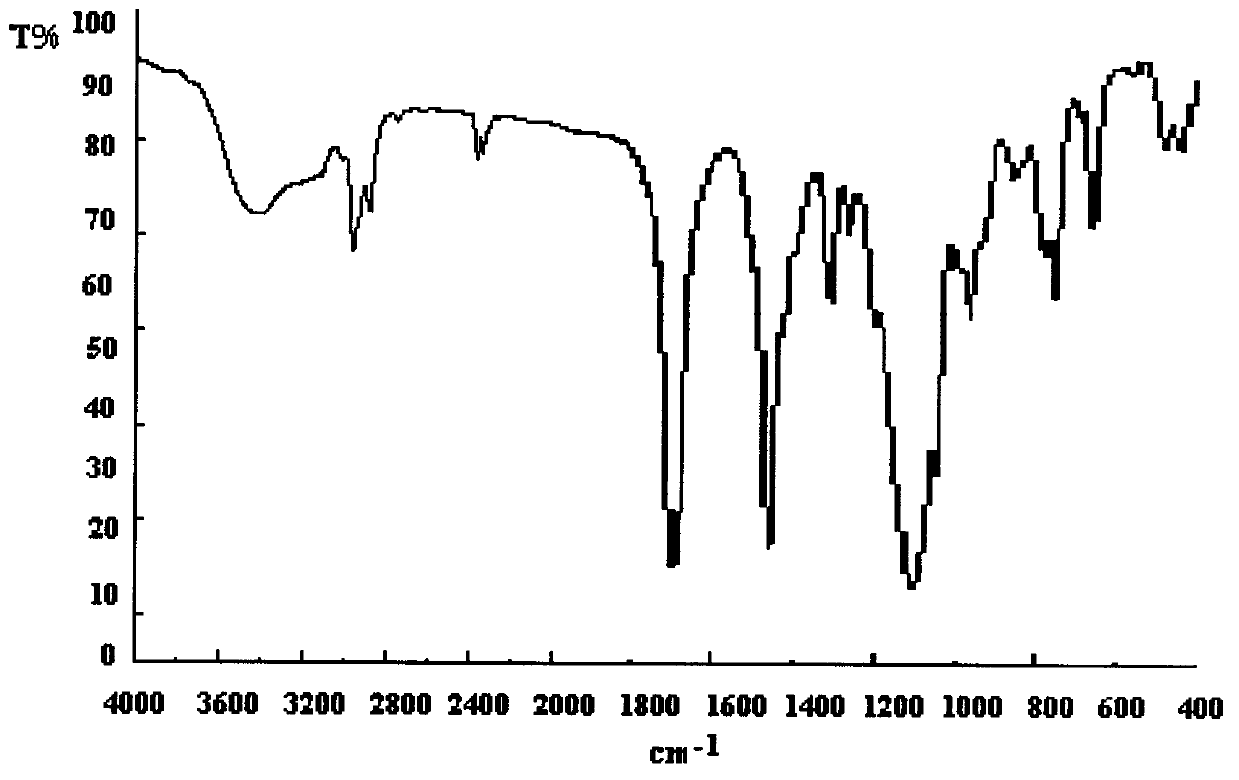

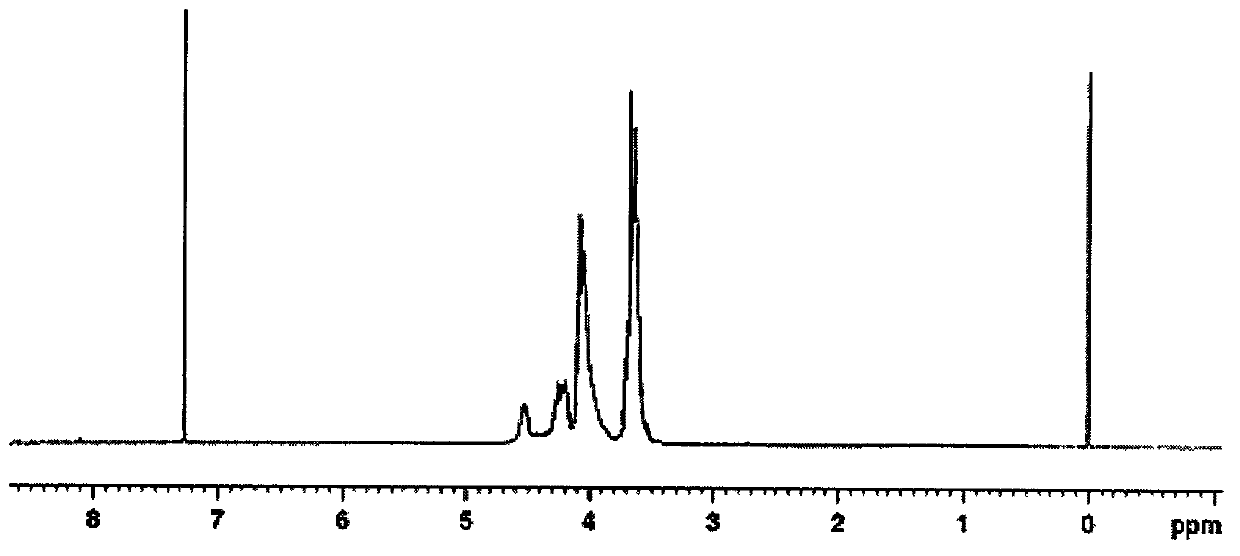

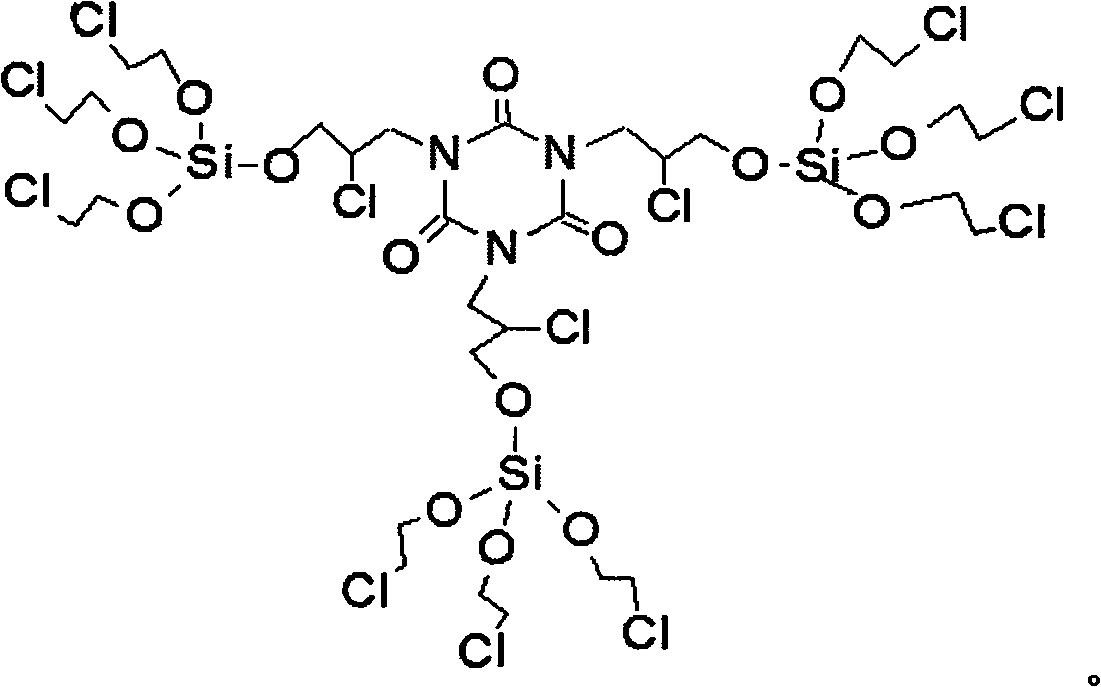

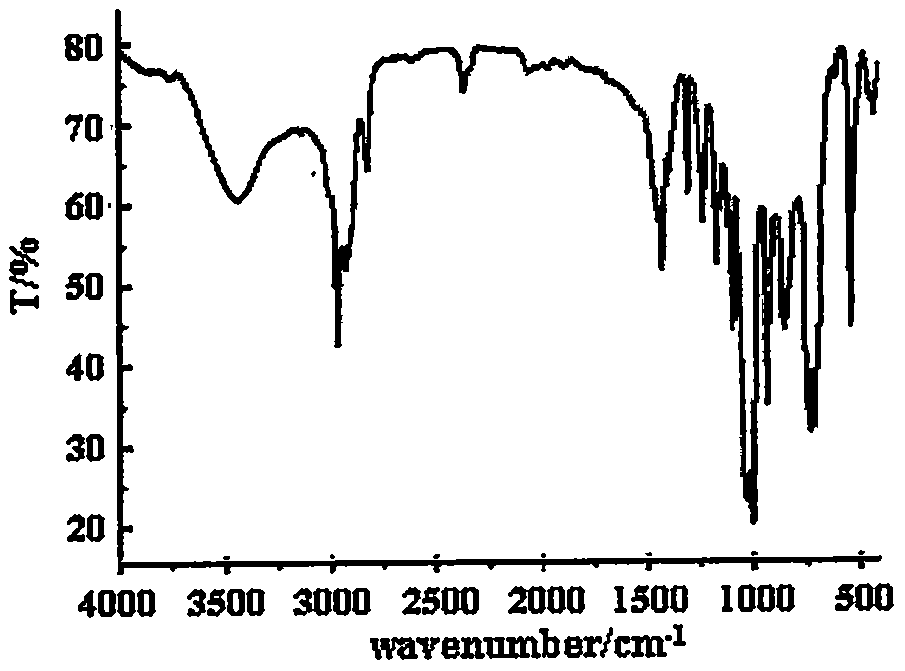

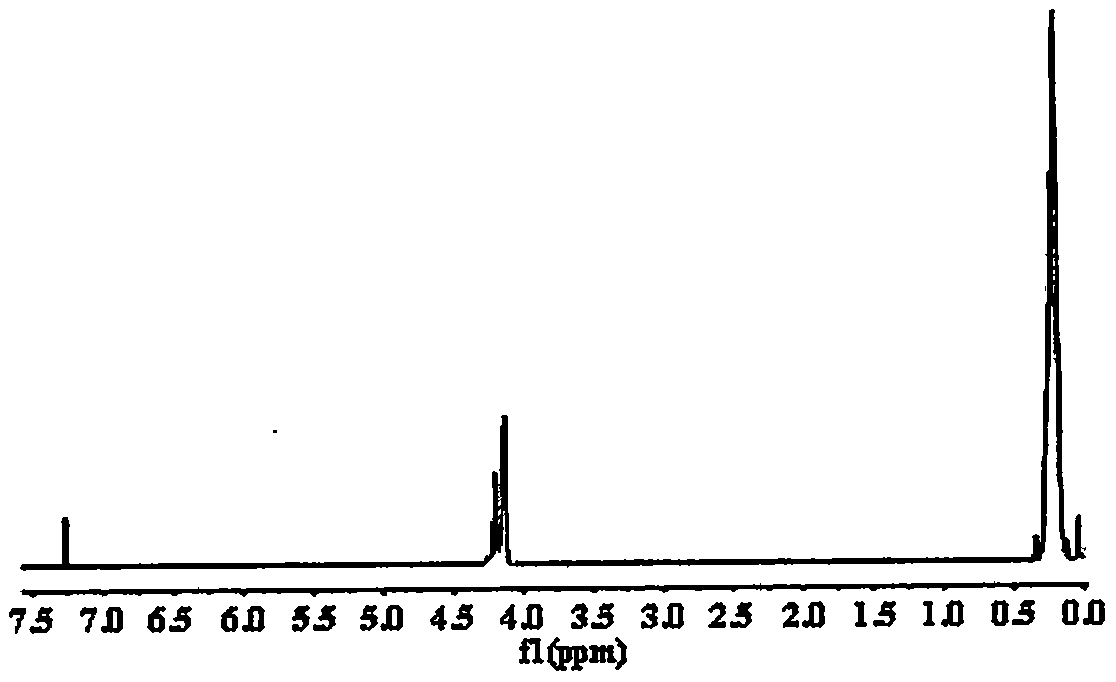

Isocyanurate chloropropyl chloroethyl silicate and preparation method thereof

ActiveCN102731545AGood compatibilityHigh synergistic flame retardant performanceSilicon organic compoundsEpoxyPolyvinyl chloride

The invention relates to a nitrogen, silicon and chlorine thee-element synergic flame retardant tri{2-chloro-3-[tri(chloroethoxy)silicon acyloxy]propyl}isocyanurate compound and a preparation method thereof. The structure of the compound is shown as a formula in the specification. The preparation method comprises the following steps: dripping organic solvent solution of triglycidyl Isocyanurate into silicon tetrachloride, and reacting for 4 to 6 hours at a temperature of between 50 and 70 DEG C; and cooling to 30 DEG C, introducing ethylene oxide under the liquid surface, reacting for 2 to 3 hours at a temperature of between 45 and 55 DEG C, and purifying to obtain the tri{2-chlor-3-[tri(chloroethoxy)silicon acyloxy]propyl}isocyanurate. The compound has good flame retardant plasticization, and is suitable for flame retardant plasticizer such as polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and the like; and the method has simple production process and low cost, and is easy for industrial production.

Owner:SUZHOU UNIV OF SCI & TECH

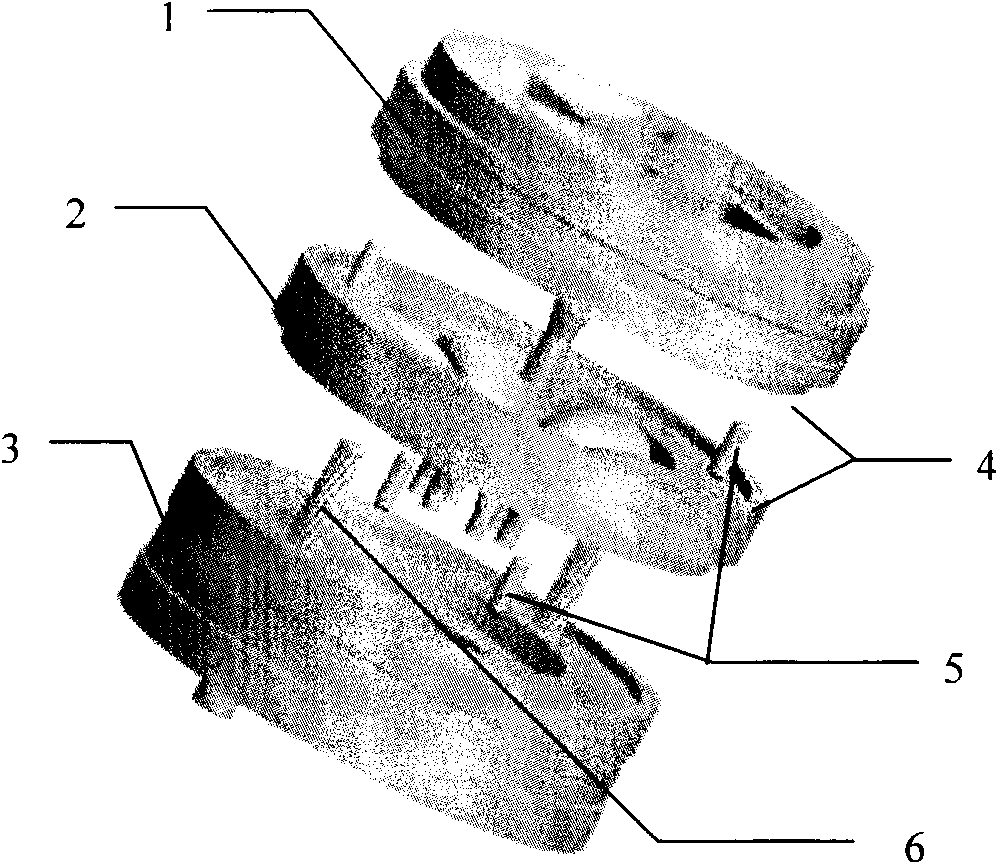

Helical tube hot-extrusion die in porous magnesium alloy

InactiveCN101633009AReduce resistanceGuaranteed dimensional accuracyExtrusion diesCircular discStructural symmetry

A helical tube hot-extrusion die in porous magnesium alloy belongs to the technical field of die processing. The helical tube hot-extrusion die comprises an upper die, a middle die and a lower die, wherein, the upper die, the middle die and the lower die are sequentially sheathed and are of disk structures, and rabbets, locating pins and bolts are respectively arranged between the upper die and the middle die as well as between the middle die and the lower die for fixation. A helical flow supply mode is adopted for the upper die of the helical tube hot-extrusion die, which significantly lowers resistance formed by helical shaping of tube blank by special helical equipment when a tubular product is extruded; and a circular welding cavity is adopted for the lower die, which is beneficial for rotary welding of a magnesium alloy material of plastic flow in the welding cavity. Meanwhile, dimensional accuracy of a metal is ensured under the action of a forming cavity working tape when the metal is extruded out of the welding cavity, and the die structure has good symmetry, thus reducing non-uniformity of feed stock flow, and avoiding cracking of tube walls when a helical aperture is formed on the magnesium alloy material. The helical tube hot-extrusion die has the advantages of high preparation and production efficiency, few waste materials, good quality and being more favorable for meeting the requirements of continuous production.

Owner:SHANGHAI JIAO TONG UNIV +1

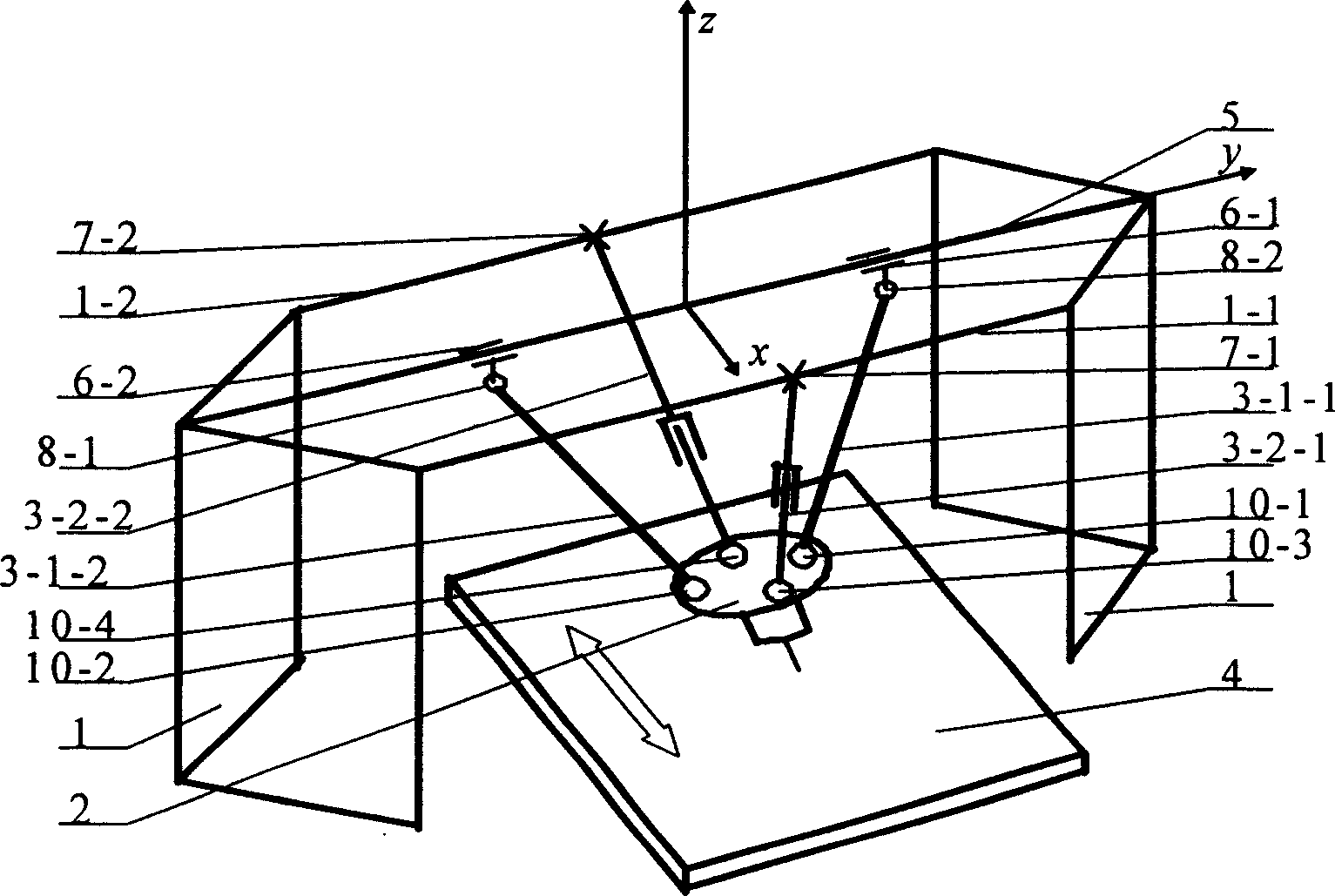

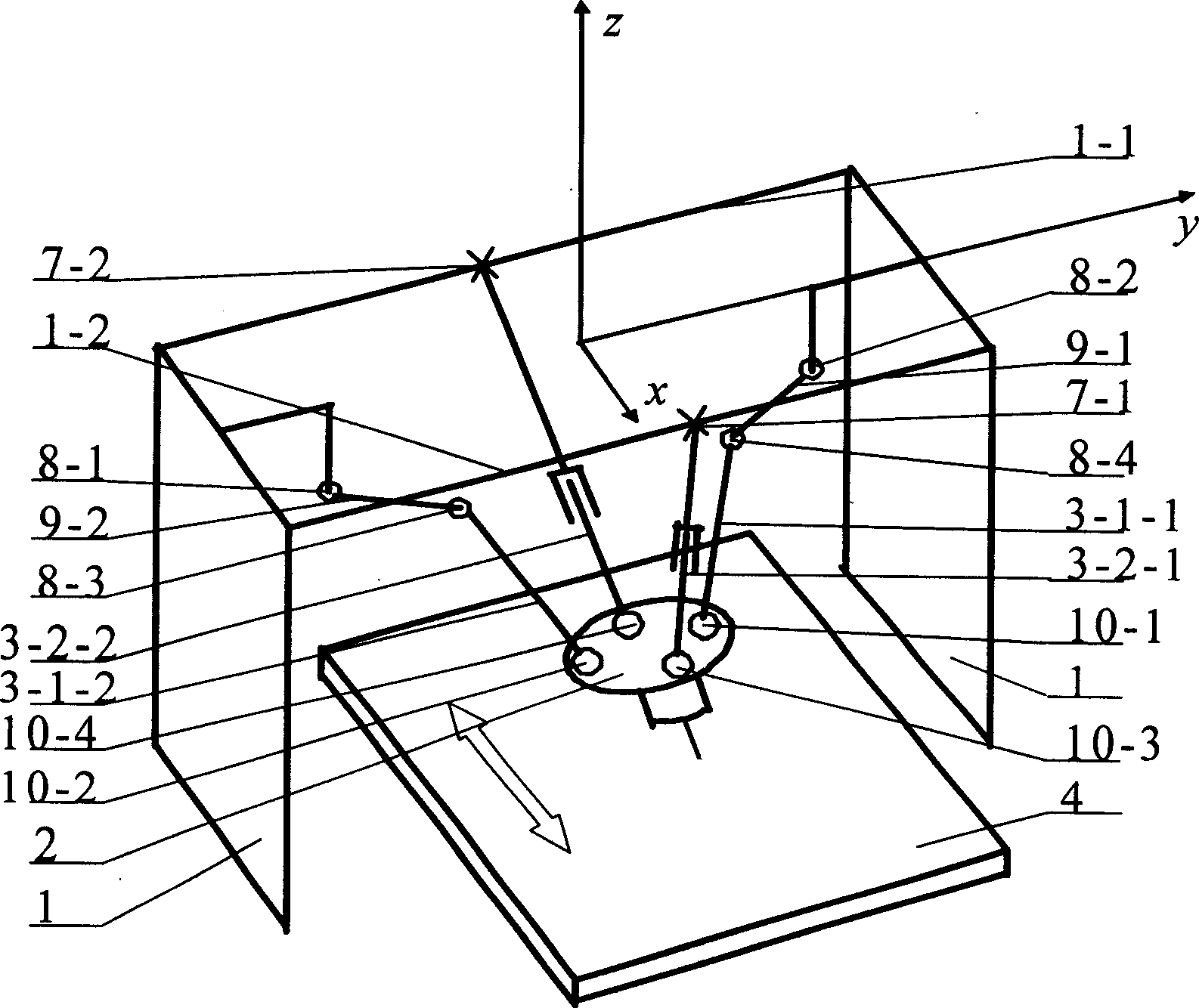

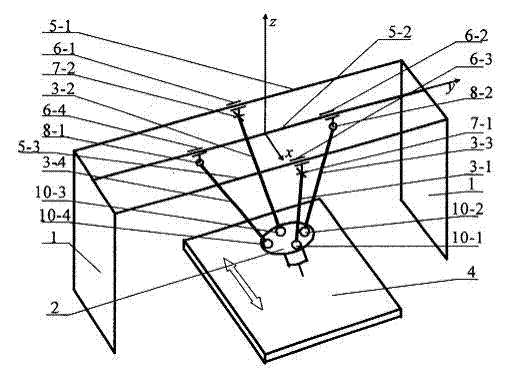

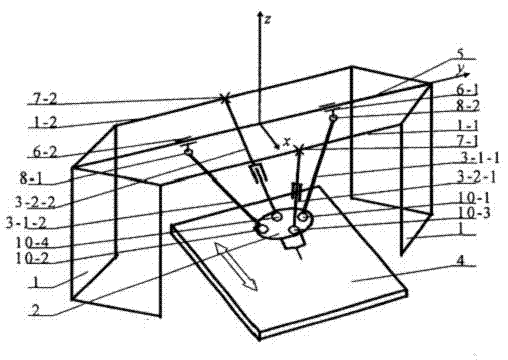

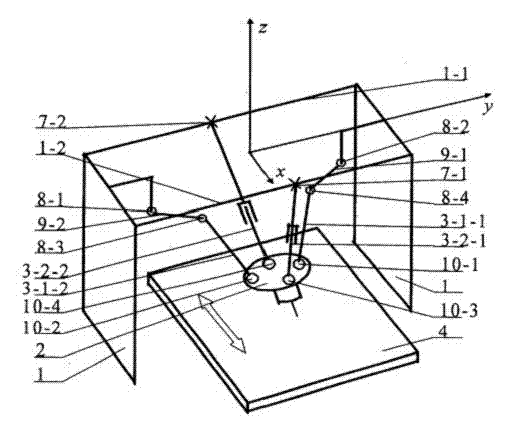

Five axis linkage parallel-tandem digital control machine tool

InactiveCN1788929ALow costSimple structureProgramme-controlled manipulatorLarge fixed membersSix degrees of freedomEngineering

The five-axis linkage serioparallel numerically-controlled machine tool is one kind of parallel machine tool superior to available six freedom parallel machine tool, which has high cost and complicated structure for five-axis motion. The five-axis linkage serioparallel numerically-controlled machine tool includes a frame; a moving platform; four link rods, each of which has one end connected to the frame and the other end hinged the operate moving platform; and one shifting work table set below the moving platform. The machine tool of present invention has high symmetry, high rigidity, high precision and high dynamic performance, no motion coupling, simple structure, low cost and easy manufacture. The present invention increases the structure forms of five-axis parallel machine tools, provides the theoretical research on four and five freedom parallel machine tools with mechanism prototype, and can realizes all the functions of available six freedom parallel machine tool.

Owner:HARBIN INST OF TECH

Road scene semantic segmentation method based on convolutional neural network

ActiveCN109635662AImprove learning effectReduce redundancyCharacter and pattern recognitionNeural architecturesHidden layerOptimal weight

The invention discloses a road scene semantic segmentation method based on a convolutional neural network. The method comprises the steps: firstly building the convolutional neural network which comprises an input layer, a hidden layer, and an output layer, and the hidden layer is composed of 13 neural network blocks, 7 upsampling layers, and 8 cascade layers; inputting each original road scene image in the training set into a convolutional neural network for training to obtain 12 semantic segmentation prediction images corresponding to each original road scene image; calculating a loss function value between a set composed of 12 semantic segmentation prediction images corresponding to each original road scene image and a set composed of 12 single hot coding images processed by the corresponding real semantic segmentation image; obtaining an optimal weight vector and an optimal offset item of the convolutional neural network classification training model; inputting the road scene imageto be subjected to semantic segmentation into a convolutional neural network classification training model for prediction to obtain a corresponding predicted semantic segmentation image. The method has the advantage of high semantic segmentation precision.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

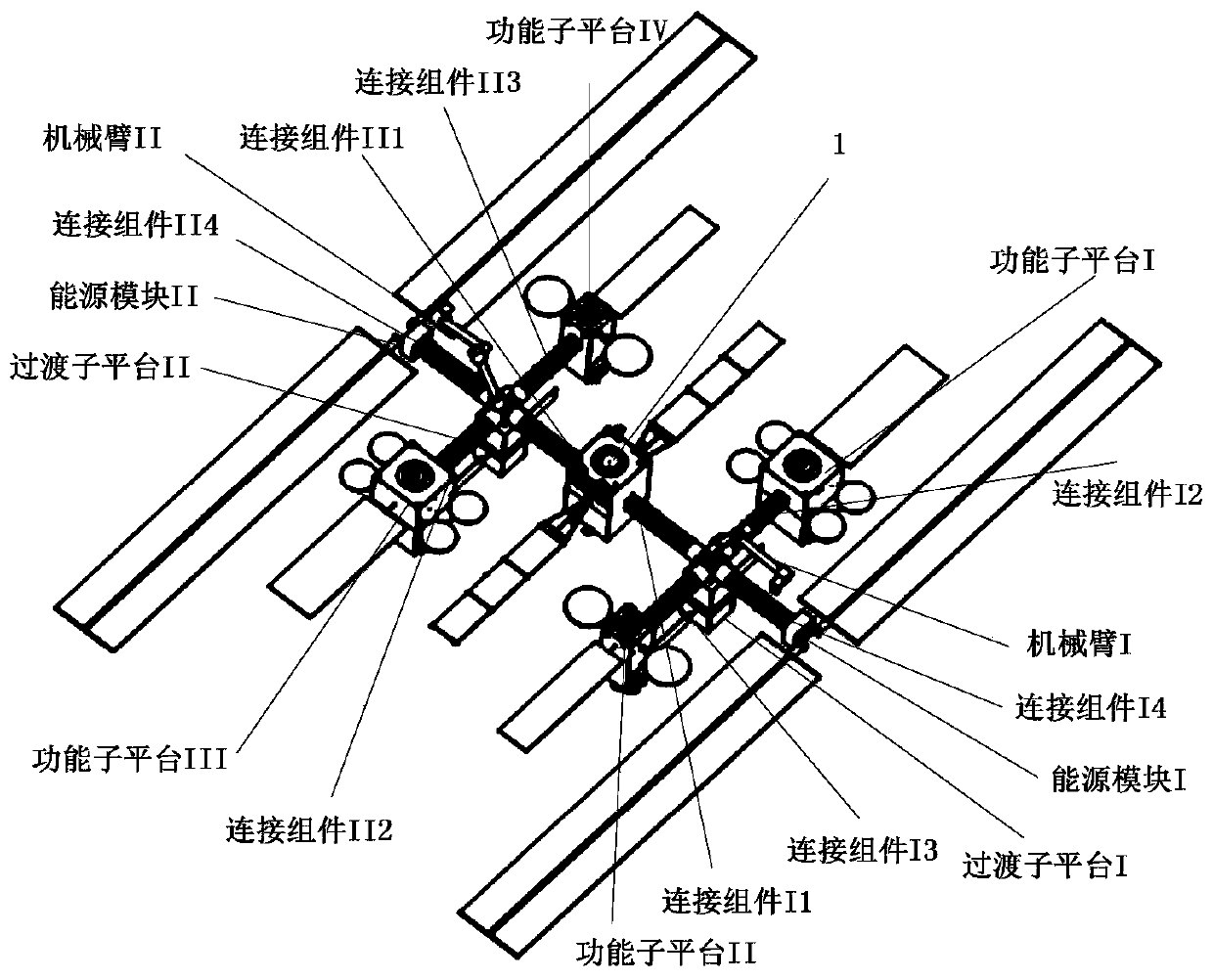

Stationary orbit ultra-large type assemblable satellite platform configuration and on-orbit assembly method

ActiveCN111422378AMeet the comprehensive bearing requirements of multiple types of loadsMeet the comprehensive bearing requirementsCosmonautic partsArtificial satellitesMechanical engineeringSatellite bus

The invention provides a stationary orbit ultra-large type assemblable satellite platform configuration, which belongs to the technical field of spacecrafts, and comprises a mother platform, a transition sub-platform I and a transition sub-platform II, a functional sub-platform I and a functional sub-platform II, a functional sub-platform III and a functional sub-platform IV, an energy module I and an energy module II, and a mechanical arm I and a mechanical arm II, wherein the mother platform is a control center of a whole satellite; the transition sub-platform I and the transition sub-platform II are respectively connected with the mother platform through connecting devices; the functional sub-platform I and the functional sub-platform II are respectively connected with the transition sub-platform I through connecting devices; the functional sub-platform III and the functional sub-platform IV are respectively connected with the transition sub-platform II through connecting devices; the energy module I and the energy module II are respectively connected with the transition sub-platform I and the transition sub-platform II through connecting devices to supply power; the mechanicalarm I and the mechanical arm II are installed on the transition sub-platform I and the transition sub-platform II correspondingly to execute an on-orbit assembling task. The platform configuration issuitable for expansion, can adapt to on-orbit construction of large satellites with the on-orbit flight weight of 10-20 t, is applied to various types of satellites and service stations, and is wide in application range.

Owner:SHANGHAI SATELLITE ENG INST

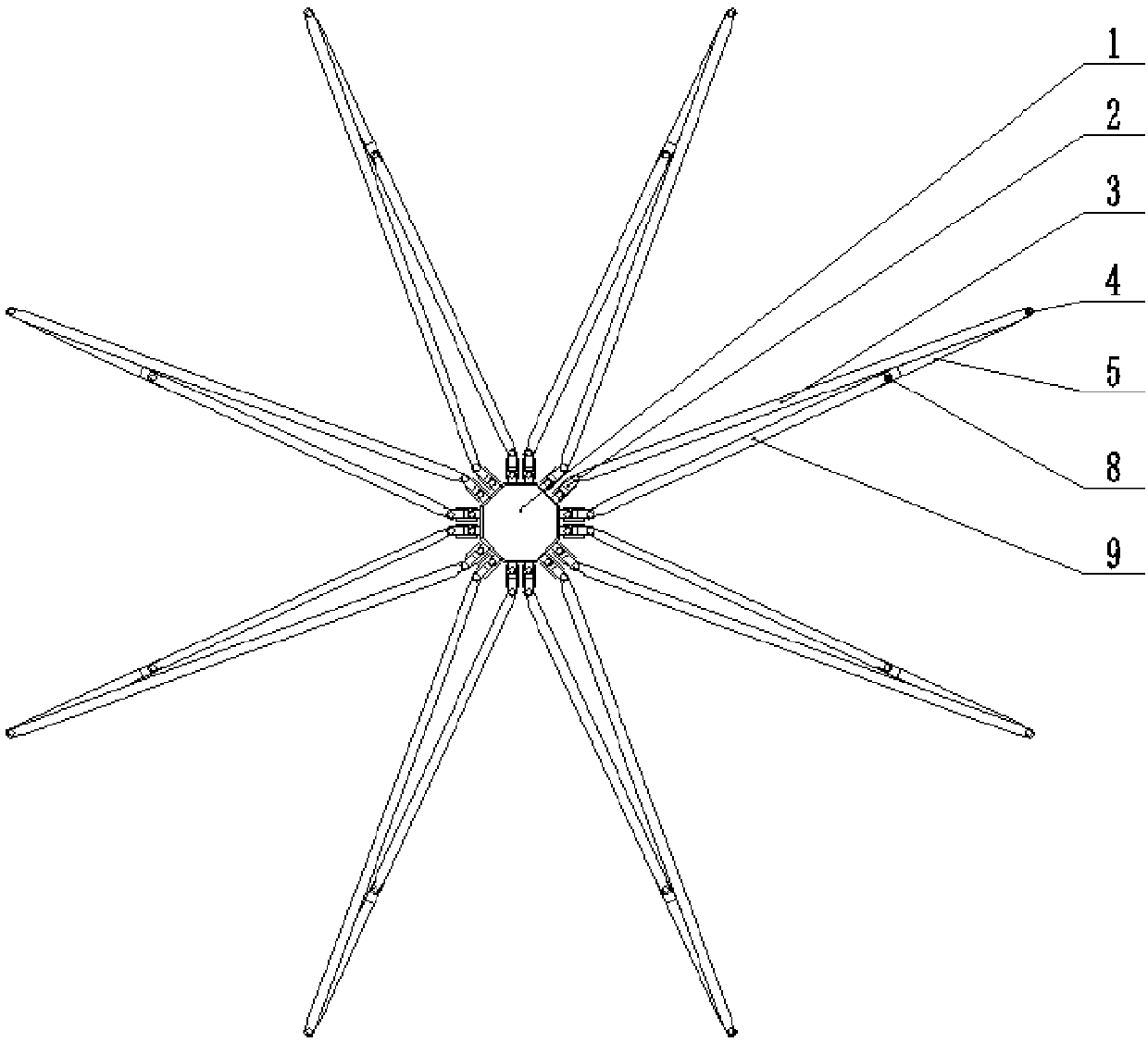

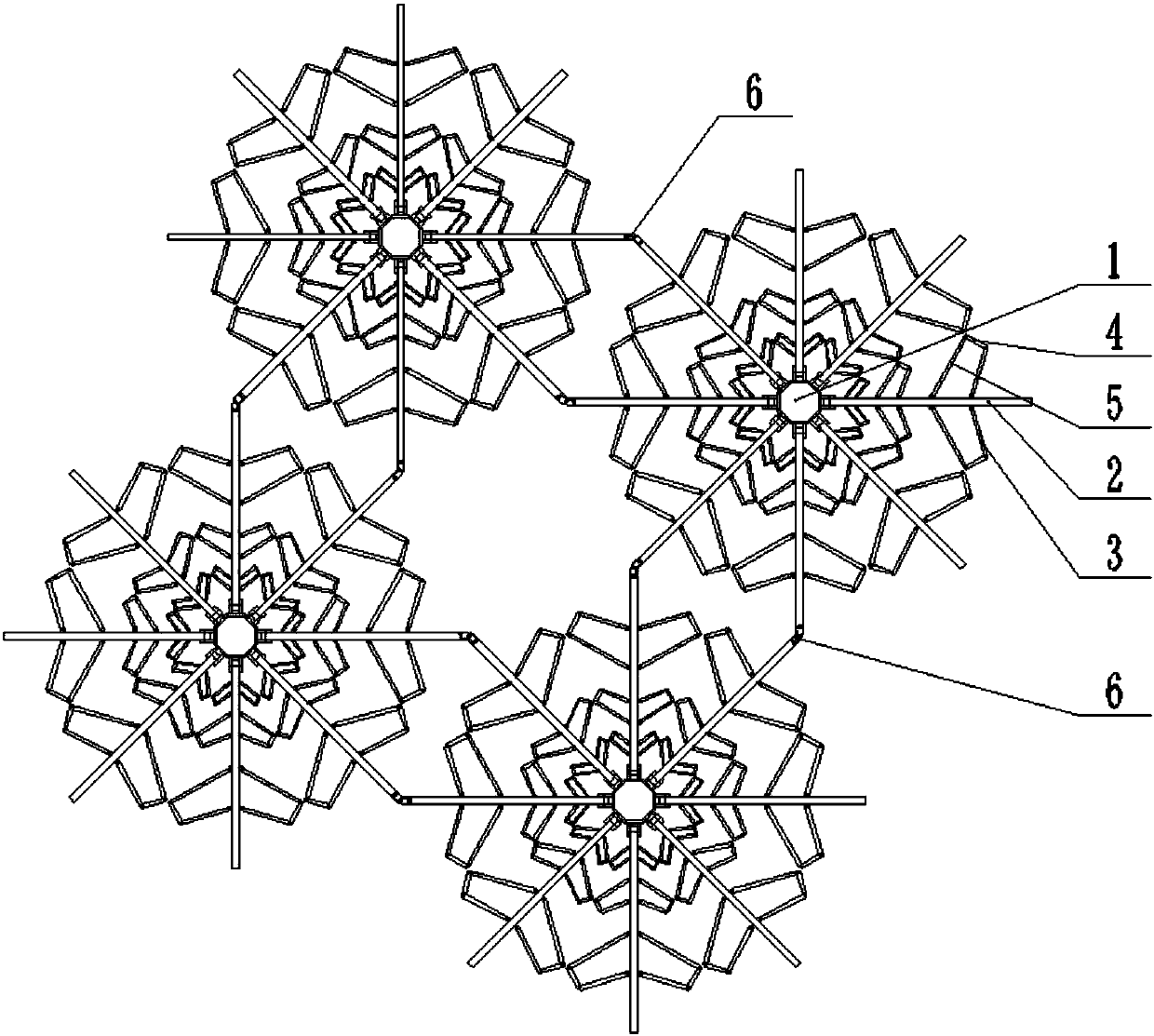

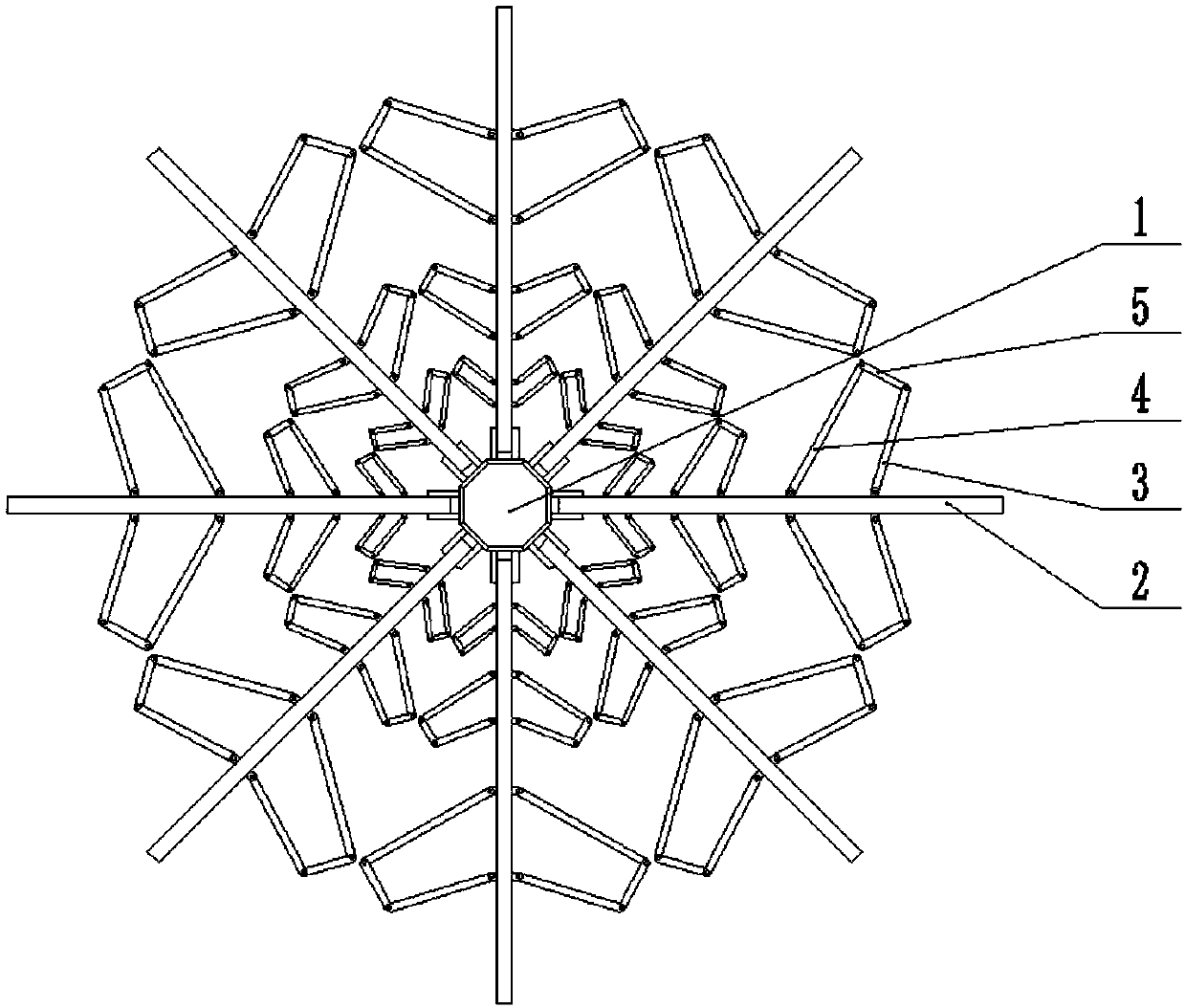

Scissors type hexagonal-prism-shaped extensible unit and space extensible mechanism formed by same

ActiveCN107331939ALarge shrink rateIncrease stiffnessPhotovoltaic supportsCollapsable antennas meansLathe faceplateStructural symmetry

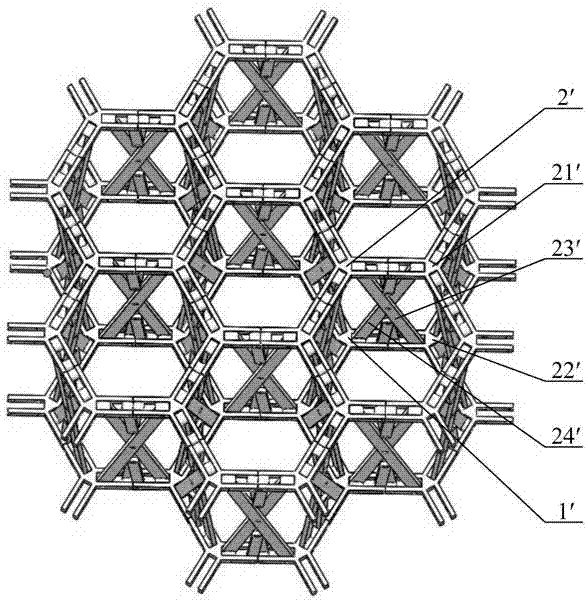

The invention relates to a scissors type hexagonal-prism-shaped extensible unit and a space extensible mechanism formed by the same. The scissors type hexagonal-prism-shaped extensible unit is a single-freedom-degree over-constrained hexagonal-prism-shaped basic extensible unit and comprises twelve faceplates, six groups of scissors type folding rods, and twelve groups of folding connecting rods. One group of folding connecting rods limits the extending degree of the basic extensible unit by the connecting rod lengths and the other eleven groups of folding connecting rods are over-constrained folding connecting rods, so that the rigidity of the basic extensible unit is improved effectively. Multiple basic extensible units are arranged closely and the adjacent basic extensible units can form a space extensible mechanism by sharing four faceplates, one group of scissors type folding rods and two groups of folding connecting rods; and the size of the pace extensible mechanism can be changed by changing the number of basic extensible units. The provided scissors type hexagonal-prism-shaped extensible unit has high structural symmetry; and different large-dimension space extensible mechanisms can be formed based on assembling of the multiple extensible units. Therefore, the scissors type hexagonal-prism-shaped extensible unit and the space extensible mechanism are suitable for constructing a space solar battery array bracket and a satellite planar reflecting antenna.

Owner:YANSHAN UNIV

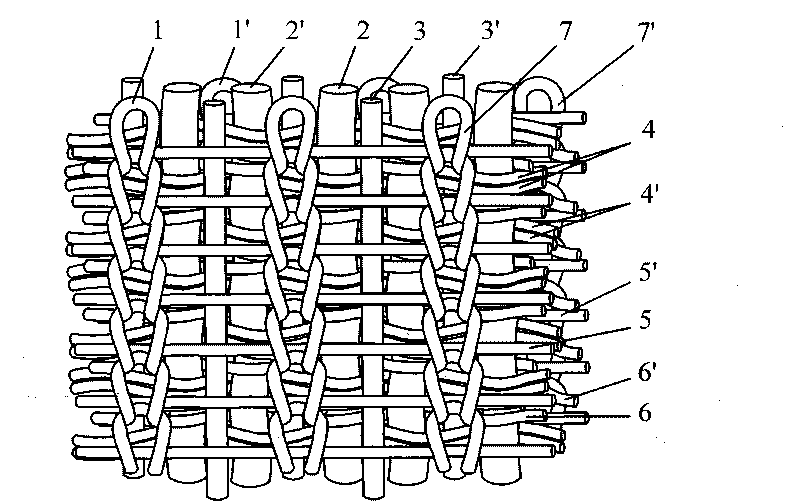

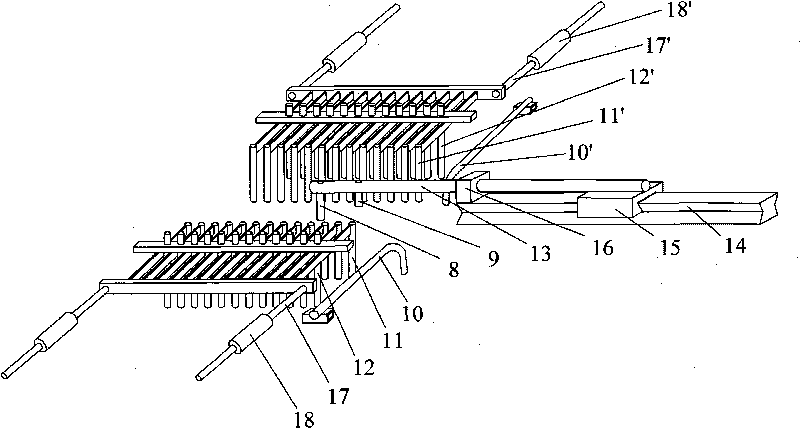

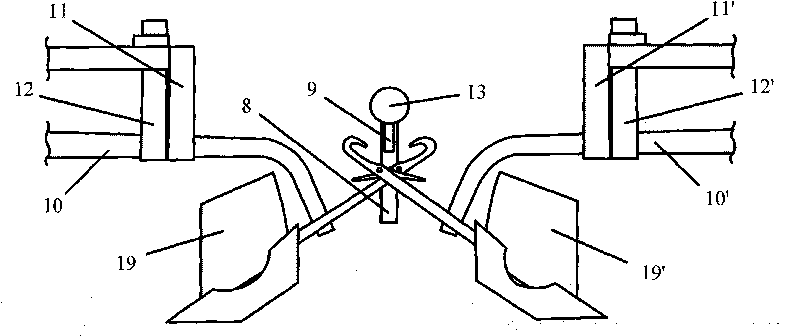

Multi-layered warp knitted weft insertion weaving knitting composite structure and weaving method therefor and yarn feeding device

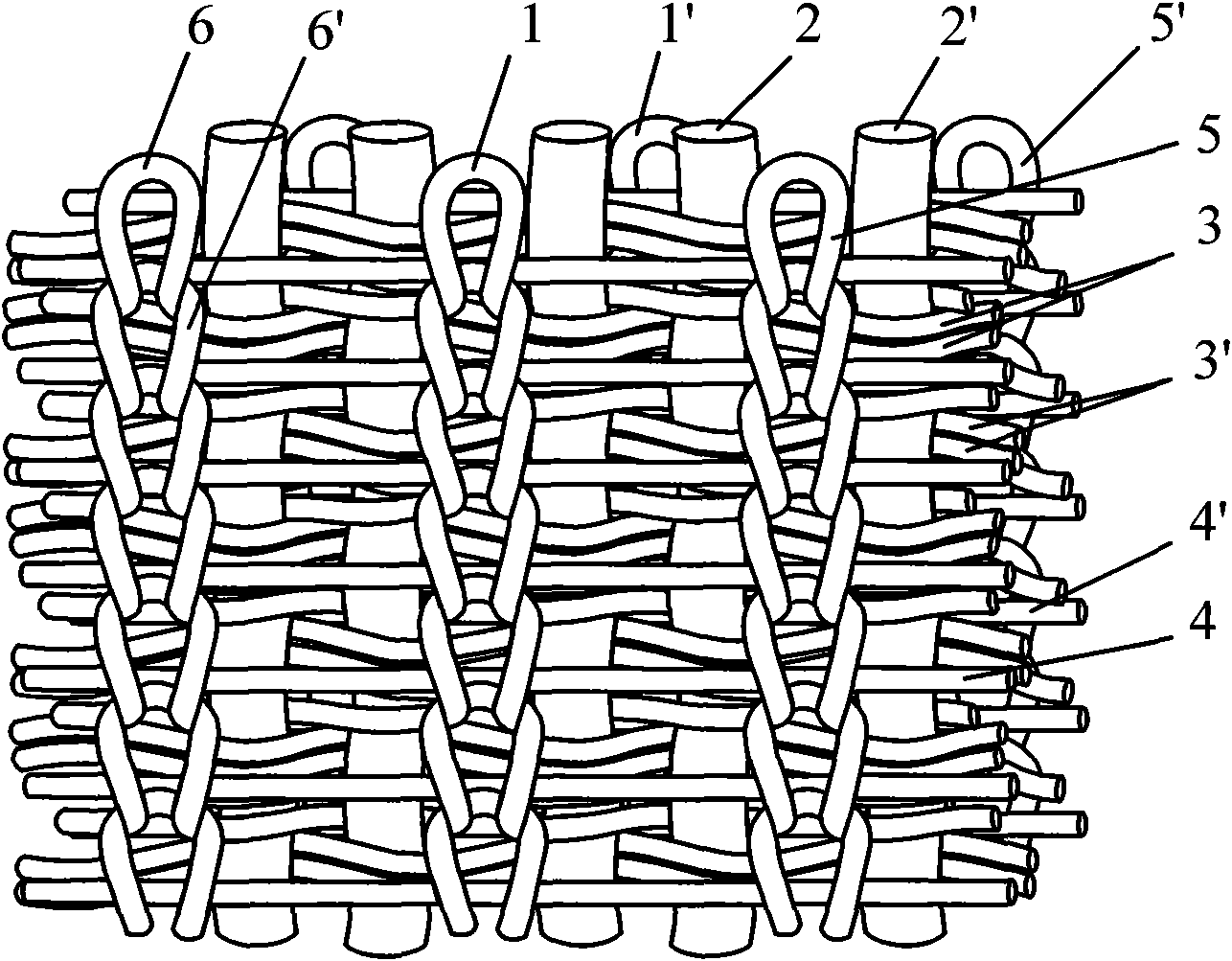

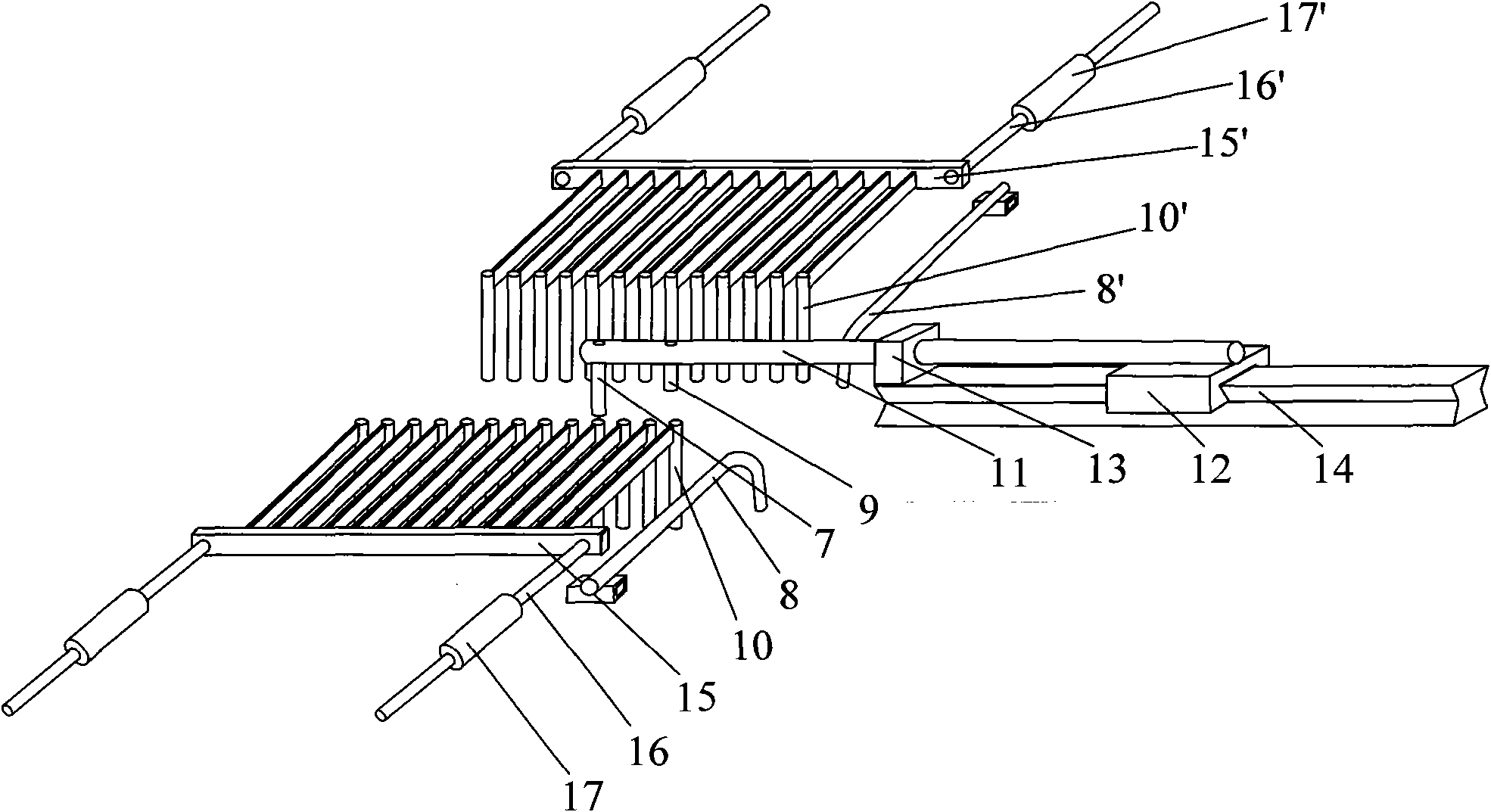

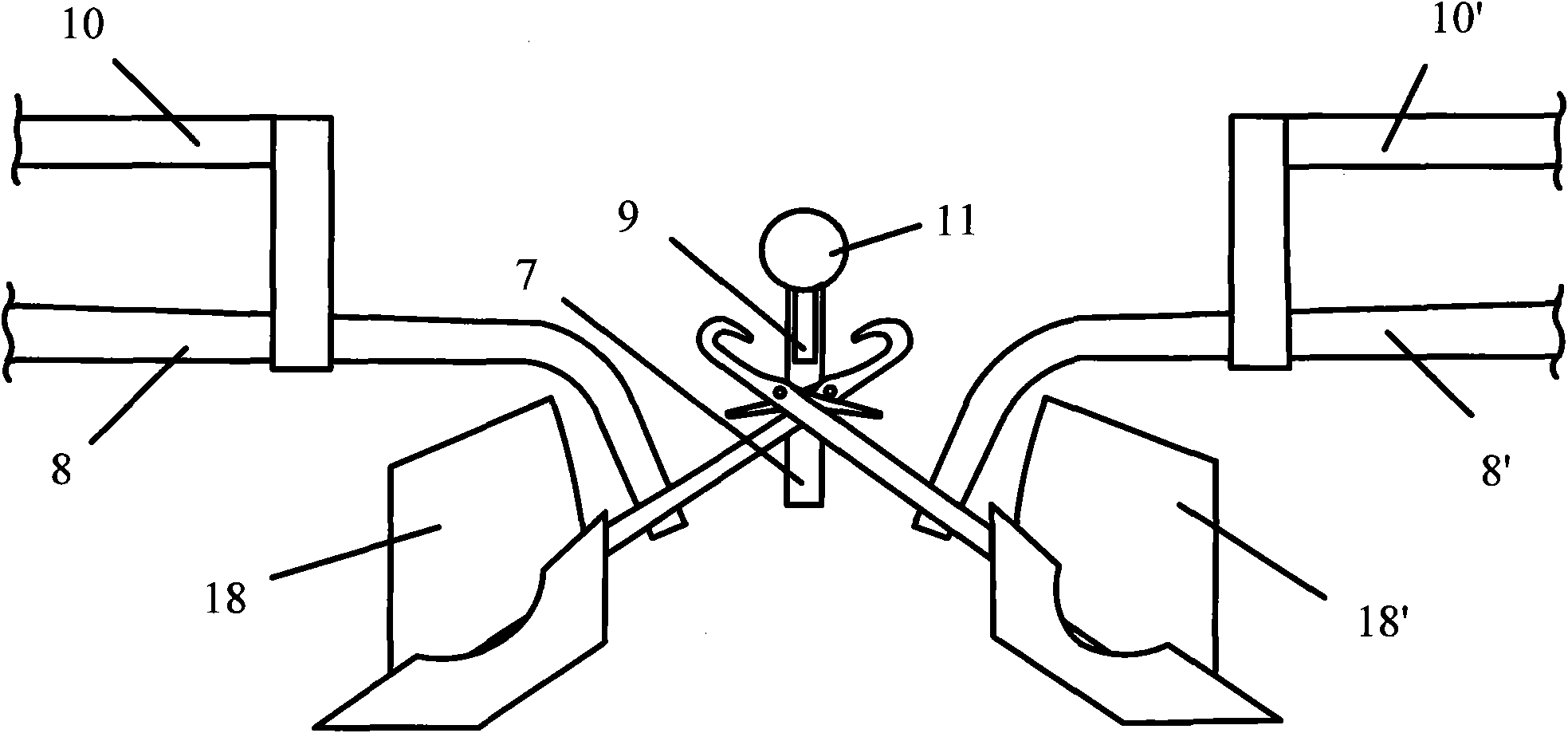

InactiveCN101736515AMeet the need for reinforced structure thicknessMany layers of liningWeft knittingEngineeringMechanical property

The invention relates to a multi-layered warp knitted weft insertion weaving knitting composite structure and a weaving method therefor and a yarn feeding device. The composite structure comprises two weft plain knitting stitches; the weaving method comprises the following steps: 4 groups of warp yarn and 3 groups of weft yarn are respectively lined into stitch wales and longitudinal rows of the two weft plain knitting stitches, so that the textile fabric can be provided with multi-layers of warp yarn and multi-layers of weft yarn at the same time; layer number of weft knitted fabric in the textile fabric is increased; number difference of lined warp yarn and weft yarn is reduced; as a result, axial mechanical property differentiation of the textile fabric is reduced, thickness of the textile fabric is increased; in addition, the textile fabric features uniform thickness and symmetrical structure, which expands application thereof in composite materials.

Owner:KAIHUI TECH CO LTD

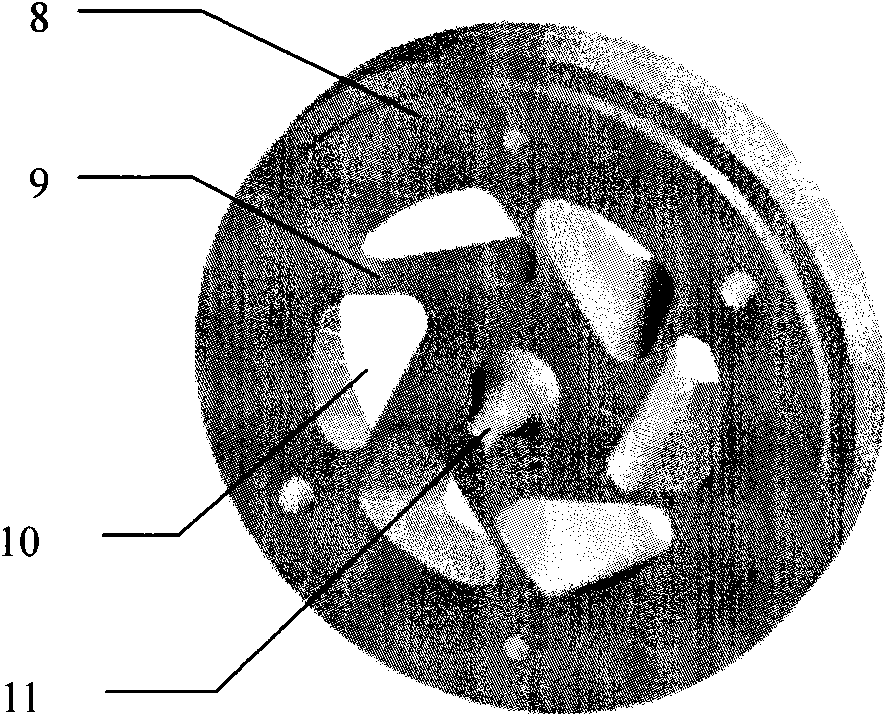

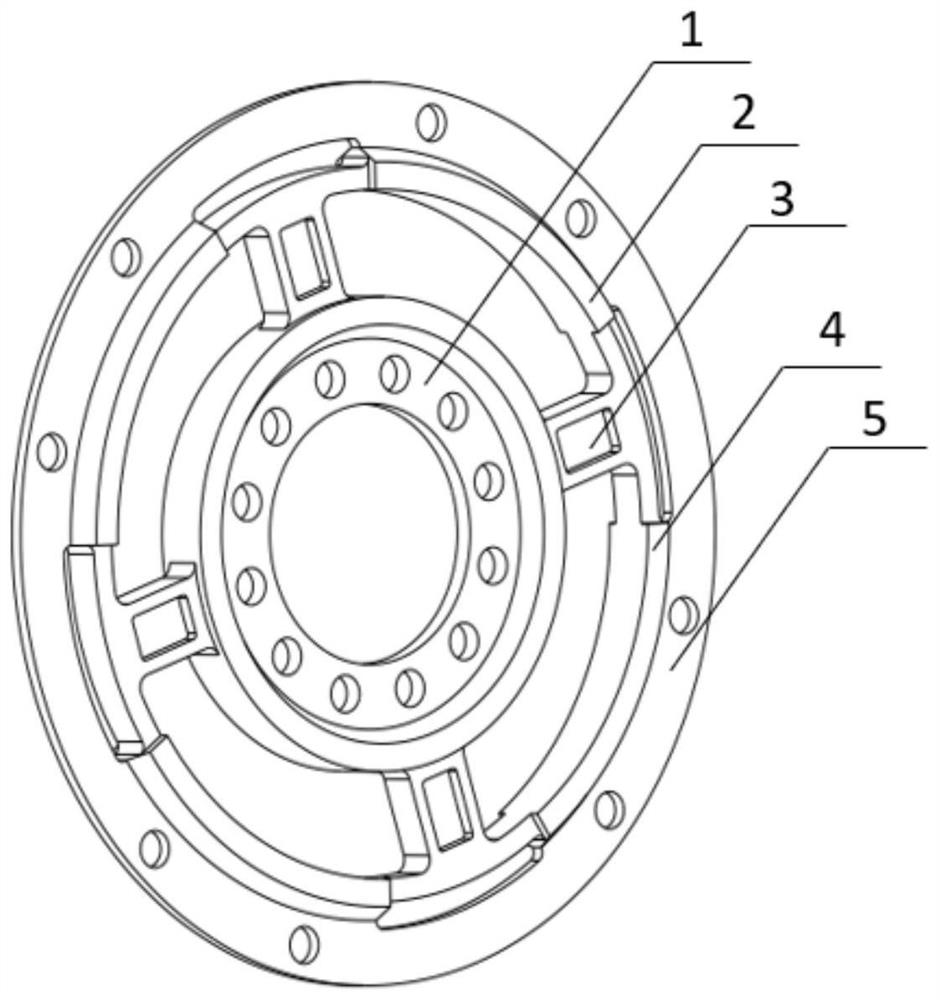

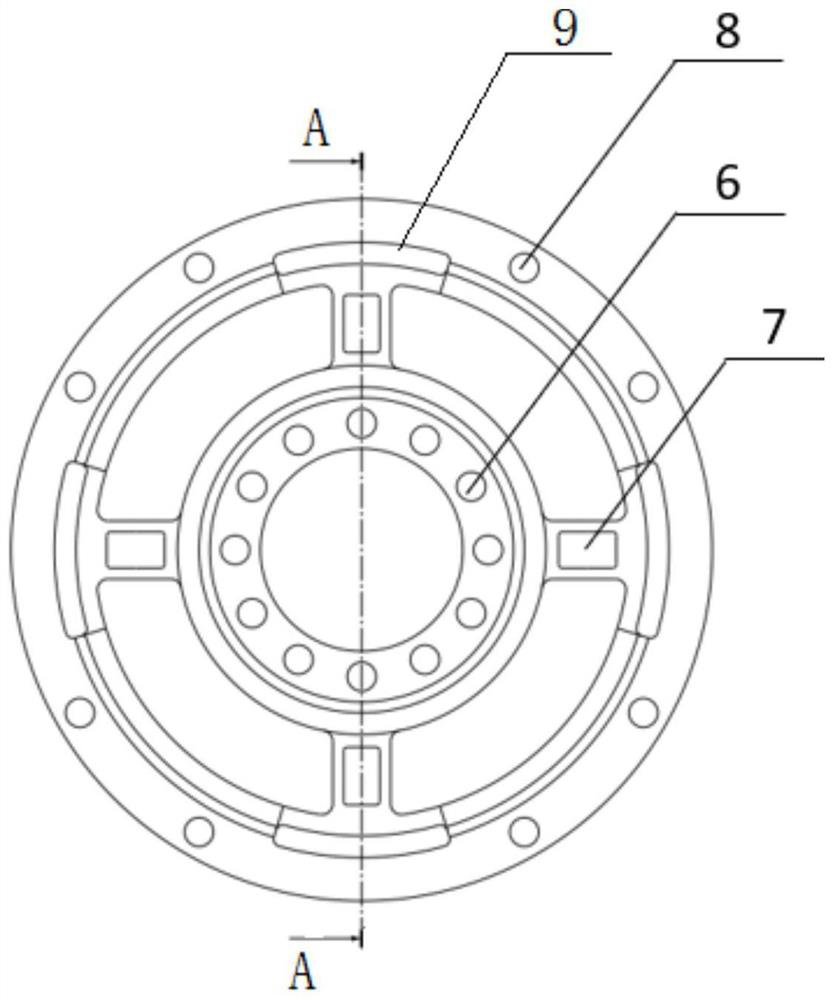

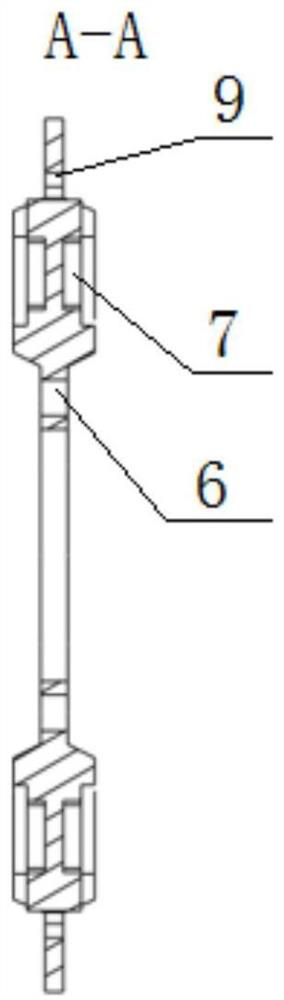

Permanent magnetic ring component and manufacturing method thereof

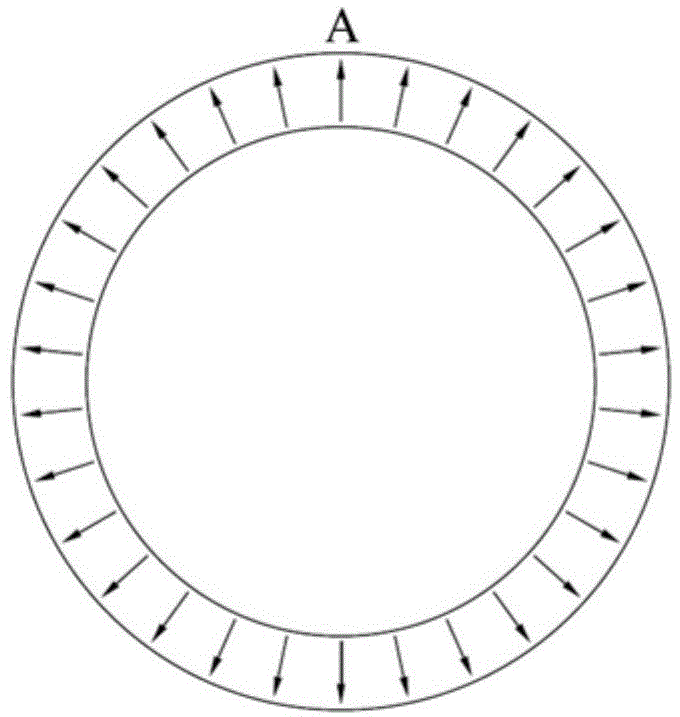

ActiveCN104157387AManufacturing and processing precision is easy to controlEasy to processInductances/transformers/magnets manufactureMagnetic materialsManufacturing technologyMagnetic poles

The invention belongs to the technical field of instruments and meters, and relates to the manufacturing technology of a permanent magnetic torquer component for an inertia type instrument, in particular to a rare earth-cobalt-based radial permanent magnetic ring component and a manufacturing method thereof. The permanent magnetic ring component is made of rare earth- cobalt-based permanent magnetic alloy materials. Multiple radial magnetic pole blocks (1) are prepared through a powder metallurgy method, each radial magnetic pole block (1) has a single magnetic pole direction A, and the multiple radial magnetic pole blocks (1) are bonded and fixed to form the cylindrical permanent magnetic ring component. The permanent magnetic ring component is reliable in mechanical strength, magnetic elements can be precisely manufactured under a neutral state, the radial magnetic field of the surface of a magnetic pole after the permanent magnetic ring component is magnetized is high in strength and good in uniformity, and the problems that a radial permanent magnetic ring is low in surface magnetic performance, poor in uniformity and stability, and not high in assembling precision are solved.

Owner:CENT IRON & STEEL RES INST

Multilayer even laid-in weaving and knitting composite structure, weaving method thereof and special device thereof

InactiveCN101581008AUniform thicknessGood structural symmetryFlat-bed knitting machinesEngineeringComposite structure

The invention relates to a multilayer even laid-in weaving and knitting composite structure, a weaving method thereof and a special device thereof. The multilayer even laid-in weaving and knitting composite structure comprises two plain weft knitted tissues. By transversely arranging weft yarns with the same layer number in each coil of the plain weft knitted tissues, the same lined weft yarn layer number and lined density of fabrics are realized, namely the thickness of the fabrics is even, the structure is symmetrical, and the application of the fabrics in a composite material is enlarged.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

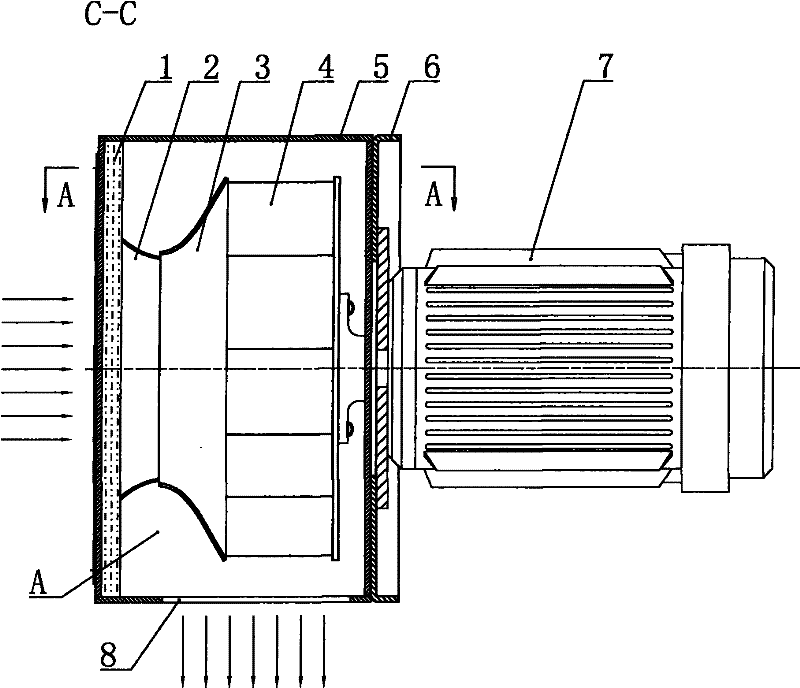

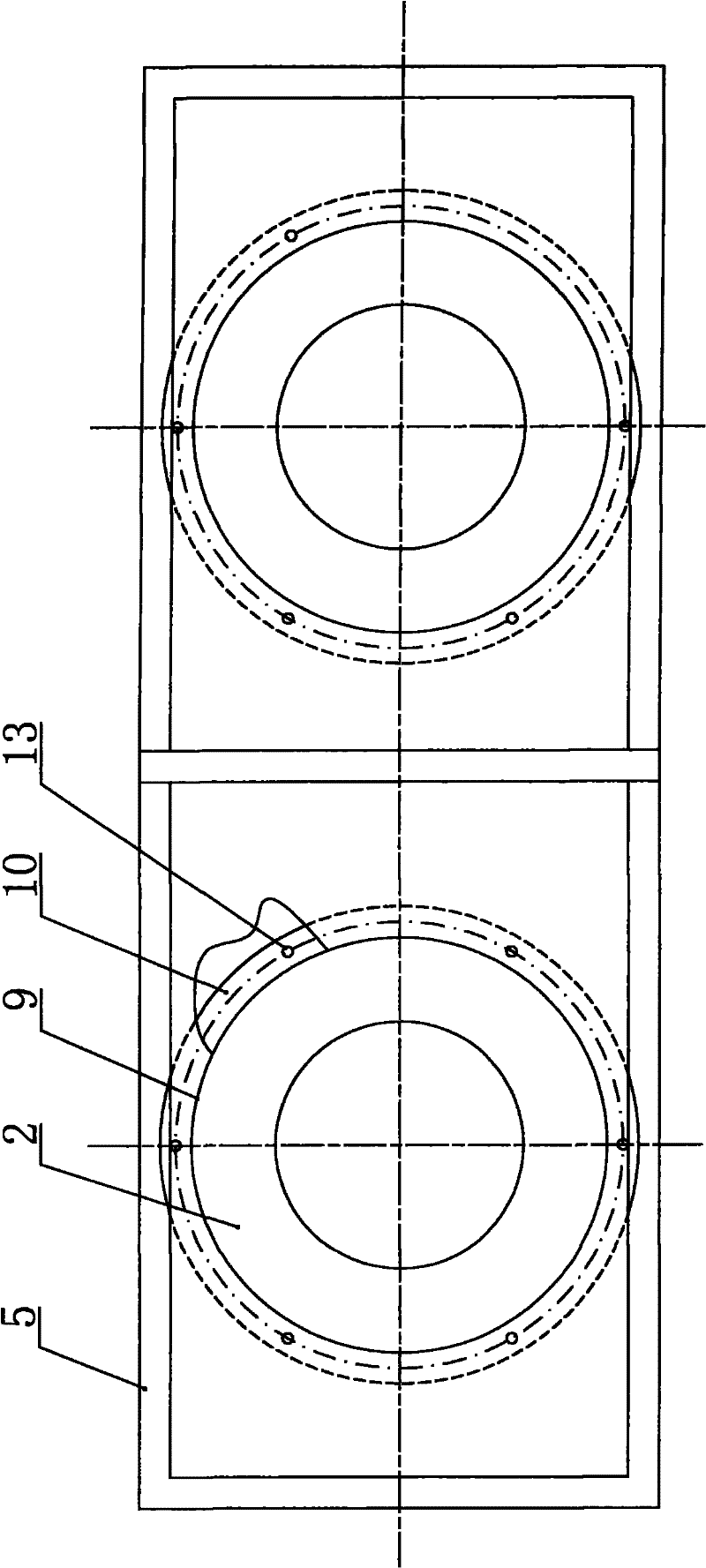

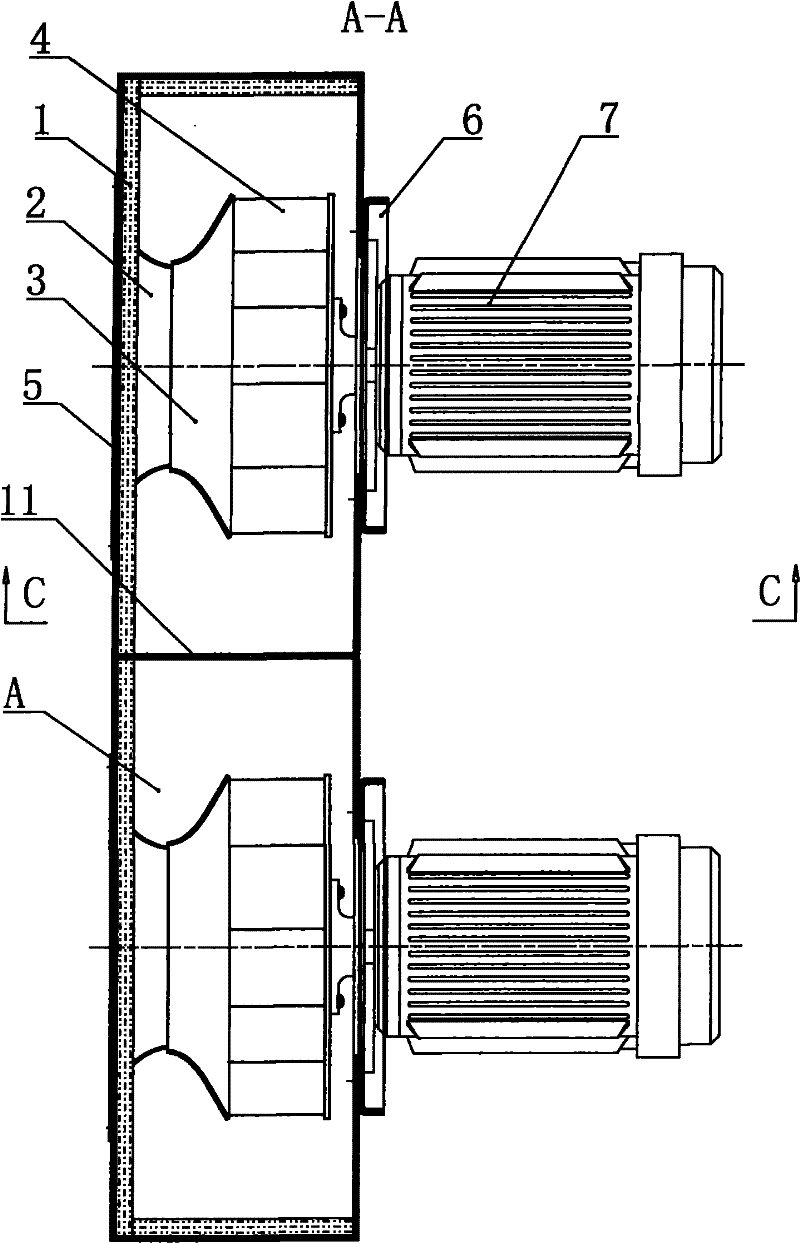

Cooling fan for traction converter of high-speed electric locomotive

InactiveCN102536857AGuaranteed cooling effectControl power consumptionPump componentsPump installationsImpellerElectric power

The invention relates to a cooling fan for a traction converter of a high-speed electric locomotive. The cooling fan comprises a rectangular box body (5), wherein a clapboard (11) is arranged at the middle of the box body (5) to divide the box body (5) into two independent cavities, a motor (7) is installed at rear side of each cavity, and an air inlet (9) and an air outlet (8) are respectively arranged at the front side and the lower side of each cavity. The cooling fan is characterized in that the rear side of each cavity is connected with the front end of the motor (7), an impeller (4) is arranged in each cavity and is coaxially installed on the output shaft of the motor (7), and two impellers (4) rotate counterclockwise during working so as not to mutually intervene. The cooling fan provided by the invention is mainly used for cooling the traction converters of motor trains with speed per hour of more than 380 km / h, and can satisfy the requirements of resisting low-temperature impact and high-speed vibration.

Owner:洛阳北玻三元流风机技术有限公司 +1

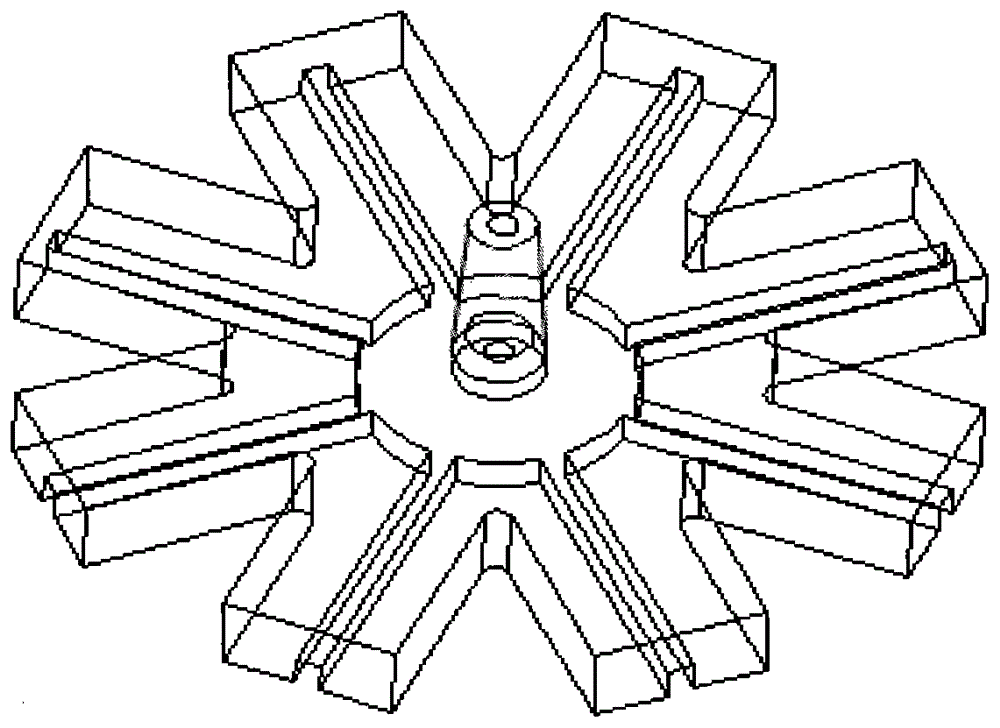

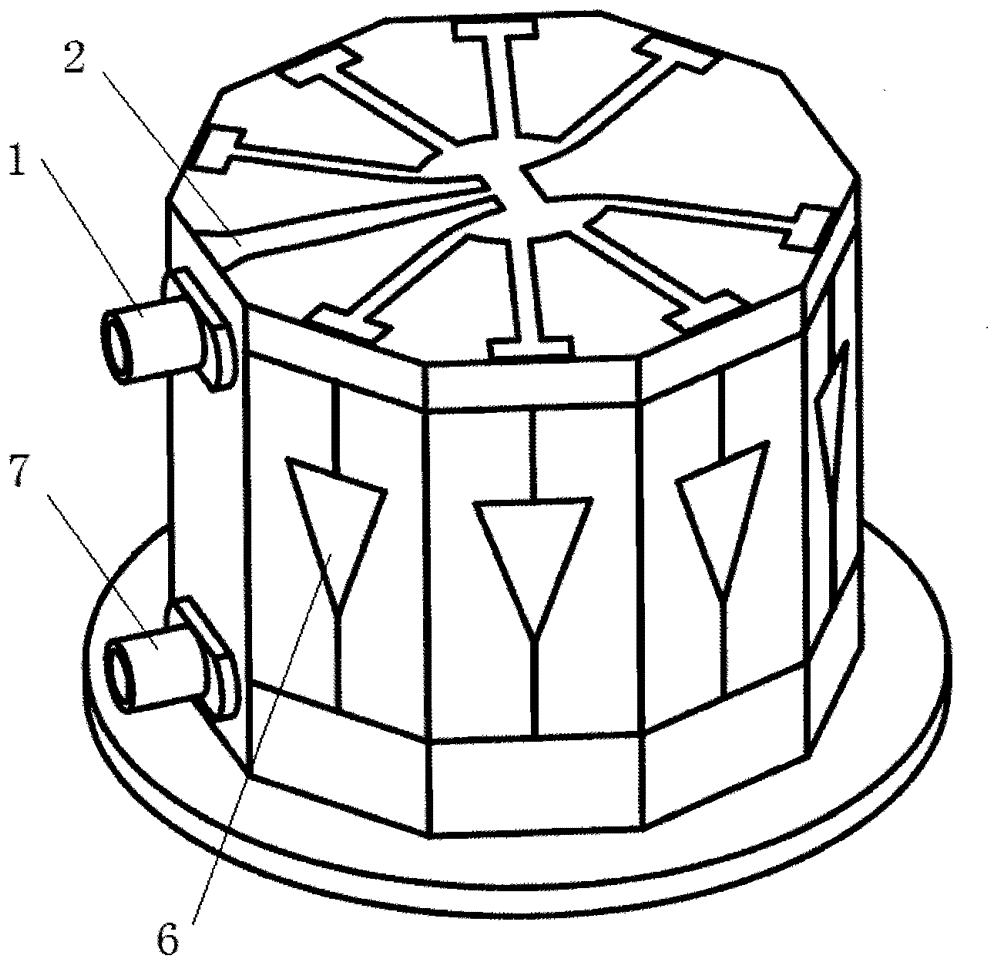

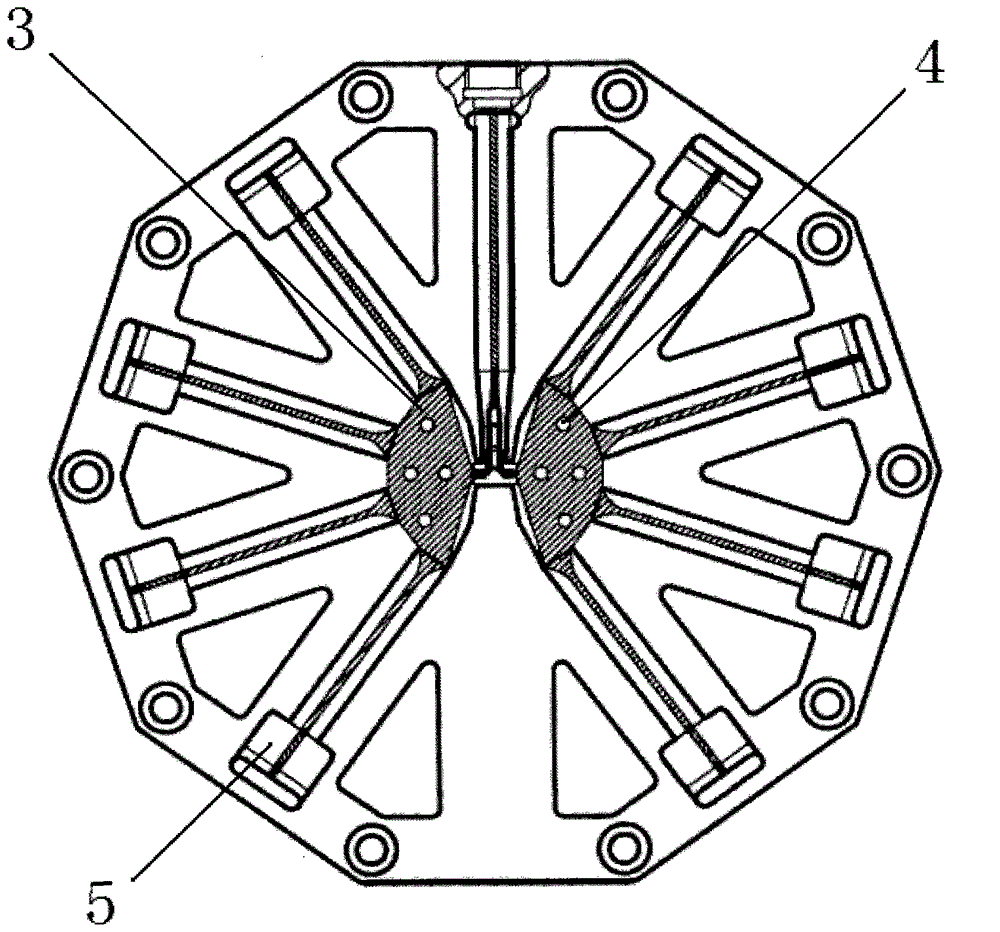

Space folding and extending mechanism with double cylinders as extensible units

ActiveCN107914897ARealize space foldingLarge folding ratioCosmonautic vehiclesCosmonautic partsStructural symmetryThree degrees of freedom

A space folding and extending mechanism with double cylinders as extensible units comprises an octagonal support base, three-degree-of-freedom hinges, bevel-edge rods, first gaskets, the first air-pressure cylinders, second gaskets and the second air-pressure cylinders. The octagonal support base is fixedly connected with the three-degree-of-freedom hinges, and the bevel-edge rods, the air-pressure cylinders and the gaskets are connected through revolute pairs. Under the conditions of vibration, collision and the like in the movement process of the mechanism, the gaskets can play a damping role, so that motion shock on the mechanism is low; the mechanism has a high structural symmetry so that different large-scale space folding and extending mechanism bodies can be formed by arranging theextensible units; the space folding and extending mechanism can be used in a space station, a communication satellite platform, a space telescope and other space missions, and has the advantages of being wide in application range and high in practicability.

Owner:GUANGXI UNIV

Processing method of bamboo board with regular bamboo joints

The invention discloses a processing method of a bamboo board with regular bamboo joints. A hole round bamboo is broken into bars and cracked into bamboo bars with certain thickness and length, rough plane, high-temperature stewing, high-pressure carbonization, drying and finish plane are performed on the bamboo bars to form bamboo chips, the bamboo board is formed through processes of color selection, material coating, blank assembly, bundling, board pressing, sanding, chase mortise, painting and the like. The blank assembly uses a central line of width of a blank board made of bamboo as a symmetric line, high-quality bamboo chips selected from the same section of round bamboo are symmetrically arranged on two sides of a central layer according to the bamboo joints, and the bamboo chips are alternately arranged in staggered mode on the same plane of the bamboo board according to inner cambered surfaces and outer cambered surfaces. The processing method is simple in process, material-saving and environment-friendly, and the bamboo board has the advantages of being even in density and hardness, high in strength and the like.

Owner:GUANGXI RONGSHUI XINYUAN WOOD PROD

Novel five-axis linkage parallel-serial numerical control machine tool

InactiveCN102476295AIncrease stiffnessGood precisionLarge fixed membersNumerical controlControl engineering

The invention discloses a novel five-axis linkage parallel-serial numerical control machine tool, which comprises a rack, a motion platform and four connecting rods, wherein one ends of four connecting rods are all connected with the rack; the other ends of the four connecting rods are hinged with the motion platform; and a moving workbench is also arranged below the motion platform. The novel five-axis linkage parallel-serial numerical control machine tool disclosed by the invention has the advantages of good structure symmetry, better rigidity, precision and dynamic performance, simple structure and low cost and is easy to manufacture, and motion parameters are not coupled. According to the novel five-axis linkage parallel-serial numerical control machine tool disclosed by the invention, the structural mode of a five-axis parallel machine tool is enriched, and a mechanism prototype is provided for the theoretical research of four-degree-of-freedom and five-degree-of-freedom parallel mechanisms. In addition, the machine tool mechanism completely can realize functions which are owned by the traditional six-degree-of-freedom parallel machine tool mechanism, and is favorable to popularize and apply.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

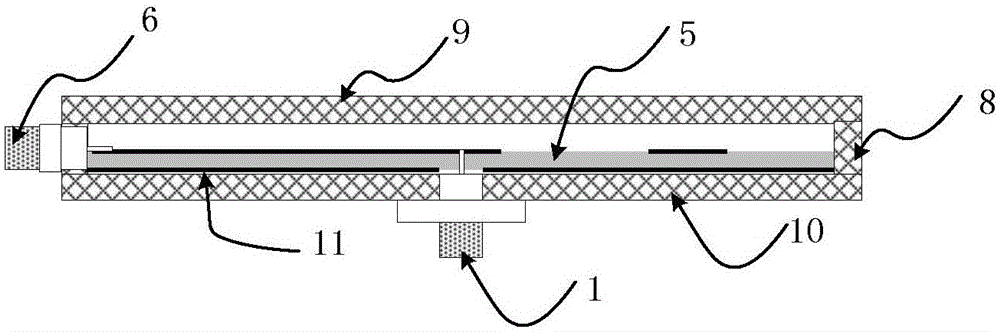

Elliptical resonance modal piezoelectric type MEMS circular ring gyroscope

ActiveCN110986908ASimple structureReduce volumeSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesGyroscopeResonance

The invention discloses an elliptical resonance modal piezoelectric type MEMS circular ring gyroscope, which comprises a substrate provided with a concave cavity, and a circular ring harmonic oscillator and clamped beams are suspended above the concave cavity; the clamped beams are uniformly distributed along the outer side of the circular ring harmonic oscillator; the circular ring harmonic oscillator is connected with a peripheral clamped structure by means of the clamped beams, the peripheral clamped structure is fixed to the substrate, a central circle between an outer circle and an innercircle on the top surface of the circular ring harmonic oscillator is used as a reference circle, heat insulation grooves penetrating through the thickness direction are uniformly distributed along the reference circle, and top electrodes of the circular ring harmonic oscillator are differentially arranged along the inner side and the outer side of the reference circle. The elliptical resonance modal piezoelectric type MEMS circular ring gyroscope is simple in structure, small in size, easy to manufacture in batches and high in mechanical sensitivity.

Owner:武汉敏声新技术有限公司

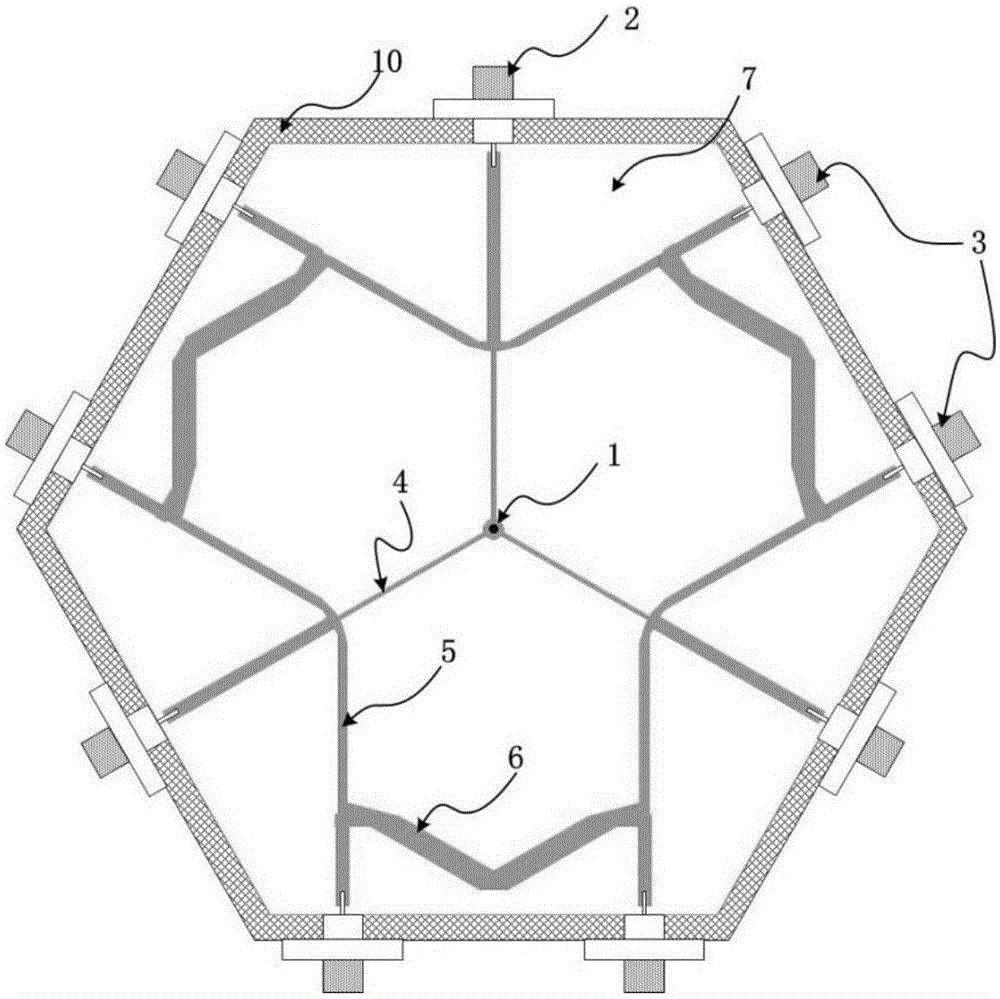

Power divider/combiner of trisected odd number structure

ActiveCN105024125ALayout Ideally SymmetricalOvercoming problems that are difficult to implement in one planeWaveguide type devicesNetwork structureTransmission line

A power divider / combiner of a trisected odd number structure disclosed by the invention can serve as a power divider to realize power distribution, and can also serve as a combiner to realize power synthesis. The power divider / combiner includes three shunt ports, six external load ports, three first branch transmission lines, six second branch transmission lines and six third branch transmission line. One ends of the three first branch transmission lines are connected to a public port located at the center, the other ends are connected to the three shunt ports respectively, on ends of the six second branch transmission lines are connected to the six external load ports respectively, and the other end of each second branch transmission line and an adjacent third branch transmission line connected in series are connected to the same shunt port in a common end manner; one ends of the two third branch transmission lines are mutually connected, and the other ends are connected to the adjacent six external load ports; and all branch transmission lines are connected to form a trisected network structure with distribution of three adjacent hexagons. The power divider / combiner of the trisected odd number structure overcomes the problem in the prior art of difficult realization in one plane.

Owner:10TH RES INST OF CETC

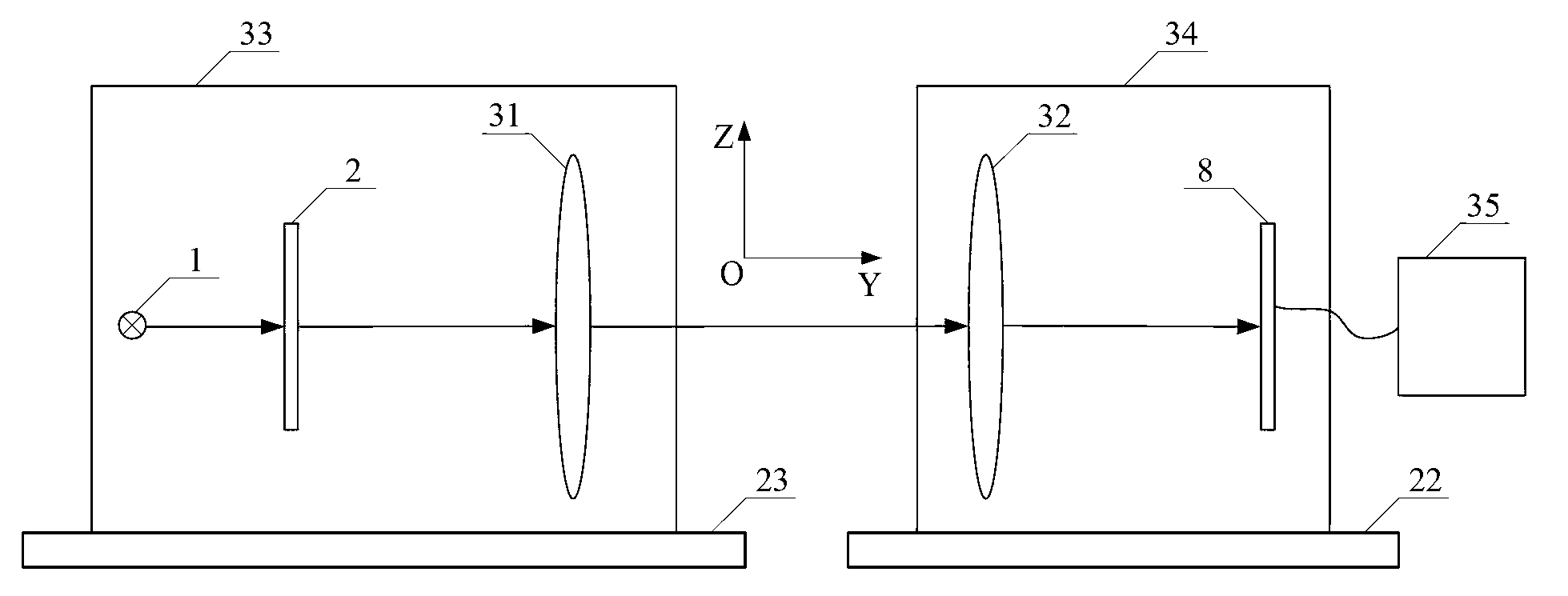

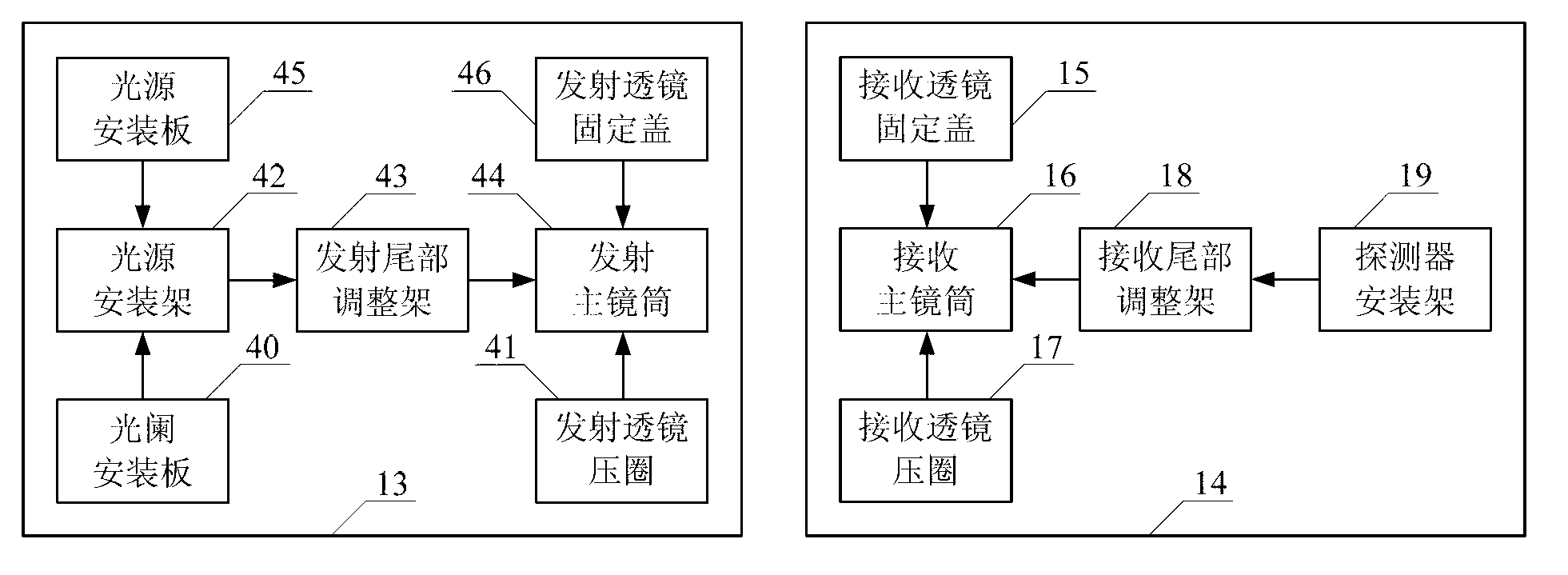

Installation device and method for arc-second-level three-dimensional optical deformation measurement device

The invention discloses an installation device and method for an arc-second-level three-dimensional optical deformation measurement device and aims at conducting reliable installation on the arc-second level three-dimensional optical deformation measurement device. The installation device is formed by a transmitting module installation device and a receiving module installation device, the transmitting module installation device is composed of a transmitting main lens cone, a transmitting tail adjustment support, a light source installation support, a transmitting lens pressing ring, a transmitting lens fixing cover, a diaphragm installation plate and a light source installation plate, and the receiving module installation device is composed of a receiving main lens cone, a receiving lens pressing ring, a receiving lens fixing cover, a receiving tail adjustment support and a detector installation support. A sliding control and pressure fixing mode is adopted to install an adjustment portion of the three-dimensional optical deformation measurement device. By means of the installation device and method, the measurement device can be reliably installed, the installation device has the advantages of being adjustable in accuracy, convenient to adjust, stable and reliable after adjustment and the like, and the installation device has good stability under physical conditions of changed environment temperature, changed stress states and the like.

Owner:NAT UNIV OF DEFENSE TECH

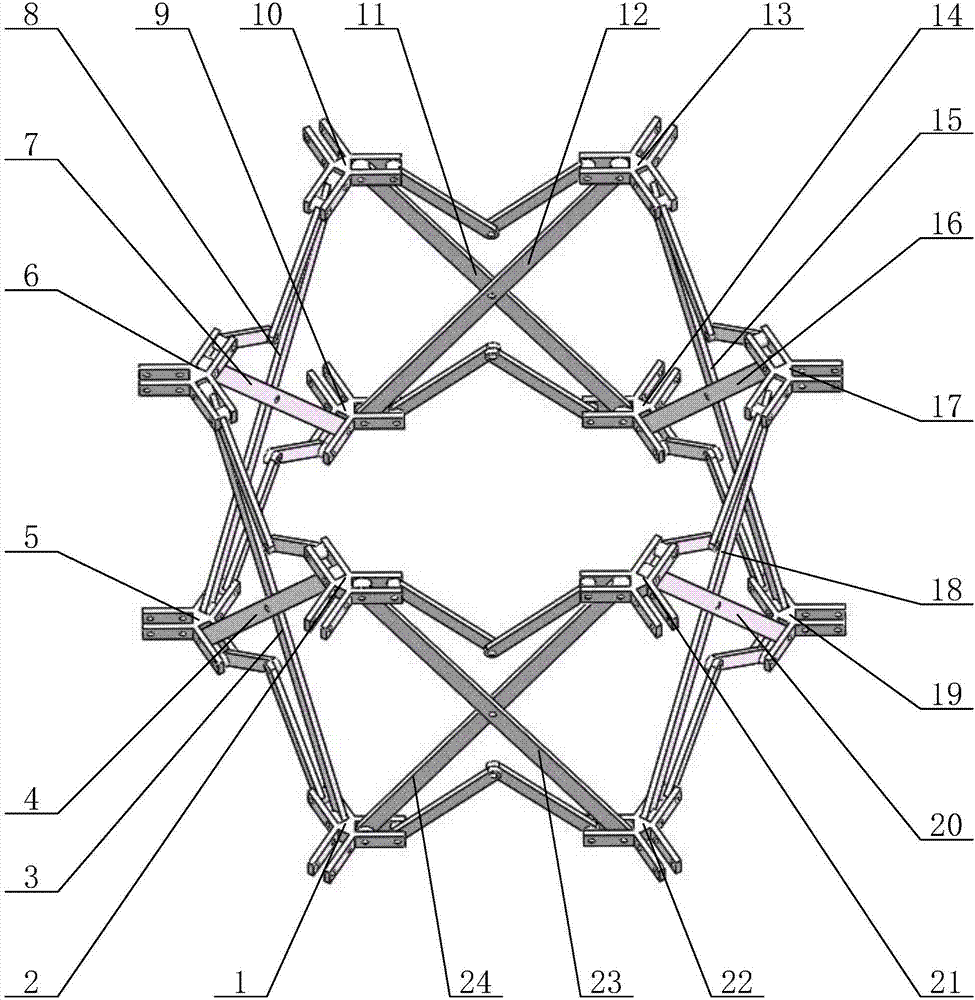

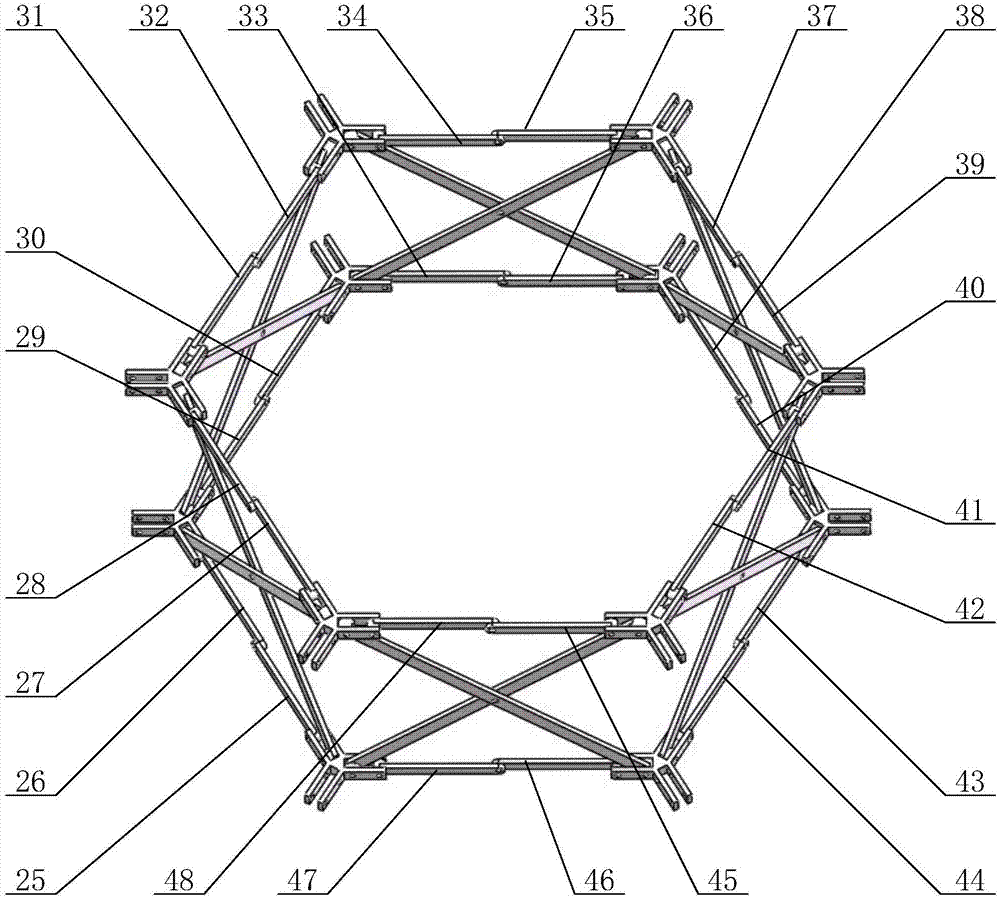

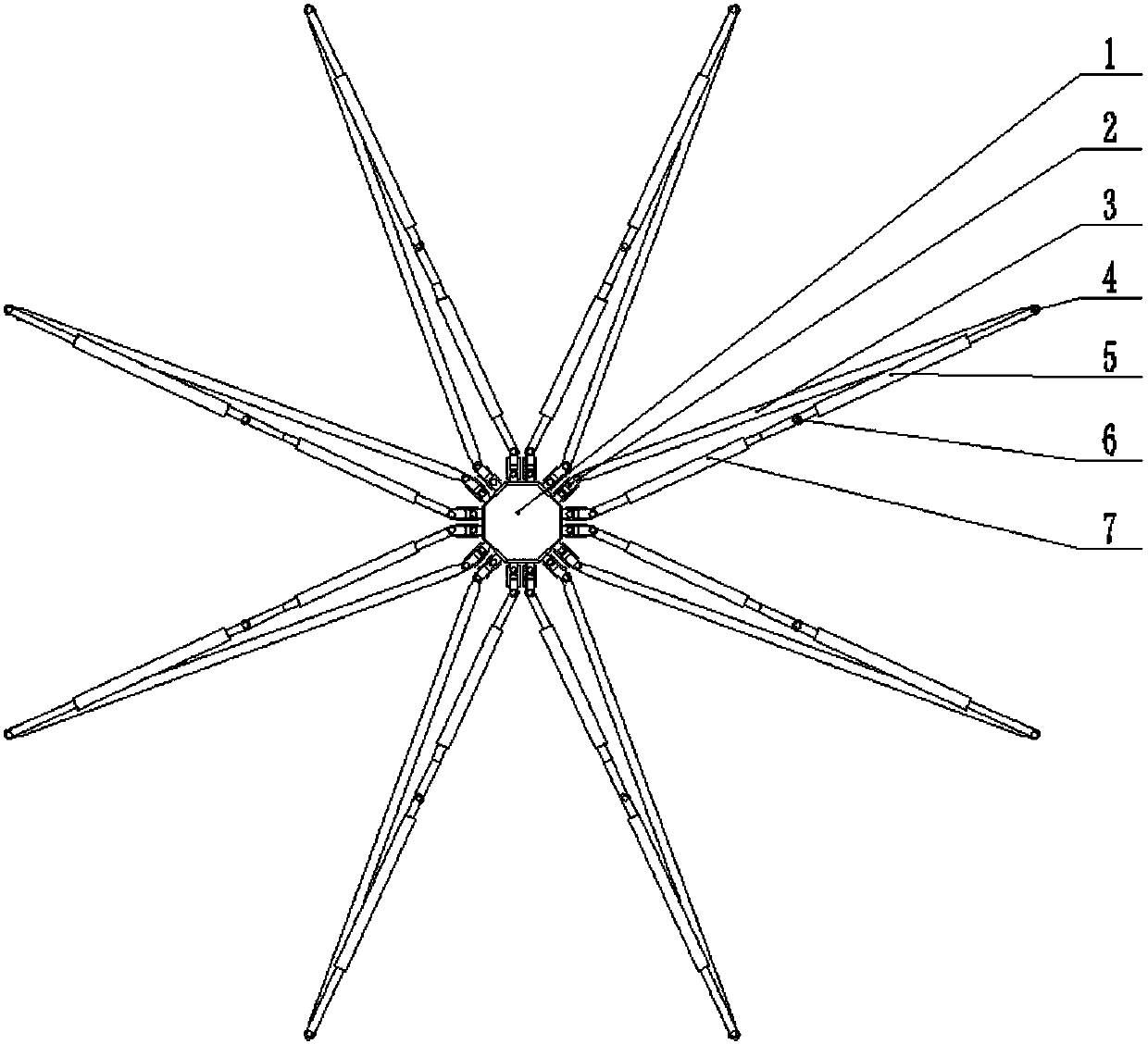

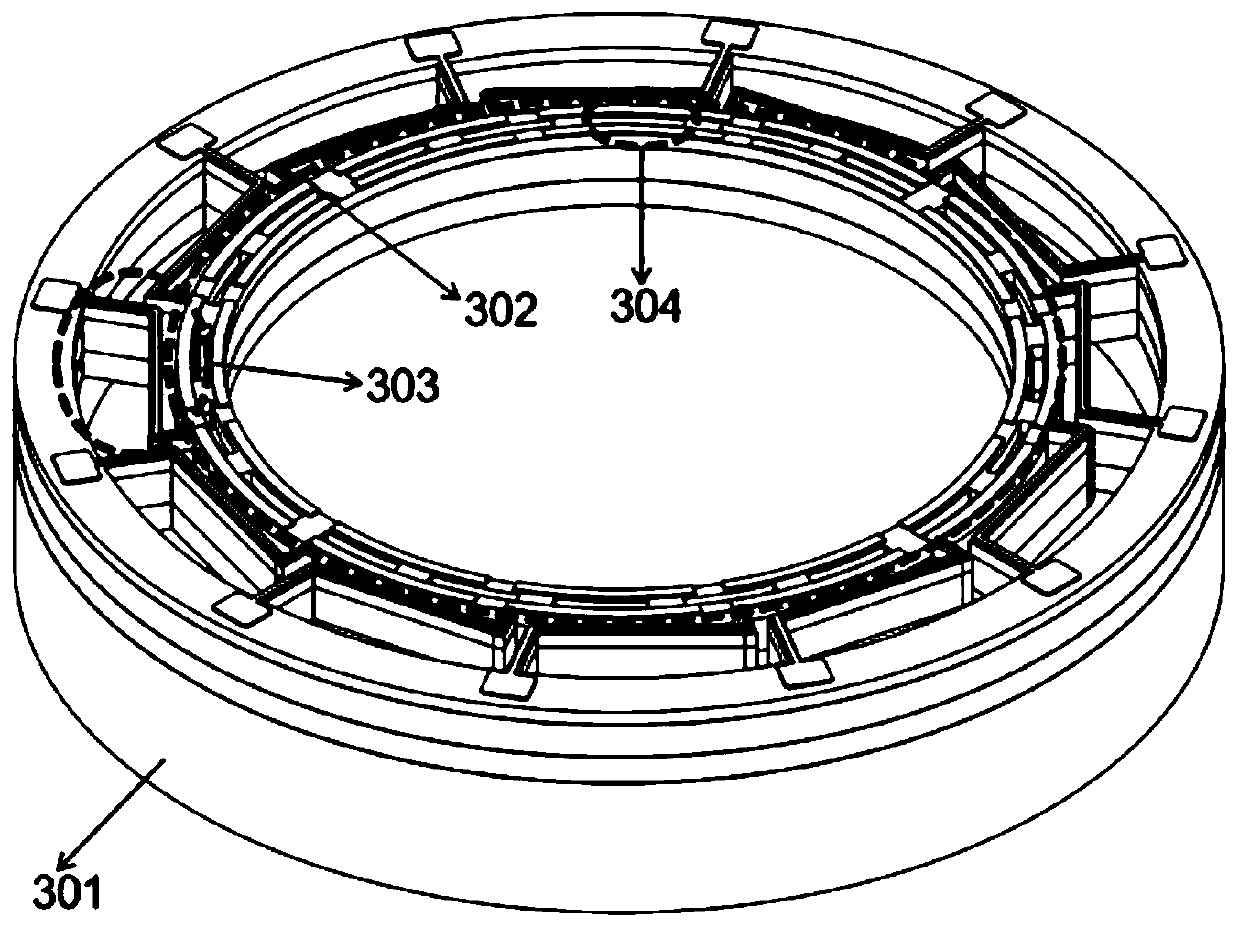

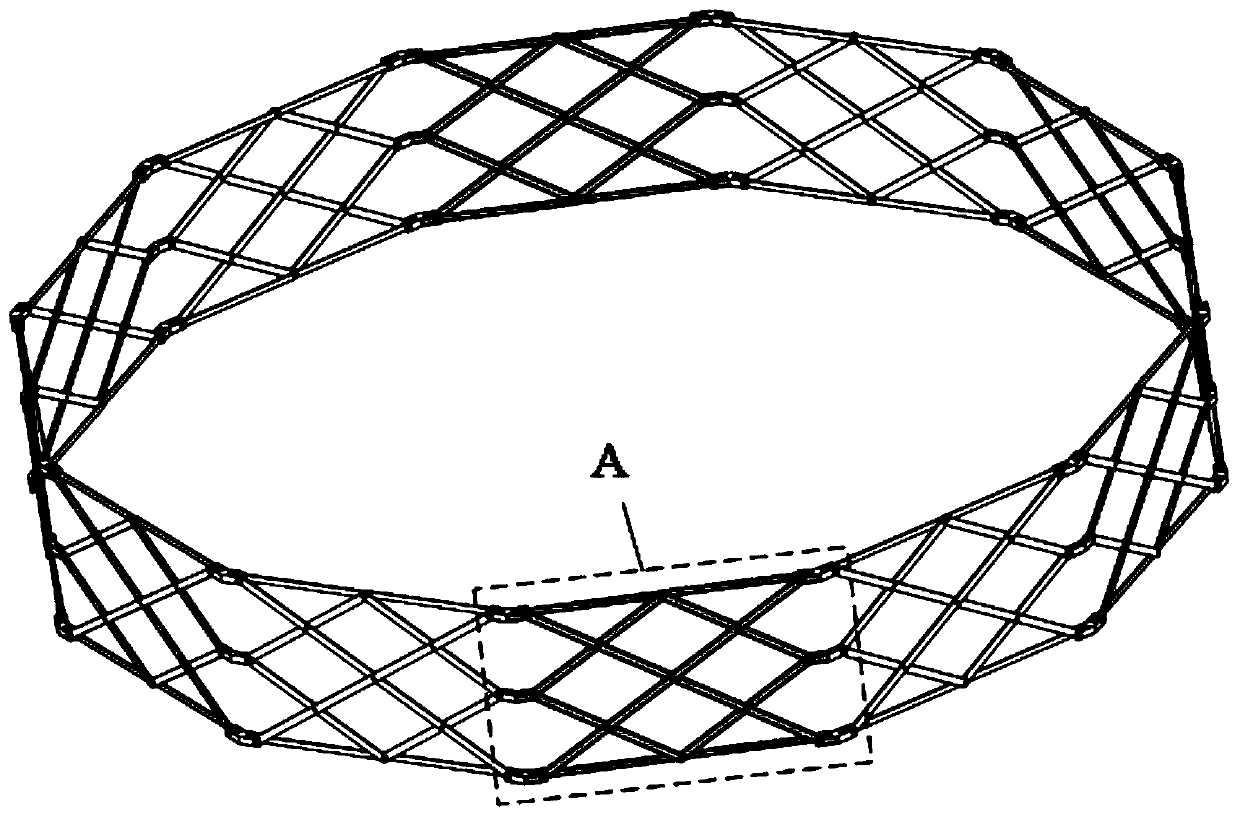

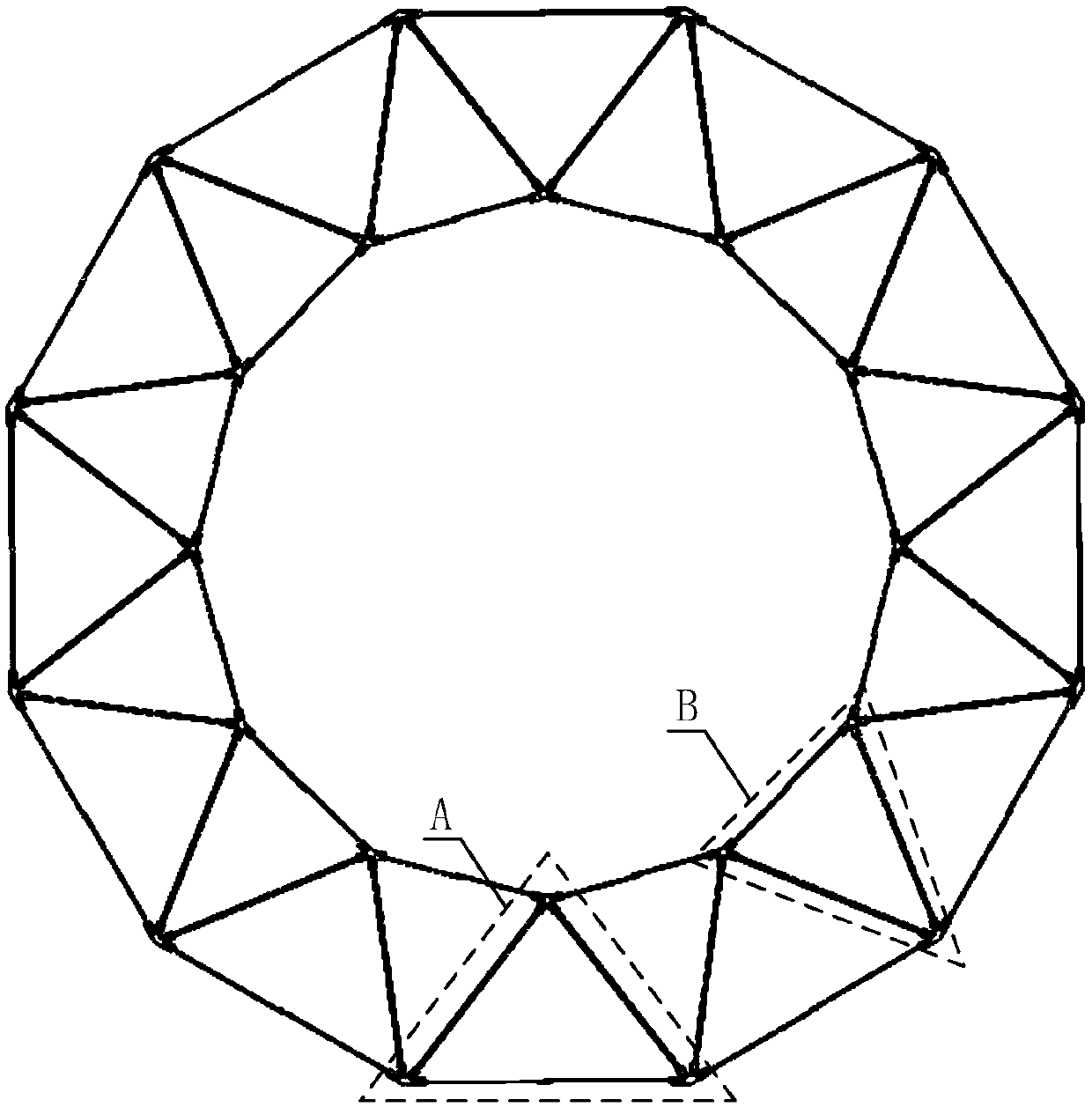

Composite scissor-like hoop truss deployable antenna mechanism

PendingCN109860974ASimple structureGood assembly and manufacturing processCollapsable antennas meansStructural symmetryEngineering

The invention discloses a composite scissor-like hoop truss deployable antenna mechanism, which comprises N deployable mechanism units of the same structure. The adjacent deployable mechanism units are connected through sharing two upper and lower node connection members and an intermediate node connection member, and a multi-faceted hoop truss mechanism is together formed. Each deployable mechanism unit comprises two scissor rods, four connecting rods, four reinforcing rods, four upper and lower node connection members and two intermediate node connection member, and all rotating auxiliary axes connected onto the scissor rods, the connecting rods and the reinforcing rods in the same deployable mechanism unit are parallel. Motion pairs in the whole mechanism are all rotating pairs, the assembly manufacturing process is good, the structure symmetry is high, hoop truss spatial deployable mechanisms with different scales can be formed through changing the number of the deployable mechanism units and the lengths of the rods, and the antenna mechanism disclosed in the invention can be used as a support mechanism to be well applied to a spaceborne hoop truss deployable antenna.

Owner:YANSHAN UNIV

Single-degree-of-freedom constrained scissor-type deployable unit and its spatially deployable mechanism

ActiveCN105799950BLarge folding ratioIncrease stiffnessCosmonautic vehiclesCosmonautic partsStructural symmetrySingle degree of freedom

Owner:YANSHAN UNIV

Three-component force measurement sensor

PendingCN111896164ASimple structureReduce volumeApparatus for force/torque/work measurementStrain gaugePhysics

The invention discloses a three-component force measurement sensor which is composed of an elastic body and a strain gauge. The elastic body is composed of a fixed end on the inner side of the circumference, a loading end on the outer side of the circumference and strain beams connected between the fixed end and an annular gap of the loading end. The four strain beams are distributed in the annular gap up, down, left and right; each strain beam is provided with four patch surfaces of a first axial patch surface and a second axial patch surface which are symmetrical along the axial direction, and a first circumferential patch surface and a second circumferential patch surface which are symmetrical in the radial direction; the pasting directions of the two strain gauges on the same patch surface point to the outer side of the circumference from the circle center of the sensor, and the strain gauges are correspondingly pasted on the patch surfaces of the strain beams in pairs so as to achieve stress in the horizontal radial direction, the vertical radial direction and the axial direction; and the strain gauges in the same component force direction are measured and are electrically connected to form a Wheatstone full-bridge circuit. The three-component force measurement sensor is high in sensitivity, small in inter-dimensional coupling degree and high in measurement precision.

Owner:JILIN UNIV +2

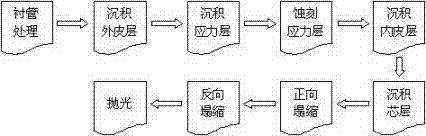

Method for making bow-shaped polarization maintaining optical fiber for Y waveguide

InactiveCN103030270ANo distractionHigh mechanical strengthGlass making apparatusGlass fibre productsPolarization-maintaining optical fiberTower

The invention belongs to a method for making a polarization maintaining optical fiber and particularly relates to a method for making a bow-shaped polarization maintaining optical fiber for a Y waveguide. A polarization maintaining optical fiber is made through adopting a modified chemical vapor deposition (MCVD) method and then drawn into the polarization maintaining optical fiber by a drawing tower. The method provided by the invention sequentially comprises the following steps of: 1, connecting a liner tube, a guide tube and a tail tube; 2, depositing an outer skin layer; 3, depositing a stress layer; 4, etching the stress layer; 5, depositing an inner skin layer; 6, depositing a core layer; and 7 enabling the perform to shrink. The method has the advantages of one-step molding and simple technology. Besides, all processes are carried out in an airtight environment and are free from external interference, and the optical fiber has excellent strength. Through the adjusting optimization of the ratio of deposited materials in a stress zone, the bow-shaped polarization maintaining optical fiber for the Y waveguide is obtained, and the requirement of a technology for making the Y waveguide is met.

Owner:BEIJING INDAL TECH RES INST

Prismatic multi-path power distributor/ synthesizer based on fan-shaped branch microstrip line

ActiveCN103985945AImprove cooling efficiencyImprove working bandwidthCoupling devicesEngineeringDistributor

The invention provides a prismatic multi-path power distributor / synthesizer based on a fan-shaped branch microstrip line. The prismatic multi-path power distributor / synthesizer based on the fan-shaped branch microstrip line is wholly prismatic and comprises a power distribution section and a power synthesis section, wherein the power distribution section and the power synthesis section are of the same structure, electromagnetic waves enter a cavity through an input end coaxial connector, and synthesized high-power signals are output from the cavity through an output end coaxial connector. An impedance deploy hole is punctured in a microstrip planar circuit of a fan-shaped branch power distribution / synthesis structure, the isolation among branches can be improved, the whole structure is connected through microstrip patches, and therefore the power distribution / synthesis structure can achieve a wide work frequency band. According to the requirement of actual power synthesis, by reasonably designing the size and position of the impedance deploy hole and the radius of the fan shape, equal-power distribution of all the branches can be achieved, and different power distribution / synthesis path numbers can be achieved conveniently according to the needs.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

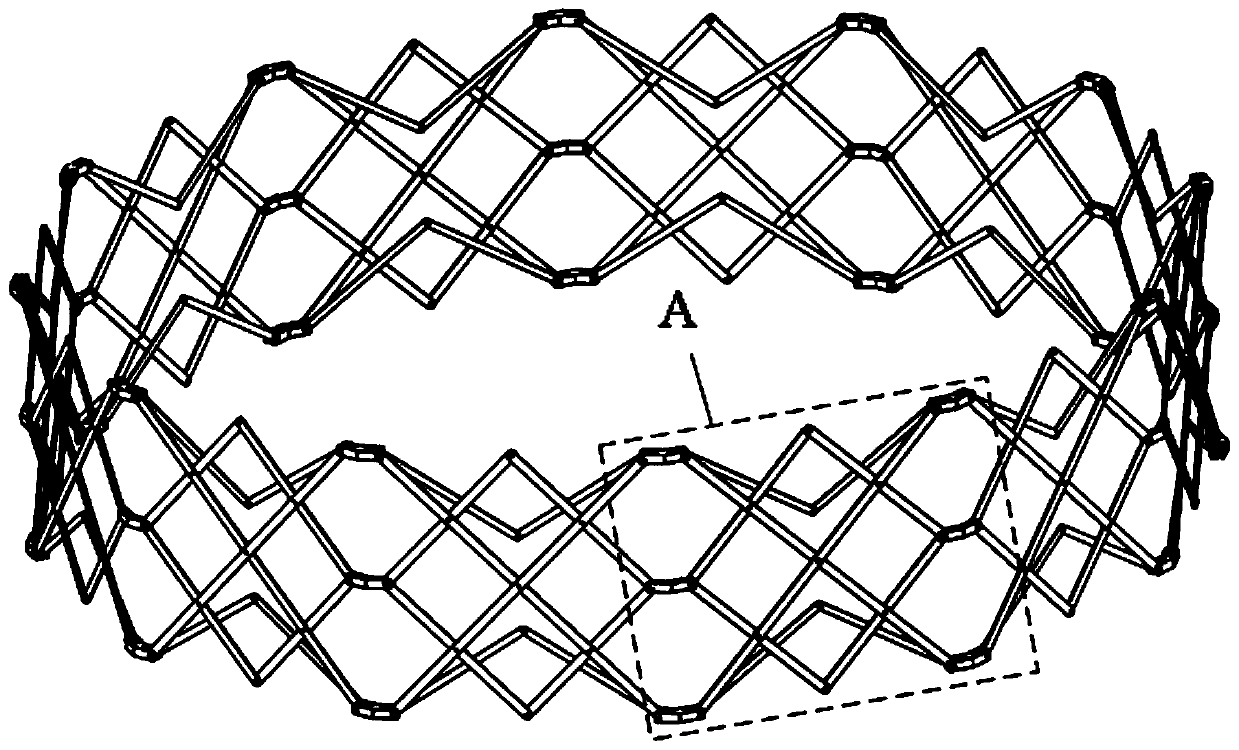

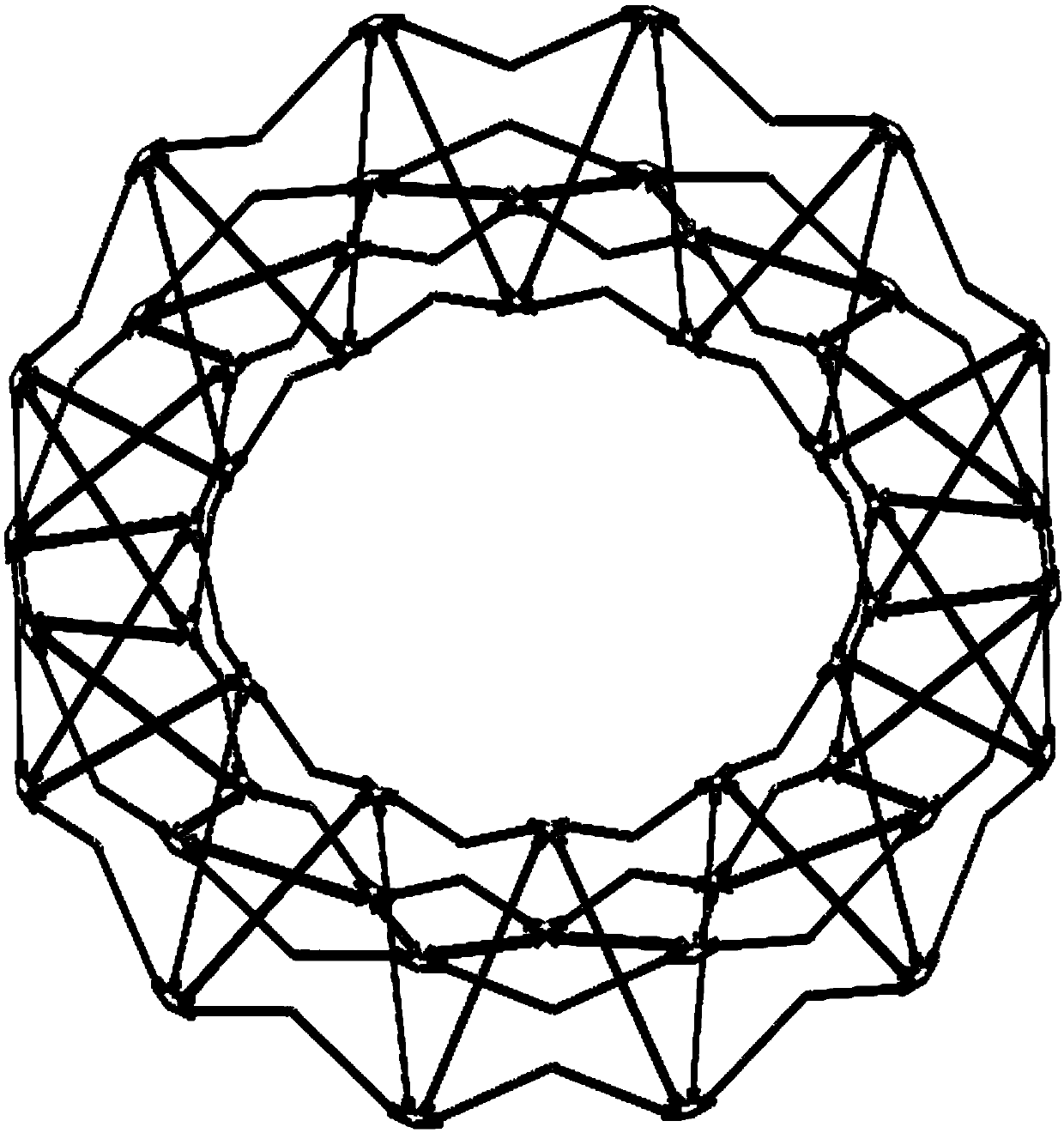

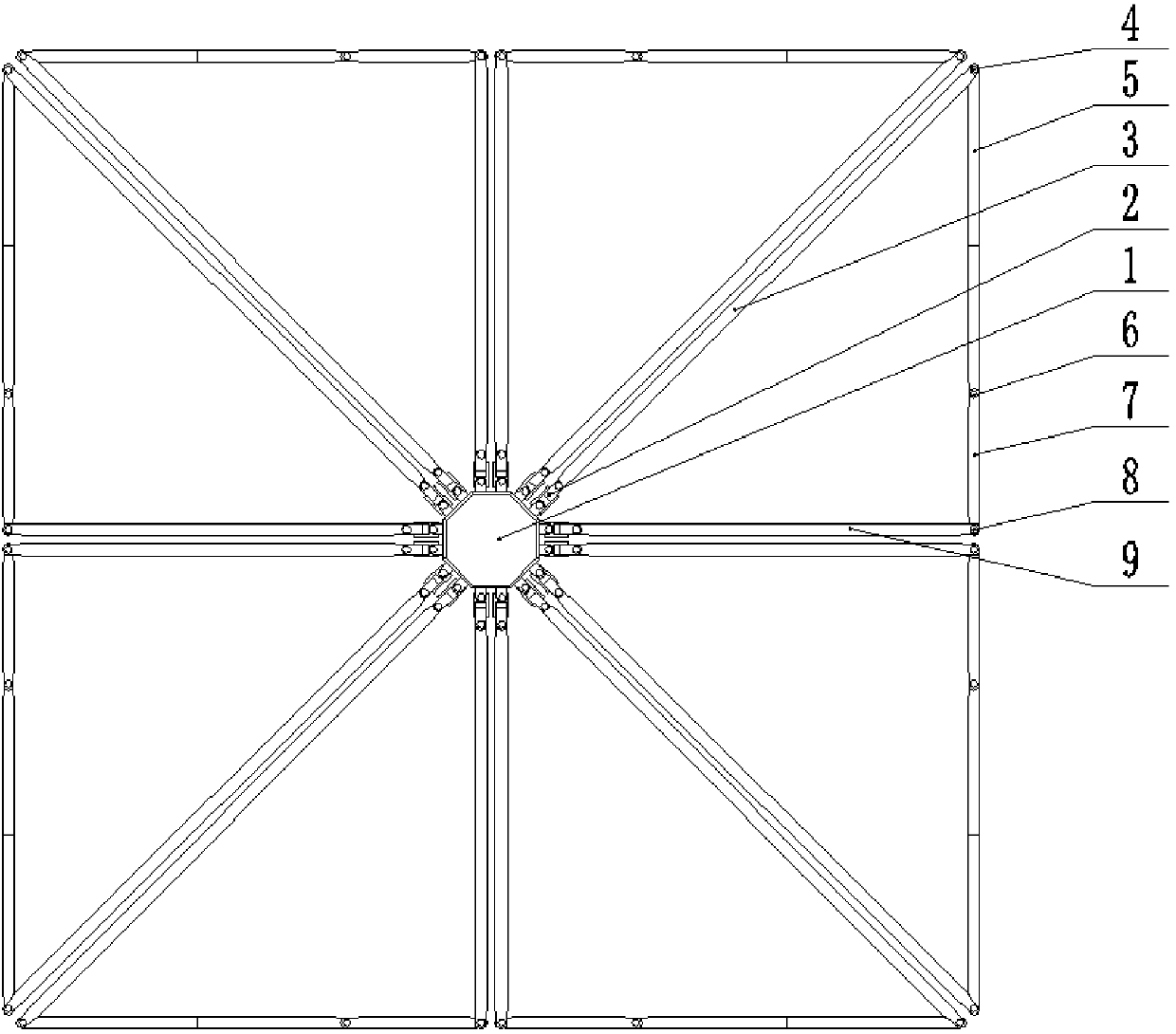

Cell array type single-degree-of-freedom peripheral truss expandable antenna mechanism

ActiveCN109638413ASimple structureGood assembly and manufacturing processAntenna supports/mountingsStructural symmetrySingle degree of freedom

The invention discloses a cell array type single-degree-of-freedom peripheral truss expandable antenna mechanism which comprises N outer-layer single-degree-of-freedom expandable mechanism units and Ninner-layer single-degree-of-freedom expandable mechanism units, the outer-layer single-degree-of-freedom expandable mechanism units are formed by connecting inner joint connecting members, inner connecting rods, intermediate connecting rods, outer connecting rods and outer joint connecting members through rotating pairs, and the two types of single-degree-of-freedom expandable mechanism units are interspersed and arranged in an array and are connected by sharing two intermediate connecting rods, two inner joint connecting members and two outer joint connecting members to form a multi-facetedperipheral truss mechanism. The overall mechanism has a high structural symmetry, the peripheral truss expandable antenna mechanisms of different scales can be formed by changing the numbers of the inner-layer and outer-layer single-degree-of-freedom expandable mechanism units in the overall mechanism and the lengths of the rods inside, and the peripheral truss expandable antenna mechanism can beapplied to a large-caliber satellite-borne antenna well.

Owner:YANSHAN UNIV

Novel outer row compressed type multi-row axial plunger pump/motor

PendingCN109139404AGood structural symmetryEvenly distributed pressing forcePositive displacement pump componentsReciprocating piston enginesDrive shaftHydraulic machinery

The invention provides a novel outer row compressed type multi-row axial plunger pump / motor, and relates to the field of axial plunger pump / motors of hydraulic machinery. The novel outer row compressed type multi-row axial plunger pump / motor comprises a shell, a cylinder body, a transmission shaft, a thrust plate, an inner swash plate and an outer swash plate; a front gland is connected with a front end cover through hexagonal screws; the front end cover is connected with the shell through hexagonal screws; the shell is connected with a rear pump cover through screws; the transmission shaft drives the cylinder body to rotate through splines, a baffle groove of the cylinder body is internally provided with a baffle, and the outer side of the cylinder body is sleeved with an outer compressedball sleeve; the outer ball surface of the outer compressed ball sleeve is hinged to the inner ball surface of an outer compressed plate, and outer row spring seats and outer row springs are installed in spring holes of the outer compressed ball sleeve; the side, close to the front end cover, of the transmission shaft is provided with the inner swash plate and the outer swash plate; and the innerswash plate and the outer swash plate are connected through swash plate positioning pins. According to the novel outer row compressed type multi-row axial plunger pump / motor, rotating bodies are of afull symmetrical structure, spring force is distributed uniformly, action baffles of the outer row springs are inserted in the cylinder body, cylinder body prepared materials are reduced, the cost isreduced, and the structure is simple and practical.

Owner:ANHUI UNIV OF SCI & TECH

Prop drawing-shaped micro-mechanical solid fluctuating modal matching gyroscope

ActiveCN103697873AIncrease stiffnessImprove impact resistanceTurn-sensitive devicesElectricityCapacitance

The invention provides a prop drawing-shaped micro-mechanical solid fluctuating modal matching gyroscope which comprises a prop drawing-shaped harmonic oscillator with four cube bulges at the four corners of the top end, four driving electrodes which are distributed above or nearby the cube bulges on the top end of the harmonic oscillator along the side face of the harmonic oscillator, and four detecting electrodes which are distributed above or nearby the cube bulges on the top end of the harmonic oscillator along the side face of the harmonic oscillator, wherein the spatial positions of the four driving electrodes are perpendicular to those of the four detecting electrodes. The gyroscope works by the means that the driving modality and the detecting modality of the prop drawing-shaped harmonic oscillator are matched with each other; the alternating voltage is applied onto the two driving electrodes on the prop drawing-shaped harmonic oscillator, and the inverse piezoelectric effect or the capacitive sensing effect enables the prop drawing-shaped harmonic oscillator to vibrate under the driving modality; in the case that an input angular velocity exists, the vibration model of the prop drawing-shaped harmonic oscillator is converted into the detecting modality, and sensitive signals generated by the piezoelectric positive effect or the capacitive sensing effect of the detecting electrodes are processed by a peripheral circuit to obtain input angular velocity signals.

Owner:SHANGHAI JIAO TONG UNIV

Space folding and extending mechanism with five-rod mechanisms as extensible units

ActiveCN107914896ASimple structureReduce weightCosmonautic vehiclesCosmonautic partsThree degrees of freedomEngineering

A space folding and extending mechanism with five-rod mechanisms as extensible units comprises an octagonal support base, three-degree-of-freedom hinges, pin shafts, bevel-edge rods, L-shaped rods, short rods and straight-edge rods. The octagonal support base is fixedly connected with the three-degree-of-freedom hinges, the bevel-edge rods are connected with the corresponding three-degree-of-freedom hinges through revolute pairs, the bevel-edge rods, the L-shaped rods, the short rods and the straight-edge rods are connected through the pin shafts, and the straight-edge rods are connected withthe corresponding three-degree-of-freedom hinges through revolute pairs. In the space folding and extending mechanism, each rod is composed of two rod bodies, movement pairs are all the revolute pairs, the structure is simple, the space folding and extending mechanism can be driven by motors, and the extending speed can be controlled through motor driving, and each extensible unit is high in stability and synchronism; the space folding and extending mechanism has the advantages of being low in mass, large in folding ratio, high in positioning precision, high in structural strength, high in stability and reliability, simple in structure and low in manufacturing cost, and the space folding process is simple.

Owner:GUANGXI UNIV

Space folding and unfolding mechanism for simulating connection of mimosa rigid hinge

InactiveCN107891995ALight in massSimple structureCosmonautic vehiclesCosmonautic partsHinge angleEngineering

A space folding and unfolding mechanism for simulating connection of a mimosa rigid hinge comprises a machine base, unfoldable units and the rigid hinge. The machine base is in a regular octagon shape. Each side of the machine base is connected with a support rod through a rotating pair. Each unfoldable unit comprises the support rods and a four-rod mechanism. One end of each support rod is connected with the machine base through the corresponding rotating pair. The two sides of each support rod are connected with the corresponding four-rod mechanism through rotating pairs. Each four-rod mechanism comprises a driving rod, a transmission rod and support connecting rods, wherein the driving rod and the support connecting rods are connected with the corresponding support rods through the corresponding rotating pairs respectively, the driving rod and the support connecting rods are connected with the transmission rod through rotating pairs. The rigid hinge is connected with the two unfoldable modules and can rotate around a rotating pair in the middle. The space folding and unfolding mechanism is light in quality, good in stability, large in folding ratio, large in structural strengthand high in reliability and precision and can be applied to aerospace tasks of communication with satellite platforms and earth observation.

Owner:GUANGXI UNIV

Flame retardant dilphosphonic heterocyclic polysilicate compound and preparation method thereof

ActiveCN109880162ANovel structureGood structural symmetryGroup 5/15 element organic compoundsEpoxyPolyester

The invention relates to a flame retardant dilphosphonic heterocyclic polysilicate compound and a preparation method thereof. The structure of the compound is shown as a formula in the description. The preparation method comprises the following steps of adding dimethyldichlorosilance and 2 to 2.4 mol of phosphocycloxy dimethylsilicate into an organic solvent; performing heat insulation reaction for 6 to 9h at 120 to 160 DEG C for completely exhausting hydrogen chloride; performing purification treatment; obtaining a product of the flame retardant dilphosphonic heterocyclic polysilicate. The compound provided by the invention belongs to an excellent silicon phosphorus cooperated flame retardant char forming agent which can be used as the flame retardant char forming agent of polyamide, polyester, polyurethane, polyolefin, epoxy resin, unsaturated resin and the like; the process is simple; the equipment investment is low; the industrialized production can be easily realized.

Owner:SUZHOU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com