Elliptical resonance modal piezoelectric type MEMS circular ring gyroscope

A resonant mode, gyroscope technology, applied in gyroscope/steering sensing equipment, gyro effect for speed measurement, instruments, etc., can solve the problem of low mechanical sensitivity and detection sensitivity, achieve good structural symmetry, reduce resonance Frequency difference, effect of reducing thermoelastic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

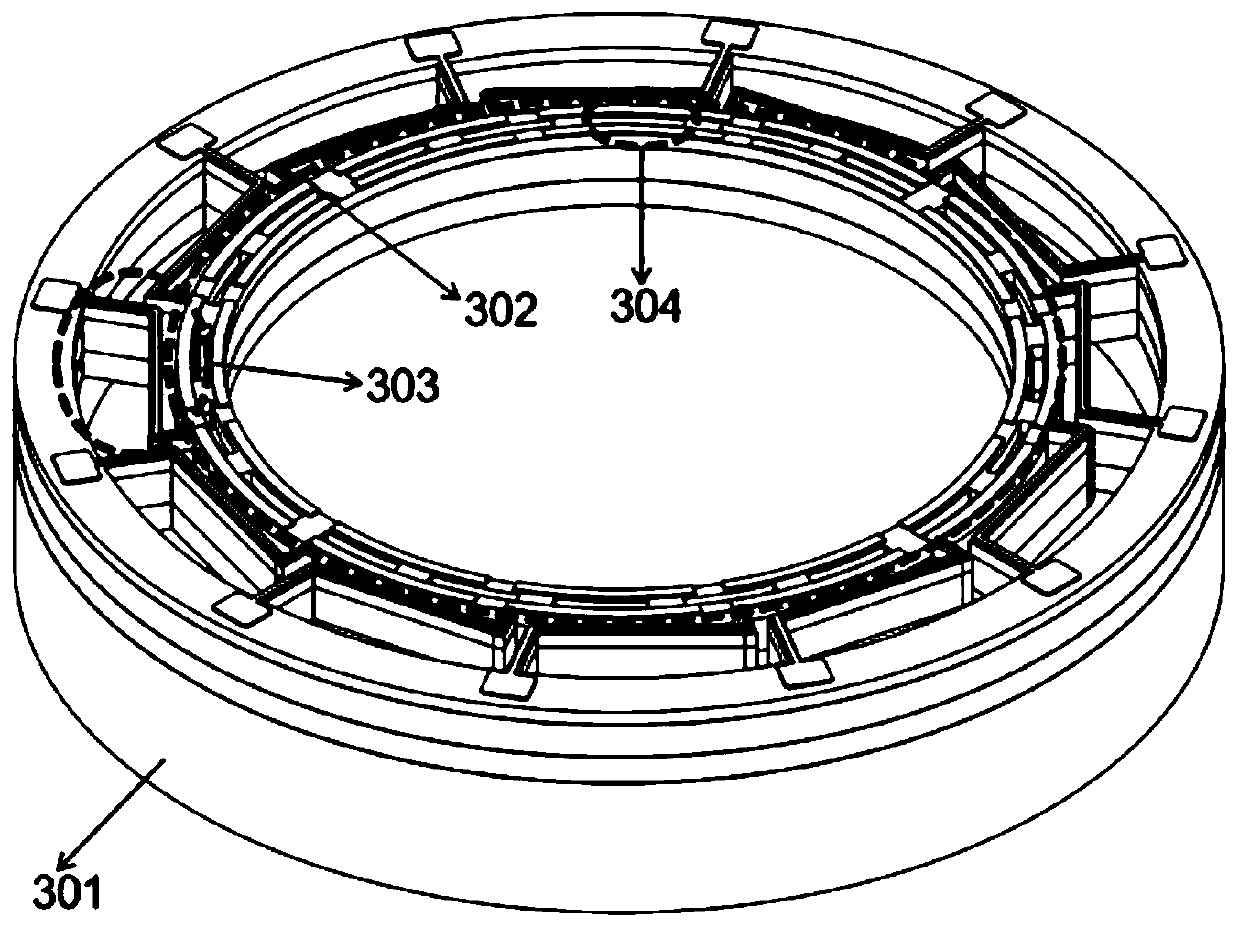

[0033] Such as figure 1 , figure 2 with Figure 5 As shown, an elliptical resonance mode piezoelectric MEMS ring gyroscope includes a substrate 101 with a concave cavity, a ring resonator 103 and a Z-shaped beam 102 suspended above the concave cavity, and twelve Z-shaped beams 102 are evenly distributed along the outer side of the ring resonator 103, and the ring resonator 103 is connected to the peripheral fixed support structure through the Z-shaped beam 102, and the peripheral fixed support structure is fixed to the substrate 101, and the outer circle on the top surface of the ring resonator 103 and The central circle between the inner circles is the reference circle, and forty heat insulation grooves 104 (obtained by etching) are uniformly distributed along the reference circle along the thickness direction, and the top electrode of the ring resonator 103 is differentiated along the inside and outside of the reference circle. Arrangement (the insulation groove 104 is se...

Embodiment 2

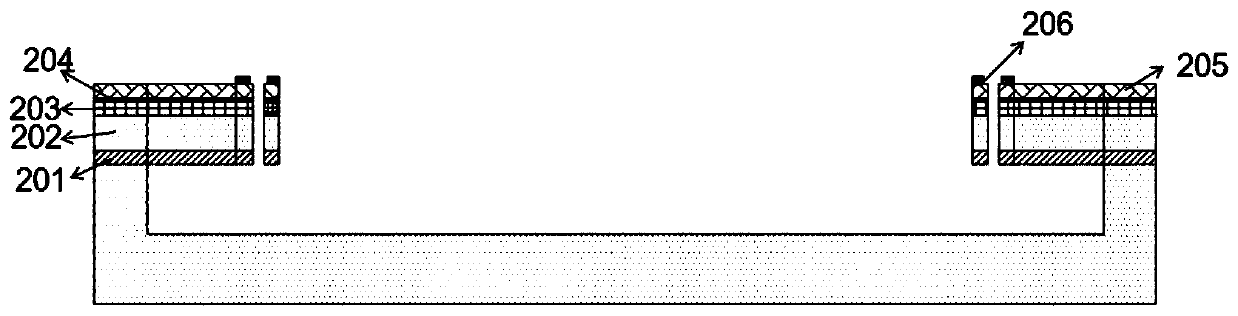

[0043] Such as Figure 3 to Figure 5 As shown, the structure of the second embodiment is basically the same as that of the first embodiment, the difference is that the ring resonator 303 includes a silicon oxide layer 401, a heavily doped silicon structure layer 402, a piezoelectric material layer 403 and The top electrode layer 404, wherein the heavily doped silicon structure layer 402 serves as the bottom electrode layer. The silicon structure layer 402 can be heavily doped to reduce the temperature coefficient of the elastic constant of the silicon material, realize passive temperature compensation, and further improve the temperature stability of the ring gyroscope.

[0044] In Embodiment 1 and Embodiment 2, Z-shaped beams (102 and 302) are used as the fixed-support beams. In fact, the fixed-support beams can also be straight beams, T-shaped beams, and the like.

[0045] In Embodiment 1 and Embodiment 2, the heat-insulation grooves (104 and 304) are all arc-shaped grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com