Single-degree-of-freedom constrained scissor-type deployable unit and its spatially deployable mechanism

A developable and free technology, applied in motor vehicles, space navigation equipment, space navigation aircraft, etc., can solve the problems of immature technology, low rigidity, many hinge points, etc., to achieve good deployment performance, good seismic performance, The effect of the larger folding ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

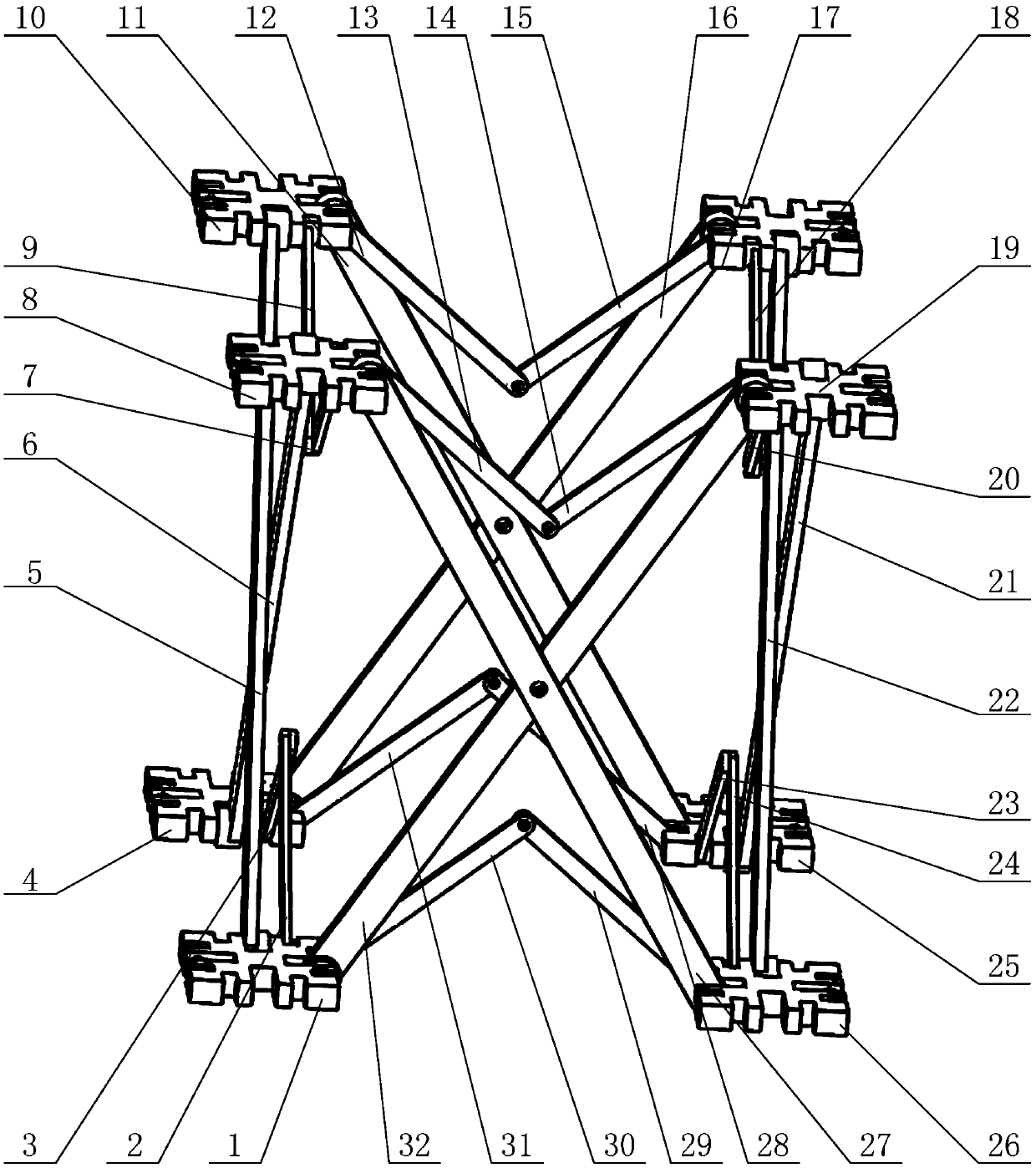

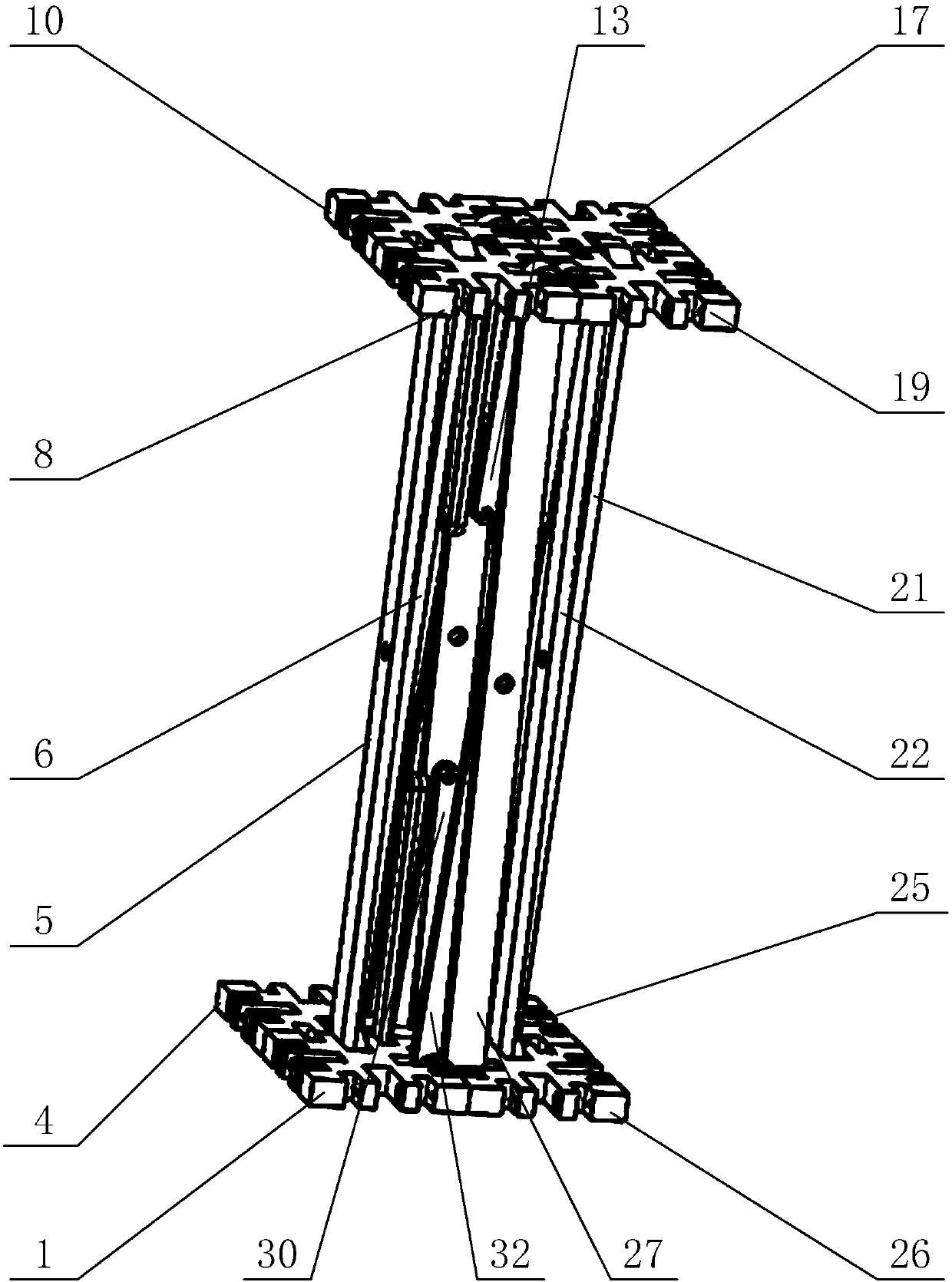

[0026] exist figure 1 In the schematic diagram of the single-degree-of-freedom constrained scissor-type deployable unit shown, the eight scissor bars have the same structure, two scissor bars form a group, and the middle of the two scissor bars is connected by a rotating pair, and the eight scissor bars A total of four sets of scissor folding rods are formed, and the four groups of scissor folding rods are symmetrically distributed on the four sides of the basic expandable unit, and the folding and extending directions of the scissor folding rods on the opposite side are the same; the structure of the sixteen connecting rods is exactly the same , two connecting rods form a group, and one end of the two connecting rods is connected by a rotating joint. Sixteen connecting rods form eight groups of folding connecting rods, which are symmetrically distributed on the upper and lower two sides of the basic expandable unit. On the surface, there are four sets of folding connecting ro...

Embodiment 2

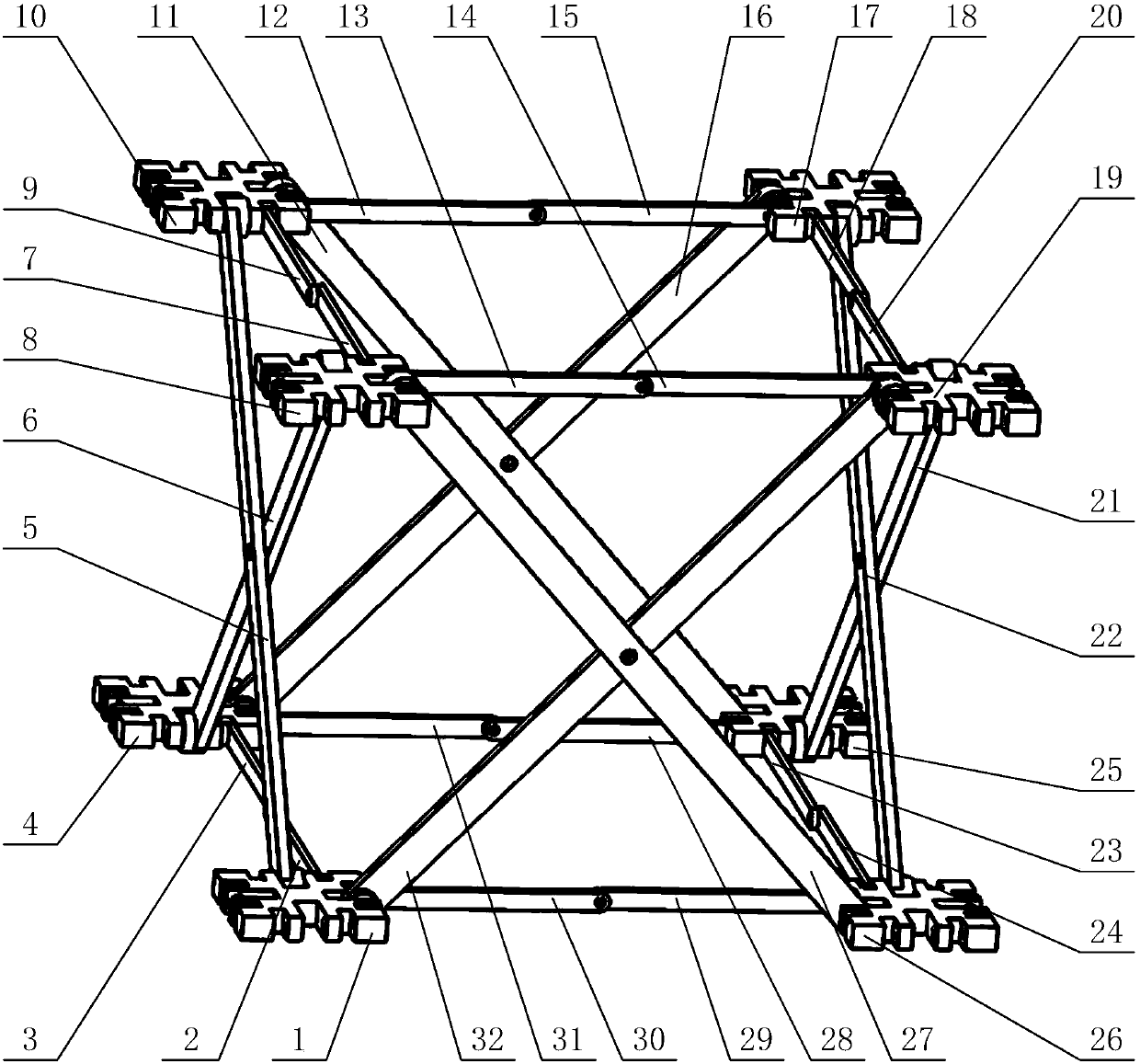

[0031] Such as Figure 4-Figure 6 As shown, the first space expandable mechanism composed of single-degree-of-freedom constrained scissor-type expandable units includes a plurality of basic expandable units. The components and connection methods of each basic expandable unit are the same as those in Embodiment 1. The expansion units are arranged horizontally in order, and the adjacent basic expandable units share four flower discs and a set of scissor folding rods, wherein the four ends of the shared set of scissor folding rods are respectively inserted into the middle slots of the four shared flower discs , connected to the faceplate through the rotating pair, the two ends of the adjacent two sets of folding connecting rods are respectively inserted into the left notches of the four shared faceplates, and connected to the faceplate through the rotating pair, the two adjacent folding connecting rods of the other two groups The ends are respectively inserted into the right slot...

Embodiment 3

[0036] Such as Figure 7-Figure 9 As shown, the second-space expandable mechanism composed of single-degree-of-freedom constrained scissor-type expandable units includes a plurality of basic expandable units, which are arranged horizontally and vertically in sequence, and adjacent basic expandable units share Four faceplates and a set of scissors folding rods are connected in the same way as the expandable mechanism in the first space; by changing the number of basic expandable units, the size of the expandable mechanism in the second space can be changed.

[0037] The horizontal arrangement and connection relationship of a plurality of basic expandable units are the same as those in Embodiment 2. When arranged vertically, the third scissor bar 11 and the fourth scissor bar 16 of the first basic expandable unit pass through the rotating pair in the middle. The second scissors folding bar connected is the common scissors folding bar with the second longitudinal basic expandable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com