Multilayer even laid-in weaving and knitting composite structure, weaving method thereof and special device thereof

A composite structure, weft insertion technology, applied in the direction of weft knitting, knitting, textile and paper making, etc., can solve the problems of application limitation, different interlining density, and structural asymmetry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

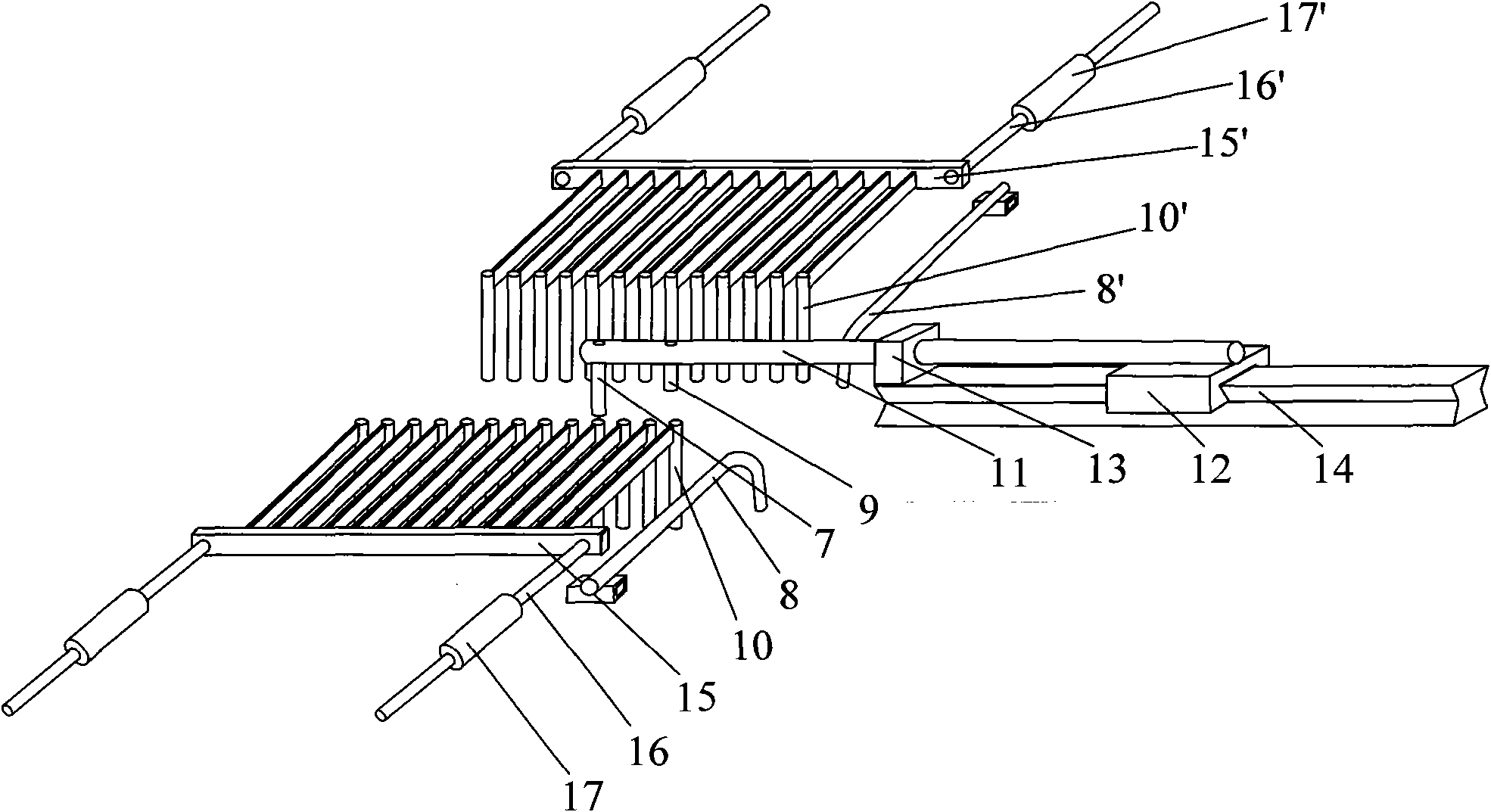

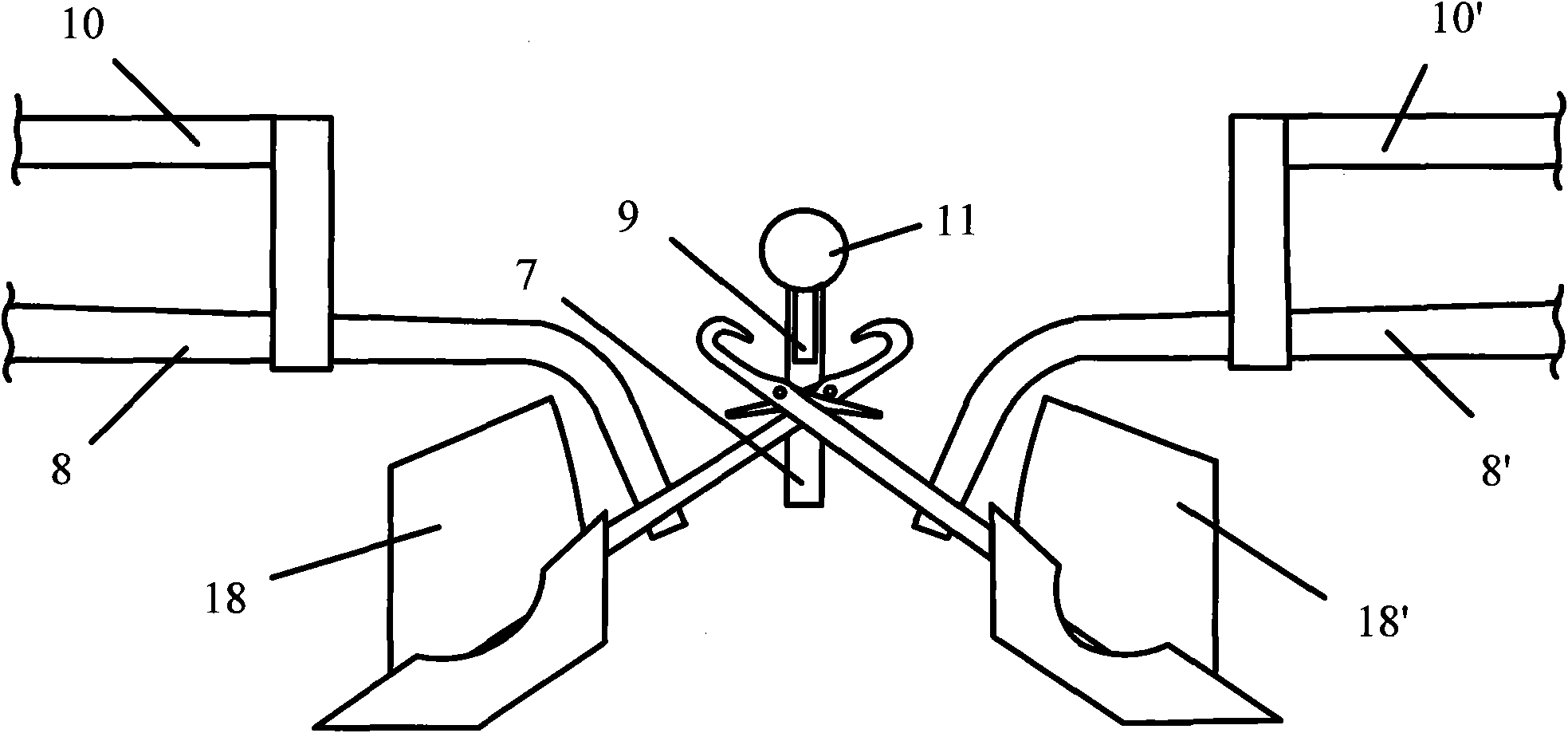

[0029] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings.

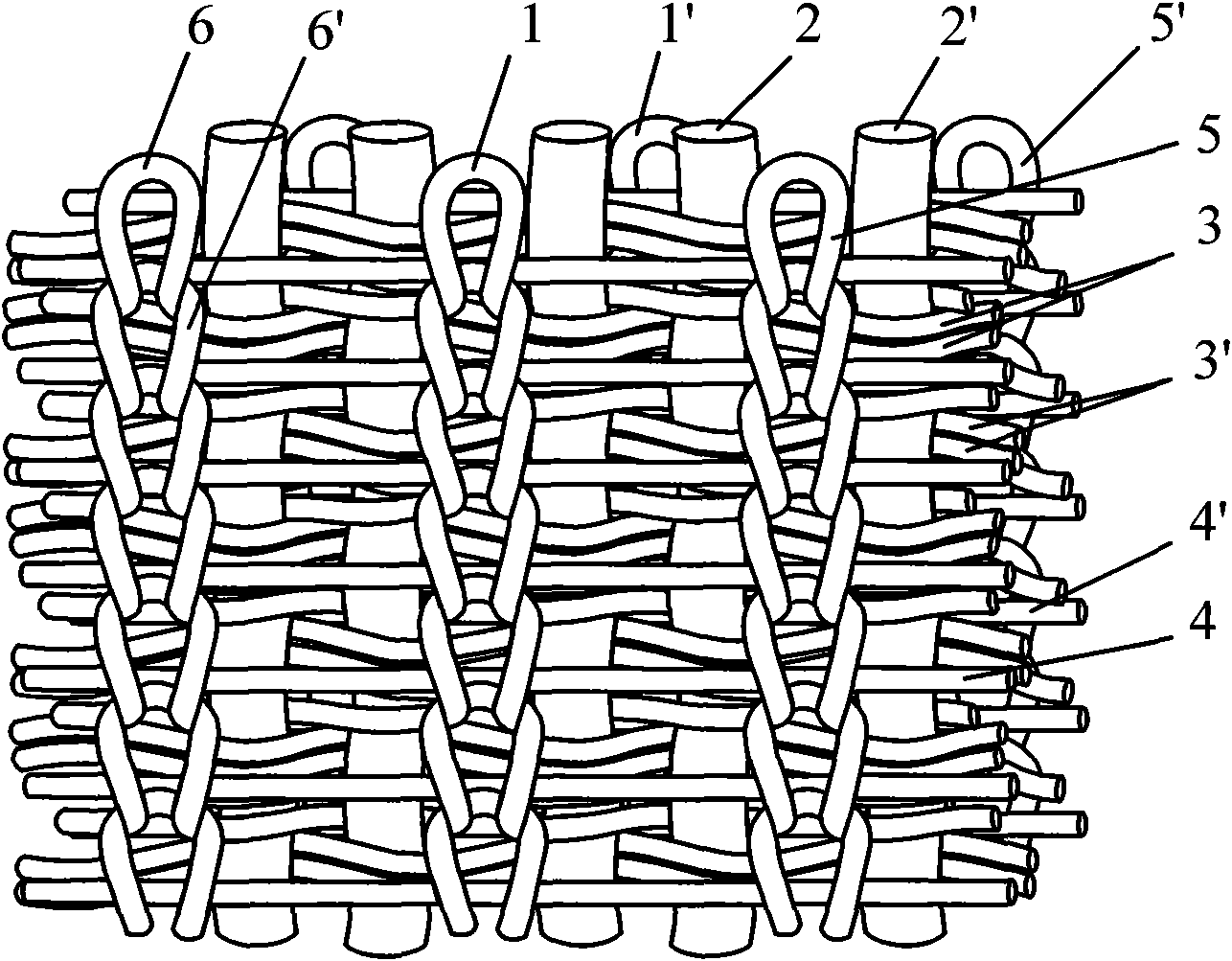

[0030] Such as figure 1 As shown, the woven and knitted composite structure with multi-layer uniform weft insertion according to the present invention includes a front weft plain stitch 1, a rear weft plain stitch 1', and a plurality of front weft plain stitches 1 The warp yarn 2 or 2' between the adjacent sinker loops of the rear weft plain stitch 1' and the three sets of weft yarns interspersed into each course, among the three sets of weft yarns, the first set of weft yarns 3 or 3' is interleaved Between two adjacent warp yarns 2 and 2', the second group of weft yarns 4 is interposed between the loops 5 of the front weft plain stitch and the warp yarns 2', and the third group of weft yarns 4' is interposed between the back weft plain stitches Between the weaving loop 5' and the warp yarn 2, the first group of weft yarns 3 or 3' ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com