Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Good resistance to sulfate attack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance concrete corrosion-resistant anti-cracking agent and producing method thereof

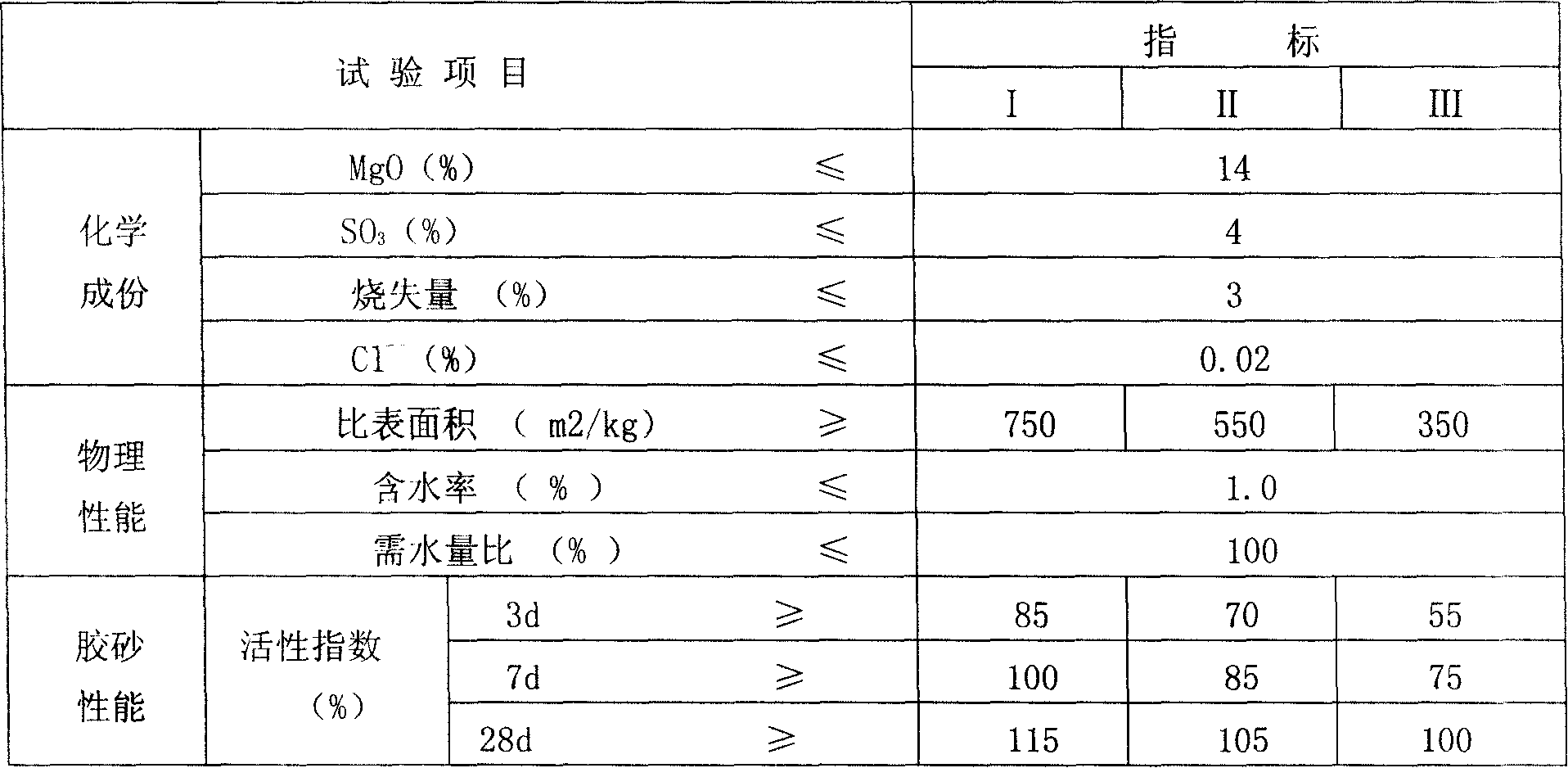

ActiveCN101168480AGood resistance to sulfate attackGood resistance to chloride ion penetrationSolid waste managementSlagNational standard

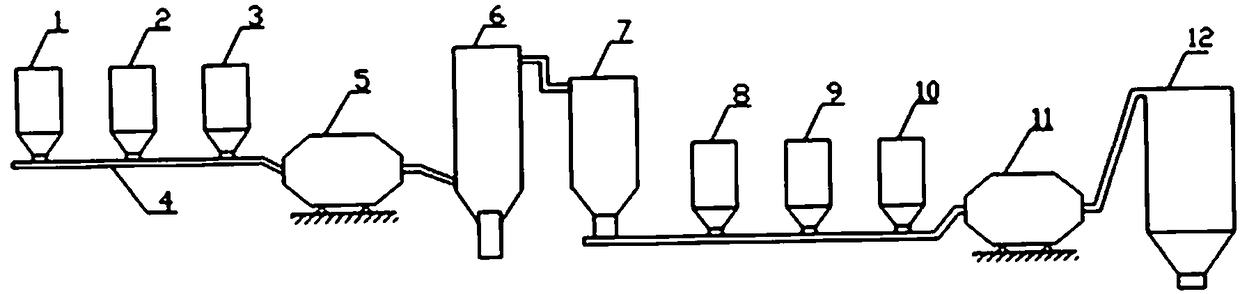

A high-property concrete corrosion-crack resistant agent is prepared from slag, coal ash, zeolite, active siliceous material, grinding aid, reduction nanometer substrate, and composite expansion component. And the preparation comprises that first feeds, dries and grinds slag, zeolite, active siliceous material, and composite expansion component or the like in an upright furnace to demanded specific surface area, grinds in a ball mill, mixes and grinds the composite mineral additive that directly prepared from powder coal ash, active siliceous material or the like at the ball mill and upright mill, to demanded specific surface area, and sprays grinding aid and reduction nanometer substrate via a special device to be atomized and injected into a pulverizer, to uniformly mix all components, to obtain product. Each technical index of the prepared high-property concrete corrosion-crack resistant agent is at least not lower than national standard. The invention has advanced production art, continuous production support, better corrosion-crack property, and simple operation.

Owner:浙江合力海科新材料股份有限公司

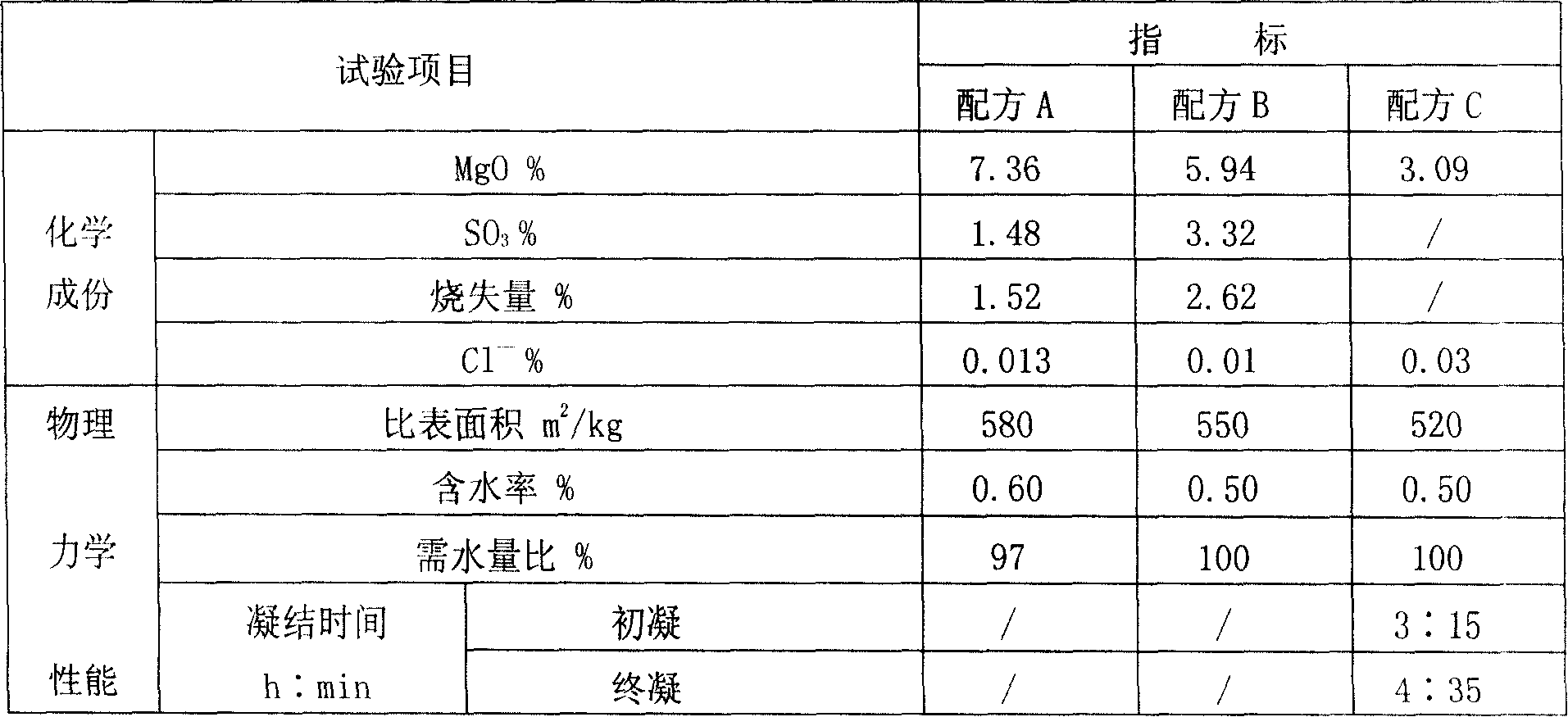

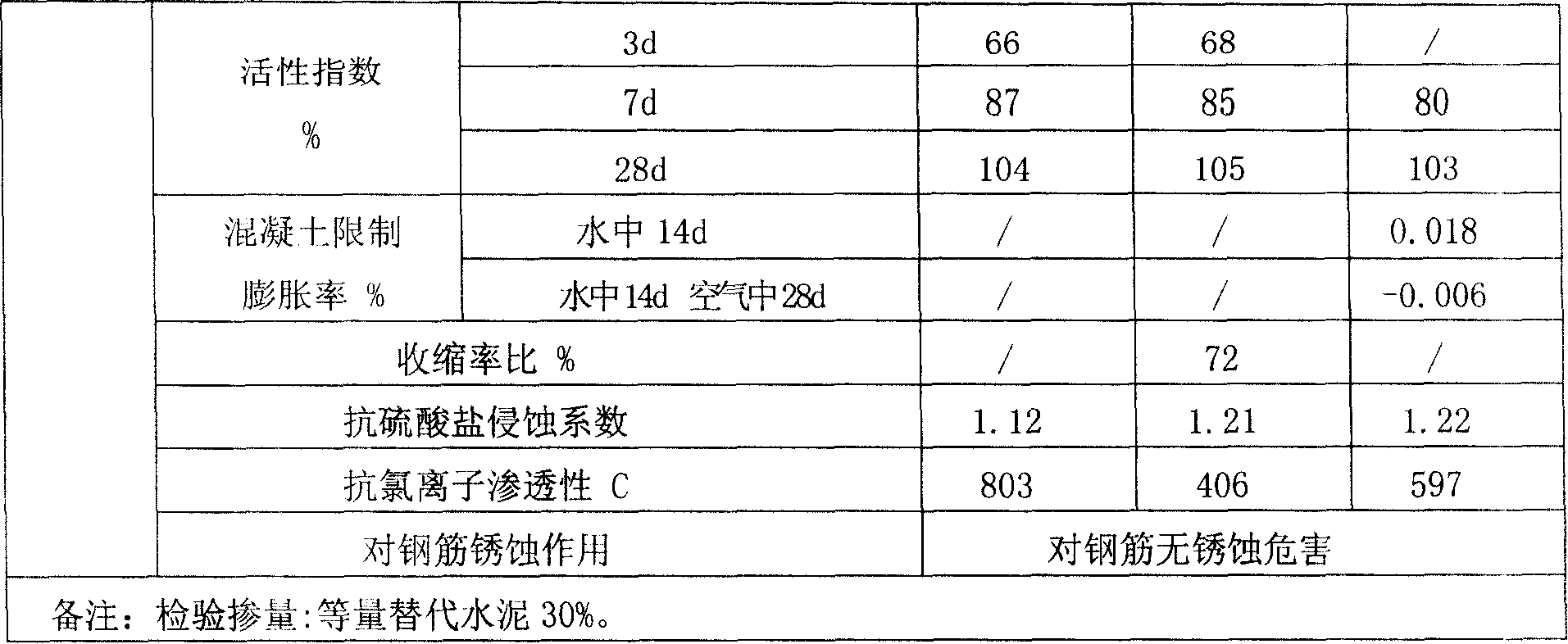

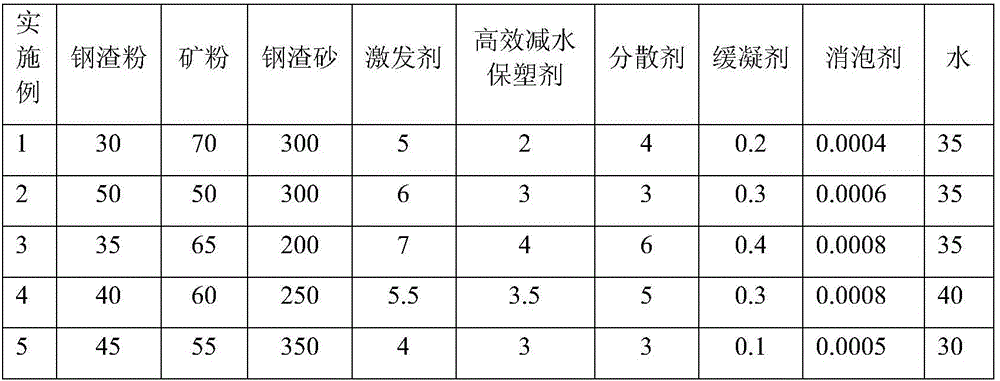

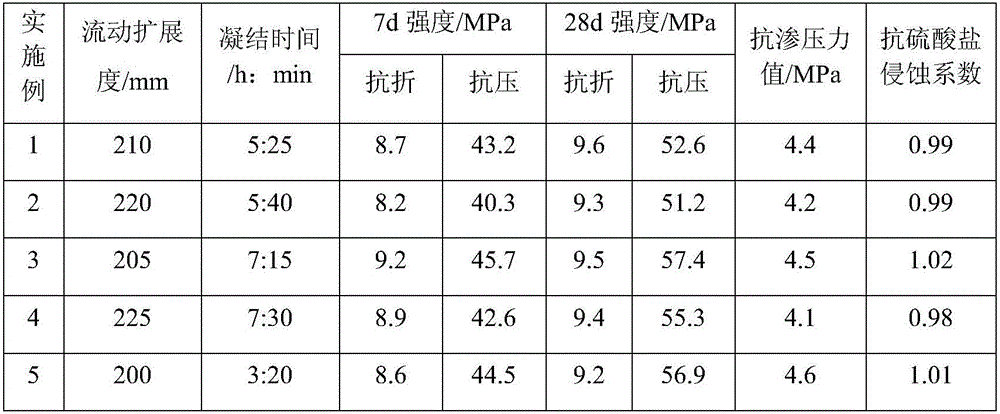

Non-cement green mortar by using steel slag as cementing material and fine aggregate and preparation method thereof

ActiveCN105859229AImprove overall utilizationImprove work performanceLeveling effectBreaking strength

The invention belongs to the field of building materials and particularly relates to a non-cement green mortar by using the steel slag as the cementing material and the fine aggregate and a preparation method thereof. The non-cement green mortar comprises the following components in weight part: 30-50 parts of steel slag powders, 50-70 parts of mineral powders, 200-350 parts of steel slag sands, 4-7 parts of activator, 1-4 parts of a water reducing agent, 3-6 parts of a dispersing agent, 0-0.4 parts of a retarder, 0.0002-0.001 part of a defoamer, and 30-40 parts of water. The non-cement green mortar is good in working performance, automatic in leveling effect, adjustable in setting time with the range of 0.5-8 hours, high in early-late strength, and excellent in impermeability and resistance to sulfate attack. The 7d breaking strength of the non-cement green mortar is larger than 8 MPa, and the compression strength thereof is larger than 40 MPa. The 28d breaking strength of the non-cement green mortar is larger than 9 MPa, and the compression strength thereof is larger than 50 MPa. Therefore, the non-cement green mortar can be widely applied to the engineering practice.

Owner:WUHAN UNIV OF TECH

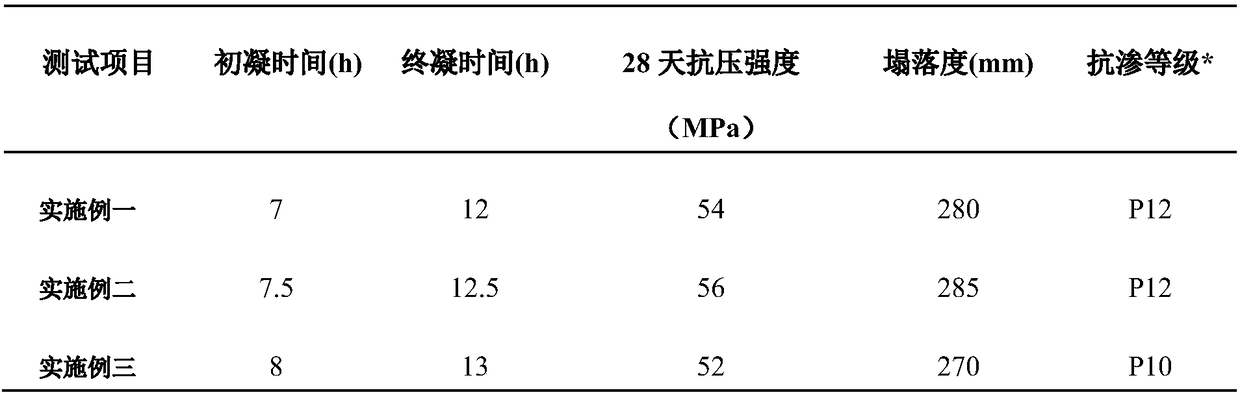

Basalt and polypropylene hybrid fiber reinforced concrete and preparing method

The invention provides basalt and polypropylene hybrid fiber reinforced concrete and a preparing method. Basalt fibers accounting for 0.1-0.5 part of the weight of a concrete matrix and polypropylene fibers accounting for 0.01-0.08 part of the weight of the concrete matrix are doped into the concrete matrix. (1) at the normal temperature, sand and stone are put into a blender to be blended for 60 s; (2) cement is put into the blender to be blended for 60 s; (3) water is added into the blender to be blended for 90 s to 120 s, and a concrete matrix is obtained; and (4) two kinds of fibers including the basalt fibers and the polypropylene fibers are mixed, and are scattered into the concrete matrix obtained in the step (3) to be blended for 120 s after the two kinds of fibers are highly scattered, and then the basalt and polypropylene hybrid fiber reinforced concrete is obtained. Compared with traditional concrete, the basalt and polypropylene hybrid fiber reinforced concrete can better adapt to complex environments such as high temperature, high heat, corrosion and the like, can be widely applied to roads, bridges, buildings, undergrounds and oceanographic engineering, and the concrete application scope is greatly expanded.

Owner:HARBIN ENG UNIV

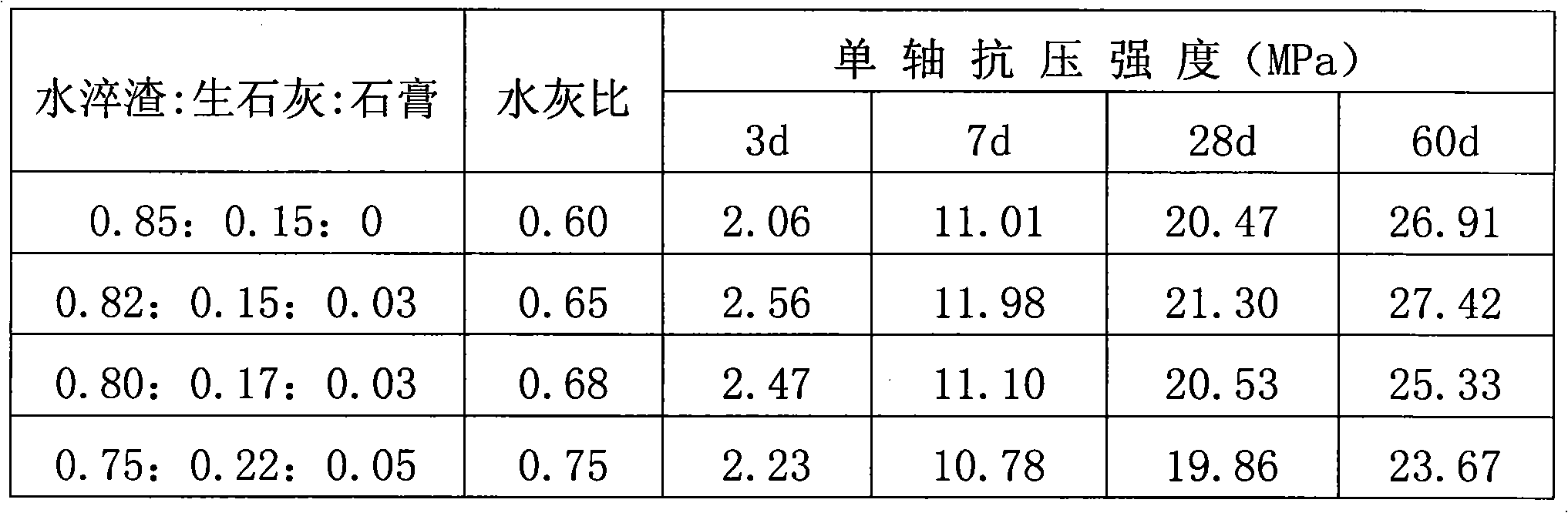

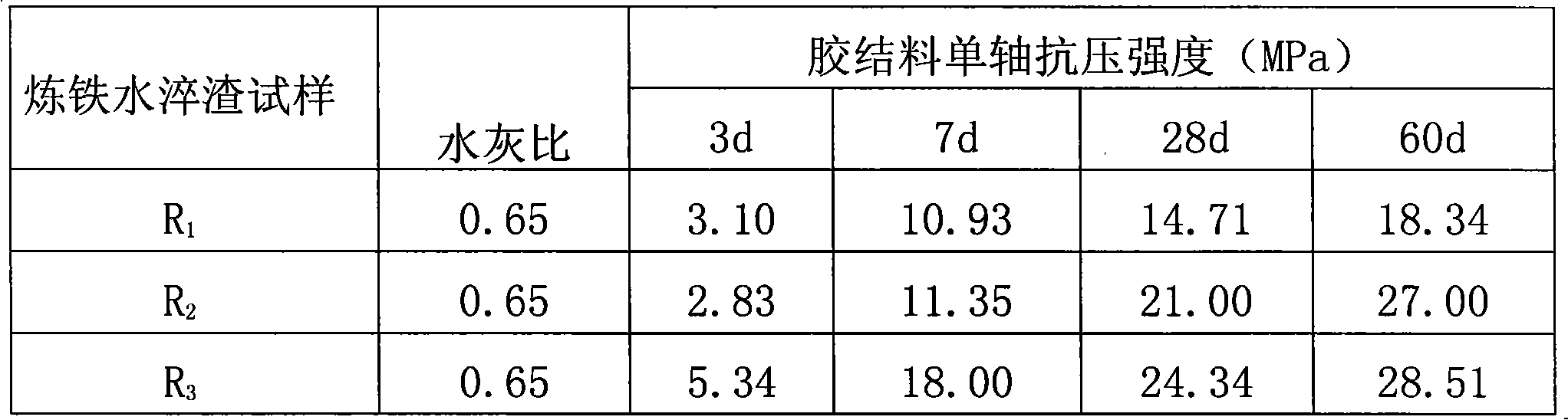

Mine-filling cementing material and preparation method thereof

The invention relates to a mine-filling cementing material and preparation method thereof. The cementing material is prepared from the following raw materials in weight percentage: 75 to 85 percent of iron-making water-granulated slag which is quenched by water, 15 to 22 percent of activating agent and 0 to 5 percent of intensifier, wherein the activating agent comprises quicklime or hydrated lime and the CaO content of the activating agent is 70 to 80 percent based on the dry weight; the intensifier comprises plaster; and the grinded granularity of the raw materials is + 0.071 millimeters and the content of the grinded raw materials is not more than 12 percent. The preparation method comprises the steps of: drying the raw materials, mixing the raw materials in a ratio, dryly grinding the raw materials to prepare dry a mine filling cementing material; or drying the raw materials, dryly grinding the raw materials respectively and then mixing the raw materials to prepare a dry material in a ratio; or mixing the raw materials in a dry weight ratio, adding water into the mixture and wetly grinding the mixture to obtain the mine-filling cementing material slurry. The mine-filling cementing material and the preparation method thereof can save cost and realize the high-efficiency waste resource recycling; tail cementing filling material prepared by adopting the cementing material of the invention has the advantages of relatively high mechanical strength, high water absorption capability and high sulphate resistance, so the min- filling cementing material is a cementing material better than cement in the aspect of mine cemented filling.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Sulfate-resistant concrete and preparation method thereof

The invention belongs to the technical field of concrete preparation, and provides a sulfate-resistant concrete. The sulfate-resistant concrete is characterized by being prepared from, by weight, 60-70 parts of sulfate-resistant cement, 30-40 parts of mineral admixture, 50-90 parts washed sand, 40-80 parts of machine-made sand, 110-160 parts of coarse aggregate, 4-6 parts of polypropylene fiber, 2-3 parts of carboxymethylcellulose, 70-90 parts of slurry forming water, 0.5-0.8 part of anhydrous ethanol, 2-3 parts of SBT-RMA concrete corrosion inhibitor and 1-2 parts of additive. The sulfate-resistant concrete solves the problems that the damage of corrosion to reinforced concrete is very serious, and sulfate-resistant concrete in the market is poor in anti-corrosion performance and short inservice life.

Owner:石家庄金隅混凝土有限公司

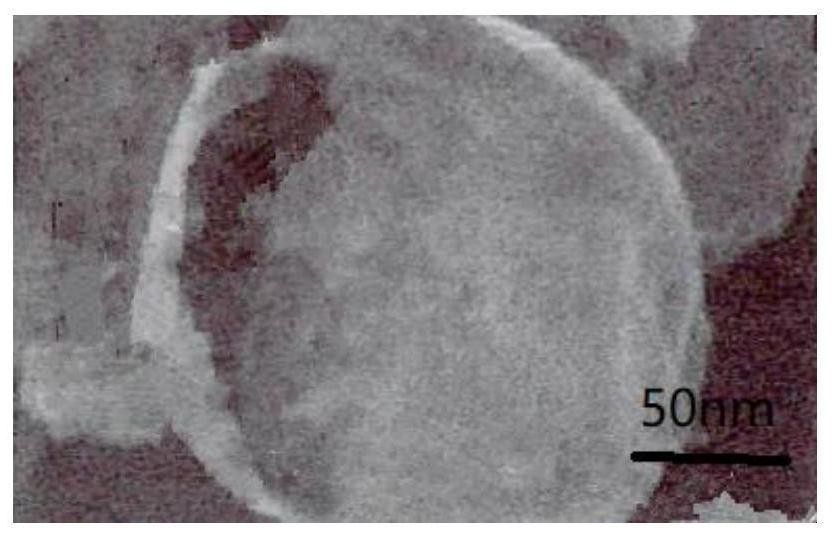

Sulfate corrosion resistant graphene-concrete composite material and preparation method thereof

The invention discloses a graphene modified glass fiber preparation method, a sulfate corrosion resistant graphene-concrete composite material and a preparation method thereof. The sulfate corrosion resistant graphene-concrete composite material is prepared from 150-240kg / m<3> of cement, 45-50kg / m<3> of coal ash, 40-60kg / m<3> of silicon ash, 600-900kg / m<3> of coarse aggregates, 70-120kg / m<3> of river sand, 20-50kg / m<3> of nano silicon dioxide, 30-50kg / m<3> of graphene modified glass fibers, 1-7.5kg / m<3> of a water reducing agent and 105-150kg / m<3> of water. By high strength and flexibility and large specific surface area of graphene, glass fiber clusters are open and roughened to be grafted to a graphene network, and consequently the graphene / concrete composite material high in strength, toughness and sulfate corrosion resistance are obtained.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

Nickel iron slag gelling material and production technology thereof

The invention relates to a nickel iron slag gelling material and a production technology, relate to the nickel iron slag gelling material, and especially relates to cement produced by the nickel ironslag and a production method thereof. The nickel iron slag gelling material comprises the following components in parts by weight: 40-70 parts of Portland cement clinker, 30-60 parts of nickel iron slag low-temperature clinker, and 1-2 parts of gypsum, wherein the nickel iron slag low-temperature clinker comprises the following components in parts by weight: 20-30 parts of nickel iron slag, 9-15 parts of quicklime, 0.5-1 part of gypsum, 5-10 parts of water, and 0.2-0.6 parts of an alkaline electrolyte. The method can effectively solve the environment problem of stacking of nickel iron slag, realizes high-efficiency resource utilization of the nickel iron slag, and reduces CO2 discharge capacity during a cement preparation process, the nickel iron slag low-temperature clinker can substitutethe Portland cement clinker to produce the gelling material, and the produced nickel iron slag low-temperature gelling material has the characteristics of low hydration heat and good anti-sulfate erosion performance.

Owner:HOHAI UNIV

Modified aluminate cement and preparation method thereof

ActiveCN112209642AImprove corrosion resistanceImprove water resistanceSolid waste managementAluminateSilicic acid

Provided modified aluminate cement is prepared from the following raw materials: aluminate cement, titanium-silicon micro-nano capsules, magnesium oxide, a phosphate, fly ash, modified acrylic emulsion and an activating agent, wherein the titanium-silicon micro-nano capsule is prepared from orthosilicate and titanate under the conditions of a surfactant and alkalinity. The aluminate cement prepared by the invention is wide in raw material source and simple in preparation method, has good high-temperature resistance, wear resistance, sulfate corrosion resistance, adhesion, crack resistance, freezing resistance, seepage resistance, corrosion resistance and aging resistance, also has good effects of adsorbing and degrading formaldehyde and organic pollutants due to the TiO2 structure, plays agood role in environmental protection, ensures the safety as a structural part, and has a wide application prospect.

Owner:山东山铝环境新材料有限公司

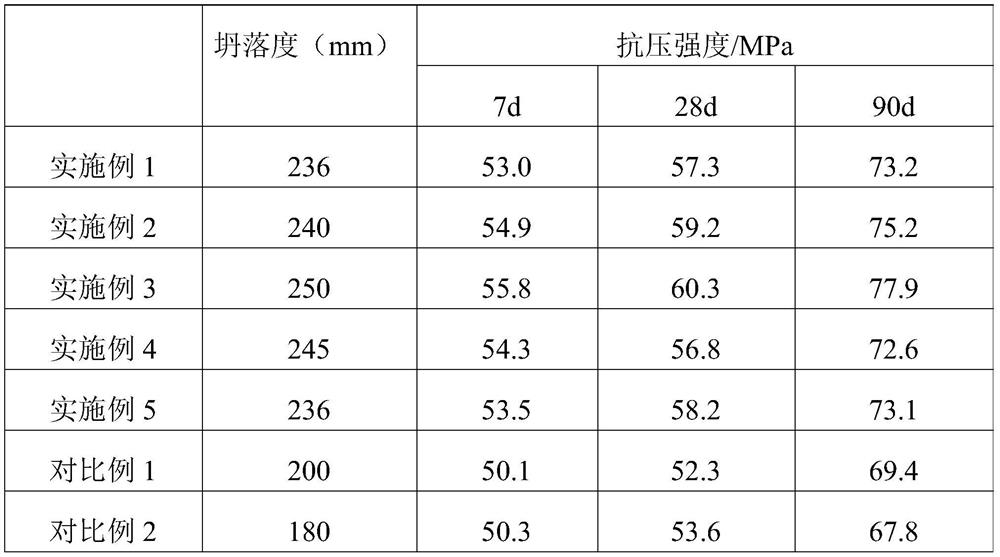

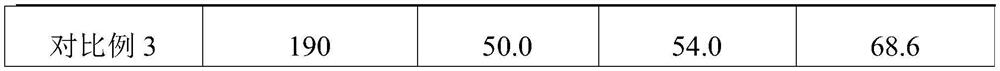

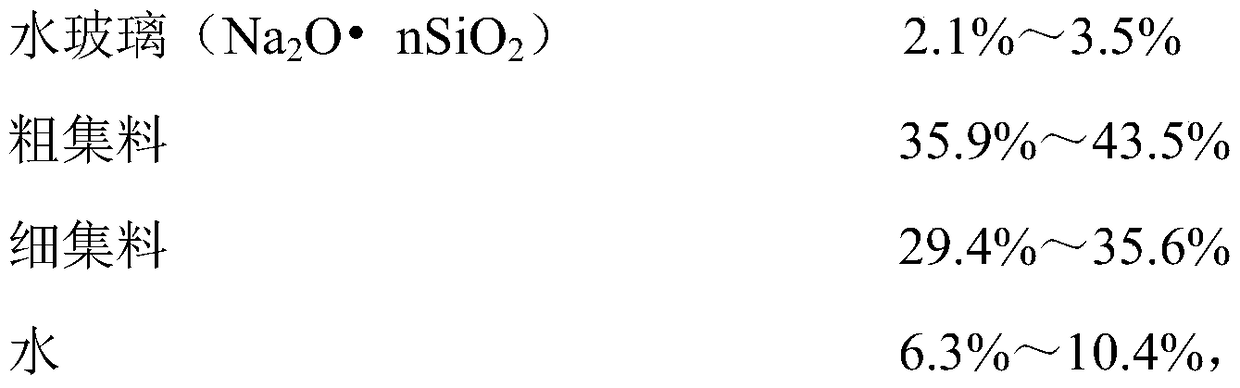

Alkali-activated concrete and preparation method thereof

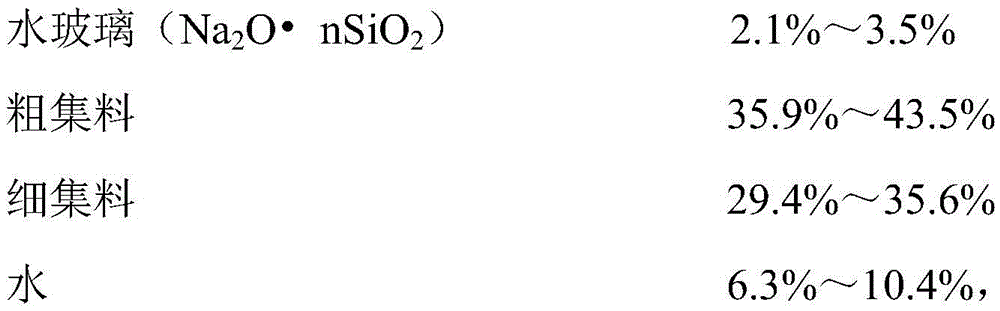

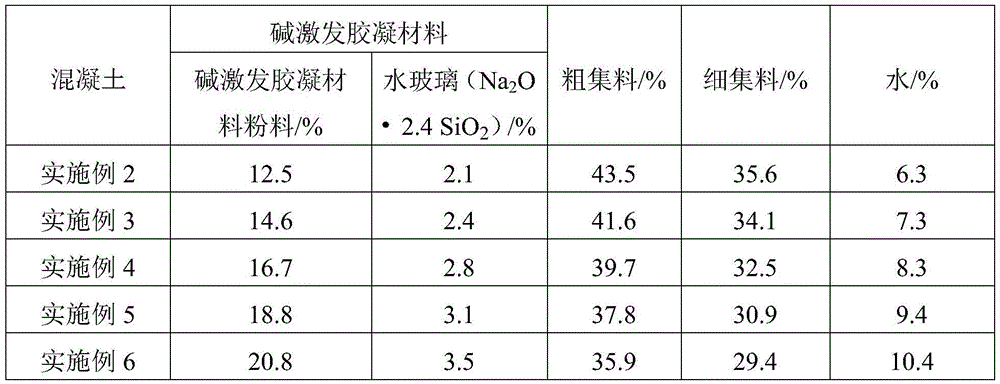

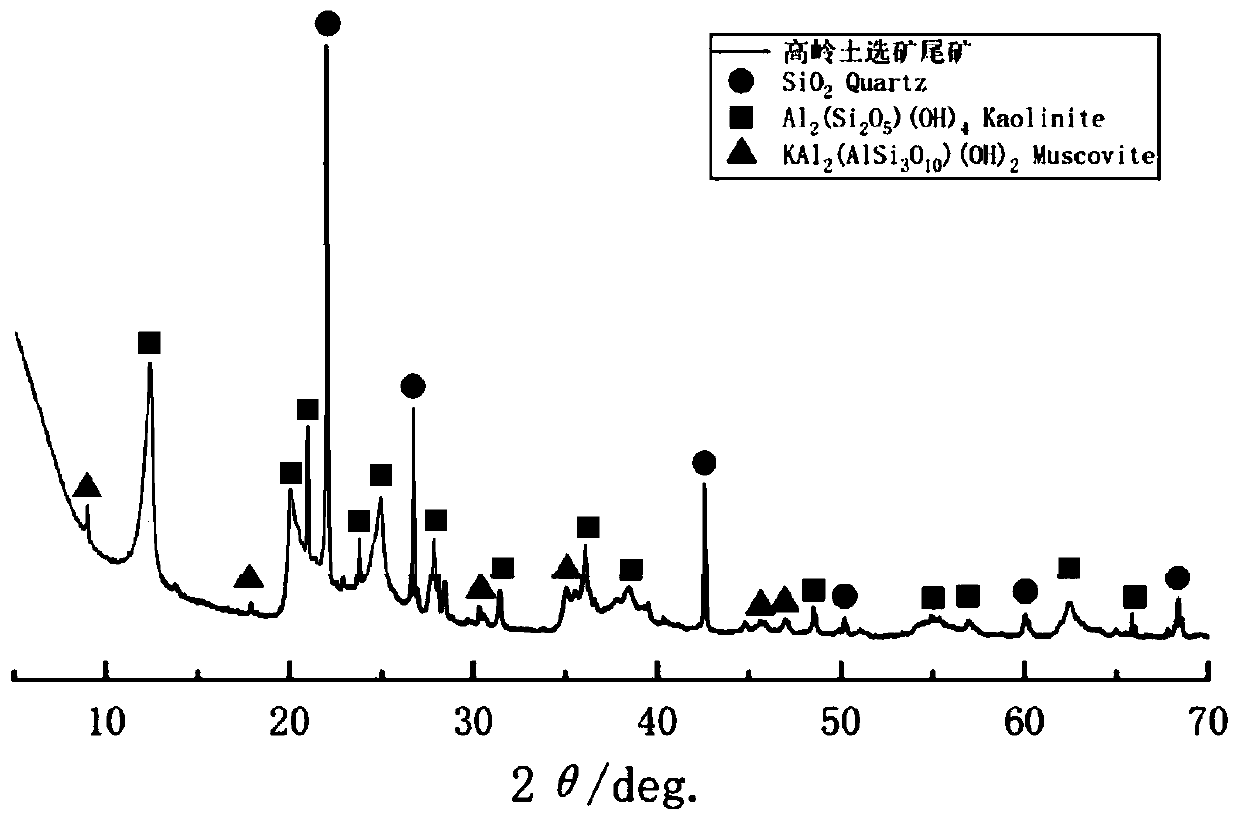

ActiveCN105601189AExpansion of application technology fieldConvenience to workFreeze and thawAlkali activated

The invention relates to alkali-activated concrete and a preparation method thereof. The alkali-activated concrete comprises components in percentage by mass as follows: 12.5%-20.8% of alkali-activated cementing material powder, 2.1%-3.5% of Na2O*nSiO2 (n is 2.00-3.00), 6.3%-10.4% of water, 35.9%-43.5% of coarse aggregate and 29.4%-35.6% of fine aggregate, wherein the alkali-activated cementing material powder comprises silicon-calcium slag micro-powder, mineral powder and superfine mineral powder. The preparation method of the alkali-activated concrete comprises steps of preparation of the silicon-calcium slag micro-powder, preparation of the alkali-activated cementing material powder, mixing of the alkali-activated cementing material powder, the aggregate and the water, addition of Na2O*nSiO2, stirring and the like. The alkali-activated concrete is prepared from novel silicon-calcium slag as a raw material, so that the alkali-activated concrete has higher freezing and thawing cycle resistance and sulfate corrosion resistance and can be applied to buildings in freezing and thawing environments and offshore or marine environments, and resource recycling is facilitated because of adoption of the silicon-calcium slag as the main raw material.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

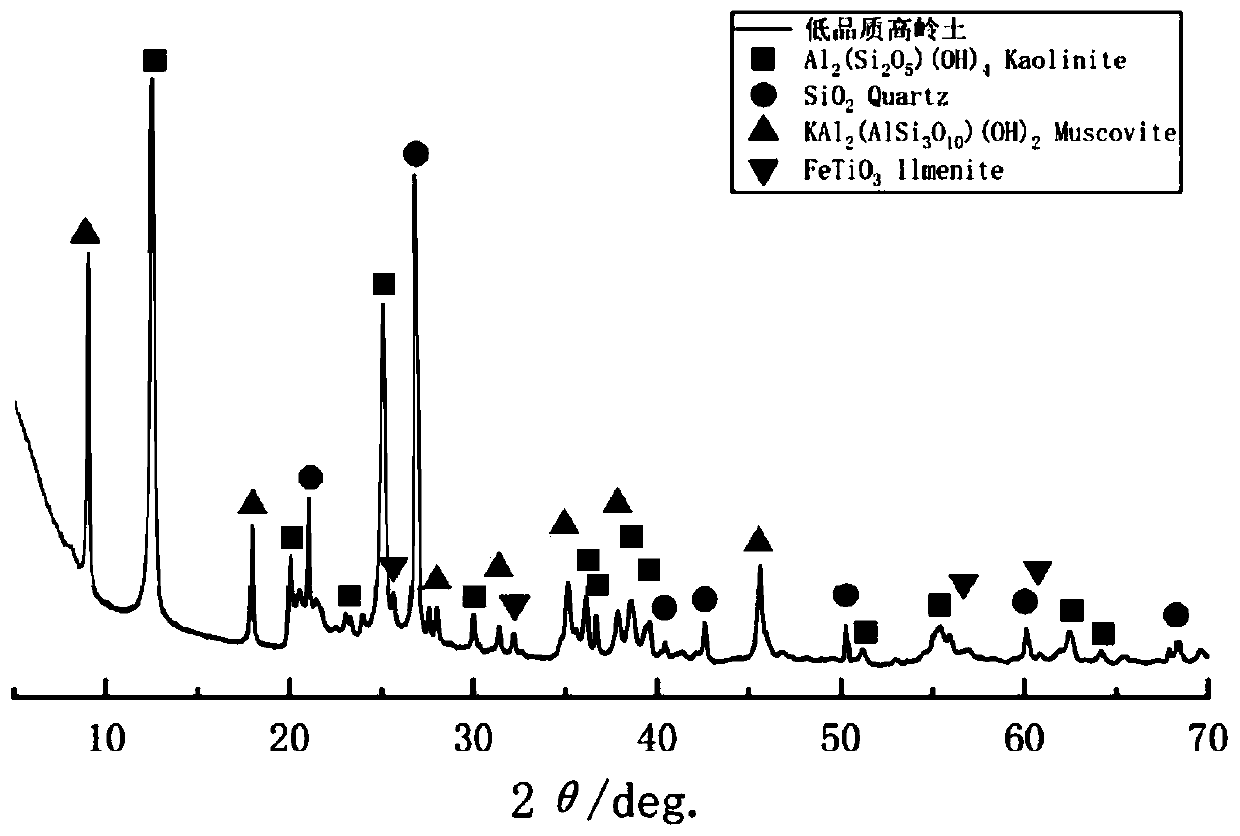

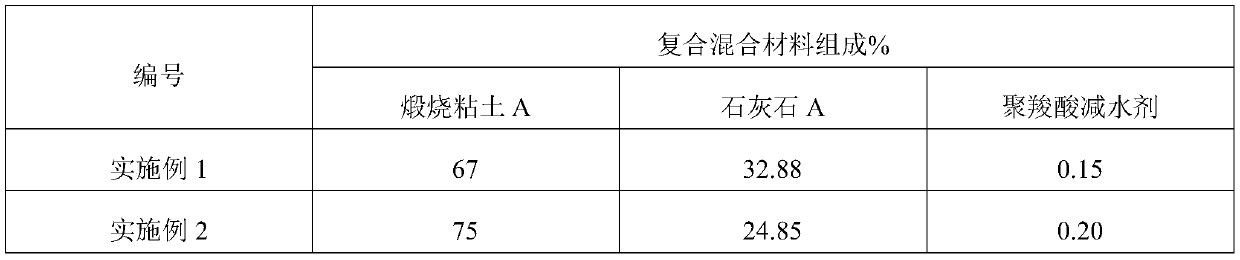

High-activity composite mixed material for improving erosion resistance of cement concrete

InactiveCN110627393ARefine the pore structure of the hardened bodyDense hydration matrixLower gradeChloride

The invention belongs to the field of building materials, and particularly relates to a high-activity composite mixed material for improving erosion resistance of cement concrete. The high-activity composite mixed material is prepared from the following raw materials in parts by weight: 50-80 parts of calcined clay, 19-49.9 parts of limestone and 0.1-1 part of a water reducing agent, wherein the mass percentage of CaO in the limestone is less than 48%. The invention provides the composite mixed material prepared from the calcined clay, the low-grade limestone and the water reducing agent, andthe composite mixed material has relatively high activity. When the composite mixed material is used in a large amount, strength of cement and concrete is not reduced, and meanwhile, sulfate corrosionresistance and chloride ion permeation resistance of the cement and the concrete can be obviously improved.

Owner:SINOMA INT ENG +1

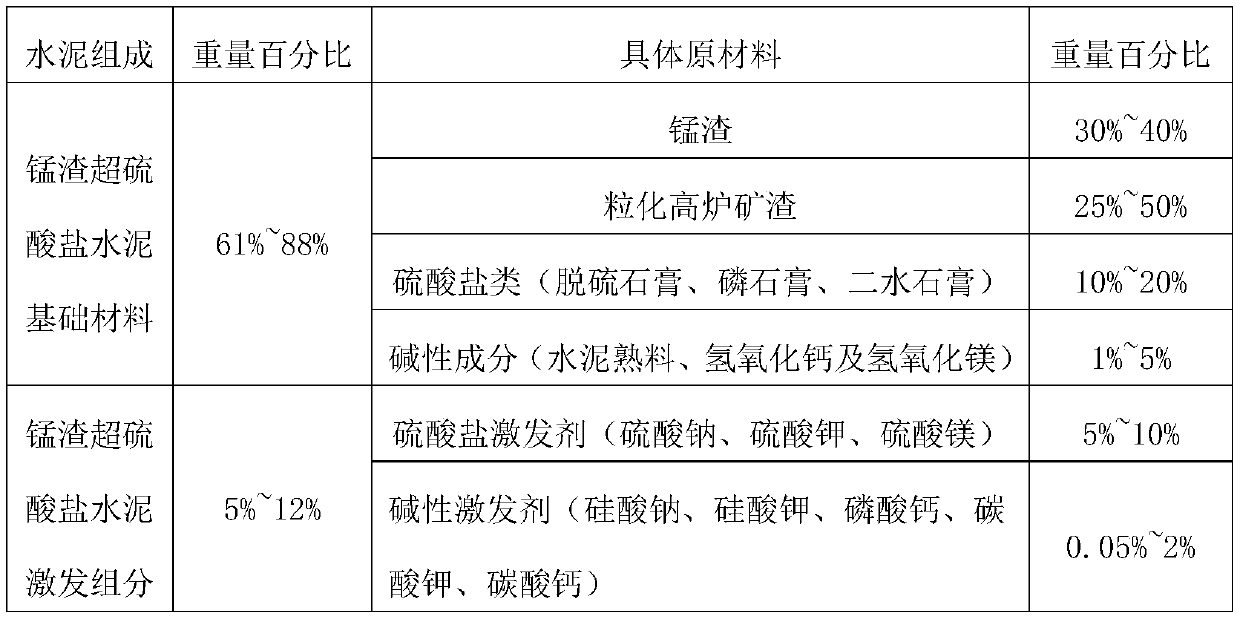

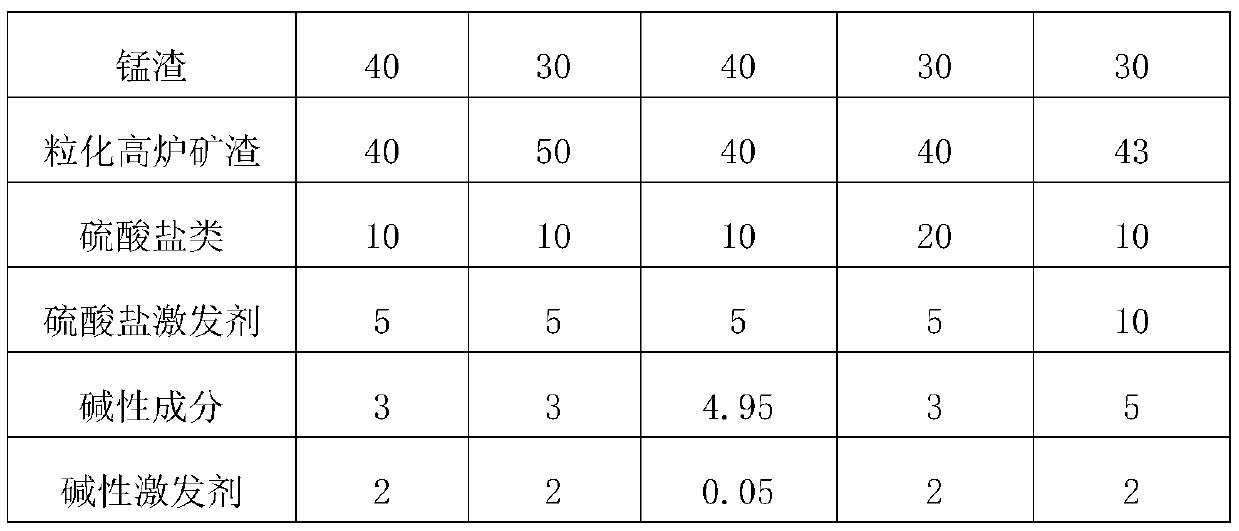

Manganese slag supersulfate cement and preparation method thereof

The invention belongs to the technical field of special cement, and particularly relates to a manganese slag supersulfate cement and a preparation method thereof. The manganese slag supersulfate cement is prepared from the components in percentage by weight: 30-40% of manganese slag, 25%-50% of granulated blast furnace slag powder, 10-20% of sulfates, 5%-10% of a sulfate activator, 1-5% of an alkaline component and 0.05-2% of an alkaline activator. The manganese slag which is a high-temperature slag waste discharged during the blast furnace smelting process of manganese iron or silicomaganeseis used as a main raw material, a material science principle is combined, the mineral characteristics of manganese slag and slag are taken as a basis, the potential hydration activity of the manganeseslag is activated by using sulfates and alkaline environment to form the initial strength, and novel manganese slag supersulfate cement with excellent properties is further designed.

Owner:中建西部建设新疆有限公司 +1

Concrete for low-grade highway and preparation thereof

The invention discloses a concrete for low-grade highway prepared by cementing materials, sandstone materials, water and sodium sulphate, wherein the cementing materials are formed by cement, carbide slag and fly ash, the weight percentage of the cement accounts for 35-45% of the cementing materials, the balance is carbide slag and fly ash with the weight ratio of 1: 2.7-3.3; the weight ratio of each component is as follows: cementing materials 9-10 weight parts, sandstone materials 35-37 weight parts, water 3.2-4 weight parts, the dosage of the sodium sulphate accounting for 3.25-3.75% of the weight total of the carbide slag and fly ash. The invention also discloses a method for preparing the concrete comprising steps of preparation of concrete mixture, construction by compaction technology and maintenance.

Owner:CHONGQING UNIV

Early strengthening flyash three-slag road forndation material

InactiveCN1483694AImprove frost resistanceHigh strengthRoadwaysSolid waste managementSlagCrushed stone

The present invention relates to an early-strength flyash three-slag road bed material, said road bed material composition includes 10%-30% of flyash, 5%-15% of slaked lime, 60%-84.5% of broken stone and 0.5%-1% of early-strength agent, and adds the water whose added quantity is 37% of the above-mentioned total weight, and the early strength agent is formed from two portions of high calcium lime and one portion of sodium sulfate, the flyash, slaked lime and broken stone are dry material, and the total content of SiO2 and Al2O3 in the flyash is greater than 70%, and the total content of active calcium oxide and magnesium oxide in the slaked lime is greater than 30%.

Owner:SHANGHAI JINGAN NEW BUILDING MATERIAL SCI INST

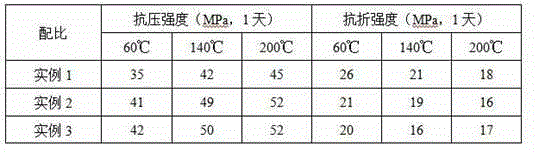

Manufacturing method of geopolymer oil well cement

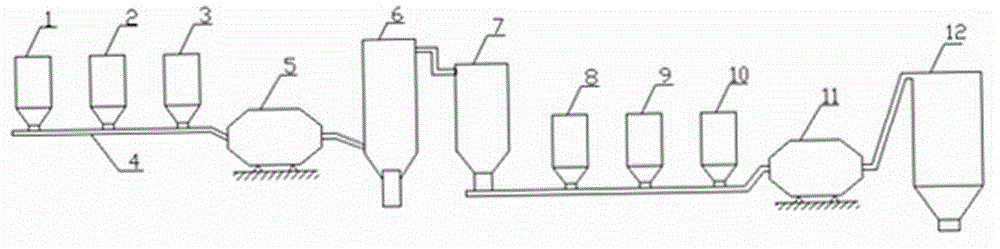

ActiveCN105776913AImprove volume stabilityImprove high temperature resistanceCement productionGeopolymerWell cementing

The invention relates to a manufacturing method of geopolymer oil well cement. The method is characterized by comprising the following steps in order: compounding, grinding, calcination, mixing, warehousing and packaging. The method provided by the invention can manufacture the geopolymer oil well cement with good volume stability, high temperature resistance, CO2 resistance, and sulfate attack resistance. And the cement can be effectively applied to oil-gas well cementation in areas with complex geological conditions, and can achieve very good cementing quality.

Owner:JIAHUA SPECIAL CEMENT

Nickel iron slag-mineral slag low-hydration-heat cementing material and preparation method thereof

The invention provides a nickel iron slag-mineral slag low-hydration-heat cementing material and preparation method thereof, and belongs to the field of building materials. The cementing material comprises the following substances in parts by mass: 46-49 parts of a low-temperature clinker and 0.5-1 part of gypsum, wherein the low-temperature clinker comprises the following substances in parts by mass: 20-40 parts of nickel iron slag, 20-30 parts of mineral slag, 20-35 parts of quick lime, 0.3-0.8 part of gypsum, 0.5-2 parts of a diluent and 8-15 parts of water. The efficient resource utilization of the nickel iron slag is realized, and the usage amount of Portland cement is effectively reduced. The nickel iron slag and the mineral slag are used as raw materials, and the quick-hard and low-hydration-heat cementing material which can partially replace the Portland cement is prepared. Compared with the Portland cement, the cementing material has the characteristics of quick hardening, lowhydration heat and good resistance to sulfate erosion.

Owner:HOHAI UNIV

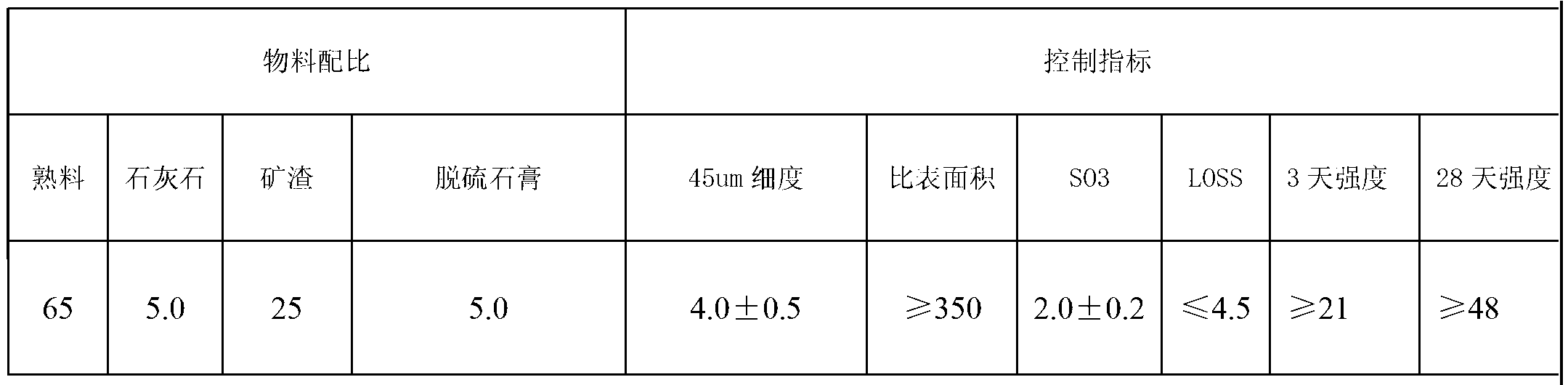

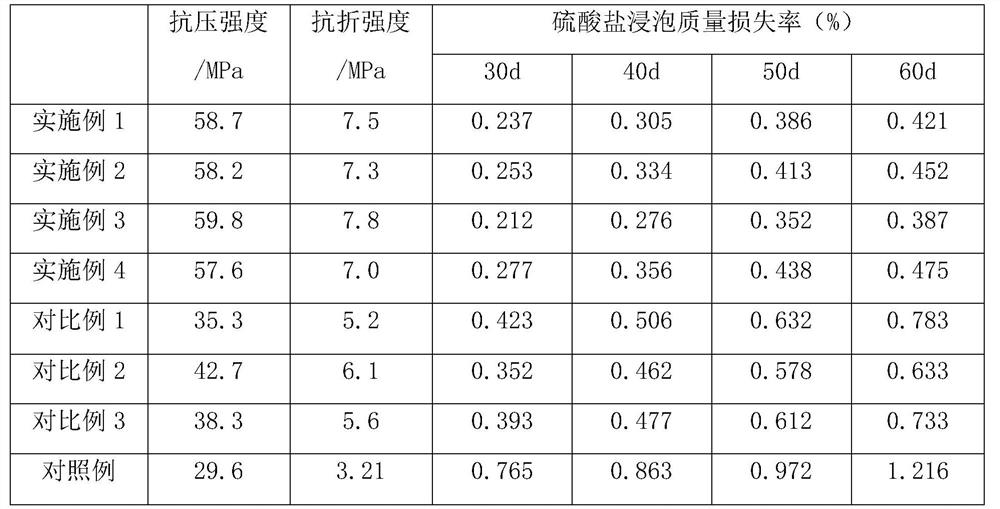

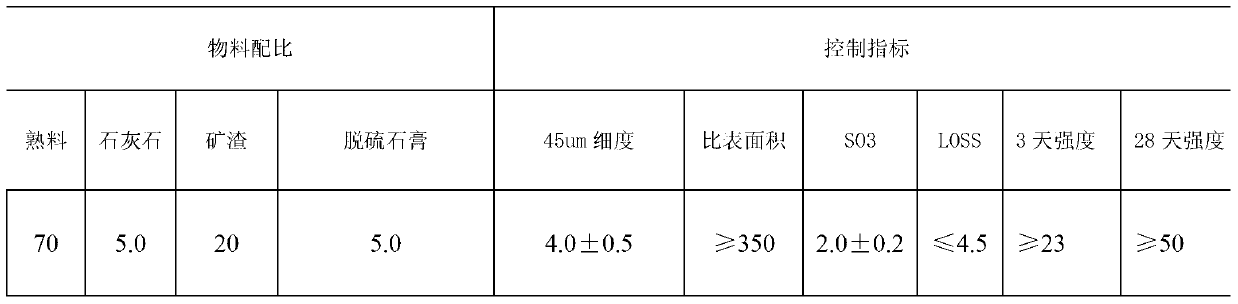

Novel Portland slag P.SB42.5 cement

InactiveCN103304161AGood resistance to sulfate attackReduce and inhibit diffusivityCement productionSlagSteel mill

The invention relates to novel Portland slag P.SB42.5 cement. The cement comprises the following components by weight percent: 64-66% of clinker, 4-6% of limestone, 23-27% of slag and 4-6% of desulfurization gypsum. The cement has the advantages that industrial waste slag ingredients generated in the production processes in steel mills are adopted, thus not only reducing the production cost but also eliminating pollution sources, achieving economical efficiency and environment friendliness, improving the later strength of the cement and ensuring the quality of engineering construction.

Owner:天津山水水泥有限公司

Alkali-activated concrete for sewage pipeline

The invention provides alkali-activated concrete for a sewage pipeline and a preparation method of the alkali-activated concrete, and the concrete material comprises the following raw materials in parts by weight: 45-75 parts of slag, 10-15 parts of silica fume, 6-12 parts of metakaolin, 5-10 parts of fly ash, 40-50 parts of water, 35-45 parts of an alkali activator, 0.25-0.5 part of an additive,0.5-1 part of fibers, 100-150 parts of fine aggregate and 75-125 parts of coarse aggregate. The anti-permeability and durability of the concrete can be remarkably improved, so that the concrete has relatively good sulfate corrosion resistance.

Owner:汪峻峰

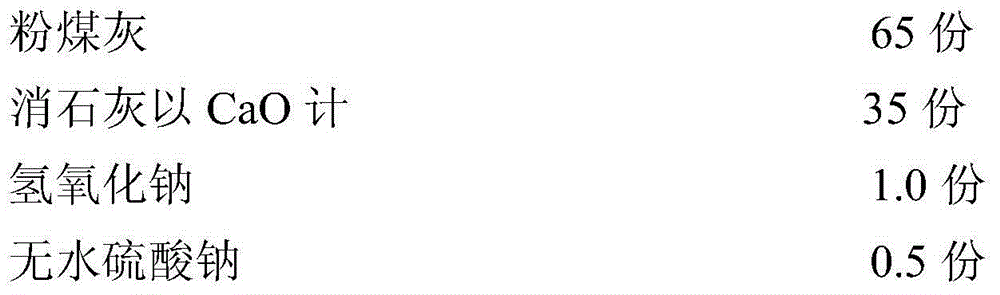

Inorganic cementing material and preparation method thereof

The invention provides an inorganic cementing material and a preparation method thereof. The cementing material is obtained by jointly grinding a composite material obtained by steam curing and calcinating material blocks or material balls prepared from coal ash, lime, an exciting agent and water, Portland cement and gypsum. The preparation method includes the steps that by mass, 65-80 parts of coal ash, 20-35 parts of effective CaO of lime and 0.5-2.0 parts of exciting agent are jointly ground into a batch mixture with the degree of fineness being 45 microns and the residue on sieve being smaller than 10%, 15-50 parts of water is added, the mixture is mixed to be uniform, then aging is conducted for 2-3 hours, the material blocks or the material balls are subjected to steam curing for 8-16 hours at the temperature of 90-98 DEG C after being formed, and a steam cured material is obtained; the steam cured material is calcinated for 15-90 minutes at the temperature of 750-1,000 DEG C and then air cooled or cooled in air, and the composite material is obtained; 60-70 parts of the composite material, 20-30 parts of Portland cement and 5-10 parts of gypsum are jointly ground till the specific area is 350-450 m<2> / kg, and the fast-setting high-strength inorganic cementing material is prepared.

Owner:HUAZHI ENERGY CONSERVATION HK

Alkali activated concrete and its preparation method

ActiveCN105601189BExpansion of application technology fieldConvenience to workAlkali activatedFreeze and thaw

The invention relates to alkali-activated concrete and a preparation method thereof. The alkali-activated concrete comprises components in percentage by mass as follows: 12.5%-20.8% of alkali-activated cementing material powder, 2.1%-3.5% of Na2O*nSiO2 (n is 2.00-3.00), 6.3%-10.4% of water, 35.9%-43.5% of coarse aggregate and 29.4%-35.6% of fine aggregate, wherein the alkali-activated cementing material powder comprises silicon-calcium slag micro-powder, mineral powder and superfine mineral powder. The preparation method of the alkali-activated concrete comprises steps of preparation of the silicon-calcium slag micro-powder, preparation of the alkali-activated cementing material powder, mixing of the alkali-activated cementing material powder, the aggregate and the water, addition of Na2O*nSiO2, stirring and the like. The alkali-activated concrete is prepared from novel silicon-calcium slag as a raw material, so that the alkali-activated concrete has higher freezing and thawing cycle resistance and sulfate corrosion resistance and can be applied to buildings in freezing and thawing environments and offshore or marine environments, and resource recycling is facilitated because of adoption of the silicon-calcium slag as the main raw material.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

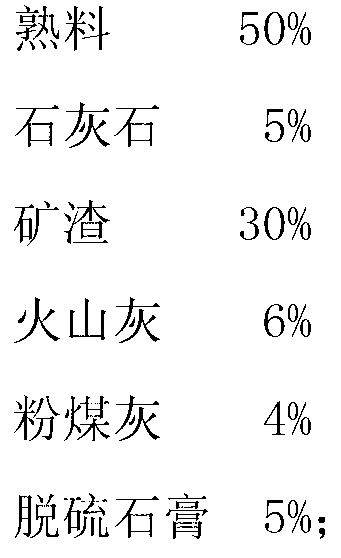

Novel Portland slag P.SA32.5 cement

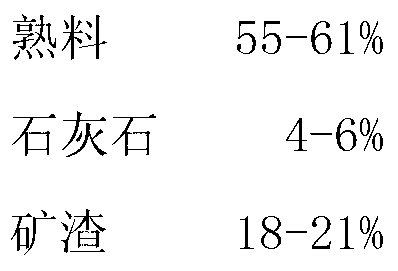

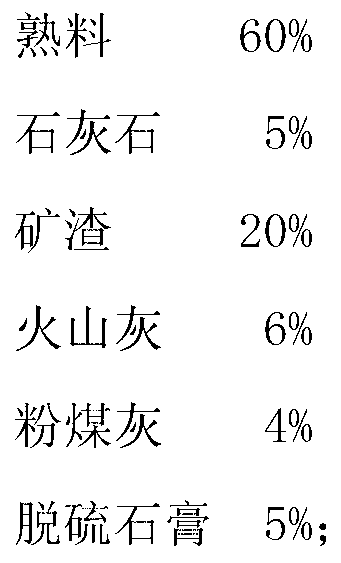

InactiveCN103304164AGood resistance to sulfate attackReduce and inhibit diffusivityCement productionSlagToxic industrial waste

The invention relates to novel Portland slag P.SA32.5 cement. The cement comprises the following components by weight percent: 55-61% of clinker, 4-6% of limestone, 18-21% of slag, 4-7% of volcanic ash, 3-5% of fly ash and 3-6% of desulfurization gypsum. The cement has the advantages that industrial waste slag ingredients generated in the production processes in steel mills are adopted, thus not only reducing the production cost but also eliminating pollution sources, achieving economical efficiency and environment friendliness, improving the later strength of the cement and ensuring the quality of engineering construction.

Owner:天津山水水泥有限公司

Sulfate-corrosion-resistant high-strength concrete doped with carbon nanofibers and preparation method of sulfate-corrosion-resistant high-strength concrete

InactiveCN112390591AImprove mechanical propertiesHigh tensile strengthHigh strength concreteModified carbon

The invention relates to the technical field of concrete, and discloses sulfate-corrosion-resistant high-strength concrete doped with carbon nanofibers and a preparation method of the sulfate-corrosion-resistant high-strength concrete. The concrete comprises the following components in percentage by mass: 15-20% of Portland cement, 20-25% of fine aggregate, 15-20% of coarse aggregate, 5-10% of modified carbon nanofibers, 1-3% of a polycarboxylate superplasticizer and the balance of water. The preparation method comprises the following steps: adding the Portland cement, the fine aggregate and the coarse aggregate into a stirrer, uniformly stirring, adding the polycarboxylate superplasticizer and the water, uniformly stirring and mixing, finally adding the modified carbon nanofibers, and uniformly stirring and mixing, thereby obtaining the product. The modified carbon nanofibers are added into the concrete, so that the sulfate corrosion resistance of the concrete is improved, and the mechanical strength of the concrete is also improved.

Owner:贺笑笑

Process for fast baking early strength silicate cement clinker

InactiveCN1693252AReduce coal consumptionIncrease productionUltimate tensile strengthMaterials science

An early-strengthening silicate cement clinker contains 3CaO.SiO2, 4CaO.Al2O3.Fe2O3, 3(CaO.Al2O3).CaSO4 and 11CaO.7Al2O3.CaF2, and is prepared by high-speed calcining method using vertical kiln. Its advantages are high productivity, early strengthening, stable latter strength, and excellent performance.

Owner:WUHAN UNIV OF TECH

Construction method of anti-corrosion road

InactiveCN108049276AHigh strengthGood resistance to sulfate attackIn situ pavingsCeramicwareFoam concreteSulfate

The invention discloses a construction method of an anti-corrosion road. The construction method includes the following steps of (1) construction site preparation, (2) anti-corrosion cement slurry preparation, (3) foam preparation, (4) anti-corrosion foam concrete preparation, (5) anti-corrosion foam concrete pouring, and (6) anti-corrosion foam concrete curing. The characteristic that coal ash and slag have good concrete active mineral admixtures is used, the coal ash and the slag are mixed in a foam concrete material, meanwhile, a proper amount of an additive is added, anti-corrosion foam concrete with the strength and sulfate attack resisting capacity better than those of ordinary silicate cement is prepared and applied to a road high fill, the service life of the road can be prolonged,and the operation stability of the road can be improved.

Owner:GUYAN TECH DEV CO LTD

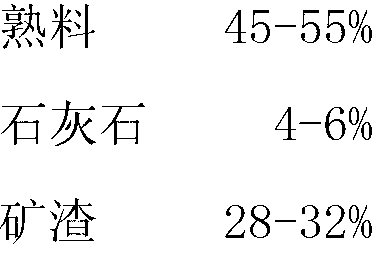

Novel Portland slag P.SB32.5 cement

InactiveCN103304163AGood resistance to sulfate attackReduce and inhibit diffusivityCement productionSlagSteel mill

The invention relates to novel Portland slag P.SB32.5 cement. The cement comprises the following components by weight percent: 45-55% of clinker, 4-6% of limestone, 28-32% of slag, 4-7% of volcanic ash, 3-5% of fly ash and 3-6% of desulfurization gypsum. The cement has the advantages that industrial waste slag ingredients generated in the production processes in steel mills are adopted, thus not only reducing the production cost but also eliminating pollution sources, achieving economical efficiency and environment friendliness, improving the later strength of the cement and ensuring the quality of engineering construction.

Owner:天津山水水泥有限公司

Novel Portland cement and preparation method thereof

The invention relates to novel Portland cement. The Portland cement comprises the following raw materials in parts by weight: 60-70 parts of clinker, 15-19 parts of ultrafine slag, 5-7 parts of limestone, 5-7 parts of gypsum, and 6-9 parts of an admixture; the admixture is prepared by silica fume, a methacrylic acid calcium salt hydrate, 1-(3-trifluoromethylphenyl)piperazine monohydrochloride, and4-(4-fluorobenzoyl)piperidine hydrochloride. At early stage of hydration, the novel Portland cement utilizes fluorine ions and calcium ions which are ionized from 1-(3-trifluoromethylphenyl)piperazine monohydrochloride and 4-(4-fluorobenzoyl)piperidine hydrochloride for forming calcium fluoride, so that a lot of calcium ions are consumed, a double electric layer structure is difficult to form onthe surface of C3S, induction period of C3S is shortened and disappear, hydration process is rapidly accelerated, and heat release rate at early stage of hydration is improved. Accordingly, the heat release rate range of the cement in a hardening maintenance phase is floated between 5-10%, cracks in hardened cement are smaller, and the strength of a cement test piece is improved.

Owner:天津山水水泥有限公司

Novel Portland slag cement P.SA42.5

InactiveCN103342480AGood resistance to sulfate attackReduce and inhibit diffusivityCement productionSlagSteel mill

The invention relates to novel Portland slag cement P.SA42.5. The cement comprises the following components by weight percent: 68-72% of clinker, 4-6% of limestone, 18-20% of slag and 4-6% of desulfurization gypsum. The cement has the positive effects that the industrial waste slag produced in the production process in a steel mill is adopted for burdening, thus not only reducing the production cost but also eliminating the pollution sources and achieving the economic property and environment friendliness; and by adopting the slag for burdening, the later strength of the cement is improved and the quality of the engineering construction is ensured.

Owner:天津山水水泥有限公司

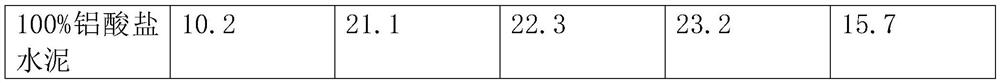

Aluminate cement resistant to corrosion of sulfate and preparation method thereof

The invention discloses an aluminate cement resistant to corrosion of sulfate and a preparation method thereof, and aims to provide an aluminate cement, which can prevent corrosion of sulfate in seawater. Innovatively, alumina is added into raw materials of cement, the phase composition of cement clinker is changed, and the phase composition of the cement clinker is controlled. The provided aluminate cement and common aluminate cement are subjected to a sulfate corrosion resisting test under same conditions, and the result shows that the anticorrosion coefficient of the provided aluminate cement is obviously increased.

Owner:ZHENGZHOU DENGFENG SMELTING MATERIALS

A kind of manufacture method of geopolymer oil well cement

ActiveCN105776913BImprove volume stabilityImprove high temperature resistanceCement productionGeopolymerWell cementing

The invention relates to a manufacturing method of geopolymer oil well cement. The method is characterized by comprising the following steps in order: compounding, grinding, calcination, mixing, warehousing and packaging. The method provided by the invention can manufacture the geopolymer oil well cement with good volume stability, high temperature resistance, CO2 resistance, and sulfate attack resistance. And the cement can be effectively applied to oil-gas well cementation in areas with complex geological conditions, and can achieve very good cementing quality.

Owner:JIAHUA SPECIAL CEMENT

A kind of sulfate-resistant graphene concrete composite material and preparation method thereof

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

A kind of ferronickel slag cementitious material and preparation technology thereof

The invention relates to a nickel iron slag gelling material and a production technology, relate to the nickel iron slag gelling material, and especially relates to cement produced by the nickel ironslag and a production method thereof. The nickel iron slag gelling material comprises the following components in parts by weight: 40-70 parts of Portland cement clinker, 30-60 parts of nickel iron slag low-temperature clinker, and 1-2 parts of gypsum, wherein the nickel iron slag low-temperature clinker comprises the following components in parts by weight: 20-30 parts of nickel iron slag, 9-15 parts of quicklime, 0.5-1 part of gypsum, 5-10 parts of water, and 0.2-0.6 parts of an alkaline electrolyte. The method can effectively solve the environment problem of stacking of nickel iron slag, realizes high-efficiency resource utilization of the nickel iron slag, and reduces CO2 discharge capacity during a cement preparation process, the nickel iron slag low-temperature clinker can substitutethe Portland cement clinker to produce the gelling material, and the produced nickel iron slag low-temperature gelling material has the characteristics of low hydration heat and good anti-sulfate erosion performance.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com