Mine-filling cementing material and preparation method thereof

A mine filling and cementing material technology, applied in the field of cementing material and its preparation, can solve the problems of low water absorption capacity, high application cost, poor cementation effect, etc., and achieve strong adsorption and water retention capacity, saving energy and manufacturing costs, and saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

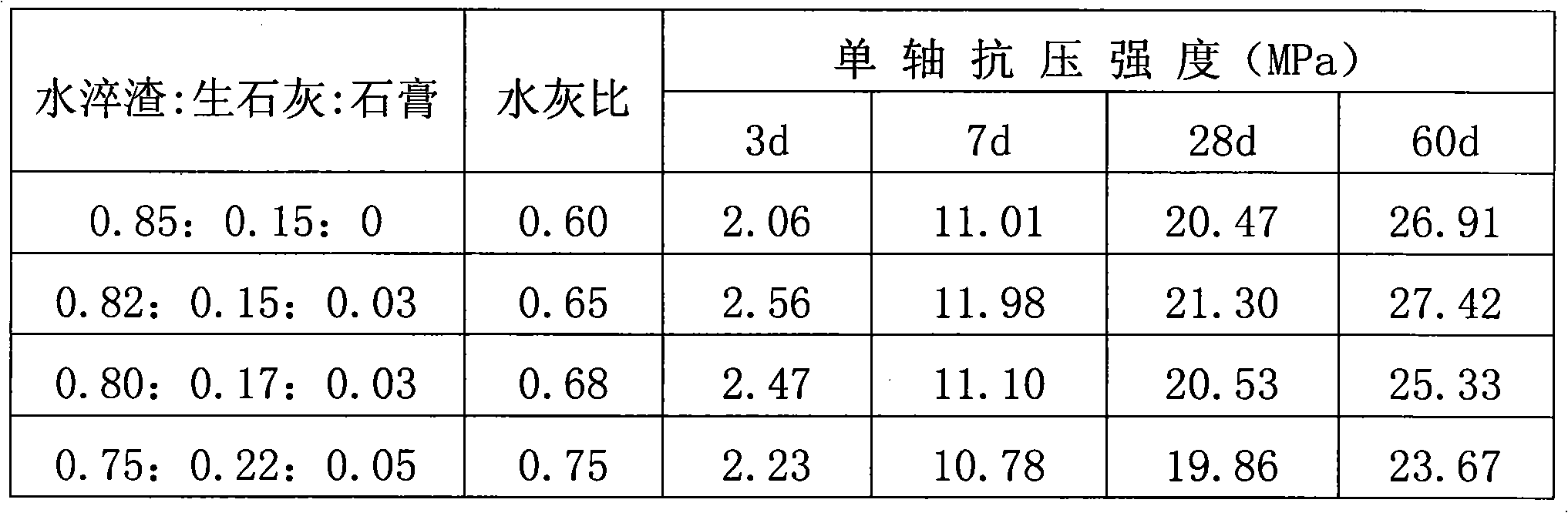

[0018] The iron-making water quenching slag is used as the main raw material, quicklime is used as the intensifying agent, and gypsum is used as the strengthening agent, which is dried and then dry-ground into powder; the iron-making water quenching slag powder, quicklime powder and gypsum powder are respectively pressed 0.85: 0.15: 0; 0.82: 0.15: 0.03; 0.80: 0.17: 0.03 and 0.75: 0.22: 0.05, and prepared into cementitious material slurry according to the water-cement ratio of 0.60-0.75, 3-day uniaxial Compressive strength: 2.23-2.56MPa; 7-day strength: 10.78-11.98MPa; 28-day strength: 19.86-21.30MPa; 60-day strength: 23.67-27.42MPa (see Table 1). Among them, the uniaxial compressive strength value obtained by the cementitious material compounded with the raw material ratio of 0.82:0.15:0.03 and the water-cement ratio of 0.65 is the highest.

[0019] Table 1

[0020]

Embodiment 2

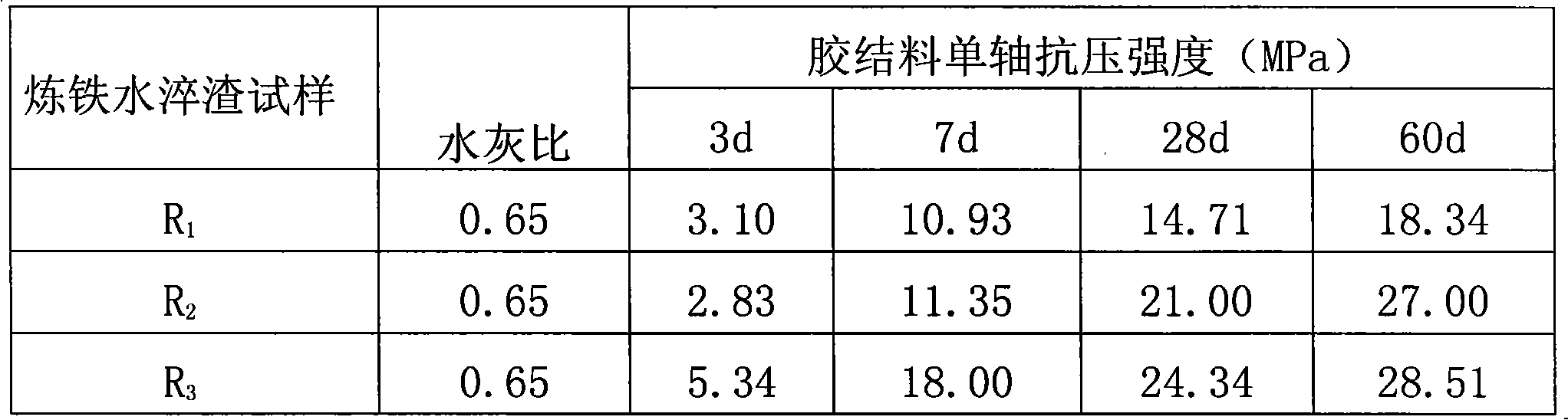

[0022] Three kinds of molten ironmaking slag R produced by three different steel mills were used respectively. 1 , R 2 , R 3 , according to the dry weight ratio of 0.82:0.15:0.03, the main material of iron-making water quenching slag, quicklime intensifier and gypsum strengthening agent are mixed, dried, ground and stirred to obtain the iron-making water produced by different steel factories. Quenched slag is used as the main raw material for the cement. The slurries of three cementing materials were prepared according to the water-cement ratio of 0.65, and the uniaxial compressive strength of the cementing material test blocks were respectively obtained (see Table 2).

[0023] Table 2

[0024]

Embodiment 3

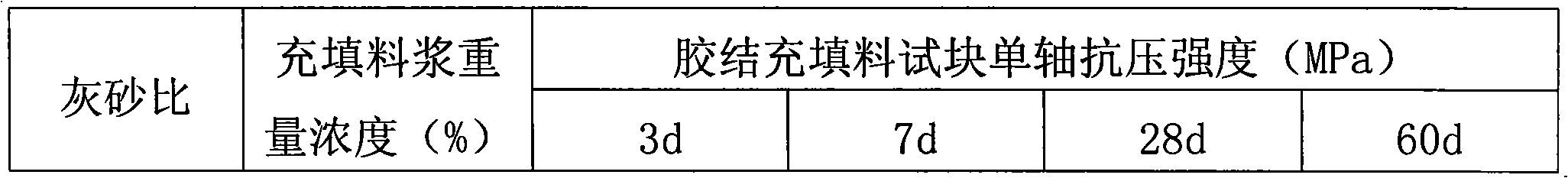

[0026] Using iron-making water quenching slag R 1 As the main raw material, quicklime and gypsum are prepared into slurry by mixing iron-making water-quenching slag main material, quicklime intensifier, and gypsum strengthening agent in a weight ratio of 0.82:0.15:0.03, and mixed with water-quenching slag and then wet-milled to form a cement material. The cementing material of the present invention is stirred and mixed with copper ore graded tailings to prepare the cemented filling, the weight concentration is 68-75%, and the lime-sand ratio is 1:4-12. The uniaxial compressive strength value of the obtained graded tailings cemented filling material test block can meet the requirements of the filling mining process (see Table 3).

[0027] table 3

[0028]

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com