Curing method for waste soil combined treatment

A technology of composite treatment and solidification method, which is applied in the solidification field of waste soil composite treatment, can solve problems such as hidden dangers of environmental safety, adverse effects, and difficulties in resource utilization, so as to reduce the moisture content of mud, improve the flow resistance, and meet the sustainable development requirements. effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

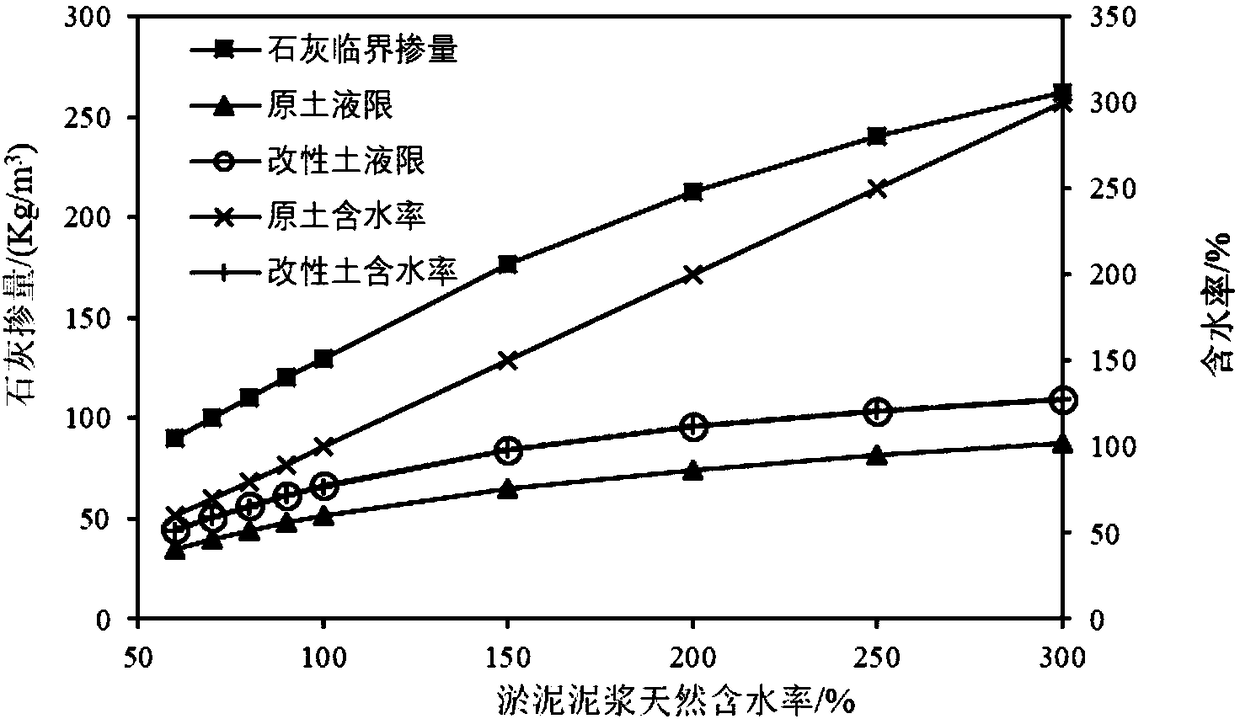

[0024] The water content of the silt in the Pudong River in Fuzhou is about 110%, which is 140kg / m 3 Put in quicklime blocks and stir them repeatedly with an excavator. The quicklime blocks react violently and release a large amount of heat. The evaporation speed of cement on the surface of the sludge is accelerated. After 12 hours, the sludge has lost its fluidity and can be transported outside.

[0025] The alkali content of the modified sludge is about 10%, and the modified sludge, mineral powder and desulfurized gypsum are mixed uniformly at a ratio of 100:35:15 to become a solidification material that can be used for soil solidification.

[0026] After the solidified material is mixed with 73% soft plastic silt at a ratio of 1:3, it is used as soft foundation backfill soil. The unconfined compressive strength is 0.21MPa at 7 days and 0.43MPa at 28 days, which meets the requirements of soft foundation. Curing requirements.

[0027] Advantages: Compared with quicklime powd...

Embodiment 2

[0029] The moisture content of silt in Nanchang Huanyu Park is 306%, according to 300kg / m 3 Put in quicklime blocks and stir them repeatedly with an excavator. The quicklime blocks react violently and release a large amount of heat. The evaporation speed of cement on the surface of the sludge is accelerated. After 12 hours, the sludge has lost its fluidity and can be transported outside.

[0030] The alkali content of the modified sludge is about 20%, and the modified sludge, mineral powder and desulfurized gypsum are mixed uniformly at a ratio of 100:80:4 to become a solidification material that can be used for soil solidification.

[0031] After the solidified material is mixed with 86% soft plastic silt at a ratio of 1:6, it is used as park roadbed soil. The unconfined compressive strength is 0.33MPa at 7 days and 0.70MPa at 28 days, which meets the design of park roadbeds Require.

[0032] Advantages: Compared with quicklime powder, the quicklime block has less grinding p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com