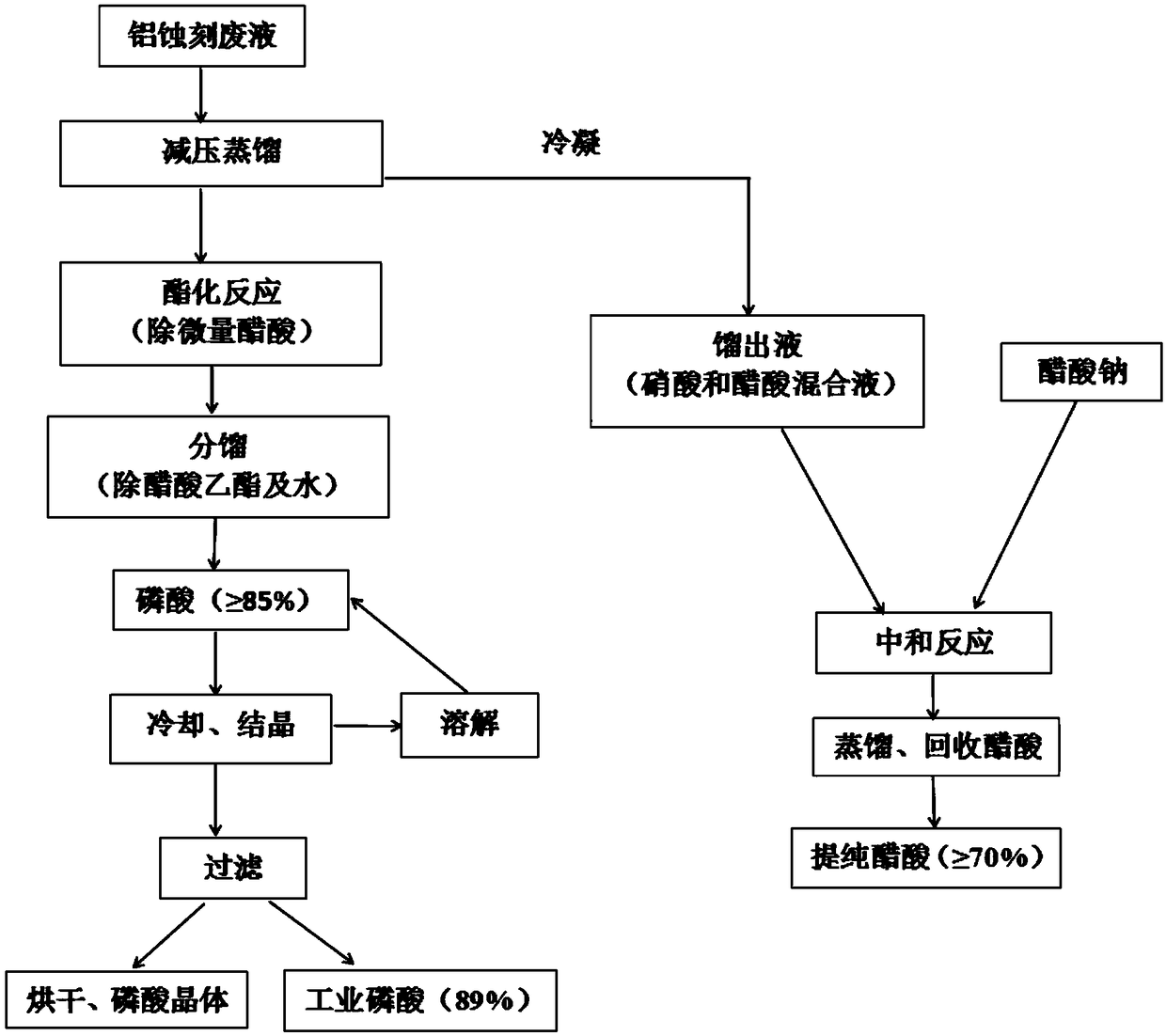

Method for recycling and utilizing phosphoric acid and acetic acid from waste aluminum etching solution

A technology of aluminum etching and phosphoric acid, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, phosphorus compounds, etc., can solve the problems of high energy consumption, no way to effectively recover acid, waste of phosphorus resources, etc., to achieve Improve economic benefits, avoid waste of resources and environmental pollution, and save raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Get 1000g of photoelectric industry etching waste liquid, its chemical composition and content are as follows:

[0027] chemical composition

h 3 PO 4

CH 3 COOH

HNO 3

h 2 o

Al

Content (mass fraction)

62.6%

10.2%

4.3%

18.9%

very small amount

[0028] Follow the steps below to recover the mixed acid in the waste aluminum etching solution:

[0029] (1) Heat 1000g of waste aluminum etching solution to 55°C, add activated carbon at a stirring speed of 120rpm, activated carbon can reduce the color and turbidity in the waste liquid, keep stirring for 1.5h, filter while it is hot, and collect the waste aluminum after removing impurities etchant;

[0030] (2) Because the boiling point and volatility of phosphoric acid, nitric acid, and acetic acid differ greatly, utilize fractional distillation to separate nitric acid and acetic acid from the waste aluminum etching solution. Distill the waste liquid under reduced...

Embodiment 2

[0035] Get 1000g of photoelectric industry etching waste liquid, its chemical composition and content are as follows:

[0036] chemical composition

h 3 PO 4

CH 3 COOH

HNO 3

h 2 o

Al

Content (mass fraction)

67.6%

9.4%

4.8%

20.2%

very small amount

[0037] Follow the steps below to recover the mixed acid in the waste aluminum etching solution:

[0038] (1) Heat 1000g of waste aluminum etching solution to 55°C, add activated carbon at a stirring speed of 125rpm, keep stirring for 2 hours, filter while hot, and collect waste aluminum etching solution after removing impurities;

[0039] (2) Distill the waste liquid under reduced pressure at 0.095Mpa and 90°C to volatilize nitric acid and acetic acid in the waste liquid, and collect 398.4g of distillate;

[0040] (3) Ethanol is added to the residual waste liquid treated in step 2 to carry out acetic acid esterification reaction. After reacting for 2 hours under stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com