High-activity composite mixed material for improving erosion resistance of cement concrete

A technology of cement concrete and mixed materials, which is applied in the field of building materials, can solve the problems of cement and concrete with reduced chloride ion penetration resistance, difficulty in ensuring strength, and reduced sulfate erosion resistance, so as to improve the ability of chloride ion penetration resistance, The effect of refining the pore structure of cement hardened body and excellent resistance to sulfate attack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

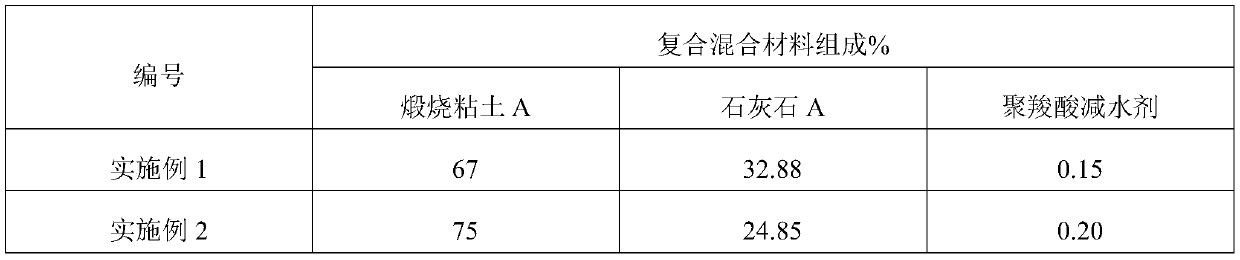

Examples

Embodiment Construction

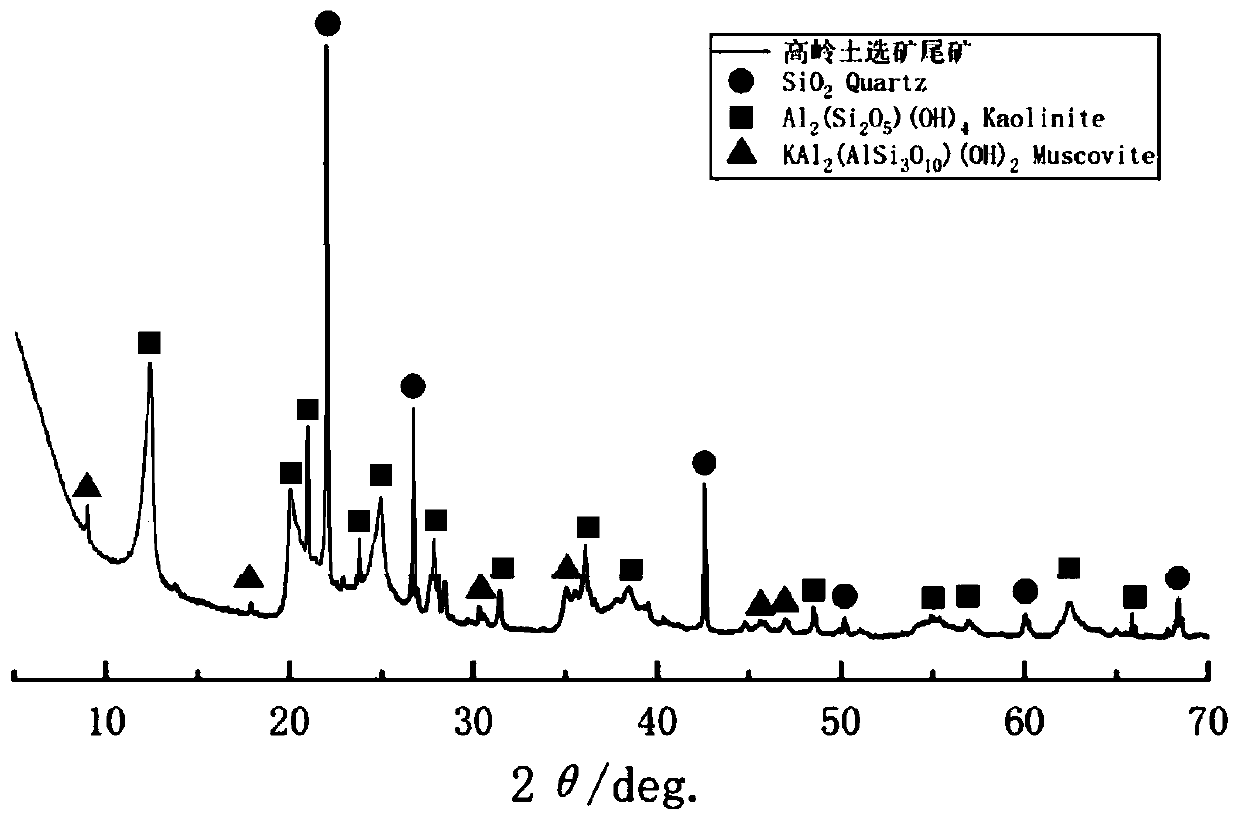

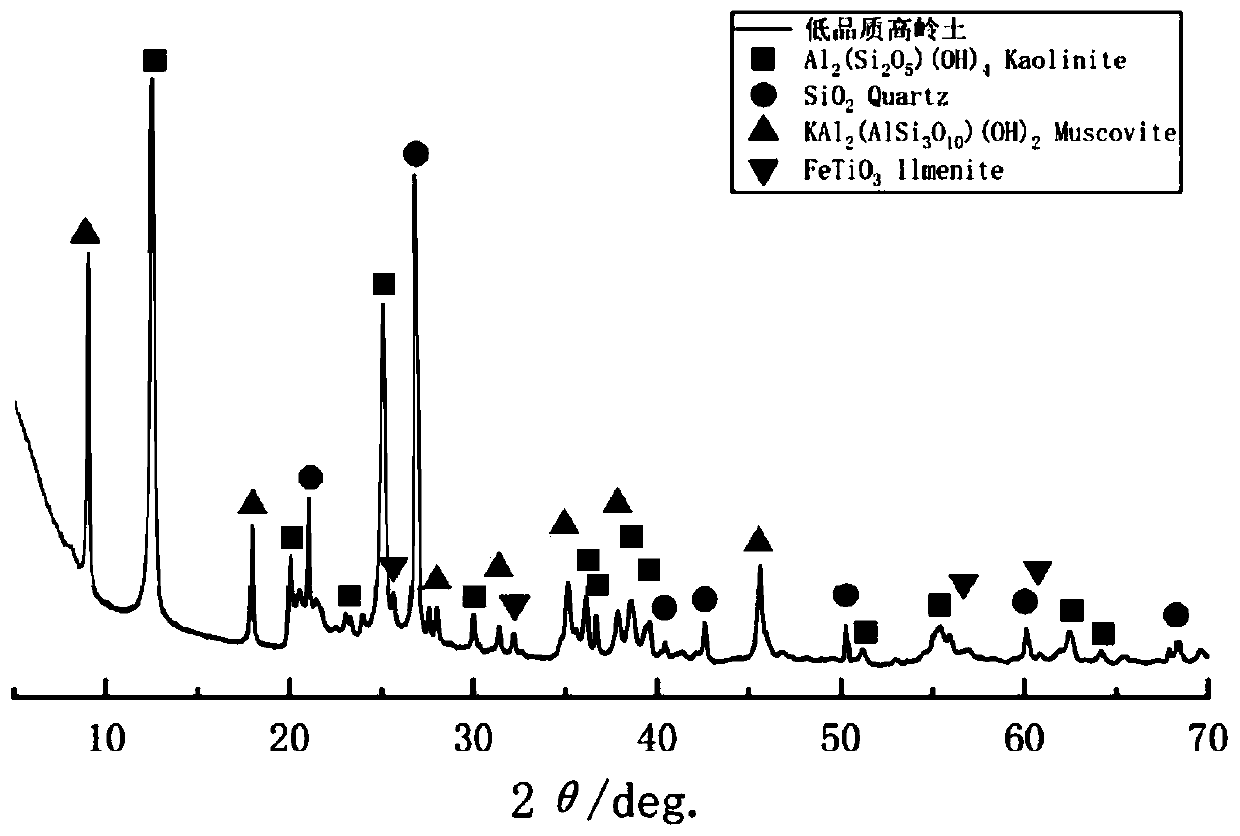

[0035]The principle of the high activity of the composite mixed material of the present invention is that the kaolin beneficiation tailings or low-quality kaolin used in the present invention contain a certain amount of kaolinite, which is dehydrated and decomposed into metakaolin after being calcined at a suitable temperature, and has a higher high Volcanic ash activity; finely ground limestone powder itself has a good particle filling effect and accelerates the hydration of cement clinker minerals; at the same time, calcite and dolomite in limestone can be combined with partial calcium hydroxide under the action of calcium hydroxide produced by clinker hydration The active aluminum component in kaolin undergoes carbonoaluminate reaction to generate hydration products such as C-A-S-H gel and mono / semi-carbohydrate calcium / magnesium aluminate, which further improves the reactivity of the composite material.

[0036] The principle that the composite mixed material of the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com