A kind of manufacture method of geopolymer oil well cement

A technology for oil well cement and a manufacturing method, which is applied in the field of oil well cement production, can solve problems such as difficulty in guaranteeing product quality stability, no production process, and great quality control problems, and achieves good industrial application prospects, simple production process flow, and high product quality. Quality remains stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

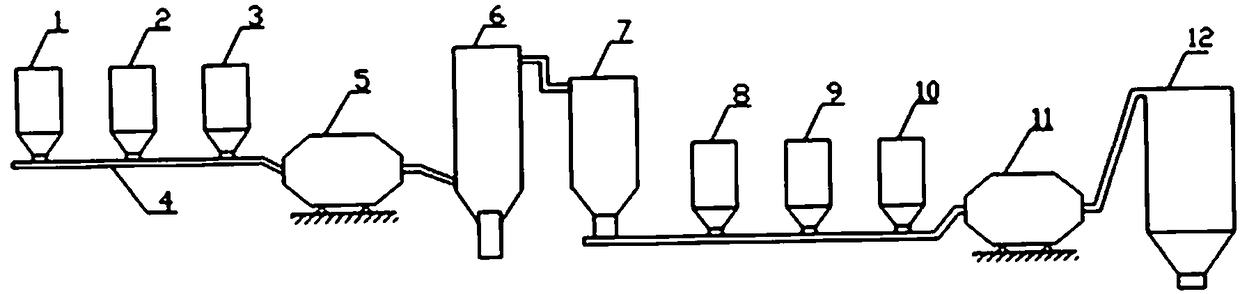

Method used

Image

Examples

Embodiment 1

[0026] Ingredients: weigh 85.5 parts of kaolinite, 10.3 parts of limestone, and 4.2 parts of dihydrate gypsum for batching;

[0027] Grinding: Send the prepared raw materials into the mill for mixing and ball milling, and the specific surface is controlled to 320 m 2 / kg;

[0028] Calcination: Send the ground raw material powder into a high-temperature furnace for calcination, the calcination temperature is 850°C, and the calcination time is 35 minutes;

[0029] Mixing: Weigh 75 parts of calcined mixed powder, 8 parts of sodium hydroxide, 10 parts of sodium silicate, and 5 parts of fly ash for batching, send them into the mill and mix them evenly, and the specific surface control value is 550 m 2 / kg;

[0030] Warehousing and packaging: Send the uniformly mixed powder into the storage warehouse, and pack it when the temperature of the cement drops below 40°C. Use airtight packaging to prevent the cement from absorbing moisture.

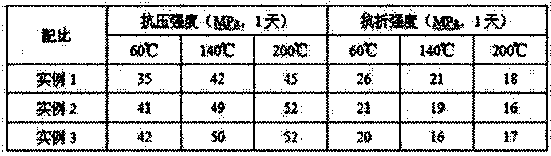

[0031] The performance parameters of the pre...

Embodiment 2

[0033] Ingredients: weigh 80 parts of kaolinite, 20 parts of limestone, and 8 parts of dihydrate gypsum for batching;

[0034] Grinding: Send the prepared raw materials into the mill for mixing and ball milling, and the specific surface is controlled to 350 m 2 / kg;

[0035] Calcination: Send the ground raw material powder into a high-temperature furnace for calcination, the calcination temperature is 900°C, and the calcination time is 40 minutes;

[0036] Mixing: Weigh 70 parts of calcined mixed powder, 8 parts of sodium hydroxide, 15 parts of sodium silicate, and 10 parts of fly ash for batching, send them into the mill and mix them evenly, and the specific surface control value is 600 m 2 / kg;

[0037] Warehousing and packaging: Send the uniformly mixed powder into the storage warehouse, and pack it when the temperature of the cement drops below 40°C. Use airtight packaging to prevent the cement from absorbing moisture.

[0038] The performance parameters of the prepared...

Embodiment 3

[0040]Ingredients: weigh 65.3 parts of kaolinite, 29.6 parts of limestone, and 5.2 parts of dihydrate gypsum for batching;

[0041] Grinding: Send the prepared raw materials into the mill for mixing and ball milling, and the specific surface is controlled to 450 m 2 / kg;

[0042] Calcination: Send the ground raw material powder into a high-temperature furnace for calcination, the calcination temperature is 980°C, and the calcination time is 50 minutes;

[0043] Mixing: Weigh 65 parts of calcined mixed powder, 10 parts of sodium hydroxide, 20 parts of sodium silicate, and 15 parts of fly ash for batching, send them into the mill and mix them evenly, and the specific surface control value is 600 m 2 / kg;

[0044] Warehousing and packaging: Send the uniformly mixed powder into the storage warehouse, and pack it when the temperature of the cement drops below 40°C. Use airtight packaging to prevent the cement from absorbing moisture.

[0045] The performance parameters of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com