Sulfate-corrosion-resistant high-strength concrete doped with carbon nanofibers and preparation method of sulfate-corrosion-resistant high-strength concrete

A carbon nanofiber and sulfate-resistant technology, which is applied in the field of concrete, can solve problems such as uneven dispersion of carbon nanofibers, reduced mechanical properties of concrete, and inability of concrete to resist sulfate erosion, so as to improve compactness, improve compactness, and excellent Effect of Sulfate Attack Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

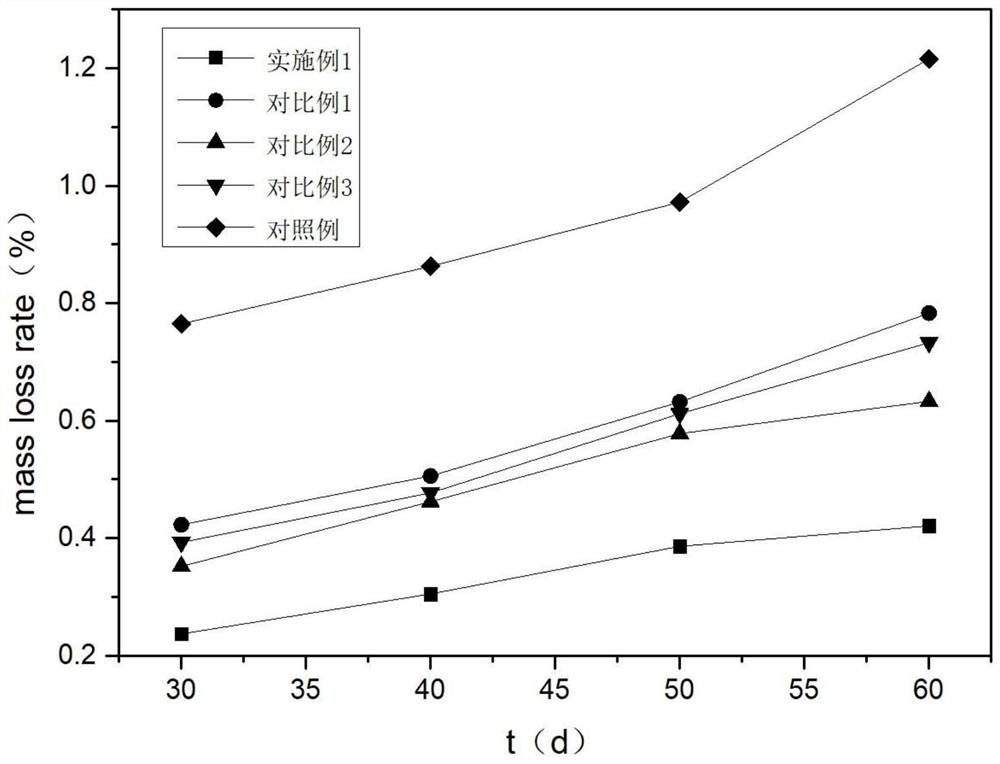

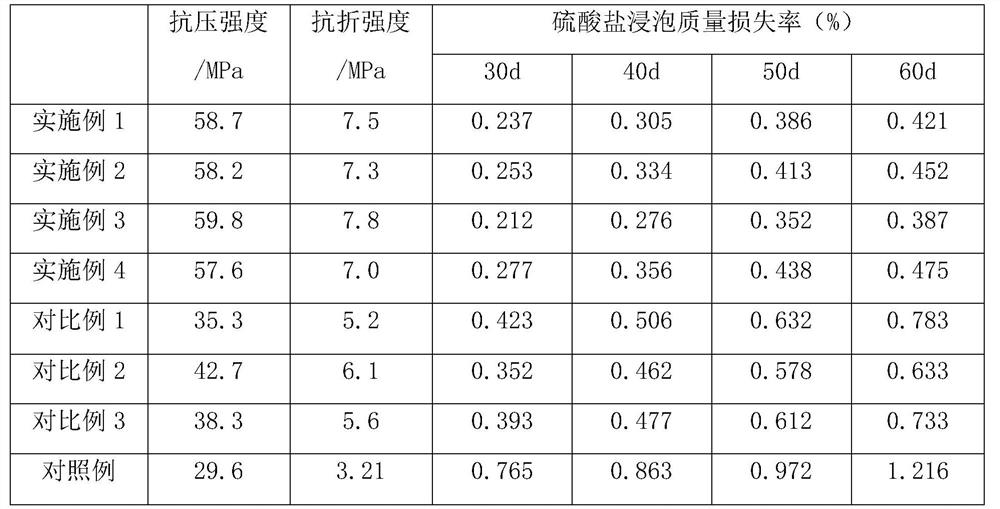

Examples

Embodiment 1

[0024] The preparation method of modified carbon nanofiber comprises the following steps:

[0025] Mix the sulfuric acid solution with a mass fraction of 70% and the nitric acid solution with a mass fraction of 30% according to the volume ratio of 1:2, stir evenly, add carbon nanofibers, heat and keep warm for 5 hours, dilute with distilled water, add ammonia water dropwise to make the solution neutral After suction filtration and drying, activated carbon nanofibers are obtained; tetraethyl orthosilicate, ethanol and deionized water are mixed evenly according to the volume ratio of 1:2:2, and then activated carbon nanofibers are added, activated carbon nanofibers and The mass ratio of tetraethyl orthosilicate is 1:4, stir and mix evenly to obtain a mixed solution, heat it in a water bath to 75°C, add dropwise an ammonia solution with a mass concentration of 25%, and the amount of the ammonia solution added is tetraethyl orthosilicate 5wt%, stirred for 2.5h, left to age for 8h,...

Embodiment 2

[0030] The preparation method of modified carbon nanofiber comprises the following steps:

[0031]Mix the sulfuric acid solution with a mass fraction of 70% and the nitric acid solution with a mass fraction of 30% according to the volume ratio of 1:2, stir evenly, add carbon nanofibers, heat and keep it warm for 4.5 hours, dilute with distilled water, add ammonia water dropwise to make the solution appear Neutral, after suction filtration and drying, to obtain activated carbon nanofibers; mix tetraethyl orthosilicate, ethanol and deionized water according to the volume ratio of 1:2:2, and then add activated carbon nanofibers to activate carbon nanofibers The mass ratio to tetraethyl orthosilicate is 1:2.5, stir and mix evenly to obtain a mixed solution, heat it in a water bath to 70°C, add dropwise an ammonia solution with a mass concentration of 25%, and the amount of the ammonia solution added is tetraethyl orthosilicate 5wt% of the ester, stirred and reacted for 1.5h, stood...

Embodiment 3

[0036] The preparation method of modified carbon nanofiber comprises the following steps:

[0037] Mix the sulfuric acid solution with a mass fraction of 70% and the nitric acid solution with a mass fraction of 30% according to the volume ratio of 1:2, stir evenly, add carbon nanofibers, heat and keep warm for 6 hours, dilute with distilled water, add ammonia water dropwise to make the solution neutral After suction filtration and drying, activated carbon nanofibers are obtained; tetraethyl orthosilicate, ethanol and deionized water are mixed evenly according to the volume ratio of 1:2:2, and then activated carbon nanofibers are added, activated carbon nanofibers and The mass ratio of tetraethyl orthosilicate is 1:5, stir and mix evenly to obtain a mixed solution, heat it in a water bath to 73°C, add dropwise an ammonia solution with a mass concentration of 25%, and the amount of the ammonia solution added is tetraethyl orthosilicate 5wt%, stirred for 3 hours, left to age for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com